3D printing shoe

3D Printed Shoes: What's Available on the Market Today?

Published on March 4, 2022 by Carlota V.

In August 2020, research firm SmarTech Analysis unveiled its second study on the 3D printing and footwear market. According to the report, this industry is expected to generate more than $8 billion in profits by 2030. And it must be said that additive manufacturing offers a number of benefits in footwear production, perhaps the most important being the ability to customize the final product. Consumers are looking for differentiation and uniqueness, and 3D technologies can meet that need. They are also able to offer custom-made products with complex designs, perfectly adapted to each individual’s morphology. Thus, thanks to 3D scanning and 3D printing, companies are imagining more efficient sneakers, futuristic shoes for high fashion or comfortable and durable soles. Yes, it should be noted that it is not always the entire shoe that is 3D printed – which is actually quite rare – but rather the upper or the sole for example. In any case, 3D printing and footwear go hand in hand, and the market certainly is showing a lot of promise! For that reason, we wanted to introduce you to a few of the most impressive 3D printed shoes currently available, whether for sports, going to the beach or just going to work.

Adidas’ Range of 3D Printed Shoes

When it comes to 3D printed shoes, we would be remiss if we do not mention the offerings from famed shoe manufacturer, adidas. The company has been using 3D printing since 2017 when it entered into a partnership with Carbon to create new shoes, starting in 2018 with Futurecraft 4D 3D printed shoes, which are still being sold. Since then, they have continued to use additive manufacturing to create unique, sustainable footwear. For example, just last year the company released two new 3D printed sneakers, the 4D Fusion and the adidas 4DFWD, the latter of which was specifically created to improve athlete performance. According to the company 3D printing adds performance thanks to the lattice structure as well as adding a lot of flexibility to its activities, from reducing lead times to offering a shoe that could be completely customized at a reasonable price.

Thanks to Carbon’s DLS technology, the adidas 4DFWD has a unique lattice midsole made of 40% bio-based material (photo credits: adidas)

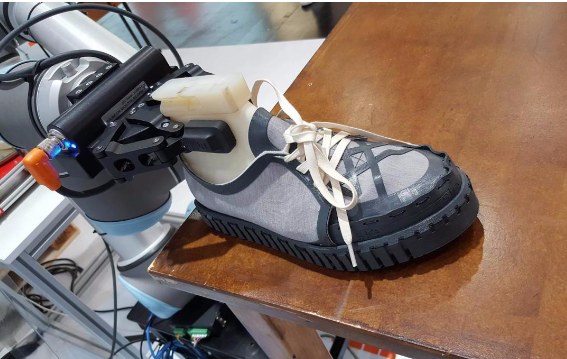

Liquid Speed from Reebok

Reebok is one of the largest and most recognized companies in the footwear industry. That’s why, a few years ago, they decided to use additive manufacturing technologies to create soles for one of their athletic shoe collections. While the rest of the shoe was made using traditional methods, the Liquid Speed incorporates a maximum fit sole. Reebok partnered with chemical company BASF, who used a liquid polyurethane material. They used a programmed robot to create the successive layers, bringing the sole to life. In addition to offering better performance and durability, the Liquid Speed has a very original design.

The Liquid Speed’s design is original

New Balance Incorporates a 3D Midsole

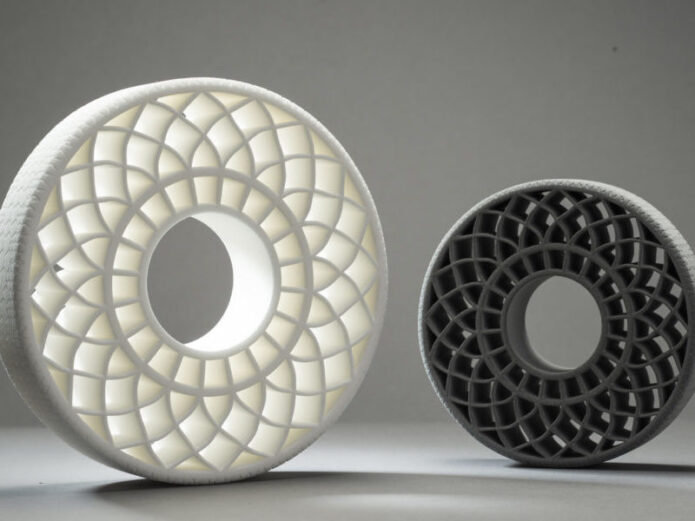

In a similar vein, New Balance has collaborated with 3D Systems to develop 3D printed midsoles. DuraForm Flex are insoles created with SLS technology from a thermoplastic elastomer material. They combine strength and flexibility and provide maximum comfort for the sports shoe. The 3D printing technology allows the production of complex structures that optimize shock absorption while making the shoe lighter. Since then, the American brand has been working with Formlabs and its stereolithography technology on the development of a Triple Cell platform to produce the FuelCell Echo.

They combine strength and flexibility and provide maximum comfort for the sports shoe. The 3D printing technology allows the production of complex structures that optimize shock absorption while making the shoe lighter. Since then, the American brand has been working with Formlabs and its stereolithography technology on the development of a Triple Cell platform to produce the FuelCell Echo.

The shoe’s midsole was 3D printed

ECCO and its customizable midsoles

ECCO is a Danish shoe manufacturer with many years of experience in the industry. In 2019, the company launched its Quant-U service aimed at customizing shoes through 3D printing. Using a 3D scanning process of the feet, it is possible to determine the orthopedic fit required for each person. With this device, ECCO designs 3D printed insoles tailored to the needs of its customers. This part is made from silicone, a material that provides stability as well as an adequate degree of cushioning. In addition, the company says the insoles are easily interchangeable and can be put in the washing machine.

