3D printing service in new york city

3D Printing Service New York | Instant Quotes Online

Our 3D printing capabilities

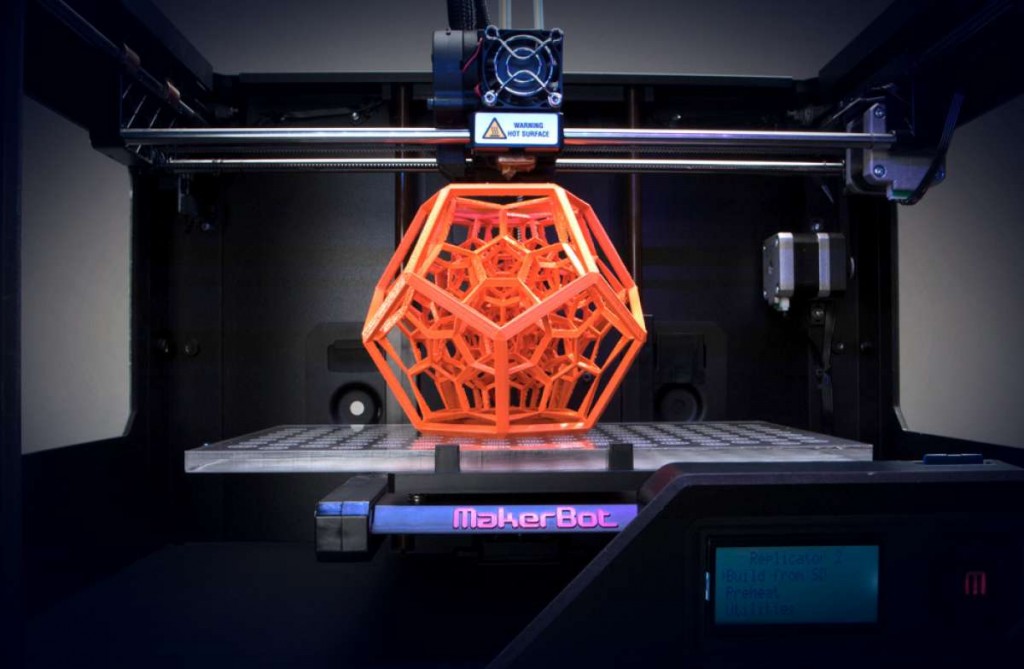

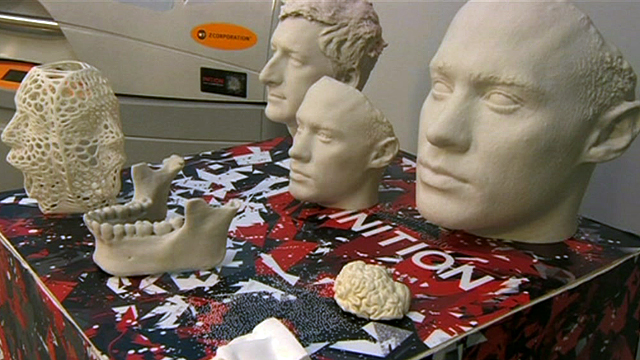

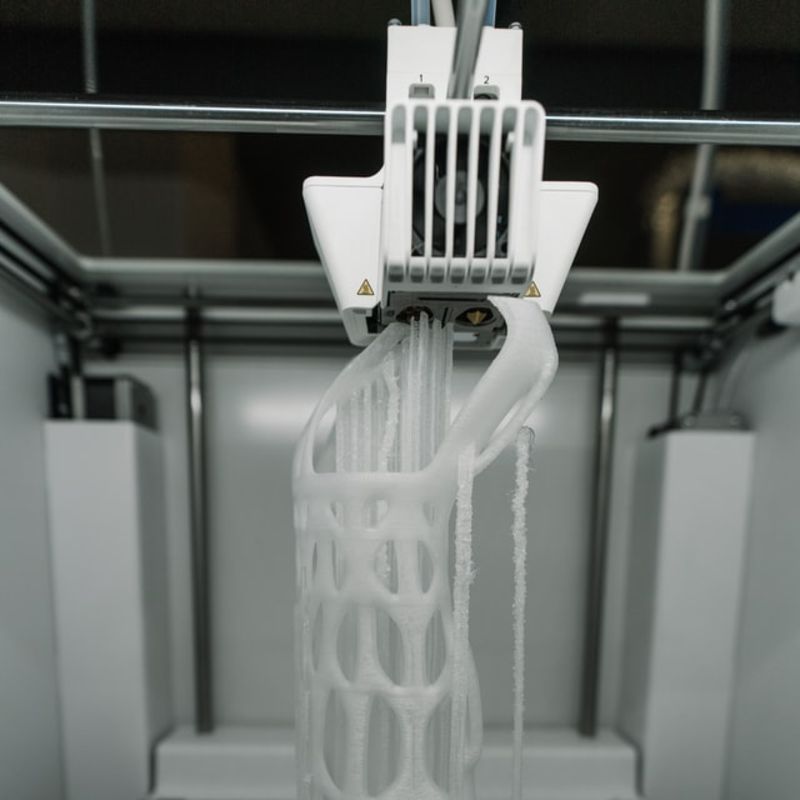

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

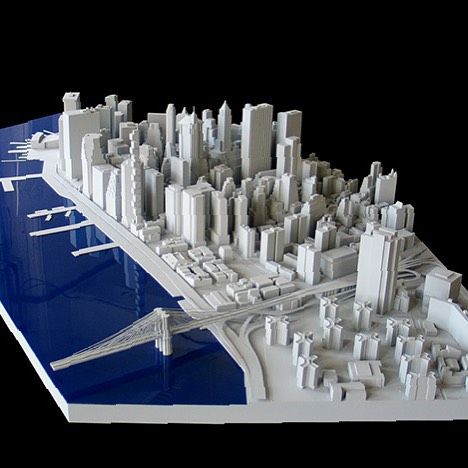

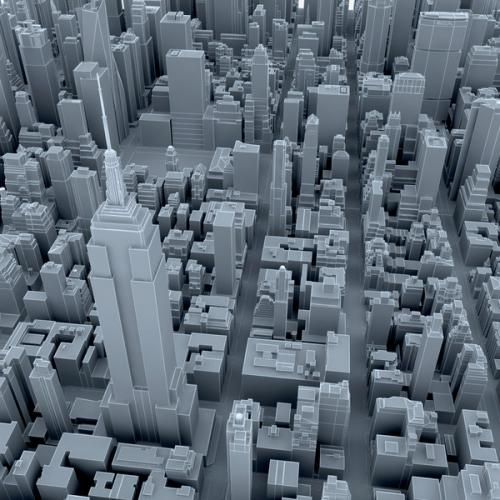

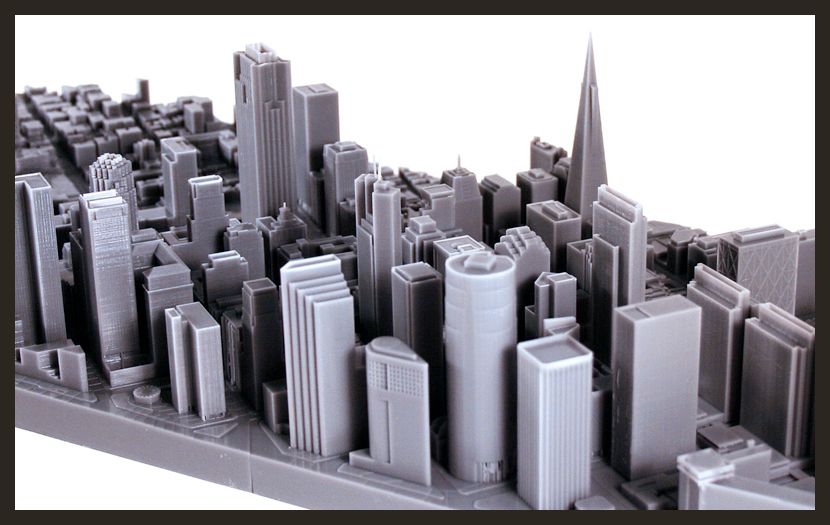

Gallery of 3D printed parts manufactured by Hubs

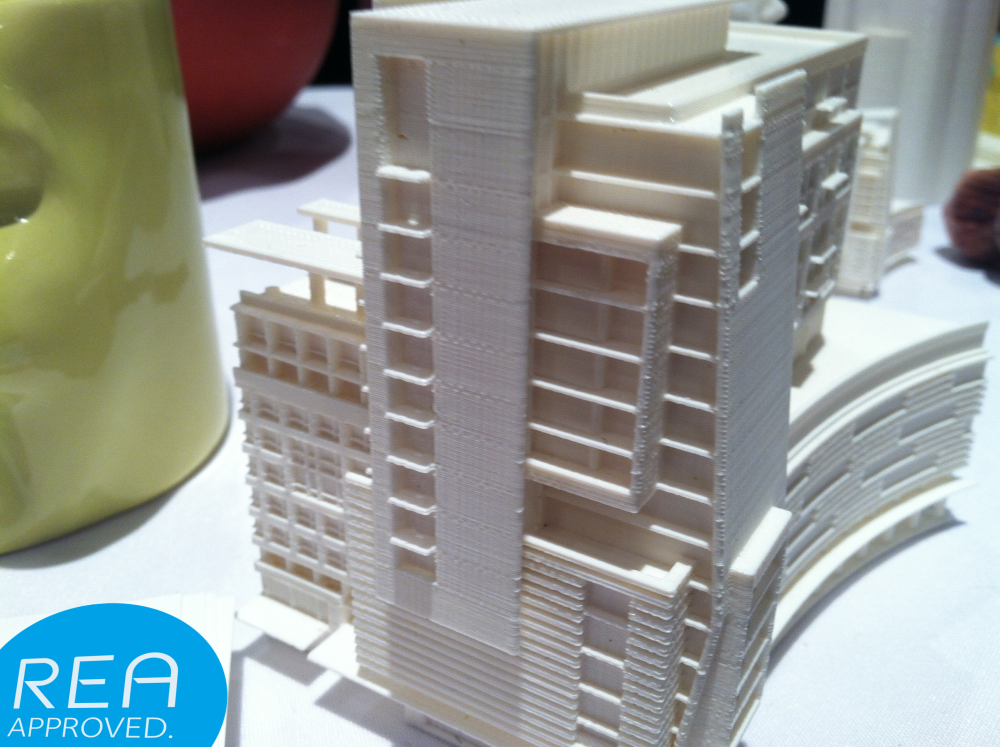

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

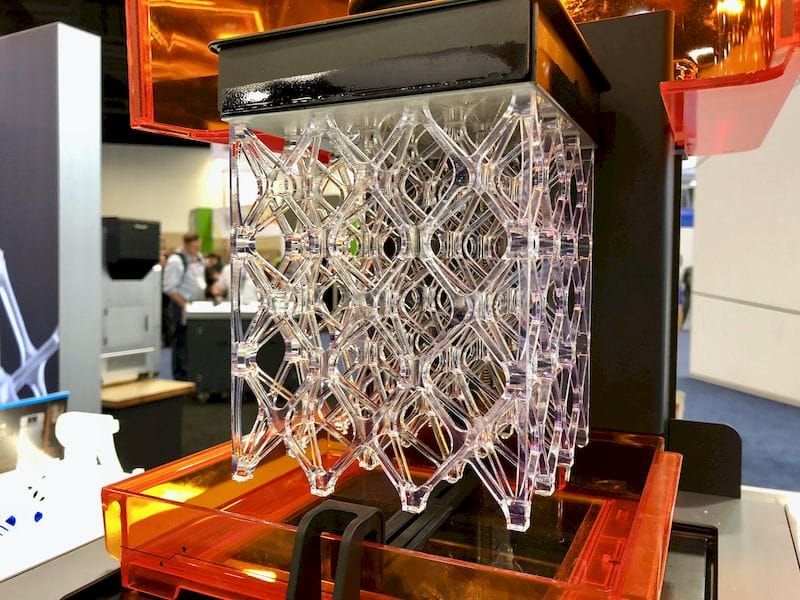

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc.

.

. -

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.9/5

Over 288 customers are satisfied with our 3D printing service.

“Great prints, great communication. Will use this seller again.”

“looks like the photos, was a tough print and will serve its purpose well”

“Just as expected. Fast delivery. No issues.”

“Awesome service and great products. Couldnt ask for more.”

“Great job and shipped quickly. Item was received before quoted delivery date. ”

“Service was quick, friendly and well done. will use in the future. ”

“Quick and courteous,with high qualify results, I would definitely work with them again”

“Very prompt communication, excellent print finish, met all my expectations.”

“The best 3D printing service in the world !”

“Always PERFECT Prints. I measure with calipers. Oh, and fast shipping. What more could you want? Best printer around!”

“Print as expected. Communication and flexibility was excellent.”

“Well packaged, on time, and got frequent updates.”

“Outstanding quality and quick delivery, would order again any time. ”

”

“Great service. Communications and speed were exceptional.”

