3D printer nozzle maintenance

How to Clean a 3D Printer Nozzle (5 Methods) – Clever Creations

Using a nozzle cleaning kit and a cleaning filament is the most effective way to clean your 3D printer nozzle. You can remove the nozzle and soak it in acetone to remove any traces of filament impurities. A brass wire brush with soft bristles will help eliminate any leftover filament residue.

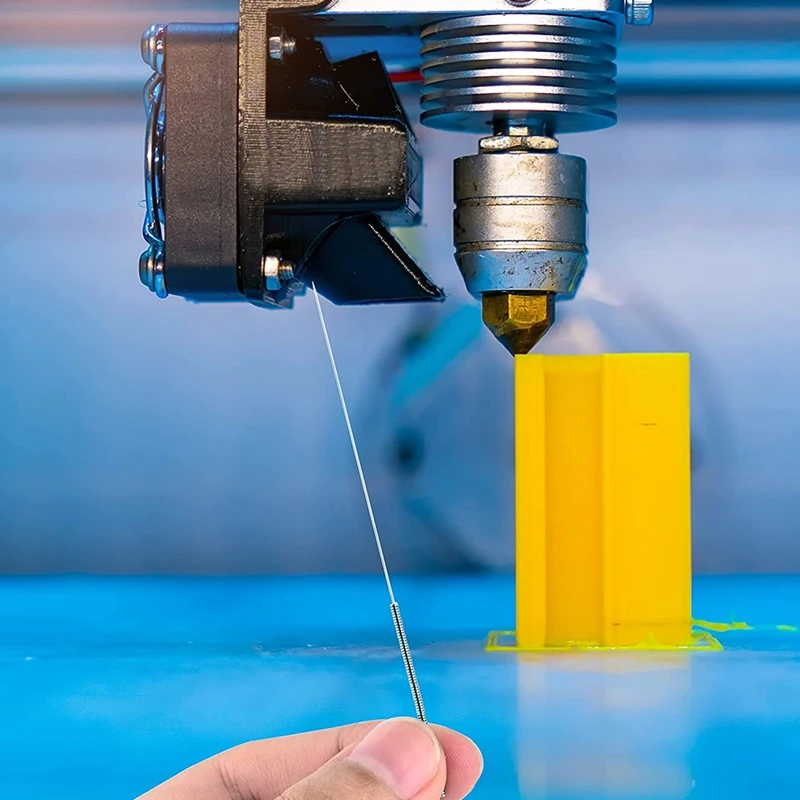

A 3D printer nozzle is a crucial element in the 3D printing process, and it is responsible for the smooth extrusion of your filament. Any clogs or blockages in the nozzles will directly affect your print quality. Clogged nozzles will lead to under extrusion, inconsistent filament flow, and uneven layers.

Even though cleaning a blocked nozzle is easy, it can be challenging to identify the clog in the first place. In this article, we’ll explain how to recognize a nozzle clog, go over the various cleaning methods and what you can do to prevent nozzle clogging in the future.

Read on to learn how to clean a 3D printer nozzle and get a smooth 3D printing experience!

How Can You Tell If a Printer Nozzle Is Clogged?

Image: squid-do via Reddit

It can be tricky to attribute print defects to clogged nozzles. However, a few notable indicators will quickly tell you whether you are dealing with nozzle clogging.

The easiest way to detect a nozzle clog is if you notice a decrease in the overall print quality. Inconsistent extrusion, missing layers, and under extrusion are a few of the side-effects of a blocked nozzle. A partial blockage in the nozzle can cause all of these problems. Similarly, a complete jam can occur due to clogged material stuck in the nozzle.

An improper first layer is another sign of nozzle clogging. If the nozzle does not extrude filament during the first layer or there’s an uneven filament flow, you might have a clog in your nozzle. However, it is helpful to eliminate any bed leveling and Z-offset issues before you check for a nozzle clog.

Additionally, filament curling right after extrusion and thinner print lines are also signs of a clogged nozzle. Recognizing these signs will help you quickly clean your nozzle and prevent further degradation of your 3D prints.

How Do You Clean a 3D Printer Nozzle?

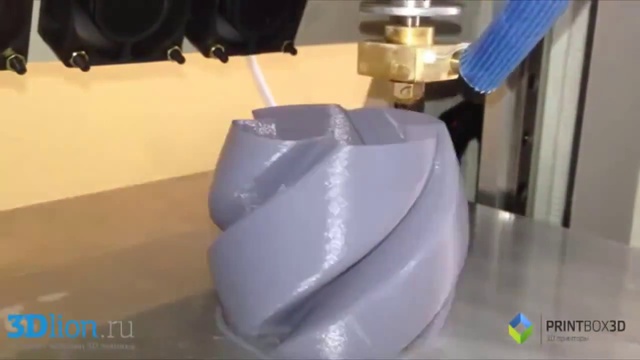

If you start to see filament deposits on the outer surface of your nozzle, it is time to clean it. 3D printer nozzle cleaning is easy, and all you need is a brass wire brush and a wiping cloth.

The brass brush prevents damage to your brass nozzles and lets you scrub any stuck printed material from your dirty nozzle.

Before starting the cleaning process, it is helpful to first heat your 3D printer nozzle. Heating the nozzle softens any stuck filament bits and lets you wipe them off more quickly.

Once you’ve scrubbed the nozzle thoroughly, you can wipe away any leftover material from its surface. A soft microfiber cloth is our go-to equipment for this.

3D printer nozzle cleaning is now complete, and you can start printing again. Remember to always keep an eye on the state of your nozzle and clean it regularly to maintain optimal print quality.

Remember to always keep an eye on the state of your nozzle and clean it regularly to maintain optimal print quality.

