Buy clip 3d printer

Carbon3D introduces CLIP, breakthrough technology for layerless 3D printing

Partners with Sequoia and Silver Lake Kraftwerk and raises $41 million

Vancouver, CANADA – March 16, 2015 – Carbon3D today emerged from stealth on the main stage of the TED conference with an innovative approach to polymer-based 3D printing that promises to advance the industry beyond basic prototyping to 3D manufacturing. The new Continuous Liquid Interface Production technology (CLIP) harnesses light and oxygen to continuously grow objects from a pool of resin instead of printing them layer-by-layer. The technology was simultaneously introduced to the scientific community as the cover story in the journal Science. Carbon3D’s CLIP technology raises the state-of-the-art in 3D printing in three ways:

- GAME-CHANGING SPEED: 25-100 times faster than conventional 3D printing

- COMMERCIAL QUALITY: produces objects with consistent mechanical properties

- MATERIAL CHOICE: enables a broad range of polymeric materials

“Current 3D printing technology has failed to deliver on its promise to revolutionize manufacturing,” said Dr. Joseph DeSimone, CEO and Co-Founder, Carbon3D. “Our CLIP technology offers the game-changing speed, consistent mechanical properties and choice of materials required for complex commercial quality parts.”

How CLIP Works

Existing 3D printing technology, or additive manufacturing, is really just 2D printing, over and over again. As a result, 3D printed parts take many hours, even days, to produce and are mechanically weak due to their shale-like layers. Using a tunable photochemical process instead of the traditional mechanical approach, Carbon3D’s layerless continuous liquid interface production technology (CLIP) eliminates these shortcomings to rapidly transform 3D models into physical objects. By carefully balancing the interaction of UV light, which triggers photo polymerization, and oxygen, which inhibits the reaction, CLIP continuously grows objects from a pool of resin at speeds 25-100 times faster than traditional 3D printing.

At the heart of the CLIP process is a special window that is transparent to light and permeable to oxygen, much like a contact lens. By controlling the oxygen flux through the window, CLIP creates a “dead zone” in the resin pool just tens of microns thick (about 2-3 diameters of a red blood cell) where photopolymerization cannot occur. As a series of cross-sectional images of a 3D model is played like a movie into the resin pool from underneath, the physical object emerges continuously from just above the dead zone. Conventionally made 3D printed parts are notorious for having mechanical properties that vary depending on the direction the parts were printed because of the layer-by-layer approach. Much more like injection-molded parts, CLIP produces consistent and predictable mechanical properties, smooth on the outside and solid on the inside.

By controlling the oxygen flux through the window, CLIP creates a “dead zone” in the resin pool just tens of microns thick (about 2-3 diameters of a red blood cell) where photopolymerization cannot occur. As a series of cross-sectional images of a 3D model is played like a movie into the resin pool from underneath, the physical object emerges continuously from just above the dead zone. Conventionally made 3D printed parts are notorious for having mechanical properties that vary depending on the direction the parts were printed because of the layer-by-layer approach. Much more like injection-molded parts, CLIP produces consistent and predictable mechanical properties, smooth on the outside and solid on the inside.

Venture Backing

Carbon3D also announced it had partnered with Sequoia Capital to lead the company’s Series A round of financing in 2013 along with Northgate Partners, Piedmont Capital Partners and Wakefield Group. Silver Lake Kraftwerk led the Series B round of financing in 2014 with Northgate Capital and Sequoia Capital, for a total raise of $41 million to commercialize the technology.

“If 3D printing hopes to break out of the prototyping niche it has been trapped in for decades, we need to find a disruptive technology that attacks the problem from a fresh perspective and addresses 3D printing’s fundamental weaknesses,” said Jim Goetz, Carbon3D board member and Sequoia partner. “When we met Joe and saw what his team had invented, it was immediately clear to us that 3D printing would never be the same.”

“We had studied the additive manufacturing ecosystem comprehensively and had concluded that the promise far exceeded the current reality in the marketplace,” said Adam Grosser, Carbon3D board member and Managing Director at Silver Lake Kraftwerk. “When we witnessed the CLIP process, we believed we had found a company that had invented a solution to speed, quality, and material selection. We are proud to work alongside Carbon3D to create a new category of 3D manufacturing.”

