The liberator 3d printer

V&A · The Liberator – The World's First 3 D Printed Handgun

Technologies often develop faster than the laws that govern them. When libertarians (those that uphold liberty as a core principle) in Texas exploited 3D printing technology to make their own gun – and especially when they started sharing the files to make it – it unleashed a panic about unregulated design. It was also the day that 3D printing lost its innocence.

The Liberator, 3D printed hand gun, Cody Wilson/Defense Distributed, May 2013, Texas, US. © Victoria and Albert Museum, LondonCody Wilson, a former law student from Austin, Texas founded Defense Distributed in 2012, to defend the civil liberty of popular access to arms. On 6 May 2013, Wilson took a crucial step in his crusade for popular access to guns when, on a private shooting range in Austin and in the presence of BBC3, he fired the world's first 3D printed gun. The next day, he released the design drawings of the gun online, open source. In the first two days of their release, 100,000 people across the world downloaded the drawings. The invention of this so-called wiki weapon sparked intense debate. It transforms the way we think about new manufacturing technologies and the unregulated sharing of designs online.

Wilson's motivation is a sincere, but very literal and libertarian interpretation of the US Constitution's Second Amendment: the right to bear arms. The ultimate moral and legal authority of that document, for Wilson, justified his actions. He christened the gun 'The Liberator'. Wilson says of his work that he "never thought of it in terms of design" – the design and distribution of the Liberator is for him a political act.

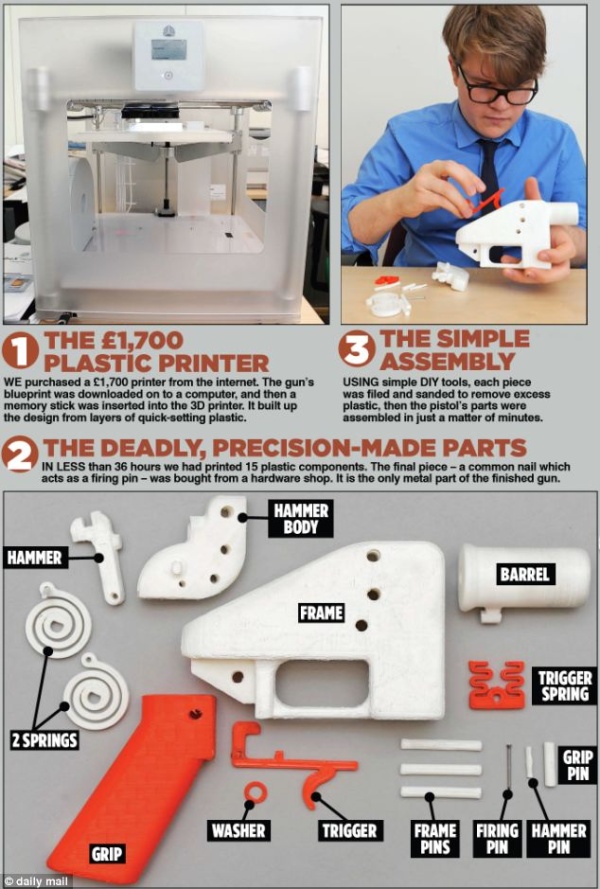

The Liberator is made of fifteen parts of ABS (Acrylonitrile Butadiene Styrene) plastic, printed individually on an industrial grade Stratasys Dimension SST 3D printer. The printing process takes around 20 hours, and the pieces can then be assembled to make a fully functioning firearm with the addition of a single metal component: a standard nail for the ring pin.

The printing process takes around 20 hours, and the pieces can then be assembled to make a fully functioning firearm with the addition of a single metal component: a standard nail for the ring pin.

The Liberator STL files were made freely available on Wilson's own search engine for 3D-printable models, DEFCAD. In Wilson's view the Liberator, in its robustness, strength, and refinement, showcases "everything that is great about 3D printing in this one design; the great tour of what is possible in 3D printing".

On 8 May 2013, Wilson and Defense Distributed were ordered by the US Government to remove a number of files from DEFCAD. The Department of State began investigating whether Wilson had willfully violated the International Traffic in Arms Regulations (ITAR). These regulations implement the provisions of the Arms Export Control Act (AECA). According to a letter issued by the State Department, by allowing the download of the design files for the Liberator, Wilson could have been contravening US export regulations by "transferring technical data to a foreign person, whether in the United States or abroad".

According to a letter issued by the State Department, by allowing the download of the design files for the Liberator, Wilson could have been contravening US export regulations by "transferring technical data to a foreign person, whether in the United States or abroad".

