Are 3d printers dangerous

3D Printing Safety at Work | NIOSH

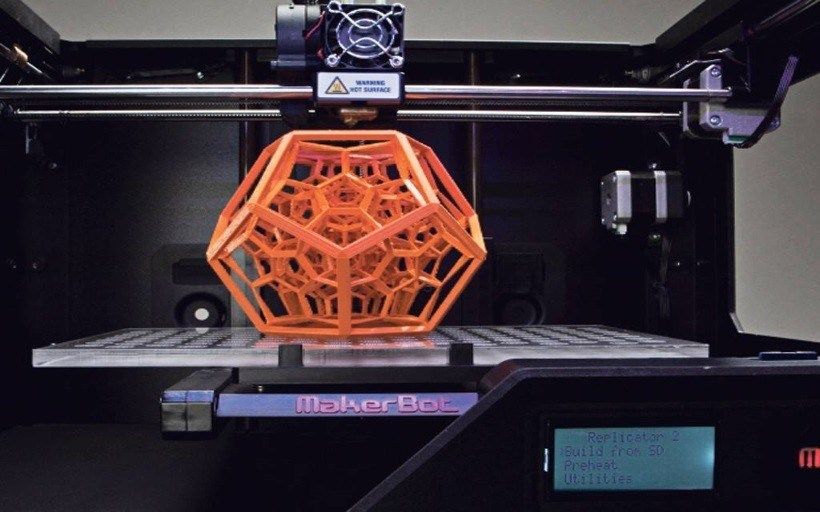

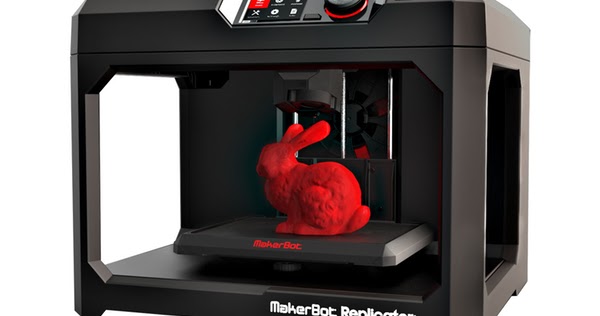

3D printing, or additive manufacturing, is increasing in popularity. This technology is becoming less expensive and more accessible to both businesses and consumers. It is currently used in a wide variety of settings, such as labs, factories, hospitals, schools, libraries, and homes. Despite its popularity, 3D printing is still a relatively new technology and there are many gaps in the information available about health and safety risks. The National Institute for Occupational Safety and Health (NIOSH) is studying the potential hazards of 3D printing and ways to reduce health and safety risks for workers.

What is 3D printing?