Turboom Wire Brush Set Scratch Brush Set for Cleaning Welding Slag...

611 Reviews

Check PriceHow Do You Unclog a Clogged 3D Printer Nozzle?

If your nozzle is already clogged, don’t worry! Cleaning a nozzle is an easy process that can be done through a couple of different methods.

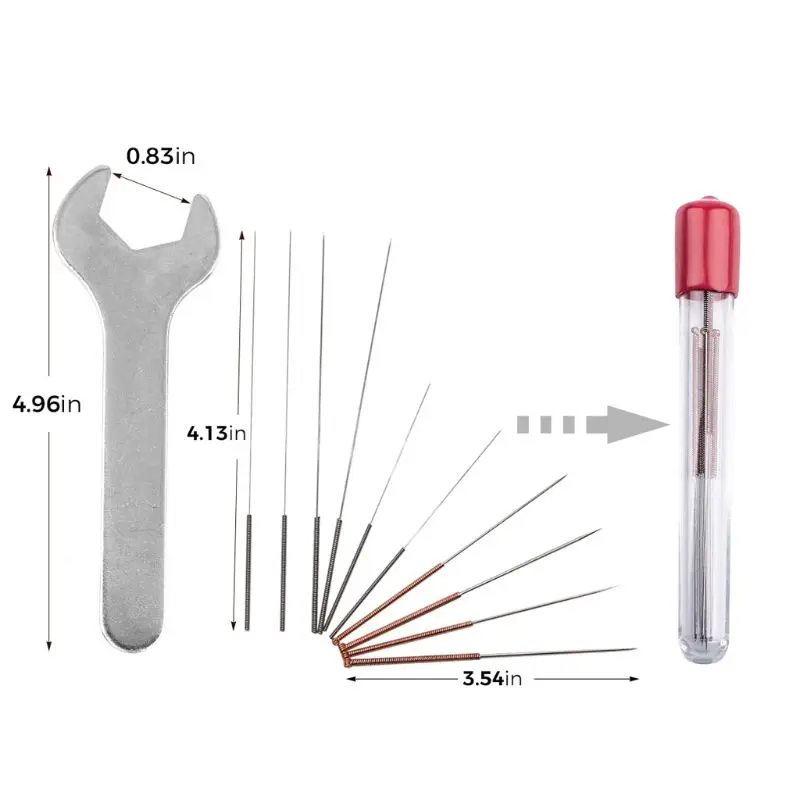

Nozzle Cleaning KitA standard nozzle cleaning kit consists of thin metal needles, tweezers, and a brush. You can use this method to clean out your nozzle by following these steps:

- Start by heating up your nozzle to right under its maximum temperature. This will help to soften any filament that is stuck inside the nozzle.

- Next, use the metal needles to pick out any larger pieces of filament that may be blocking the nozzle.

- Once the larger pieces have been removed, use the nozzle brush to clean out any smaller bits of filament.

- Finally, use the tweezers to remove any final pieces of filament or debris.

3D Printer Nozzle Cleaning Kit - 0.4mm Needles and Tweezers Toolkit...

1,422 Reviews

Check PriceCold Pull

A cold pull or an atomic pull is often used to unclog the nozzle and remove any debris inside it. It is an easy technique and requires no disassembly or cleaning tools to remove the clog.

Using Nylon filament will give the best results. However, you can also use PLA, ABS, or a dedicated cleaning filament (more on this later) if Nylon is not available.

First, you need to heat the nozzle to the printing temperature of your filament. After that, you will have to manually push the filament until it extrudes out of the nozzle. You can now let your hot end cool down while pushing the filament into the nozzle.

In the final step, you need to first remove the extruded material from the nozzle tip. Then set the printer temperature to 85-90 °C. Once it reaches this temperature, slowly pull the filament out of the nozzle completely.

You might have to perform this procedure several times to remove any dirt and filament bits from the inside of your nozzle. You can stop once you notice the cold pulled filament is free from debris.

Soaking the Nozzle in Acetone

A nozzle cleaning kit and cold pull might not always be practical with filaments like ABS, and your nozzle might still be clogged. When it comes to ABS, removing the nozzle and soaking it in acetone is a good way to clear clogs.

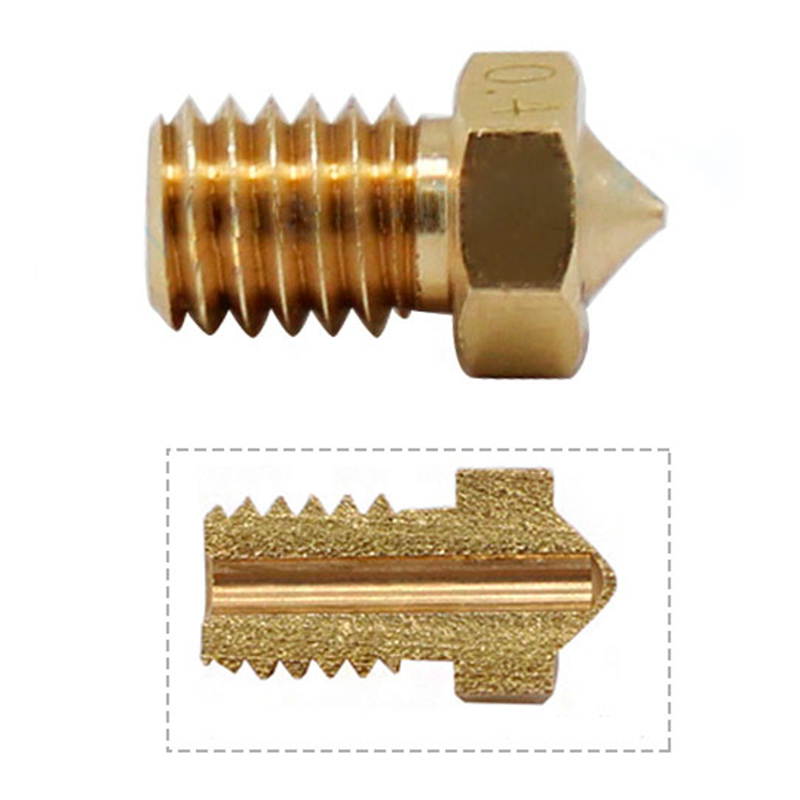

Start by heating the nozzle before removing it from the hot end. Heating the nozzle frees it up slightly from the heater block and makes it easy to unscrew. You can use a spanner or a nozzle removal tool to remove the nozzle safely and efficiently.

