3D printing without tape

Blue Tape for 3D Printing: The Complete Guide [2021]

3D Printing has rapidly grown in popularity and accessibility. What used to only be possible in advanced laboratories is now possible in the comfort of the home!

Whatever your purpose for 3D printing, whether professionally or just for fun, there are many components that play into the quality of the final product. One of the most important is bed adhesion.

Here is the ultimate guide to 3D printing with blue painters tape.

3D Printing Bed AdhesionWhat is 3D printing bed adhesion?Bed adhesion in 3D printing is how well the printed plastic parts are able to stick to the build plate. Good bed adhesion means that the plastic will not be easily removed or nudged, while poor bed adhesion means that it might move around during the printing process.

Essentially, as the filament hardens on the build plate, bed adhesion is what keeps everything in place. If the plastic pieces become top-heavy or get bumped, adhesion to the build plate is what keeps everything in place.

Bed adhesion is an important part of the 3D printing process. Luckily, there are special products designed to create the perfect amount of bed adhesion. Here are the reasons why bed adhesion is so crucial in 3D printing.

Not enough adhesion

If the 3D printed parts are loose enough to move around during the printing process, it can ruin the entire build. 3D printing requires exact measurements, so any sort of movement can misalign the entire build.

Too much adhesion

Alternatively, if the build plate has too much adhesion, it can be difficult to remove the plastic components. Any particularly thin pieces can potentially become damaged by the greater force required to remove them from the adhesion.

What kind of adhesives are used for 3D printing?Options for 3D Printing Bed Adhesion

PEI Sheets

PEI sheets, or Polyetherimide sheets, are adhesive plastic sheets designed to withstand the cycles of heat in 3D printing. On one side, they adhere to the build plate, and on the other they allow you to build your 3D prints.

On one side, they adhere to the build plate, and on the other they allow you to build your 3D prints.

While are supposed to be reusable for up to a month, the soft plastic can be dented and damaged very easily. A build plate that isn’t perfectly level can ruin a print. Investing in a PEI sheet can be risky because if it is damaged during an early print, the sheet can become unusable.

Adhesive Spray

Another option for bed adhesion is adhesive sprays. You simply spray the adhesive onto the plate and start printing. This route is easy and allows you to maintain a level bed. Plus, cleaning up is simple too, as most sprays are soluble in water.

Even though this is certainly a convenient method of getting your prints to stick, it is not the most effective. Getting an even stickiness to the bed with a spray can be difficult, and often it can be hard to get the bed to be sticky enough.

Glue

Using a glue stick is a way to keep your prints in place during 3D printing. Special glue designed for 3D printing is available at a relatively low cost. All you have to do is rub the glue stick where you are going to be printing, and the printer will take care of the rest.

Special glue designed for 3D printing is available at a relatively low cost. All you have to do is rub the glue stick where you are going to be printing, and the printer will take care of the rest.

However, like PEI sheets, they can create an unlevel bed. If too much glue builds up in one spot, the print can become crooked. Also, clean up can be kind of a pain because the glue will stick to the plate and the print.

