3D printing standards

A guideline for 3D printing terminology in biomedical research utilizing ISO/ASTM standards | 3D Printing in Medicine

- Review

- Open Access

- Published:

- Amy E. Alexander1,

- Nicole Wake ORCID: orcid.org/0000-0002-8441-60592,3,

- Leonid Chepelev4,

- Philipp Brantner5,

- Justin Ryan6 &

- …

- Kenneth C. Wang7,8

3D Printing in Medicine volume 7, Article number: 8 (2021) Cite this article

-

3480 Accesses

-

16 Citations

-

6 Altmetric

-

Metrics details

Abstract

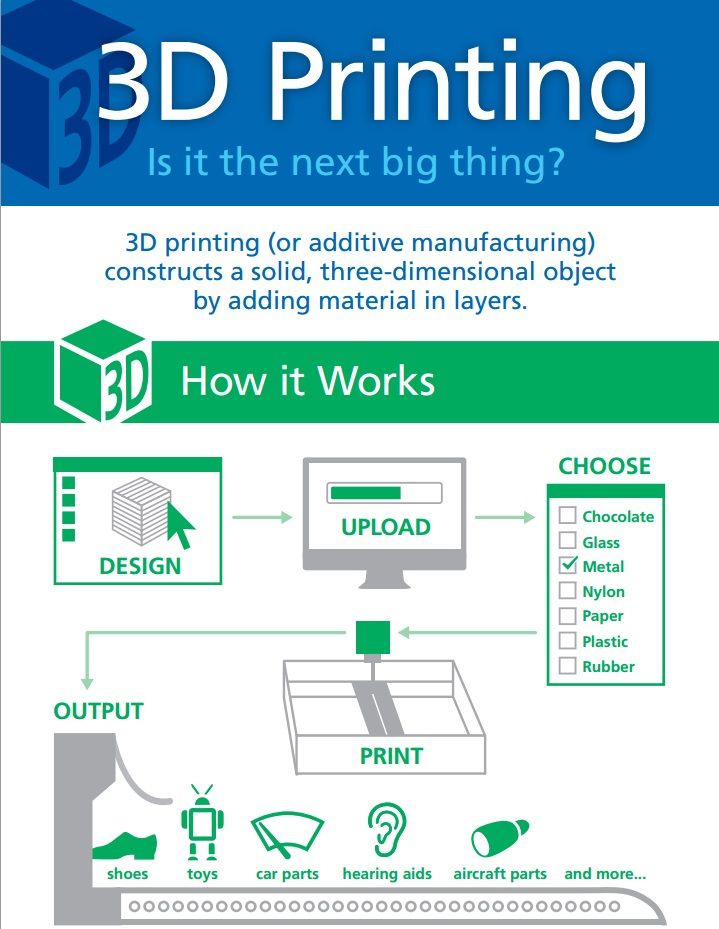

First patented in 1986, three-dimensional (3D) printing, also known as additive manufacturing or rapid prototyping, now encompasses a variety of distinct technology types where material is deposited, joined, or solidified layer by layer to create a physical object from a digital file. As 3D printing technologies continue to evolve, and as more manuscripts describing these technologies are published in the medical literature, it is imperative that standardized terminology for 3D printing is utilized. The purpose of this manuscript is to provide recommendations for standardized lexicons for 3D printing technologies described in the medical literature. For all 3D printing methods, standard general ISO/ASTM terms for 3D printing should be utilized. Additional, non-standard terms should be included to facilitate communication and reproducibility when the ISO/ASTM terms are insufficient in describing expository details. By aligning to these guidelines, the use of uniform terms for 3D printing and the associated technologies will lead to improved clarity and reproducibility of published work which will ultimately increase the impact of publications, facilitate quality improvement, and promote the dissemination and adoption of 3D printing in the medical community.

Introduction

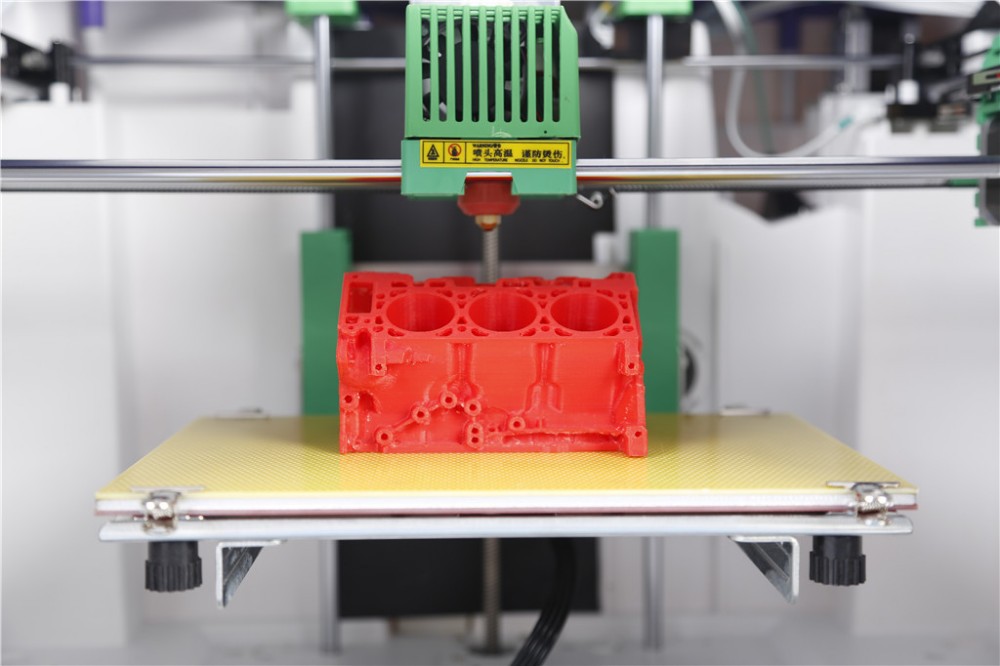

Three-dimensional (3D) printing, also known as additive manufacturing or rapid prototyping, refers to a process of creating a physical object from a 3D digital model, typically by laying down or solidifying a material layer by layer in succession. First reported in 1986 [1], 3D printing now comprises many distinct printing technologies used in a wide range of industries. With this growth has come a proliferation of terms used to refer to 3D printing technologies, where some of these terms are commercial trademarks, non-standard terms, and/or poorly defined terms.

First reported in 1986 [1], 3D printing now comprises many distinct printing technologies used in a wide range of industries. With this growth has come a proliferation of terms used to refer to 3D printing technologies, where some of these terms are commercial trademarks, non-standard terms, and/or poorly defined terms.

The need for standardized terminology has long been recognized in clinical research and medical practice, because a common vocabulary promotes clarity and reproducibility. Within imaging, standard lexicons have been developed for a variety of imaging technologies [2,3,4] as well as for the clinical interpretation of imaging exams [5,6,7,8].

Standard terminology in the domain of clinical 3D printing has been an important goal since the founding of the journal 3D Printing in Medicine [9], and a comprehensive analysis of the literature led to the recommendation that the term “3D printing” be adopted as an inclusive term covering technologies also described with other terms such as “rapid prototyping” and “additive manufacturing” [10]. Recent work by the Radiological Society of North America (RSNA) has brought 3D printing terms to the RadLex project, a radiological ontology for use in reporting, decision support, data mining, education, and research [11].

Recent work by the Radiological Society of North America (RSNA) has brought 3D printing terms to the RadLex project, a radiological ontology for use in reporting, decision support, data mining, education, and research [11].

