3D printer must haves

Top 15 Must-Have 3D Printer Accessories and Tools

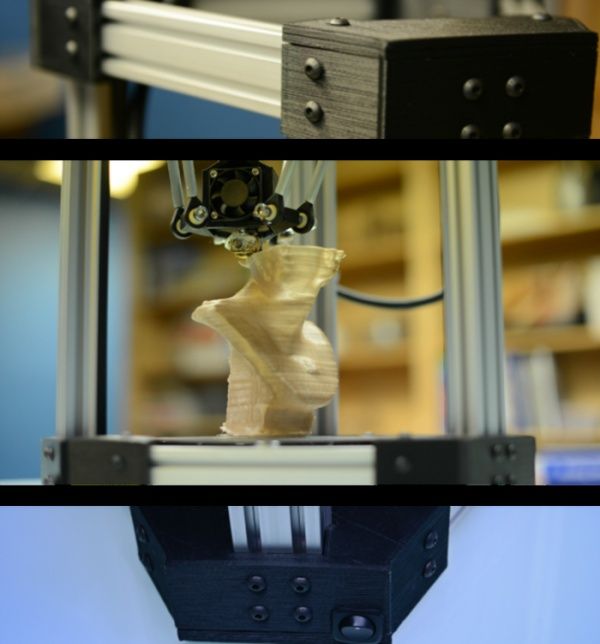

3D printing industry has seen an accelerated growth in development over the years. From the massive and quite expensive 3D printers in the past, the models available today are more compact, affordable and easy to use. However, successful 3D printing does not only depend on the 3D printer itself. There are a variety of 3D printer accessories that play an important role when it comes to the quality of the final product.

With the right accessories, you can turn your average 3D printer into an incredible machine and you can be more assured that your prints will come out exactly as desired.

From removing support material to improving bed plate adhesion, here is a list of the top 15 3D printer accessories that will help you get the most of your 3D printer.

Disclosure: There are affiliate links in this article. As an Amazon Associate I earn from qualifying purchases.

Filament Storage Container

Get it on Amazon / AliExpress / Banggood

One of the most important accessories a 3D printer owner must possess is an appropriate filament storage container.

Most of the 3D printer owners don’t pay attention to that, which can lead to so many problems like clogging, bad layer adhesion, breakage, etc. That’s why it is very important to safely store your filaments in a moisture free environment.

The first option is a filament box, which keeps your filament dry, dust-free, and also dispenses filament. It has temperature and humidity sensor, and you can also print directly from the box.

Vacuum Sealed Storage Containers

Get it on Amazon

Another great option are vacuum sealed storage containers. They come in a pack of 5, which is pretty awesome.

Masking Tape

Get it on Amazon / Banggood

Masking tape is one of the most widely used 3D printing accessories. It is used to help each print adhere better to the print bed and is highly recommended. Furthermore, the finished print is much easier to remove from the bed as well as protect it from scratches.

Make sure you choose masking tape with a width of at least 5 cm (2 inches). Having a wider tape means you’ll need fewer strips to cover your print bed, which will lead to better results.

Alternative: Kapton Tape

Get it on Amazon / Banggood

Although masking tape has been widely used for covering print beds and is cheaper option, Kapton tape is much better in the long term since it handles high temperatures better. This tape also prevents severe warping resulting in a much better 3D print. Kapton tape can be combined with other products, such as hairspray for best results.

PVA Glue Stick

Get it on Amazon / Banggood

When 3D printing, it’s vital to ensure good adhesion of your print to the build plate. So, another way to increase plate adhesion is covering your print bed with washable glue stick. You can apply glue directly to your build plate and wipe it off easily with water.

This is one of the best bed adhesion solutions and works well with most materials, except for those prone to very high warpage like ABS and polycarbonate.

It works pretty well and it can easily be found at a wide variety of stores and at a very reasonable price.

Alternative: Hair Spray

Get it on Amazon

Many people also recommend spraying the bed with hair spray. Using hairspray to add an extra layer of ‘stickiness’ to your print bed is a quick and easy process.

But you must be careful with this method because using hairspray regularly and without proper care can damage your printer.

3D Print Removal Tool

Get it on Amazon / Banggood

Sometimes you might find that your 3D print has stuck to your build plate. A 3D print removal tool, or spatula, can easily solve this problem. All you need to do is to put it gently underneath the print and carefully lift it up. You can also use this tool for scraping off little bits of filament.

You probably got a one with your 3D printer, but that’s just a generic spatula which sometimes doesn’t do the job.

This set of different spatulas ensures you always have the right tool for removing any object you print. These spatulas are as thin as a knife blade, but without the sharp edge. They’re also usually angled in such a way that you can hold the handle parallel to the bed. It will prevent you from scratching the tray or damaging the part. I consider this set as an essential 3D printer accessory.

Carving Tools

Get it on Amazon / Banggood

When printing parts with a lot of little details and supporting material, you need to do some extra work to get a good finished look. For finishing the 3D prints where a little work is required, this set of carving tools is perfect for smoothing out your final product by removing excess filament and bringing to perfection all the little details.

This set contains 12 different carving tools of varying shapes and sizes that will meet most of your needs.

Alternative: Diamond Needle File Set

Get it on Amazon / Banggood

Another tool perfect for working on small, delicate projects is a diamond needle file. This set includes 6 pieces with different shape and size, and each one serves a different purpose.

This set includes 6 pieces with different shape and size, and each one serves a different purpose.

Pliers

Get it on Amazon / Banggood

Needle-nose pliers can allow you to get into the fiddly areas of your 3D printer and your prints while providing a good, strong grip. Always look for a good quality pair of pliers with a rubberized, slip-resistant grip.

They can be used to remove jams in your 3D printer, to cut filaments, or to install new filaments. Sometimes, the prints get stuck to the print beds, so they can also be used to remove those prints.

Tweezers

Get it on Amazon / Banggood

A full set of tweezers with various shapes and sizes is a must when it comes to the more complicated tasks with 3D printing. They offer a very good and cheap solution for very fine and high precision adjustments in your 3D printer or printed parts.

They’re great for plucking oozing filament from the extruder nozzle without burning your fingers. Also, they can be used for post-processing finishing of your prints.

Also, they can be used for post-processing finishing of your prints.

Sandpaper

Get it on Amazon / Banggood

Having a set of sandpapers in a variety of different grits can be very useful in the post-processing step of your printing. A good sandpaper will help you define the details on your print and smooth out any rough edges and surfaces.