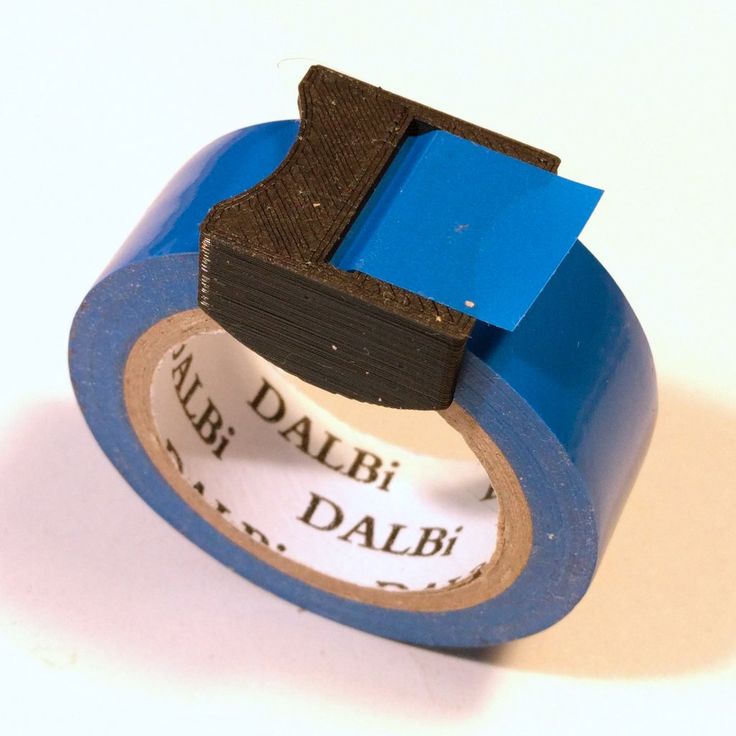

Blue Painter’s Tape

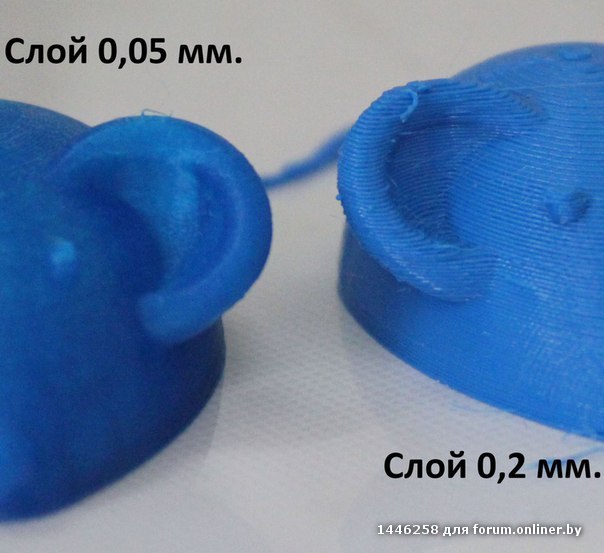

Specialized blue painter’s tape is a great option for creating bed adhesion. The porous nature of the blue tape allows PLA nylon, and other filaments to stick directly to the back of the tape. Painter’s tape is also heat resistant so it can withstand heated beds and the heat of the filament.

While it does take some set up, the price of the supplies and the quality of the printed parts are unmatched.

How to Use Blue Tape for 3D PrintingClean the Surface

Before you start applying the tape, you should clean your printing bed of all residue. This lets the tape stick and helps to keep your plate level.

This lets the tape stick and helps to keep your plate level.

Taping a 3D Printer Bed

While it will take a few minutes to properly tape your build plate, the prep work is not too difficult and can quickly be mastered.

With the adhesive side down, lay the tape down side by side. You want to be as precise as possible with this step so that there are no gaps that could let the filament through, but you also do not want any overlap of the tape which would cause the surface to be uneven.

Tape Diagonally

A key tip for taping a build plate is to lay the pieces of tape diagonally. When laying out the pieces side by side, start from one corner at a forty-five degree angle and work your way over.

This is helpful because it keeps the tape from warping with the print. If the straight edges of the print line up with the straight edges of the tape, the tape can lift off the plate as the filament cools.

Remove Bubbles with a Scraper

As you lay the pieces of tape down, be sure that there are no bubbles underneath the tape. To ensure this, run a scraper over every piece as you place it.

To ensure this, run a scraper over every piece as you place it.

You want to be gentle so that you do not damage or tear the tape, but you must be firm enough to remove any imperfections. If there is a piece of tape that becomes unusable, tear it off and try again; it is better to waste one piece of tape than an entire print!

Trim the Tape

When sizing up the strip of tape, pull it so it is longer than the width of the plate. Then when placing it, be sure to leave plenty of slack on either side of the plate. With a sharp razor, carefully slice the ends of the tape so it is flush with the sides of the plate.

If you don’t have a razor, it is also an option to wrap the excess tape underneath the bottom of the plate. However, this can affect the leveling of the build plate.

Avoid Touching the Top of the Tape

During this whole process of taping your build plate, try to touch the top of the tape as little as possible. The oils in your fingers can affect the porousness of the tape.

The oils in your fingers can affect the porousness of the tape.

If you are trying to print onto tape that you have been touching a lot, the oils from your hands may keep your parts from adhering to the tape. It is not so impactful that you need to wear gloves to place the tape, but just keep your contact to the tape at a minimum.

Preparing the Surface of the Tape

Once you have your blue painter’s tape on the build plate, there are various ways you can prepare the surface of your tape. Depending on what kind of adhesion you are looking for, you can use different methods for your own work.

You want to find the best balance between adhesion and clean removals that you can. If it has too much grip, the parts will not be easily removed. This could rip the tape or damage the parts. Too little adhesion will keep the printed parts from staying in place.

Unprepped Blue Tape

Leaving the blue tape untreated is a viable way to get adhesion. The porous nature of the tape allows the filament to attach itself, keeping your printed parts in place.

This method of adhesion should give you extremely clean removals. However, for prints that are top-heavy or unbalanced, you may need more adhesion to keep them steady and attached.

Scuffed Blue Tape

A simple trick you can use to add more adhesion to your blue tape is to scuff up the surface. Just take a dry sponge and rub-down the spot that you want to add adhesion to. By doing this, you increase the porousness of the tape, allowing the filament to stick to it even more.