To learn more visit: https://carbon3d.com

Media kit: https://carbon3d.com/media-kit

About Carbon3D

Carbon3D, a Silicon Valley based company, was founded in 2013 in Chapel Hill, NC. Working at the intersection of hardware, software and molecular science, Carbon3D is delivering on the promise of 3D printing, allowing commercial customers to go beyond prototyping to achieve 3D manufacturing. The Continuous Liquid Interface Production technology (CLIP) was originally developed by Professor Joseph DeSimone, Professor Edward Samulski, and Dr. Alex Ermoshkin and introduced simultaneously at TED 2015 and to the scientific community (Science, 2015). Since its inception, Carbon3D has partnered with Sequoia Capital to lead the company’s Series A round of financing in 2013 along with Northgate Partners, Piedmont Capital Partners and Wakefield Group. Silver Lake Kraftwerk led the Series B round of financing in 2014 with Northgate Capital and Sequoia Capital, for a total raise of $41 million to date.

Working at the intersection of hardware, software and molecular science, Carbon3D is delivering on the promise of 3D printing, allowing commercial customers to go beyond prototyping to achieve 3D manufacturing. The Continuous Liquid Interface Production technology (CLIP) was originally developed by Professor Joseph DeSimone, Professor Edward Samulski, and Dr. Alex Ermoshkin and introduced simultaneously at TED 2015 and to the scientific community (Science, 2015). Since its inception, Carbon3D has partnered with Sequoia Capital to lead the company’s Series A round of financing in 2013 along with Northgate Partners, Piedmont Capital Partners and Wakefield Group. Silver Lake Kraftwerk led the Series B round of financing in 2014 with Northgate Capital and Sequoia Capital, for a total raise of $41 million to date.

About Sequoia

The Sequoia team helps a small number of daring founders build legendary companies. We spur them to push the boundaries of what’s possible. In partnering with Sequoia, companies benefit from our unmatched community and the lessons we’ve learned over 40 years working with Steve Jobs, Larry Ellison, John Morgridge, Jerry Yang, Elon Musk, Larry Page, Jan Koum, Brian Chesky, Drew Houston, Adi Tatarko and Jack Dorsey, among many others. In aggregate, Sequoia-backed companies account for more than 20% of NASDAQ’s total value. We’re proud that their success also fuels great causes: since 2000 alone we have returned more than $10 billion to non-profits like the Ford Foundation, Mayo Clinic and MIT.

In aggregate, Sequoia-backed companies account for more than 20% of NASDAQ’s total value. We’re proud that their success also fuels great causes: since 2000 alone we have returned more than $10 billion to non-profits like the Ford Foundation, Mayo Clinic and MIT.

About Silver Lake Kraftwerk

Silver Lake Kraftwerk is part of Silver Lake, the global leader in technology investing with over $23 billion in combined assets under management and committed capital and a team of approximately 110 investment and value creation professionals located around the world. Silver Lake Kraftwerk focuses on providing growth capital to technology innovators with established business models in the energy and resource sectors. Silver Lake Kraftwerk targets companies globally that leverage technology and business model innovation to improve energy efficiency, reduce waste and emissions, harness renewable energy, and more efficiently use natural resources, among other applications. For more information about Silver Lake Kraftwerk and its entire portfolio, please visit www. silverlake.com.

silverlake.com.

Clip best 3D printer models・Cults

Powerstrip mounting clips

Free

6mm Pegboard hooks and baseplates (for custom designs)