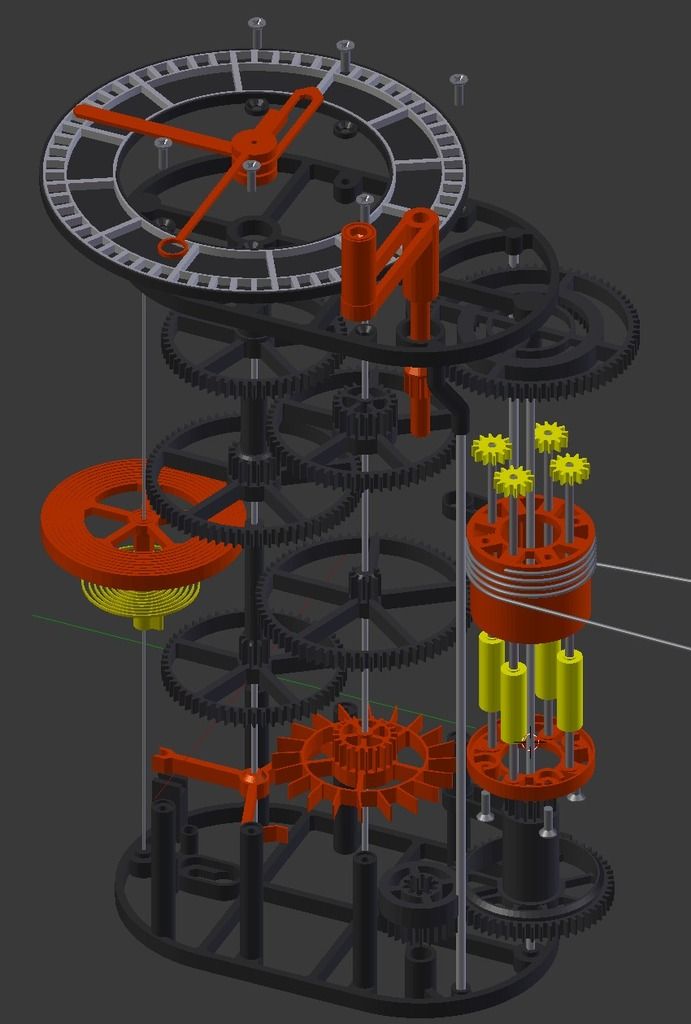

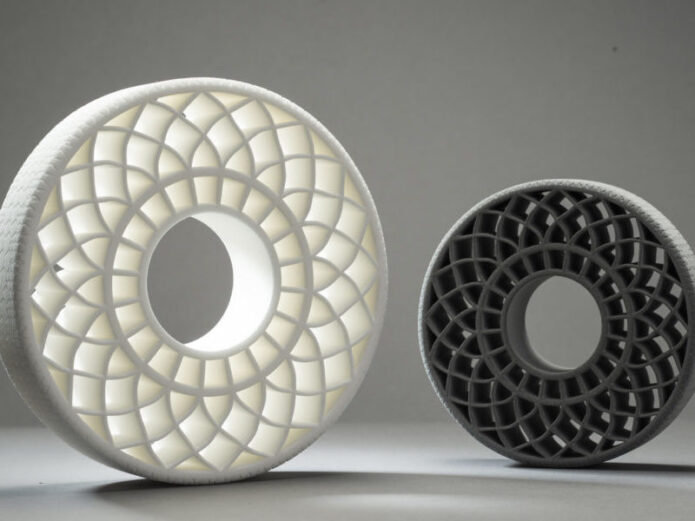

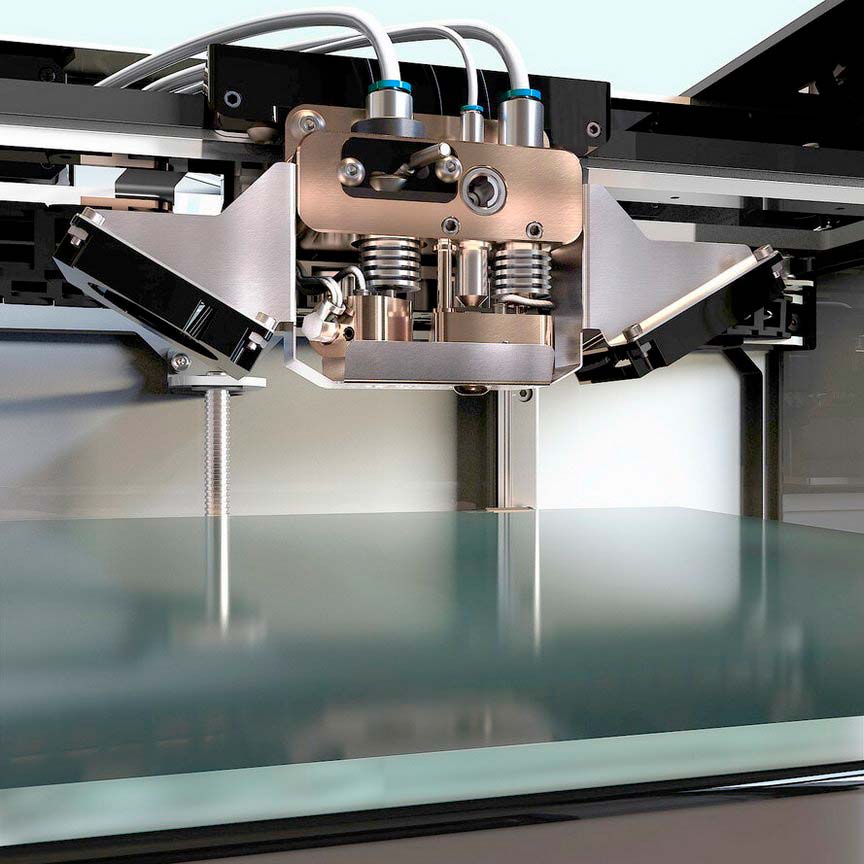

3D printers create three-dimensional (or 3D) objects via computers. A computer file “tells” the 3D printer what object to create and how. 3D printers essentially stack layers of a material to get the desired product. Different types of 3D printers do this in different ways. For example, some use high temperatures, some use ultraviolet light, and others use lasers. 3D printers also use different print materials, such as plastics, rubbers, and metals.