As 3D printing technologies continue to evolve, the importance of standard terminology increases. An analogous situation may be found in the development of magnetic resonance imaging (MRI). As MRI became more commonplace and the term “nuclear” was dropped from the lexicon, leaders and professional societies recognized the need to establish a standard technical language for these techniques [12, 13]. Similarly, promoting a standard lexicon in the domain of 3D printing will serve to enhance work in this area in many ways. Use of uniform terms for indexing of the literature will lead to improved discoverability of related work, and also improved clarity in the exchange of ideas, techniques and results. The most immediate need is for standardized terms to refer to the different types of 3D printing technologies.

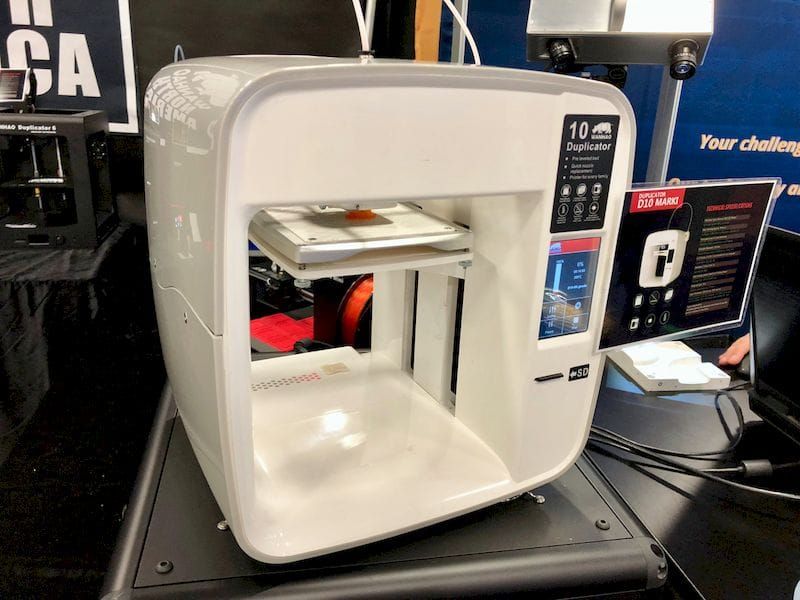

Current state

As clinicians, researchers, and scientists around the world publish their work in clinical 3D printing, it is clear that the usage of terms varies widely. Some authors utilize common trademarked terms for describing a print technology (e.g., fused deposition modeling, or “FDM”, is a trademark of Stratasys, not a general technology descriptor) [14]. Other authors use less-common synonyms for key terms (e.g., “rapid prototyping” instead of “3D printing”). The journal 3D Printing in Medicine and its articles can be made more consistent through the adoption of standard nomenclature.

There are existing standards for 3D printing terminology. The foremost standard is the “ISO/ASTM 52900 Standard Terminology for Additive Manufacturing – General Principles – Terminology”, which replaced “ASTM 52900:2015 Standard Terminology for Additive Manufacturing Technologies” in March of 2020 [15]. With regard to 3D printing technologies, this standard defines seven distinct types of 3D printing processes. Courses like MIT’s Additive Manufacturing for Innovative Design and Production have adopted this nomenclature [16]. In addition, accrediting bodies such as SME (formerly the Society of Manufacturing Engineers) rely on this nomenclature to certify individuals to work competently in this space through the SME Additive Manufacturing Certification [17]. Adhering to such standards is a natural way to extend the consistency of the published literature.

Courses like MIT’s Additive Manufacturing for Innovative Design and Production have adopted this nomenclature [16]. In addition, accrediting bodies such as SME (formerly the Society of Manufacturing Engineers) rely on this nomenclature to certify individuals to work competently in this space through the SME Additive Manufacturing Certification [17]. Adhering to such standards is a natural way to extend the consistency of the published literature.

Table 1 lists the seven standard terms for 3D printing technology types described by ISO/ASTM 52900 along with several additional fields. The first column shows the ISO/ASTM term itself. For each such term, one or more additional terms related to the standard term are shown in the second column. These additional terms include commercial examples of the given technology type, and non-standard synonyms or subtypes of the technology type. A brief description of each standard term is provided by the authors in the third column for quick reference. However, readers are encouraged to review ISO/ASTM 52900 for formal definitions. The final column lists the associated RadLex identifier for each standard term.

However, readers are encouraged to review ISO/ASTM 52900 for formal definitions. The final column lists the associated RadLex identifier for each standard term.

Full size table

Evaluation

In order to evaluate terminology usage, a review of the 61 articles published in 3D Printing in Medicine, Springer Nature, from its inception through May 2020 was performed [18]. First, titles were assessed for the presence of the term “3D printing” and any synonyms. The published papers were also reviewed to determine if “3D printing” and ISO/ASTM generalized standard terms were used in the text of the manuscript; if not, any alternative terms utilized were noted. 49 (80.3% of all published manuscripts) of these referenced “3D printing” in the title; and 58 manuscripts (95.1%) mentioned “3D printing” in the body of the manuscript at least once. Other common synonyms included “additive manufacturing,” “modeling,” and “rapid prototyping.” With regard to 3D printing technologies, these papers commonly refer to specific machines without identifying a technology type. These papers also commonly use trademarked terms such as “polyjet,” “stereolithography,” and “fused deposition modeling.” In some cases, descriptions of material properties (e.g. “multicolor”) are presented as a proxy for the printing technology used. Only 6 (9.8%) manuscripts reference specific 3D printing technologies using ISO/ASTM standardized nomenclature. The inconsistent use of terminology illustrated here creates an impediment for researchers.

49 (80.3% of all published manuscripts) of these referenced “3D printing” in the title; and 58 manuscripts (95.1%) mentioned “3D printing” in the body of the manuscript at least once. Other common synonyms included “additive manufacturing,” “modeling,” and “rapid prototyping.” With regard to 3D printing technologies, these papers commonly refer to specific machines without identifying a technology type. These papers also commonly use trademarked terms such as “polyjet,” “stereolithography,” and “fused deposition modeling.” In some cases, descriptions of material properties (e.g. “multicolor”) are presented as a proxy for the printing technology used. Only 6 (9.8%) manuscripts reference specific 3D printing technologies using ISO/ASTM standardized nomenclature. The inconsistent use of terminology illustrated here creates an impediment for researchers.

Recommendations

In order to promote consistency in the literature, the term “3D printing” should be used in manuscripts instead of synonyms such as “additive manufacturing” or “rapid prototyping. ” Similarly, authors should take note of the standard general ISO/ASTM terms for 3D printing technologies and apply these as appropriate. Any research communication or statement pertaining to the set of technologies encompassed by a given standard ISO/ASTM term should always utilize the appropriate standard term. For example, a review broadly discussing vat photopolymerization technologies should use the standard term “vat photopolymerization” rather than terms that may either denote a specific implementation of a more general technology or act as incomplete synonyms due to an inappropriately narrow reference to a set of specific patented technologies, such as stereolithography (SLA), continuous liquid interface production (CLIP), or direct light processing (DLP). In this setting, the use of non-standard terms hinders research discoverability and inappropriately constricts the scope of the communication. In all cases, terms identifying specific 3D printing technology implementations should be accompanied by the corresponding general standard ISO/ASTM technology type with its first mention and where appropriate throughout the manuscript.

