Creaform 3d scanner price

Creaform launches the HandySCAN Silver Series 3D scanner - technical specifications and pricing

0Shares

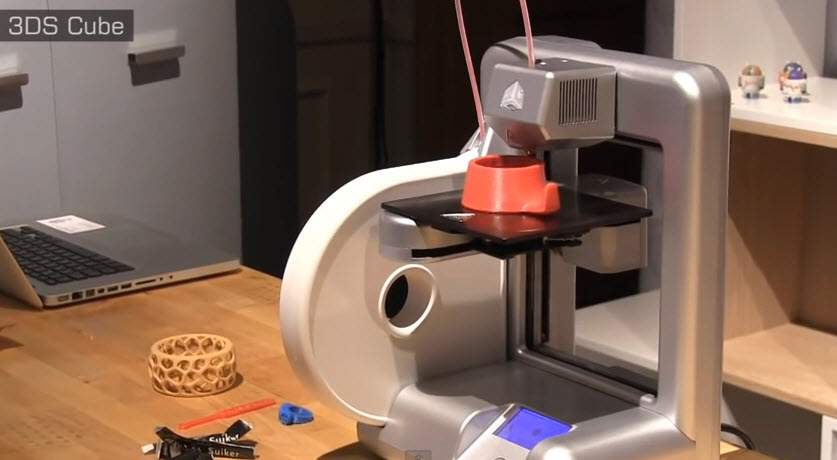

3D measurement system manufacturer Creaform has announced the launch of its latest handheld 3D scanner.

The HandySCAN 3D Silver Series is available in two models: the HandySCAN 307 at $19,990 and the higher-performance HandySCAN 700 at $29,900. Aimed at professional engineers and technology companies, the device is intended to provide repeatable metrology-grade 3D measurements for product development and reverse engineering applications.

“For the professionals who need to adapt quickly to their customers’ needs and provide better answers to their inquiries, a reliable 3D scanning solution is indispensable,” states Simon Côté, Product Manager at Creaform. “The possibilities presented by gathering such precise data can open doors to new projects and strengthen the partnerships with existing clients. It cannot be overstated how 3D scanning and 3D printing technologies have become vital for any small-to-medium sized company. ”

Professional 3D scanning with Creaform

Based in Québec, Creaform already has an extensive portfolio of professional 3D scanning devices. Go!SCAN, the company’s most affordable line, is capable of capturing full color 3D models with a setup time of just five minutes. With a focus on accessibility and ease-of-use, the entry-level range is designed to be usable by individuals of any background in a pick up-and-play manner.

For those looking for more in the way of performance, the HandySCAN and MetraSCAN ranges might be a little more suitable. Built for manufacturing and metrology professionals working in dynamic manufacturing environments, these premium 3D scanner lines offer high-precision measurements for engineering projects.

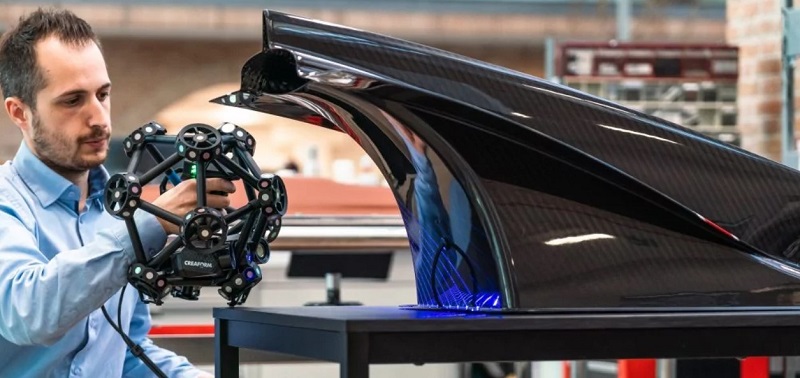

Scanning a Koenigsegg with the HandySCAN Silver Series. Photo via Creaform.The HandySCAN 3D Silver Series

The latest addition to the HandySCAN range is characterized by its precision and versatility. Operating on seven red laser crosses, the Silver Series provides users with a scan area measuring 275 x 250mm, an accuracy of up to 0.03mm, and a measurement resolution of up to 0.05mm. With a recommended part size ranging from 0.1 – 4m, the device is reportedly compatible with a whole host of object types, regardless of complexity, surface finish, or color.

Operating on seven red laser crosses, the Silver Series provides users with a scan area measuring 275 x 250mm, an accuracy of up to 0.03mm, and a measurement resolution of up to 0.05mm. With a recommended part size ranging from 0.1 – 4m, the device is reportedly compatible with a whole host of object types, regardless of complexity, surface finish, or color.

At 0.85kg, the Silver Series is lightweight and portable. Designed for both in-house and on-site use, the scanner fits comfortably in a small suitcase and can be set up in around two minutes. It triangulates its own relative position using in-built optical reflectors, meaning it can be used as a standalone device with no tripod or external tracking equipment. Featuring a simple UI and real-time visualization functionality, Creaform’s Silver Series boasts a “shallow learning curve” regardless of the user’s experience level.

The new Silver Series 3D scanning a helmet. Photo via Creaform.Technical specifications and pricing

Below are the technical specifications for the HandySCAN 3D Silver Series. The 3D scanner is available to order now, starting at $19,990.