We recommend buying a set of good quality sandpaper from a well-known brand, from coarse (120 grit) to fine (1000 grit or more). Good quality sandpaper does not wear out easily, making it last longer and saving you money in the long run.

Alternative: Rotary Tool

Get it on Amazon / Banggood

As an alternative, you can use a rotary tool with different accessories, which will make things much easier and accurate as well.

Digital Caliper

Get it on Amazon / Banggood

A digital caliper is a must-have tool for detail-oriented 3D print maker. When 3D printing, there can be a lot of measurements involved, so this tool will help you increase efficiency and accuracy, which is very important.

When 3D printing, there can be a lot of measurements involved, so this tool will help you increase efficiency and accuracy, which is very important.

It enables you to make very precise measurements of a part you want to replicate in 3D, to verify the dimensions of a calibration print, or to check the precision of the measurements of your prints versus the dimensions in the source CAD model.

Calipers are also handy for checking the accuracy of your 3D printing filaments, since the actual filament diameters often differ from what is advertised. This will help you make the necessary adjustment.

The key to successful 3D print lies in getting a good first layer. And to get a good first layer, you need to have the right print bed surface which needs to have a smooth finish and to be rigid and durable as well.

Some people like to swap out their default print beds for glass plated ones, because they handle heat better and won’t warp the printed parts as easily.

Borosilicate Glass Bed

Get it on Amazon / Banggood

Borosilicate glass can withstand extremely high temperatures, since it’s tempered. Also, it helps giving the print a smooth finish. When buying glass print bed make sure its dimensions match your model of 3D printer.

Also, it helps giving the print a smooth finish. When buying glass print bed make sure its dimensions match your model of 3D printer.

Alternative: Heat Bed Platform Sticker

Get it on Amazon / Banggood

This printing surface is compatible with almost every printing material. You can print directly onto the surface without any additional adhesives. Once you’re done printing, it is very easy to remove your printed part without damaging it.

You can use it for multiple prints and all you need to do is to wipe down with isopropyl alcohol between prints. Also, it can be easily cut to the desired size with a utility knife.

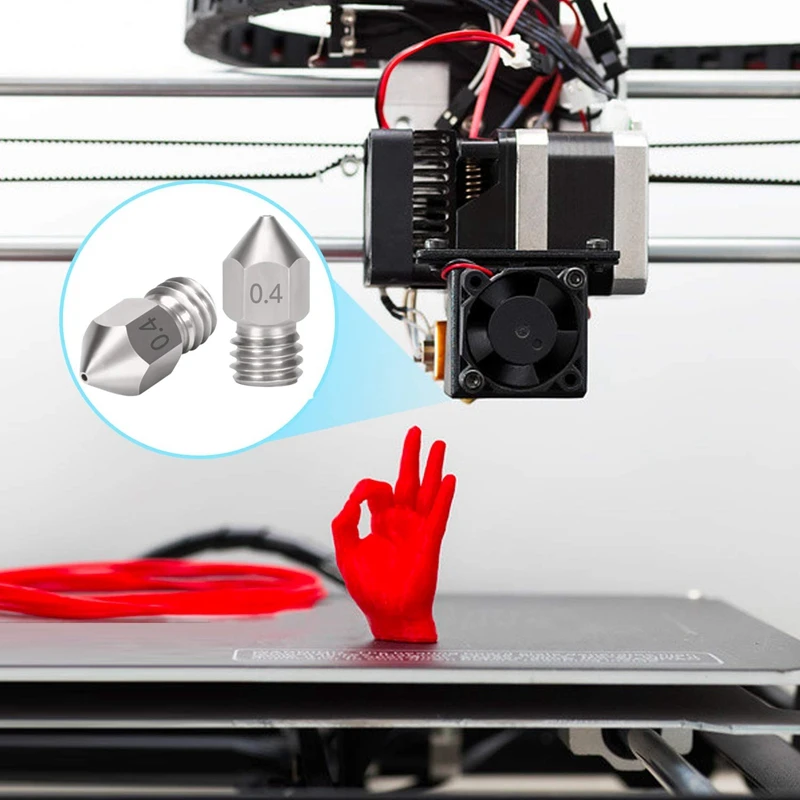

Nozzle Set

Get it on Amazon / Banggood

Nozzles come in many different shapes and sizes, but they all have the same function. Why would you want to have more than one size nozzle?

There are a few reasons why: for example, you want to print a larger model quickly, so you need to use a larger nozzle; you want fine details on your print, or you have an intricate print, so you need to use smaller nozzle; or your current nozzle gets clogged, so you need to replace it.

Nozzle Cleaning Kit

Get it on Amazon / Banggood

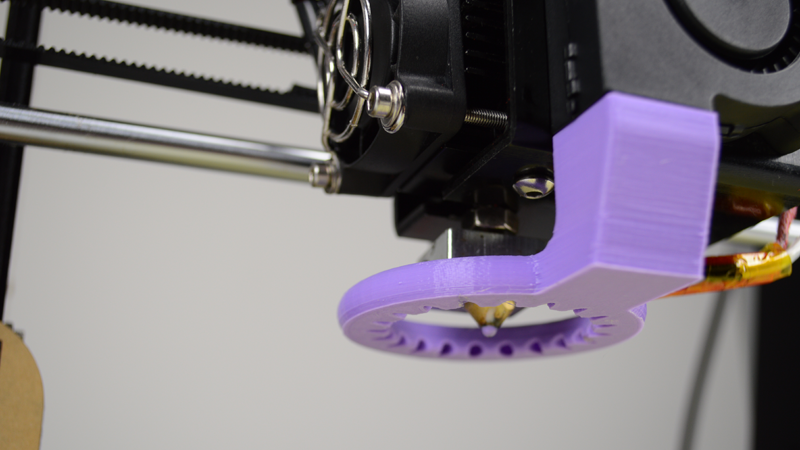

The extruder nozzle can easily get clogged with melted plastic after frequent use. It is one of the most significant parts of your 3D printer, so it is very important to keep it maintained, ensuring the quality of your 3D prints.

Cleaning the nozzles is not as easy as it seems, so you want to make sure you have the right tool for this purpose. There are special nozzle cleaning kits, designed for cleaning different sizes of nozzles, so as long as you have this accessory, you’ll always be able to keep your 3D printer clean and ready for the next print.

Solutions for Better Finish

After a part comes out of the printer, it needs to undergo a surface finishing process before it’s ready for use because you can often see its laminated appearance and roughness. So, there are so many reasons to finish a 3D printed part, for example, you might want to enhance its appearance, to smooth out uneven surfaces, or to improve its durability.