Free

Powerboard Clips

Free

Car Roof Clip for Cables

Free

LED Strip clip

Free

Cable clips

Free

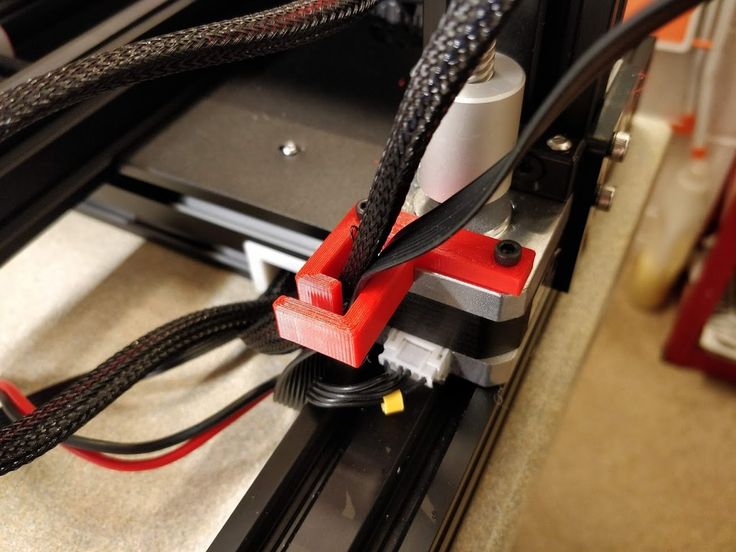

Cable tidy clip for 20mm aluminum extrusion / 3D printers

Free

Nativity SVG Bundle / Cut File / Cricut / Commercial use / Nativity SVG / Christmas SVG / Christmas Decoration / Clip art / Vector

€4.47

BMW Clip for accelerator cable

€2.99

Poster Clip

Free

RJ45 Ethernet Plug Protector

Free

Clip TomTom GPS air vent mounting bracket

€2

GoPro Clip for camera

Free

Max Solarzord Clip Arm

€1. 25

25

SKYDIVE PAPER CLIP

€0.75

Holster Belt Clip

€3.92

HPA PROWIN - Redline n7 Milsim G2 ALIGMENT CLIP

€22 -25% €16.50

Creality Ender 3 Bowden clip and extruder flag

Free

Bowden clip

Free

Led strip clip

Free

Ghost

Free

Speaker Stand clip, Cable clip for around 38-39mm Spaerker Box Holder, Wire holder, Omnitronic MO-5

€1.50

Shortened RepRap Endstop Holder

Free

Ender 3 Pro Display Ribbon Cover

Free

Attachment

Free

Gutter light clip

€1. 38

38

Quick shoes ties

Free

GOAL MESH CLIP

Free

Mini Maglite Holster

Free

Tight Tolerance Calibration Clips

Free

Vertical Blinds Valence Brackets

Free

RB3 Extruder Cable Restraint

Free

Filament Clip 1.75mm

Free

Valorant Sage hairclip

€5

Gundam Lacus Clyne Hairclip

€4

BMW E36 CUP HOLDER

€25 -50% €12.50

BMW E36 DOOR CLIP HOLDER 3 VL

€10 -50% €5

BMW E36 DOOR CLIP HOLDER 2 VL

€10 -50% €5

Printerbot desk clip for 8 mm desk

Free

Tactical Kerrygold

Free

Cube Clip for Vine Plant

Free

Cable Clip

Free

BMW E36 DOOR CLIP HOLDER 1 VL

€10 -50% €5

Sig 365 Magazine Holster

Free

Battery/Electronics holder for TrackIR Clip

Free

Bumper case frame for JBL GO 2 to use with carabineer to clip on a hiking backpack bag

€1. 02

02

Delica L400 hood rod clip

Free

3.5” Patio Cover Beam Clip

Free

3D printed music video: luckyea77 — LiveJournal

? Categories:- Technology

- Music

- Cancel

An independent musician has created a teaser for his music video using 3D printing technology. He is sure that this is the cheapest and most effective way to draw attention to his work using new approaches.

Musician prash, who made the video, explained that he didn't have the budget for a big job, but he wanted his music to be accompanied by visual effects. He noted that lyric videos have become a more accessible way, which is gaining popularity among bloggers.

He noted that lyric videos have become a more accessible way, which is gaining popularity among bloggers.

The video is a 3D printing timelapse - prash has embedded words into various layers of printed objects. Thus, as the prints are stacked on the building slab, the words become visible to the time lapse camera. He enhanced the scene by shaping the prints to refer to the lyrics and using eye-catching swirls and stripes.