Photo Credits: ECCO Quant-U

Wiivv Goes for Customization

Wiivv is a young Canadian company that specializes in the production of 3D printed soles and flip-flops, entirely adapted to the wearer’s morphology. Thanks to a Smartphone application, the user can directly scan his or her foot, send their data to the company and receive a customized solution a few weeks later. Take flip-flops for example: thanks to 3D printing, Wiivv can customize certain elements of the shoe such as the straps or the vertical strap. The objective is of course to offer more comfort to the user. The company is equipped with a machine park in San Diego and the product is made using SLS technology.

Wiivv’s flip-flops are fully customizable

Sustainable 3D Printed Shoes

How can you best combine fashionable footwear with a responsible environmental conscience? By using additive manufacturing! Chris Margetts, founder of The Sole Theory and fashion brand Humans Are Vain, uses recycled textiles to make his 3D printed shoes. He explains, “There is a strong demand for more sustainable products. There is no doubt that there will be consumers who want to buy this type of footwear when we launch it on the market.” He is deliberately using the fibers from clothing he once loved to turn into composite materials. This way, they can be used as material for 3D printing to create new shoes. The fibers are ground up and turned into filament for ZYYX Labs’ 3D printer.

He explains, “There is a strong demand for more sustainable products. There is no doubt that there will be consumers who want to buy this type of footwear when we launch it on the market.” He is deliberately using the fibers from clothing he once loved to turn into composite materials. This way, they can be used as material for 3D printing to create new shoes. The fibers are ground up and turned into filament for ZYYX Labs’ 3D printer.

Photo Credits: The Sole Theory

HERON01, the Fully 3D Printed Sneaker

Attention sneaker fans: the 3D printed HERON01 is sure to be a crowd-pleaser. This shoe was made entirely by additive manufacturing by the American company Heron Preston, named after its founder Heron Preston Johnson. For this model, the founder of Heron01 is particularly focused on the theme of sustainability, as no glue or toxic materials were used in the production process. It was also possible to dispense with the use of seams, which means that the shoe can be completely recycled. The scraps and waste can eventually be used to make a new product. The design idea that goes beyond traditional shoe making is also reflected in the shoe’s features: low ankle cutouts, printed scales and textures, and the bird’s foot pattern on the sole.

The scraps and waste can eventually be used to make a new product. The design idea that goes beyond traditional shoe making is also reflected in the shoe’s features: low ankle cutouts, printed scales and textures, and the bird’s foot pattern on the sole.

The HERON01 sneaker (photo credits: HERON01)

Natives Shoes and its 3D Printed Shoes

Canadian manufacturer Native Shoes launched the Liquid Printed Natives project with the intention of developing everyday objects using advanced methods such as additive manufacturing. As part of this, the company used liquid rubber to 3D print shoes. The manufacturer says it used a 50% recycled ethylene vinyl acetate (EVA) material to achieve greater flexibility and a more rubbery appearance. What stands out about Native Shoes’ project is the speed of production, with the company explaining that 3D technologies have significantly reduced manufacturing time compared to traditional methods. They also offer consumers a high level of customization.

The shoes would be 3D printed directly into a tray containing a reusable water-based viscous gel formula

Eco-Friendly Sandals

We continue in this trend of 3D printed sandals with the Organic collection, imagined by a young student in fashion design, Lucie Trejtnarová. In collaboration with the material manufacturer Fillamentum, she 3D printed the outer sole of the sandal on which she sewed several organic fabrics made from fibers extracted from pineapple or coconut leaves. The printed sole had to be strong enough to support this fabric, so Lucie chose a TPU that was flexible enough but resistant to abrasion and wear. It also has a recyclable character, a key component for the young woman.

Mycelium Shoe, Futuristic Shoes

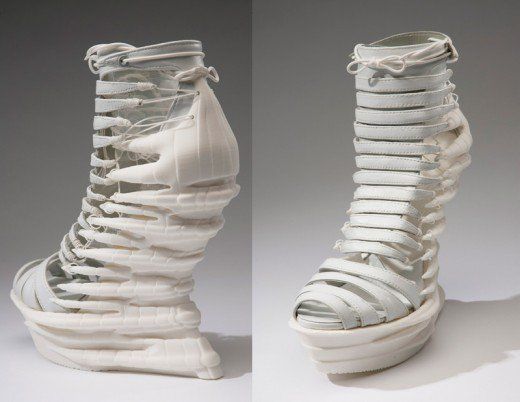

Imagined by the design studio Ica and Kostika, the Mycelium Shoe pair is entirely 3D printed on an SLS machine. Rather imposing by its shape, its size and its design, it does not go unnoticed in the street – besides, only 5 pairs were created. Its designers claim that these 3D printed shoes are very comfortable because they are entirely customized to the person’s feet: the 3D file is made from scanned data. It remains to be seen if walking in them is fun!

Its designers claim that these 3D printed shoes are very comfortable because they are entirely customized to the person’s feet: the 3D file is made from scanned data. It remains to be seen if walking in them is fun!

Only 5 pairs were created

Hilos, The Sustainable 3D Printed Shoe

Portland-based startup Hilos was founded in 2019 and wants to transform the way shoes are made, combining technology and craft. Through additive manufacturing, the company hopes to address environmental issues, while providing quality footwear. Recyclable, this shoe is made through selective laser sintering and is designed from TPU, because of its flexibility and strength. The company confides that, with the help of 3D printing, it is able to bring new product lines to market in just two weeks, compared to the industry average of 12 to 15 months.