Depending on the 3D printing material, you can choose acetone, or XTC-3D high performance 3D print coating.

Acetone

Get it on Amazon

By using acetone, you can easily achieve a smooth and polished surface to your ABS 3D prints. A thin layer of this product is just enough to get a better finish. Be very careful when deciding to use acetone, since it is not compatible with all materials.

XTC-3D High Performance 3D Print Coating

Get it on Amazon

We know that ABS can be smoothed with acetone, but when it comes to PLA, that’s not the case. This epoxy is a protective coating for smoothing and finishing 3D printed parts.

You just need to mix the two liquids together and apply the mixture onto any 3D print. It dries uniformly without leaving brush strokes. Working time is about 10 minutes, and it takes about 4 hours to cure.

Super Glue

Thicker: Get it on Amazon

Thinner: Get it on Amazon / Banggood

Super glue has endless supply of uses for 3D printing jobs, and is incredibly effective. It can be used to fill in gaps, to repair broken parts, and to combine two or more smaller 3D printed parts together.

It can be used to fill in gaps, to repair broken parts, and to combine two or more smaller 3D printed parts together.

Different types of glue are used for different jobs. For example, for filling gaps a thicker type of glue is required whilst for delicate procedures, like combining two components together, a thinner type of glue is more appropriate.

Alternative: Acetone

Get it on Amazon

Acetone can be used for bonding 3D printed parts made of PLA, ABS or HIPS. In fact, it can be used for any material soluble in acetone. It gives very strong bond, and, if done properly it creates invisible seam.

Additional 3D Printer Accessories – 3D Scanner

Get it on Amazon / Banggood

Having a 3D scanner will take your 3D printing experience to the next level, as it enables you to create accurate 3D models from actual real objects.

There are so many portable, relatively cheap and easy to use scanners on the market. It’s an ideal choice for anyone who wants a compact device that’s easy to carry around and is one of the most beginner-friendly machines around.

It’s an ideal choice for anyone who wants a compact device that’s easy to carry around and is one of the most beginner-friendly machines around.

Read more: Creality CR-10 V3 Review – Is It the Best Mid-Range 3D Printer?

Conclusion

Choosing the right 3D printer accessories greatly increases the chances of creating a flawless 3D print. These decent investments can make the 3D printing process much easier and enjoyable.

Which of these 3D printer accessories do you already use? Do you have some other useful 3D printer accessories that are not on the list and should be? I’d love to hear about it in the comments section below.

If you want to buy a 3D printer check out our list of the best budget friendly 3D printers that are ideal for hobbyists and beginners who are just getting started.

Top 6 Essential 3D Printer Accessories

3D printer accessories are additional tools and parts that fulfill a specific function or requirement of the 3D printing process. For example, some filaments like PVA and Nylon need to be dried to print properly and produce higher quality 3D printed parts and reducing the risk of failing a print job. The most common 3D printer accessories include filament dryers, vacuum containers, dry boxes, different sized 3D printer nozzles, hardened nozzles, 3D printer carts, and 3D printer bed adhesive.

For example, some filaments like PVA and Nylon need to be dried to print properly and produce higher quality 3D printed parts and reducing the risk of failing a print job. The most common 3D printer accessories include filament dryers, vacuum containers, dry boxes, different sized 3D printer nozzles, hardened nozzles, 3D printer carts, and 3D printer bed adhesive.

- Filament Dryer: PrintDry Filament Pro

- Vacuum Container: PrintDry Vaccuum Container

- Drybox: Polybox

- 3D Printer Carts: Raise3D Pro2Plus printer cart Raise3D Pro2 printer cart

- 3D Printer Bed Adhesive: Magigoo, Magigoo PP, Magigoo PA

- Hardened nozzles: Raise3D hardened nozzle

Why Are Filament Dryers Necessary in 3D Printing?

Most filaments print at 200C or above, and filaments must be dry before beginning the printing process. If a filament is still wet during printing, the moisture from the wet filament will vaporize in the nozzle. This will have a high chance of printing failure and cause a poor final print quality. Nylon and PVA are two typical examples of filaments absorb moisture from the air. It is necessary to dry them out before printing. It is recommended to dry out PLA and ABS filaments if they were exposed to air for more than one week, especially in an area that contains high humidity. A useful 3D printer accessory that dries out filaments is the PrintDry Filament Dryer Pro. PrintDry Filament Dryer Pro is a storage box that provides a heated environment that bakes filaments. The heated-environment of the dryer allows moisture to escape, ensuring that the filament remains dry.

This will have a high chance of printing failure and cause a poor final print quality. Nylon and PVA are two typical examples of filaments absorb moisture from the air. It is necessary to dry them out before printing. It is recommended to dry out PLA and ABS filaments if they were exposed to air for more than one week, especially in an area that contains high humidity. A useful 3D printer accessory that dries out filaments is the PrintDry Filament Dryer Pro. PrintDry Filament Dryer Pro is a storage box that provides a heated environment that bakes filaments. The heated-environment of the dryer allows moisture to escape, ensuring that the filament remains dry.

Vacuum Containers Are Important 3D Printer Accessories

Filaments that absorb moisture can be kept dry between print jobs so the next printing job can begin without delay. A 3D printer accessory such as the PrintDry Vaccum Container will keep filaments dry in storage. The PrintDry Vaccum Container features a special vacuum valve and pump which suck the air out of the container creating a vacuum seal. The vacuum seal prevents moisture in the air from entering the storage container. The PrintDry Vacuum Container indicates when the vacuum seal has been created. The center of the vacuum valve will collapse inwards from its original dome shape once the vacuum seal is created.

The vacuum seal prevents moisture in the air from entering the storage container. The PrintDry Vacuum Container indicates when the vacuum seal has been created. The center of the vacuum valve will collapse inwards from its original dome shape once the vacuum seal is created.

Why and How Do Dryboxes Benefit the 3D Printing Process?

When filaments are dried, it means low moisture has left the filament. If the material property is hydrophilic, meaning if the dried filament is left in the open air, it will begin to absorb moisture, making it wet again. And wet filaments lead to a failed print job. Sometimes filaments used in projects with a longer printing time are exposed to the moisture in the air longer. In such cases, after a certain amount of hours, the filaments can become wet again which will lead to a failed print job. A 3D printer accessory such as the Polybox is a dry box that works with industrial 3D printers to keep filaments dry during the printing process. The PolyBox features a filament guide tube from the PolyBox to the 3D printer’s extruder to prevent any moisture from affecting the filament during the printing process.