“This is a neat use of 3D printing, and a clever one at that. We are confident that prash has created a unique video, and it is much more impressive than the questionable 3D printing that stars use just to be mentioned in the context of new technologies,” notes Hackaday.

TAGS: 3D printer

Subscribe

-

Scientists were able to increase the strength of products created using metal 3D printing

Control sample forgotten by the pneumatic pole of modern

-

PERM POLYTECH SCIENTISTS FOUND A WAY TO IMPROVE THE QUALITY OF 3D PRINTING

Appearance of a hot tip Today, innovative 3D printing technology is used in various fields: from the entertainment industry to…

-

SCIENTISTS OF THE PERM POLYTECH CREATE A NEW METHOD OF OBTAINING ULTRA-LIGHT MATERIAL FOR AIRCRAFT AND CARS

Graphene has unique properties and is used in the aerospace and automotive industries and in flexible electronics.

In particular, his…

In particular, his… -

Startup started printing salmon for restaurants on a 3D printer

An Israeli company began supplying 3D-printed plant-based salmon to restaurants. Plantish in Israel hopes to…

-

Printing technology for wearable mosquito repellent devices developed

A new type of mosquito repellent device was developed in Germany. Using a 3D printer, the active ingredients are encapsulated and…

-

3D printed rocket fuel has been tested

3D printed rocket engines and propellants have been successfully tested. Researchers from the American startup Firehawk announced…

-

SAMARA POLYTECH LEARNED TO MAKE PARTS FROM METAL WITH THE HELP OF 3D PRINTING

Scientists of the Department of Casting and High-Efficiency Technologies of the Samara State Technical University (SamSTU) tested the technology ...

-

An even simpler way to 3D print buildings has been invented

The first construction 3D printers have already begun to be used in practice: in China, they printed a concrete embankment, in the States, barracks. American…

printed on a 3D printer

During tests, scientists found that the tensile strength of the new titanium alloy is more than 1,600 MPa. Research results published…