DEFCAD was ordered to cease hosting and distributing the STL files for the Liberator and a number of other designs. Wilson was not breaking any laws in the production of the firearms themselves. Wilson is fully licensed to manufacture both Title One (rifles, shotguns and handguns) and Title Two weapons (improvised weapons and machine guns). But suspicion revolved around Defense Distributed operating a not-for-profit exchange of information – one of the problems was that Wilson was not seeking to monetise the Liberator.

The potential punishment enforced by ITAR for each violation of the AECA is a ten-year prison sentence. If only 0.1 percent of the 100,000 downloads were to non-US citizens, Wilson was looking at spending the rest of his life in prison. The gun he designed has come to exemplify what Wilson calls an 'empty space in the law'.

The gun he designed has come to exemplify what Wilson calls an 'empty space in the law'.

The V&A has acquired three Liberators as part of it's Rapid Response Collection: one in its component parts, one assembled, and one that had been fired by Wilson. We have also acquired the CAD files and some 3D printed AK47 and AR15 lower receivers and magazines that show the development of Wilson's thinking from making replacement parts for existing semi-automatic rifles, to the development of the Liberator itself.

This article is an edited extract from '3D Printing an Empty Space in the Law' by Louise Shannon, and was originally published in Volume 38: The Shape of Law, January 2014.

Background image: The Liberator, 3D printed hand gun, designed by Cody Wilson/Defence Distributed, manufactured by Digits2Widgets, 2013, US. Museum no. CD.1:1 to 16-2013. © Victoria and Albert Museum, London

Test-Firing The World's First Fully 3D-Printed Gun

“Alright. One…two…”

Before “three” arrives, a shot reverberates across the overcast central Texas landscape. A tall, sandy blond engineer named John has just pulled a twenty-foot length of yellow string tied to a trigger, which has successfully fired the world’s first entirely 3D-printed gun for the very first time, rocketing a .380 caliber bullet into a berm of dirt and prairie brush.

“Fuckin’ A!” yells John, who has asked me not to publish his full name. He hurries over to examine the firearm bolted to an aluminum frame. But the first to get there is Cody Wilson, a square-jawed and stubbled 25 year-old in a polo shirt and baseball cap. John may have pulled the trigger, but the gun is Wilson’s brainchild. He’s spent more than a year dreaming of its creation, and dubbed it “the Liberator” in an homage to the cheap, one-shot pistols designed to be air-dropped by the Allies over France during its Nazi occupation in World War II.

Unlike the original, steel Liberator, though, Wilson’s weapon is almost entirely plastic: Fifteen of its 16 pieces have been created inside an $8,000 second-hand Stratasys Dimension SST 3D printer, a machine that lays down threads of melted polymer that add up to precisely-shaped solid objects just as easily as a traditional printer lays ink on a page. The only non-printed piece is a common hardware store nail used as its firing pin.

Wilson crouches over the gun and pulls out the barrel, which was printed over the course of four hours earlier the same morning. Despite the explosion that just occurred inside of it, both the barrel and the body of the gun seem entirely unscathed.

Wilson scrutinizes his creation for a few more seconds, then stands up again. “I think we did it,” he says, a little incredulous.

Last August, Wilson, a law student at the University of Texas and a radical libertarian and anarchist, announced the creation of an Austin-based non-profit group called Defense Distributed, with the intention of creating a firearm anyone could fabricate using only a 3D printer. The digital blueprints for that so-called Wiki Weapon, as Wilson imagined it, could be uploaded to the Web and downloaded by anyone, anywhere in the world, hamstringing attempts at gun control and blurring the line between firearm regulation and information censorship. “You can print a lethal device. It’s kind of scary, but that’s what we’re aiming to show,” Wilson told me at the time. “Anywhere there’s a computer and an Internet connection, there would be the promise of a gun.”

The digital blueprints for that so-called Wiki Weapon, as Wilson imagined it, could be uploaded to the Web and downloaded by anyone, anywhere in the world, hamstringing attempts at gun control and blurring the line between firearm regulation and information censorship. “You can print a lethal device. It’s kind of scary, but that’s what we’re aiming to show,” Wilson told me at the time. “Anywhere there’s a computer and an Internet connection, there would be the promise of a gun.”

On May 1st, Wilson assembled the 3D-printed pieces of his Liberator for the first time, and agreed to let a Forbes photographer take pictures of the unproven device. A day later, that gun was tested on a remote private shooting range an hour's drive from Austin, Texas, whose exact location Wilson asked me not to reveal.

