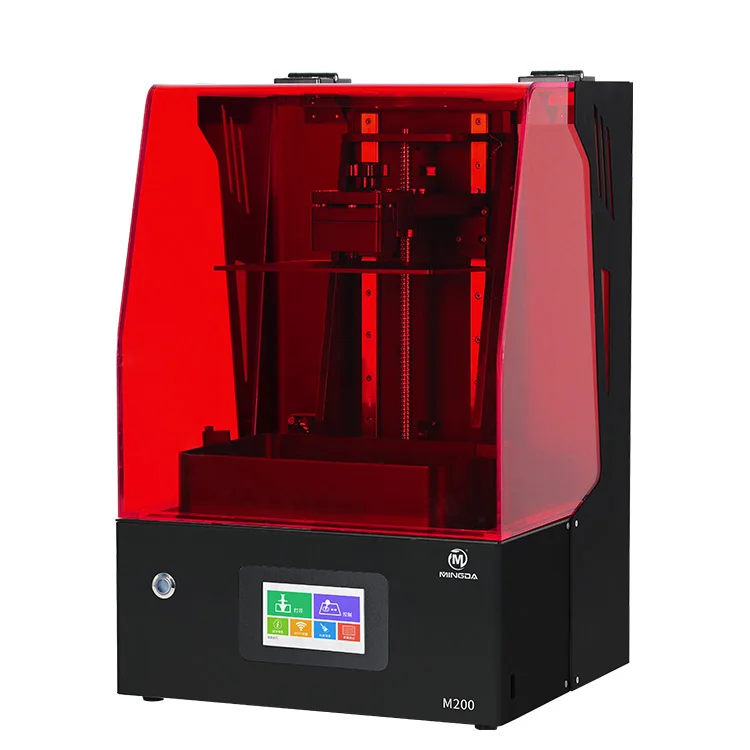

3D resin printer large

Large Resin 3D Printers: Buyer's Guide 2022 (Affordable & Commercial)

For some, size matters – and a normal-sized resin 3D printer just won’t cut it. For you size kings and queens, bigger is better, and you shouldn’t have to compromise on your quest for the biggest resin 3D printer around.

And with resin printing becoming more affordable than ever before, buying a large resin 3D printer vs outsourcing larger resin prints to a service has never been more cost-effective.

Why buy a large resin 3D printer?

First, by keeping prototyping in-house you retain full control, you can prototype as fast as your printer will print, and you still don’t have to compromise on size.

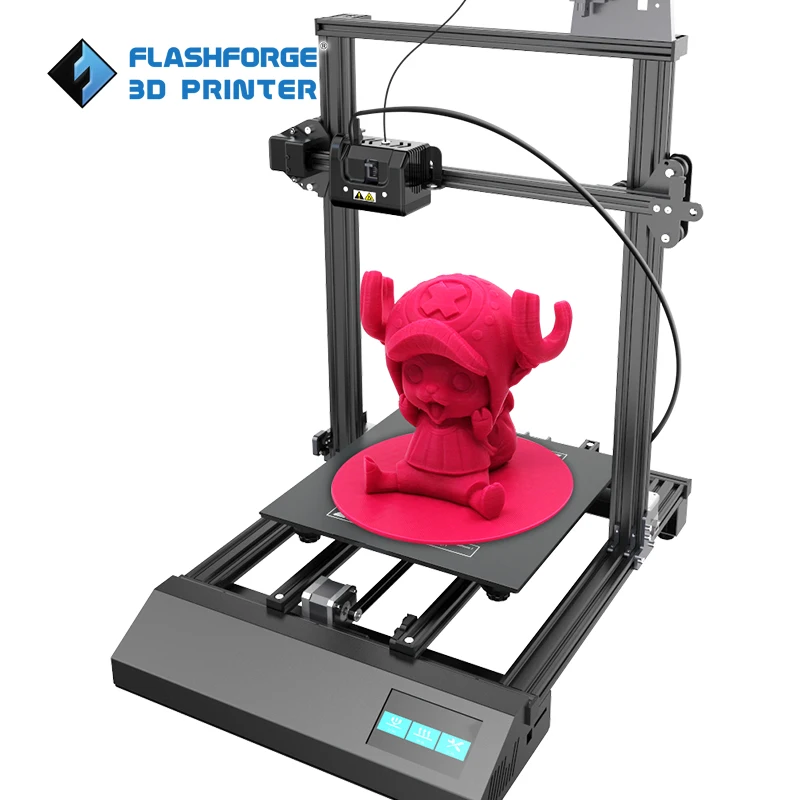

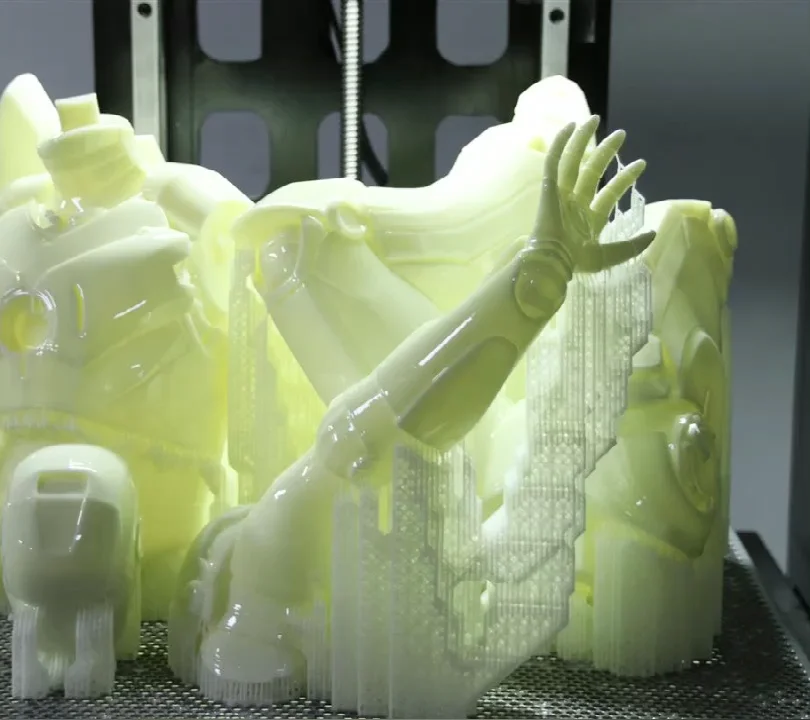

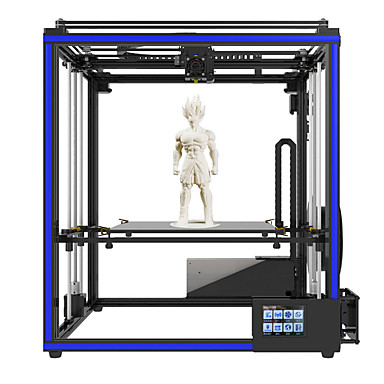

Resin printers typically have smaller build volumes than their FDM counterparts, focusing instead on outrageous quality and incredibly smooth surface finishes. However, this creates problems when you want to prototype larger parts, such as helmets or tools and equipment. With a large resin 3D printer, you’re free to print human-sized resin parts that can be tested right away.

And even if you’re a hobbyist looking to print large cosplay pieces or other parts, some large format resin 3D printers have become so affordable that you can even get in on the action at home.

We have therefore picked our recommendations for the best build volume format resin 3D printers, in both more affordable and commercial and industrial price ranges and specs, so you can pick the ideal printer for you.

The best large resin 3D printers: affordable and commercial

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Affordable

1. Elegoo Saturn

- Price: $499 — Available at Elegoo store here / Available at Amazon here

- Large resin 3D printer build volume: 192 x 120 x 200 mm

The Elegoo Saturn packs a powerful punch with its 8.9-inch 4K monochrome LCD, offering fast (2-3 seconds per layer) printing — a 60% improvement on Elegoo’s cheaper Mars Pro, and with upgraded stellar quality.

The build volume is far larger than most entry-level large resin 3D printers at 192 x 120 x 200 mm, and while this isn’t large enough for printing tools prototypes like spades, for example, you can still print most normal-sized resin parts here. And for smaller resin prints like casts for jewelry, small prototypes, or fun home projects, you can fit many within each print run.

The upgraded Z-axis moves more precisely and accurately – and you’ll see the differences as it churns out delightful resin prints. The printer contains 54 LEDs to accurately print and solidify resin more uniformly than ever before. It’s also built to need less frequent leveling – saving you hassle – and the Elegoo Saturn is known for great adhesion when printing.

2. Phrozen Mighty 4K

- Price: $599 — Available on Phrozen store here / Available on Amazon here

- Build volume: 7.9” x 4.9” x 8.7”

Designed for printing both single big models and multiple smaller resin prints in one batch, you can print your favorite cool models here, or excellent quality prototypes — the Phrozen Mighty 4K slots in nicely, along with the Mono X, in this prosumer category; high quality enough for commercial use, but also cheap enough for home use.

The upgraded Z-axis stabilizes the printer and prevents any wobbling that could affect print quality, and the 4K screen offers fantastic quality at turbo speed — just 2 seconds per layer.

You can use your own resins with the Phrozen Mighty 4K – you’re not restricted to Phrozen’s resins, though they do offer their own with ideal print settings for perfect prints. Overall, like the Elegoo Saturn and Anycubic Mono X, it’s an excellent mid-range resin 3D printer with large build volume.