The PolyBox features a filament guide tube from the PolyBox to the 3D printer’s extruder to prevent any moisture from affecting the filament during the printing process.

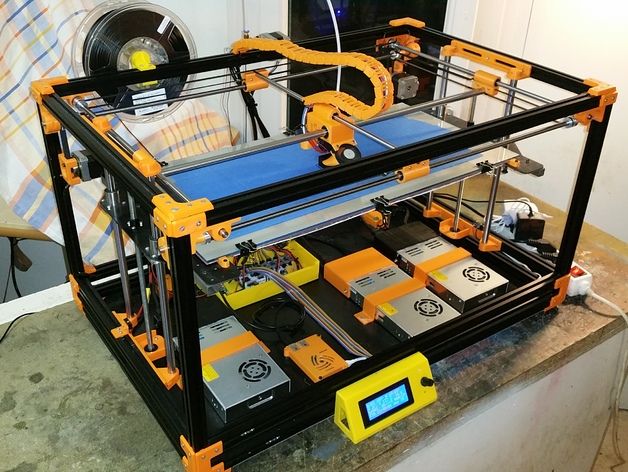

3D Printer Carts Are Practical and Make 3D Printing Easier

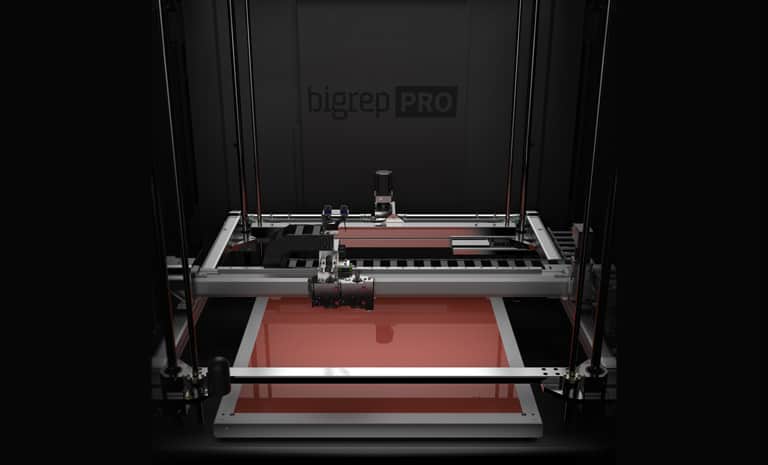

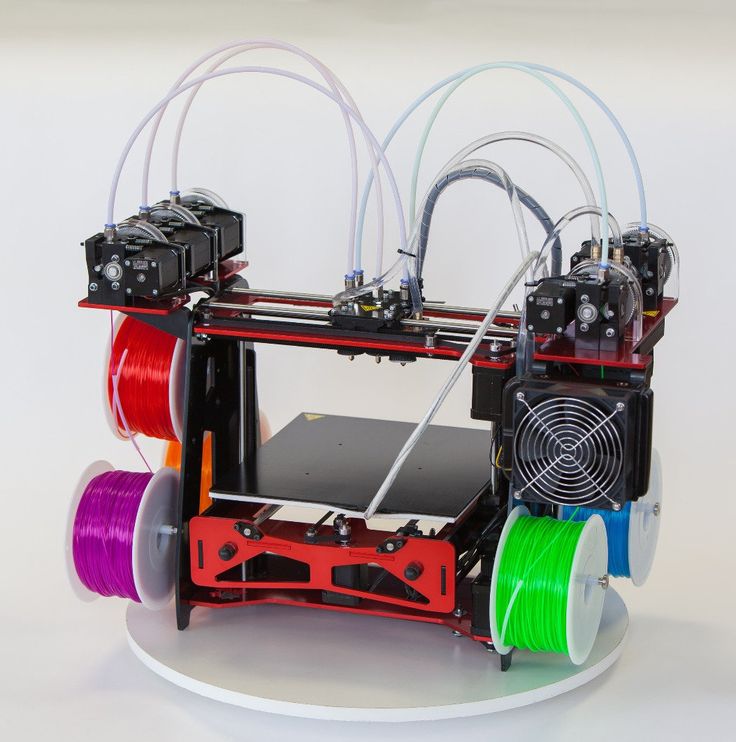

Professional 3D printers such as dual extruder 3D printers and large format 3D printers that are larger than desktop 3D printers need a dedicated workspace. Carts are an excellent way of giving the 3D printer its needed workspace. For example, Raise3D offers pedestal printer carts with wheels to roll around. These pedestal carts are designed to keep work at eye-level. Raise3D pedestal carts can bring the printer to the proper operating height so the user can easily operate the 3D printer without having to bend over. Finally, the carts also help to organize any tools needed during the 3D printing process while also storing accessories, filaments, and parts.

More 3D printer accessories can assist the 3D printing process. However, each application is different, and it is imperative to evaluate what specific applications and printing projects require. For example, it is recommended to keep spares of common consumables such as hot ends, build plates, buildtak, nozzles, and more. For any additional questions, contact Raise3D.

However, each application is different, and it is imperative to evaluate what specific applications and printing projects require. For example, it is recommended to keep spares of common consumables such as hot ends, build plates, buildtak, nozzles, and more. For any additional questions, contact Raise3D.

3D Printing Adhesive is Necessary for Some Filaments

Filaments need to be able to stick to the build plate of the 3D printer while the part is being built up during the printing process. Some 3D printers come with a plain glass plate and it is mandatory to apply an adhesive to the glass plate to make a print stick to the glass plate. 3D printers with glass plates are not recommended because applying the glue is a messy process. The glass plate itself could also break becoming a potential hazard. However, Raise3D professional 3D printers feature a build plate with a buildtak surface. A buildtak surface is a great sticking surface for most 3D printing materials. However, certain 3D printing materials require extra adhesive to stick to the surface. In such cases, glue sticks, like MagiGoo, are a good complimentary 3D printer accessory.

However, certain 3D printing materials require extra adhesive to stick to the surface. In such cases, glue sticks, like MagiGoo, are a good complimentary 3D printer accessory.

In general, it is recommended to have at least one extra build plate to swap out for each printer. However, there are certain situations in which having a spare build plate to swap out is practical. For example, it may be necessary to change to a different 3D printing material, and that material may require a different print bed. Other times the production process may be quicker if the printer bed holding a finished 3D printed part is removed and replaced with a fresh print bed to continue the next print job, instead of waiting to take out the finished 3D printed part first.