The verdict: it worked. The Liberator fired a standard .380 handgun round without visible damage, though it also misfired on another occasion when the firing pin failed to hit the primer cap in the loaded cartridge due a misalignment in the hammer body, resulting in an anti-climactic thunk.

The printed gun seems limited, for now, to certain calibers of ammunition. After the handgun round, Wilson switched out the Liberator’s barrel for a higher-charge 5.7x28 rifle cartridge. He and John retreated to a safe distance, and John pulled his yellow string again. This time the gun exploded, sending shards of white ABS plastic flying into the weeds and bringing the Liberator’s first field trial to an abrupt end.

Update: Defense Distributed's CAD file for the Liberator and its video introducing the gun are now online.

On the ride back to Austin after that first test-fire, Wilson seemed less than satisfied with the relative success of his 3D printed creation. He fixated on its misfiring and brooded about the tight deadline he'd given himself to work out its kinks before sharing the design on the Web. “I feel no sense of achievement," he told me. "There's a lot of work to be done."

He fixated on its misfiring and brooded about the tight deadline he'd given himself to work out its kinks before sharing the design on the Web. “I feel no sense of achievement," he told me. "There's a lot of work to be done."

And the most significant test of the Wiki Weapon was still to come, a moment of truth that may have been looming in Wilson's mind after watching his first prototype explode into plastic shrapnel: Firing the Liberator by hand.

***

By Friday at noon, photographs of the world's first 3D-printed gun published on this site set off a new round of controversy in a story that has shoved one of the most hyped trends in technology into one of the most contentious crossfires in American politics. New York Congressman Steve Israel responded to Defense Distributed's work by renewing his call for a revamp of the Undetectable Firearms Act, which bans any firearm that doesn't set off a metal detector. "Security checkpoints, background checks, and gun regulations will do little good if criminals can print plastic firearms at home and bring those firearms through metal detectors with no one the wiser," read a statement sent to me and other reporters.

Update: On Sunday, New York Senator Charles Schumer echoed Israel's call for that new legislation to ban 3D-printable guns. "A terrorist, someone who's mentally ill, a spousal abuser, a felon can essentially open a gun factory in their garage," Schumer said in a press conference.

Israel and Schumer are hardly the first to oppose Wilson's gun-printing mission. Last August, Defense Distributed's fundraising campaign was booted from the crowdfunding platform Indiegogo. In October, 3D printer maker Stratasys seized a printer leased to the group after it found out how the machine was being used. And Wilson says he's lost access to two workshop spaces after those renting to him learned about his mission. Instead, Defense Distributed has had to move its workshop to a 38-square-foot room at the southern edge of Austin that's about the size of a walk-in closet, hardly larger than the refrigerator-sized 3D printer it houses.

But at each roadblock, the group has found a detour. It's raised funds from donors through the digital payment system Bitcoin, which thanks to that crypto-currency's rising value now accounts for 99% of Defense Distributed's assets, according to Wilson. In March it received a federal license to manufacture firearms, which Wilson has framed and posted on the wall of the group's miniscule workshop. And it's complied with the Undetectable Firearms Act by inserting a six ounce cube of non-functional steel into the body of the Liberator, which makes it detectable with a metal detector--Wilson spent $400 on a walk-through model that he's installed at the workshop's door for testing. "Our strategy is overcompliance," he says. (There's no guarantee, of course, that anyone who downloads and prints the Liberator will insert the same chunk of detectable metal. )

)

The group's initial success in testing the Liberator may now silence some of its technical naysayers, too. Many skeptics (include commenters on this blog) have claimed that no plastic gun could ever handle the pressure and heat of detonating an ammunition cartridge without deforming or exploding. But Defense Distributed's design has done just that. After the test-firing I witnessed, Wilson showed me a video of an ABS plastic barrel the group printed attached to a non-printed gun body firing ten rounds of .380 ammunition before breaking on the eleventh.

Even Wilson himself says he's not sure exactly how that's possible. But one important trick may be the group's added step of treating the gun's barrel in a jar of acetone vaporized with a pan of water and a camp stove, a process that chemically melts its surface slightly and smooths the bore to avoid friction. The Dimension printer Defense Distributed used also keeps its print chamber heated to 167 degrees Fahrenheit, a method patented by Stratasys that improves the parts' resiliency.

Defense Distributed's goal is to eventually adapt its method to work on cheaper printers, too, like the $2,200 Replicator sold by Makerbot or the even cheaper, open-source RepRap. Even if a barrel is deformed after firing, Defense Distributed has designed the Liberator to use removable barrels that can be swapped in and out in seconds.