” Similarly, authors should take note of the standard general ISO/ASTM terms for 3D printing technologies and apply these as appropriate. Any research communication or statement pertaining to the set of technologies encompassed by a given standard ISO/ASTM term should always utilize the appropriate standard term. For example, a review broadly discussing vat photopolymerization technologies should use the standard term “vat photopolymerization” rather than terms that may either denote a specific implementation of a more general technology or act as incomplete synonyms due to an inappropriately narrow reference to a set of specific patented technologies, such as stereolithography (SLA), continuous liquid interface production (CLIP), or direct light processing (DLP). In this setting, the use of non-standard terms hinders research discoverability and inappropriately constricts the scope of the communication. In all cases, terms identifying specific 3D printing technology implementations should be accompanied by the corresponding general standard ISO/ASTM technology type with its first mention and where appropriate throughout the manuscript. For example, consider a manuscript evaluating the relative accuracy of printers utilizing the CLIP subtype of the broader vat photopolymerization technology type. It would be inappropriate for such a manuscript to assert that observations derived using CLIP printers are valid for all vat photopolymerization printers, and the more specific term to include the trade name of the 3D printer should be used so that the readership will know the name of the printer used. However, it would still be important for authors to note that CLIP is a subtype of the standard technology type vat photopolymerization.

For example, consider a manuscript evaluating the relative accuracy of printers utilizing the CLIP subtype of the broader vat photopolymerization technology type. It would be inappropriate for such a manuscript to assert that observations derived using CLIP printers are valid for all vat photopolymerization printers, and the more specific term to include the trade name of the 3D printer should be used so that the readership will know the name of the printer used. However, it would still be important for authors to note that CLIP is a subtype of the standard technology type vat photopolymerization.

Where the intent of a research communication is to refer to a specific set of printing technologies, non-standard commercial or non-commercial terms should be used to facilitate communication and reproducibility. The purpose is to be descriptive and consistent, as opposed to supporting or marketing any particular product. 3D printing is inherently different than the “MRI” example alluded to above because technologies (hardware, software, materials) use different physics to create the 3D printed part. If an anatomic model or an anatomic guide is printed on a Form3 printer, the generalized standard term is vat photopolymerization and the Form3 printer should be noted. For example, a model of the left atrial appendage was printed using vat photopolymerization (Form3, Formlabs, Cambridge, MA). Table 2 describes additional examples of 3D printer referencing. The Radiological Society of North America-American College of Radiology (RSNA-ACR) 3D printing registry includes a data dictionary and the registry recognizes via drop-down menus 108 3D printers across 13 manufacturers with their respective generalized standard terms [19, 20].

If an anatomic model or an anatomic guide is printed on a Form3 printer, the generalized standard term is vat photopolymerization and the Form3 printer should be noted. For example, a model of the left atrial appendage was printed using vat photopolymerization (Form3, Formlabs, Cambridge, MA). Table 2 describes additional examples of 3D printer referencing. The Radiological Society of North America-American College of Radiology (RSNA-ACR) 3D printing registry includes a data dictionary and the registry recognizes via drop-down menus 108 3D printers across 13 manufacturers with their respective generalized standard terms [19, 20].

Full size table

In accordance with widely established publication practices, the use of commercial trademarks in publication titles and manuscript text is permitted to facilitate communication. Numerous examples of such utilization of commercial trademarks exist. For example, within medical imaging literature, numerous publications incorporate names of trademarked MRI sequences within titles and article text [21,22,23,24,25]. However, the use of any subjective and/or scientifically unsubstantiated positive or negative language in relation to commercial or trademarked product descriptors is unacceptable; reviewers and editors should recognize such language and require that manuscripts be edited accordingly. Authors should avoid subjective adjectives that are not supported by data and make changes when requested. For example, a commercial technology or product should not be described as ‘user-friendly’, ‘accurate’, or ‘reliable’ outside of the context of objective assessments establishing such descriptors.

Numerous examples of such utilization of commercial trademarks exist. For example, within medical imaging literature, numerous publications incorporate names of trademarked MRI sequences within titles and article text [21,22,23,24,25]. However, the use of any subjective and/or scientifically unsubstantiated positive or negative language in relation to commercial or trademarked product descriptors is unacceptable; reviewers and editors should recognize such language and require that manuscripts be edited accordingly. Authors should avoid subjective adjectives that are not supported by data and make changes when requested. For example, a commercial technology or product should not be described as ‘user-friendly’, ‘accurate’, or ‘reliable’ outside of the context of objective assessments establishing such descriptors.

Titles and content

Manuscripts should use the term “3D printing” in the title and in the main body of the text, instead of synonyms such as “additive manufacturing,” “rapid prototyping,” or “3D manufacturing. ” This use represents a divergence from the ISO/ASTM standard which uses the term “additive manufacturing”. “3D printing” has far exceeded other terms with regard to adoption and use by the global medical and non-medical community. This descriptivist approach to promoting “3D printing” above other terms will enhance indexing and searching capabilities of readers.

” This use represents a divergence from the ISO/ASTM standard which uses the term “additive manufacturing”. “3D printing” has far exceeded other terms with regard to adoption and use by the global medical and non-medical community. This descriptivist approach to promoting “3D printing” above other terms will enhance indexing and searching capabilities of readers.

As detailed above, manuscripts using non-standard terms and trademarks (e.g., “fused deposition modeling”, “polyjet”, “multi jet fusion”) should use the ISO/ASTM term instead (e.g., “material extrusion”, “material jetting”, “powder bed fusion” respectively) in the title as needed and throughout the manuscript. In cases where reference to a more specific commercial term or other non-standard term constitutes an important element of the work presented, such terms should be used in conjunction with the relevant ISO/ASTM term (Table 3).

Table 3 Examples of title and content corrections to comply with the recommendations hereinFull size table

Authors are recommended to specifically cite the technologies, the printers (make, model), and types of printing materials (feedstock) and other post-processing consumables utilized in the research reported. However, given the rapid and on-going evolution of printers, feedstock materials, and consumables, authors should expect that readers may be unfamiliar with the specific technologies, brands and machines mentioned in a given manuscript. It is suggested that authors include the generalized ISO/ASTM nomenclature at least once per technology reported in a manuscript.

However, given the rapid and on-going evolution of printers, feedstock materials, and consumables, authors should expect that readers may be unfamiliar with the specific technologies, brands and machines mentioned in a given manuscript. It is suggested that authors include the generalized ISO/ASTM nomenclature at least once per technology reported in a manuscript.

Descriptions of material properties should not be used as proxies for 3D printing technologies. Rather, materials and technologies should be described separately.

Conclusions

By following these recommendations, authors working in medical 3D printing will improve the clarity and reproducibility of their work. The expanding literature in this field will be easier to search. Researchers and clinical users will have enhanced capabilities to interpret published results. These benefits will improve the value of publications, facilitate quality improvement, and promote the dissemination and adoption of 3D printing in the medical community.

References

Hull CW. Apparatus for production of three-dimensional objects by stereolithography [Internet]. 1986 [cited 2016 Aug 7]. Available from: http://www.google.com/patents/US4575330

AAPM Working Group on Standardization of CT Nomenclature and Protocols. AAPM CT Lexicon [Internet]. The American Association of Physicists in Medicine. 2012. Available from: https://www.aapm.org/pubs/CTProtocols/documents/CTTerminologyLexicon.pdf

Wagenaar DJ, Weissleder R, Hengerer A. Glossary of molecular imaging terminology. Acad Radiol. 2001;8(5):409–20. https://doi.org/10.1016/S1076-6332(03)80549-4.