Different Glues Are Necessary for Different Filaments

However, sometimes different types of glue are required for different kinds of filaments. For example, MagiGoo also offers MagiGoo PA and MagiGoo PP. MagiGoo PP works with PP filament. The molecular structure of PP filament makes it difficult for the PP filament to adhere to other materials, like the 3D printer bed. MagiGoo PP will help models made with PP filament stick to the printer bed.

MagiGoo PP works with PP filament. The molecular structure of PP filament makes it difficult for the PP filament to adhere to other materials, like the 3D printer bed. MagiGoo PP will help models made with PP filament stick to the printer bed.

MagiGoo PA is intended to work only with PA filament. There are three main types of PA filament which can either be grafted together or reinforced with carbon or glass. PA has difficulty sticking to the 3D printer build plate with a tendency to warp, making them a challenge to print with. MagiGoo PA is intended to address these PA specific concerns while retaining the high-quality and user-friendly design of the original MagiGoo.

Magigoo PAHow Do Different Sized 3D Printer Nozzles Impact 3D Printing?

Having different 3D printer nozzles is essential for different types of print jobs. For example, bigger nozzles, like a .8 3D printer nozzle, prints out more material and a thicker layer height. This means the print job can be completed faster. It is common to use a bigger nozzle with a thicker layer height to quickly produce a 3D printed part. However, print quality and finer features are usually compromised in the final printing result. For example, the print layer will be more obvious in the final 3D printed part. However, this compromise may not matter for certain applications or can be adjusted in the post finishing. In such cases, this form of printing will save printing time. In contrast, smaller nozzles, like a .4 3D printer nozzle are necessary to print a thinner layer height.

This means the print job can be completed faster. It is common to use a bigger nozzle with a thicker layer height to quickly produce a 3D printed part. However, print quality and finer features are usually compromised in the final printing result. For example, the print layer will be more obvious in the final 3D printed part. However, this compromise may not matter for certain applications or can be adjusted in the post finishing. In such cases, this form of printing will save printing time. In contrast, smaller nozzles, like a .4 3D printer nozzle are necessary to print a thinner layer height.

The thinner layer height and smaller nozzle sized will be able to produce finer details and produce a better print quality in the final 3D printed part. In general, doubling the value of the layer height should cut the print time down by about half, but it always varies from model to model.

| Nozzle Size | Layer Height | Print Time |

|---|---|---|

. 4mm nozzle 4mm nozzle | .2 layer height | 42 hours, 15 minutes, and 32 seconds |

| .8mm nozzle | .4 layer height | 16 hours, 36 minutes, and 52 seconds |

Why Are Hardened Nozzles Essential For 3D Printing?

Nozzles do not just come in different sizes. There are also hardened nozzles that are mandatory for applications that require filaments made with composite materials such as carbon fiber, glass fiber, etc. For a full list of such filaments, click here. Composite materials are harder than brass and will be abrasive to the brass nozzle. This will damage the brass nozzle by enlarging the nozzle tip size. When this occurs, the print file settings no longer match the actual nozzle size on the 3D printer. In this situation, the print quality decreases, and the risk of a failed print job increases.

There are three kinds of hardened nozzles. The first is a brass nozzle with a hardened coating, such as the current hardened nozzles on the Raise3D printers. Since the nozzles are mainly brass, the heat conductivity is not affected, meaning the printing temperature is not affected much. Finally, brass nozzles with a hardened coating are the most affordable. However, it is recommended to keep spare hardened coated nozzles to replace the hardened nozzle whenever the coating wears off.

Since the nozzles are mainly brass, the heat conductivity is not affected, meaning the printing temperature is not affected much. Finally, brass nozzles with a hardened coating are the most affordable. However, it is recommended to keep spare hardened coated nozzles to replace the hardened nozzle whenever the coating wears off.

The second type is a high-speed steel nozzle with WS2 coating. It is abrasion-resistant, with a high printing performance, and priced between the brass nozzle with a hardened coating and the brass nozzle with a ruby tip.

The third and final type of hardened nozzle is a brass nozzle with ruby tips. Brass nozzles with ruby tips have an overall good printing performance, but they are also quite expensive. It is not uncommon for brass nozzles with ruby tips to be priced as high as $100 per nozzle.

Connect with Raise3D:

Have you had a great experience with Raise3D that you would like to share? Please contact us at inquiry@raise3d. com. We look forward to hearing from you.

com. We look forward to hearing from you.

For more information about Raise3D printers and services, browse our website, or schedule a demo with one of our 3D printing experts.

8 nuances worth paying attention to

Sooner or later, everyone learns about 3D printing. And only a few lucky people, imbued with the opportunities that 3D printing opens up, catch themselves thinking that they want to purchase a 3D printer. The desire gradually develops into a serious decision and the search for the right option begins. And here the potential buyer is faced with the fact that he does not fully understand what to choose among the whole variety of 3D printers. We will try to answer this question in as much detail as possible. What to look for, and how to make a choice? We want to offer a small checklist of the nuances that you need to pay attention to when choosing a 3D printer. You need to decide for yourself for what tasks you will use this technique? What features should a 3D printer have to solve your problems?

Tip 1 : Decide on 3D printing technology

The first step is to decide on the technology of 3D printing. There are two main paths here. If you are faced with the task of manufacturing high-precision and miniature products, such as jewelry, then 3D printers using SLA or DLP technology are suitable for you. Such printers are specially designed for the manufacture of high-precision models. 3D printing in these printers occurs using a laser beam that illuminates the photopolymer resin. Hence the accuracy of the models. Prominent representatives of this segment: Form 2 3D printer or B9 3D printercreator If you are faced with a wider range of tasks, and functionality, part size, and low manufacturing cost are more important, then an FDM printer will suit you. 3D printing on this equipment involves layer-by-layer melting of plastic. If according to SLA printers everything is clear. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

There are two main paths here. If you are faced with the task of manufacturing high-precision and miniature products, such as jewelry, then 3D printers using SLA or DLP technology are suitable for you. Such printers are specially designed for the manufacture of high-precision models. 3D printing in these printers occurs using a laser beam that illuminates the photopolymer resin. Hence the accuracy of the models. Prominent representatives of this segment: Form 2 3D printer or B9 3D printercreator If you are faced with a wider range of tasks, and functionality, part size, and low manufacturing cost are more important, then an FDM printer will suit you. 3D printing on this equipment involves layer-by-layer melting of plastic. If according to SLA printers everything is clear. The scope of their application is jewelry, dentistry, high-precision prototypes of small parts. Then we will dwell on FDM printers in more detail. There is a lot more variety of different options for implementing printers.