Wilson hasn't shied from the growing controversy around his project. The Sandy Hook, Connecticut massacre in which a lone gunman killed twenty children and six adults only increased his sense of urgency to circumvent the anticipated wave of gun control laws. As Congress mulled limits on ammunition magazines larger than ten rounds, Defense Distributed created 3D-printable 30-round magazines for AR-15 and AK-47 rifles. In March, it released a YouTube video of a 3D-printable AR-15 lower receiver that can fire hundreds of rounds without failing. The lower receiver is the regulated body of the gun. Anyone who prints it can skirt gun laws and order the rest of the weapon's parts by mail.

Much of the criticism has focused on Wilson himself, by far the most visible figure in Defense Distributed's collection of 15 on-and-off volunteer designers and engineers spread across the world. He's received more than a dozen death threats, along with many wishes that someone would use his own 3D printed weapons to kill him. Wired included Wilson in its list of the 15 most dangerous people in the world. The Coalition To Stop Gun Violence calls him a "hardcore insurrectionist" who advocates anti-government violence. "This guy is basically saying 'print your own guns and be ready to kill government officials,'" says Ladd Everitt, a CSGV spokesperson. "The fact that we’re not talking about [him in those terms] after the Boston bombings is incredible."

But Wilson denies advocating any sort of violent revolt in America. Instead, he argues that his goal is to demonstrate how technology can circumvent laws until governments simply become irrelevant. "This is about enabling individuals to create their own sovereign space. ..The government will increasingly be on the sidelines, saying 'hey, wait,'" says Wilson. "It's about creating the new order in the crumbling shell of the old order."

..The government will increasingly be on the sidelines, saying 'hey, wait,'" says Wilson. "It's about creating the new order in the crumbling shell of the old order."

Wilson doesn't deny that his gun could be used for murder or political violence. "I recognize that this tool might be used to harm people. That's what it is: It's a gun," he says. "But I don't think that's a reason to not put it out there. I think that liberty in the end is a better interest."

He prefers to think of his Liberator in the same terms as its namesake, the one built for distribution to resistance fighters in Nazi-occupied countries in the 1940s. That plan was conceived in part as a psychological operation aimed at lowering the occupying forces' morale, Wilson says, and he believes his project will strike a similar symbolic blow against governments around the world. "The enemy took notice that weapons were being dropped from the sky," he says. "Our execution will be better. We have the Internet."

***

On a blazing Saturday afternoon, Wilson returns to the remote firing range where he first tested the Liberator. None of his Defense Distributed compatriots have joined him this time--John the engineer is away at the annual meeting of the National Rifle Association in Houston. But Wilson is accompanied by his father, Dennis, a lawyer from Little Rock, Arkansas who has flown in to witness a historic moment: His son plans to fire a fully 3D-printed weapon by hand for the first time.

None of his Defense Distributed compatriots have joined him this time--John the engineer is away at the annual meeting of the National Rifle Association in Houston. But Wilson is accompanied by his father, Dennis, a lawyer from Little Rock, Arkansas who has flown in to witness a historic moment: His son plans to fire a fully 3D-printed weapon by hand for the first time.

Wilson has spent the last few days tweaking the Liberator's CAD file and re-printing its barrel, hammer and body to realign its firing pin and solve the misfire issue. But he becomes quieter as the moment of testing approaches. His father asks how far it is to the nearest hospital: a 45 minute drive. We consider how to make a tourniquet if things go badly. "You guys are going to make me lose my nerve," says Wilson, smiling nervously.

Everyone but Wilson falls back behind him. Wilson opens the case holding the newly-printed pieces and assembles them, then loads the gun and inserts ear plugs into his ears.

He inhales sharply, aims the Liberator, fires it, and then exhales, in quick succession.

"Outstanding," says Dennis Wilson. "Congratulations, my son."

Wilson visibly relaxes. He shakes his father's hand with his own fully-intact digits. Later he'll examine the gun and find no obvious signs of damage other than a cracked pin used to hold the barrel in place.

For a few moments, Wilson seems lost for words. His expression is hidden behind his sunglasses. Then he says the first thing that comes to his mind. "Well, there are going to be some changes around here."

—

Follow me on Twitter, and check out my new book, This Machine Kills Secrets: How WikiLeakers, Cypherpunks and Hacktivists Aim To Free The World’s Information.

Related on Forbes:

Gallery: Ten Wild Things You Can 3D Print At Home

10 images

View gallery

Meet the Liberator, the world's first 100% 3D printed pistol

IoSMI materials contain only foreign media assessments and do not reflect the position of the InoSMI editorial staff

A shot is fired at the count of three, the echo of which spreads across the Texas prairie . John, a tall, wheat-haired engineer, has just pulled a seven-meter cord tied to the trigger and quite successfully fired the world's first fully 3D printed pistol.