Industries traditionally used 3D printing for prototyping. However, it is now also used for production. Industries using 3D printing include the automotive, aerospace, electronics, medical, and many others.

Potential Hazards of 3D Printing

3D printing hazards vary depending on the type of printer and materials used. For example, print materials that are powders are more likely to be inhaled or cause skin problems than others. 3D printers that use lasers have different hazards than printers that use high temperatures to melt materials. Some common hazards include:

- Breathing in harmful materials: 3D printing can release particulates and other harmful chemicals into the air.

- Skin contact with harmful materials: Users can get hazardous materials, such as metal powders, solvents and other chemicals, on their skin.

- Static, fire and explosion: Some materials used can be flammable or combustible.

High temperatures from some printers can cause burns.

High temperatures from some printers can cause burns.

Ways to Protect Workers from 3D Printing Hazards

NIOSH has studied multiple ways to reduce exposure to 3D printing hazards. Some options include

- Limiting equipment access to trained or authorized personnel

- Using enclosures for 3D printers and ventilation to capture chemical emissions

- Using materials with lower emissions

- Reducing time spent near the printer while it is running

- Training workers on potential hazards and how to protect themselves

- Wearing appropriate personal protective equipment, such as safety glasses, gloves, or lab coats

The ways to reduce exposure depend on the type of printer and materials used. NIOSH has created two posters to help workers explore ways to reduce potential 3D printing hazards. One poster focuses on 3D printing with metal powders and the other focuses on filaments:

- 3D Printing with Metal Powders: Health and Safety Questions to Ask

- 3D Printing with Filaments: Health and Safety Questions to Ask

Help NIOSH Learn More about 3D Printing

Do you use 3D printing in your workplace? You can help NIOSH continue assessing 3D printing hazards and controls. Companies can contact the Nanotechnology and Advanced Materials Field Studies Team to assess possible work-related health hazards with 3D printing in their workplace.

Companies can contact the Nanotechnology and Advanced Materials Field Studies Team to assess possible work-related health hazards with 3D printing in their workplace.

More Information

- Additive Manufacturing

- NIOSH Science Blog: Characterizing 3D Printing Emissions and Controls in an Office Environment

- 3D Printing with Metal Powders: Health and Safety Questions to Ask

- 3D Printing with Filaments: Health and Safety Questions to Ask

Are They Dangerous? – Clever Creations

Yes, 3D printer fumes can be dangerous. In the 3D printing process, the melting of plastic releases harmful particles into the air. Notably, the melting of ABS, PETG, and Nylon filaments emits particles that may induce headaches, nausea and irritate the eyes and nasal tract.

3D printers are getting increasingly common in households and industries alike. With this, there is a concern about whether or not they are entirely human-friendly. After all, fused deposition modeling (FDM) 3D printing works by melting plastic. This raises the question of 3D printing safety and long-term exposure to 3D printer fumes.

After all, fused deposition modeling (FDM) 3D printing works by melting plastic. This raises the question of 3D printing safety and long-term exposure to 3D printer fumes.

In this article, we’ll understand the various health-related concerns surrounding 3D printing. We’ll look at the multiple filaments and how safe they are. Then, we’ll go over some of the ways you can mitigate the risks associated with using a 3D printer. The article aims not to scare you away from 3D printing but instead make you more aware of the risks and associated measures you can take to protect yourself.

Let’s dive a little deeper and see if things really are that bad.

What are 3D printer fumes?

The smell that comes while you’re 3D printing with PLA, ABS, or any other filament, is due to the release of various chemicals in those filaments. These vapors of multiple chemicals are termed 3D printer fumes. There are two main elements in the 3D printer’s fumes – VOCs and UFPs.

Volatile Organic Compounds (VOCs) are a mixture of chemicals with a high vapor pressure at room temperatures. The sweet smell of PLA filament, the scent that comes when you melt ABS, or the pleasing scent of fresh paint are all due to the release of VOCs in the air. VOCs are not potentially life-threatening, but long-term exposure to them may cause severe side effects.

The sweet smell of PLA filament, the scent that comes when you melt ABS, or the pleasing scent of fresh paint are all due to the release of VOCs in the air. VOCs are not potentially life-threatening, but long-term exposure to them may cause severe side effects.

Ultrafine particles (UFPs) are particles with a size less than 0.1 μm or 100 nm in diameter. They are notoriously difficult to filter out due to their small size. These particles enter the body through our lungs and cause inflammation in the nasal areas and the eyes.