ATHOS, 3D Printed Climbing Shoes

Developed by a group of students in Barcelona, ATHOS climbing shoes are gaining in popularity. Also known as “climbing shoes”, this type of shoe must fit the athlete’s foot perfectly to improve grip and prevent slipping. Usually, to make sure they have a good fit, athletes wear climbing shoes that are smaller than theirs, which causes pain and deformity of the foot. This is why the team behind ATHOS wanted to create custom-made climbing shoes that meet the needs of each climber. To do this, they use HP’s MultiJet Fusion 3D printing technology and BASF’s TPU material. The process to get the ATHOS shoes is very simple: just scan your feet with 3 photos, customize the shoes to your liking, and once you get them home, you can start climbing!

Also known as “climbing shoes”, this type of shoe must fit the athlete’s foot perfectly to improve grip and prevent slipping. Usually, to make sure they have a good fit, athletes wear climbing shoes that are smaller than theirs, which causes pain and deformity of the foot. This is why the team behind ATHOS wanted to create custom-made climbing shoes that meet the needs of each climber. To do this, they use HP’s MultiJet Fusion 3D printing technology and BASF’s TPU material. The process to get the ATHOS shoes is very simple: just scan your feet with 3 photos, customize the shoes to your liking, and once you get them home, you can start climbing!

Photo Credits: ATHOS

Pleko, the Carbon Fiber Shoe for Running

The brainchild of Italian middle-distance runner Miro Buroni and the Diadora company, the Pleko is a shoe made up of many 3D printed components. The 3D printed parts include the insole, outsole, spikes and ribs. Designed from composite materials, carbon fiber to be precise, and with the help of the powder sintering process, these different elements have made it possible to manufacture a shoe that is flexible, resistant to wear and tear and above all customizable. Indeed, thanks to 3D scanning and software that simulates the movements during a race, the teams behind the shoe are able to offer a durable and comfortable solution to athletes.

Indeed, thanks to 3D scanning and software that simulates the movements during a race, the teams behind the shoe are able to offer a durable and comfortable solution to athletes.

Photo Credits: CRP Technology

A 3D Printed Shoe for Dance

The Purmundus Challenge 2021 competition was won by Act’ble, a start-up company that collaborated with top athletes to develop a new pointe shoe. Intended for classical ballet and contemporary dance, the shoe is called “New Pointe Shoe Sole”. Expected to last five times longer than traditional pointe shoes, the shoe was designed to significantly reduce the physical pain dancers experience during ballet. To make the shoe, the team 3D printed the sole, but did not specify what process they used or the materials that make up the shoe.

Photo Credits: Act’ble

The Parametriks Print 001, a Shoe Entirely Printed from a Single Material

Earlier this year, designer Nathan Smith unveiled the Parametriks Print 001 sneaker, a 3D printed shoe designed using parametric design. This method, using design and material science to engineer parts, resulted in a shoe that stands out from the crowd for its comfort. To develop the Parametriks Print 001, Nathan Smith says he used Grasshopper, a plug-in included in Rhinoceros 3D modeling software. As for the manufacturing of the shoe, the designer explains that he relied on SLA machines and used TPU.

This method, using design and material science to engineer parts, resulted in a shoe that stands out from the crowd for its comfort. To develop the Parametriks Print 001, Nathan Smith says he used Grasshopper, a plug-in included in Rhinoceros 3D modeling software. As for the manufacturing of the shoe, the designer explains that he relied on SLA machines and used TPU.

Photo Credits: Parametriks

What do you think of these 3D printed shoes? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

How 3D printing revolutionizes the footwear industry

3D Learning Hub

See all categories

Contents:

- Introduction

- Designers and 3D printing

- 3D printed footwear: try a new manufacturing process and new materials

- Are 3D printed shoes for everybody?

- 3D printed sneakers

- What about the future of 3D printed footwear?