The 3D scanner is available to order now, starting at $19,990.

| HandySCAN 307 | HandySCAN 700 | |

| Accuracy | Up to 0.04mm | Up to 0.03mm |

| Volumetric accuracy | 0.02mm + 0.1mm/m | 0.02mm + 0.06mm/m |

| Measurement resolution | 0.1mm | 0.05mm |

| Mesh resolution | 0.2mm | 0.2mm |

| Measurement rate | 480,000/s | 480,000/s |

| Light source | 7 red laser crosses | 7 red laser crosses + extra line |

| Laser class | 2M | 2M |

| Scanning area | 275 x 250mm | 275 x 250mm |

| Stand-off distance | 300mm | 300mm |

| Depth of field | 250mm | 250mm |

| Part size range | 0. 1 – 4m 1 – 4m | 0.1 – 4m |

| Weight | 0.85kg | 0.85kg |

| Dimensions | 77 x 122 x 294mm | 77 x 122 x 294mm |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the new Silver Series 3D scanning a helmet. Photo via Creaform.

Tags Creaform HandySCAN 3D Silver Series Simon Côté

Kubi Sertoglu

Kubi Sertoglu holds a degree in Mechanical Engineering, combining an affinity for writing with a technical background to deliver the latest news and reviews in additive manufacturing.

Creaform 3D Scanners - Portable 3D Scanning Technologies

800-688-3234

Fast and Versatile 3D Scanners

Together with Creaform, GoEngineer offers a variety of portable 3D scanning technologies that have been developed to meet the specific needs of a wide range of applications including aerospace, automotive, and oil & gas industries. From professional-grade to metrology-grade, they provide users with highly accurate, portable, and easy-to-use solutions.

From professional-grade to metrology-grade, they provide users with highly accurate, portable, and easy-to-use solutions.

Creaform 3D Scanners deliver accurate, high-resolution, and repeatable results, regardless of the measurement setup quality or user experience. Featuring dynamic referencing, both the scanner and part can move during measurement and still provide an accurate and high‑quality scan.

don't miss this upcoming webinar!

Solving Productivity Issues Through 3D Scanning - Deciding between Handheld and Automated 3D Scanning

April 13, 2022 at 10am PT

In webinar Jerome-Alexandre Lavoie, Product Manager at Creaform, will present tools that will help manufacturing companies analyze whether automation is more suitable for their activities than handheld 3D scanning. To better understand the potential of transitioning to automation and show how robot programming is accessible to everyone, Olivier Plamondon, Technical Product Manager at Creaform, will go through a complete automated quality control project in a live demonstration. To round off this webinar, Kyle Shannon, Business Development Manager A-QC at Creaform, will discuss the cost-benefit of transitioning to automation, and the expected return on investment.

To round off this webinar, Kyle Shannon, Business Development Manager A-QC at Creaform, will discuss the cost-benefit of transitioning to automation, and the expected return on investment.

Join Creaform’s experts and discover which handheld or automated 3D scanning solution is right for YOUR workflow.

Very simple 3D scanning process

The straightforward data acquisition process generates extra fast results, with real-time visualization and direct mesh output. These 3D scanners are up and running in less than five minutes and require no rigid setup or prior experience from the user. You can scan parts in virtually any size, material, or color.

3D scanning where you need to go Our 3D scanners are handheld, light, and they fit into a small suitcase. Because they have no mechanical constraint, they allow total freedom of movement and can be brought and used virtually anywhere.

Creaform 3D Scanners ensure highly-accurate measurements, regardless of the environment (instability, vibrations, thermal variation, etc.) or operator skills. Our scanners use software algorithms that simplify the measurement process and greatly increase data accuracy.

GO!SCAN 3D

Accuracy:

0.050 mm (0.0020 in)

Resolution:

0. 100 mm (0.0039 in)

100 mm (0.0039 in)

Go!SCAN 3D

Structured White LED Light

LEARN MORE

HandySCAN 3D

Accuracy:

0. 025 mm (0.0009 in)

025 mm (0.0009 in)

Resolution:

0.025 mm (0.0009 in)