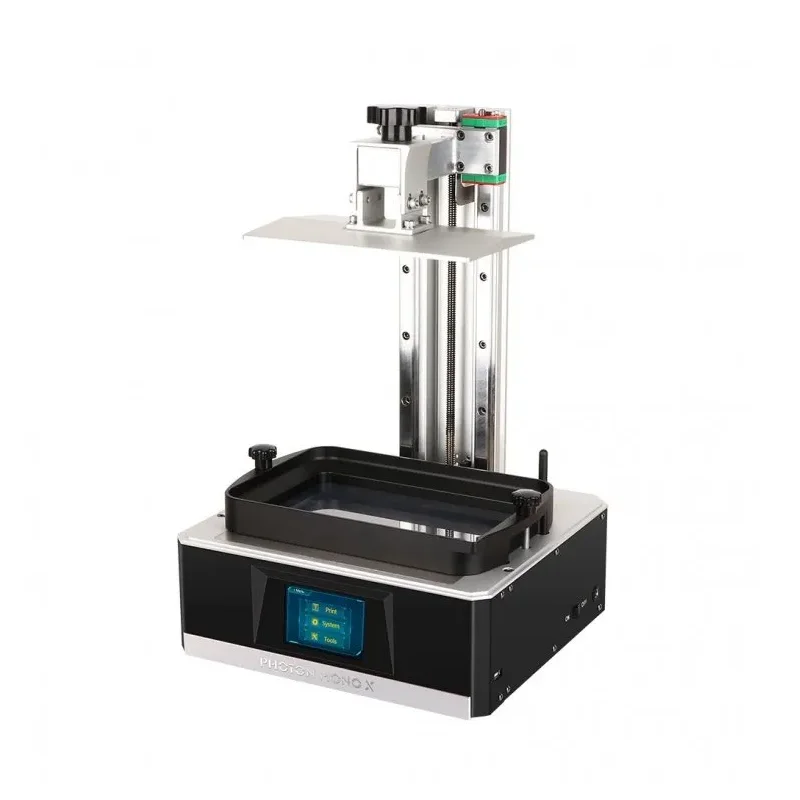

3. Anycubic Photon Mono X

- Price: $599 — Available at Anycubic Store here / Available on Amazon here

- Large resin 3D printer credentials: 192 x 120 x 245 mm build volume

The tallest of our cheaper large resin 3D printers, the Anycubic Mono X manages all this while also being a complete speed demon — it prints layers in just 1-2 seconds!

This is down to the 8.9-inch 4K monochrome screen, pushing the limits of mid-range resin printing, and reaching speeds 4x faster than the original Anycubic Photon released that released back in 2018. What progress!

What progress!

It has a number of built-in safety features which are great if you’re planning to use it for home use and have curious kids inevitably drawn to the mysterious yellow-orange box — and it will immediately stop printing after opening the cover.

The upgraded UV matrix is more uniform for more consistent quality, which when combined with the 4K screen offers blistering quality. The dual linear rails on the Z-axis prevent any wobbling or vibrations affecting precision, and the printer can be connected via Anycubic’s app so you can seamlessly monitor your prints remotely. Convenient!

Overall, it’s a great and fast larger resin 3D printer for home and commercial use.

Professional large resin 3D printers

4. Peopoly Phenom / Phenom L / Phenom Noir / Phenom XXL

Peopoly Phenom

- Price: $1,999 — Available at Matterhackers here

- Print volume: 276 x 155 x 400 mm

Hailed as the most popular large format MSLA printer around, the Phenom is an enormous resin printer that switches up from the MOAI, now adopting MSLA to improve speeds using LED lights to print entire layers simultaneously.

It uses Chitubox so if you’re upgrading from a lower-cost printer you probably already tried this out and have experience and it’s accurate up to 72 micrometers resolution.

Phenom L — Even larger resin 3D printer

- Price: $2,499 — Available at Matterhackers here

- Print volume: 345 x 197 x 400 mm

You can even then choose to upgrade and go further and buy the Phenom L, an even larger resin 3D printer for an extra $500. Resolution falls to 90um, but print volume explodes to 345 x 194 x 400 mm — it’s gigantic!

You can easily print prototype helmets, tools, and other larger resin prototypes in this large-format resin build area.

Phenom Noir

- Price: $3,699 — Available at Matterhackers here

- Build volume: 294 x 165 x 400mm

You may be wondering why the Peopoly Phenom is more expensive than the Phenom, especially since it has a smaller print area, and is this a guide to large resin 3D printers.

The Phenom Noir is one of Peopoly’s highest-end 3D printers, with precise 77um resolutions as well as faster printing speeds and fantastic consistency across the print via its UHD monochromatic LCD screen. And when we say speed upgrades, we don’t mean incremental 10% increases – it’s around 3x faster than the standard Peopoly Phenom! If you want precision and speed with your larger resin prints, the Phenom Noir is perfect.

Phenom XXL — Massive resin 3D printer

- Price: $7,499

- Build volume: 527 x 296 x 550 mm

But you can go even larger. The Peopoly Phenom XXL resin 3D printer prints up to 527 x 296 x 550 mm resin models, which Peopoly highlights as being 4x bigger than Formlabs Form 3L.

It features a very high quality 4K LCD panel which Peopoly calls “industrial quality”, so you retain accuracy even on very large prototypes. The biggest on our list, and one of the biggest resin 3D printers in the world, the Phenom XXL should be able to print any liquid resin prototype you’ll never need.

5. Formlabs Form 3L

- Price: $10,999 — Available at Dynamism here

- Build volume: 335 x 200 x 300 mm

Designed specifically for large-scale resin part production, the Formlabs 3L build on Formlabs is already stellar reputation and brings it to the big leagues.

It uses the same Formlabs technology as on the Form 3, with two precision LPUs (Light Processing Units) for fantastic precision and consistency throughout, and Formlabs stress that this indeed is the ideal solution to save your business money by no longer outsourcing your prototyping and fabrication.

Numerous case studies show helmets printed in exquisite detail, shovel prototypes (though even with the printer’s large build area, it required three parts), nozzles, and even high-resolution full-size Teenage Mutant Ninja Turtle models — if you’re a design studio or uber-wealthy superfan.

It’s easier to use than most commercial large resin 3D printers, and seeks to minimize hassle and the steep learning curve across the board — such as by offering automatic resin dispensing, simplifying the entire slicing and software workflow, and with the delightfully intuitive 5. 5-inch full-color touchscreen.

5-inch full-color touchscreen.

If you’re running a 3D printer farm you can manage them all via the cloud, and you can also make use of Formlabs’ wide resin selection: standard, engineering, flexible, tough and durable, dental or medical, and even jewelry casting resins — you can make almost anything for any industry use with the Form 3L.

6. Photocentric Liquid Crystal Magna

- Price: $15,000+

- Print volume: 510 x 280 x 350 mm

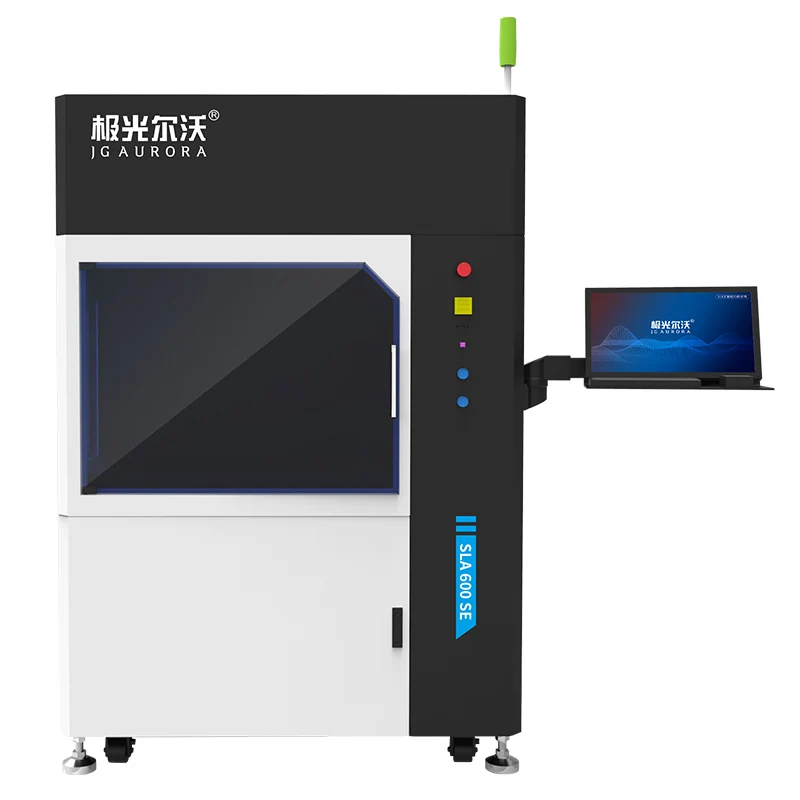

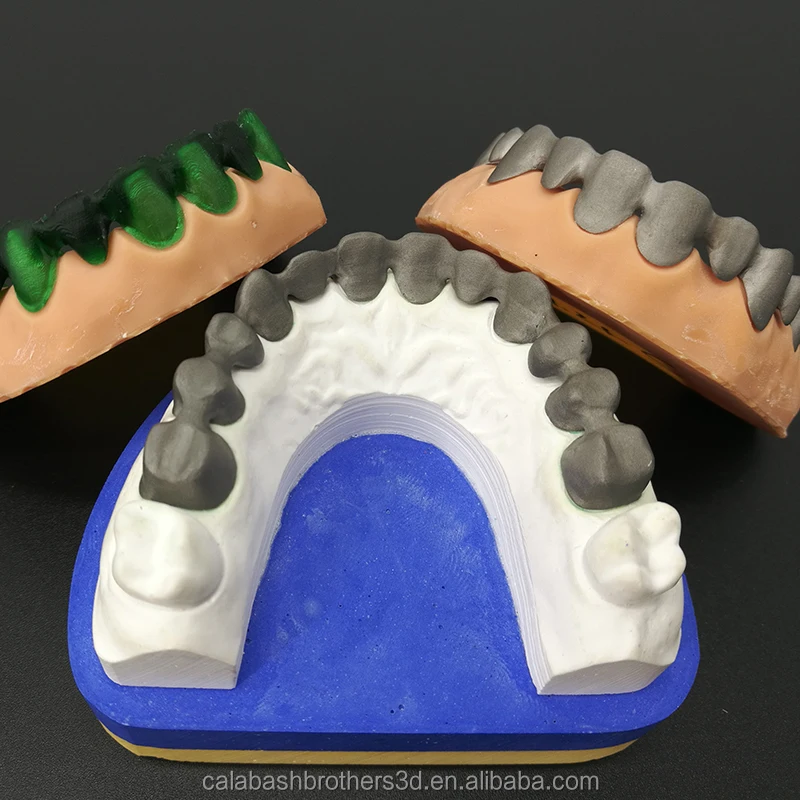

British company Photocentric make some of the highest resolution LCD printers around for industry, with the LC Magna designed for precise dental and product design prototyping at large scales and sizes.

