3D resin printer ventilation

DIY Ventilation and Filtration for 3D Printing

This 4D Filtration resource is user-supported by donations, affiliate links, and/or ads.

Last Updated: June 6th, 2022

The following simulations are intended to provide a comparison between common ventilation setups for 3D printers. The animations represent the behavior of the particulates and VOCs that are suspended by airflow. The exact concentrations present during printing are not accounted for as these may be touched on in future works.

Grow tents are an affordable and effective option to keep the heat in for both FDM and resin printers. Duct from fume extractors can easily be attached to a grow tent - this is ideal for FDM printers. For resin printers, grow tents can be used to enclose the printer and vent the fumes out a window - this is occurs when you do not have access to a work area outside the residence (ie: garage, shed, etc).

Table of Contents

- Worse Case: Indoors With No Ventilation

- Best Case: Outdoors

- Ideal Case: Garage or Separate Room, No Enclosure

- Ideal Case: Garage or Separate Room, Grow Tent Enclosure

- Using Filtration For Mitigation & Secondary Defense

Assumptions

- The small resin printer is simplified to a 20" cube.

- Air temperature is 90°F (32°C), and there is an external wind speed of 5 mph (2.2 m/s).

- The room size is 12x16' (3.7x4.9 m).

- The airflow is represented by transparent brown arrows; the particles are the spheres, colored by the legend dependent on their velocity.

Worst Case Scenario

Sealed Room With No Ventilation

A completely sealed room allows for the particle concentration to increase.

The mixture remains suspended by free convection that is powered by heat from electronics, sunlight, and artificial light.

Best Case Scenario

Balcony or Patio With 5 mph Wind

While not always practical, placing the printer outside allows for particles to be swiftly carried away by a light wind.

The goal of ventilation is to attempt to reach this behavior while the printer is indoors.

Garage or Indoor Ventilation

Garage or Room With Box Fan

Perhaps the cheapest garage or indoor solution, the good ol' plop a fan in the window method will move a lot of air but will gradually expose the entire room to the external temperature. In a garage, this could work when it is warm outside, but the cool winter air can result in print failures. A small heater will be needed in this case.

In a garage, this could work when it is warm outside, but the cool winter air can result in print failures. A small heater will be needed in this case.

The simulated box fan is rated at 1,800 CFM and ≈0.10 inH2O.

Garage or Room With Box Fan & Cracked Window

Slightly opening a window allows for air to enter the room, ensuring that there are no stale pockets of air.

This case will be common for most rooms due to air leaking in through cracks, ducts, and under doors.

The static pressure experienced by the fan is lowered, thereby increasing the flow rate.

Garage or Room With Box Fan & Open Window

Fully opening a window or door maximizes the circulation and ventilation of the air-particle mixture.

Remember that this showcases the particle behavior and not the concentration.