HandySCAN 3D

Blue & Red Laser High Resolution

LEARN MORE

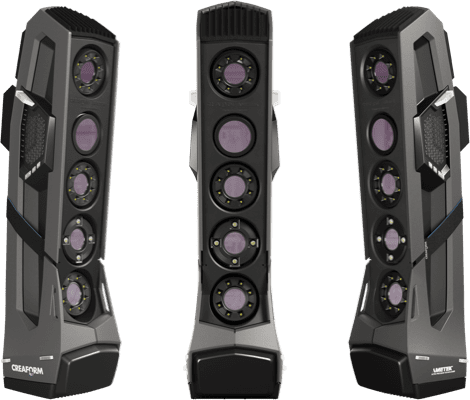

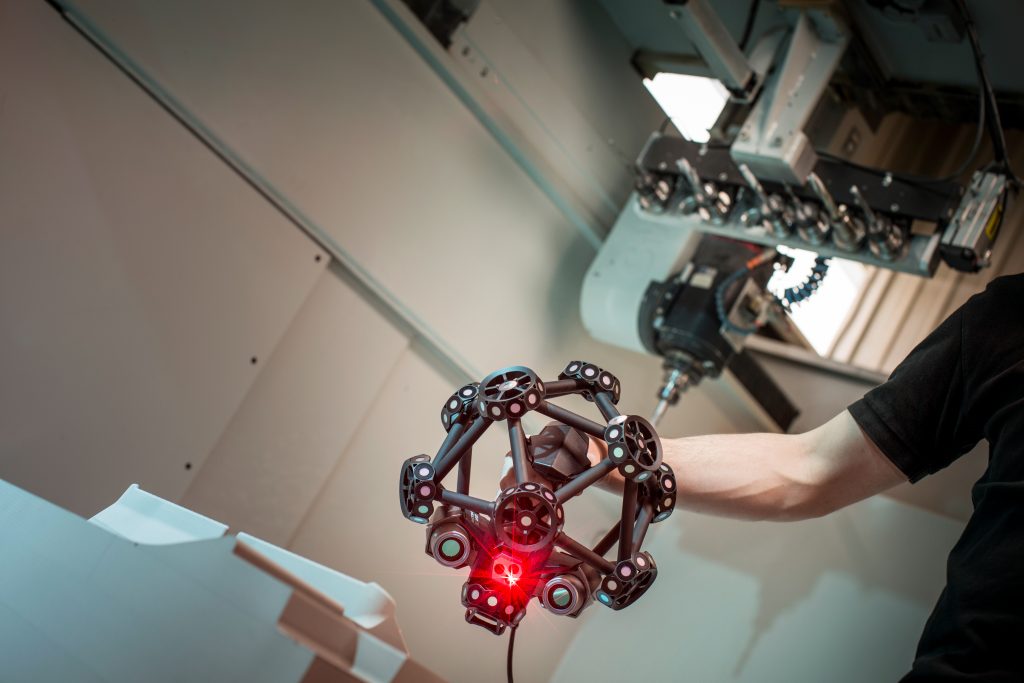

MetraSCAN 3D

Accuracy:

0. 044 mm (0.0017 in)*

044 mm (0.0017 in)*

Resolution:

0.050 mm (0.0020 in)

MetraSCAN 3D

Red Laser Light Technology

LEARN MORE

HandyPROBE

Accuracy:

0. 025 mm (0.0009 in)

025 mm (0.0009 in)

Part size range:

0.2-6 m (0.7-20 ft)

HandyPROBE

Portable CMM

LEARN MORE

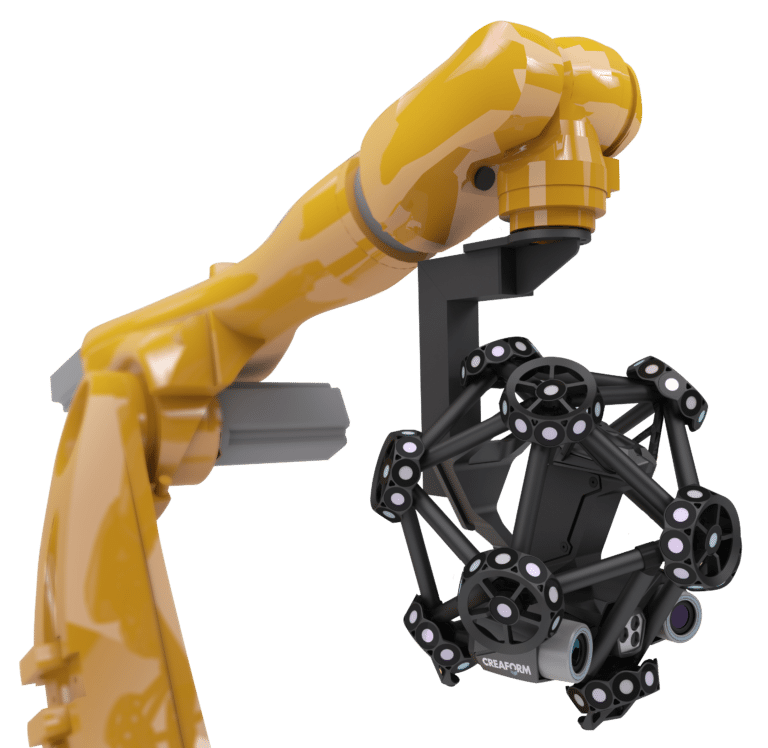

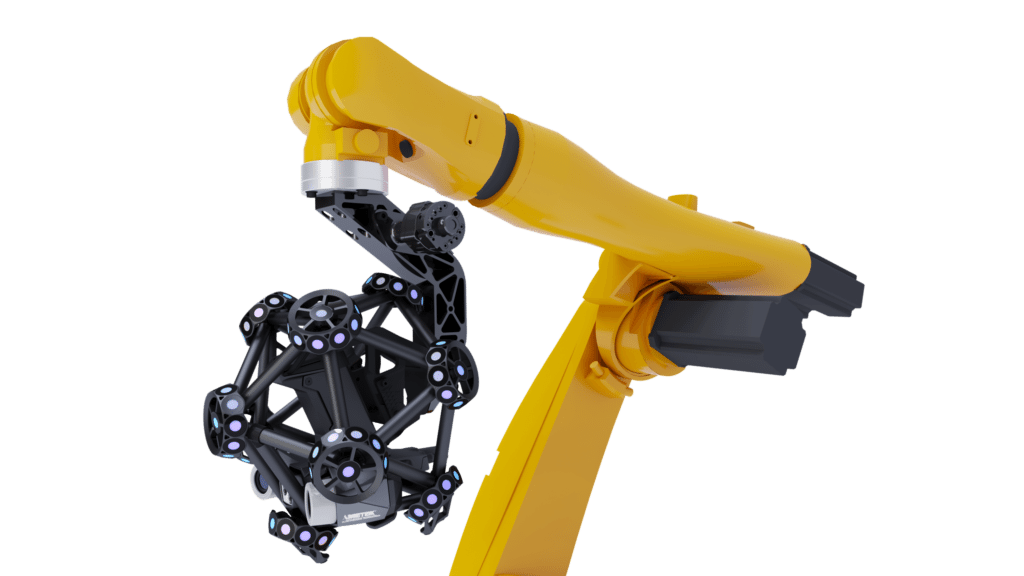

MetraSCAN 3D R-Series

Accuracy:

0. 025 mm (0.0009 in)

025 mm (0.0009 in)

Resolution:

0.025 mm (0.0009 in)

R-Series

Robot Mounted Automation

LEARN MORE

Add-On Hardware

MaxSHOT 3d

Large-scale metrology projects

- Automatic feedback on measurement quality

- Designed specifically for photogrammetric applications

- 50% lighter than traditional photogrammetric devices

AADS specializes in the design, manufacturing of specialized Jeep vehicles for governmental organizations. AADS uses their Go!Scan Spark scanner to reverse engineer and validate custom parts.