After you’ve removed the nozzle, soak it in a cup with a layer of acetone for around 30 minutes. The acetone will help to dissolve any ABS filament that is stuck inside the nozzle.

Recommended:

How to Melt and Dissolve PLA Filament

Once the soaking is complete, you can use a wire brush to remove any final bits of filament. Be sure to also clean the nozzle tip as this is where most of the clogs occur.

Be sure to also clean the nozzle tip as this is where most of the clogs occur.

You can now reassemble your 3D printer and start printing again. Make sure to properly dry the nozzle first. A paper towel or soft cloth is just fine for this.

Remember to always keep an eye on your nozzle and clean it regularly to maintain optimal print quality.

Using a Heat Gun

While an acetone soak is helpful for ABS filament, it is not as effective on other filament materials. Especially PETG and Nylon are fairly non-reactive to acetone.

When dealing with these filaments, a heat gun will help clear your nozzle clog.

The first step is to remove the nozzle from the 3D printer hot end or extruder assembly. This is the same as what you would do for ABS soaking.

Next, you will need to heat the nozzle with the heat gun until the filament inside melts.

Once the filament has melted, you can use a thin needle or a wire brush to remove any debris from the nozzle. Be careful, the nozzle is hot at this point.

After cleaning the nozzle, you can now reattach it to the hot end assembly and start printing again. Make sure that the nozzle is properly cooled down before reattaching it.

Wagner Spraytech 0503038 HT400 Heat Gun, Dual Temperature Hot Air Tool...

21,592 Reviews

Check PriceHow Often Should You Clean a 3D Printer Nozzle?

At a minimum, you should clean your 3D printer nozzle when you change filament materials. It is easy for nozzles to clog from leftover material after a filament change.

For example, when you switch from ABS filament to PLA, some ABS material might be left in the nozzle. As PLA prints at a lower temperature than ABS, the leftover ABS will not melt and result in a nozzle clog.

Another reason for nozzle clogs is dirt and dust particles that enter along with the filament. If you continuously print with dirty filament, the debris can accumulate in the nozzle over time and clog the nozzle.

Because it can be a challenge to keep your filament free from dust and dirt, you can clean the nozzle after every 100-200 printing hours as prevention.

Generally, if you notice a decrease in print quality, that is usually a sign that your nozzle is starting to get clogged and needs cleaning. You can do this regardless of how long or with which materials you have been 3D printing.

How to Prevent 3D Printer Nozzle Clogs

Regularly Use 3D Printer Cleaning Filament

3D printing cleaning filament is the easiest way to clean your nozzles from the inside. It is made up of a material specifically used to clean and purge plastic out of injection molding machines. You need to extrude it at the printing temperature of your filament until you notice a clean white strand of material coming out of the nozzle, free of any debris or filament color.

Even though cleaning filament may seem slightly expensive, it does work effectively and clears out any partial clogs. And you only need a small amount. You can use it after every 100-200 hours of printing for effective cleaning of your nozzles and to prevent nozzle clogs.

NovaMaker 3D Printer Cleaning Filament 1. 75mm Natural,...

75mm Natural,...

1,727 Reviews

Check PriceReplace Worn-out Nozzles

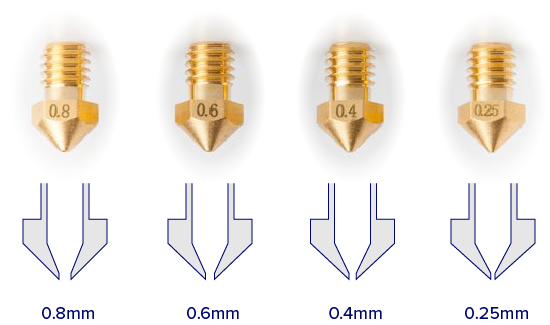

You want your nozzle opening to look round.This nozzle is already showing some signs of wear, but still has some print hours left in it.Brass nozzles undergo a lot of wear due to the constant friction of the filament. This wear accelerates when you use abrasive filaments like glow-in-the-dark, carbon fiber, and metal-filled filaments.

Not only do abrasive filaments wear out the nozzle opening, but the tiny metal particles of the nozzle material can start accumulating. This can block filament flow and lead to filament jams.

If you regularly use abrasive filaments or notice a lot of nozzle wear, it’s a good idea to replace your brass nozzle more often.

Alternatively, you can use stainless steel or other hardened nozzles. These are more resistant to abrasive filaments and have a higher lifespan than your typical plain brass nozzles.

Fix the PTFE Tube Hot End Gap

In a PTFE-lined 3D printer hot end, the tube goes all the way inside and sits right on top of the nozzle. If the gap is not flush between the PTFE tube and the nozzle, the melted filament will ooze out of it. Eventually, there will be a build-up of plastic filament within the hot end, leading to filament jamming.