This increases the adhesion of the tape, but it still allows for very clean removal of printed parts. The downside is, it will limit the lifespan of your tape. If you continue scuffing the same spot print after print, the tape will become worn down more quickly and will stop giving you quality results.

Glue on Blue Tape

Another option to greatly increase adhesion is combining blue tape with other methods of adhesion. Spraying hairspray or adhesive spray on top of the tape can give it more grab, and adding glue to the tape can increase it even more!

However, adding too much adhesive can cause problems. If you have a print with a large surface area stuck to the tape, it can be very challenging to remove it cleanly from the build plate.

If you have a print with a large surface area stuck to the tape, it can be very challenging to remove it cleanly from the build plate.

Additionally, while you can clean glue and spray off of the build plate, you cannot clean it off of tape. Using alcohol to clean glue off of the tape ruins porousness, making it unusable for future prints.

When to Add More Adhesion to the Build Plate

The typical rule of thumb is the more surface area that is in contact with the plate, the greater the adhesion will be. This is a good rule to take into account when dealing with bed adhesion. Blue painter’s tape will already provide great adhesion even without any added prep work.

Large-Based Parts

If your printed part has a wide base that will be making a lot of contact with the build plate, it could be unwise to add more adhesion. It could become difficult to remove the part even without added adhesion.

Small-Based Parts

On the other hand, printed pieces that have small legs or slim bases will not attach as firmly to the tape. These pieces may need additional adhesion to keep it in place.

These pieces may need additional adhesion to keep it in place.

The best way to remove a 3D printed part from a taped bed is simply to wrench it loose with your hand. Do this carefully though, because applying too much force could snap your part.

You want to use this method if you can because it will preserve the quality of your tape, letting you use it again for future prints. However, if the adhesive of the tape is too strong, use these tricks to remove your printed parts safely.

Pry with a Putty Knife

After trying to wiggle the printed part free with your hand, the next course of action should be to use a putty knife to pry the piece off of the plate. If you can, slide the knife under a corner and work around the part, gently prying the piece free.

Remove the Tape

If that does not work, then the next step will be to remove the tape from the build plate. You can use your knife to make tears in the tape so you can remove it all.

Spray Isopropyl Alcohol

It is possible that the tape will tear up everywhere except for underneath the part. In this instance, you will want to spray or rub a solution made up of alcohol and water around the base of the piece. Wait a few seconds and the printed part and the tape underneath should remove easily.

Adjust the Height of the Nozzle

If your printed pieces are so hard to remove that you need to resort to removing the tape and spraying alcohol after every print, you may just need to adjust the height of the nozzle. The filament might be taking too long to cool between leaving the nozzle and contacting the plate, so it is seeping too deeply into the pores of the tape.

Start by raising the distance between the nozzle and the build plate by .1mm for your next print. Then continue raising it by this increment until you find that your parts are easy to remove but still have enough adhesion to the bed to get the job done.

When to Remove Blue Tape from a 3D Printer Bed

If you treat your blue tape carefully, you can get several weeks of use (up to 20 prints) out of a single taping. The more care you take with placing and maintaining your tape, the longer it will work for you.

The more care you take with placing and maintaining your tape, the longer it will work for you.

If you need to apply alcohol, tear up the tape, or the filament stops sticking to it, you will have to apply a fresh layer of tape to the build plate.

How to Remove Blue Tape from a 3D Printer Bed

Once you decide that it is the proper time to remove the tape, the process is as simple as unsticking it from the plate. If you have trouble getting it off in spots where parts were built, spray some alcohol and wait ten seconds. It should come off cleanly after that.

Once you have removed all of the tape, you should clean the build plate with alcohol so that there is no adhesive residue left behind. Once you have a clean build plate, you are ready to retape it to begin your next print!

Common QuestionsDoes blue painter's tape work on heated beds?

Because blue painter’s tape is heat resistant, it is able to withstand the heat generated by a heated 3D printing bed. Quality painters tape will not come loose from the bed or become misshapen from the heat.

Quality painters tape will not come loose from the bed or become misshapen from the heat.

PLA and PETG are the best filaments for sticking to blue tape. They seep into the tape, allowing for grip to take place with no extra adhesives applied. ABS will stick to blue tape if you add some sort of extra adhesive.

Can masking tape be used for 3D printing?While masking tape can be used for 3D printing, it is not nearly as effective. Even though a roll of masking tape is similarly priced to blue tape, the rolls are typically slimmer so it takes more tape to cover the build plate.

Additionally, masking tape does not remove cleanly like painters tape does, meaning you will have to work a lot harder to clean your build plate once you are done with a layer of masking tape.

Is investing in blue tape to improve bed adhesion worth it?YES! Blue painter’s tape is an extremely cheap way to get bed adhesion for your 3D prints. With other products, you need to worry about potentially damaging your bed adhesives, but a build plate can be covered with blue tape for less than a dollar.