AADS uses their Go!Scan Spark scanner to reverse engineer and validate custom parts.

Download The AADS Creaform Case Study

Creaform 3D scanners are handheld and are non-contact. This versatility enables 3D technology to support four preservation categories: 3D archives, virtual museums, restoration, and preservation.

READ MORE

Plastic blow molding company Blowtech reduced their process time by 50% with 3D scanning. Originally t

he company had to ship the parts to an external service partner for inspections.

Originally t

he company had to ship the parts to an external service partner for inspections.

Download The Blowtech Creaform Case Study

Request More Information on Creaform 3D Scanners

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom.

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

Online Store

FREE SOLIDWORKS Tools

Enjoy this collection of small ‘macros’ that were tailored to help our customers. These free SOLIDWORKS tools are for you to use, review, and modify. SOLIDWORKS Automation Tools

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet, SL, or Metal 3D printers. 3D Printing Services

3D Printing Services

3D scanners and 3D scanning/modeling services in Nizhny Novgorod

We develop

industry solutions

based on modern

3D technologies

3D equipment from the world's leading manufacturers

: from

handheld 3D scanners to 9003 volumetric scanning systems

Connect with us Cases

Optimizing

production processes

using

3D technologies

3D scanning and 3D modeling services

based on our own laboratory

prototyping

Cases Cases

Data processing software

scan

and simulation

Connect with us Cases

We develop industry-specific solutions

based on modern

3D technologies

3D equipment from leading manufacturers: from handheld 3D scanners to robotic volumetric scanning systems

Connect with us Cases

We optimize production processes

using

3D technologies

3D scanning and 3D modeling services based on our own prototyping laboratory

Connect with us Cases

Data processing software

scan

and simulation

Connect with us Cases

Multivendor

As official partners of world leaders, we offer optimal solutions for business tasks. Prices from the manufacturer

Prices from the manufacturer

Expertise

We find the best solutions using advanced foreign experience

Comprehensive approach

We analyze, develop, implement, supply equipment and train your staff

Multivendor

As official partners of world leaders, we offer optimal solutions for business tasks. Prices from the manufacturer

Expertise

We find the best solutions using advanced foreign experience

Comprehensive approach

We analyze, develop, implement, supply equipment and train your staff

We offer

solutions based on 3D technologies

- Create a digital twin using

3D scanning, view in VR - 3D scanning and 3D modeling services

- We select equipment for tasks and budget

- we train, serve

- Rental and leasing of equipment

Leave a request, we will audit your needs and find the best solution.

We offer

solutions based on

3D technologies

- Creating a digital twin using 3D scanning, viewing in VR

- 3D scanning and 3D modeling services

- We select equipment for tasks and budget

- We supply, launch, launch we train, serve

- Rental and leasing of equipment

Leave a requestwe will audit your needs and find the best solution

3D handheld scanners

Simplifies the process of scanning objects compared to

with large stationary measurement equipment.

Ability to digitize complex details, regardless of size,

material or object color. High accuracy and resolution

measurements, improved reliability and scanning speed

3D handheld scanners

Simplifies the process of scanning objects compared to large stationary measurement equipment. The ability to digitize complex details, regardless of the size, material or color of the object. High measurement accuracy and resolution, increased reliability and scanning speed

High measurement accuracy and resolution, increased reliability and scanning speed

Official partner

Portable solution for fast and realistic 3D shooting even in harsh environmental conditions with environmental protection, battery life up to 4.5 hours. The most economical in its class