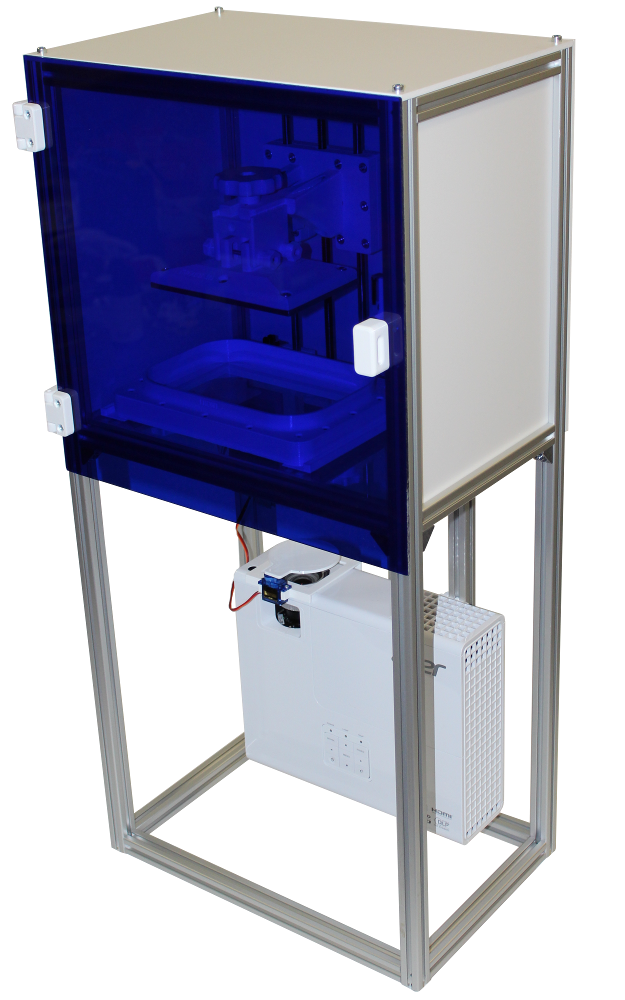

Garage or Indoor Enclosure and Ventilation

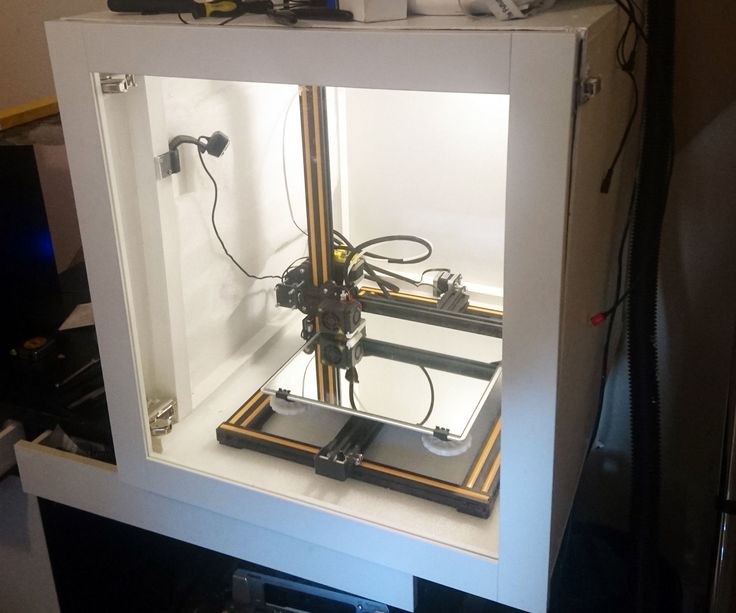

Grow Tent Enclosure With Ventilation

This is an ideal solution for ventilating since the particles are contained and there is minimal impact on the air temperature of the residence.

The simulated enclosure is a grow tent that lets air in through the zipper and small cracks.

The ventilation is provided by a 120mm fan with a meager 40 CFM and 0.11 inH2O. This level of fan prevents excess heated/cooled indoor air from being lost during printing. However, when the enclosure is opened, the small fan is not able to extract the fumes as well as tube-axial (inline) fans.

Recommended Ventilation Equipment

Grow Tent Inspiration

A grow tent could be used:

- outdoors to block wind, sun, rain, and critters on a patio or balcony

- indoors to vent directly outside

- in a garage to help contain heat and optimize venting

- with a fume extractor before being vented

- to fit a printer + a wash & cure station if wide enough

- as a fume hood if using a strong inline fan

See Grow Tents

Sample Size = 178

Install Filtration as a Secondary Defense

Installing ventilation should always be the primary focus, with filtration acting as a secondary defense. In the event that ventilation is not possible then fume extractors can be utilized so long as they are maintained and the filters replaced regularly. For FDM printers, installing filtration is often a necessity since the vast majority of filaments are temperature sensitive.

In the event that ventilation is not possible then fume extractors can be utilized so long as they are maintained and the filters replaced regularly. For FDM printers, installing filtration is often a necessity since the vast majority of filaments are temperature sensitive.

Even if ventilation is installed, you may feel more comfortable with the extra layer of defense provided by an air cleaner. For FDM printers, the focus will be split on removing both particulates and VOCs, whereas SLA will be primarily VOCs.

Particulates can be efficiently removed with MERV 11-16 or HEPA filters. HEPA filters are not always the best option since they often have a lower flow rate compared to a MERV filter, but they perform well for fume extraction.

The efficient removal of VOCs will require a bed of activated carbon granules or pellets. Impregnated foam is not recommended since it is not as efficient nor as long-lasting as granules. The capture efficiency of professional/industrial activated carbon systems can be 92-98%, but smaller units with a carbon thickness of 1-2 inches can have an efficiency of 40-60%. The capture efficiency of carbon will vary depending on the chemicals, impregnation, thickness, temperature, air speed, and etc. The efficiency will decrease when the carbon surpasses a saturation threshold dependent on the thickness of its mass transfer zone.

The capture efficiency of carbon will vary depending on the chemicals, impregnation, thickness, temperature, air speed, and etc. The efficiency will decrease when the carbon surpasses a saturation threshold dependent on the thickness of its mass transfer zone.

Filtration - Fume Mitigation

These small air cleaners are designed to be placed inside the cover of a resin printer. The units only use activated carbon so they be able to capture an estimated 40-60% of fumes until they become saturated. Particulates will not be captured to any meaningful extent. The P Mini air cleaner's files are free to download, it uses a blower fan with a higher static pressure, the extra battery capacity gives hours of additional use, and the thick carbon bed will have a longer life and higher capture efficiency.