With other products, you need to worry about potentially damaging your bed adhesives, but a build plate can be covered with blue tape for less than a dollar.

Blue tape is cheap, resilient, and simple to use. If you need a simple solution to your bed adhesion problems, blue tape could be the answer you are looking for.

Shop Blue Painter's Tape

Can You 3D Print Without a Heated Bed? Tips & Tricks

Why pay more for your 3D printer to have a heated bed when you could save some money and get by not having one? If heated beds were really necessary, wouldn’t all 3D printers have one?

The truth is, if you plan to save money by buying a budget 3D printer, ruling out heated beds could be a good tactic. Though, you may be making your experience less pleasant.

It turns out that while you could 3D print without one, 3D printer heated beds are actually important to ensuring your 3D print goes smoothly. Without one, you’ll face a few issues that are mentioned below.

Why Do 3D Printers Have A Heated Bed?

3D printers have a heated bed for a few reasons:

- Models adhere to the build platform.

- Reduces warping of the bottom layers by keeping the filament warm.

- 3D print a variety of materials.

- Easily remove the project after printing.

Many 3D printers now come with a heated bed. They help with the 3D printing process so much that some people won’t 3D print without one.

I’m on the threshold of falling into that category myself.

How Does the Heated Bed Improve 3D Prints?

Heated beds prevent the base of models from cooling and losing its ‘stickiness’, making the model stationary on a single spot throughout the 3D print.

Some thermoplastics require good adhesion, so the heated bed will allow you to print many more materials. Whereas a cold plate usually limits you to PLA.

By keeping the base of the 3D print hot, the model becomes less prone to warping. If the model was allowed to warp, it could also negatively affect the rest of the model.

If the model was allowed to warp, it could also negatively affect the rest of the model.

The Problem of 3D Printing Without A Heated Bed

My first test print with a 3D printer without a heated bed, the Anycubic Mega Zero, did not come out how I expected it to at all.

The SD card came with a model of an owl for testing purposes. Within 5 minutes, the base of the model snapped off on the platform and was stuck to the extruder. Not a great first experience…

On the second try, the model stuck but after the model was complete, I noticed that the bottom base of the model had warped over the course of the print.

A close look reveals the base of the model is curved and the corners are lifted.I didn’t lose hope. I went online for solutions and found one that has been working for me. We’ll get to those tips later.

Cons of Heated Plates

Seeing all of the benefits, it seems like a no brainer to include the heated bed for all of your 3D prints. However, there are some negatives to consider.

The constant heating of the base of the model can cause expansion on the bottom layers. This can deform and reduce the accuracy of the model.

Furthermore, you’ll spend more time waiting for not only the extruder to heat up but the heated bed as well. It’s also another parameter that needs adjusting and testing to find the right settings.

3D Printing Without a Heated Bed

Can you 3D print without a heated bed?

Yes, it’s possible, but you won’t experience any of the benefits of having the heated plates. Moreover, you will mostly be limited to using PLA filament.

3D printing without a heated bed works fine but you may experience some problems, such as the 3D printed model not sticking to the print platform.

Don’t worry, here a few easy common fixes you can use.

Use Tape for Part Adhesion

Since the bottom of a model can’t be made to stick to the platform through heating, we can compensate by using a material that’s easy for the hot filament to stick to. This is the method I’ve opted for since it’s the (somewhat) least messy way to 3D print without a heated bed.

This is the method I’ve opted for since it’s the (somewhat) least messy way to 3D print without a heated bed.

I have been using masking tape but it leaves a lot of residue on the plate, and it tears easily. If you can, use blue painter’s tape the get the job done neatly.

Anycubic Mega Zero using masking tape on the build plate.Kapton tape is supposed to be one of the best tapes to use as plastic sticks to it easily, and the cooled product can be pulled off easily without damaging the part or plate. However, it needs to be applied very carefully to avoid air bubbles.

Glue Stick or Hair Spray Treatment

Yes, very professional. Sarcasm aside, a quick search on online 3D Printing Communities shows that using a thin layer of glue stick or hairspray on your cold build plate is a common fix and can do wonders.

Keep The Build Plate Warm

If you live in a cold climate, you could experience even more problems without a heated bed. If possible, keep your 3D printer in the warmest room of your house.

To keep the 3D Printer build platform warm, consider buying a 3D printer with an enclosure, or construct one yourself. The enclosure will trap the heat, helping to maintain the build plate’s temperature.

Here’s a cool 3D printer enclosure plan from Instructables.

Design for Easy Model Removal from Tape

I’ve found that my 3D printed models easily stick to masking tape. I haven’t tested out blue painter’s tape yet, but if you have experience with it let me know in the comments.