Research results published…

Photo

Hint http://pics.livejournal.com/igrick/pic/000r1edq

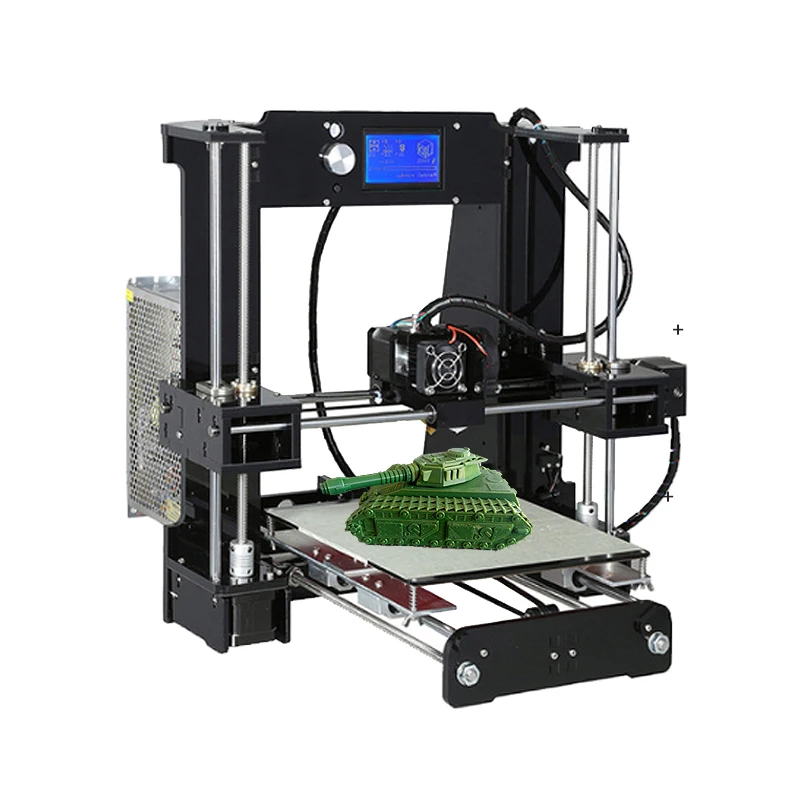

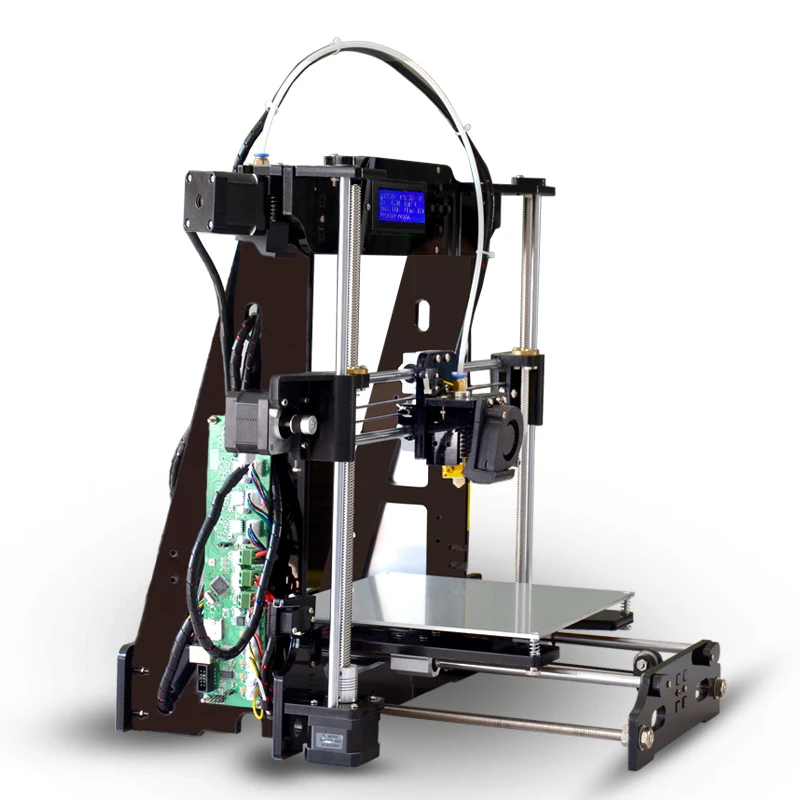

Large print area 3D printer

Create functional plastic items up to 2.5 meters!

Learn more

Discovery 3D Printer is a Spanish-made line of industrial 3D printers for creating large-sized products and prototypes using FFF / FDM technology.

Discovery 3D Printer Additive Machines produce high-strength thermoplastic objects for industries ranging from shipbuilding and automotive to architecture and medicine.

Tasks to be solved

Replacement of spare parts or lost parts at machine building, shipbuilding, oil and gas and energy enterprises

Production of small and medium series of products as an alternative to injection or molding of plastic parts

3D printing of large-sized end products, components and tooling in the automotive, shipbuilding and oil and gas industries

Creation of outdoor and interior design objects and design products for construction, manufacturing facing materials

Production of functional prototypes for research and development and design offices in mechanical engineering, shipbuilding and aircraft building

Manufacture of large-size waxes or burnt-out master models for metal casting and metallurgy

Creation of auxiliary fastening equipment, printing of templates for robotic equipment (robots, cobots, robotic arms or carts)

Looking for a 3D printer for your needs?

Leave a request for a personal consultation!

Solutions catalog

3D Printers

Discovery 3D Printer 2021

More details

Super Discovery 3D Printer Workstation

2 in 1: unique combination of large format 3D printer and milling system

More details

Your unique 3D printer

Need to print more 6 meters?

We will develop an individual solution with any build chamber for your needs. tasks - for printing products of any size!

tasks - for printing products of any size!

Choose the right solution for you - compare characteristics of different models

Compare 3D printers

Solutions catalog

3D Printing Consumables

Do you have questions about 3D printing media?

Set them to our experts online!