4D Filtration - P Mini

DIY

Battery: 5,000 mAh

Carbon: 50 g

Dimensions: 53x53x133 mm

4D FiltrationPrintablesThingiverse

Anycubic - AirPure

$23

Battery: 2,000 mAh

Carbon: 13. 6 g

6 g

Dimensions: 46x46x115 mm

AnycubicAmazonAliExpress

Elegoo - Mini Air Purifier

$25

Battery: 2,000 mAh

Carbon: 13.6 g

Dimensions: 44x44x107 mm

ElegooAmazonAliExpress

Filtration - Fume Extractors

Fume extractors are designed to remove the majority of containments from the air leaving an enclosure. The Promethean air cleaner is offered as an affordable alternative that can be hooked up using duct, be inside an enclosure, or next to the printer - the higher flow rate allows it to act similar to a normal air cleaner. The BOFA air cleaners utilize HEPA media, have a thicker carbon bed, and are a bit more quiet - the downside is the price bump. Fume extractors are ideal for resin and FDM.

4D Filtration - Promethean

DIY or $150

MERV Filter: $15

Activated Carbon: $10+

Airflow: 11-27 cfm

Noise: 41-68 dB

Protection: Particulates & VOCs

via MERV & Activated Carbon Granules

4D Filtration

BOFA - Print Pro 2

$770

Combo Filter: $260

Airflow: 26. 5 cfm

5 cfm

Noise: <44 dB @ "typical"

Protection: Particulates & VOCs

via HEPA & Activated Carbon Granules

BOFAMatterHackers

BOFA - Print Pro 3

$1,200

Combo Filter: $260

Airflow: 88 cfm

Noise: <57 dB @ "typical"

Protection: Particulates & VOCs

via HEPA & Activated Carbon Granules

BOFAMatterHackers

Filtration - DIY

Canisters of carbon are an affordable option for DIY fume extraction for resin printers. The canisters can be used to filter and recirculate the air in an enclosure such as a grow tent, or they can be used to capture the majority of contaminants before venting. These do not capture particulates to any meaningful extent, thus they should not be used for FDM by themselves.

Carbon Canisters

$38+

Amazon - VivosunAmazon - AC Infinity

Activated Carbon

$5+

Make sure to get coconut shell carbon

4D FiltrationAmazon - USAmazon - CAAmazon - UKAmazon - AU

To compare resin printers, browse resin, and get equipment inspiration visit our Ultimate Resin Guide.

To compare FDM printers via an interactive table, side-by-sides, and in-depth articles.

Application & Safety FAQ answers common questions about resin.

Ventilation Simulations has animations for common DIY venting setups, and Heating Resin Printers during winter provides data for specific heat sources.

Our Resin Print Settings Table has associated images, mixes, and does a resin giveaway.

To browse resin properties and find your ideal strong, durable, flexible, or high-temp resin visit our Resin Properties Table. To find properties of filaments, visit our FDM Properties Table.

Disclaimer: You assume all responsibility and risk for the use of, but not limited to, the resources, advice, and opinions of 4D Filtration or its employees. 4D Filtration or its employees do not assume any liability or create any warranty for the use of any information. 4D Filtration may receive commissions for referral links. Prices are approximated for simplicity and they may fluctuate due to sales or markdowns. Amazon .com should refer you to your local amazon site if you are not in the United States; there is a chance Amazon's link redirect system will take you to a different product.

Amazon .com should refer you to your local amazon site if you are not in the United States; there is a chance Amazon's link redirect system will take you to a different product.

Back to Resources!Check out our Resin Guide!

Did we miss anything or do you have any information worth an update? Let us know!

Like the resources? Consider supporting us via donation, referral links, or purchases!

How to Ventilate a 3D Printer Properly – Do They Need Ventilation? – 3D Printerly

3D printer fumes and pollutants are usually overlooked by people, but it’s important to ventilate your 3D printer properly.

There are some great ventilation systems that you can make use of to have your 3D printing environment safer and less harmful to people around it.

The best way to ventilate a 3D printer is to put your 3D printer in an enclosure and have a ventilation system that properly tackles the small particulates that 3D printers emit. Make sure you have carbon filters to get rid of the smaller particles that a HEPA filter won’t get rid of.

The rest of this article will answer some key questions on 3D printer ventilation, as well as detail some nice ventilation systems that you can implement yourself.

Do You Need Ventilation for a 3D Printer?

During the printing process, you might have smelled the odor that is produced by the printer. To expel this odor out of the machine and workspace, you can use good ventilation.

However, the quality and smell of odor depends on the type of material that is used for printing purposes. For example, PLA is much safer when it comes to the smell than other filaments such as ABS.

Other than the smell, we also have small particles that are emitted from heating thermoplastics at such high temperatures, the higher the temperature, the worse the particles usually.

It also depends on the chemical makeup of the thermoplastic in the first place. If you are printing with ABS, Nylon or resin material in SLA 3D printers, proper ventilation is highly recommended, along with a mask.