It’s super-fast, large, and accurate, with Photocentric’s own resins helping keep costs lower over the long term. Photocentric also manufactures a wash module for washing prints and a curing module for curing prints that require this, and the LC Magna has been used to prototype and manufacture glasses, dental models, models figurines, and even motorbike engines.

The 4K 137-micron display delivers accuracy over the entire build area, using the benefits of anti-aliasing, and uses Photocentric’s patented blow-peel technologies to prevent some of the negative effects of large resin build areas coming into play.

Overall, it’s costly but offers key benefits as a big resin 3D printer in large-scale industry and prototyping.

Further reading:

- The best resin 3D printers

- DIY SLA 3D printers you can build yourself

- The best large 3D printer (FDM and other technologies)

- Best 3D printers for small businesses

- Top professional 3D printers

- 500x500x500mm 3D printers

- Best wash and cure stations

Top-Notch Equipment with Big Build Volume

Veterans of additive manufacturing know that the first 3D printing technology to appear was stereolithography — it was as far back as 1986. Since then, there’ve been developed plenty of other methods like FDM and SLS; on the other hand, the popularity of stereolithography technology drastically increased when resin 3D printers became much more affordable and advanced. As a result, now the market offers a variety of options for printing in photosensitive resins, with multiple smart features and build volumes for different purposes.

As a result, now the market offers a variety of options for printing in photosensitive resins, with multiple smart features and build volumes for different purposes.

Credit: allthat3d.com

This is Top 3D Shop, and in this article, we are going to tell you about large resin 3D printers. Read on to learn about the most notable models and their peculiarities, as well as the applications of SLA printing and the criteria to be taken into account when choosing such equipment.

What is a large resin 3D printer?

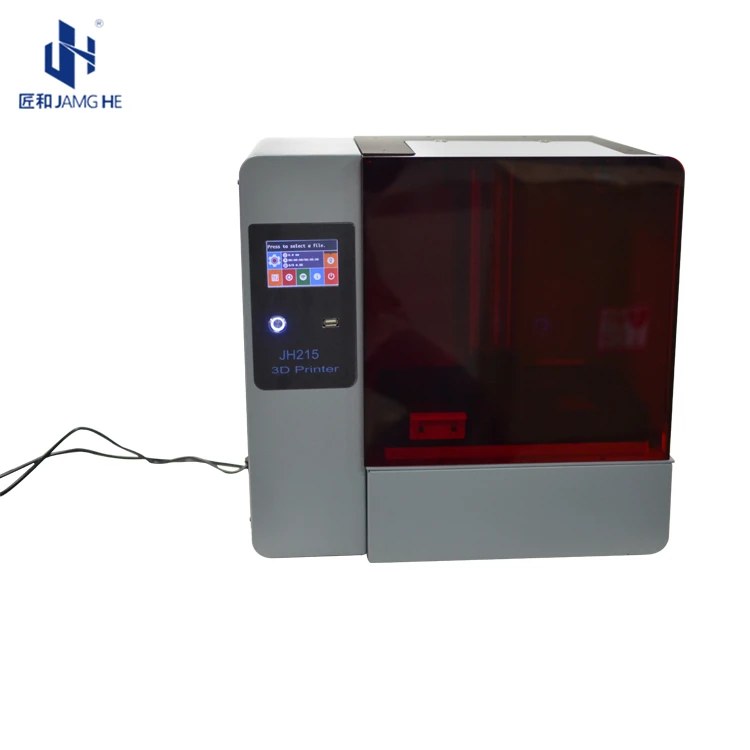

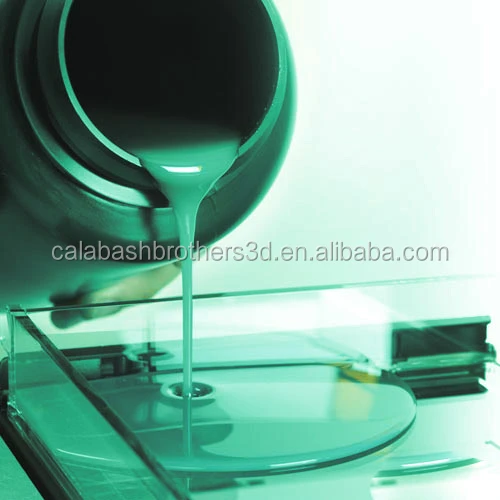

Before we get to discussing specific models and their pros and cons, let’s have a brief look at the technology called vat photopolymerization. As the name suggests, it’s the process of turning a liquid polymer into a solid object under UV light exposure. Vat polymerization comes in three main types which are SLA, DLP, and LCD (or MSLA).

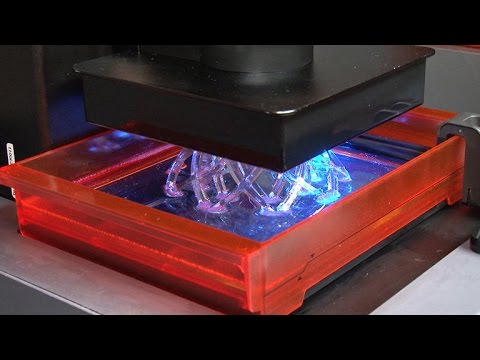

We’ve already mentioned that the first 3D printing technology was SLA (Stereolithography Apparatus) invented and patented by Chuck Hull in 1986. Like the other vat polymerization technologies, this one cures photosensitive resin, layer by layer, to print a 3D object. The difference lies in the source of UV light used for polymerization. SLA employs the UV laser to “draw” each layer of the future model. The method provides high quality prints but the downside of that is the trade-off in speed.

Like the other vat polymerization technologies, this one cures photosensitive resin, layer by layer, to print a 3D object. The difference lies in the source of UV light used for polymerization. SLA employs the UV laser to “draw” each layer of the future model. The method provides high quality prints but the downside of that is the trade-off in speed.

(Sometimes resin 3D printing in general can be referred to as SLA 3D printing, although it may cause ambiguity.)

Credit: burkhartdental.com

DLP (Digital Light Processing) technology uses a digital light projector screen as a light source. This technology gives you a significant gain in speed, as a whole layer is cured all at once. On the other hand, classic SLA printers can feature higher resolution compared to those using a projector.

The newest type of vat polymerization technology is called LCD (which stands for Liquid Crystal Display). It’s pretty similar to DLP, but instead of a projector it uses an LCD as a mask for the light coming from an array of UV LEDs.