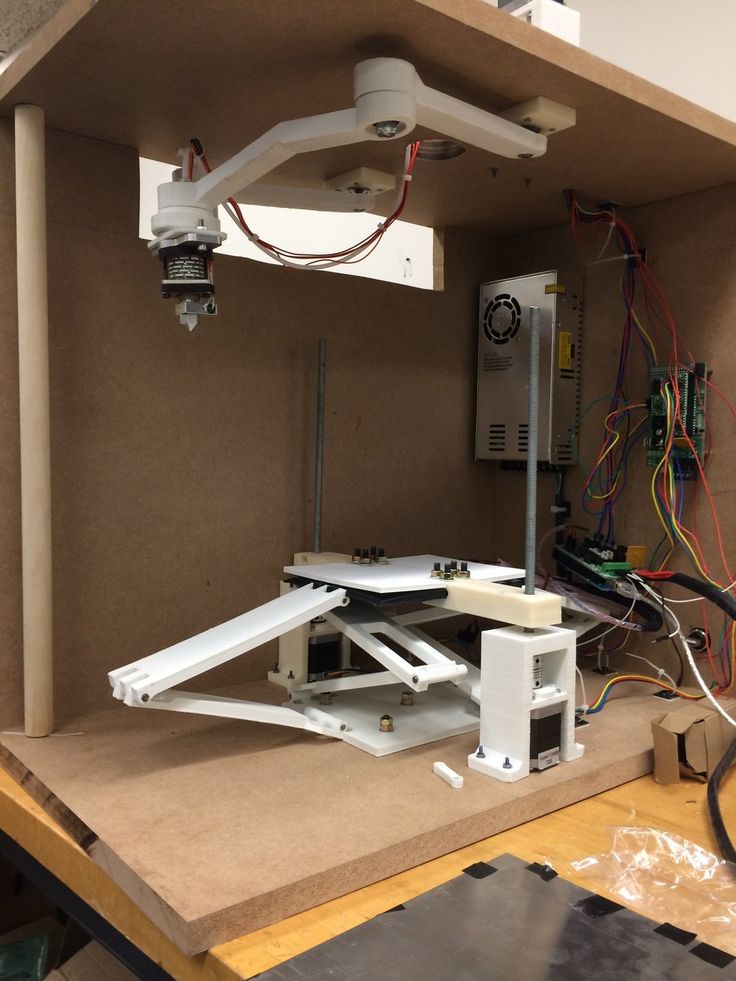

Stationary 3D scanners

for small and medium molds

Allows you to quickly measure a physical object and recreate its accurate digital

3D model. It became possible to modify existing

products without drawings, speed up the production of new parts, improve

quality and reduce the percentage of defects in production.

Designed to scan small, complex objects

in full

automated mode

Official partner

Features a customizable 3D scanning area and are designed to scan small, complex objects in a fully automated manner. Exceptional ease of use

Stationary 3D Scanners for Small

and Medium Forms

Features a customizable 3D scan area for scanning small, complex objects in a fully automated fashion. Exceptional ease of use

Exceptional ease of use

Official partner

Features a customizable 3D scanning area and are designed to scan small, complex objects in a fully automated manner. Exceptional ease of use

Industrial 3D scanners

Industrial 3D scanners for large molds and

robotic systems for 3D scanning. We offer innovative

equipment for 3D scanning of large objects both in open areas

and in industrial environments. Our

specialists will guide you on the functionality and possibilities of using

equipment, conduct an audit and help you choose a

device for specific tasks

Official partner

FARO 3D scanners for large objects for both outdoor and industrial applications. All models are equipped with a sealed housing that protects against environmental influences

Official partner

FARO 3D scanners for large objects for both outdoor and industrial applications. All models are equipped with an environmentally sealed enclosure

All models are equipped with an environmentally sealed enclosure

Official Partner

Known for their unsurpassed accuracy and quality at both close and medium distances and designed for reverse engineering, BIM and similar applications

Industrial

3D scanners

Large mold industrial 3D scanners and 3D scanning robots. We offer innovative equipment for 3D scanning of large objects both in open areas and in industrial environments. Our experts will guide you on the functionality and possibilities of using the equipment, conduct an audit and help you choose a device for specific tasks

Official Partner

Creaform 3D Scanning Robots - An incredibly fast and accurate solution for automated quality control

Official partner

FARO 3D scanners for large objects for both outdoor and industrial applications. All models are equipped with an environmentally sealed housing

Official Partner

Known for their unsurpassed accuracy and quality at both close and medium distances, designed for reverse engineering, BIM and similar applications

Software

Software products from world leaders for data processing

scanning and modeling. Our experts will help you choose

Our experts will help you choose

software, advise on the possibilities of

practical application of each of the software products

Official partner

Easily and efficiently process and manage scanned data through automatic object recognition, registration and scan positioning

Official partner

Complete software solution for reverse engineering, analysis and product quality control, continuously updated and intuitive software interface

Official partner

Creaform software products allow you to work with 3D scan data and refine it for 3D printing or transfer to CAD software

Software

Software products from the world's leading scanning and simulation data processing. Our experts will help you choose software, advise on the possibilities of practical application of each of the software products

Official partner

Complete software solution for reverse engineering, analysis and product quality control, continuously updated and intuitive software interface

Official partner

Creaform software products allow you to work with 3D scan data and refine it for 3D printing or transfer to CAD software

Official partner

Easily and efficiently process and manage scanned data through automatic object recognition, registration and scan positioning

We will select a 3D scanner

for your needs

Submit an application

We will select

3D scanner

for your tasks

Submit an application

Our partners

3D scanning services

Architectural measurements of buildings and facades.

3D scanning of exteriors

3D scanning of exteriors 3D scanning of real estate objects helps to carry out facade surveys, measurements and surveys of buildings in a short time. With the help of laser scanning, you can quickly and easily control the design and construction process, take architectural measurements and calculate accurate surface areas.

3D scanning services

Create dimensional drawings

Our experts will make a measurement drawing of the object using a 3D scanner, which is then easily transformed into a familiar 2D plan with exact dimensions. We offer 3D technologies that will significantly reduce the time of work at the measurement stage and will make it possible to measure any object of any size and space geometry.

3D scanning services

Reverse engineering (reverse engineering)

Reverse engineering allows you to quickly create the most accurate digital model of a product, even of complex geometry. This model can be modified, printed and used for subsequent production. Reverse engineering services are widely used in mechanical engineering, as well as for the production of individual parts on CNC machines.

This model can be modified, printed and used for subsequent production. Reverse engineering services are widely used in mechanical engineering, as well as for the production of individual parts on CNC machines.

3D scanning services

Part geometry quality control. Metrological analysis, wear and deformation measurement

Thanks to 3D scanning, quality control and metrological analysis in production takes much less time and effort than with traditional methods. 3D scanners make it possible to carry out incoming and outgoing inspections, analyze the relative position of elements in a product, and monitor the quality of forming surfaces.

3D scanning services

Large object scanning

Scanning large objects allows you to save time and money, as well as quickly obtain an accurate 3D model that helps the specialist to identify even small defects in the product. You can order a 3D scanning service and quickly receive a complete digital archive of finished products and prototypes designed by our experts.