If the gap is not flush between the PTFE tube and the nozzle, the melted filament will ooze out of it. Eventually, there will be a build-up of plastic filament within the hot end, leading to filament jamming.

The gap is caused due to faulty PTFE tube couplings. As the couplings wear out, the PTFE tube starts sliding in and out of the hot end, creating a gap between itself and the nozzle. Extruder skipping and under extrusion are signs of a filament jam in the hot end.

You should immediately rectify the PTFE tube gap within the hot end if you notice these issues.

The first thing here is to make sure that the PTFE tube has been cut flush at a 90° angle. If it has a slope to it, it will never perfectly align with the hot end.

Secondly, it helps to use replace worn-out pneumatic couplings with new ones on both the extruder assembly and the hot end assembly. This ensures that the PTFE tube stays in place over time.

PTFE Bowden Tube (1M) 1PCS+ 6pcs KJH04-M6 Fittings + 6pcs JP4-01. ..

..

149 Reviews

Check PriceUse High-Quality Filament

A high-quality filament will reduce nozzle clogs while also giving you high print quality. Manufacturers of high-quality filament ensure that their product contains little to no impurities, is produced in a dust-free environment, has a consistent diameter, and is properly vacuum packed to reduce as many imperfections in the material as possible.

We have created an overview of the highest quality filament in our Best PLA, Best ABS, and Best PETG articles. We recommend you check these brands out if you suspect your clogged nozzles are caused by low-quality filament.

While these filaments may be more expensive than budget materials, they are often worth the extra money.

They don’t only save time, but their results are better too. If you are looking to sell your 3D prints and make money with your 3D printer, quality filaments can be a worthwhile investment.

Keep Filament Clean and Dust-Free

A clean 3D printing space contributes significantly to preventing nozzle clogs. If your plastic filament is exposed to the outside environment while printing, it will pick up dust particles that clog your nozzle. After printing with it, you need to store it away from sunlight and in a storage box to prevent the accumulation of dust on it.

If your plastic filament is exposed to the outside environment while printing, it will pick up dust particles that clog your nozzle. After printing with it, you need to store it away from sunlight and in a storage box to prevent the accumulation of dust on it.

Another way you can protect your 3D printing setup from dust and dirt is by using a 3D printer enclosure. These don’t only keep the current filament in the printer clean, but also the 3D printer itself.

Frequently Asked Questions

How do you clean a clogged nozzle with PLA?

In order to clean a clogged nozzle with PLA, you will need to disassemble the printer and remove the nozzle. Once the nozzle is removed, you can use a small wire, needle, or other small pointed tool to clear any debris that may be blocking the opening. You might need to heat the nozzle up with a lighter to melt the plastic filament.

Be careful not to damage the nozzle while cleaning it.

How do you clean an Ender 3 nozzle after printing?

It’s important to clean your Ender 3 nozzle regularly to prevent clogs and ensure quality prints. After every print, it is advisable to clean the nozzle with a brass wire brush. This will remove any debris or build-up that may have occurred during the printing process.

After every print, it is advisable to clean the nozzle with a brass wire brush. This will remove any debris or build-up that may have occurred during the printing process.

A clean nozzle will ensure that your prints are of the highest quality and avoid any potential issues such as clogging or poor adhesion.

Conclusion

A clean 3D printer nozzle gives you the best print results and helps prevent damage to the 3D printer caused by clogs. Periodic cleaning of your 3D printer nozzle ensures fewer chances of sudden breakdown and prevents downtimes.

Degradation in the print quality, coupled with under extrusion and inconsistent filament extrusion are some of the indicators of a blocked nozzle. You can quickly unclog the nozzle using a nozzle cleaning kit and a wire brush and periodically use a cleaning filament. Especially the cleaning filament is useful for keeping nozzles clean.

When dealing with ABS filament, you can soak the nozzle in an acetone bath to soften the filament. This makes it a lot easier to remove.

This makes it a lot easier to remove.

Let us know your experience with 3D printer nozzle cleaning. If you find this article helpful, share it with your peers to help them prevent nozzle clogs and keep their 3D printers running smoothly.

How to Clean Your 3D Printer Nozzle & Hotend Properly – 3D Printerly

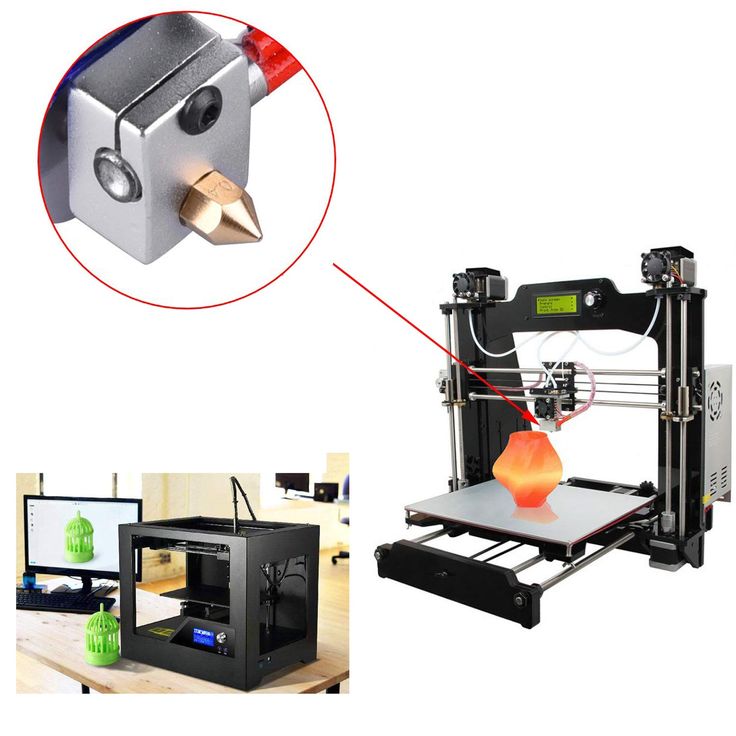

The nozzle and hotend on your 3D printer go through plenty when it comes to 3D printing, so properly cleaning them is essential. If you don’t properly clean them, you can run into quality issues and inconsistent extrusion.