Credit: phrozen3d.com

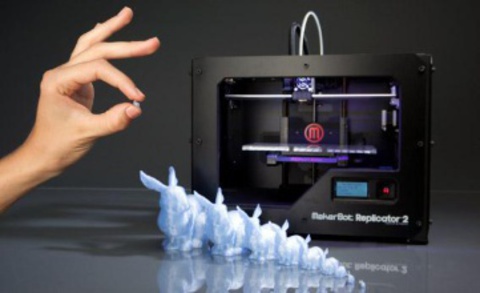

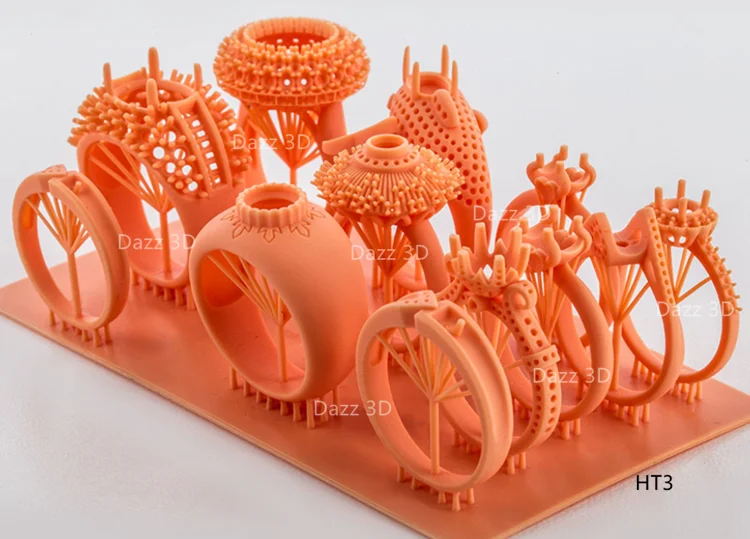

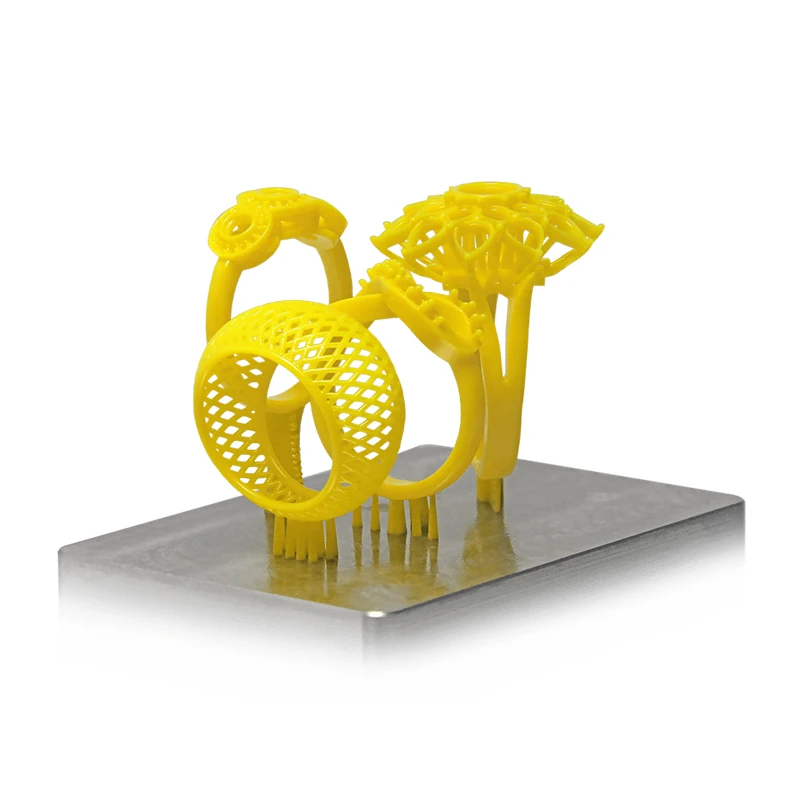

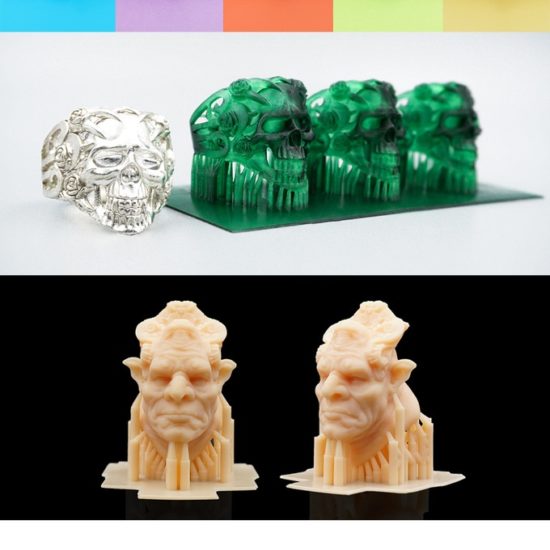

As was already mentioned, the popularity of resin 3D printers is growing rapidly as they are becoming more advanced and user-friendly, and definitely less pricey. First these devices were used for printing small objects requiring high accuracy and flawlessly smooth surfaces, like in jewelry. But some users wanted to have bigger prints without compromising on quality. So eventually, resin 3D printers acquired bigger build volumes, and now we can speak of a great number of large resin 3D printers that entered the market.

Uses of a large resin 3D printer

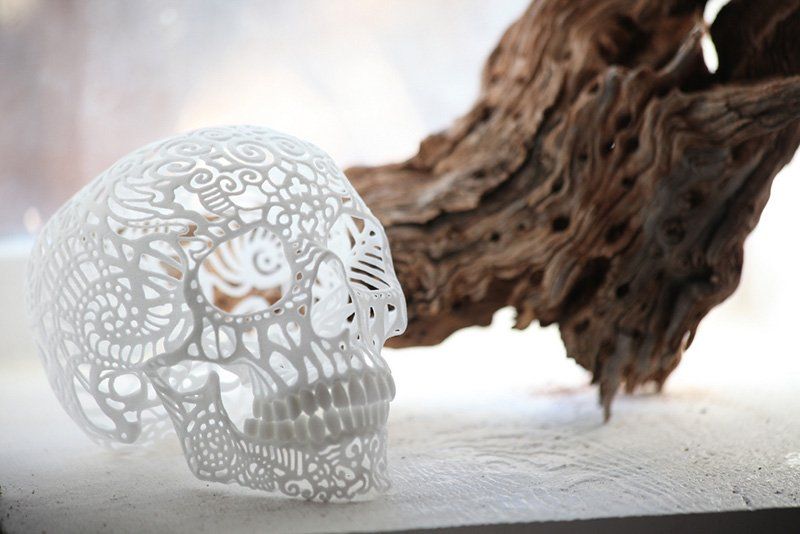

Resin 3D printing with its precision, time-saving, and the opportunity of using a great variety of materials with different characteristics, is highly recommended for use in many sectors like jewelry, healthcare, engineering, aerospace, automotive, robotics, education, and more. This technology helps to create complex finely-detailed models which would be difficult to produce using traditional methods. Let’s look at some examples.

Let’s look at some examples.

Medical and dental tools

Healthcare is one of the industries that benefit most from resin 3D printing. The variety of applications is numerous: from producing medical tools, which, being made of special medical resins, are biocompatible and can be sterilized in a usual way, to making organ models that help doctors make surgery preparations. In dentistry, special dental resins are utilized to produce models of crowns and bridges, surgical guides, splints and retainers with incredible accuracy.

Credit: instituteofdigitaldentistry.com

Gifts and toys / miniatures

Resin 3D printing technology has already been highly appreciated by hobbyists looking for a simple way of making miniatures and customized figures. Toy and gift industries also greatly benefit from employing 3D printing in manufacturing. One more interesting application of the technology in the toy industry is repairing toys and creating spare parts for them.

Credit: facfox.com

Education and entertainment

As the resin 3D printing industry grows, educational institutes are starting to use it for research and education purposes. Both students and professors utilize 3D printers for a variety of purposes like printing visual AIDS or models for their projects. In some colleges, professors make use of 3D printers while telling the students about additive manufacturing technology. There are a lot of sites that offer huge selections of free 3D printing models for entertainment and educational purposes.

Credit: 3dstartpoint.com

The best large resin 3D printers: affordable, commercial and industrial

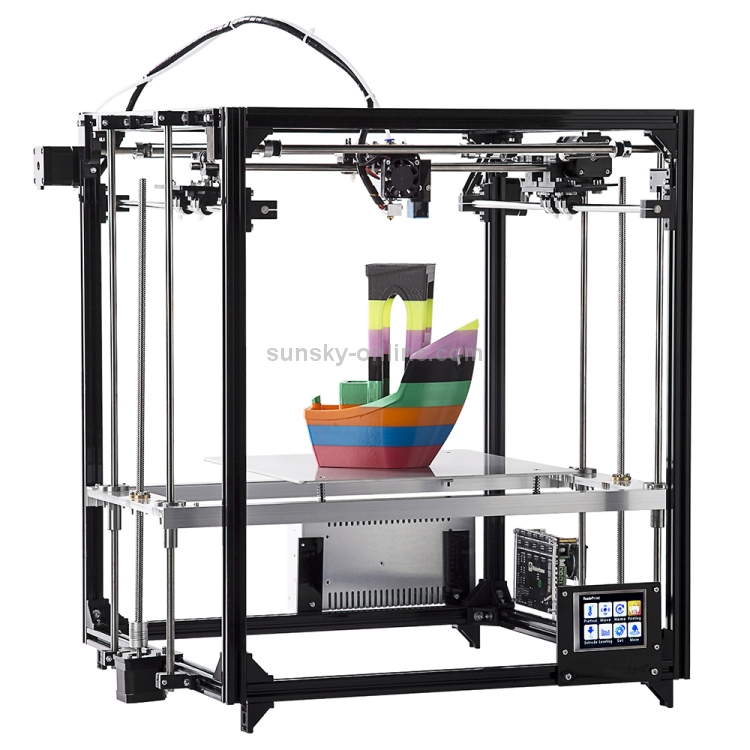

A wide variety of large format resin 3D printers can be divided into three categories, let’s call them affordable, commercial, and industrial devices. Printers relating to the first category are the best choice for home use, as they are quite affordable and not very big in size. They can also be used for the needs of small businesses, and would be perfect in the field of education. The category of commercial printers is aimed at small and medium-sized businesses, but some consumers can also become interested in buying such a device, especially if they are planning on printing some huge ambitious projects, like, for instance, certain elements for cosplay costumes. Commercial large-scale resin 3D printers normally have more spacious build volumes than devices from the category of affordable printers. And, last but not least, industrial printers with their impressively high performance and no less impressive price are mostly targeted at large manufacturing companies with high production volumes.

They can also be used for the needs of small businesses, and would be perfect in the field of education. The category of commercial printers is aimed at small and medium-sized businesses, but some consumers can also become interested in buying such a device, especially if they are planning on printing some huge ambitious projects, like, for instance, certain elements for cosplay costumes. Commercial large-scale resin 3D printers normally have more spacious build volumes than devices from the category of affordable printers. And, last but not least, industrial printers with their impressively high performance and no less impressive price are mostly targeted at large manufacturing companies with high production volumes.