Services

3D scanning

Architectural measurements of buildings and facades.

3D-scanning of exteriors

3D-scanning of real estate objects helps to carry out facade surveys, measurements and surveys of buildings in a short time. With the help of laser scanning, you can quickly and easily control the design and construction process, take architectural measurements and calculate accurate surface areas.

Creation of measurement drawings

Our experts will make a measurement drawing of the object using a 3D scanner, which can then be easily transformed into a familiar 2D plan with exact dimensions. We offer 3D technologies that will significantly reduce the time of work at the measurement stage and will make it possible to measure any object of any size and space geometry.

Reverse engineering (reverse engineering)

Reverse engineering allows you to quickly create the most accurate digital model of a product, even of complex geometry. This model can be modified, printed and used for subsequent production. Reverse engineering services are widely used in mechanical engineering, as well as for the production of individual parts on CNC machines.

This model can be modified, printed and used for subsequent production. Reverse engineering services are widely used in mechanical engineering, as well as for the production of individual parts on CNC machines.

Part geometry quality control. Metrological analysis, wear and deformation measurement

With 3D scanning, quality control and metrological analysis in production takes much less time and effort than with traditional methods. 3D scanners make it possible to carry out incoming and outgoing inspections, analyze the relative position of elements in a product, and monitor the quality of forming surfaces.

Large object scanning

Scanning large objects allows you to save time and money, as well as quickly obtain an accurate 3D model that helps a specialist to identify even small product defects. You can order a 3D scanning service and quickly receive a complete digital archive of finished products and prototypes designed by our experts.

Applications

Engineering

Aerospace

Automotive

Creating measurement drawings

Creating a measurement drawing of an object is very easy with a 3D scanner that will allow you to easily transform a 3D object into a familiar 2D plan with exact dimensions. 3D equipment significantly reduces the work time of a specialist at the measurement stage and makes it possible to measure an object of any size and space geometry.

3D equipment significantly reduces the work time of a specialist at the measurement stage and makes it possible to measure an object of any size and space geometry.

Integration of scanned data

into CAD for further editing or comparison of

with a mathematical model

3D scanning produces a highly accurate 3D model that can calculate the area of the scanned surface much faster than traditional methods. 3D scanning technologies help to solve the problems of collision detection, calculation of useful areas of objects, design deviations and preservation of cultural heritage.

Restoration of project documentation

With the development of 3D technologies, it became possible to create project documentation in a short time, identify discrepancies between real objects and drawings, and analyze the state of the building. 3D scanning allows you to recreate lost design documentation and make changes to it in just a few hours, instead of several days of measuring work with the traditional method.

Verification of product assembly in design

Thanks to 3D scanning technologies, it has become much easier to design and manufacture new components, parts and assemblies, as well as to control the assembly of products at all stages of production. In a few hours you can get a 3D model of the source and make calculations and check the assembly of parts.

Exact copy

products

3D scanning makes it possible to make exact copies of products and high quality standards in a fairly short time.

3D scanning services help to ensure the production of high-precision copies of products for import substitution of parts.

We invite you to our showroom

in Nizhny Novgorod

We invite you to visit our high-tech showroom. Most of the

virtual reality equipment is in the public domain.

Let's have a test drive, discuss the possibilities and have a good time!

Make appointment

We invite

to our showroom

in Nizhny Novgorod

We invite you to visit our high-tech showroom. Most of the virtual reality equipment is in the public domain. Let's take a test drive, discuss the possibilities and have a good time!

Most of the virtual reality equipment is in the public domain. Let's take a test drive, discuss the possibilities and have a good time!

Make appointment

Application examples

EDUCATION

Creaform ACADEMIA educational 3D solution

Creaform ACADEMIA is an affordable 3D educational suite. It includes a wide range of 3D measurement technologies for various educational profiles: scientific and technical orientation, applied and natural sciences, industrial design, archeology, as well as research projects.

Here are some recent examples of the use of ACADEMIA in educational institutions in the Czech Republic.

The Vocational School of Automotive and Engineering Design in České Budějovice provided students with the opportunity to use ACADEMIA 3D scanners and the VXmodel and VXinspect software modules for reverse engineering and quality control of auto parts.

The Vocational Secondary School of Glassmaking in Valašské Meziříči (UNESCO Associated School) chose ACADEMIA for 3D scanning of handmade glass products and for 3D printing of models of various sizes

CONSTRUCTION

3D printing of a villa prototype

Challenge: create a visual model of a villa in a short time

Solution: 3D print a white light-cured polymer building prototype on a ProtoFab SLA600 DLC stereolithographic 3D printer @3dprotofab

Result:

• A stylish architectural model of the villa was made, the structure of the building, furnishings and other exterior elements were carefully reproduced

• Thanks to the use of an SLA printer with a large build chamber (600 × 600 × 400 mm), a model with excellent detail was quickly created

• Post-processing completed: polishing and painting model

• Lead time - 1 day

TRANSPORT

3D printed subway train components

Large items such as the front of a tram, as well as various parts of railway and road transport, can now be 3D printed in a single printing session. The use of plastic granules instead of filament (Direct Extrusion of Pellet technology) greatly simplifies the creation of not only prototypes, but also finished parts in record time and at a much lower cost.

The use of plastic granules instead of filament (Direct Extrusion of Pellet technology) greatly simplifies the creation of not only prototypes, but also finished parts in record time and at a much lower cost.