The best way to clean your 3D printer nozzle and hotend are to take apart the hotend and use a nozzle cleaning kit to clear out the nozzle. Then clean off any stuck filament around the nozzle with a brass wire brush. You can also use a cleaning filament to push through the nozzle.

There are more details and other methods that you can use to clean your 3d printer nozzle and hotend properly, so keep on reading to find out how to get this done.

Symptoms of Clogged Nozzle on Your 3D Printer

Now, there are clear symptoms that the nozzles are clogged or jammed because they are not clean.

Continuous Adjustment of Feed Rate

You would have to adjust the feed rate or the flow settings again and again, which you never did before this time. This shows that your nozzle has started to clog, and the particles are accumulating there.

The Problem in Extrusion

The extrusion, the very first layer of the printing, will start to look uneven and would not stay consistent throughout the whole printing process.

Motor Thumping

Another symptom is the motor that is driving the extruder starts thumping means you would see it jumping backward because it can’t keep up with the other parts that make it turn.

Dust

You would see more dust than usual around the extruder and motor part, which is a clear sign that you need to clean everything starting from your nozzle.

The Odd Scraping Sound

One thing you can notice in terms of noises is an odd scraping sound which the extruder is making because it is grinding the plastic and it cannot push the gear fast enough now.

Other Symptoms

The printer would start showing print blobs, uneven or rough printing, and a poor layer adhesion feature.

How to Clean Your Nozzle

There are a few methods that people use to clean their nozzles, but generally, it comes down to heated up the nozzle to a fairly high temperature and manually pushing through filament.

It’s usually done with a needle from a good nozzle cleaning kit.

A good nozzle cleaning kit that you can get from Amazon for a great price is the MIKA3D Nozzle Cleaning Tool Kit. It’s a 27-piece kit with plenty of needles, and two type of precise tweezers for your nozzle cleaning worries.

When a product has great ratings on Amazon, it’s always good news, so I would definitely go with it. You have a 100% satisfaction guarantee and quick response times if ever needed.

After heating up your material, using a high-quality needle works wonders.

What this does it heat up any built-up material, dust and dirt within the nozzle then push it out straight through the nozzle. You are likely to get a build up of dirt if you are printing with many materials which have different printing temperatures.

If you print with ABS and some filament gets left inside the nozzle then you switch to PLA, that leftover filament is going to have a hard time being pushed out at lower temperatures.

How to Clean Outside of 3D Printer Nozzle

Method 1

You can simply use a paper towel or napkin to clean the nozzle when it has cooled down. This should usually do the trick to clean the outside of your nozzle.

Method 2

If you have larger, stubborn residue on the outside of your 3D printer nozzle, I would recommend heating your nozzle up to around 200°C, then using needle nose pliers to pick the plastic off.

3D Printer Nozzle Cleaning Brush

For rigorous cleaning of your nozzle, I would suggest you buy a good quality cooper wire toothbrush, which will help you get all the dust particles and other residues from the nozzle.

But remember, always heat the nozzle before using the brush to get it to the temperature where it was in its last printing session.

A solid nozzle cleaning brush from Amazon is the BCZAMD Copper Wire Toothbrush, specially made for 3D printer nozzles.

You can use the tool even if the wires get deformed. The best thing about this tool is that it is very handy, and you can easily hold the brush while cleaning the surface and sides of the nozzles.

Best 3D Printer Cleaning Filament

NovaMaker Cleaning Filament

One of the better cleaning filaments out there is the NovaMaker 3D Printer Cleaning Filament, which comes vacuum-sealed with desiccant to keep it in optimal conditions. It does an amazing job cleaning out your 3D printer.

You get 0.1KG (0.22lbs) of cleaning filament. It has excellent heat stability, allowing it to have a wide range of cleaning abilities. It goes anywhere from 150-260°C without giving you issues.

The slight viscosity of this cleaning filament means you can take easily take residual material out of the nozzle without it jamming inside.

Using cleaning needles alongside this is a great solution to prevent your nozzle clogging while transitioning between lower and higher temperature materials.

It is recommended to use the cleaning filament at least every 3 months for regular maintenance and unclogging procedures.

eSun Cleaning Filament

You can use the eSUN 3D 2.85mm Printer Cleaning Filament, which has a size of 3mm and gets easily inside the nozzle.

The good thing about it is that it possesses a certain level of adhesive quality, which clears out everything and will not clog the extruder during cleaning. You can use it for cleaning the nozzle and extruder both before and after the printing.

It has a wide cleaning range of almost 150 to 260 degrees Celsius that allows you to take up the temperature to a good level to let the particles inside the printer soften up for the removal.

How to Use 3D Printer Cleaning Filament

Cleaning filament can be used in your 3D printer to do cold and hot pulls which are popular methods widely used by 3D printer users.

A hot pull is perfect for getting those large carbonized materials out of your nozzle when there is a serious blockage. A cold pull is where you remove the remaining smaller residue so that your nozzle is completely cleaned up.

To use your 3D printer cleaning filament, load the filament as you usually would into your 3D printer until it has replaced your old filament and actually extrudes from the nozzle.

Change the extruder temperature to make sure it stays hot, for a temperature between 200-230°C. Then extrude a few centimeters of filament, wait, then extrude more a few times.