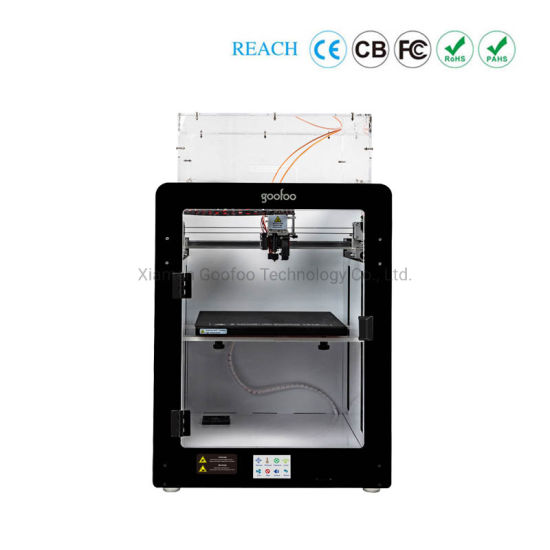

Affordable

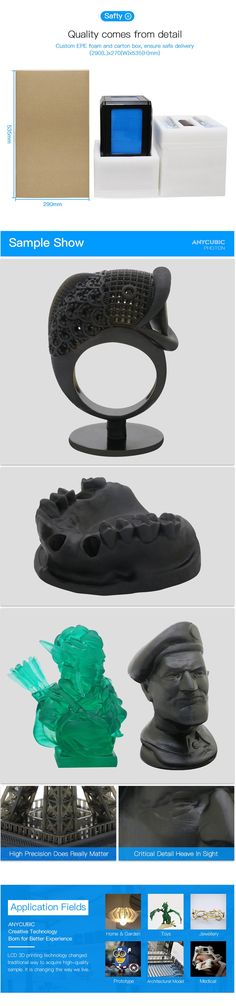

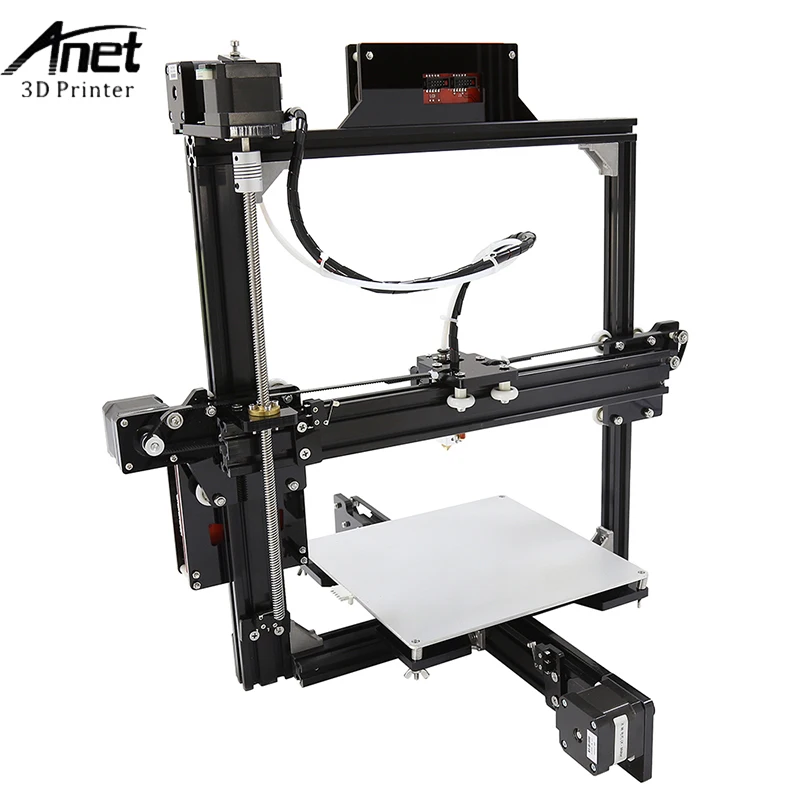

Anycubic Photon Mono X 3D printer

The Anycubic Photon Mono X is a high-speed LCD resin 3D printer. It boasts a 4K resolution panel which allows for high accuracy of printing with a single layer depth not exceeding 0.01 mm. The printing speed is impressive — it takes only 1–2 seconds to print a layer. The Photon Mono X features a spacious build volume of 192х120х245 mm. Built-in safety functions are helpful if you are planning to use the printer at home with kids. The Photon Mono X offers a number of convenience features, such as Wi-Fi and remote control. All this makes the Anycubic Photon Mono X one of the best large format resin 3D printers in its price range.

The Photon Mono X features a spacious build volume of 192х120х245 mm. Built-in safety functions are helpful if you are planning to use the printer at home with kids. The Photon Mono X offers a number of convenience features, such as Wi-Fi and remote control. All this makes the Anycubic Photon Mono X one of the best large format resin 3D printers in its price range.

Credit: @leandro_benignoart / Instagram

Pros

- high printing speed

- great resolution

- Wi-Fi connectivity

- strong brushed aluminum panel

- built-in safety functions

Cons

- rather expensive

- some users complain of the software performance

Phrozen Sonic Mighty 4K resin 3D printer

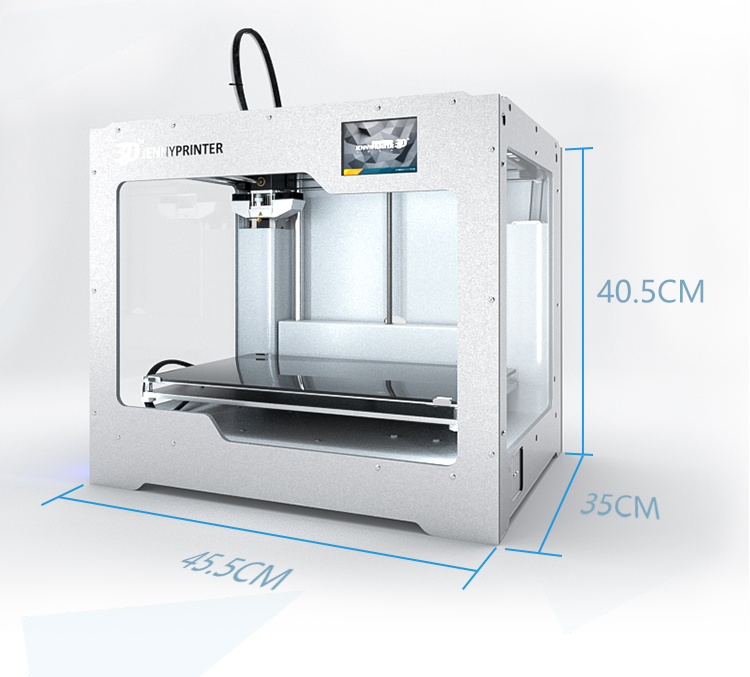

The Phrozen Sonic Mighty 4K offers one of the largest build volumes in its price range — 200x125 x220 mm. The machine is designed for printing one big model or multiple smaller parts in one batch. A 9.3-inch 4K monochrome LCD screen offers excellent printing quality alongside the high speed. The printer is equipped with a 5-inch touchscreen for navigation and settings configuring. The device is compatible with the free Chitubox slicer optimized to work with resin 3D printers. The Phrozen Sonic Mighty 4K would become a good choice both for commercial and home use. The printer is widely used in dentistry.

A 9.3-inch 4K monochrome LCD screen offers excellent printing quality alongside the high speed. The printer is equipped with a 5-inch touchscreen for navigation and settings configuring. The device is compatible with the free Chitubox slicer optimized to work with resin 3D printers. The Phrozen Sonic Mighty 4K would become a good choice both for commercial and home use. The printer is widely used in dentistry.

Credit: printablescenery.com

Pros

- high printing speed

- excellent print quality

- large build volume for its class

- easy operation

Cons

- resin vat is not easy to fit

- small touchscreen

Creality LD-006 3D printer

Like most large volume resin 3D printers in this segment, the Creality LD-006 is based on LCD technology. The device features a new 8.9-inch monochrome LCD screen with 4K resolution. The build volume is decent enough — 192x120x250 mm. The Creality LD-006 boasts a renewed vat which adds to the user’s convenience. The vat has a liquid level line which helps to control the resin expenditure, and special stands to prevent the FEP film from being damaged. The LD-006 has a built-in air filtering system, which seems to be pretty useful when working with resins that are characterized by strong odor.

The Creality LD-006 boasts a renewed vat which adds to the user’s convenience. The vat has a liquid level line which helps to control the resin expenditure, and special stands to prevent the FEP film from being damaged. The LD-006 has a built-in air filtering system, which seems to be pretty useful when working with resins that are characterized by strong odor.

Credit: fabbaloo.com

Pros

- high resolution and print quality

- convenient vat

- built-in air filtration system

- great touchscreen

Cons

- no Wi-Fi connection

- a bit pricey

Uniz IBEE 3D printer

The Uniz IBEE is a multi-purpose desktop LCD 3D printer of medium size. It offers an 8.9-inch 4K monochrome LCD screen and the build volume of 192x120x200 mm. Its new optical system employs a collimated light source, providing the 1000:1 contrast ratio. The device has a wide range of connectivity options including Wi-Fi, and comes with the proprietary powerful and user-friendly software, which makes the Uniz IBEE a win-win choice for beginners.

Credit: uniz.com

Pros

- great quality of printing

- decent build volume

- rich connectivity options

- easy to use

Cons

- changing the vat film requires a lot of time

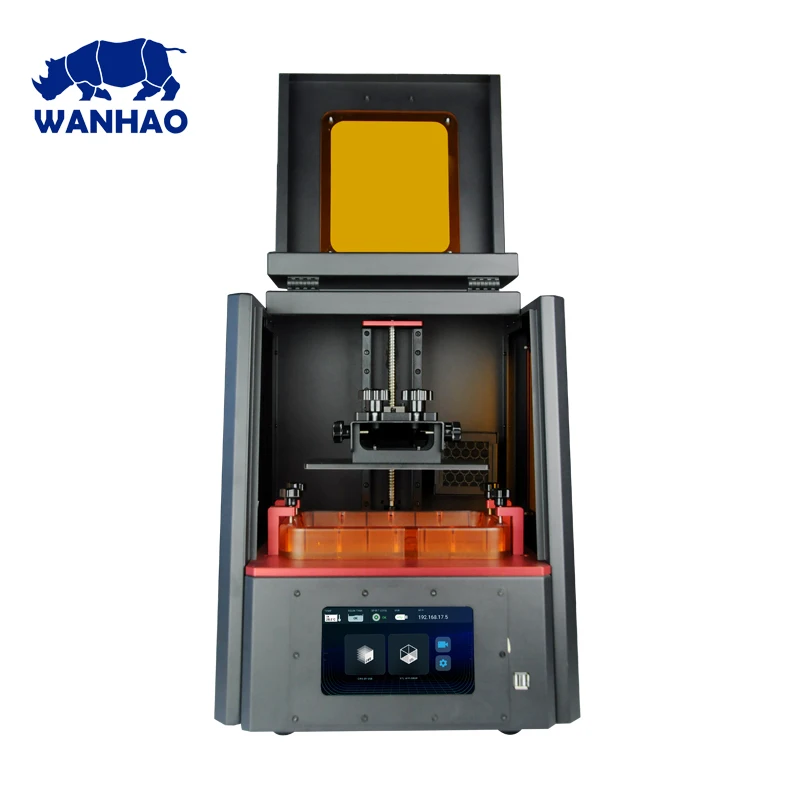

Commercial

Phrozen Sonic MEGA 8K resin 3D printer

The Phrozen Sonic MEGA 8K stands out among other large resin 3D printers as it provides both stunning print quality and one of the largest print volumes on the market. Its 15-inch 8K mono LCD panel allows you to print at 43-micron resolution, which gives you almost twice more detailed prints than most competitors can offer. The Sonic MEGA 8K comes with a pre-calibrated build plate, which means your printer is ready for use right out of the box. The device has a full-metal exterior and its more than competitive price makes it the best choice for those seeking for really large and highly detailed prints.