Introduction

Designers and 3D printing

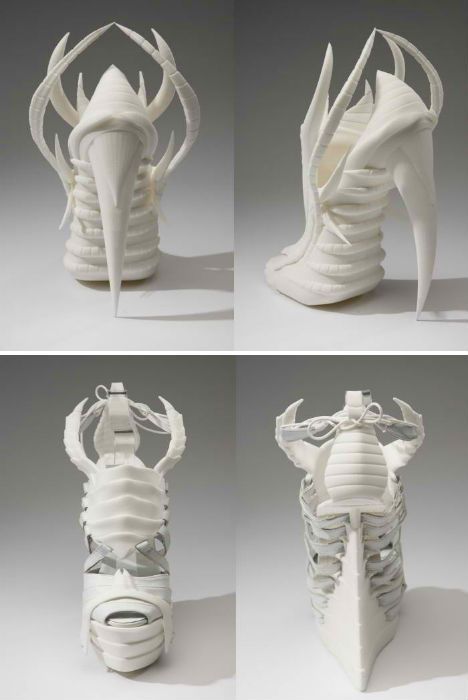

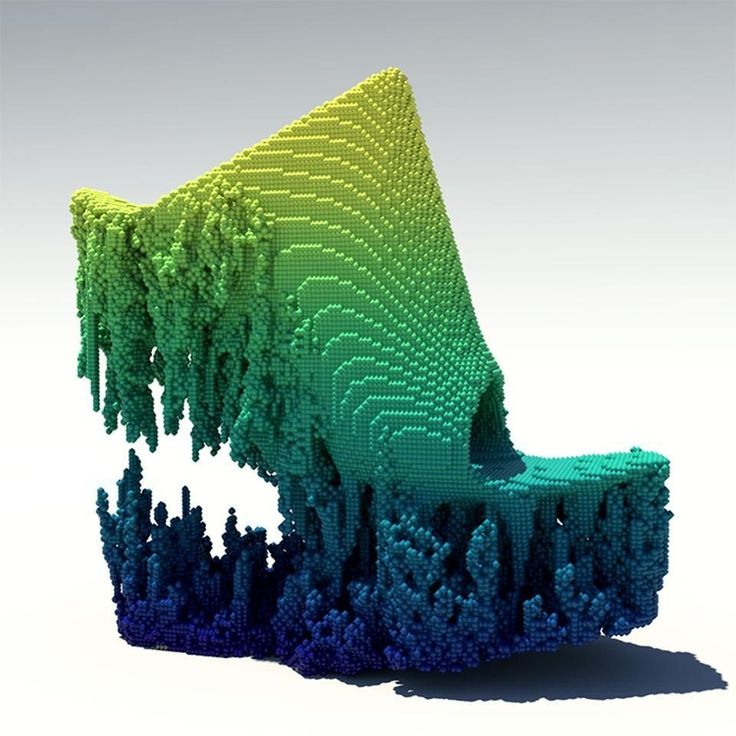

As we saw with the Virus Collection 3D printing allows designers to create clothes. But its utility in the fashion tech doesn’t end here because it’s also possible to create shoes with astonishing designs.

But its utility in the fashion tech doesn’t end here because it’s also possible to create shoes with astonishing designs.

For example, Zoe Jia-Yu Dai, a designer based in Taiwan and specialised in footwear, created “Breaking the 3D Mould”, a shoes collection with 3D printed parts. This technology allows designers to go further with the design structures. It is a way to change the manufacturing process. It’s easier to create organic structures with additive manufacturing, than with a traditional process.

It is obviously a good way to create prototypes to work on the design of any shoe. Some designers only focus on the design of the shoes. Melissa’s shoes are a great example of the possibilities offered by the 3D printing technology when it comes to design. Check out our blogpost about Melissa’s footwear experiments.

Silvia Fado, a spanish footwear designer, uses 3D printing and laser cutting to do rapid prototyping. Inspired by engineering and architecture, Silvia Fado focusses on style but not only since she’s also interested in the movement of the body, the wearability of the shoes, and the comfort elements that are part of the shoes. She works on the aesthetic and on the functional value of footwear.

She works on the aesthetic and on the functional value of footwear.

3D printed footwear: a good way to try a new manufacturing process and new materials

Rethink your production

Like in other sectors, 3D printing can be used to develop new manufacturing processes. It can give more possibilities and opportunities to any company. For example: Feetz. It is an American startup run by Lucy Beard. They make custom shoes, easy to wear and with a nice style. On top of that, Feetz is also committed to protect the environment.

They developed their own 3D printer, using a Fused Filament Fabrication technique, and their own 3D printing material: a patented polymer. They wanted to rethink the whole manufacturing process, in order to make it more sustainable. Feetz uses recycled and recyclable materials, no water and reduced by 60% their carbon footprint. Moreover there is no material waste because with 3D printing you only use the quantity that you need.

Their use of 3D printing in their manufacturing process shows that it is possible to change the way the shoes industry affects the environment.

Try out high performance 3D printing materials

New high-performance materials are now available on the market and particularly adapted to the creation of shoe parts, such as midsoles.

The perfect example for that is TPU. Indeed, objects printed with Thermoplastic Polyurethane are offering advanced properties, which is perfect to get durable, strong, and flexible parts. With Sculpteo’s online 3D printing service, you will have the choice between two different TPU options for the creation of shoes or midsoles: Ultrasint® TPU 88A and Ultrasint® TPU01 a perfect 3D printing material choice if you need to produce parts requiring shock absorption, high elasticity, and energy return. For flexible lattices and complex parts, this TPU material is ideal.

Are 3D printed shoes for everybody?

It’s easy to get a pair of 3D printed shoes made with a 3D printing technology. For instance, Feetz collaborated with the designer Seth Aaron to launch a shoe line together, inspired by a Japanese, 1960s mid-century modern look. You can buy those shoes on their website.

You can buy those shoes on their website.

But you can also get custom made shoes, as they are offering different models from slides and sneakers for men and women, to wedges with a lattice design. To get your 3D printed shoes, you have to download their app to 3D scan your feet in order to get a 3D model. Then, you just have to choose the shoes among the different models that Feetz offers. They will make you a ready-to-wear pair of shoes based on the 3D model of your feet.

Continuum Fashion also launched ready-to-wear pairs of shoes, created thanks to 3D printing. With Additive Manufacturing, it is possible to give life to organic forms. The project shows that 3D printing shoes actually make sense to create ready-to-wear. Moreover, you can produce them faster than with traditional manufacturing.