Article CAS PubMed Google Scholar

Informatics Standard Terminology [Internet]. American College of Radiology. 2020 [cited 2020 May 26]. Available from: https://www.

acr.org/Practice-Management-Quality-Informatics/Informatics/Terminology

acr.org/Practice-Management-Quality-Informatics/Informatics/TerminologyBreast Imaging Reporting & Data System [Internet]. American College of Radiology. 2013 [cited 2020 May 26]. Available from: https://www.acr.org/Clinical-Resources/Reporting-and-Data-Systems/Bi-Rads

Fardon DF, Williams AL, Dohring EJ, Murtagh FR, Gabriel Rothman SL, Sze GK. Lumbar disc nomenclature: version 2.0: recommendations of the combined task forces of the North American Spine Society, the American Society of Spine Radiology and the American Society of Neuroradiology. Spine J. 2014;14(11):2525–45. https://doi.org/10.1016/j.spinee.2014.04.022.

Article PubMed Google Scholar

Hansell DM, Bankier AA, MacMahon H, McLoud TC, Müller NL, Remy J. Fleischner society: glossary of terms for thoracic imaging. Radiology. 2008;246(3):697–722. https://doi.org/10.1148/radiol.

2462070712.

2462070712.Article PubMed Google Scholar

Lexicon Table 2020 [Internet]. American College of Radiology. 2020 [cited 2020 May 26]. Available from: https://www.acr.org/-/media/ACR/Files/RADS/LI-RADS/Lexicon-Table-2020.pdf

Rybicki FJ. 3D Printing in Medicine: an introductory message from the Editor-in-Chief. 3D Print Med. 2015;1:1.

Article Google Scholar

Chepelev L, Giannopoulos A, Tang A, Mitsouras D, Rybicki FJ. Medical 3D printing: methods to standardize terminology and report trends. 3D Print Med. 2017;3:4.

Article Google Scholar

Wang KC. Standard lexicons, coding systems and ontologies for interoperability and semantic computation in imaging. J Digit Imaging. 2018;31(3):353–60. https://doi.org/10.1007/s10278-018-0069-8.

Article PubMed PubMed Central Google Scholar

Edelman RR. The history of MR imaging as seen through the pages of radiology. Radiol Radiological Society of North America. 2014;273:S181–200.

Google Scholar

Glossary of MRI Terms [Internet]. American College of Radiology. 2020 [cited 2020 May 26]. Available from: https://www.acr.org/-/media/ACR/Files/Radiology-Safety/MR-Safety/MRGlossary.pdf

Redwood B. Additive manufacturing technologies: An overview [Internet]. 3D Hubs. 2020 [cited 2020 Sep 16]. Available from: https://www.3dhubs.com/knowledge-base/additive-manufacturing-technologies-overview/

F42 Committee. ISO/ASTM52900 Additive Manufacturing – General Principles – Terminology [Internet]. West Conshohocken, PA: ASTM International; 2015. Available from: https://www.

astm.org/Standards/ISOASTM52900.htm

astm.org/Standards/ISOASTM52900.htmAdditive Manufacturing for Innovative Design and Production [Internet]. Massachusetts Institute of Technology. 2019 [cited 2020 May 26]. Available from: https://learn-xpro.mit.edu/additive-manufacturing

Additive Manufacturing Certification [Internet]. SME. 2016 [cited 2020 May 26]. Available from: https://www.sme.org/training/additive-manufacturing-certification/

3D Printing in Medicine [Internet]. Springer Nature; Available from: https://threedmedprint.biomedcentral.com/

3D Printing Data Dictionary [Internet]. National Radiology Data Registry Support. 2020 [cited 2020 Oct 30]. Available from: https://nrdrsupport.acr.org/support/solutions/articles/11000073770-3d-printing-data-dictionary

3D Printing Registry [Internet]. American College of Radiology. [cited 2020 Oct 30]. Available from: https://www.

acr.org/Practice-Management-Quality-Informatics/Registries/3D-Printing-Registry

acr.org/Practice-Management-Quality-Informatics/Registries/3D-Printing-RegistryTsang JCH, Yip WH, Lau CSL, Li KM, Lee YYP, Wong JKT, Ahuja AT. Visualization of normal intra-parotid facial nerve on MR: BTFE or GRASS? Clin Radiol. 2009;64(11):1115–8. https://doi.org/10.1016/j.crad.2009.03.012.

Article CAS PubMed Google Scholar

Hao W, Peng W, Wang C, Zhao B, Wang G. Image quality of the CAIPIRINHA-Dixon-TWIST-VIBE technique for ultra-fast breast DCE-MRI: comparison with the conventional GRE technique. Eur J Radiol. 2020;129:109108. https://doi.org/10.1016/j.ejrad.2020.109108.

Article PubMed Google Scholar

Elster AD. Gradient-echo MR imaging: techniques and acronyms. Radiology. 1993;186(1):1–8. https://doi.org/10.1148/radiology.186.1.8416546.

Article CAS PubMed Google Scholar

Eley KA, Delso G. Automated 3D MRI rendering of the craniofacial skeleton: using ZTE to drive the segmentation of black bone and FIESTA-C images. Neuroradiology. 2020.

Sun T, Jiang L, Zhang Z, Zhang C, Zhang H, Wang G, Qian Z. Feasibility of free-breathing T1-weighted 3D radial VIBE for fetal MRI in various anomalies. Magn Reson Imaging. 2020;69:57–64. https://doi.org/10.1016/j.mri.2020.03.004.

Article PubMed Google Scholar

Download references

Acknowledgements

None.

Availability of data and material

N/A.

Funding

N/A

Author information

Authors and Affiliations

Department of Radiology, Mayo Clinic, Rochester, MN, USA

Amy E. Alexander

Department of Radiology, Montefiore Medical Center, Albert Einstein College of Medicine, 111 East 210th Street, Bronx, NY, 10467, USA

Nicole Wake

Department of Radiology, NYU Langone Health, NYU Grossman School of Medicine, Center for Advanced Imaging Innovation and Research (CAI2R) and Bernard and Irene Schwartz Center for Biomedical Imaging, New York, NY, USA

Nicole Wake

Department of Radiology, Stanford University, Stanford, CA, USA

Leonid Chepelev

Department of Radiology, University Hospital Basel, Basel, Switzerland

Philipp Brantner

3D Innovations Lab, Rady Children’s Hospital, San Diego, CA, USA

Justin Ryan

Department of Diagnostic Radiology and Nuclear Medicine, University of Maryland School of Medicine, Baltimore, MD, USA

Kenneth C.

Wang

WangImaging Service, Baltimore VA Medical Center, Baltimore, MD, USA

Kenneth C. Wang

Authors

- Amy E. Alexander

View author publications

You can also search for this author in PubMed Google Scholar

- Nicole Wake

View author publications

You can also search for this author in PubMed Google Scholar

- Leonid Chepelev

View author publications

You can also search for this author in PubMed Google Scholar

- Philipp Brantner

View author publications

You can also search for this author in PubMed Google Scholar

- Justin Ryan

View author publications

You can also search for this author in PubMed Google Scholar

- Kenneth C. Wang

View author publications

You can also search for this author in PubMed Google Scholar

Contributions

All authors contributed to manuscript writing and manuscript editing. All authors also read and approved the final manuscript.

All authors also read and approved the final manuscript.

Corresponding author

Correspondence to Nicole Wake.

Ethics declarations

Ethics approval and consent to participate

N/A.

Consent for publication

All authors provided consent for publication.

Competing interests

- Financial Disclosures related to this work: none.

- Financial and Non-Financial Disclosures not related to this work:

○ NW - In-Kind Research Support, Stratasys, Ltd. Consultant, GE Healthcare.

○ KW – Co-founder, DexNote LLC. Consultant UCSF.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated in a credit line to the data.