“So let's go, One, two…”

At the count of three, a shot rings out, echoing across the Texas prairie. John, a tall, wheat-haired engineer, has just pulled a seven-meter cord tied to the trigger and quite successfully fired the world's first fully 3D printed pistol. A .380 caliber bullet entered a mound of clay covered with bushes.

“Damn it! Exactly!" yells John, who asked me not to give his last name. He hurries to check the gun bolted to the aluminum frame. But before him, 25-year-old Cody Wilson, a man with a square jaw and short hair in a baseball cap and T-shirt, reaches the weapon. Yes, John fired the shot, but the gun is Wilson's creation. He dreamed of creating it for more than a year and even gave it a name - Liberator (Liberator), thereby paying tribute to the cheap, single-shot pistols of the same name that the Allies parachuted into the skies over occupied France during World War II.

He hurries to check the gun bolted to the aluminum frame. But before him, 25-year-old Cody Wilson, a man with a square jaw and short hair in a baseball cap and T-shirt, reaches the weapon. Yes, John fired the shot, but the gun is Wilson's creation. He dreamed of creating it for more than a year and even gave it a name - Liberator (Liberator), thereby paying tribute to the cheap, single-shot pistols of the same name that the Allies parachuted into the skies over occupied France during World War II.

But unlike the first Liberator steel pistol, Wilson's weapon is made entirely of plastic. 15 of its 16 parts were created inside a used $8,000 Stratasys Dimension SST 3D printer. This printer uses a computer program to deposit plastic layer by layer on a three-dimensional object, creating solid objects with the same ease with which a conventional printer applies ink to pages. The only part not printed is a regular hardware store nail that acts as a striker.

Wilson crouches in front of a pistol and draws the barrel from it, which was printed that same morning in four hours. Although there had just been an explosion inside, neither the barrel nor the body of the gun was damaged in the slightest.

Although there had just been an explosion inside, neither the barrel nor the body of the gun was damaged in the slightest.

Wilson checks his brainchild for a few more seconds, then gets up and says, "I think we did it." At the same time, his facial expression is a little incredulous and skeptical.

Last August, University of Texas law student, radical libertarian and anarchist Wilson announced the incorporation of Defense Distributed, a non-profit organization in the city of Austin, with the goal of making firearms with nothing more than a 3D printer. At the same time, the creation of such weapons should be available to everyone. Wilson was going to call this weapon Wiki Weapon and put its electronic drawings on the Internet so that anyone from anywhere in the world could download them. By doing so, he intended to nullify all attempts at gun control and blur the line between gun regulation and information censorship. “You can print a deadly device. It sounds a little scary, but that's what we're going to show,” Wilson told me at the time. “Wherever there is the Internet and a computer, weapons can appear.”

“Wherever there is the Internet and a computer, weapons can appear.”

On May 1st, Wilson assembled his Liberator from printed parts for the first time and gave permission to a Forbes photographer to take pictures of the unverified weapon. The weapons were tested the next day at a remote private shooting range an hour from Austin. Wilson asked not to reveal the exact location of the shooting range.

The verdict is: the gun works. The Liberator was fired with a standard .380 cartridge. No noticeable damage was found on the pistol after the shot, although another time there was a misfire, because the firing pin did not hit the primer of the cartridge exactly due to misalignment. As a result, everyone heard an unpleasant sharp and dull knock.

There is a limited amount of ammo available for printed weapons. After firing the pistol cartridge, Wilson loaded the Liberator with a more powerful 5. 7x28 rifle cartridge. He moved back to safety with John, and John pulled the yellow cord a second time. This time, the gun exploded, sending chunks of white plastic flying into the air. The first field trials of the Liberator came to an abrupt end.

7x28 rifle cartridge. He moved back to safety with John, and John pulled the yellow cord a second time. This time, the gun exploded, sending chunks of white plastic flying into the air. The first field trials of the Liberator came to an abrupt end.

Heading back to Austin after the first test firing, Wilson was very unhappy with the relative success of his printed offspring. He seemed to fixate on the misfire and began to mournfully reflect on the rigid schedule he had made for himself in order to eliminate all the shortcomings before posting the blueprints of the gun on the net. “I don't have the feeling of winning,” he told me. “There is still a lot of work to be done.”