3D printed sneakers

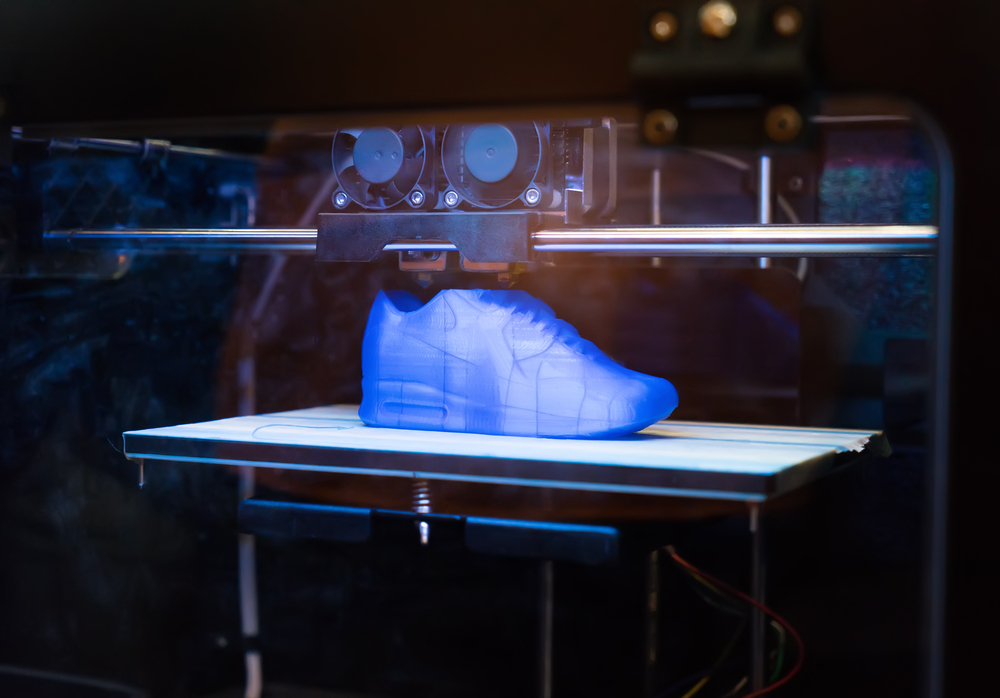

A running shoe can now be partially created with 3D printing technology. Actually, the midsoles of running shoes are particularly suitable for 3D printing. Big shoe manufacturers are using additive manufacturing. For example, brands like Adidas, Nike, New Balance and Under Armor have already printed sneakers. You can already customize your shoes thanks to Adidas, by choosing the look and the color of it, but you will soon be able to go further. Adidas already made a limited edition of FutureCraft 3D, using 3D printing. The brand now unveiled FutureCraft 4D, a footwear with a midsole created in partnership with Carbon 3D, using a new process called Digital Light Synthesis (formerly known as CLIP). Thanks to digital light projection, oxygen-permeable optics and liquid resin, this process can produce a durable and resistant polymeric goods. These Futurcraft 4D shoes will offer a personalized support for athletes and are allowing mass customization. New Balance Zante Generate is another similar project, these sneakers have a partially 3D printed midsole. It is a pair of running shoes with a flexible midsole that offers a good support. Nike also uses 3D printing a lot for prototyping and they are proud to say that they use Selective Laser Sintering to create their prototypes.

Big shoe manufacturers are using additive manufacturing. For example, brands like Adidas, Nike, New Balance and Under Armor have already printed sneakers. You can already customize your shoes thanks to Adidas, by choosing the look and the color of it, but you will soon be able to go further. Adidas already made a limited edition of FutureCraft 3D, using 3D printing. The brand now unveiled FutureCraft 4D, a footwear with a midsole created in partnership with Carbon 3D, using a new process called Digital Light Synthesis (formerly known as CLIP). Thanks to digital light projection, oxygen-permeable optics and liquid resin, this process can produce a durable and resistant polymeric goods. These Futurcraft 4D shoes will offer a personalized support for athletes and are allowing mass customization. New Balance Zante Generate is another similar project, these sneakers have a partially 3D printed midsole. It is a pair of running shoes with a flexible midsole that offers a good support. Nike also uses 3D printing a lot for prototyping and they are proud to say that they use Selective Laser Sintering to create their prototypes. Indeed, you can work and rework on a shoe design very easily thanks to rapid prototyping. They made a partnership with HP, who released the HP Multi Jet Fusion, and will certainly work on new projects soon.

Indeed, you can work and rework on a shoe design very easily thanks to rapid prototyping. They made a partnership with HP, who released the HP Multi Jet Fusion, and will certainly work on new projects soon.

Rethinking the manufacturing process

Nike also uses 3D printing a lot for prototyping and they are proud to say that they use Selective Laser Sintering to create their prototypes. Indeed, you can work and rework on a shoe design very easily thanks to rapid prototyping. They made a partnership with HP, who released the HP Multi Jet Fusion, and will certainly work on new projects soon. Indeed, Nike, is using additive manufacturing to prototype its products, and in 2017, their use of 3D printing was estimated to provide a 10% cost efficiency. With their partnership with HP, mass production could be on its way with the use of these powerful 3D printers. These big leaders of the footwear industry have to start using additive manufacturing in order to keep on being competitive and improve their processes on a different level: it can be for product development, customization, or mass-production.

Fully 3D printed shoes?

There is still a lot of work to get the fully 3D printed shoe. Nevertheless, some product developments are going in this direction: Olivier Van Herpt is using 3D scans and 3D printing to create new shoe structures, making them unique, lightweight and quite resistant. These 3D printed shoes have a unique style but are custom-made, meaning that they guarantee you the perfect fit. But Olivier Van Herpt is not the only person working on fully 3D printed shoes. Some other creators like Nicholas Unis are starting their footwear business with fully 3D printed products.What about the future of 3D printed footwear?