Reprints and Permissions

About this article

Updated Standard Provides Fundamental 3D-Printing Design Guidance to Streamline Production

Since the 1940s, engineers have used a common design language — a set of definitions, symbols and practices — to draft engineering drawings that can serve as clear manufacturing blueprints or inspection checklists.

While this system still works well for many traditional manufacturing methods, it has not equipped engineers to produce clear and consistent design documents for additive manufacturing, commonly called 3D printing. And the absence of standard methods of communication leaves room for information about 3D-printing designs to be lost in translation.

This week the American Society of Mechanical Engineers (ASME) published an updated standard — based in large part on research by the National Institute of Standards and Technology (NIST) — that includes language specifically for 3D printing. ASME’s standard, titled Y14.46 Product Definition for Additive Manufacturing, identifies important features unique to 3D printing and outlines how they should be documented.

The guidance could help engineers from a broad array of industries communicate to manufacturers, product inspectors and others more effectively. Its widespread adoption could clear a persistent roadblock to the application of 3D printing at a larger scale, unlocking the environmental and economic benefits associated with the technology.

“The industry is in a digital transformation right now, moving away from physical 2D drawings, and additive manufacturing is one of the catalysts since it requires digital 3D models,” said Fredric Constantino, an ASME project engineering adviser. “And if you’re working on one of those models, this standard will guide you in making it understandable to both 3D printers and other people.”

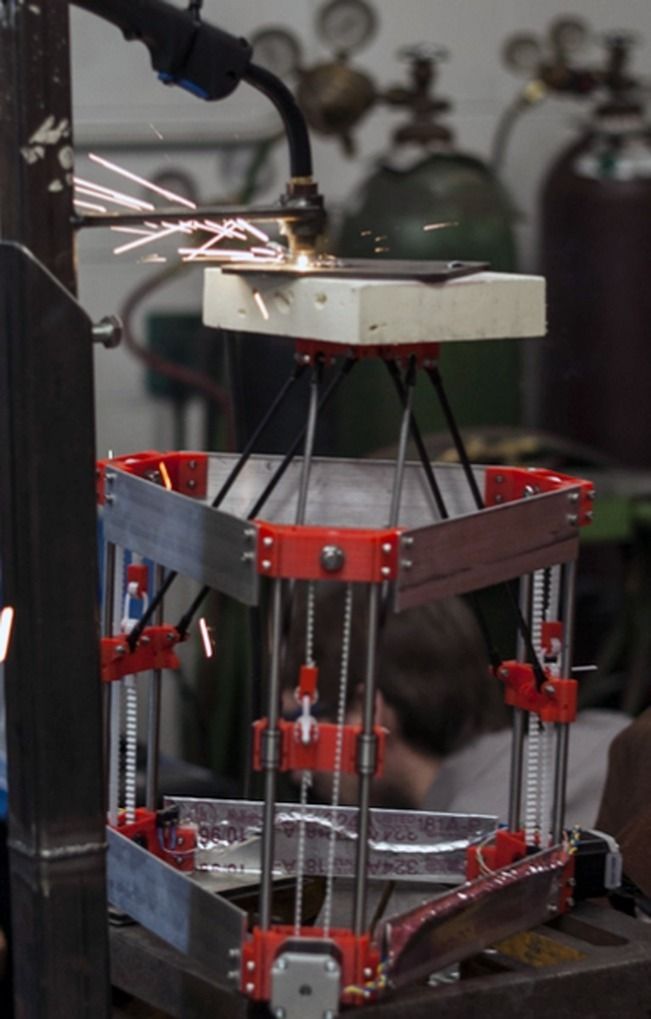

With subtractive manufacturing, a common production method, machines carve out parts from blocks of raw material according to instructions, which can be outlined in a digital or physical 2D drawing. By contrast, additively manufactured products take shape from the ground up, as printers churn out one layer at a time, fusing them into a predetermined shape that can only be dictated by a 3D model.

In addition to producing less waste than subtractive methods, 3D printing also allows for designs of higher complexity, such as those that are not completely solid, but partially hollow, filled with a meshwork that could come in many forms.

“Additive manufacturing has opened the door to a lot of unique design opportunities for engineers, but that freedom also creates challenges in communicating complex designs,” said NIST mechanical engineer Paul Witherell.

The lack of a consensus on how to convey aspects of a product related to 3D printing’s distinct capabilities has muddled communication between different organizations and created a barrier to more widespread use of the technology.

ASME responded to this roadblock in 2014, forming a committee of several dozen engineers from industry, academia and the federal government. The group, co-led by Witherell through 2019, sought to produce a uniform approach for defining 3D-printed products.

“We weren’t looking for ad hoc solutions. We were looking for solutions that could be standardized and implemented by the community to address these challenges with communication,” Witherell said. “We already know we can make good parts with additive manufacturing. Now the goal is to make lots of parts with additive manufacturing, and this is a necessary step. ”

”

The committee developed the standard over the course of several years, drawing on input from 3D-printing experts and NIST research. They also incorporated feedback on a draft version of the standard released in 2017.

With the new guidance, the group introduces concepts to address not only the nuances of 3D-printing designs themselves, such as their potentially intricate internal geometry, but the peculiarities of the printing process. Factors, including the orientation of a print and whether temporary structural supports are printed, can influence the strength, durability and other properties of the end product.

Since printers need digital product information to be presented in a particular way, the guidance also includes a section on how to package 3D-model-based data so that it’s machine readable.

Designers are meant to reference the new standard along with several previously established standards, which cover basic design considerations that are relevant to a broad array of manufacturing methods.

3D printing holds several clear advantages over more well-established manufacturing methods, but it has not been implemented nearly to the same degree. One reason for this has been the lack of a fundamental way to get design ideas across — a gap now filled due to the efforts of ASME and NIST.

If adopted by major players in manufacturing, the standard could improve communication for 3D printing, potentially making for a more sustainable and efficient manufacturing industry in the future. However, expanding the standard along the way will be key.

“Some of ASME’s other standards go 10 years, 20 years without revision, but additive manufacturing is advancing so rapidly. We aim to keep pace by adding to this standard as time goes on,” Constantino said. “We expect it to evolve quickly.”

For more information, visit ASME’s Additive Manufacturing Collection and NIST’s Measurement Science for Additive Manufacturing Program.

Manufacturing, Additive manufacturing and Standards

How are 3D printing standards improving the performance of Olympic athletes?

You are here

Home

Some of the Olympic cycling teams competing in Tokyo made extensive use of 3D scanners and 3D printers to customize equipment and fit bike parts exactly to the requirements of the athletes. The teams used 3D printers to make new bike handlebars and chains, avoiding the use of expensive tooling/moulds.

The teams used 3D printers to make new bike handlebars and chains, avoiding the use of expensive tooling/moulds.

Use of 3D printing to help athletes outside the Tokyo Olympics

To be fair, 3D printing advances are being applied to other sports disciplines as well. For athletes competing in the upcoming Paralympic Games, for example, 3D printing offers an effective way to create lighter and more aerodynamic prostheses, as well as wheelchairs.

Chevrolet is now actively outfitting its INDYCAR and NASCAR race cars with 3D printed parts including oil tanks, intake manifolds and fuel tank caps. The company uses this technology both at the stage of prototyping and at the stage of final production. London-based Cavendish Imaging is using the technology to produce protective masks that allow athletes with facial injuries (such as a broken nose/cheekbone) to continue playing. Using special software, the company 3D-scans the athlete's face and creates a model, on the basis of which the individual protective mask is printed.