A 2016 study has demonstrated the excessive release of VOCs when using ABS, Polycarbonate, and Nylon filaments. Similarly, another study on Ultrafine particle emissions highlights 3D printers as high emitters of UFPs.

It is clear that using a 3D printer creates emissions in its environment. But are these dangerous or toxic for your health?

Are fumes from a 3D printer harmful?

The short answer to whether 3D printer fumes are harmful is yes. However, 3D printers can use various types of filament materials, and each material is made up of various compounds. Accordingly, the fumes emitted from these filaments vary as well.

However, 3D printers can use various types of filament materials, and each material is made up of various compounds. Accordingly, the fumes emitted from these filaments vary as well.

In the same 2016 research paper mentioned above, researchers have thoroughly examined the various VOCs emitted by different filaments.

Let’s look at the most popular plastic filaments in more detail.

ABS filament fumes

Acrylonitrile-Butadiene-Styrene (ABS) is a commonly used 3D printing filament both by hobbyists and professionals. It is superior in its strength and rigidity and makes an excellent material for practical applications due to its high temperature resistance.

One of the biggest downsides of ABS filaments is that when it melts, it releases Styrene, a potentially harmful and carcinogenic VOC. Long-term exposure to ABS fumes is also related to nausea, headaches, and fatigue. The UFPs released by ABS are also higher compared to printing with other 3D printing filaments (∼2 × 1010 to ∼9 ×1010 particles per minute).

PLA filament fumes

PolyLactic Acid (PLA) is one the most popular 3D printing filaments used in hobbyist 3D printers. It is mostly made up of corn starch, sugar, or maize. These materials are renewable raw materials, and hence PLA is a comparatively sustainable 3D printing plastic.

When you melt PLA filament, it releases Lactide into the atmosphere. This is a non-toxic chemical, however, and is relatively safe to be around. PLA is a low emitter of VOCs and UFPs as compared to other 3D printing filaments. Still, you should be cautious of long-term exposure to PLA fumes as their long-term effects are unknown.

PETG fumes

Polyethylene Terephthalate Glycol (PETG) is a 3D printing filament favored by many. It combines the ease of printing with PLA and ABS’s strong chemical and mechanical resistance into a single material.

A recent study on PETG 3D printing noted that PETG releases Ethylbenzene and Styrene, both toxic and carcinogenic chemicals. While we cannot firmly determine the concentration and emission of VOCs and UFPs from this study, it still recommends caution with long-term exposure to PETG fumes.

Nylon fumes

Nylon is primarily an industrial 3D printing plastic. It offers extreme durability and more wear and tear resistance than ABS filament. That said, it also emits harmful fumes, of which over 90% consists of Caprolactam.

The EPA has not classified Caprolactam as a Carcinogenic substance in its findings; still, long-term exposure can irritate the eyes, nose and cause respiratory disorders in humans. The 2016 study also found out that the emission rate of VOCs while 3D printing Nylon was the highest ∼at 180 μg/min. This suggests that even short-term exposure to these fumes may result in unpleasant side effects of printing with Nylon.

Resin 3D printing fumes

Resin 3D printing doesn’t melt any material but instead cures 3D printer resin using a light source, typically an LCD screen or a laser. The process is notorious for its foul smell, and hence a majority of resin 3D printers come with a tightly sealed enclosure. Some of the best resin printers even include air filtration systems.

A recent study published by Chemical Insights concluded that although the VOCs emitted during resin 3D printing are significantly less than those from FDM printing, there are still potential toxic chemicals being released. Notably, formaldehyde (a carcinogen), acetaldehyde, and methyl isobutyl ketone are being emitted during the resin 3D printing process.

Even though these chemicals were well within the recommended limits, prolonged exposure to this mix of chemicals can irritate susceptible individuals’ eyes and the skin.

Recommended:

Resin vs Filament 3D Printers: What’s the Difference?

How to reduce risks from harmful 3D printer fumes?

We’ve now understood that there are indeed risks associated with 3D printer fumes. While they are not instantly deadly, we still need to take safety and health precautions to enjoy the 3D printing hobby and mitigate any risks. In this section, we’ll go over some of the techniques you can use to enjoy a harmless 3D printing experience without worry.

Ventilate your workspace

The one common thing that we’ve observed in all the studies is that the 3D printers emit a constant stream of VOCs and UFPs when in operation. The risks associated with these fumes have less to do with the chemicals themselves and more to do with their concentration in the air.