3D printed footwear can easily be integrated to your daily life, for example Phits, with their 3D printed insoles, are a good example. Some projects are really accessible to anybody, and could be developed more widely. Personalized pairs of shoes are now accessible to everybody and mass customisation will gain ground in the upcoming years.

Indeed, 3D printing is a great way to get shoes perfectly adapted to your feet. Big brands are making partnerships with major actors of Additive Manufacturing such as HP, and are including the 3D printing process in the production of some of their models. 3D printed shoes, thanks to brands like Nike or Adidas are now entering the mass production era.

Designers will continue to work with 3D printing as it allows to create incredible designs with a lot of freedom. For example, Zoe Jia-Yu Dai is definitely not going to stop working with 3D printing. As she’s interested in men and children’s footwear, new projects could be launched really soon.

The footwear industry is more linked to 3D printing than you might think. All these examples show that there are different ways to create shoes. It can be to push design boundaries or to change manufacturing methods by finding an ecological way to produce, or even to get shoes or insoles made to measure for more comfort. Reasons to create 3D printed shoes are numerous, and it could be pushed further in the upcoming years!

Do you want to start your 3D printing business in the footwear industry? Well, here is our first advice: Choose the right 3D software. Getting the perfect shoe design software will help you start your best project.

Getting the perfect shoe design software will help you start your best project.

You have a 3D model and you want to prototype a pair of shoes, or anything else? You can upload a model on our online 3D printing service.

You want more news about the latest innovations in the 3D printing industry? Don’t hesitate to subscribe to our weekly newsletter.

Related Topics

- Return to Top

Get the latest 3D printing news delivered right to your inbox

Subscribe to our weekly newsletter to hear about the latest 3D printing technologies, applications, materials, and software.

3D printing in footwear

We recently talked about the use of 3D printing to create orthopedic insoles, which was brought back from Formnext 2017, and there we also saw a prototype Adidas sneaker with a 3D printed sole. This is an interesting topic, let's delve into it a little more.

Major sports shoe manufacturers are investing considerable time and money into developing ways to apply 3D printing to the footwear industry. Companies like Reebok, Under Armor, Adidas, Nike and New Balance are showing that they see 3D printing as the future of the footwear industry.

What is it, advertising and PR on the hype raised around additive technologies, or a sober calculation and a look into the future?

Let's try to figure it out.

Under Armor

3D printing company EOS North America Inc and Under Armor have joined forces to develop the commercial production of 3D shoes.

EOS North America and Under Armor partner to help Under Armor scale their 3D printed footwear business.

The use of laser sintering technology, as well as the use of EOS's experience in industrial 3D production, will help develop the Under Armor shoe business. Together they intend to work on the composition of new powders and the development of sintering technology.

Under Armor plans to use EOS technology to 3D print shoe parts from powder.

To highlight their partnership, at Formnext 2017, the companies showcased UA's new ArchiTech Futurist footwear together.

Nike

Nike also designs shoes using 3D printing technology. In 2017, Footwear News wrote:

“Prodways' 3D printed shoe parts, insoles and soles made from thermoplastic polyurethane (TPU) are being used to speed up the production of running shoes and improve their performance.

While Nike has yet to announce mass production of 3D printed shoes, Nike executives appreciate the potential of Prodways' materials and 3D printers to improve shoe quality and increase production speed.”

Nike is using 3D printing in prototyping with French company Prodways.

Nike has already created 3D printed shoes, although they were off-the-shelf products for professional athletes.

For example, in 2013 the company introduced and in 2014 released 3D printed football boots and running shoes.

New Balance

New Balance launched a running shoe in 2016 with a fully 3D printed Zante Generate sole.

Zante Generate is a New Balance running shoe with a fully 3D printed outsole, created in collaboration with 3D Systems.

Working with 3D Systems, NB used DuraForm TPU powder to 3D print sneaker parts. The soles were printed using SLS technology, a trial batch consisted of 44 pairs.

Reebok

Reebok is no stranger to 3D printing, back in 2016 the company introduced its new Liquid Factory 3D technology.

Reebok's first 3D printed sneaker was called the Liquid Speed.

The Reebok Future team, which is responsible for introducing new technologies at Reebok, has partnered with the chemical giant BASF, which developed the 3D printing resin used by the company.

Head of Reebok Development Bill McInnis says:

With this process, we can create an entire shoe by programming a robot to draw it, layer by layer, from a high-strength liquid material. This results in a sole with completely new properties, much more resilient than traditional sneaker rubber soles, and transmitting momentum more precisely. Liquid Factory creates a shoe that stretches and wraps around the foot for 3D support.>>

The company didn't stop there. Together with the Modla design studio, they developed the Modla X Reebok 3D, a 3D printed training mask for athletes.

The polymer part of the mask, which was designed using Ultimaker 2 FDM printers for prototyping, is produced using EOS 3D printers using SLS technology.

The inner parts, silicone, and soft part of the mask, made of Flexweave material, were laser cut.

The mask is designed to limit the access of air, which increases the load on the lungs and contributes to the endurance training of the body as a whole. The load is adjusted by turning the front of the mask, which switches the silicone valves inside.

The following functionality is not announced, but we think that with some minor modifications, the mask will also serve as a respirator from urban dust, which is so much in the air in hot weather.

Adidas

In 2017, Adidas announced a partnership with Silicon Valley-based Carbon.

One of the leading brands in the advancement of 3D printing in footwear, Adidas, has partnered with Carbon to apply a 3D printed outsole made with their Digital Light Synthesis (DLS) technology to a Futurecraft 4D model.

Together they created the Futurecraft 4D 3D printed insole. This is not only an interesting technical solution, but also a hot topic - the number of mentions on Instagram is growing.