But the most important test of the "wikiweapon" has not yet taken place. This is the moment of truth that must have been spinning in Wilson's mind when he saw his first prototype blown to plastic shreds. To shoot a pistol, you must hold it in your hands.

***

By Friday afternoon, photos of the world's first 3D printed handgun were posted online and sparked a new wave of controversy over the much-touted technology that caused a huge crossfire in American politics. New York State Congressman Steve Israel has responded to the development of Defense Distributed with new calls for a revision of the law banning the manufacture of weapons that cannot be found by metal detectors. “Checkpoints, customer checks, and gun laws will be of no use if criminals can print plastic firearms in their homes and then safely smuggle them through metal detectors,” reads a statement that Israel sent to me and other journalists.

New York State Congressman Steve Israel has responded to the development of Defense Distributed with new calls for a revision of the law banning the manufacture of weapons that cannot be found by metal detectors. “Checkpoints, customer checks, and gun laws will be of no use if criminals can print plastic firearms in their homes and then safely smuggle them through metal detectors,” reads a statement that Israel sent to me and other journalists.

Breaking News: On Sunday, New York State Senator Charles Schumer backed Israel's call for new legislation to ban 3D-printed guns. "Any terrorist, any person with a mental disorder, any domestic tyrant and criminal will be able to open a weapons factory right in his garage," Schumer said, speaking at a press conference.

Israel and Schumer are far from the first to oppose Wilson and his work on printed weapons. In August last year, Defense Distributed was denied a fundraising campaign on Indiegogo. In October, 3D printer maker Stratasys confiscated a printer loaned to Defense Distributed after it found out what it was being used for. In addition, Wilson says he was denied access to two workshops when the tenants found out what kind of work he was doing. The company had to relocate its workshop to a 4-square-foot room in South Austin. It is the size of a small closet, and the 3D printer, which itself is the size of a refrigerator, can hardly fit there.

In addition, Wilson says he was denied access to two workshops when the tenants found out what kind of work he was doing. The company had to relocate its workshop to a 4-square-foot room in South Austin. It is the size of a small closet, and the 3D printer, which itself is the size of a refrigerator, can hardly fit there.

But every time Defense Distributed ran into obstacles, they found a way around it. She collected donations from donors using the Bitcoin electronic payment system. Now, thanks to the rapid rise in the price of this cryptocurrency, 99% of Defense Distributed's assets belong to Bitcoin. In March, she received a federal firearms license, which Wilson framed and hung on the wall in his organization's tiny workshop. In addition, she fully complied with the requirements of the law on undetectable firearms, since Wilson inserted a 170-gram non-functional steel cube into the body of the gun so that it could be detected with a metal detector. Wilson spent $400 on this model, which he set up in the doorway of a test shop. “Our strategy is full and even excessive compliance,” he says. (Of course, there is no guarantee that all other manufacturers of the Liberator will insert a piece of metal into its body in the same way to detect a pistol.)

Wilson spent $400 on this model, which he set up in the doorway of a test shop. “Our strategy is full and even excessive compliance,” he says. (Of course, there is no guarantee that all other manufacturers of the Liberator will insert a piece of metal into its body in the same way to detect a pistol.)

Defense Distributed's first handgun test success will now help silence some tech skeptics. Many critics (including commentators on this blog) have argued that no plastic pistol can handle the pressure and heat that comes with detonating a cartridge, and that the barrel is bound to deform or explode. However, the Defense Distributed design did the trick. After the test firing, which I observed, Wilson showed me a video of these tests. The plastic barrel he printed was attached to a non-3D printed gun body. It fired ten shots of .380 caliber ammunition, and broke only on the eleventh.

Even Wilson himself admits that he does not understand how this is possible. But there is one important trick here. The fact is that the barrel of the pistol was additionally treated with acetone, which was then removed by evaporating it with a frying pan with water and a tourist burner. During this treatment, the bore is slightly chemically melted and becomes smoother, reducing friction. In addition, the Defense Distributed printer chamber is maintained at 75 degrees Celsius, which increases the toughness of the parts. Stratasys has patented this technology.

The fact is that the barrel of the pistol was additionally treated with acetone, which was then removed by evaporating it with a frying pan with water and a tourist burner. During this treatment, the bore is slightly chemically melted and becomes smoother, reducing friction. In addition, the Defense Distributed printer chamber is maintained at 75 degrees Celsius, which increases the toughness of the parts. Stratasys has patented this technology.

Defense Distributed's goal is to gradually adapt this technology for use on other, cheaper printers, such as the $2,200 Replicator that Makerbot sells or less. Even if the barrel deforms after firing, it can be removed and replaced with a new one in a matter of seconds.