⠀

The photo shows components for a subway train printed on an additive Super Discovery 3D Printer (CAF project). With a build chamber of 1300 x 2500 x 1000 mm, this printer is the perfect answer to the new needs of large format 3D printing.

Our clients

and more than 200 clients

Getting started

Why is it beneficial?

3D scanning is the most advanced way of converting a physical object into a digital format, which helps to significantly optimize the production process for solving problems of quality control and reverse engineering. Modern 3D scanners are capable of digitizing a wide variety of objects, from miniature parts to buildings and structures. They are attractive due to their optimal price-to-accuracy ratio, high measurement speed and

LET'S DISCUSS THE PROBLEM AND WE WILL GIVE THE APPROXIMATE COST OF THE SOLUTION.

Can

3D technologies replace traditional production methods?

Today, additive technologies are able to effectively complement classical processes or replace them at a certain stage of the cycle. However, in the near future, in the context of Industry 4.0, additive manufacturing will become an integral part of the technological processes in the enterprise.

LET'S DISCUSS THE PROBLEM AND WE WILL GIVE THE APPROXIMATE COST OF THE SOLUTION.

How do I know if it makes sense

for my business to use

3D technology?

Our company has a research laboratory for the development of complex industry solutions for the individual tasks of the customer. We study problems and plan solutions, perform testing, product post-processing and data analysis.

LET'S DISCUSS THE PROBLEM AND WE WILL GIVE THE APPROXIMATE COST OF THE SOLUTION.

My company is ready

to the introduction of

3D technologies.

What

What should I do?

Our team of highly qualified experts, engineers and technologists will develop and implement unique 3D solutions for your industrial plant, research center, and small and medium business projects.

LET'S DISCUSS THE PROBLEM AND WE WILL GIVE THE APPROXIMATE COST OF THE SOLUTION.

News

October 2022

October 2022

October 2022

Overview of Creaform Metrascan 3D scanners / Sudo Null IT News

Let's talk about Creaform Metrascan - professional 3D scanners for industrial applications, including part geometry control, and reverse engineering. Learn more from this article.

About Creaform

Source: coarchitecture.com

In 2002, Bank of Canada invested $200,000 in a 3D scanner startup led by Martin Lamontagne. From that moment began the history of Creaform. Two years later, Lamontagne was named the "Best Young Entrepreneur of Quebec. " His business brought in $5,000,000 and grew by 50% annually.

" His business brought in $5,000,000 and grew by 50% annually.

Source: pressreader.com

Creaform creates and markets 3D measurement equipment and participates in the development of innovative solutions in partnership with other companies.

Manufacturer specializes in the creation of tools for 3D scanning, non-destructive testing, reverse engineering, quality control and digital modeling (FEA/CFD).

Creaform equipment is in demand in various fields:

- In heavy engineering;

- In healthcare organizations;

- In the manufacture of household appliances;

- In the automotive industry;

- In the aerospace industry;

- In the mining and processing industries;

- In the production of electricity;

- In educational and scientific institutions.

In 2013, Creaform became part of AMETEK Ultra Precision Technologies, a division of AMETEK Inc. , a world renowned manufacturer of electronic tools and electromechanical devices with over $4 billion in annual sales.

, a world renowned manufacturer of electronic tools and electromechanical devices with over $4 billion in annual sales.

Source: trends.directindustry.com

On March 1, 2018, Fanny Truchon took over the Creaform Business Line. For the previous 5 years, she served as the company's vice president of customer service.

Creaform's headquarters and manufacturing facilities are located in Quebec. Scientific and technical centers operate in Grenoble and Levis. Sales centers operate in Europe, Asia and America: Italy, France, Germany; China, Korea, Japan, Thailand, Singapore, USA and Brazil.

Creaform Metrascan 3D Scanners

Source: industryarena.com

Creaform's 3D scanner principles are:

Protect measurements from adverse environmental conditions. Vibrations, unstable lighting, temperature fluctuations and inexperience of the operator do not affect the accuracy of the result. Creaform scanner algorithms are aimed at facilitating the measurement process and increasing the accuracy of the information received

Creaform scanner algorithms are aimed at facilitating the measurement process and increasing the accuracy of the information received

TRUporability - 3D scanning anywhere.

Compact size, light weight, easy transport - everything you need to work 3D scanners almost anywhere.

TRUsimplicity - easy workflow.

It takes less than 5 minutes to collect information, process data, visualize and display a grid for objects of almost any size, color and material. To work with the device does not require pre-configuration or special user experience.

How it works

Source: creaform3d.com

The laser beams of the 3D scanner are directed at the subject, the camera captures the intersection points of the beams and the object. A laser tracker or accessory monitors the spatial position of the scanner. To connect parts of the image, small stickers of a given size, called marks, are used.

Source: creaform3d.com

MetraSCAN, Go! SCAN, HandySCAN - three models, three ways to collect data.

Each device determines its location in space in relation to the scanned object using different algorithms.

MetraSCAN is the most accurate device in this range. The principles of operation are similar to those of HandySCAN. MetraSCAN can operate as a stand-alone handheld device. However, it was originally designed to work with the C-track device. More about it in the paragraph "Optional equipment".

METRASCAN 750 (Elite)

Source: creaform3d.com

Specifications

Price METRASCAN 750 on request

METRASCAN 750 ELITE price on request

METRASCAN 350 (Elite)

Source: creaform3d.com

Price METRASCAN 350 on request

METRASCAN 350 ELITE price on request

Scope of supply

Source: aniwaa

Scope of supply:

- MetraSCAN 3D scanner

- VXelements software

- Stand

- Calibration sphere

- FireWire cable

- Flight case

- 1 year labor and parts warranty

Optional equipment

C-Track

Source: aniwaa. com

com

The MetraSCAN handheld scanner is housed in a frame with marks to determine its location in space. The work of the scanner is to process data about the shape and surface of the scanned object, it is not tied to reference marks. They are searched for by the C-track, which is equipped with two cameras spaced apart to "capture" a large amount of space.