“Arrived quickly with updates throughout the process, exactly as requested.”

“My order was printed and shipped quickly. Excellent service and communication.”

“I ordered a print at the cheapest level and the quality is much better than I anticipated. These guys examined my drawings in no time, got the print started, snapped images post-print, and got it out the door in the same day. A+ service.”

“Great part, works and fits exactly as i needed”

“Excellent service. Great person. Very helpful. Quality work!!!”

“Perfect. Prints were started the day of upload and delivered before the deadline. Quality is near perfect! ”

“Great communication and custom part fit perfectly. Thanks! ”

“Always a wonderful experience and perfect print. Thank you!”

“Fast turnaround, quality print, good price.”

“Very quick and professional. Will buy from again. ”

“Great communication and printed parts looked great. Highly recommend!”

Highly recommend!”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near New York

Middletown, NY Scranton, PA Binghamton, NY

Kingston, NY East Stroudsburg, PA Union, NY

Utica, NY Poughkeepsie, NY Ramapo, NY

Parsippany

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

3D Printing | Large-Scale | The Factory NYC

3D-Printing

LARGE-SCALE 3D-PRINTING SERVICES

Massive 3D PrintsWe offer large-scale 3d printing for artists, engineers, and designers. Start your Project |

Oversized 3D-printed headphones with built-in audio made for City Eventions |

Start thinking in 3DRapid large-scale 3D Printing opens up a world of possibilities. The Factory NYC can take any object, scan it or model it, and bring it to massive scales. Our 3D Printer using a proprietary UV-cured acrylic polymer which allows a whole new scale and speed of rapid prototyping:

|

The future of storytelling is sculptural(and it's here)

Click to set custom HTML |

Big Print EnergyThe Factory NYC is the only event fabricator in NYC with a large-format 3D-printer — and its up to a 100x times faster than typical 3D Printing; and there is no size limit. We can print and assemble hundreds of parts to build forms at colossal scales. |

Requirements

| Adding sculpture to your next event is easy. You don't need 3D modelers on your team — we have you covered. The only requirement is bring your vision with a budget.

Even if you just have a 2D logo or design on pen and paper. We can create a digital model from scratch, and/or use 3D models from open source libraries. There are many ways to get started. |

Huge 3D-Printing — Get Inspired and Imagine

Delivering amazing projects, daily. | Our team of installers works throughout the New York City greater area. Local, domestic, and international delivery available through air, land, and sea. |

Join our Email list:

Sign up, and we'll share the latest event fabrication technologies:

90,000 Qin Dynasty 3D Printing, MakerBot's New Adventures, and More News of the Week! News

Subscribe to the author

Subscribe

I do not want

7

Makerbot to the production of 3D printers

Until recently, in 2013, the legendary company Makerbot bathed in the rays of Glory and rested on the laurels. With the successful Replicator 2 3D printer on hand and a growing stream of orders, MakerBot opened its own factory in Brooklyn. Then disaster struck: the scandal with the raw fifth generation seriously tarnished the company's reputation, and its founder, Bree Pettis, moved to Stratasys, and then completely left the big stage. MakerBot began reshuffles and mass layoffs. Now the company has broken another bottom, announcing the cessation of production of "replicators" in New York.

With the successful Replicator 2 3D printer on hand and a growing stream of orders, MakerBot opened its own factory in Brooklyn. Then disaster struck: the scandal with the raw fifth generation seriously tarnished the company's reputation, and its founder, Bree Pettis, moved to Stratasys, and then completely left the big stage. MakerBot began reshuffles and mass layoffs. Now the company has broken another bottom, announcing the cessation of production of "replicators" in New York.

Like a true manager, MakerBot CEO Jonathan Jaglom keeps a good face on a bad game. The 3D printers will be manufactured by the international company Jabil Circuit, which provides contract manufacturing services for electronics. According to Jaglom, “Working with Jabil will enable us to better position ourselves in a rapidly changing marketplace and reduce production costs in order to become more competitive on the global stage. We expect that a more flexible manufacturing model will allow us to quickly change production volumes based on current demand and without the constant costs of running a factory in New York. ”

”

In simple terms, this means that MakerBot is shutting down facilities in an area of 20,000 square meters. meters and transfers production abroad - where exactly, you have to choose Jabil. Most likely to China or Malaysia. For the company's employees, this means another wave of mass layoffs, but apparently, MakerBot has no other choice. Despite the company's claims of commitment to the "Brooklyn culture", localized production can not afford it, and the company somehow needs to be saved. At least, there should be no problems with production in China, because craftsmen from the Celestial Empire have been successfully stamping clones of "replicators" for so long and successfully.