This innovation reduces the athlete's downtime associated with injury and prevents further injury while healing. The company's masks have already been worn by several professional football and rugby players, including former Chelsea Football Club captain John Terry and footballer Sergio Ramos. Most bicycle helmets are made of foam, which is not completely safe when dropped. HEXR has created a new type of helmet in polyamide 11 (PA 11). The product is made by 3D printing to provide maximum personalization through 3D scanning of the shape of the head and thus increase protection.

Another sport supported by the 3D printing industry is surfing. The French startup Wyve is already developing surfboards using this technology, which allows you to create personalized products with an original translucent design. The company produces boards from recycled plastic waste, offering the end user a reliable solution with optimal performance. An original way to combine sustainability and innovation in one project. 3D printing of sports shoes may soon be on the stream. More and more sporting goods manufacturers including Adidas, Nike and Reebok are using the technology in question. A prime example is the Adidas 4D Fusion sneakers. The reason for the growth in the use of 3D printing in this area is again the possibility of personalization. 3D technologies can be used to scan a consumer's foot, develop a 3D model, and print in record time. The result is footwear adapted to the morphology, needs and style of the consumer. When it comes to ski boots, skiers often have to choose between high performance and comfort: boots that are too loose, yet more comfortable, can't provide the level of control they need. Using the latest 3D printing technology, Tailored Fits has developed ski boots that combine comfort and performance. Thanks to 3D scanning technology, Tailored Fits can 3D print the inside of the boot to suit any individual, providing a direct transfer of energy. And the buckle-free design ensures free circulation, helping you feel the slopes and keep your toes cool.

3D printing of sports shoes may soon be on the stream. More and more sporting goods manufacturers including Adidas, Nike and Reebok are using the technology in question. A prime example is the Adidas 4D Fusion sneakers. The reason for the growth in the use of 3D printing in this area is again the possibility of personalization. 3D technologies can be used to scan a consumer's foot, develop a 3D model, and print in record time. The result is footwear adapted to the morphology, needs and style of the consumer. When it comes to ski boots, skiers often have to choose between high performance and comfort: boots that are too loose, yet more comfortable, can't provide the level of control they need. Using the latest 3D printing technology, Tailored Fits has developed ski boots that combine comfort and performance. Thanks to 3D scanning technology, Tailored Fits can 3D print the inside of the boot to suit any individual, providing a direct transfer of energy. And the buckle-free design ensures free circulation, helping you feel the slopes and keep your toes cool.

The Value of 3D Printing Standards

In short, in the world of sports today, 3D printers are being used to produce a variety of objects that improve the performance of athletes: from sneakers and ski boots to surfboards and racing car parts. This technology additionally comes to the rescue in case of accidents and injuries.

International standards have played a decisive role in ensuring the reliability, efficiency and safety of 3D printers and related device components, as well as consumables used in advanced equipment in this category. A number of technical committees and subcommittees make a significant contribution to standardization work. For example, ISO / IEC STK 1, a joint technical committee of the International Electrical Commission (IEC; IEC) and the International Organization for Standardization (ISO; ISO), develops standards on the topic of 3D printing and 3D scanning , including the fundamental standards that form the basis of new documents.

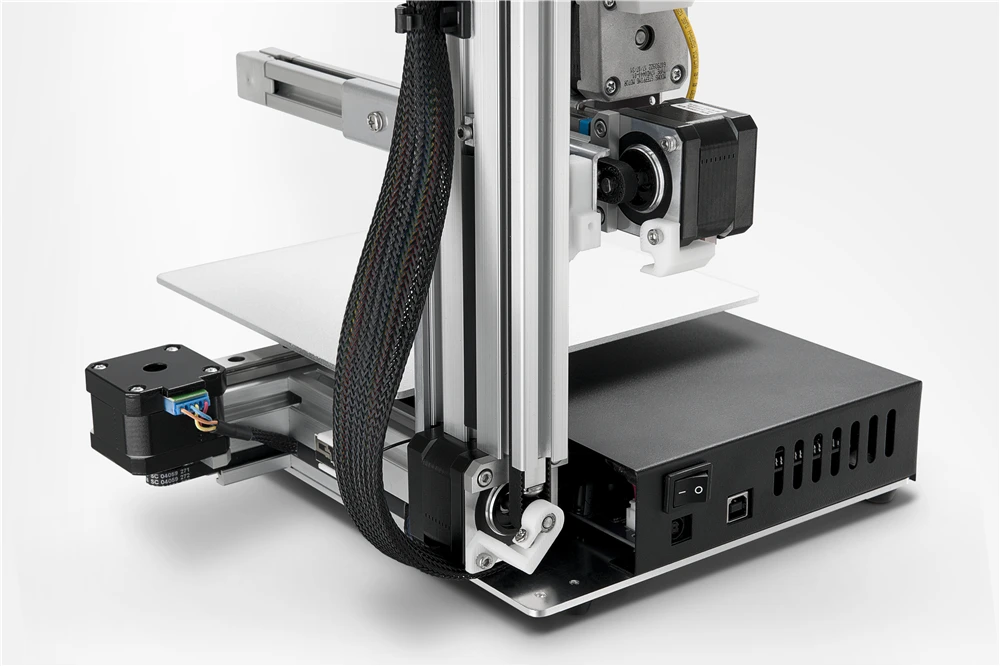

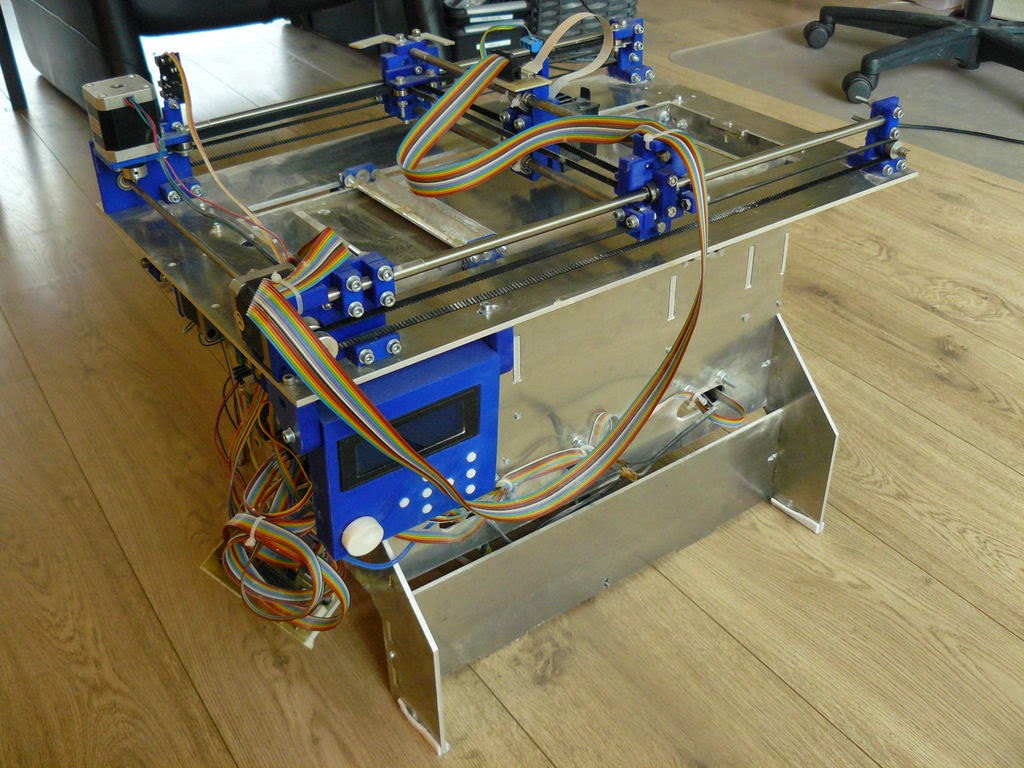

In addition, a number of IEC technical committees and subcommittees are working to determine the feasibility of preparation, development and harmonization of international standards on electrical and electronic components installed inside 3D printers. Relevant parts and components include, but are not limited to, switches and relays covered by IEC/TC 17 (Switching and control gear) and TC 121 (Switching and control gear and low voltage assemblies) technical committees. Servo drives and stepper motors used to move the extrusion head of the 3D printer / sintering laser are covered by TC 2 (Rotating Equipment) standards. Power supplies for 3D printers cover papers authored by TC 9 experts6 (Transformers, reactive coils, power supplies and their combinations).