After this, you can remove the cleaning filament, load up the filament you want to print with, then make sure the cleaning filament is completely displaced after starting your next print.

This filament can be used to clean the printers print core by applying hot and cold pulls. Hot pulls are used to get the biggest parts of carbonized material out of the print core and are highly recommended when the print core is clogged.

With a cold pull, the remaining small particles will be removed, ensuring the print core is completely clean.

How to Clean a Hotend Tip Covered in PLA or ABS?

You can use a failed ABS print, push it onto the tip and push it straight up. But first, you have to heat the hotend to almost 240°C, and then when you have applied the failed ABS print, let the hotend cool down for a minute.

After this, pull or twist off the piece of ABS, and you will get a clean hotend.

If you are having trouble with cleaning the hotend covered in PLA, you can follow this procedure, which I am going to explain.

You have to first heat the hotend to a temperature of 70°C, and then you need to grab the PLA from any side with a pair of tweezers, or you can use pliers but carefully.

The best thing about PLA is that it gets soft on high temperature and makes it easy to be pulled off, leaving the hotend clean.

Cleaning an Ender 3 Nozzle Properly

Method 1

Cleaning Ender 3 nozzle would require you to open up its fan shroud and remove it from its place to get a more clear view of the nozzle. Then, you can use an acupuncture needle to break the particles which are stuck in the nozzle.

This would help you to make the particle break into small pieces. Then you can use a filament from the top size of the nozzle from the extruder part and enter it from there until it comes out with all those particles.

Method 2

You can also remove the nozzle completely from the printer and then clean it by heating it at a high temperature with a hotgun to let the particles soften up and then use a filament, let it stay inside for a while and then do a cold pull.

Keep doing this cold pull until the filament starts coming out clean.

How Often Should I Clean My 3D Printer Nozzle?

You should clean your nozzle as and when it gets fairly dirty or at least every 3 months for regular maintenance. If you don’t clean your nozzle too often, it’s not the end of the world, but it does help to give your nozzle more life and durability.

I’m sure there are plenty of people who rarely clean their nozzles and things are still working fine.

It depends on how often you print with your 3D printer, what nozzle material you have, what 3D printer materials you are printing with, and your other maintenance.

Brass nozzles can last a very long time if you exclusively print with PLA at low temperatures and have your bed leveling methods perfect.

3d printer maintenance

3DPrintStory 3D printing process 3d printer maintenance

3d printer, like any other piece of equipment, needs maintenance. And if you haven’t done it until today, it’s better to start right after reading this short article.

And if you haven’t done it until today, it’s better to start right after reading this short article.

I won't categorize maintenance into daily, weekly, or monthly because each of you types at a different rate. For someone, a 3d printer can stand turned off all week, while for someone it works 24 hours a day. Therefore, to a greater extent, you yourself have to determine how often you will carry out maintenance on your 3d printer.

Have you ever heard of preventive maintenance? This is one of the pillars of the concept of general equipment care, the essence of which is that after the equipment has been used for a certain period of time, preventive inspections, various types of scheduled repairs and revisions are made, excluding the possibility of equipment operation in conditions of progressive wear. So you and I, as owners of one piece of equipment or a whole fleet of 3d printers, must track down the precursors of major malfunctions - whether it is extraneous noise during printer operation or an unscrewed screw.

Technical inspection of the 3d printer

Therefore, the first thing we will talk about today is the control and inspection of the 3d printer components to identify deviations that lead to breakdowns, which in turn can lead to equipment downtime. What should you pay attention to first of all?