A good enough ventilation system can work very well for ensuring that the surrounding air is clean and not contaminated.

It is said that the average running time for a 3D print can be around 3-7 hours, which is almost a quarter of the whole day when it is producing fumes.

To avoid any kind of harmful effect on your health or body, you seriously need to set up a ventilation system.

Ventilation While Using PLA

PLA is made up of eco-friendly material that produces sweet-smelling fumes that are laced with ultra-fine particles (UFPs) and volatile organic compounds (VOCs).

Technically, these both materials are not harmful to your health according to the research, but exposure to them daily may cause issues, especially to those with respiratory issues.

An open window or air purification system should work well enough for ventilating PLA.

Although many studies and research mention that PLA is safe, it is hard to measure the marginal health risks over time, and they take many years to properly test for. The risk may be similar to other ‘hobby-type’ activities such as woodworking, painting or soldering.

The risk may be similar to other ‘hobby-type’ activities such as woodworking, painting or soldering.

One study did test PLA for its emissions, and they found that it mostly emits Lactide which is known to be quite harmless. You should keep in mind that different types of PLA are created differently.

One brand and color of PLA could be harmless, while another brand and color of PLA isn’t as safe as you may think.

Many of the studies on emissions from 3D printers are in proper workplaces with many things going on, rather than your standard desktop home 3D printer, so its hard to generalize the findings.

Although it may not be completely safe, the studies show that PLA isn’t very risky, especially compared to other activities that we do on a regular basis.

Even going into a big city with all the pollution from vehicles and factories are said to be a lot worse than 3D printers.

Ventilation for ABS

According to the Journal of Occupational and Environmental Hygiene, materials commonly used for 3D printing such as PLA, ABS, and nylon can be a source of potentially dangerous VOCs.

ABS has been shown to result in high VOC emissions when heated at those higher temperatures, the main one being a compound called Styrene. It isn’t harmful in small portions, but breathing in a concentrated amount on a daily basis can be harmful to your body.

The concentration of the VOCs however, aren’t as dangerously high as it requires to have serious negative health effects, so printing in a well-ventilated, large room should be good enough to 3D print safely.

I would recommend not 3D printing ABS in a space where you are occupying for long periods of time. If you are 3D printing in a small room with poor ventilation, the rise of VOC concentration in the air can be troublesome.

The UFPs and VOCs produced by ABS during the 3D printing process contains Styrene. This material is not harmful in small portions; however, breathing in it on a daily basis can harm your body.

This is the reason why ventilation is needed during the printing process with ABS.

I would ensure that you are at least using an enclosure with some type of ventilation, ideally in a larger room.

How to Ventilate a 3D Printer

The best thing you can do to ventilate a 3D printer is to make sure your 3D printer chamber or enclosure is sealed/airtight, then to connect a vent from your chamber to the outside.

Some people use a window fan and put it near a window where your 3D printer is to then blow air out of the house. When printing with ABS, many users do this, and it works well to eliminate noticeable smells.

Installing Air Purifiers

Air purifiers have become common in major cities to keep the air clean. Similarly, you can use these air purifiers for your places where 3D printing is being performed.

Purchase a small air purifier and install it next to your 3D printer. Ideally you can put an air purifier within an enclosed system that contains your 3D printer so that the contaminated air passes through the purifier.

Ideally you can put an air purifier within an enclosed system that contains your 3D printer so that the contaminated air passes through the purifier.

Look for the enlisted features in an air purifier:

- Have high efficient particulate air (HEPA) filters.

- A charcoal air purifier

- Calculate the size of your room and select the purifier according to it.

Air Extractors

Air Extractors are considered to be one of the best solutions to improve the ventilation of an enclosed room. Its working is explained below for you:

- It sucks in the heated air.

- Exchange the heated air with the cool air from outside.

- It uses a fan and suction pipes.

There are two main types of extractors that you can easily purchase from the market, i.e., Twin Reversible Airflow Extractors with and without Thermostats.