A closed room with a single 3D printer can be more harmful than a well-ventilated workspace with multiple 3D printers. The goal is to ensure good ventilation in the workspace using air filters, fans, and windows. This limits the concentration of harmful chemicals in the air and maintains good air quality in the room.

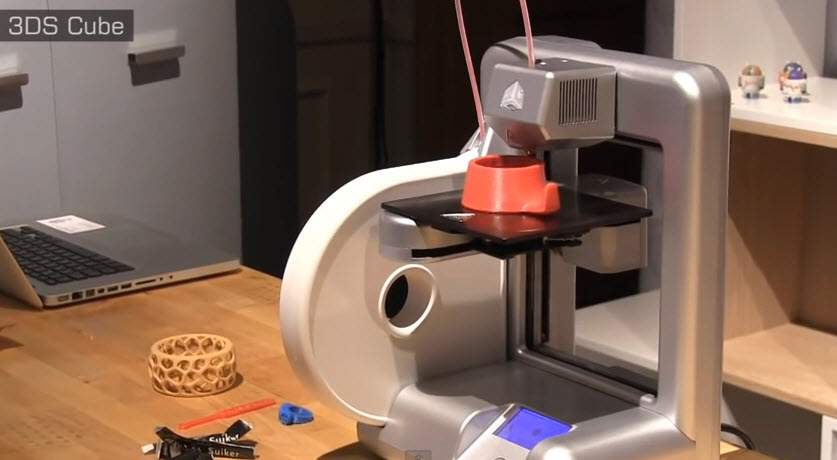

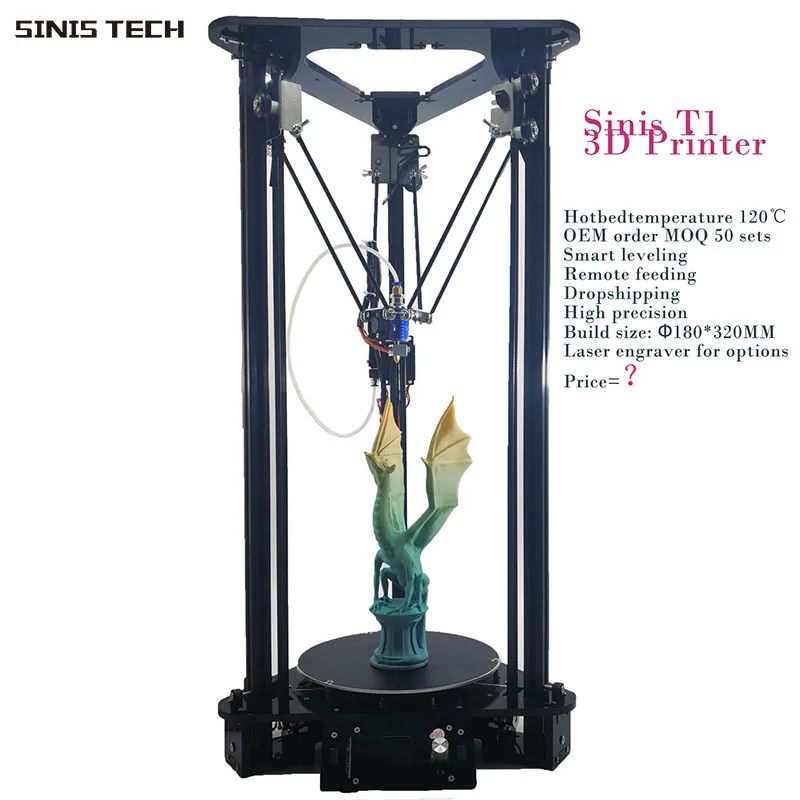

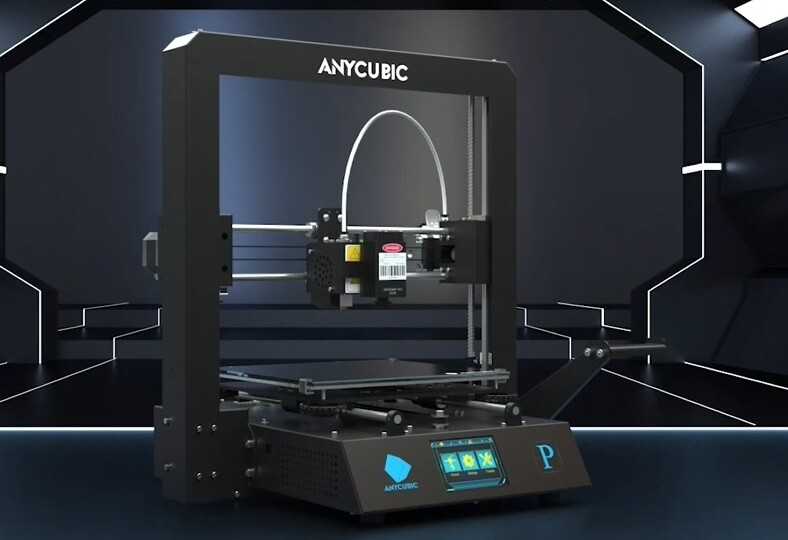

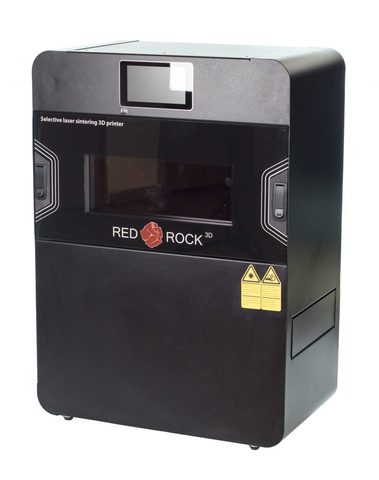

Get a 3D printer enclosure

Many hobby-level 3D printers are of open-frame design. This helps manufacturers save costs associated with an enclosed structure. This does mean that, while in operation, the 3D printer releases toxic fumes directly into the atmosphere.

In the case of enclosed 3D printers, you can avoid this problem. These contain VOCs and UFPs significantly and prevent these compounds from freely spreading to your room. Some enclosed printers even come with a filtration system and fans.

Some enclosed printers even come with a filtration system and fans.

Recommended:

The 9 Best Enclosed 3D Printers

Aside from limiting the transmission of harmful fumes into the workspace, enclosures also reduce any filament smell and printing noises.

But these 3D printers can be expensive, and so many people accept the trade-off that comes with the open-frame design. You can, however, opt for one of the many DIY 3D printer enclosure ideas that are available.

Creality even offers official enclosures for their 3D printers, like the popular Ender 3, that you can upgrade with when you feel ready. It is one of the many popular Ender 3 upgrades or Ender 5 upgrades that you can do to improve your 3D printing experience.

Image: cisardom via Thingiverse

A DIY 3D printer enclosureIf you are willing to put in the time and effort, you can also build your own DIY 3D printer enclosure. There are plenty of designs available, such as this IKEA Lack enclosure that fits many 3D printers.

Print with safer material