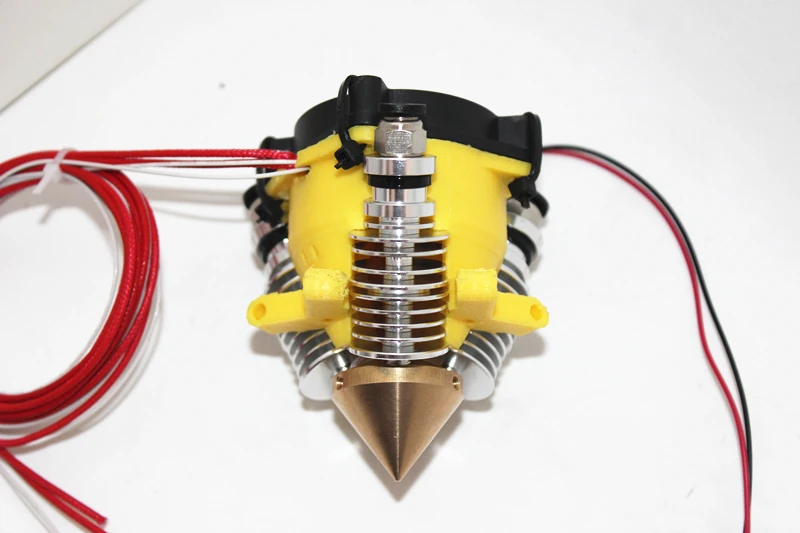

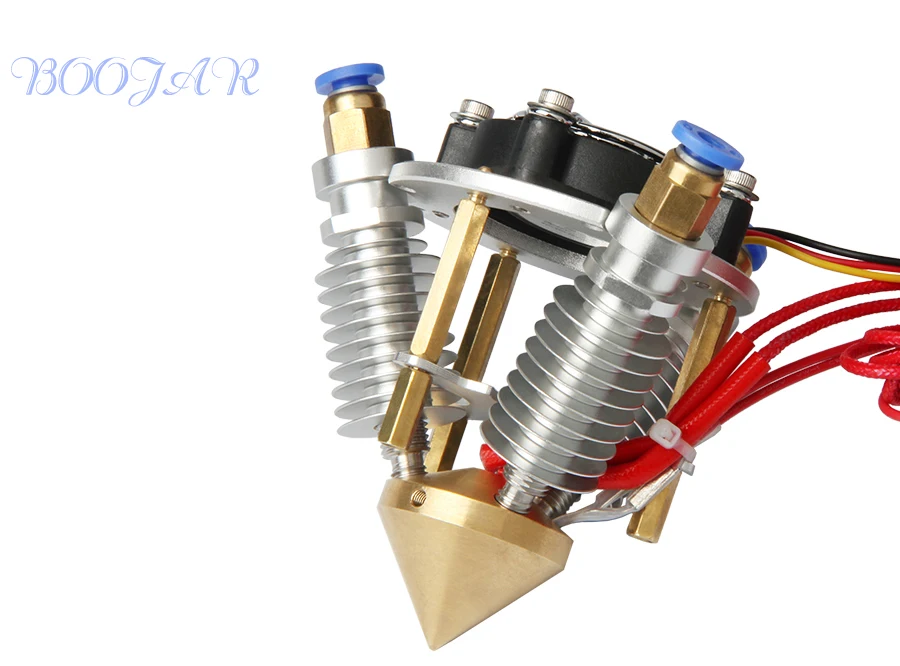

Extruder. It is worth checking it for leakage of the plastic melt and the nozzle-cylinder interface, so the accumulation of polymeric material can form either from above or below the heating block. In case of detection, at least pull the nozzle, or rather, disassemble and clean all elements from polymer material. By noticing the leaking nozzle in time, we can prevent the failure of the thermistor heaters.

From the extruder, move on to the inspection of the kinematics. First to the shafts. Be sure to control the appearance of wear on the shafts, as it often happens that the user does not notice that the linear bearing is wedged, and corresponding marks, scuffs appear on the shafts. Up to a certain point, or rather, depth, they can be removed by grinding, and then not. Therefore, the sooner such wear is diagnosed, and the linear bearing is replaced, the less likely it is to get an expensive shaft replacement.

Up to a certain point, or rather, depth, they can be removed by grinding, and then not. Therefore, the sooner such wear is diagnosed, and the linear bearing is replaced, the less likely it is to get an expensive shaft replacement.

Just like shafts, belts are subject to wear. This can be either wear on the working surface of the belt or damage to the cord. In any case, during the inspection, check the condition and tension of the belt. Why tension? Because once you pull the belt, you can break the integrity of its cord. Naturally, such a belt will need to be changed. If you notice the wear of the belt in time, you will have time to order it and the 3d printer will not stand idle, waiting for the spare part to arrive.

Speaking of belts, it's worth checking stepper motor pulleys along with them. Namely, whether there is no idle rotation. If necessary, tighten the lock screws. Always check the kinematics of the 3d printer for any play. For the most part, play will affect the quality of the surface of the printed product, but this check should not be neglected. Take the carriage and move your hands to a break, try to pull it. If you do not notice characteristic knocks, then everything is in order. If you notice, then check the tension of the screws. Axes misalignment during 3D printing can also lead to both linear bearing failure and high shaft wear.

Take the carriage and move your hands to a break, try to pull it. If you do not notice characteristic knocks, then everything is in order. If you notice, then check the tension of the screws. Axes misalignment during 3D printing can also lead to both linear bearing failure and high shaft wear.

| |

You should also check if the fan for blowing the 3d printer board and the extruder heatsink is working. I understand that in some models of 3d printers, the manufacturer did not worry about ease of maintenance, but this should not be neglected, as overheating can lead to failure of the stepper motor drivers.

If you have something to add to the inspection list, write about it in the comments, and we will go directly to maintenance.

3d printer maintenance

What actually needs to be serviced?

Let's start with cleaning. More specifically, from cleaning the filament feed mechanism. There are several ways to get it contaminated. You can get rid of one of them very easily by installing a so-called filament filter. It is a box with a sponge placed inside, which is designed to clean the bar from accumulated dust and other contaminants. A very simple thing. Link to the 3d model on Thingiverse. If you have a bowden extruder, you can clean the filament feed tube from dust by simply blowing it.

You can get rid of one of them very easily by installing a so-called filament filter. It is a box with a sponge placed inside, which is designed to clean the bar from accumulated dust and other contaminants. A very simple thing. Link to the 3d model on Thingiverse. If you have a bowden extruder, you can clean the filament feed tube from dust by simply blowing it.

Your 3d printer table also needs to be kept clean. I periodically wipe it with a cloth dipped in acetone. It is better to do this procedure with a glove in order to avoid skin contact with acetone.

The table lift screw also needs to be cleaned of dust and dirt before being lubricated. As for the lubricant itself, I read a lot of opinions on this matter and came to the conclusion that the best choice is ordinary Litol-24. I use it both for lubricating screws and for lubricating linear bearings. We lower the table down, apply lubricant to the screw above the nut, then raise the table to the upper end position and apply lubricant from below the nut and drive the table again. Then, if excess grease has formed, remove them.

Then, if excess grease has formed, remove them.

Also take the time to extruder. Clean the model fan and radiator from dust and dirt. The best way to do this is with a vacuum cleaner. In my 3d printer, the manufacturer did not bother about the ease of removing the extruder, so this procedure is quite time consuming.

Pay attention to the shafts. If your linear bearing seals are working well, then you should see a buildup of dust mixed with grease in the end positions of the axles. It is worth deleting it as it accumulates. The easiest way to do this is with a paper towel.