The most important components are the various types of lasers used to sinter metals and polymers. TC 76 (Optical Radiation Safety and Laser Equipment) is the leading body for the standardization of lasers, including high-power laser equipment used in industrial facilities and research centers that serve, among other things, the 3D printing industry.

Source

Tags:

3D scanners, 3D printers, Tokyo Olympics, Application of 3D printing to help athletes, 3D scanning, new type of polyamide 11 (PA 11) helmet, 3D technology, 3D technology print, sneakers Adidas 4D Fusion

Other materials:

- How 3D printing is developing the medical industry

- Additive manufacturing of molding tooling from polymer and composite materials

- Additive technologies in the system of secondary vocational and higher education

- House on a printer: developers talk about 3D printing of new buildings in St. Petersburg

- Quality is the top priority

Attention!

We accept news, articles or press releases

with links and images. [email protected]

Requirements for 3D models for 3D printing and CNC processing

01/16/2017 in 3D modeling, Instructions

Contents:

- Introduction

- Product creation process.

- Requirements for models for 3D printing and CNC processing.

- Fixing non-critical bugs with NetFabb.

- Fixing non-critical bugs with MeshMixer.

- Fixing non-critical bugs with Materialize Magic.

- Examples of the most common errors.

Introduction.

In this article, we will talk about the basic and general parameters that a model must meet in order to obtain high-quality 3D printed products. Let's discuss common errors that occur in the process of creating three-dimensional models in terms of a high-quality polygonal mesh and how to quickly fix them. Requirements for 3D models and quality issues in terms of the accuracy of manufactured parts are described in another article: The actual size of the product after 3D printing.

The process of creating a product.

Structure of the additive manufacturing process for the production of products:

| Designer / 3Dartist | 3D printing service | Discussed errors |

1. Create a 3D model Create a 3D model | ||

| 2. Export/convert 3D model to required format | 3. Checking the model for suitability | 4. Compliance / non-compliance with the minimum allowable thicknesses. |

| 6. Preparation of control program for 3D printer (GCode) | 5. Compliance / non-compliance with the requirements for the polygonal mesh of the 3D model. | |

| 7. 3D printing process. | ||

| 9. Quality control. | 8. Post-processing process. |

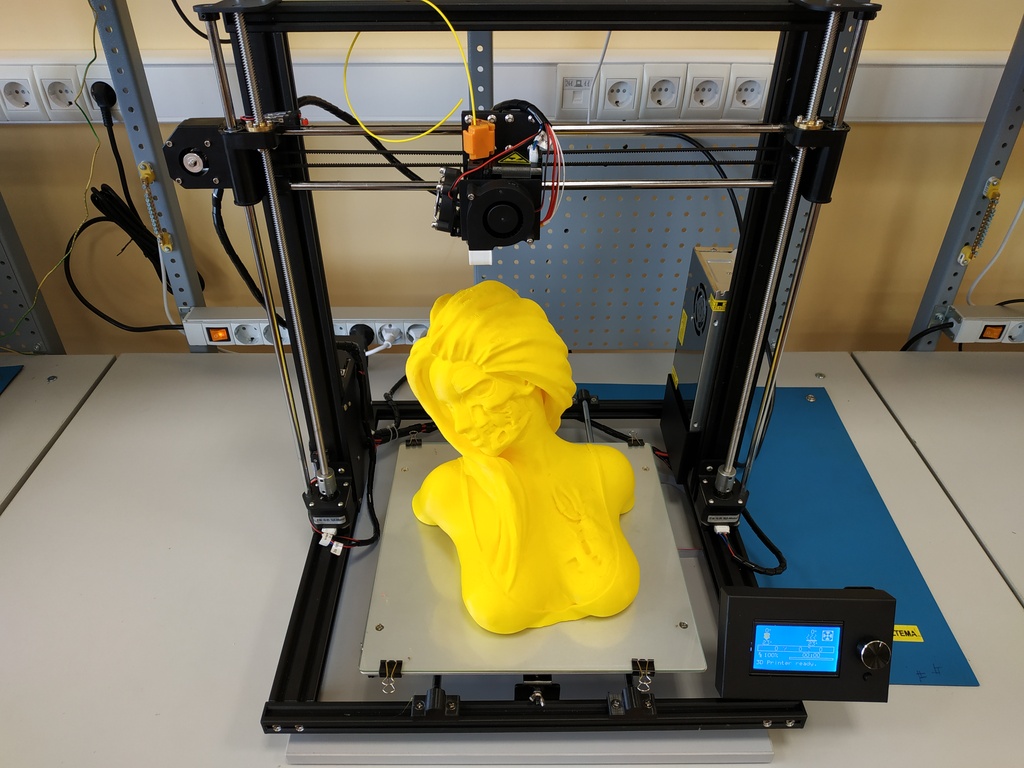

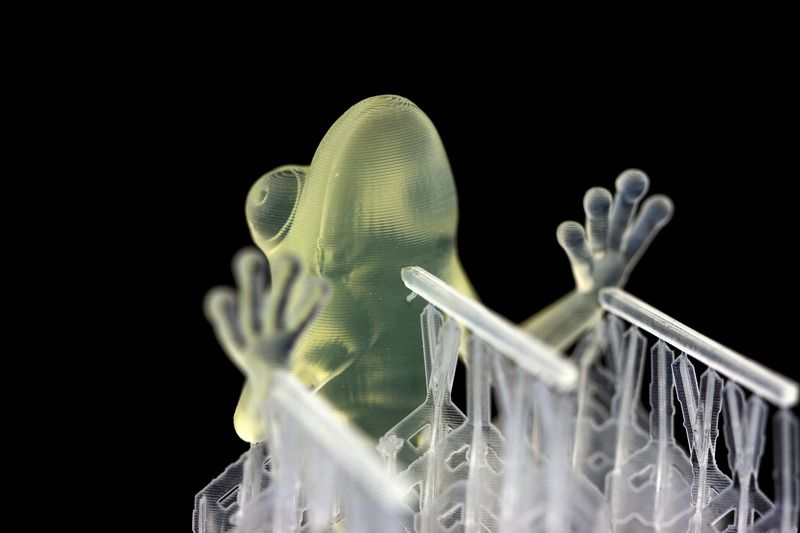

In accordance with the presented algorithm, at the first stage of product creation, a 3D model is developed using modeling programs in accordance with the terms of reference and standards requirements. After that, it is necessary to export the data of the simulation result program file to a format accepted by the program of the additive manufacturing control machine (for example, “STL”). The modeling process can now be done not only in solid format, but also immediately in STL. Before the next stage, possible defects in the model are identified. A model intended for 3D printing must be hermetic, monolithic and not contain cavities and gaps in the walls, which is ensured using special programs. Next, the information from the STL file is converted into commands, following which the 3D printer produces a product, this is the so-called GCode.