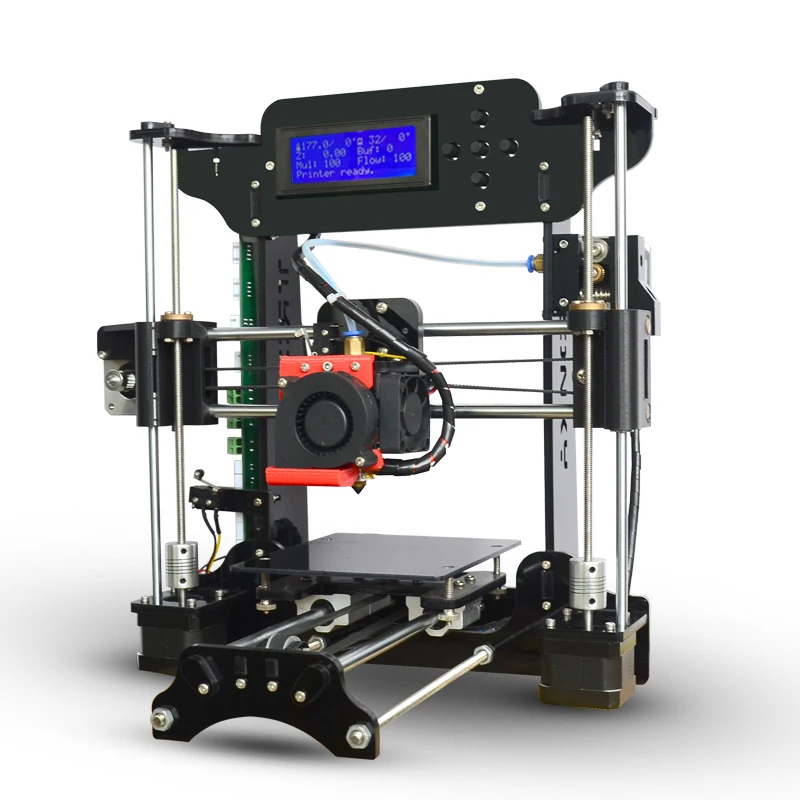

Building a 3D Printer Enclosure

You can consider building an enclosure for your printer. It basically involves creating an air-tight enclosure equipped with carbon filters, a fan, and a dry-hose that runs outside your home.

In the enclosure, the carbon filter will trap styrene and other VOCs, while the hose will let the air pass through. This is an effective ventilation process which you can make at home.

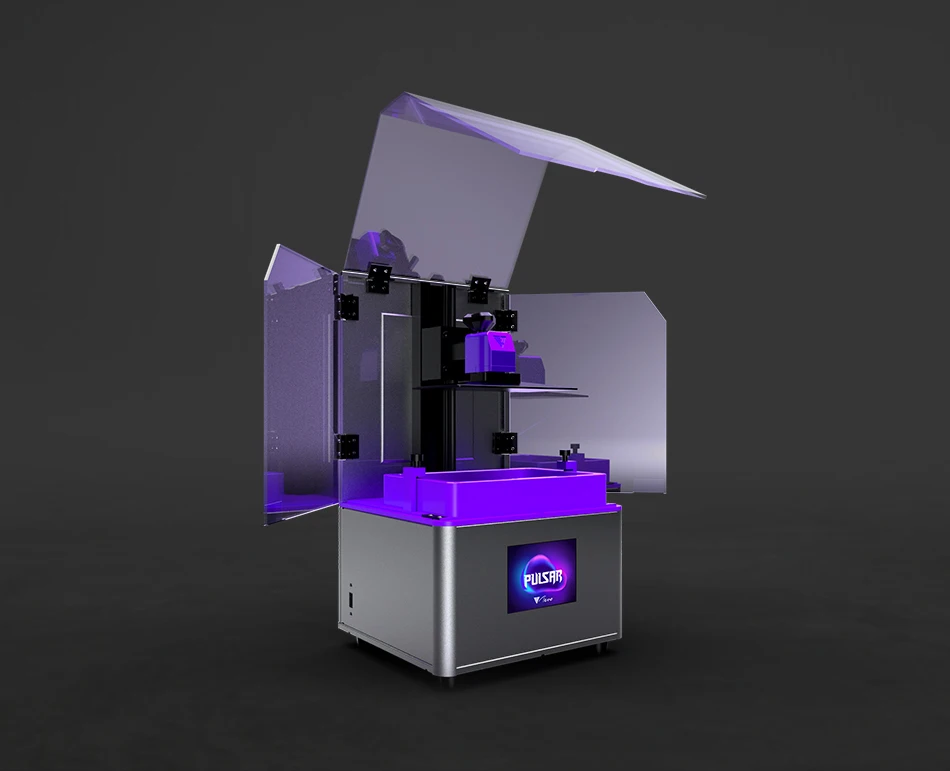

3D Printer with Built-in Filtration

There are very few printers that come with a built-in HEPA filtration. Even the manufacturers are aware of the fumes, but nobody bothers installing a filtration.

For example, UP BOX+ is one of the printers that come with HEPA filtration solutions that filter out tiny particles.

You can choose to get a 3D printer with built-in filtration, but these are usually more expensive so be prepared to pay extra for this feature.

The Elegoo Mars Pro is a good example of this which has a built-in carbon air filter to remove some VOCs and resin odor from the air.

How to Ventilate a Resin 3D Printer?

The best way to ventilate a resin 3D printer is to create a negative pressure enclosure which directs air away the enclosure to a space outside. Long term exposure to resin fumes are unhealthy, even if they don’t smell.

Most people don’t have a dedicated ventilation system and are looking for a simple fix to help ventilate their resin 3D printers.