Moving on to the lubrication of linear bearings. In theory, they should be stuffed with the right amount of grease at the factory. Moreover, this basic packing is calculated for the entire life of the bearing, but whether the Chinese do it or not is unknown. When I bought linear bearings, I found that they are only covered with a liquid lubricant to prevent corrosion, so it’s better to remove and stuff the same lithol inside, because it doesn’t make sense to smear it on the guides, since the seals will simply remove it and nothing will get inside.

Do not neglect the maintenance of your 3d printer and it will serve you faithfully for a long time! I hope the material was useful to you.

3D Printer Maintenance / Articles

Share:

Source:

ATECO - specialized lubricant for 3D printers

Such machines require some maintenance from time to time, which may not be obvious to a 3D printer newbie. It is recommended that the printer be serviced at least once a month. With intensive use (for example, 24/7 printing), perhaps even more often.

This short post has organized and selected the main activities that will allow you to keep the printer in proper quality.

Check bolt connections Clean fans and electronics Check belt tension

Lubricate and clean guides and guide pins Clean glass table Clean nozzle Base alignment

Keys M6, M8 and M10

Klyuchishthniki M2 and M3 Spatula Brush and brush

Wire brush lubricant (I, for example, use silicone lubricant)

needles for cutting nozzles (are included . Instead, with less convenience, ordinary small diameter needles can be used

Instead, with less convenience, ordinary small diameter needles can be used

Paper towels

1. Check bolted connections

First of all, unplug your printer. This will allow you to move the extruder along the axes without the risk of damaging the motors, as well as eliminating potential hazards when cleaning electronics.

Printing vibrations loosen bolted connections. It is logical that in order to maintain high print quality, the nuts sometimes need to be tightened.

It's best to start with the bolts that hold the base:

Then check the screws holding the motors:

With the base and motors out of the way, check the bolts on the X-axis:

Finally, make sure that the pulleys on the motor shafts are properly tightened:

20002 Fan blades - a place where dust constantly accumulates. As a rule, this leads to a deterioration in the cooling capacity of the fan, which, in turn, leads to sad consequences for the electronics.

As a rule, this leads to a deterioration in the cooling capacity of the fan, which, in turn, leads to sad consequences for the electronics.

First remove the fan from the plastic frame - this will make it much easier to clean. Then, using a brush, clean the blades on both sides.

Now it's the turn of the electronics. There is no need to disconnect all the wires, but when cleaning, be extremely careful and careful not to accidentally damage any element of the board.

Now clean the extruder fans. To do this, move the carriage to the extreme right position and carefully remove the left extruder. Remove the radiator along with it. Clean them with a brush in the usual way.

Before you go further with the brush, pay attention to the inside of the extruder (since you removed the fan anyway). Most likely it will be in the dust or the remnants of the material, mercilessly ground by the pressure wheel. If so, clean up the area with a small brush:

If so, clean up the area with a small brush:

Now that you have cleaned the inner chamber, return the fan and heat sink to their rightful place. Remember that the fan with the sticker must face towards the extruder, otherwise the airflow will go in the wrong direction. The front fan does not need to be removed for cleaning - just gently clean it between the blades.

3. Belt tension check

Using the printer for a long time can cause the belt tension to loosen significantly. Check - if so, then just tighten the tensioner bolts:

4. Lubrication and cleaning of guides and studs

Both the guides and studs in the Z axis should always be clean and well lubricated - this is almost guaranteed to get rid of unnecessary vibrations and annoying squeaks.

Let's start with the guides. First, clean them with a paper towel. After removing all the dirt, take a clean towel and, dropping lubricant on it, wipe the smooth guides properly.

After removing all the dirt, take a clean towel and, dropping lubricant on it, wipe the smooth guides properly.

After the smooth guides have been cleaned and oiled, brush over the running pins. Then lubricate all the nuts on the Z axis transmission rod. Don't forget the cylindrical flanges as well.

5. Glass table cleaning.

If you use varnish as an adhesion promoter, you may notice that over time the old layers of varnish combine into bizarre bumps that can seriously damage the first print layer. Also, sometimes pieces of plastic from a previous print (for example, raft elements) may remain on the platform.

The easiest way to clean a glass table is to place it under running hot water and work with a spatula for a while. The table itself, of course, must first be removed from the printer.

6 . Nozzle cleaning.

A step that is considered quite dangerous - hundreds of thrown out “hot ends” are proof of this.

The hot end is the part of the extruder where the plastic filament is directly heated and extruded. Sometimes, for various reasons, the nozzle becomes clogged, which leads to incorrect operation of the printer.

The first thing to do is unscrew the protective element surrounding the hotend (relevant for the gefeshi). Then, power on:

Now, using the LCD screen, return the carriage to the “home” position. (Menu > Control > Move axis > Auto home).

After that, you need to move the extruder to the point 100.0 mm X and 160.0 mm Z. This position provides the most free access to the hot end. This is done effortlessly through Jog mode in the same menu as auto home.

Now we need to unload the filament (Menu > Control > Filament > Unload).

At this point, the nozzle starts to heat up, so be careful not to touch it to avoid injury.

After removing the filament, insert the cleaning needle into the nozzle and move it up and down for a few seconds. The extruder itself must remain warm. These movements allow you to clear a possible blockage of plastic.

Now you need to clean the tip of the hot end from the outside. Taking extreme care not to damage the thermistor cable or the ceramic heater, clean the nozzle with a wire brush.

After you have finished servicing, cool the extruder (for example, by turning off the mains). After the temperature drops to ~40 degrees, return the protective cover to its place.

7 . Base alignment.

Platform calibration is a familiar operation. If for some reason you do not know how to calibrate a table for Hephaestos, you can always look at the tutorial from the manufacturer.

Final.

That's the end of our note! After these simple steps, your printer will be ready for a new battle, and regular maintenance will allow it to delight you with high-quality printing for a long time to come.