To obtain a coordinate reference system for the scanner, at least 4 marks, C-track tracks an area up to 16.6 cubic meters in front of it. To bind the coordinate system to the object, marks can be placed on the part under study. When changing the relative position of the C-track and the object, the relationship between the scanner and the object is preserved.

Scanning starts immediately after the C-track finds several marks to create a reference frame in space. C-track keeps track of marks on the device so as not to lose its position in the working coordinate system. Collaboration of devices provides ample opportunities to scan large objects, such as aircraft and cars, in automatic mode and using a relatively small number of tags.

CUBE-R

Source: creaform3d.com

C-Track, managing computer complex.

System features:

- High performance: checks up to hundreds of objects per day, including details of complex geometric shapes;

- Multifunctionality: simultaneously collects and analyzes information;

- Reduced footprint: 4.1m x 4.1m x 3.1m;

- Processing of large and heavy parts: weighing up to 1.5 tons, volume - up to 3 m along any coordinate axis;

- Ready to work: the system is completed, does not require integration;

- Automatic calibration mode during continuous data processing;

- Industrial design: adapted to the production environment.

Software

Source: creaform3d.com

Creaform offers several software license options:

- Computer license;

- Hardware key license;

- Network license.

Creaform software features comparison:

VXelements

Source: creaform3d.com

VXelements is an integrated software platform for combining all Creaform 3D scanning and measurement technologies. It is a working environment for other software modules (VXscan, VXprobe, VXshot, etc.) and a convenient, simple user shell.

VXmodel

Source: www.youtube.com

VXmodel is an easy-to-use program for preparing a 3D scan mesh for reverse engineering or 3D printing. Software options:

- Screen cleaning;

- Filling voids;

- Grid alignment;

- Mesh simplification;

- Create mesh-based surfaces.

VXinspect

Source: youtu.be

VXinspect - The software integrates the results of digital information processing and photogrammetric measurements. Solves the following tasks:

Solves the following tasks:

- Comparison of the resulting digital models in CAD with the original objects;

- Control of parameters of received models and original parts and tools;

- Control of conformity of manufactured parts to originals or standard;

- Checking the tool and its fixtures;

- Alignment;

- Deformation tracking;

- Dynamic measurement.

VXtrack

Source: creaform3d.com

VXtrack is designed to solve the following tasks:

- Robot calibration and orientation;

- Track and control complex assembly processes;

- Real-time correction of inaccuracies that occur during data processing;

- Deformation tracking during testing.

Compare with Shining Freescan Trak

Both devices: Shining Freescan Trak and Creaform Metrascan operate on a similar principle: a symbiosis of a 3D scanner with a tracking tracker that determines the position of the scanner in relation to the digitized object.

Specification comparison:

Application examples

Product quality control at MDC DESIGN srl

Source: creaform3d.com

MDC DESIGN srl is a rapidly growing company and a leading supplier of control systems and sensors for process automation in the automotive and aerospace industries. The work of MDC DESIGN srl is based on strict compliance with quality standards. The company produces a wide range of devices, from simple instrument stands to innovative systems with complex electronic components.

Source: creaform3d.com

During the production of large equipment, the company was faced with the task of finding a device for measuring and creating models of parts in three-dimensional space. The tool had to process information and transform data with maximum accuracy.

MDC DESIGN management said they chose Creaform because their values matched. Accuracy and speed are priority principles of both companies. MDC DESIGN was pleased with the choice of supplier, also due to the high level of staff training and high-quality technical support.

Accuracy and speed are priority principles of both companies. MDC DESIGN was pleased with the choice of supplier, also due to the high level of staff training and high-quality technical support.

The Creation of American Magic, New York Yacht Club

Source: sail-world.com

The American Magic is the United States candidate for the 2020 America's Cup, considered by yachting enthusiasts to be the most prestigious international event. The history of the competition began in 1851, forty-five years before the Olympic Games.

Source: creaform3d.com

Creaform is the official 3D technology provider for the nearly 23m American Magic. The yacht develops a speed of more than 92 km/h thanks to innovative technologies and modern materials used by Airbus engineers to create a hydrofoil yacht.

Source: creaform3d.com

Working with sailing experts and engineers, Creaform's metrology team scanned the carbon fiber hull of the yacht. We analyzed the influence of the geometry of parts on the streamlining of the vessel, studied the possibilities of improving the characteristics of the hull. The Creaform team was delighted to be part of the evolution of American Magic and are proud to have helped improve the yacht's design features.

We analyzed the influence of the geometry of parts on the streamlining of the vessel, studied the possibilities of improving the characteristics of the hull. The Creaform team was delighted to be part of the evolution of American Magic and are proud to have helped improve the yacht's design features.

24 Hours of Le Mans

Source: sport.ru

To control the cars of the race participants, the FIA used the Creaform MetraSCAN 3D scanner.

Source: creaform3d.com

The task before the experts was to check the compliance of each car with the rules of racing. Each test was to take no more than 10 minutes. The problem was solved using MetraSCAN scanners.

https://youtu.be/bJPw8UEuoNA

Conclusion

Source: creaform3d.com

3D laser scanners are high-precision, high-speed equipment for use in various areas where accuracy and speed of obtaining three-dimensional models of physical objects are required.