To easily remove 3D models from masking tape without having the tape rip, forcing me to replace and waste tape, I design my parts differently.

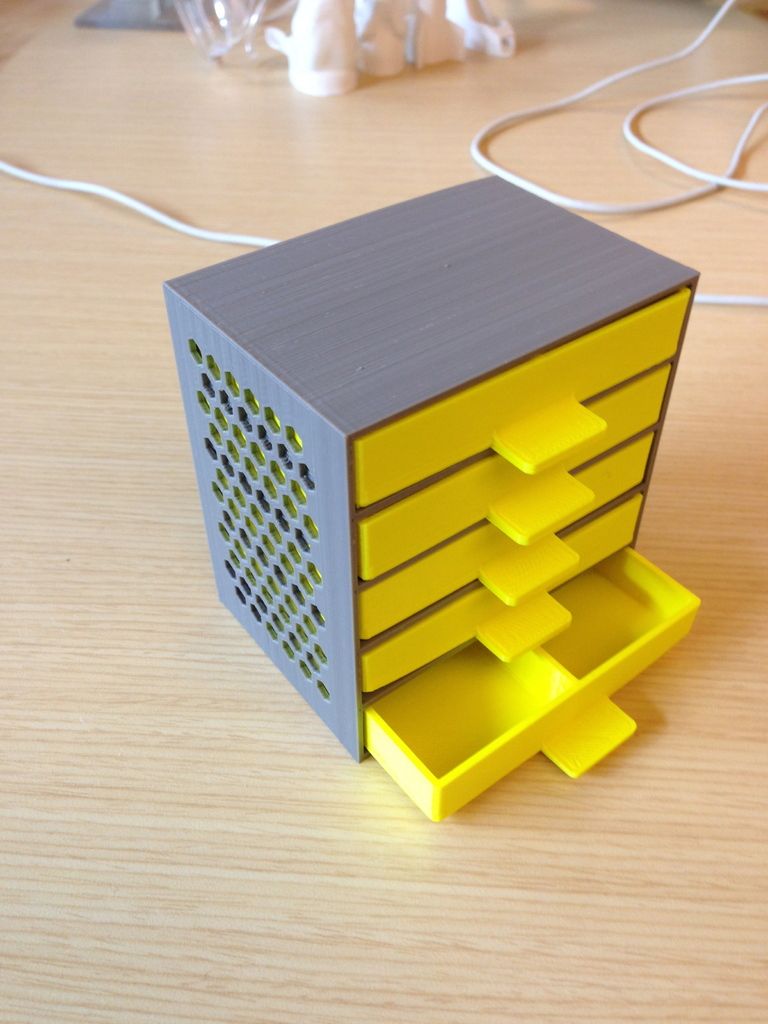

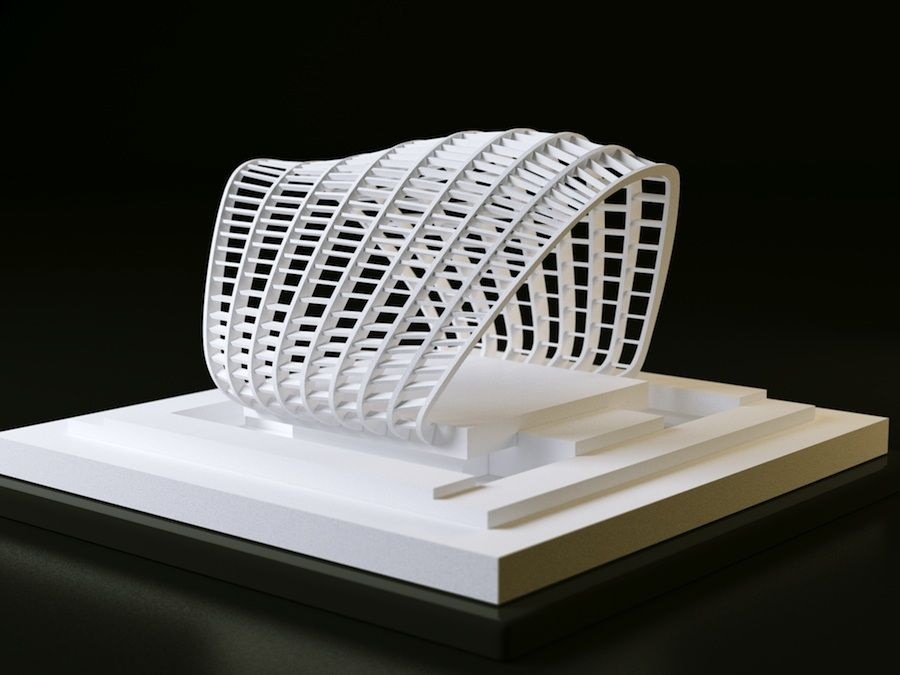

By making the base narrow (seen in the image below) I reduce the surface area making contact with the tape. This makes the bond between the part and the tape much weaker.