In the best imperial tradition

Polymaker has come up with a great demonstration of what Polysher can do, a 3D printed aerosol smoothing machine. To do this, the developers invited an artist named Tian Tian. The object of the demonstration was a 3D printed vase processed with Polysher and hand painted by the artist in the style of the Qin Dynasty.

School of Design and Digital Arts at Shanghai Aurora College. The artist has a particular fondness for antique vases. The vases of the Qin Dynasty date back to the 13th century, and the delicate decorations were created with careful strokes of a fine brush. The smoothness of the vessels is of great importance, since any irregularities can distort the movement of the brush and ruin the drawing. Of course, in the case of raw 3D printed models, layering leads to just such difficulties, but after smoothing the vase in Polysher, the artist managed to achieve the desired result.

What's more, Tian Tian liked the idea of creating art with 3D printing: "When I decorate a vase created by another designer, there always comes a point where I can't fully express myself in the drawing." Very Zen, Tian. However, the popularity of Polysher is also ensured in the Russian market. Read more about Polysher here.

With the breeze and without the cortege

Holland is remarkable not only for its love of bicycles and 3D printing, but also for the fact that all segments of society are exposed to this love. So Economics Minister Henk Kamp could not resist the opportunity to ride a 3D printed bicycle. A two-wheeler called Arc Bicycle was printed by a team of students from the Delft University of Technology with the help of technical experts from MX3D.

The run-in took place during the Innovation Expo in Amsterdam, where more than two hundred innovations were showcased. More than 4,000 entrepreneurs and academics, as well as about 70 ministers from all over the European Union, came to the exhibition. MX3D, a start-up that builds the world's first 3D printed bridge and, at its leisure, helps students make bicycles with its 3D printed welder robot, was also featured.

The bike weighs about the same as a regular steel frame version. “It was important for us to create a functional object that people use on a daily basis. Since we are students in the Netherlands, the idea of a 3D printed bicycle came to our minds. The bike frame serves as a good demonstrator due to multidirectional loads,” explains one of the designers, Stef de Groot. Someone who, but Minister Kamp appreciated the project at its true worth. As for MX3D, their project to 3D print a canal bridge in the center of Amsterdam is due to be completed in 2017.

REC takes Europe by storm

The Russian company REC signed an agreement to supply consumables to the German retailer iGo3D. The agreement was reached at the Hannover Messe industrial fair taking place these days. This time we are talking about 20 tons of branded filament, which is very popular in the domestic market.

This time we are talking about 20 tons of branded filament, which is very popular in the domestic market.

“Due to the popularity of the brand and the high quality of the products, demand is growing rapidly. Today, together with German partners, we are signing an agreement for the supply of our products. This contract and the growth of the market as a whole will allow our company to expand production and increase its share in the European market,” commented Nikita Gavrilov, CEO of REC.

Subscribe to the author of

Subscribe

I do not want

7

How 3D-Plot will change the jewelry industry "Treasures of St. Petersburg"

Three-dimensional seal-one of the revolutionary inventions that have gained quite widespread widespread in recent years . It can fundamentally change the traditional jewelry industry, and today we will talk about what changes await us in the next five years.

B 1983 year American engineer Charles Hull (Charles Hull) discovered a new printing method that allows you to create three-dimensional objects. 3D printers work on the principle of layer-by-layer “growing” of a solid model and form an exact copy of a digital 3D prototype. Unlike a two-dimensional printer that outputs two-dimensional information to a sheet of paper, its three-dimensional counterpart is already capable of outputting information in three dimensions at once, that is, creating three-dimensional physical objects.

3D printing has exploded in the past few years, driven by the mass production of 3D printers at more affordable prices, the development of digital technology and the expansion of the list of materials used in printing. They say that the third industrial revolution is just around the corner.

Jewelry belongs to the category of products that can be created with 3D printers today. Amazon.com, the number one U.S. online supermarket, already has a section for 3D merchandise, where "printed" jewelry has a whole "shelf" in its own category called "jewellery for those who keep up with fashion. "

"

This is a great opportunity for independent designers looking to tap into a large consumer market. Printing your own designer jewelry is already becoming a fashion trend in the West.