Wilson does not hesitate to talk about the controversy and controversy surrounding his project. The massacre in Sandy Hook, Connecticut, in which one shooter killed twenty children and six adults, has forced him to look for ways around pending gun control laws with renewed vigor. While Congress was debating limits on magazines larger than 10 rounds, Defense Distributed 3D-printed 30-round magazines for the AR-15 rifle and AK-47 assault rifle. In March, she posted on YouTube a video of the bottom of the AR-15 receiver, which is guaranteed to fire hundreds of shots. There are restrictions on this item. Anyone who can print it can easily order the rest of the rifle parts by mail.

While Congress was debating limits on magazines larger than 10 rounds, Defense Distributed 3D-printed 30-round magazines for the AR-15 rifle and AK-47 assault rifle. In March, she posted on YouTube a video of the bottom of the AR-15 receiver, which is guaranteed to fire hundreds of shots. There are restrictions on this item. Anyone who can print it can easily order the rest of the rifle parts by mail.

Wilson himself was criticized as the most visible figure in the Defense Distributed team of about 15 volunteer designers, designers and engineers scattered around the world. He was threatened to be killed many times, and many wished Wilson that someone would shoot him with a weapon he had printed. The Wired edition included Wilson in their list of the 15 most dangerous people in the world. The Coalition to End Gun Violence calls him a "staunch rebel" who advocates anti-state violence. "This guy is essentially saying, 'Print your own guns and be prepared to kill government officials with them,'" said Ladd Everitt, spokesman for the Coalition to End Gun Violence. "It's unbelievable that after the Boston bombings we never started talking about him in those terms."

"It's unbelievable that after the Boston bombings we never started talking about him in those terms."

But Wilson states that he does not advocate any violence or riots in America. Its purpose is to demonstrate how technology can be used to circumvent the law until the state becomes useless. “It's about empowering people to create their own sovereign space… The state will increasingly be sidelined, asking us to slow down,” Wilson says. “It is about creating a new order on the ruins of the old order.”

Wilson does not deny that his weapons could be used for murder or for political violence. “I acknowledge that this device can be used to harm people. But it's a weapon, he says. “However, I don’t think it should be banned because of that. I think freedom is more important in the end."

He tends to think of his pistol as a liberator, as its namesake, with which the French Resistance fought during the years of occupation. Then it was part of a psychological operation aimed at reducing the morale of the invaders. Wilson believes that with his project he will deliver a similar symbolic blow to states around the world. “The enemy has taken note that weapons are falling straight out of the sky,” he says. “But our performance will be even better. We have internet."

Wilson believes that with his project he will deliver a similar symbolic blow to states around the world. “The enemy has taken note that weapons are falling straight out of the sky,” he says. “But our performance will be even better. We have internet."

***

On a hot Saturday afternoon, Wilson returns to the remote shooting range where he tested his pistol for the first time. This time no one from Defense Distributed joined him, and even Engineer John went to Houston for the annual National Rifle Association conference. But along with Wilson went his father Dennis, who works as a lawyer in Little Rock, Arkansas. He flew in to witness a historic moment: his son decided to test-fire a 3D-printed handgun for the first time.

Over the past few days, Wilson has been editing the blueprint file and reprinting the barrel, firing pin, and body repeatedly, trying to match the firing pin and fix the misfire problem. But as the moment of testing approaches, he becomes calmer. The father asks how many kilometers to the nearest hospital. 45 minutes drive. We are thinking about how to make a tourniquet if everything ends badly. “You guys are making me nervous,” Wilson says, smiling uneasily.

The father asks how many kilometers to the nearest hospital. 45 minutes drive. We are thinking about how to make a tourniquet if everything ends badly. “You guys are making me nervous,” Wilson says, smiling uneasily.

Everyone stays behind while Wilson himself opens the case with the newly printed parts and collects them. After that, he loads the assembled pistol and puts on ear protectors.

Wilson takes a sharp breath, aims, fires, then exhales.

“Great,” says Dennis Wilson. “Congratulations, son.”

You can see how Wilson relaxes. He shakes his father's hand with his own, which is safe and sound. He would then check the gun and find no obvious signs of damage - other than a crack in the pin that secures the barrel.

Wilson is silent for a few seconds, unable to find words. His eyes are hidden behind sunglasses. Then he says the first phrase that comes to his mind: "Well, we are waiting for some changes here."

Liberator (pistol)

For World War II single-shot pistol, see FP-45 Liberator. For the shotgun, see Winchester Liberator.

For the shotgun, see Winchester Liberator.