Using a minimal base-plate surface area contact area for easy removal without a heated bed.The only problem I’ve encountered with doing this is that the bottom of the part is prone to warping.

Conclusion

While you can 3D print without a heated bed, I would recommend using a 3D printer that has one, as you will have the option to use it.

If you’re a beginner, then you will most likely start with 3D printing PLA; in which case, 3D printing without a heated bed should be fine for now. As long as you follow the tips, you should be fine.

Many budget 3D printers have a heated bed, so there’s no reason to start without one!

From classics to mysticism. My print surface test.

Subjects:

1. Blue Male Scotch

2. Capton tape

3. film Lomond Self -adgeSive Inkjet Film 1708411

4. Sitall glass

5. Catalyst - beer - beer 'Velkopopovicky Kozel'

Blue masking tape

Great for printing small PLA parts without heating the bed. With an increase in the area of \u200b\u200bthe part, the edges rise along with the adhesive tape.

Kapton tape

I glue fresh tape, smear 'Light Goat' beer on a table warmed up to 110 degrees.

The bottom surface of the part (ABS) is smooth, except for the corners, which were unpleasantly raised. It does not adhere very well to fresh beer and the beer itself remains a brown film on the bottom surface of the part. Beer is easily washed off with water. The part separates well from the table after cooling, but it cannot be left overnight. The plastic begins to pull the tape and air bubbles form under the tape.

Such a surface after a few days of printing

Left the part overnight and the kapton wrinkled.