Credit: reddit. com

com

Pros

- excellent print quality

- huge build volume

- pre-calibrated build plate

- great value for money

Cons

- rather slow printing speed

Uniz Slash 2 Pro 3D printer

The Uniz Slash 2 Pro is an upgraded version of the popular Slash 3D printer. Its liquid cooling system together with the intelligent heat management provides fast curing time which results in high printing speed. The printer uses LCD 3D printing technology and is equipped with a 4K LCD screen. The build volume is 192x120x400 mm, which is quite enough for most projects. The Uniz Slash 2 Pro sports a durable resin vat with the automatic level control.

Credit: uniz.com

Pros

- extremely fast printing speed

- large build volume

- high printing accuracy

- quite affordable

- durable resin vat

- powerful and user-friendly software

Cons

- no touchscreen for the printer control

Phrozen Sonic XL 4K resin 3D printer

The Phrozen Sonic XL 4K is a large format resin 3D printer specially designed for the dental industry, although it perfectly suits the needs of jewelry production, prototyping, and other industries requiring high-accuracy printing. It features a monochrome LCD matrix with a resolution of 3840x2160 and a pretty large print area. One of the advantages of the Sonic XL 4K is the support of various types of resins by different manufacturers. The optical system of the device has been improved compared to the previous models. The Phrozen Sonic XL 4K also has a more powerful ParaLED® 3.0 module which provides an even layer thickness over the entire area of the build plate.

It features a monochrome LCD matrix with a resolution of 3840x2160 and a pretty large print area. One of the advantages of the Sonic XL 4K is the support of various types of resins by different manufacturers. The optical system of the device has been improved compared to the previous models. The Phrozen Sonic XL 4K also has a more powerful ParaLED® 3.0 module which provides an even layer thickness over the entire area of the build plate.

Credit: reddit.com

Pros

- fast printing speed

- large build volume

- fine precision

- compatibility with various resin types

- a lot of connectivity options

Cons

- no warranty for the building platform and the LCD screen

EPAX X156 3D printer

With a 345x194x400 mm build volume, the EPAX X156 is one of the largest resin 3D printers in the market. The printer features a 15.6-inch 4K RGB screen which is less durable and requires more time to cure the layers, compared to monochrome screens. The good news is that in the case of the EPAX X156 it doesn’t seem much of a problem as the manufacturer provides the opportunity to upgrade the device with a smaller but more durable 4K monochrome screen with the same resolution and a 4 times faster printing speed.

The good news is that in the case of the EPAX X156 it doesn’t seem much of a problem as the manufacturer provides the opportunity to upgrade the device with a smaller but more durable 4K monochrome screen with the same resolution and a 4 times faster printing speed.

Credit: reddit.com

Pros

- super large build volume

- fine precision and great surface finish

- factory-leveled printing plate

- large metal resin vat

Cons

- small touchscreen (3.5 inches)

- RGB LCD screen is less durable and features a slower printing speed (although can be upgraded to monochrome)

Formlabs Form 3 / 3L

Credit: formlabs.com

The Formlabs Company has developed a completely new proprietary printing technology called LFS (Low Force Stereolithography) for its Form 3/3L models. This technology, based on SLA, ensures edge-to-edge consistency of the print quality. The major difference between the two models is the build volume, which is 145x145x185 mm for the Form 3 and 335x200x300 mm for the Form 3L. Both printers can work with various resin types which increases their versatility and allows their use in different industries.

The major difference between the two models is the build volume, which is 145x145x185 mm for the Form 3 and 335x200x300 mm for the Form 3L. Both printers can work with various resin types which increases their versatility and allows their use in different industries.

Credit: formlabs.com

Pros

- large build volume (for the 3L model)

- high printing speed

- very user-friendly, allows fully automatic one-click printing

- works with a great number of various resin types

Cons

- support structure is required for every build

- some users reported problems with dust inside the laser unit

Peopoly Phenom Prime

Credit: peopoly.net

The Peopoly Phenom Prime is a large resin LCD 3D printer featuring a great monochrome 12.5-inch 5.5K screen, which allows printing with a resolution of 51 microns. The device boasts a huge 276x155x400 mm build volume. The Phenom Prime has an improved cooling system compared to its predecessor, the Phenom model.

The Phenom Prime has an improved cooling system compared to its predecessor, the Phenom model.

Credit: peopoly.net

Pros

- one of the biggest resin 3D printers

- monochrome high resolution LCD screen

- supports various resin types

Cons

- loud printing process

Industrial

Industrial large resin 3D printers are to meet special requirements, one of them being definitely an extremely high printing speed. None of the existing technologies is capable of providing such speed level. The growing demands for high-speed 3D printing have led to developing such ultra-fast printing technologies as CLIP and LSPc. Let’s see what’s so special about them.

Nexa3D vs Carbon3D

The CLIP (Continuous Liquid Interface Production) technology was developed by the Carbon 3D Company. Like with SLA technology, the models are printed layer by layer, but you don’t have to wait for each layer to be cured, since the technology harnesses oxygen as an inhibiting agent. This allows for printing speed 25–100 times higher than that of any other existing 3D printing technology. Such an approach not only decreases production time, but also removes the layering effect in the print structure. The CLIP technology is presented by two models: Carbon M1 and Carbon M2 with build volumes of 144х81х330 and 190х118х326 mm respectively. These models can not be called affordable, but they quickly caught the attention of big companies like Adidas, Ford, and others. These companies highly appraised the advantages of high-speed and at the same time low-cost production, compared to traditional manufacturing.

This allows for printing speed 25–100 times higher than that of any other existing 3D printing technology. Such an approach not only decreases production time, but also removes the layering effect in the print structure. The CLIP technology is presented by two models: Carbon M1 and Carbon M2 with build volumes of 144х81х330 and 190х118х326 mm respectively. These models can not be called affordable, but they quickly caught the attention of big companies like Adidas, Ford, and others. These companies highly appraised the advantages of high-speed and at the same time low-cost production, compared to traditional manufacturing.

Credit: YouTube

Credit: 3dbeginners.com

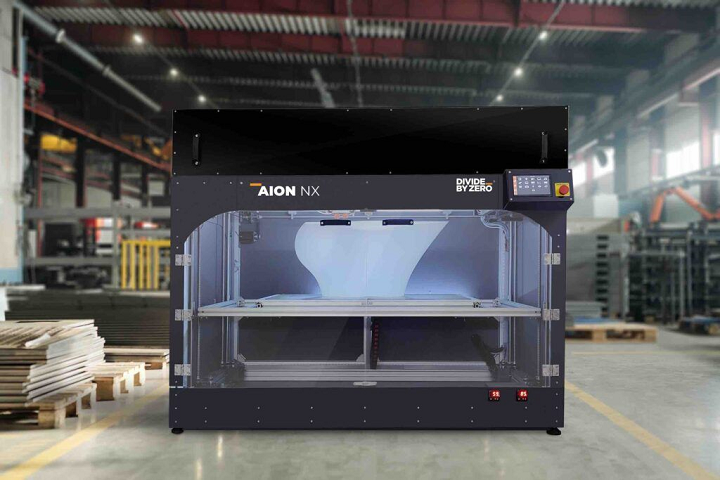

The LSPc (Lubricant Sublayer Photocuring) technology by the Nexa3D Company uses a similar principle to CLIP, being different in some features. Nexa3D produces two models based on LSPc technology – NXE400 with a print volume of up to 16 liters and the 7-liter NXE200. These models are suitable for both industrial prototyping and small-volume manufacturing. The LSPc printers are equipped with replaceable resin cartridges, so you don’t have to refill the vat during the printing process. Nexa3D printers can work with a great number of different materials, which makes them suitable for use in the aerospace and car industries, consumer goods, electronic equipment, and many other fields.

The LSPc printers are equipped with replaceable resin cartridges, so you don’t have to refill the vat during the printing process. Nexa3D printers can work with a great number of different materials, which makes them suitable for use in the aerospace and car industries, consumer goods, electronic equipment, and many other fields.

Credit: nexa3d.com

The main advantage of the ultra-fast printing technologies is an extremely high printing speed which gives the user absolutely new experience in 3D printing. However, such devices are highly expensive and sometimes the manufacturers don’t even sell them to consumers, which makes such printers completely unsuitable for home use and even for small businesses. Still, they can be a great choice for large manufacturing enterprises affiliated with large production volumes.

How to choose a good large resin 3D printer

When it comes to choosing a large resin 3D printer among the numerous solutions offered by manufacturers, one can feel a little bit frustrated as the choice is too vast and not always obvious. Besides, each user usually has special requirements in mind, thus what’s essential for one person can be of no importance for another. We’ve already given you the list of the models worth considering, and now let’s name the key features that’ll help you find the best large resin 3D printer that you’ll be fully content with.

Besides, each user usually has special requirements in mind, thus what’s essential for one person can be of no importance for another. We’ve already given you the list of the models worth considering, and now let’s name the key features that’ll help you find the best large resin 3D printer that you’ll be fully content with.