Following the video above should improve your ventilation for a resin 3D printer.

Remember, resins are toxic and can become allergic to your skin, be careful while using them.

Are 3D Printer Fumes Dangerous?

Not all, but some 3D printer fumes are dangerous and can cause serious damage to the health. As previously described, those UFPs are the more dangerous kind of emissions, where they can be absorbed into the lungs, then into the bloodstream.

According to the research done by the Georgia Institute of Technology, 3D printer fumes can negatively impact the quality of indoor air leading to potential respiratory health issues.

The regulations provided by OSHA actually throw light on the fact that 3D printer fumes are dangerous for health and the environment.

According to the research done on 3D printing filament, ABS is considered more toxic than PLA.

PLA is made up of eco-friendly substance, thus it is less harmful. This is one of the reasons why PLA is so commonly used, especially over ABS, because of its safety and non-smelling properties.

How safe are 3D printing resins?

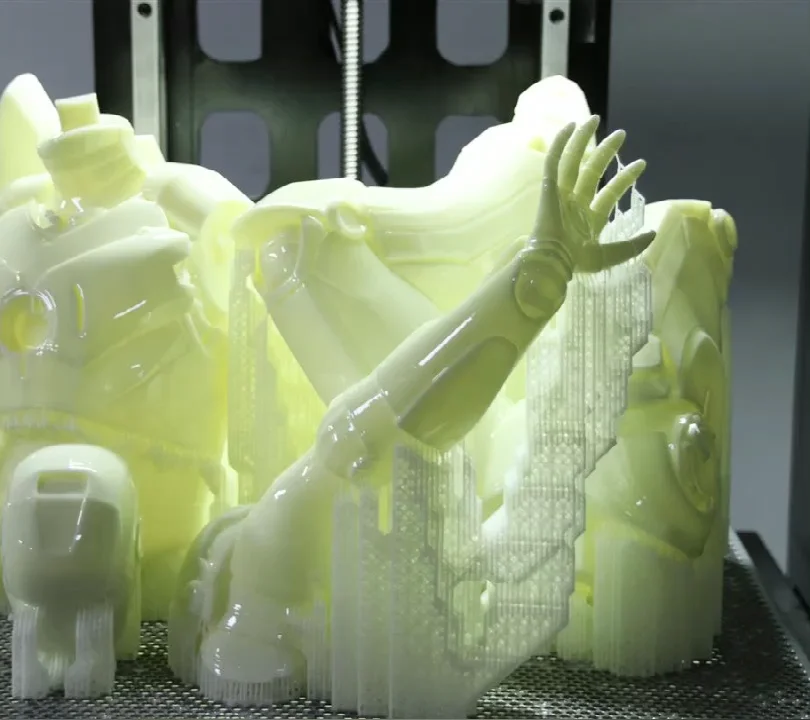

Filament Deposition Modeling (FDM) material extrusion is the most popular polymer 3D printing method, but resins are becoming more and more important to consumers. Resin technologies such as stereolithography (SLA) were previously only used in dental laboratories, engineering departments and manufacturing plants due to the high cost of the equipment. Now that machines have become more affordable, more and more ordinary users are using SLA technology, which calls into question their safety.

Resin technologies such as stereolithography (SLA) were previously only used in dental laboratories, engineering departments and manufacturing plants due to the high cost of the equipment. Now that machines have become more affordable, more and more ordinary users are using SLA technology, which calls into question their safety.

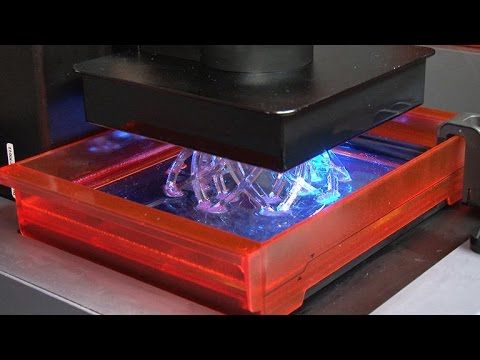

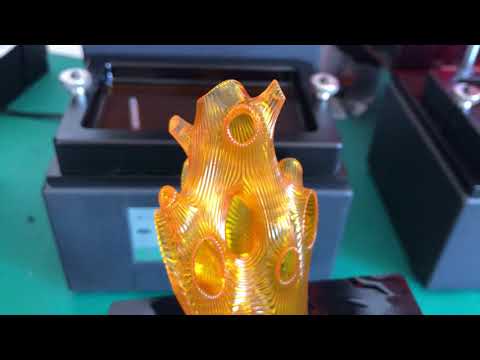

Unlike FDM devices, resin printers use photosensitive liquids to print, curing materials with ultraviolet light. Liquid polymers pose a greater potential health risk than raw materials in fiber form. The toxicity of the resource may put off some users, but printing with resin can be safe if the right algorithm is followed.