Discovery 3D Printers work with all thermoplastics, including:

- PLA / PLA

- biodegradable polymer provides a smooth and sliding surface products. Designed to obtain detailed and completely ready-to-use objects

- ABS / acrylonitrile butadiene styrene

- impact-resistant material is able to withstand heavy loads and high temperature, resistant to heat, moisture and various alkalis

- PET / polyethylene terephthalate

- is a hard and strong material with high abrasion resistance.

Excellent suitable for making gears, carriages and guides

Excellent suitable for making gears, carriages and guides - PA / polyamide

- hard engineering plastic with excellent mechanical properties characteristics. Widely used in various industries

- ASA / acrylonitrile styrene acrylate plastic

- analogue of ABS, characterized by increased weather resistance, minimal shrinkage and high impact strength

- Nylon

- is elastic, wear-resistant and remarkably durable. Good suitable for printing functional parts and mechanisms

- HIPS / polystyrene

- Lightweight, alkali and acid resistant polymer. deserved popular in traditional manufacturing due to its impact resistance

Benefits of Discovery 3D Printer Solutions

ISO 9001 Certified Products

World's Largest Build Chamber 3D Printer

Custom Printer Design

The only CNC-integrated 3D printer on the market to finish milling a part after printing

Accelerate the creation of new products with a dual extrusion system

Repair and replace products faster and more economically than contractors

Ability to use a large number of third-party materials

Platform self-levelling function for automatic compensation of irregularities

Case studies

Airbus 3D FDM parts printing

| Industry: | Aircraft |

| Equipment: | Super Discovery 3D Printer |

| Material: | CFRP SABIC LNP™ THERMOCOMP™ AM EZ006EXAR1 |

Created a strong mold for autoclave forming parts with a sealed surface and a low coefficient of thermal expansion.

3D printed car bumper

| Industry: | Automotive |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Prototype car bumper printed, measuring 1800 x 600 x 4500 mm and weighing 12 kg.

Large format 3D printed chair

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer |

| Material: | 3D850 |

Printed design armchair measuring 45 x 50 x 95 cm and weighing 18 kg.

3D printed architectural statue

| Industry: | Architecture |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with cellulose fiber |

Printed sturdy statue, 1. 87m high and 45kg weight.

87m high and 45kg weight.

3D printed rail components

| Industry: | Railway industry |

| Equipment: | Super Discovery 3D Printer |

| Material: | plastic |

The front part of a tram for CAF was made in one printing session.

3D printed helicopter seat

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Printed helicopter seat measuring 120 x 70 x 45 cm and weighing 20 kg.

3D printed internal combustion engine

| Industry: | Engineering |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | Premium PLA |

Prototype of an internal combustion engine was created, the dimensions of which were 100 x 60 x 50 cm and the weight was 5. 5 kg.

5 kg.

3D printed exclusive piece of furniture

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS plastic |

A custom and exclusive chair created without the need for any further finishing.

Architectural 3D printed in durable ABS with cellulose

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS plastic |

A street sculpture has been made that fully implements the initial decorative idea of the project.

Dior boutique window dressing

| Industry: | Advertising |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | plastic |

3D printed oversized bottles for exclusive display at Dior's flagship stores.

Prototype FDM cap

| Industry: | Design |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | 3D850 |

Prototype cap printed at 29 x 19 x 4.5 cm and weighing 146 g.0233

Prototype of a modular toilet is printed, measuring 2200 x 1700 x 1200 mm and weighing 250 kg. At the same time, the weight of the product was reduced by almost 50%.

3D printed marine ventilation grille

| Industry: | Shipbuilding |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Printed air vent grille measuring 59 x 89 x 4. 5 cm and weighing 3500 g.

5 cm and weighing 3500 g.

3D printed motorcycle functional part

| Industry: | Automotive |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | PACF |

Printed motorcycle part measuring 42.5 x 16.5 x 4.5 cm and weighing 165 g.0234

Prototype printed with support measuring 10 x 9 x 2.5 cm and weighing 18 g

Created a square mold that measures 10 x 10 x 2 cm and weighs 67 g.

Printed fender for a wheel measuring 55 x 16 x 20 cm and weighing 645 g.

3D printed and post-processed a high strength mold for wind turbine blades.