The bottom surface is glossy, but bubble holes remain

Lomond film

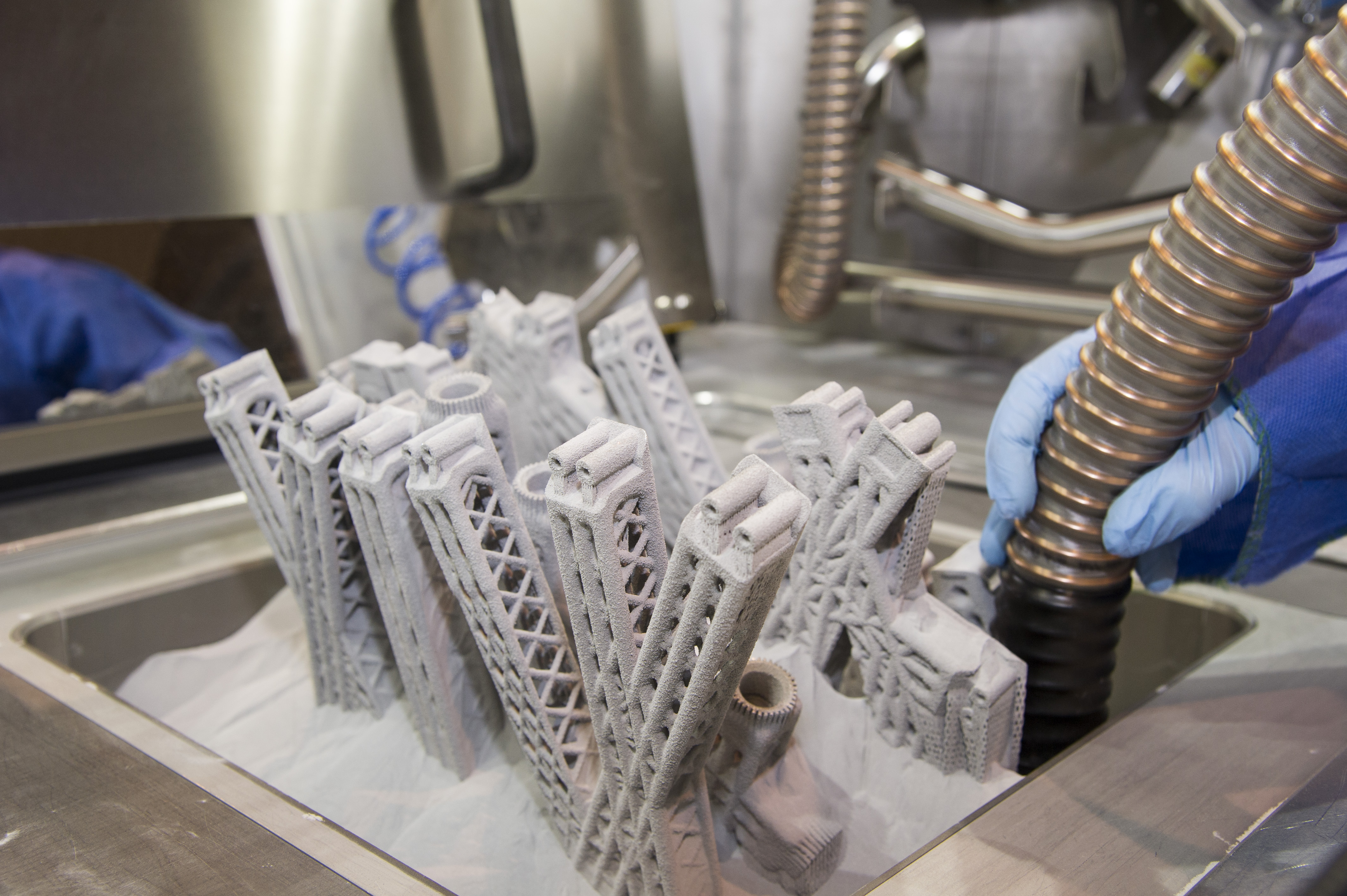

I looked at this film for a long time, but the moment came when it was time to replace the Kapton and I decided to experiment. I cut the film into two equal sheets and glued one onto the washed surface of borosilicate glass.

I cut the film into two equal sheets and glued one onto the washed surface of borosilicate glass.

I completely forgot that the top layer of the film must be thoroughly washed off with water. At first, the ABS filament did not want to stick to the surface. After several calibrations of the nozzle relative to the table, the print still went. But the result did not satisfy me at all - the corners of the part were raised.

After the first print, there are air gaps under the film along the contour of the part.

I rubbed the surface of the film with my finger and remembered that the top layer needed to be washed off, which I did.

Sweat this bottom surface is obtained from ABS parts at Lomond. Minus one - it is very difficult to tear off the detail from the film.

After a few days of printing, air bubbles begin to increase and appear on the underside of the part. But this film is much denser and stronger than Kapton tape, so you can print much more before the appearance of obscene-sized bubbles.

But this film is much denser and stronger than Kapton tape, so you can print much more before the appearance of obscene-sized bubbles.

Bubbles under the film.

Sitall glass

Let's move on to the mystical-cosmic material. So far, unexplored material that few people held in their hands.

Sitalls are crystalline materials obtained by introducing catalysts into molten glass, as a result of which crystallization centers appear in the volume of the material, on which crystals of the main phase grow. The term "sitalls" was proposed by the professor of Moscow Chemical Technology Institute. DI. Mendeleeva I.I. Kitaygorodsky and comes from the words "glass" and "crystal" . For the first time glass-ceramics were made in the 50s. 20th century Materials similar to sitalls are called pyroceram, devitroceram, glassceram abroad. Glass-ceramics have high strength, hardness, wear resistance, low thermal expansion , chemical and thermal resistance, gas and moisture impermeability.

Packaging

Wipe thoroughly with 646 Thinner. Reconfigured the dimension along the Z axis. Started printing the gear from the Prusa i3 Rework kit. ABS 265 degrees, table 116 degrees.

The result disappointed me. At 76 degrees on the table, the part is removed by hand, as if it had just been placed on glass.

Added 2 degrees to the table.

Brim cannot be printed. At a table temperature of 85 degrees, the part can be removed from the glass.

Now I wonder how Brim works. I'm printing an extruder part from the Prusa i3 Rework kit. If Brim will hold parts with a large bottom area, then this will be ideal, but so far I have not noticed any advantages in adhesion.

Table 118 degrees.

Looks like Kapton without beer so far.

Table 122 degrees. Model cal.stl from the Mendel90 project. I lowered the nozzle along Z by 0. 1 mm.

1 mm.

Additional bubbles have appeared on the bottom surface of the part.

Tried to remove underprinted part from hot bed (119 degrees). Came off very easily.

I wiped the glass with alcohol - no effect.

Since the effect is like that of Kapton without beer, I decided to smear it with beer. The temperature of the table is 118 degrees.

This result is already acceptable. It shoots great.

A little tack on a large part, just like beer should be.

My findings

Blue tape. Great for small PLA parts. Does not require table heating.

Kapton tape. Good for medium sized ABS and PLA parts. It is obligatory to heat the table and apply a layer of beer. Brim is required. If you print infrequently, then enough for a long time.

Lomond film 1708411. PLA did not print with plastic. Well suited for large-sized ABS plastic parts, until the moment comes to remove the part, it is very difficult to tear off (you can hit the part sideways). Brim (Brim) is not needed - gears without Brim are great. Dyuzhit longer kapton. Recommended for perfectionists.

Well suited for large-sized ABS plastic parts, until the moment comes to remove the part, it is very difficult to tear off (you can hit the part sideways). Brim (Brim) is not needed - gears without Brim are great. Dyuzhit longer kapton. Recommended for perfectionists.