Build volume

The build volume or the printing area defines the maximum size of your future project. The larger the build volume – the larger laser sword you can print. But if you are not that ambitious and gonna print something of a smaller size, you may not restrict your choice by this parameter. Besides, larger build volume usually means bigger size of the printer itself. It also requires more consumables.

LED array

LED array, or LED matrix, is used in LCD 3D printers as the light source to cure the printed layers. Manufacturers develop different optical systems trying to get the consistent lighting possible on the entire build plate, as it directly affects the print quality.

Production speed

DLP and LCD printers generally have a faster production speed than SLA models. Monochrome LCD matrix provides much higher printing speed than a color one, as the latter absorbs more light and the layers are cured more slowly. It’s up to you, whether you need really speedy printing or better save a little money.

Resolution and precision

Important parameters that define how similar your print will be to the original. Resolution and precision are often regarded as synonyms; but nevertheless these two words are close in their meanings, there's a certain difference. Resolution can be defined as the X-Y dimensions (horizontal resolution) and layer thickness in micrometers (vertical resolution). The less the layer thickness is, the higher resolution your printer has, which results in smoother and more detailed prints. Precision rather refers to the consistency of the printer, in other words, it shows if it is capable of providing expected results in every print. If you need fine-detailed prints, then resolution is a crucial thing for you. But don’t forget that higher resolution always means slower printing speed.

If you need fine-detailed prints, then resolution is a crucial thing for you. But don’t forget that higher resolution always means slower printing speed.

Stability

The quality of your prints depends to a great extent on how stable your printer is, if there’s any undesired wobbling during the printing process. To ensure the stability, all the printers in our list are equipped with double linear Z-axis rails to move the build platform up and down. You can also make some steps to improve your device’s stability. First put it on a sturdy, heavyweight surface. Then put a foam or rubber pad under the printer to absorb vibrations. You can also reduce printing speed if this option is not very important for you.

Credit: all3dp.com

Print bed adhesion

It sometimes happens that your prints don’t stick to the print bed, but rather to the FEP film or to the resin vat. It means that the first layer of your project has poor adhesion to the build plate. To stop this, you should make sure you have enough bottom layers and the bottom layer has enough time to harden. You can use PTFE spray on your FEP film and let it dry to create a lubricant preventing the resin from sticking to the resin vat.

To stop this, you should make sure you have enough bottom layers and the bottom layer has enough time to harden. You can use PTFE spray on your FEP film and let it dry to create a lubricant preventing the resin from sticking to the resin vat.

Economical

When one is choosing a large resin 3D printer, price can become an important factor as such machines, although becoming more affordable, still cost a lot. If you don’t want to spend extra money, you’d better check all the features to decide what you’re ready to pay for. Such parameters as high printing speed and extreme resolution make the device more expensive, but one can always find a reasonable compromise depending on their needs. Another important thing to keep in mind is consumables. Some printers allow using different types of resins produced by third-party manufacturers, which is great, as you can always choose the best option that suits your budget.

Conclusion

Large resin 3D printers are becoming more and more popular. As the technology’s developing rapidly, such machines have entered a lot of various industries, where they successfully meet the goal of high-speed precise printing at a relatively low cost. The vast variety of different resin types, offered by manufacturers, allows for use of resin 3D printers in almost any industry, when one wants to get a finely detailed object with a flawlessly smooth surface, be it dentistry, jewel industry, aircrafting, or even shoes manufacturing, like this famous Adidas 4DFWD model with 3D printed midsoles.

As the technology’s developing rapidly, such machines have entered a lot of various industries, where they successfully meet the goal of high-speed precise printing at a relatively low cost. The vast variety of different resin types, offered by manufacturers, allows for use of resin 3D printers in almost any industry, when one wants to get a finely detailed object with a flawlessly smooth surface, be it dentistry, jewel industry, aircrafting, or even shoes manufacturing, like this famous Adidas 4DFWD model with 3D printed midsoles.

Credit: adidas.com

It’s not only businesses that benefit from the technology of resin 3D printing, but also consumers, as the market of affordable resin 3D printers is growing really fast. So, if you want to purchase the best large resin 3D printer, we do hope that this article will answer your questions and help you make the right choice.

Choosing a liquid photopolymer for a 3D printer. Classification of materials for SLA/DLP 3D printing.

Contents:

- Introduction

- SLA Overview

- SLA Standard Resins

- Standard photopolymer resin - Standard

- Clear Photopolymer Resin - Clear

- Engineering photopolymer resins

- Rigid photopolymer resin - Tough (like ABS)

- Durable photopolymer resin - Durable (PP-like)

- Heat resistant photopolymer resin - Heat resistant

- Rubber-like photopolymer resin - Rubber-like (Elastic)

- Ceramic photopolymer resin - Ceramic filled (Hard)

- How to choose the right resin for your application

- Dental and medical SLA resins

- Medical Device Photopolymer Resin - Custom Medical Appliances (Class I Biocompatibility)

- Dental Long Term Biocompatible Resin (Class IIa Biocompatible)

- Biocompatibility class I vs biocompatibility class IIa

- Cast SLA resins

- Cast resin for jewelry making

- Generalized rules

Hello everyone, Friends! With you 3DTool!

This article compares photopolymer resins using Formlabs SLA 3D printing products –

Catalog of photopolymer 3D printers

Photopolymers from FormLabs

Detailed review of the Formlabs Form 3 3D printer

Introduction

The stereolithography prints plastic parts with high resolution, good fine detail and smooth surface. Due to the variety of photopolymer resins available for SLA, this technology is used in many different industries:

-

"Standard" photopolymers are used for prototyping

-

Engineering photopolymers have certain mechanical and thermal properties

-

Dental and medical photopolymers have biocompatibility certificates.

-

Cast photopolymers have a zero ash content after burning.

SLA 3D Printing Resin Overview

SLA uses a laser to cure a liquid photopolymer resin. This process is called photopolymerization. Various combinations of polymers and other additives that are part of the resin allow you to get different material properties.

The main advantages and limitations that are common to all resins in SLA 3D printing are:

Benefits:

Weaknesses:

Base Resins for SLA

Post-Processing SLA/DLP 3D Printing Article

Standard photopolymer resin - Standard

Standard resins produce parts with high stiffness, detail and a smooth surface. The low cost of resins, from $250 per liter, makes them ideal for prototypes.

The color of the resin also affects its properties. For example, in FormLabs products, gray resin is suitable for models with fine details, and white resin for parts that require the smoothest possible surface.

Benefits of using Standard grade resins:

Cons Standard:

Also included in the class of "Standard" photopolymer resins from FormLabs is the Color KIT - a set of special dyes and "Color Base" photopolymer resin for mixing and obtaining a variety of color solutions. This eliminates the need for painting parts after 3D printing.

This eliminates the need for painting parts after 3D printing.

FormLabs Engineering Photopolymer Resins

Engineering resins have a range of properties for injection molded plastics.

All engineering resins require additional UV curing, such as using the Form Cure, to achieve their maximum properties.

Tough photopolymer resin - Tough (ABS equivalent)

Tough resin was developed for models that need to withstand high loads and be durable.

This material produces strong, shatter-resistant parts and functional prototypes such as snap-on housings.

Pros:

Cons:

Ideal for: functional prototypes, mechanical parts

Durable photopolymer resin - Durable

Durable resin is a wear-resistant and flexible material with mechanical properties similar to polypropylene.

Durable photopolymer produces models with a smooth glossy surface and high resistance to deformation.

Durable Resin is ideal for:

- Bushings and bearings;

- Various functional compounds

Pros:

Cons:

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

-

Low heat distortion temperature

-

Low flexural strength (lower than hard resin)

Ideal for: functional prototypes.

Refractory Photopolymer Resin - Formlabs High Temp Resin

The heat resistant resin is ideal for parts that require high temperature resistance and operate at high temperatures.

Formlabs High Temp Resin provides the highest melting point (HDT): 238°C at 0.45 MPa.

The resin should be used to print detailed, accurate prototypes with high heat resistance.

Pros:

Cons:

Flexible Resin

Rubber-like resin allows flexible parts to be made. This material has a low tensile strength and high elongation at break and is well suited for parts that will be bent or compressed.

It can also be used to add ergonomic features to multi-material assemblies such as: dies, wearable prototypes, handles, pads and grips.

Pros:

-

High flexibility (high elongation at break)

-

Low hardness (simulates 80A durometer rubber)

-

High impact resistance

Cons:

-

Doesn't have all the properties of real rubber

-

Requires extensive support structures

-

Material properties deteriorate over time as the part is exposed to ultraviolet radiation (sunlight)

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

Ideal for flexible prototyping.

Ceramic photopolymer resin - Rigid Resin

This resin is reinforced with glass, which provides very high rigidity and a polished surface. The polymer is very resistant to deformation and is excellent for 3D printing thin elements.

Ideal for: molds and tooling, jigs, manifolds, retainers, electrical and automotive fixture housings

Thermal management components printed with SLA ceramic (hard) resin. Image credit: Formlabs

How to choose the right resin for your application

The table below shows the main mechanical properties of photopolymers for SLA:

Source: Formlabs

Standard resin ( standart ) has high tensile strength but is very brittle (very low elongation at break) so it is not suitable for functional parts. The ability to create a good part surface makes it ideal for visual prototypes and art models.

Durable ( durable ) resin has the highest impact strength and elongation at break of any other SLA material. Best suited for prototyping parts with moving parts and latches. It lacks, however, the strength of thermoplastic 3D printing materials such as SLA nylon.

tough tough resin is a compromise between the material properties of tough and standard resin. It has a high tensile strength, so it is best suited for rigid parts that require high hardness.

heat resistant resin ( heat resistant ) can withstand temperatures above 200 o C, but has poor impact strength and is even more brittle than standard resin.

ceramic ( ceramic reinforce ) resin has the highest tensile strength and flexural modulus, but is brittle (poor elongation at break and toughness). This resin is preferred for thin wall parts that require increased rigidity.