3D printed car wheel

| Industry: | Automotive |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

A wheel for a car was made, the diameter of which was 440 mm, and the weight of the product was 5 kg.

3D printed designer vase

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS with carbon fiber |

Printed vase in ABS for excellent interlaminar adhesion and minimal warping.

Geometry 3D printing

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS with carbon fiber |

A pyramid is printed using an 8mm extruder with a smooth surface thanks to the built-in milling system.

More projects and examples of 3D printing in production - on the blog 3D experts

Go to blog

Useful materials

Webinar on 3D printing large objects with complex geometry

- How can 3D printing help you optimize production?

- Features of FDM technology for printing products up to 2.

5 meters

5 meters - Benefits of using 3D plastic printing

- Real cases

Large Format Plastic 3D Industrial Printing Brochure

Benefits of FDM Technology, Overview of Equipment and Consumables, industries and implementation examples - this and much more in one material!

About the manufacturer

CNC Barcenas / Spain

is one of the leaders in the European market for large format 3D printing.

The company specializes in the production of industrial 3D printers Discovery 3D Printer for printing large-sized products and prototypes based on FFF/FDM technology.

discovery3dprinter.com

Take a closer look at Discovery 3D Printer solutions - take a virtual tour of companies!

3D TOUR OF COMPANY

About us

iQB Technologies is a Russian distributor of 3D printers, consumables, 3D scanners and software from the world's leading manufacturers.

We provide complete 3D solutions, print services and scanning, as well as training specialists in the use of 3D technologies in their work.

iQB Technologies is the exclusive distributor of Discovery 3D Printer solutions in Russia.

3D printers are available for order

in this section .

iqb.ru

Why you should order a 3D printer in iQB Technology?

Best prices for this class of equipment

3D printer training

A wide range of integrated solutions: 3D printer + 3D scanner + software

Provision of services for the implementation, maintenance and repair of 3D equipment throughout Russia

Participation in public procurement and tenders

Still have questions?

Our experts will advise you free of charge on Discovery 3D Printer solutions

Frequently Asked Questions

Which technology to choose: the method of fusing granules (FGF) or polymer filaments (FFF / FDM)?

What are the kinematics and mechanics of the Discovery equipment?

In this respect, all Discovery equipment differs from budget additive solutions. The products are based on the kinematic diagram of a CNC machine. Gears, pulleys, lead screws, no belts. HIVIN rail guides are used. The entire structure is made with European quality from advanced products in the machine tool industry.

The products are based on the kinematic diagram of a CNC machine. Gears, pulleys, lead screws, no belts. HIVIN rail guides are used. The entire structure is made with European quality from advanced products in the machine tool industry.

What consumables can be used with Discovery products?

Any material (other than PEEK and PEKK) sold in bars or pellets. First of all, thanks to the heating of the table to 175 ° C and vacuum fixation, as well as due to the installed nozzles made of hardened steel.

How is such a large print platform heated?

A matrix of separate equidistant heaters is built into the platform from the bottom side; these modules provide uniform heating of the surface of the printing platform. The maximum recorded temperature difference over the entire area is 3°C.

How to speed up printing on such large dimensions?

There is a special method for properly emptying the internal volume, which you can learn more about from our technical experts. This procedure will have very little effect on the strength and elasticity of the print object, but will still reduce the time by up to 60%.

This procedure will have very little effect on the strength and elasticity of the print object, but will still reduce the time by up to 60%.

It is important to consider that with a large range of large-sized products, it is better to consider Super Discovery 3D Printer or Super Discovery 3D Printer Workstation with a capacity of up to 11 kg / h (depending on the material used).

Is it possible to upgrade this equipment for a specific enterprise?

Yes. Most of the Discovery machines can be upgraded for a specific production project. This is possible, since the equipment was designed for the tasks of Production 4.0, and our specialists will help to integrate it correctly.

What is the warranty for this equipment?

24 months, which is 1.5 - 2 times longer than analogues from Europe, Russia and China. Permanent customer support is provided directly by the vendor or iQB Technologies specialists.

How to get a high quality product so that it can be handed over as a final product?

3D printing is basically a high quality blank process.