Nuance 2: Evaluate your needs

Of course, you always want to get all the best and with maximum opportunities. Do you need all this to solve your current problems? What can be cited as an example? For example, the size of the working area of the FDM 3D printer. There are printers on the market with a large print area (1m x 1m x 1m), and with a very small one (100mm x 100mm x100mm). But for most tasks, a certain standard has already developed. This is the printable area within 200 x 200 x 200 mm. With slight fluctuations in size in one direction or another. Most 3D printers have exactly this size of the working area. This volume is enough to solve 95% of any tasks. But options are possible ... If you plan to manufacture small parts, then a smaller size will probably be enough for you. But if your work will be related to manufacturing, for example, a master model for casting, or large prototypes, then only then it makes sense to pay attention to a printer with a large print area. In other cases, the size of the print area larger than the standard is nothing more than a nice bonus. But as they say, you have to pay for everything. Therefore, most often it makes sense to focus on the “standard” print area. And even if the part you need to print is larger than the working area of your 3D printer, you can always cut it in a special editor, and then print 2 parts of the model and glue them together.

In other cases, the size of the print area larger than the standard is nothing more than a nice bonus. But as they say, you have to pay for everything. Therefore, most often it makes sense to focus on the “standard” print area. And even if the part you need to print is larger than the working area of your 3D printer, you can always cut it in a special editor, and then print 2 parts of the model and glue them together.

Nuance 3 : Decide on the complexity of the products

You should decide for yourself how complex models you will print on a 3D printer. If you plan to manufacture complex prototypes, or complex art models, then you need a 3D printer that can print with two materials. This is necessary so that your printer can print supports from soluble material. If the models are not the most complex, then you can get by with one extruder and save the budget. A complex model is a model with a large number of elements suspended in the air, or a model whose elements have angles of more than 30 degrees.

Point 4: Decide on the list of materials to be used.

Another important point. You must immediately determine for yourself a list of possible materials with which you are going to print. This primarily applies to materials with a high degree of shrinkage, such as ABS and Nylon. In order to print with such materials, a heated table is clearly required in a 3D printer. And it is very desirable to have a closed case to provide a thermal circuit around the model. If you plan to print only with PLA plastic. You don't need a heated table. But still it is better that the printer has a heated table. Now the difference in the cost of printers with a heated table is practically the same as the cost without it. But you get a universal solution with which you can perform the full range of tasks facing a 3D printer. One more moment. Ability to print with flexible materials Quite a number of 3D printers face the problem of printing with flexible materials. Of course, printing with various Flexes and Rubbers is very interesting at first glance. But the use of these materials in life is not very common. Usually, for most people, this happens like this: A couple of models are printed, and the understanding comes that this is not a fast and rather complicated process. And this is where the acquaintance with flexible materials ends. Therefore, it makes sense to demand such an opportunity from the printer if printing with such materials is very necessary.

Of course, printing with various Flexes and Rubbers is very interesting at first glance. But the use of these materials in life is not very common. Usually, for most people, this happens like this: A couple of models are printed, and the understanding comes that this is not a fast and rather complicated process. And this is where the acquaintance with flexible materials ends. Therefore, it makes sense to demand such an opportunity from the printer if printing with such materials is very necessary.