The graphs below compare the mechanical properties of the most common SLA materials visually:

Comparison chart for elongation at break and toughness for common SLA printing specifications and standard media. Image courtesy of Formlabs.

Stress-strain curves for conventional SLA technologies and standard materials. Image credit: Formlabs

Pros:

Cons:

- Moderate wear and tear resistance

Ideal for: Surgical aids and appliances

Dental Long Term Biocompatible Resin - Dental Long Term (Class 2A biocompatible)

0114

These resins are specially formulated for long term dental fixtures. Class 2A biocompatible resins can come into contact with the human body for up to a year.

High resistance to breakage and wear make this resin ideal for making rigid cotter pins or retainers.

Pros:

Cons:

-

High price

Ideal for: durable dental instruments, fracture and wear resistant medical parts, rigid cotter pins, retainers

What is the difference between class 1 and class 2a biocompatibility?

Class 1 biocompatibility rules apply to materials that are allowed to be used for:

-

non-invasive devices that come into contact with intact skin

-

devices for temporary use or short-term use in the mouth or ear canal or in the nasal cavity

-

reusable surgical instruments

Class 2a biocompatibility rules apply to materials that are allowed to be used for:

-

devices that come into contact with bodily fluids or open wounds

-

devices used to introduce substances into or remove substances from the human body

-

invasive short-term devices such as invasive surgical items

-

long-term implantable devices placed in the teeth

Photopolymer resins in SLA 3D printing for jewelers

Jewelry resins

This material allows you to print models with fine details and a smooth surface without leaving ash or residue after burning.

Cast resin allows you to get the finished product directly from design to precision casting with just one 3D printed part. It is suitable for making jewelry and other small and complex components.

Pros:

Cons:

Ideal for: investment casting, jewelry making

SLA/DLP 3D printer catalog

Photopolymers from FormLabs

Post-Processing SLA/DLP 3D Printing Article

Well, that's all we have! We hope this article was useful for you!

You can order Formlabs SLA 3D printers or ask your questions and find out the status of your order, you can

- Email: [email protected]

- By phone: 8(800)775-86-69

- Or on our website: http://3dtool.ru

-

Don't forget to subscribe to our YouTube channel:

Subscribe to our groups in social networks:

In contact with

Photopolymer 3D printer

3D printers can be sorted not only by the printing technologies used, but also by the consumables used. In this section, we will look at devices that use photopolymer resins to build models.

In this section, we will look at devices that use photopolymer resins to build models.

- 1 Consumables

- 2 Laser stereolithography (SLA)

- 3 Projector stereolithography (DLP)

- 4 Multi-jet (MJM and PolyJet)

- 5 3D pens

- 6 Additional illumination

Consumables

Photopolymer resins are liquid polymers that harden when exposed to light. As a rule, such materials are sensitive to the ultraviolet range, which determines the design of photopolymer printers. One of the common design elements is a transparent colored cap or housing made of a material that filters ultraviolet radiation. This is done both to protect the user's eyes and to protect the supplies inside the printer from exposure to sunlight and background lighting.

Photopolymer resin loaded into Form 1 3D printer

The physical properties of resins after polymerization vary widely. Both rigid and flexible options are available, transparent and matte. A wide selection of colors is also available. Resin consistency and exposure times also vary, so a range of compatible media should be considered when choosing a printer.

Both rigid and flexible options are available, transparent and matte. A wide selection of colors is also available. Resin consistency and exposure times also vary, so a range of compatible media should be considered when choosing a printer.

The last aspect to consider when choosing a material is its toxicity. There are both quite toxic options and biologically safe ones.

The cost of consumables can be considered the Achilles' heel of photopolymer printing. The plants themselves are already reaching quite acceptable price levels, but it is still quite difficult to find inexpensive photopolymer resins. It is hoped that the proliferation of inexpensive photopolymer printers will lead to an increase in the production of consumables and lower prices.

Laser Stereolithography (SLA)

SLA Model

The firstborn of photopolymer printing and modern 3D printing in general. The technology was developed in 1984 by Charles Hall, who later founded 3D Systems.

SLA printers use laser emitters to cure the photopolymer supply.

A typical SLA printer consists of a consumable tray sitting under a build platform driven vertically by a raise/lower mechanism.

Alternatively, the cuvette itself can be driven - what matters is the relative movement of the platform and the container. Above the cuvette is a laser emitter and a mirror system for deflecting the laser beam.

During the printing process, the platform is immersed in the consumable for the thickness of one layer of the digital model.

Since photopolymer resins can be quite thick, a leveling mechanism is often used to speed up the process.

SLA printer operation diagram

After leveling, the process of illumination of the material begins. Illumination is produced by laser irradiation. Most photopolymer resins are designed to cure (polymerize) when exposed to ultraviolet light, which determines the choice of laser frequency. The movement of the beam along the X and Y axes is determined by the operation of the deflecting mirrors.

The movement of the beam along the X and Y axes is determined by the operation of the deflecting mirrors.

After the drawing of the layer is completed, the platform is immersed in the material for the thickness of one more layer, and the process is repeated with the drawing of the next layer of the digital model.

Animation of the build process

SLA printing takes quite a long time, and printers using this method tend to have relatively small build areas.

This is mainly due to the high cost of laser emitters: printing large objects with a single laser will take too much time, and installing additional emitters and mirrors will complicate the design, increase the installation dimensions and raise the price to an unacceptable level for most users.

Despite the success of this technology, projected stereolithography is considered to be a more promising, albeit very similar, method.

Projector Stereolithography (DLP)

Formlabs Form 1 Desktop DLP Printer

A close relative of laser stereolithography, this method uses digital LED projectors instead of laser machines with mirror deflection systems. The method became popular due to the development of technology for the production of low-cost high-resolution digital projectors by Texas Instruments.

The method became popular due to the development of technology for the production of low-cost high-resolution digital projectors by Texas Instruments.

Layers are illuminated using a digital projector that highlights the patterns of the entire layer, which distinguishes this method from SLA, where the "picture" emerges progressively using an ultraviolet laser.

A similar approach has previously been used on SGC-type units, but this technology used physical photomasks, making the process costly, time consuming, slow and noisy.

FTI continues to exist, a development of SGC that is virtually indistinguishable from DLP printing, as it also uses digital LED projectors.

DLP printer design

Simultaneous illumination of an entire layer using projectors can significantly speed up the printing process even compared to SLA printers that have a high scanning speed (ie beam movement).

In addition, these printers are less sensitive to rough physical impact due to the absence of delicate mirror systems.

The absence of mechanical mirror systems improves accuracy. Finally, the cost of projectors sets them apart from laser systems.

Projection size can be quite significant, reaching the average of popular FDM printers.

An interesting feature of DLP printers is the ability to "reverse" or "reverse" printing.

In this case, the projector is installed under a transparent (material choice for transparency in relation to ultraviolet light) cuvette, and the platform does not sink into the material, but gradually rises, pulling out the layers of exposed polymer.

This approach eliminates the alignment mechanism and achieves even higher Z resolution than SLA printers.

In addition, the size of models in height is not limited by the depth of the cuvette, which favorably affects the dimensions of the printer and the possibility of increasing the build area.

Multi-jet printing (MJM and PolyJet)

MJM printer 3D Systems ProJet 3500HDMax

MJM and PolyJet technologies are practically indistinguishable from each other. The name difference comes from the respective patents: Multi Jet Modeling is owned by 3D Systems, while PolyJet is owned by rival Stratasys.

The name difference comes from the respective patents: Multi Jet Modeling is owned by 3D Systems, while PolyJet is owned by rival Stratasys.

The very principle of multi-jet polymer printing was developed by the Israeli company Objet, which eventually became a division of Stratasys.

Multi-jet printing technology combines features of 3D inkjet printing (3DP) and projection stereolithography (DLP).

How the MJM PolyJet printer works

Models are built by spraying photopolymer using linear arrays consisting of multiple nozzles.

The applied layer is immediately exposed to ultraviolet lamps - as a rule, two processes occur simultaneously.

By the time the array reaches the end of the build chamber, the previously deposited material is hard enough to print a new layer.

Composite models created on the ProJet 3500 DP dental printer

This approach allows for very high printing speeds, but is characterized by high design complexity, which negatively affects the cost of such installations and limits their distribution to professional use.

One of the advantages of MJM and PolyJet technologies is the ability to create composite structures from photopolymer resins with different physical characteristics.

It is therefore possible to create models with easily removable supports, use multiple colors and use flexible and rigid materials in parallel within the same model.

3D Pens

CreoPop 3D Resin 3D Pen

Recently, there has been a craze for hand-held printing devices called 3D pens. At the moment, there are three main options for such devices: drip-jet pens (DOD), called BioPen and used in the development of new methods for treating damaged tissues, FDM 3D pens, which are manual extruders (essentially similar to the usual hot glue guns, but using thermoplastics) and developments in 3D-drawing with photopolymer resins.

CreoPop 3D pen was the first "handheld photopolymer printer". The design of this device is quite simple, because the most complex function, positioning, is performed by the user himself. The pen only extrudes resin through the tip surrounded by LED emitters.

The pen only extrudes resin through the tip surrounded by LED emitters.

CreoPop 3D pen in action

This way the resin hardens immediately after application, allowing you to literally draw on air.

The advantage of such handles over FDM-analogues is the low operating temperature - there are no heating elements in the device. As a result, with such pens you can even draw on the skin.

In addition, a wide range of photopolymer resins with different physical properties can be used with such devices, which greatly expands the range of possible applications. At a minimum, this is a relatively inexpensive, but entertaining toy.

The only drawback is the relatively high cost of consumables, but such devices are unlikely to require large volumes of photopolymer resin for domestic use.

Additional Lighting

Final Lighting of Resin Models in a Homemade Camera

Full curing of models can take quite a long time, so models during SLA and DLP printing are only partially polymerized, sufficient to maintain the physical shape of the part.