The modeling process can now be done not only in solid format, but also immediately in STL. Before the next stage, possible defects in the model are identified. A model intended for 3D printing must be hermetic, monolithic and not contain cavities and gaps in the walls, which is ensured using special programs. Next, the information from the STL file is converted into commands, following which the 3D printer produces a product, this is the so-called GCode.

During this procedure, you must select the desired scale of the part, the correct position in space, and accurately position the model on the work surface. The result of the whole process, strength, surface roughness of the part and material consumption depend on this . After the settings are made, the model is divided into layers of material, which are “fitted” into the body of the part in one working cycle of the additive machine. This process is called slicing. Slicing is done using the software supplied with the machine, or using special tools (Simplify, Skein-forge, Slic3r, KISSlicer, MakerWare, etc. ). The G-code obtained in the previous step is transferred to the 3D printer via flash memory or via a USB cable. In the process of preparing and setting up the additive machine, calibration, preheating of the working bodies, selection of the model material and setting the parameters of the equipment operation modes that depend on it are performed. On professional level devices, this step can be combined with the slicing process procedures. After all the preparatory operations are completed, the printing process starts, that is, the layer-by-layer combination of materials. Its duration depends on the type of technology and the selected parameters for the accuracy and quality of the part.

). The G-code obtained in the previous step is transferred to the 3D printer via flash memory or via a USB cable. In the process of preparing and setting up the additive machine, calibration, preheating of the working bodies, selection of the model material and setting the parameters of the equipment operation modes that depend on it are performed. On professional level devices, this step can be combined with the slicing process procedures. After all the preparatory operations are completed, the printing process starts, that is, the layer-by-layer combination of materials. Its duration depends on the type of technology and the selected parameters for the accuracy and quality of the part.

Requirements for models for 3D printing and CNC processing.

- List of file formats by 3D technologies.

- FDM (ABS, PLA, FLEX, HIPS, etc.): .STL .OBJ

- SLS (polyamide): .STL .OBJ

- SLA, DLP (photopolymer): .

STL .OBJ

STL .OBJ - SLM (metal): .STL+STP(STEP) .OBJ+STP(STEP)

- Multicolour plaster: .OBJ+texture .WRL+texture

- Polygon mesh.

- The mesh must be uniform and closed. A model consisting of several polygonal meshes is not allowed! Intersection of polygonal meshes is not allowed! Holes in the grid are not allowed!

- Multiple models in one file are not allowed. Each object needs to be saved as a separate file.

- The number of polygons must not exceed 500,000.

- Wall thickness must be at least the specified values for each technology.

- Inverted normals are not allowed! The outer normal should face outward. This problem is especially common when mirroring the model in some 3D modeling programs.

- The dimensions of the model must correspond to the dimensions of the real object.

In 95% of cases, file errors are not critical and can be easily corrected using specialized programs that can be easily found on the Internet. Even if you are sure that everything is in order with the model, it does not hurt to check it once again for correctness.

Even if you are sure that everything is in order with the model, it does not hurt to check it once again for correctness.

NETFABB - as a solution to most file errors.

MESHMIXER is a powerful and convenient alternative.

- Wall thickness analysis of the model.

It should be understood that there are several 3D printing technologies. They differ not only in the materials used, but also in the accuracy of the equipment. Different equipment has its own resolution. Therefore, before sending the file for printing, it is necessary to make sure the quality of the model in terms of the specified thicknesses in the walls, rods, mesh ceilings. Detailed article about checking models for thickness.

Fixing non-critical bugs with NetFabb.

NETFABB (download for PC or download for Mac) is a program that allows you to solve almost any issue related to 3D printing. Let's go through the main functions of this software, which AutoDesk itself bought at one time.

The program shows the outer part of the polygon in green, its inner normal in red. Ideally, the model should be all green. If you observe red spots, then these are polygons that are turned outward. If the entire model is highlighted in red, then the entire mesh is turned inside out.

Even if the model is green, but there are errors in your file, the program will display a big exclamation point in the lower right corner of the screen, and will not be able to calculate the volume of your model.

To treat the model, click on the red cross on the toolbar at the top of the screen. The program will put you into the treatment mode, and will indicate in yellow the breaks in the polygonal mesh, if any.

This program has functions for removing or adding polygons, changing sizes or proportions. (I will leave these functions for independent study). I recommend that you study the entire toolbar in order to easily understand how, where and which polygons we can select and what we can change.

To invert normals, select the polygons that look “in the wrong direction” and click on the “invert normals” button. Then click on the “Apply Repair” button.

If your model was initially all green or inverting the normals didn't remove the exclamation point, and the volume has not yet been calculated, you need to apply automatic treatment. To do this, go back to the treatment mode by clicking on the red plus. In the treatment mode, select "Automatic treatment", then select "Default Repair" and click "Extrude".

The program has now done its best to repair the model automatically. Click "Apply Repair".

Typically, these steps should have fixed your model. If after the performed operations an exclamation mark is on and there is still no volume, then you are among those 5% when the model has critical errors and errors are laid down at the modeling stage.

Fixing non-critical bugs with MeshMixer.

Autodesk MeshMixer is a free software for working with 3D mesh models. You can download the program from the link. The program does not have tools for creating 3D models, but a wide range of tools for modifying them and preparing them for 3D printing. The main difference between this software and NETFABB is that MESHMIXER officially supports the latest versions of macOS. For me, this is a decisive factor, because I always carry a MacBook with me, and a Windows computer is only in the office. In turn, NetFabb stopped supporting software for macOS.

You can download the program from the link. The program does not have tools for creating 3D models, but a wide range of tools for modifying them and preparing them for 3D printing. The main difference between this software and NETFABB is that MESHMIXER officially supports the latest versions of macOS. For me, this is a decisive factor, because I always carry a MacBook with me, and a Windows computer is only in the office. In turn, NetFabb stopped supporting software for macOS.

As in the case of Netfabb, you need to drop the model in STL format into the MeshMixer program window.

At first glance, the model looks good, but let's try to test it for 3D printing suitability (mesh requirements). To do this, you need to analyze the model for errors. To do this, go to the “Analisis” section, then click on the “Inspector” button.

On the screen, we can see how the program highlighted areas on the model with bright colors that do not meet the requirements, which means they have errors.

In order to fix (cure) these errors, click on the “Auto Repair All” button. The program will try to remove errors automatically. Checking before 3D printing is a must. Even if outwardly the model seems suitable to you, it is still worth checking. In the picture below, you can see the errors that are inside the mesh, although everything looks good with the model.

However, this treatment does not always help. For example, if the model has a huge number of errors that the program is not able to remove automatically, then you will have to correct the model yourself in the program where the model was originally created. In case of a large number of errors, the program will indicate their presence even after you have tried to do automatic treatment. The picture below is an example of a very large number of shortcomings and errors that the program is not able to remove by itself.

This usually happens when the model is being prepared for rendering rather than 3D printing. That is, there is a huge number of surfaces, but they are not connected into a single grid.

That is, there is a huge number of surfaces, but they are not connected into a single grid.

Fixing non-critical errors with Materialize Magic

The 3D model healing feature in Materialize Magic is located in the Fix tab.

After that, select the “Correction Wizard” command. Next, you need to alternate the “Update” and “Autocorrect” buttons.

Do this several times. Sometimes for a long time. Until the moment when the number of errors becomes minimal or disappears altogether.

After the upgrade, the result shown below can be considered successful. All checkboxes must be green.

Complete the treatment by following the recommendations and save the corrected model!

Very important point! Treatment in automatic mode occurs according to the principle of adding or removing polygons. Therefore, after automatic treatment, fully check the model for the correct form.

Learn more