This is not only an interesting technical solution, but also a hot topic - the number of mentions on Instagram is growing.

Marvel comic book hero Black Panther

Canadian model Adrianna Ho

Sneakers on sale from mid-February, cost about $300.

Digital Light Synthesis is a Carbon process that uses breathable optics, digital projection and pre-set photopolymer resins to produce durable polymer products. Futurecraft 4D is Adidas' first application of DLS technology.

DLS gives products strength and elasticity.

Carbon says their unique technology will provide never-before-seen durability, strength and resilience to 3D printed products. Adidas is aiming to release 100,000 pairs of shoes using this technology by the end of 2018.

This is not Adidas' first experience with additive manufacturing. A few years ago, the company collaborated with Shining 3D to design the Springblade sneaker.

The management of Adidas was quite an experiment and was going to continue cooperation with Shining 3D, but something didn’t work out - we didn’t hear about their joint activities anymore, there was only a mention of Adidas on the Shining 3D website, among partners.

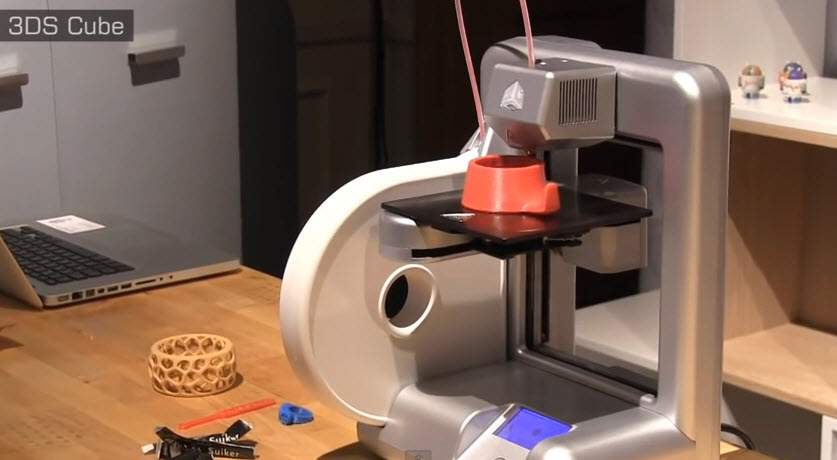

Do it yourself

Some simple types of shoes can already be printed by any owner of a conventional FDM-3D printer. For these purposes, even the simplest Prusa is suitable, as you can see in this video:

Slippers, shoe soles, uppers for costume shoes (for cosplay or carnival). Thingivers and other 3D sharing resources are full of such projects.

https://www.thingiverse.com/thing:980191

https://www.thingiverse.com/thing:597498

https://www.thingiverse.com/thing:1178775

https://www. thingiverse.com/thing:2314052

thingiverse.com/thing:2314052

https:/ /www.thingiverse.com/thing:1587947

There are also real works of art.

Of course, the strength and convenience of such homemade products is a big question, but this is only the beginning.

Conclusions

As you can see, despite the raised advertising hype, quite working models are created, which often surpass shoes made by traditional methods, not only in terms of consumer properties, but also in terms of manufacturability in production.

3D printing in shoe production gives less weight to shoes, more opportunities to change elasticity and stiffness, due to the complex internal structure of the print, plus the widest field for designing and inventing new forms that would be impossible to create using traditional methods.

Considering that the main players in the sports footwear market have been developing in this direction for several years, we can hope that 3D-printed shoes will become available to the public very soon.

You can order 3D printing at Top 3D Shop — rich experience, a wide choice of materials and a large fleet of equipment allow us to fulfill any order.

Want more exciting news from the world of 3D technology?

Follow us on social. networks:

VK

YouTube

TOP 3D Shop - your expert in the 3D technician market

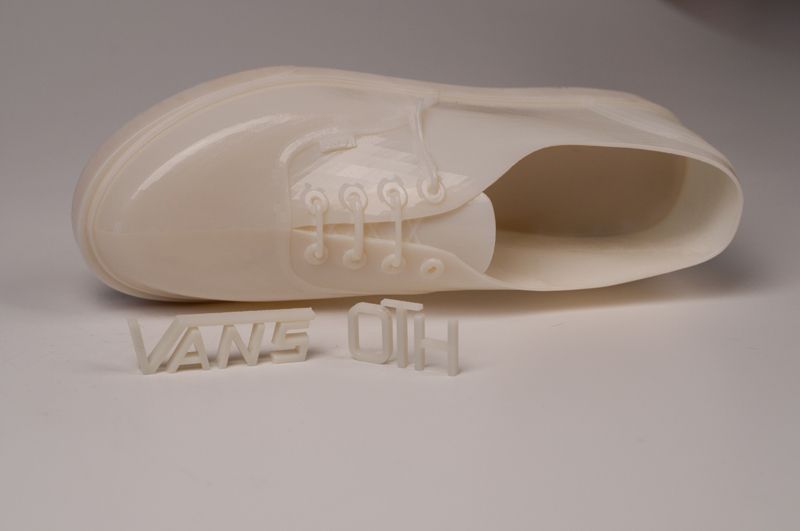

SLA 3D Printing shoes

550, well -developed PROTOFAB design, the new design 3D printing is known to revolutionize industries like dentistry and aerospace, but 3D printing is also making a significant impact in places that not everyone might expect. An example of this is the impact of 3D printing on the footwear industry, an industry with which ProtoFab is now closely associated. Let's take a look at how one of China's biggest shoe brands is using SLA 3D printing at the heart of its design process.