Liberator is a physical, 3D printed single shot gun, the first such printable firearm design has become widely available on the Internet. [2] [3] [4] The Open Source Solid Distributed Defense developed the weapon and published the plans online on May 6, 2013. The plans were downloaded over 100,000 times in the two days before the US State Department demanded, for Defense Distributed to abandon their plans. [1]

Weapon plans are still posted online and are available at file sharing sites such as Pirate's Cove [5] [6] and GitHub. [7]

July 19, 2018 U.S. Department of Justice reached a Distributed Protection settlement allowing blueprints for 3D printed firearms to be sold over the Internet effective August 1, 2018 [8]

July 31 2018 U.S. President Donald Trump posted on Twitter about the decision to allow the online release of Liberator files: “I'm looking into 3D plastic guns being sold to the public. Already talked to the NRA, doesn't seem to make much sense! " [9]

Already talked to the NRA, doesn't seem to make much sense! " [9]

The same day the tweet was posted, a federal judge stopped the release of blueprints to make the Liberator due to it being an untraceable, undetectable 3D printed plastic gun, citing considerations security. [10]

Contents

- 1 Namesake and concept

- 2 Withdrawal plans and hosting The Pirate Bay

- 3 Reception

- 4 Usage history

- 0120 5 See also

- 6 Recommendations

- 7 external link

Namesake and concept

The pistol is named after the FP-45 Liberator, a single-shot pistol that George Hyde designed and that the internal production department of General Motors Corporation mass produced for the US Office Strategic Services (OSS) in World War II. The OSS planned to drop the weapon from the air into occupied Europe for the use of resistance forces. [11] [12] [13] It is believed that the Liberator, an OSS project, was also used as a psychological warfare tool. [11] Occupying forces in Europe will have to weigh evidence of handgun proliferation as a factor when planning to counter civil resistance, which will complicate their strategy and affect morale. However, although they were used in France, there is little evidence that the pistols were ever dropped into occupied Europe in large numbers. [11]

[11] Occupying forces in Europe will have to weigh evidence of handgun proliferation as a factor when planning to counter civil resistance, which will complicate their strategy and affect morale. However, although they were used in France, there is little evidence that the pistols were ever dropped into occupied Europe in large numbers. [11]

To the physical The release of Liberator on the Internet can be seen as an attempt by Defense Distributed to more successfully carry out a historic psychological operation and as a symbolic act of supporting resistance to world governments. [13] [14]

Withdrawal plans and hosting The Pirate Bay

Digital Liberator pistol from Distributed Defense

A few days after publication, the US State Department of Defense Trade Enforcement Administration sent a letter to Defense Distributed to withdraw Liberator plans from the public domain. [15] The Department of State justified this claim by claiming the right to regulate the flow of gun-related technical data and its role in enforcing the Arms Export Control Act of 1976.

However, the design soon appeared on Booty Bay (TPB) , which has publicly declared its protection of information. Quoted on TorrentFreak: “TPB has been running for almost 10 years without shutting down a single torrent due to outside pressure. And he will never do that." [6]

The site will post a statement on their Facebook page:

So obviously there are some 3D prints of weapons in the physics section of TPB. Prints now claimed by the US government. Our position, as always, is not to delete torrents if their content matches the description of the torrents. Press weapons [is] a very serious issue that will be discussed for a long time. We do not condone the use of firearms. We believe the world needs fewer weapons, not more. However, we believe that these fingerprints will remain on the Internet regardless of blocking and censorship, since this is how the Internet works. If there is a lunatic who wants to print weapons to kill people, he or she will do it.

With or without TPB. It's better to have these printouts on the open internet (TPB) and make them available for peer review (comment threads) than half-hidden in the darker parts of the internet.

- Pirate Bay , May 10, 2013

Reception

Original copies of the Liberator were constantly acquired by the Victoria and Alberta Museum, [16] [18] and a copy of the pistel pistolletet and a copy at the London Science Museum.

Write to Registry Lewis Page derided the Liberator by stating "it's no more a pistol than any other very short piece of plastic pipe - 'gun'" and likened it to a 19 pistol50s. zip gun. [19]

Usage history

ATF 3D printed firearms test with ABS material

3D printed firearms ATF test with VisiJet

May 2013 Yle TV2 as current events program Ayankohentaen fabricated the Liberator pistol under the supervision of a licensed gunsmith and fired under controlled conditions.

Click to... [+] enlarge. (Credit: Michael Thad Carter for Forbes)

Click to... [+] enlarge. (Credit: Michael Thad Carter for Forbes)