Sitall glass. Printed with ABS only. Brim is required. The bottom part is glossy. On clean glass, the edges bend like on Kapton without beer. Be sure to smear with beer and get the 'eternal' kapton. The part can be easily removed already at 80 degrees on the table. Ideal for those who want to automate the process of removing a part from the table using a manipulator or improvised men :)

Again about fixing the part on the table

3D printing

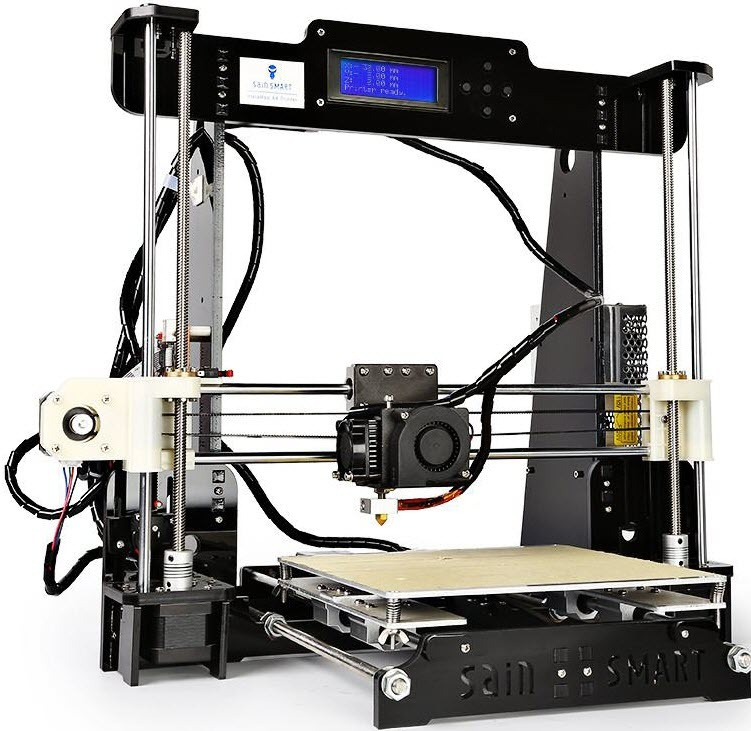

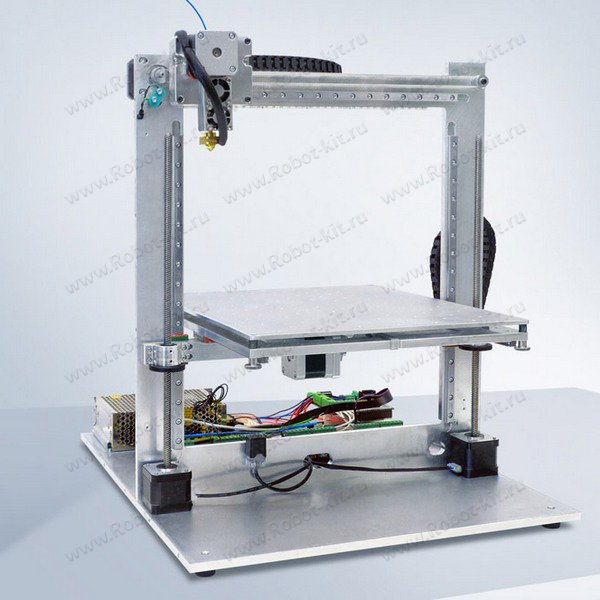

PrintBox3D One Prusa i3 Hephestos

A lot has already been written about different options - borosilicate glass, blue tape, stationery glue, hairspray, etc., but no one has written about double-sided tape, the most ordinary double-sided tape

price 200-250r for 50m.

I have a Geeetech i3 B RepRap printer with heated bed and borosilicate glass at work PrintBox 3D One. In the instructions for the printbox, they wrote: smear the glass with clerical glue, it’s suitable for PLA, but not very good for ABS or HIPS, the edges are bent and the figure is strongly led.

Long experiments to identify the best table cover option showed that the most effective option, the most ordinary double-sided tape, is not necessary when printing PLA, where table heating is not required, but when printing ABS or HIPS - nowhere without it, and even temperature the table does not have to be kept in the region of 100-110 degrees, 80-90 is enough, the adhesive tape does not lose its properties at this temperature, the plastic holds tightly to the table and the edges do not bend. And most importantly - easy removal of the part - just before removing, we warm up the table to 90-95 degrees and the part can be freely removed!

If you need to remove the adhesive tape (checked on the glass), on the contrary, cool the table to room temperature and remove - there are practically no marks on the table

Subscribe to the author

Subscribe

Don't want

6

Article comments

More interesting articles

DrProg

Loading

11/08/2022

1518

9

Subscribe to the author

Subscribe

Don't want

We continue to reveal the incredible opportunities of enterprises from the Middle Kingdom, up to.