Qiaodan is one of the biggest sports shoes brands in China.

Qiaodan is one of the most popular sports shoes brands in China with annual sales of more than 4 billion RMB. We started working with them in 2016 and gave them one of our SLA450 machines. Like all shoe brands, Qiaodan needs to constantly develop new products and designs to stay fresh in a highly competitive market. Time to market is critical in an industry where trends come and go, making the design process more efficient is a top priority. This is where 3D printing comes in.

We started working with them in 2016 and gave them one of our SLA450 machines. Like all shoe brands, Qiaodan needs to constantly develop new products and designs to stay fresh in a highly competitive market. Time to market is critical in an industry where trends come and go, making the design process more efficient is a top priority. This is where 3D printing comes in.

Our Vice President of Sales Damon Hoshabo stands next to Qiaodan's Chief Designer

The Traditional Method: Slow Prototyping

Traditionally, Qiaodan and its competitors used CNC epoxy resin models during the prototyping phase of a new product. In the shoe industry, it is necessary to make physical models of the sole (the rubber bottom of the shoe) before deciding whether to proceed with production. The old epoxy models were quite detailed, but had a few shortcomings. First of all, the production of such models took a long time, often more than 2 weeks, from sending the project to an external contractor to actually receiving the physical model and being able to evaluate it. Of this time, about a week was taken up by the actual processing, but the actual delivery time would normally have been much longer due to limitations in the contractor's capacity, communication issues, courier delays, and some other outsourcing-related whims. Qiaodan says that previously only 15 days were allocated for this process, and 8 days would be the best scenario. In comparison, their 3D printer can now produce the same model in about 20 hours, and the entire process, including 3D modeling and post-processing, takes 2 or 3 days at most. Qiaodan regularly prints 6 models at the same time on its SLA450, which speeds up the process even more.

Of this time, about a week was taken up by the actual processing, but the actual delivery time would normally have been much longer due to limitations in the contractor's capacity, communication issues, courier delays, and some other outsourcing-related whims. Qiaodan says that previously only 15 days were allocated for this process, and 8 days would be the best scenario. In comparison, their 3D printer can now produce the same model in about 20 hours, and the entire process, including 3D modeling and post-processing, takes 2 or 3 days at most. Qiaodan regularly prints 6 models at the same time on its SLA450, which speeds up the process even more.

This 3D prototype outsole was made in 8 hours

It's hard to overstate how important this level of time saving is to a manufacturer like Qiaodan. Having to wait a week to see a prototype design is bad enough, but if changes are required, then even more time is wasted. Even in the best case, it will take more than a week before the revised design is in the hands of the development team. The negative impact of this is twofold. First, product development can easily drag on much longer than originally anticipated, and if multiple revisions are needed, an entire month could disappear with minimal progress. This can cause a new product to miss key dates, such as summer shoes hitting shelves at the end of the season. Secondly, it is much harder to justify the risk on a bold idea when there is a need to rethink it. This has an impact on pushing designers towards conservative designs, especially when there are time constraints. When models can be produced quickly, the design team is much more willing to experiment, which has a positive effect on the creativity of the brand as a whole.

The negative impact of this is twofold. First, product development can easily drag on much longer than originally anticipated, and if multiple revisions are needed, an entire month could disappear with minimal progress. This can cause a new product to miss key dates, such as summer shoes hitting shelves at the end of the season. Secondly, it is much harder to justify the risk on a bold idea when there is a need to rethink it. This has an impact on pushing designers towards conservative designs, especially when there are time constraints. When models can be produced quickly, the design team is much more willing to experiment, which has a positive effect on the creativity of the brand as a whole.

This designer is working on a 3D model of sports shoes

SLA printing has a very significant advantage in the design process. No matter how complex the structure design is, and no matter the curve and hollow structure and texture of the project, the software can execute the simulation directly and upload the simulation file to the printing equipment for quick prototyping.

Keep everything under one roof

Sole Prototypes

Another major benefit of 3D printing for Qiaodan is that they can support the entire design process on site. CNC equipment is bulky, expensive, and requires specialized operators, so it doesn't make sense to make such a huge investment to produce only a small number of prototypes. The only option is to outsource this step to a prototyping specialist, which causes a number of problems. First of all, the need to physically ship the model from the prototype company to Qiaodan slows down an already slow process. There is also the issue of trade secrets and the potential for unpublished designs to be leaked to competitors or the public. Keeping the entire process under one roof also means that Qiaodan has complete control over the quality. External providers don't always live up to expectations and communication problems are hard to avoid. With a factory-installed 3D printer, the same people who produce the model are the same people who designed it, simplifying the process and reducing the chance for errors.

Qiaodan ProtoFab SLA450 3D printer

SLA vs. CNC

CNC prototype (left), 3D printed prototype (center), actual shoe sole (right)

little difference between the two methods. The appearance of SLA printed models is very similar to their traditional epoxy models, and the level of detail is also similar. While CNC machining theoretically allows for a wider range of materials, this is not the case for sole prototypes. The photosensitive resin used in the SLA has all the properties that the design team needs.

Detail of a 3D printed prototype

Long term investment

The only thing that may put other companies off in a similar situation is the initial cost of purchasing an industrial SLA printer. While this is a significant one-time expense, in the long run there is no doubt that it was worth it for Qiaodan. For starters, the cost per part is significantly lower for 3D printing compared to external CNC machining. While SLA resin is not inexpensive, not having to pay outside contractors represents a significant savings.