What are the Potential Risks of Resins

The word "toxicity" is troubling, but according to definitions developed by occupational health and safety professionals, any substance that, under certain conditions, can cause health problems or disease, is "toxic". According to this formulation, many substances around us are potentially dangerous, including perfumes and mattress filling. But are there any particular risks when using liquid resins for 3D printing?

But are there any particular risks when using liquid resins for 3D printing?

The main concern with photopolymer resins is that they can cause skin irritation on contact. In some cases, contact of the substance with unprotected skin results in burns and blisters, which may require medical attention. If the materials come into contact with the eyes, they will cause irreparable damage.

Many resins are sensitizers, which means that prolonged exposure sometimes causes a mild allergic reaction. The chemicals that make up most resins are irritants that provoke the appearance of dermatitis - inflammation of the skin due to rejection of foreign elements. The skin quickly absorbs such chemicals, so prolonged contact with the composition or exposure to a large dose can lead to more serious consequences.

Another problem with resin 3D printing is air pollution. The material releases fumes, potentially reducing indoor air quality (IQA). Poor IQA scores can lead to headaches, fatigue, or more serious reactions such as breathing problems. These effects are due to volatile organic compounds (VOCs) and other small particles that cause an inflammatory response in the airways, leading to swelling or tenderness.

These effects are due to volatile organic compounds (VOCs) and other small particles that cause an inflammatory response in the airways, leading to swelling or tenderness.

Long-term effects from working with liquid polymer are rare but significant:

• If the vapors are inhaled for a long time, chronic diseases of the respiratory system may appear.

• Some of the VOCs emitted by resins are suspected to be carcinogens, so they are likely to cause cancer after prolonged exposure.

• Constant physical contact can lead to severe allergies.

Standards and manufacturer's instructions

On the other hand, most resins on the market do not pose a significant hazard. Companies that produce such materials must comply with government standards and additional recommendations ISO 9001. Regulations ensure that chemicals produced by businesses are minimally harmful. However, some hazardous elements, such as asphalt fumes and synthetic mineral fibers used in fiberglass, are still widely used and over half a million workers are exposed to them.

Manufacturers usually provide Material Safety Data Sheets (MSDS) that list any potential health concerns. For example, corneal burns from overexposure to the eyes, or nausea and vomiting if swallowed. All these documents are provided in order to provide users with maximum safety when using consumables.

Some compounds may be more dangerous than others for certain people. If a person does not know if they are allergic to any materials, they should act as if they are and handle the product with care.

Safety Steps

Several government agencies have conducted research into the safety of epoxy 3D printing. They all showed that long-term emissions from printing are mostly negligible, although risks exist if proper precautions are not taken. Since studies have found traces of hazardous substances when working with resin formulations, safety regulations must be observed.

3D printing resins are not as scary as they seem, but they still need to be handled with care. First of all, direct contact of the mass liquid with any part of the body must be avoided. Safety goggles and nitrile or latex gloves should always be worn to prevent toxins from getting into the eyes or onto the skin.

First of all, direct contact of the mass liquid with any part of the body must be avoided. Safety goggles and nitrile or latex gloves should always be worn to prevent toxins from getting into the eyes or onto the skin.

Also make sure that the workplace is well ventilated. Ventilation is critical for any 3D printer, but especially for resin printing equipment. It is best to work under an exhaust hood, but if this is not possible, it is advisable to print near an open window with a fan.

Read the safety data sheet from the manufacturer before opening the photopolymer container. If there are any special instructions regarding the use of the material, then they are reflected in the document.

Finally, residues or waste must not be dumped into the sewer, as this can be harmful to the environment. Either dispose of it in the manner recommended by the manufacturer, or dry with UV light until the mass hardens.

Resin printing is safe when proper precautions are taken

When the user knows what risks resin compositions present, he will be safe from trouble. Although 3D printing consumables are toxic, but if the safety procedures are strictly followed, then working with these materials becomes not dangerous. With the right precautions, there is no reason to avoid 3D printing with resin.

Although 3D printing consumables are toxic, but if the safety procedures are strictly followed, then working with these materials becomes not dangerous. With the right precautions, there is no reason to avoid 3D printing with resin.

16 Must-have 3D Printing Accessories for Resin Printers

Resin printers are getting cheaper and more affordable, and 3D printers like the Anycubic Photon and Elegoo MARS are lowering resin printing costs like never before. However, resin printing is much more complex than FDM printing, so you may need many different accessories. Some of them will make your life easier, others will make you safer, and all of them will help you start your journey. Here are 16 of the best accessories for your resin printer.