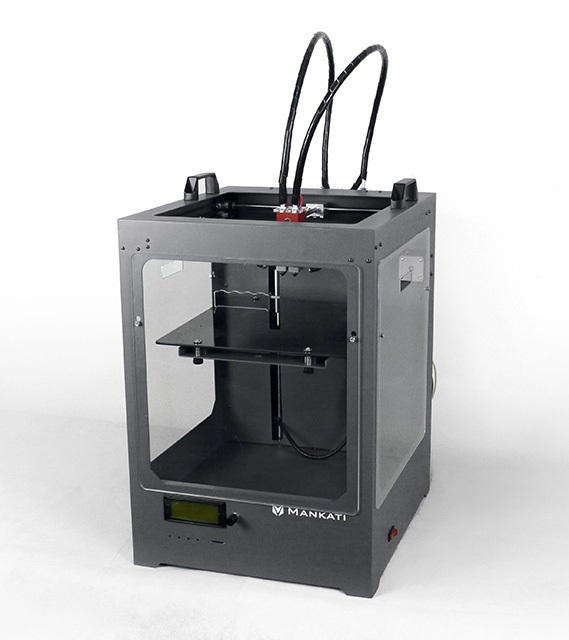

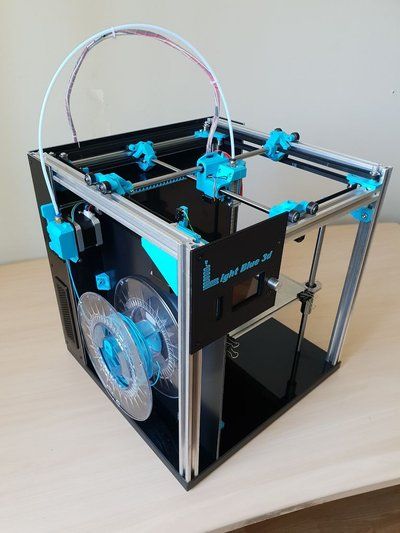

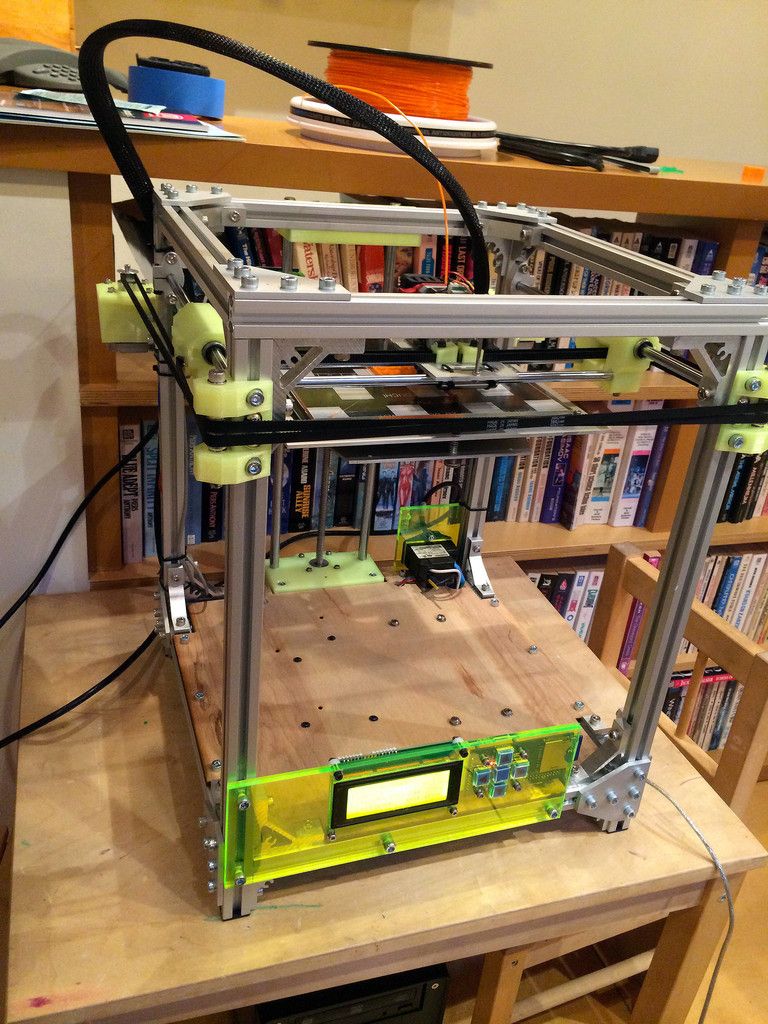

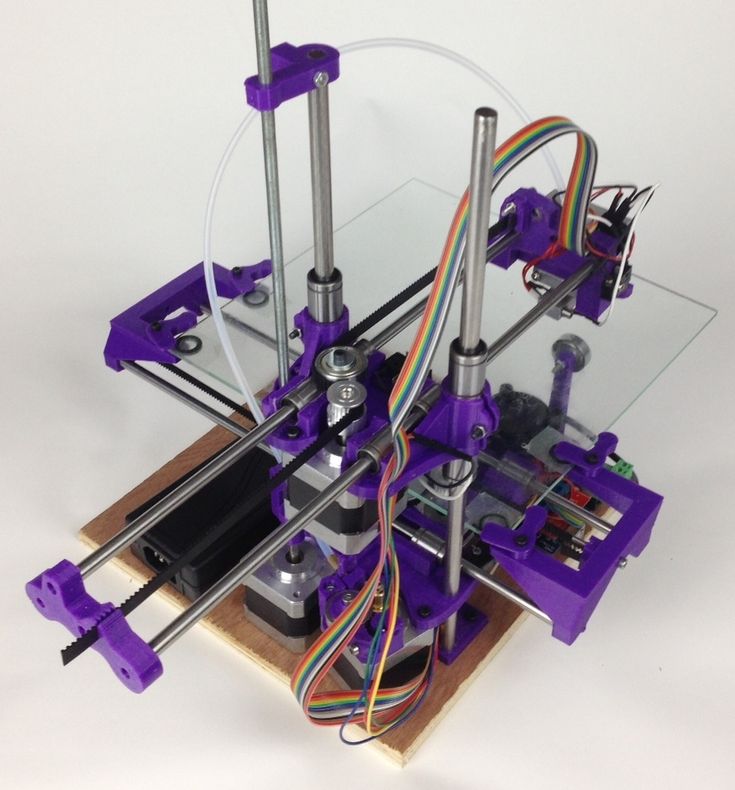

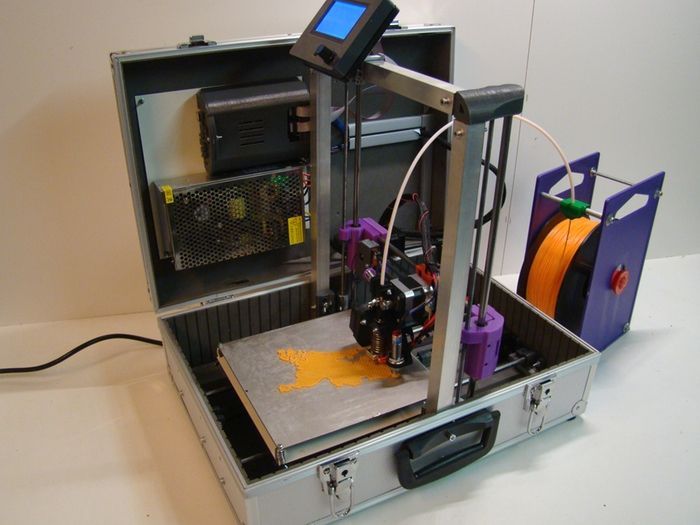

Nuance 5: Construction and kinematics

Next, you need to pay attention to the design of the 3D printer. Even if you are not a great specialist in technology, you can immediately see that some printers have an open design. And others are closed. As they like to be called in the Russian-speaking community "cubes". What does the appearance say? Printers with an open design, usually have kinematics with a horizontally moving table (based on Prusa 3D printers). This kinematics has some inherent flaws. Such as, not the highest print speed and possible print quality problems associated with the complexity of the settings. First of all, this is the so-called wobble. Also, the lack of a closed case can cause print quality problems with high shrinkage plastics (ABS, Nylon). The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by leading manufacturers on the market. Such printers are built according to the lifting table scheme. And they lack most of the shortcomings that are inherent in printers from the previous group. “Cubes” usually have a closed body, which allows the highest quality printing with plastics with a high degree of shrinkage. Closed case printers are more rigid. This results in better quality printing. The kinematics of moving the print head is represented by various designs.

This kinematics has some inherent flaws. Such as, not the highest print speed and possible print quality problems associated with the complexity of the settings. First of all, this is the so-called wobble. Also, the lack of a closed case can cause print quality problems with high shrinkage plastics (ABS, Nylon). The main advantage of printers of this design is their price. It is usually lower. But as you know, you have to pay for everything. In this case, the worst performance. The so-called "cubes" today, is the main design, which is represented by leading manufacturers on the market. Such printers are built according to the lifting table scheme. And they lack most of the shortcomings that are inherent in printers from the previous group. “Cubes” usually have a closed body, which allows the highest quality printing with plastics with a high degree of shrinkage. Closed case printers are more rigid. This results in better quality printing. The kinematics of moving the print head is represented by various designs. They have their pros and cons. But most of them have advantages over moving table printer circuits.

They have their pros and cons. But most of them have advantages over moving table printer circuits.