The list of materials for the production of jewelry using 3D printing is also constantly expanding. For example, New York-based Shapeways, a 3D printing hub for designers and developers, added platinum, 18k gold, 14k rose gold, and 14k white gold to its range of metals that can be used for 3D printing. Today, this company offers the widest selection of materials for 3D printing of jewelry.

US President Barack Obama, in his 2013 State of the Union address, said that 3D printing has great potential to revolutionize the manufacturing method by which almost everything is made.

What does all this mean for the traditional jewelry industry?

From the point of view of the end user, this is simplicity, convenience and high speed of receiving your order. For example, you have lost one of your earrings and want to order a replacement for the lost one. Using 3D printing, you can simply purchase a file with a three-dimensional model of your earrings (CAD file) and print the missing pair at home on your own 3D printer or contact one of the printing centers. True, if there are stones in the earrings, you will need the help of a jeweler who will install them in the product.

Using 3D printing, you can simply purchase a file with a three-dimensional model of your earrings (CAD file) and print the missing pair at home on your own 3D printer or contact one of the printing centers. True, if there are stones in the earrings, you will need the help of a jeweler who will install them in the product.

From a jewelry retailer's point of view, there are also many advantages. First, there is no need to spend money on inventory and its maintenance. It will exist in virtual form, as a catalog of designs and accompanying samples. It will be enough for the seller to stock up on raw materials, materials and computer files to make an order.

High print-on-demand speeds mean that the need for stockpiles of finished goods is reduced, so manufacturers can cut costs for warehouse space, storage, and warehousing personnel.

3D printing will allow manufacturers to significantly reduce the cost of production, in particular by reducing labor costs. In other words, instead of jewelry masters, the main work will be done by . .. industrial printers. In small-scale and piece production, this can reduce the cost by 2-3 times.

.. industrial printers. In small-scale and piece production, this can reduce the cost by 2-3 times.

“With our platform, the cost and labor savings are phenomenal. There is no longer a jeweler with a blowtorch on our bench. We enable consumers to create jewelry in real time,” Forbes quotes Eddie Bakhash, CEO of New York-based jewelry company American Pearl.

American Pearl is one of the pioneers of 3D printing in the jewelry world. The company offers the service of recreating a piece of jewelry from its photograph. First, a 3D computer model of the product is prepared. Then a three-dimensional printer based on it forms an exact copy. The polisher and stone setter complete the process by presenting a sparkling duplicate of the piece to the client. Ideal for restoring lost family values, for example. American Pearl has a patented computer-aided design (CAD) system and a Solidscape T-76 3D printer.

3D printing has the potential to bring production back to countries that today mostly import goods. The main problem of competitiveness, in particular, of American jewelry manufacturers is the high cost of labor in the United States. They cannot compete with cheap foreign production (read: China, Thailand and India) in the cost of production.

The main problem of competitiveness, in particular, of American jewelry manufacturers is the high cost of labor in the United States. They cannot compete with cheap foreign production (read: China, Thailand and India) in the cost of production.

3D printing solves this issue simply - the printer does not need to pay a salary, only the purchase price and materials.

In addition, there will be localization of production, it will be concentrated closer to the consumer. Hence, the reduction of costs for cargo transportation and all other logistics of finished products. It is likely that the role of large mass production centers will also gradually decline.

Manufacturers, both small and large, will find it much easier to turn ideas into working models and marketable products. The flexibility of 3D printing-based manufacturing will allow production of test batches without the high cost of a new production process.

Of course, the spread of 3D printing will raise many new questions.

Individual parts at 72" (177cm), and even larger with sectional fabrication. Start with a napkin sketch, a physical object to scan, or with fully engineered CAD files. Our design and production team at The Factory NYC will bring your project to life.

Individual parts at 72" (177cm), and even larger with sectional fabrication. Start with a napkin sketch, a physical object to scan, or with fully engineered CAD files. Our design and production team at The Factory NYC will bring your project to life. By printing sculptures in multiple sections with interlocking joints, we can assemble even room-sized sculptures and beyond.

By printing sculptures in multiple sections with interlocking joints, we can assemble even room-sized sculptures and beyond. Today, there's nothing more powerful to realize this new vision than large-scale 3D printing. It's here, competitively priced, and within your brand's reach:

Today, there's nothing more powerful to realize this new vision than large-scale 3D printing. It's here, competitively priced, and within your brand's reach: We can accommodate your design concept for most situations:

We can accommodate your design concept for most situations: