3D printing wellington

3D printing digital fabrication | Wellington Faculty of Architecture and Design Innovation

3D printing digital fabrication | Wellington Faculty of Architecture and Design Innovation | Victoria University of WellingtonFind out about the range of 3D Printing fabrication equipment at the Wellington Faculty of Architecture and Design Innovation.

The Faculty have a range of 3D printing equipment for physical model production and exploration of 3D print processes, which support teaching and research.

Our technical staff provide inductions to all students wishing to use the 3D printing equipment. However, some Industrial Design program courses have significant 3D printing-specific content and tutorials.

Most equipment is able to be used by students as self-help, however some equipment due to the cost and complexity of operation such as the Stratasys J750, are provided as a print bureau.

Stratasys J750 colour voxel printer

View gallery

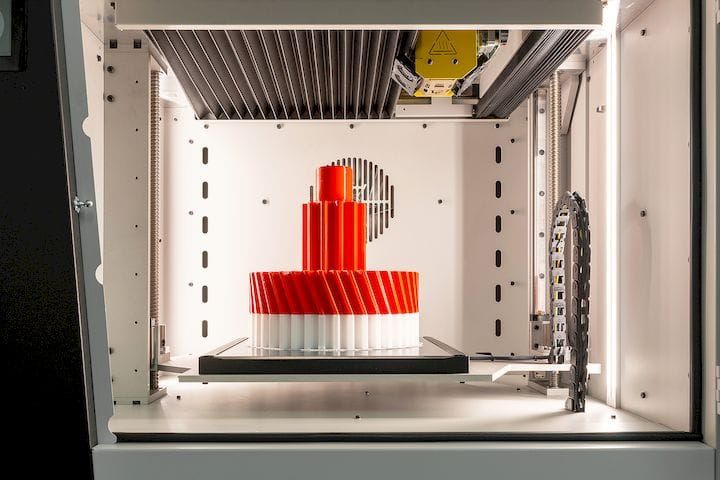

The Stratasys J750 is a full colour multi-material poly-jet 3D printer able to print flexible and rigid models in full colour. Enabling rapid production and iteration of fully finished working prototypes right here in our workshop. CAD files can be imported as .STL files into GrabCAD for colour and flexibility assignment then built directly by the J750.

Our J750 is also capable of VOXEL printing.

We are part of a group of universities on an invitation-only research agreement which positions Te Herenga Waka—Victoria University of Wellington in an exclusive community of seven universities globally, including Harvard and MIT, who have access to Stratasys advance materials and software beta-versions for trial and development. The invitation acknowledged the School of Design Innovation’s MADE research group as one of the world’s top research groups achieving excellence in 3D printing research and teaching.

BigRep one FDM 3D printer

View gallery

The BigRep printer is a form of FDM (Fused Deposition Modelling) dual filament feed 3D printer. The BigRep can also handle larger 3mm filament. It has a build volume of approximately one cubic metre, making it one of the largest capacity off-the-shelf FDM printer models in the world.

It has a build volume of approximately one cubic metre, making it one of the largest capacity off-the-shelf FDM printer models in the world.

The printer is operated by a specialist technician but postgraduate students can use it for approved thesis research. The printer uses software such as Simplfy-3D and an open source derivative of Cura—Blade 3D slicer.

UP Box desktop 3D printers

View gallery

The faculty has a large suite of approximately fifty UP Box Fused Deposition Modelling (FDM) 3D printers. They are located in the workshops and Industrial Design studios around the campus.

FDM machines are a common ‘sketch modeller’ used in educational setting due to low operating costs per build, ease of use and support, and ability for students to operate them directly with good results with only moderate levels of training.

Students wishing to use 3D printers for their course work can book into 3D printer workshop training sessions. Students taking courses requiring the use of 3D printers will receive in-depth tuition as part of their design course work.

Thermo Scientific Process 11 Parallel Twin-Screw Extruder

View gallery

The Process 11 Parallel Twin-Screw Extruder is used to produce polymer compounds and 3D printing filaments by blending thermoplastics and additives. The filament compositions are then used in the FDM 3D printers, enabling investigation and experimentation of the materials in our workshops, and with industry partners in joint research projects.

Upcycled and novel materials produced are used on the UP Box, Ultimaker and BigRep 3D printers to test filament compositions and produce useable prototypes. The extruder is used by specialist staff and postgraduate students for their thesis research.

ConAir NCF-810 Plastic Granulator

The ConAir Granulator NCF-810 is designed to grind up recycled plastics into a fine flake for use in the Thermo-Scientific process-11 extruder. Currently it has a 5mm grind filter installed. Ground plastics are caught in a hopper or vacuum extracted out of the hopper into a vacuum device/vacuum cleaner.

The granulator is fundamental to enabling in-house recycling of printed product, and experimentation of recycling processes and material compositions for FDM 3D printers.

Technical assistance

If you need help with our technical facilities, get in touch with our technical staff.

Victoria University of Wellington - Stratasys

January 26, 2022

Stratasys 3D printing makes the traditionally impossible, possible.

Limitless possibilities

In New Zealand, the word “tutü” means to fidget or fiddle with something allowing you to learn with your hands. For Victoria University of Wellington (VUW), 3D printing is an outstanding educational tool for tutü, helping students across many disciplines understand complex theories and prepare for the workforce.

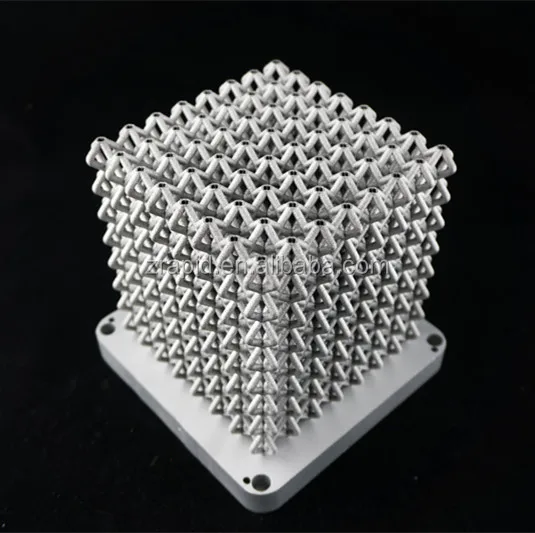

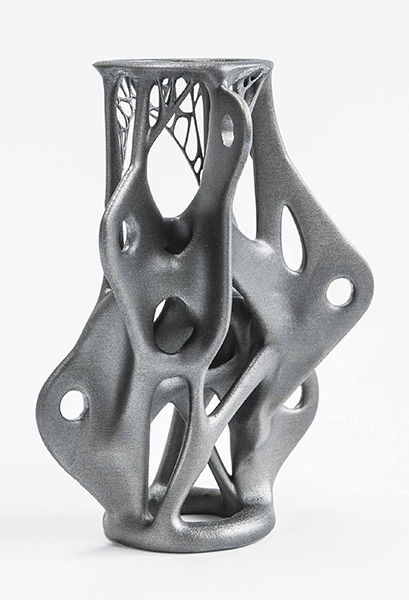

“The industrial design profession has historically used 3D printing technology to make prototypes of products that will be mass-produced using traditional mechanical engineering methods,” said Ross Stevens, program director of the university’s Industrial Design department. “As my experience with 3D printing processes grew, I became more interested in the printers’ ability to make the traditionally un-makeable. This shift led to intricate and diverse objects more derived from bioengineering than mechanical engineering.”

“As my experience with 3D printing processes grew, I became more interested in the printers’ ability to make the traditionally un-makeable. This shift led to intricate and diverse objects more derived from bioengineering than mechanical engineering.”

Building a future.

For Stevens, who has been using Stratasys 3D printers since 2004, applied learning is downright transformational. 3D printing is a particularly important gain in a world where colleges want to attract and retain students in the STEM subjects of science, technology, engineering and math. 3D printing not only supports tutü, it reduces the time associated with production so Stevens can help more students and departments.

Stevens’ FUN (Future Under Negotiation) program helps students in nonengineering disciplines prepare for the future with applied learning. Stevens uses 3D printing to help the classes build fictional scenarios using coding, rendering and multi-property 3D printing. “We can achieve a lot with today’s materials, but with emerging materials, we’ll be able to do much more very soon,” said Stevens. The university prefers PolyJetTM 3D printing technology from Stratasys because it offers the multi-color, multi-property printing the school needs.

“We can achieve a lot with today’s materials, but with emerging materials, we’ll be able to do much more very soon,” said Stevens. The university prefers PolyJetTM 3D printing technology from Stratasys because it offers the multi-color, multi-property printing the school needs.

VUW turned to 3D printing not long after the nation retracted its trade barriers and most of its production industries moved offshore. “We lost most of our mass production jobs, and as a result, our university started exploring emerging technology that would lead to new job creation,” Stevens said.

As my experience with 3D printing processes grew, I became more interest in the printers' ability to make the traditionally un-makeable. This shift led to intricate and diverse objects more derived from bio engineering than mechanical engineering.

Ross Stevens, Victoria University of Wellington

Students create complex details.

Students at VUW have 3D printed a custom facial prosthesis that costs just $100 to produce (versus $1,000 for a traditional product,) shoes that use accurate 3D scanning to make a personalized pair with enhanced biomechanical performance. Students also created hi-fi speaker drivers that incorporate structurally intricate details printed in both hard and soft materials during a single printing process.

Students also created hi-fi speaker drivers that incorporate structurally intricate details printed in both hard and soft materials during a single printing process.

For classics professor Diana Burton, having a 2500-year-old Roman kylix bowl scanned and 3D printed was a dream come true. She can now reenact Roman drinking games with her students. Stevens’ colleague Bernard Guy applied industrial design craft to both the scans and the 3D prints to create realistic qualities of weight and feel for the student festival. “The original chalice was in a glass cabinet because it was so special,” says Stevens. “To some extent, the applications that aren’t always obvious are among the most interesting.”

Filming the 3D printed aquatic sea creature. The students attached the creatures to string to simulate underwater behavior.The university also works closely with Weta Workshop, a New Zealand firm that develops special effects and props for movies like “Lord of the Rings” and “Avatar. ” As a research project, students recently designed 3D printed aquatic creatures for use as dynamic and interactive

” As a research project, students recently designed 3D printed aquatic creatures for use as dynamic and interactive

film props. The project titled Lissom presented a more physical and realistic alternative to using computer-generated imagery in film. The 3D printed sea creatures were filmed inside a tank of water and closely mimicked the different animal behaviors.

To other schools considering 3D printing, Stevens believes the best is yet to come. “Goodness knows what Stratasys will come up with over the next few years. Is it reactive materials, bio-printing or perhaps adding an electrical current that will make the printed objects move?” Stevens said. “The possibilities are virtually limitless.”

Students look at their 3d printed work.Custom 3D Printing near you

9 3D Printing Services ready to take your order now and ship parts to Paraparaumu, Wellington, New Zealand. Through our platform, you can order 3D printing of prototypes, spare parts and any projects according to your own design without restrictions in size and quantity. If you know exactly which technology, material or application is right for your project, use the filters to narrow your search results. For clarity, study the portfolio of services with examples of printed products, as well as the rating. This will help evaluate the experience of the company with products of various types.

If you know exactly which technology, material or application is right for your project, use the filters to narrow your search results. For clarity, study the portfolio of services with examples of printed products, as well as the rating. This will help evaluate the experience of the company with products of various types.

Download files to compare prices of local 3D printing services

Download filesor contact us for a discount on large orders.

If you are looking for a 3D printing service with delivery to Paraparaumu, Wellington, New Zealand, then you have come to the right place. All companies that provide prototyping and printing services near you are listed above.

How much does it cost to 3D print my products?

To find out the cost of services, select a company and use the "Quick Order" button. Based on your 3D model in STL, PLY, OBJ or 3MF format, we will automatically determine the cost of 3D printing. If you are not sure which service to choose, use the order button at the top of the page to compare prices from all eligible print services.

How can I order a print without a 3D file?

3D printing starts with a model, so a 3D file is needed to make the part. Most printing and additive manufacturing companies can help you with a simple 3D design. For more complex modeling tasks, we recommend hiring a professional.

How to choose a 3D printing service?

Treatstock strives to provide a transparent workflow between the 3D printing company and the client for the best result. In order for you to have complete information about the future performer, we show the company's printers and customer ratings. On the public page of each service, you will also find a complete list of their services.

How does it work?

- Download 3D file for instant order;

- Specify order details and delivery address;

- Confirm order;

- Track the progress of your order in the Purchases section;

- Get your finished product.

Our support team is always ready to help. To learn more about the different types of 3D printing, check out our Technology Guide, as well as our Materials Guide for information on them.

To learn more about the different types of 3D printing, check out our Technology Guide, as well as our Materials Guide for information on them.

Technology

- Model of layer -by -layer laser

- Cherench Separation 9002 9002 9002 9002 9002 9002 9002 9002 9002 9002 9002 9002 9002 9002 9002 9002 9002 9002 9002 9002 9002 9002 9002 9002 9002 9002 9002 9002

- SLS)

- PolyJet and PolyJetMatrix

- Laser stereolithography (SLA)

- Full color inkjet (CJP)

- Digital light processing (DLP)

- UV Direct Printing (DUP)

Vickers Wellington STL File・3D Print Design Download 3D・Cults

SR-71 Blackbird

1,80 €

Boeing KC-135

2.50 €

EC145

2. 50 €

50 €

YF-23 Stealth Fighter

2,50 €

M4A1 Abrams

3 €

Panavia Tornado

2,50 €

B-29

3 €

Boeing 367-80

2 €

Best 3D Printer Files in Home Category

LOOP STOOL CURVY

10 €

Compton Beer Mat / Drinks Coaster

Free

Plywood Box Joint (3mm thick)

Free

Halloween set

10 €

Cylinder textured box

Free

Batman logo Wall Clock Ikea STOMMA

Free

shopkins cupcake cookie cutter

0,50 €

Pencil sharpener

Free

Bestsellers in the Home category

Wall shelf "Oyster mushroom"

2,40 €

Clothes hanger

1,80 €

Key hanger with pokemon balls (Pikachu, Gengar)

2. 03 €

03 €

BOWL FOR YOUR FURRY FRIEND

1,30 €

1/14 Excavator - Vulpa 505

65.09 €

Clothes hanger "Wolf"

2,20 €

Ladle for boiler

3.68 €

Bag stopper

1 €

Egg cracker

1.03 €

Pencil with dinosaur gluttony

1.92 €

Bordeaux, Octopus

2.45 €

Cat in pencil holder

1.05 €

Crystal corner decor - print in place

1.62 €

Candlestick - Arbre de vie

1,20 €

Gengar Pokemon Planter Vase Pencil Holder

2.