Nuance 6: Diameter and changeable nozzle

Most 3D printers on the market come with 0.3-0.4mm nozzles. This is enough to solve the vast majority of tasks facing a 3D printer. Some of the printers have the ability to install a nozzle of a different diameter, others do not. As we wrote above, the need to print with nozzles with a diameter other than 0.3-0.4 mm arises very infrequently. This mainly concerns, or personal experiments, or some very specific tasks. If you do not plan to do this, then this opportunity is not so necessary. What do we mean by specific tasks? This is especially true for printing large items, where it is very important to reduce the printing time. This can be achieved by using large diameter nozzles. For example, with a diameter of 0.6-0.8 mm, or even a diameter of 1 mm. For printers with a large printable area, the ability to change nozzles is already a vital necessity. Therefore, here, as in the case of a heated table, the ability to change nozzles is a good bonus. It is not mandatory, but very useful if you do not have to pay extra for it.

For printers with a large printable area, the ability to change nozzles is already a vital necessity. Therefore, here, as in the case of a heated table, the ability to change nozzles is a good bonus. It is not mandatory, but very useful if you do not have to pay extra for it.

Nuance 7: Print thickness

It is important to understand that most models on a 3D printer are printed with a layer of 0.1-0.2 mm. These are the optimal values that allow you to achieve quality and acceptable print speed. There are a certain number of printers that allow you to print with a layer of less than 0.05 mm, and get very high quality prints. But then there is the problem of a sharp increase in print time. And if such print quality is important to you, then it probably makes sense to turn your attention to 3D printers, which we talked about at the very beginning of the article. These are 3D printers using SLA or DLP technology.

Nuance 8: Extruder type

Today there are two main types of extruder. This is a direct extruder in which the bar feed motor is located in the printhead itself. And the so-called Bowden extruder, where the plastic feed motor is located on the body. And the plastic itself is fed to the extruder through a fluoroplastic tube. What are the advantages and disadvantages of each type of extruder? Bowden extruder, due to the lack of a motor on the print head, has less weight. And therefore, it has greater positioning accuracy, which affects the print quality. And a higher speed of movement, which, accordingly, has a positive effect on the speed of printing. But it has one drawback. It is usually difficult to print with flexible plastics on a Bowden extruder. Such as Rubber or Flex. All its positive features, this extruder reveals when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the now standard plastic with a diameter of 1.75 mm. And therefore, users of printers with such plastic are often deprived of the opportunity to use new types of materials.

This is a direct extruder in which the bar feed motor is located in the printhead itself. And the so-called Bowden extruder, where the plastic feed motor is located on the body. And the plastic itself is fed to the extruder through a fluoroplastic tube. What are the advantages and disadvantages of each type of extruder? Bowden extruder, due to the lack of a motor on the print head, has less weight. And therefore, it has greater positioning accuracy, which affects the print quality. And a higher speed of movement, which, accordingly, has a positive effect on the speed of printing. But it has one drawback. It is usually difficult to print with flexible plastics on a Bowden extruder. Such as Rubber or Flex. All its positive features, this extruder reveals when using plastic with a diameter of 2.85-3.00 mm. But this type of plastic is less common than the now standard plastic with a diameter of 1.75 mm. And therefore, users of printers with such plastic are often deprived of the opportunity to use new types of materials. Which are primarily produced in the most common form factor of 1.75mm. The direct extruder usually doesn't have such big problems with flexible plastics. Easier to set up, but due to the greater mass of the print head, it is inferior to the Bowden extruder in terms of speed and positioning accuracy. What to prefer? This is the user's choice. We just wanted to talk about the pros and cons of these extruder types. Of course, there are many more nuances when choosing a 3D printer. But we think that even our small list will force you to look and study some points that you may not have thought about more closely. And it will save you time and money when choosing a 3D printer. 3Dtool company has extensive experience in the 3D equipment market. We work with leading Russian and foreign manufacturers, offering high-quality equipment for a reasonable price. Our service center is staffed by highly qualified specialists who are able to solve any problem in the shortest possible time, and all offered 3D printers come with a 1-year warranty.

Which are primarily produced in the most common form factor of 1.75mm. The direct extruder usually doesn't have such big problems with flexible plastics. Easier to set up, but due to the greater mass of the print head, it is inferior to the Bowden extruder in terms of speed and positioning accuracy. What to prefer? This is the user's choice. We just wanted to talk about the pros and cons of these extruder types. Of course, there are many more nuances when choosing a 3D printer. But we think that even our small list will force you to look and study some points that you may not have thought about more closely. And it will save you time and money when choosing a 3D printer. 3Dtool company has extensive experience in the 3D equipment market. We work with leading Russian and foreign manufacturers, offering high-quality equipment for a reasonable price. Our service center is staffed by highly qualified specialists who are able to solve any problem in the shortest possible time, and all offered 3D printers come with a 1-year warranty.

In our assortment you can always find 3D printers for your tasks:

1) Budget 3D printers

2) 3D printers for business

3) Large area 3D printers

4) SLA and DLP 3D printers

Do you have any questions?

Call: +7 (495) 324-07-90 (Moscow) and 8 (800) 775-86-69 (toll-free in the Russian Federation) or write to the mail: [email protected] and our employees will be happy to give you a detailed consultation on any topic of interest.

What should be the ideal 3D printer?

Personal diaries

Subscribe to the author

Subscribe

Don't want to

4

Decided to dream a little. I ask everyone to join me and don't downvote too much :'(

Maybe someone will take a risk and invest in such a startup)))

were considered a luxury, but now they are the standard no longer surprise anyone, for example, a heated table, a double extruder, a reusable table cover, etc.

In my opinion, the future lies with the following features:

- self-cleaning of the table (from dust, plastic residues and after canceling unsuccessful printing)

- foolproof in the form of limit switches, sensors, cameras and microphones - the model comes off the table - the printer increases the temperature, or the vacuum table in general, or the table itself is lubricated with glue))) rewound, clicks appeared - the printer starts self-diagnosis

- adaptive autoslicing - only models are loaded into the printer, Gcode is generated automatically. Plus adaptation for shrinkage / tightening in the form of a decrease in print speed, temperature changes, etc.

- the ability to add the required number of extruders - two is not enough - add a third, not enough - add more (most likely it will work like on CNC machines with a drum tool change mechanism)

- auto detachment of the part after printing is completed extruder with a rotation of 45 degrees (combine the classic approach and kr-30 kreality)))

- and most importantly - a built-in coffee machine to enjoy the view of 3D printing

Have ideas for the perfect printer - write in the comments)))

interesting articles

AlekS

Loading

10/19/2022

450

eight

Follow the author

Subscribe

Don't want

I will leave here this collection for Exorcism and resurrection of boards from BTT

https://g.