- Made for cleaning: pickle container / bath model

- Safety first: black nitrile gloves

- Stamp Removal: BuildTak 3D Stamp Removal Tool

- Spill Absorbent: Amazon Pantry Paper Towel

- For cleaning do not drink: 91% isopropyl alcohol (6 packs)

- When things go wrong: plastic spatula

- Not for teeth!: soft bristle toothbrush

- Get rid of the bad: 100 micron paint sieves

- Permanent filter: tea strainer

- Don't Save: Film FEP

- Hard light: UV light

- Don't go blind: goggles

Recruitment

Thanks to the amazing 3D printing community, we have this gem. This small salt container has a strainer that is perfect for cleaning your models. Simply fill the container with isopropyl alcohol and place your model in the filter. You can then use the filter to pull it out of the tub when it's ready.

This small salt container has a strainer that is perfect for cleaning your models. Simply fill the container with isopropyl alcohol and place your model in the filter. You can then use the filter to pull it out of the tub when it's ready.

$14 at Amazon

Security Choice

It might seem odd to have something like gloves as one of your leading picks, but trust me; You don't want to put resin on your skin. Nitrile gloves are the single most important item on this list, and a good supply will save you some serious chemical burns. Resin printing is fun and rewarding, but I had a bad reaction just from getting splattered on me. Be safe.

- $10 at Amazon

- $11 at Walmart

It's basically just a pallet knife or paint scraper, but it's important to remove the imprint from the build plate onto the resin bath without damaging it. I like to use this extra wide knife which allows me to get the maximum purchase of a model without stressing it out.

- $23 at Amazon

- $20 at Matterhackers

I have yet to find a better cleaning material than paper towel for cleaning resin and you will need a good supply as resin is dirty and stains if you don't clean it quickly. The paper towels you find in pharmacies aren't as absorbent, and the resin doesn't wipe off as well.

$10 at Amazon

Cleaning resin can be dirty. After you have printed the model and before it is fully cured, you should wash it in an isopropyl alcohol bath. This removes excess resin so your model looks really good. You will be using quite a lot, so keep it handy and keep it safe.

$19 at Amazon

Not every print is a winner. Sometimes your print doesn't stay on the print platform and you need to remove it from the FEP sheet in the bath. Using a metal scraper will ruin the FEP almost immediately, so use a plastic scraper instead.

- $7 at Amazon

- $5 at Walmart

Once you have detailed prints, you need to get rid of excess resin from all lines. Using these soft bristled toothbrushes works great, but you have to be as gentle as possible. If you scrub too hard, you may damage the print.

Using these soft bristled toothbrushes works great, but you have to be as gentle as possible. If you scrub too hard, you may damage the print.

- $13 at Amazon

- $11 at Walmart

You often need to change resin when 3D printing and it is very important that no cured resin is added to it. These nylon filters are perfect for resin filtration and the included funnel is a godsend.

- $13 at Amazon

- $9 at Walmart

If you don't like the idea of disposable filters, you can always use these metal tea strainers. Remember that you need to wash them with hot soapy water after each use. Otherwise, the resin will harden on them and render them useless.

- $9 at Amazon

- $8 at Walmart

All 3D printed parts break at some point. Be prepared for the worst and keep a spare FEP film handy. It's not the cheapest option, but it's good quality and lasts a long time in most DLP printers.

$19 at Amazon

The final step in completing the resin printing is curing, which is done in bright sunlight or using a UV lamp. This lamp is powerful and can be used to create a cool UV curing station with a little elbow grease.

- $21 at Amazon

- $45 at Matterhackers

Just last week I didn't wear glasses. Some resin mixed with alcohol splashed on my eyelid. I had a red chemical burn there for four days. This stuff is not a joke of people; Wear all the protection you can.

- $9 at Amazon

- $9 at Walmart

It may seem like overkill, but the resin gives off harmful fumes. If you don't have a great ventilation system, then a respirator is essential. If you're planning on spray painting your prints, you'll still want one of these.

$20 at Amazon

This ultrasonic jewelry cleaner is an alternative to a pickle jar and is ideal for automatic cleaning of prints. All you have to do is insert your fingerprint, add isopropyl alcohol, then set the timer for 3-5 minutes and leave. The cleaner will do the rest. It even has a handy trash can for easy removal.

The cleaner will do the rest. It even has a handy trash can for easy removal.

- $48 at Amazon

- $63 at Walmart

These little players are usually designed to showcase beautiful things. Luckily, they also work to treat fingerprints. If you place your print on a turntable and then use a UV light, the model will rotate, allowing for even curing from all sides.

$9 at Amazon

Although resin printing is not carcinogenic, it can be smelly and the fumes can irritate your eyes and nose. You should always use resin 3D printers in a well-ventilated area, but having an air purifier certainly can't hurt. This will remove any significant irritants from the air. This works on any shape or smoke from your workshop.

- $100 at Amazon

- $85 at Walmart

These things are important

I know it sounds like a broken record telling you to be careful, but that's because it's important. I love this hobby and I want you to enjoy it too.