If you don’t want to deal with toxic fumes, the best solution is to avoid using 3D printer filament that gives off these fumes. ABS and PETG are made up of complex toxic chemicals and release high concentrations of VOCs in the air during the printing process. If you don’t strictly need to 3D print with these plastics, it is best to avoid them altogether.

If you do want to print with these materials, sticking to the best PETG and best ABS filament brands is recommended to avoid low quality brands that add harmful additives.

Then we have PLA filament. PLA is great for many reasons, the best of them all is that it is relatively safe and emits little to no harmful VOCs. Instead, what you get is the sweet smell from the melting of the sugars in the PLA. For settings like the classroom, home office, or kids’ bedroom where safety is extra important, PLA filament is the safest option.

Recommended:

The 10 Best PLA Filaments for 3D Printing

Air quality monitor

An air quality monitor is a great way to keep a check on the air quality in your 3D printer’s workspace. Not only can you get safety and health-related information like VOC and CO2 levels, but you can also track humidity levels to make sure you don’t expose your filament to too much moisture.

Not only can you get safety and health-related information like VOC and CO2 levels, but you can also track humidity levels to make sure you don’t expose your filament to too much moisture.

Image: Gary Peng via hackaday

Air quality monitors can be home-builtIt can provide you with a sense of relief when it comes to harmful fumes. You don’t have to speculate about the air quality, and you can simply look at the data to see if what you are doing is safe or not. It also helps you to tweak your ventilation and filtration systems to ensure that you are always within a safe zone.

Airthings 2930 Wave Plus - Radon & Air Quality Monitor (CO2, VOC,...

2,972 Reviews

Check PricePick an optimal location for your 3D Printer

Good workspace ventilation and an optimal location for your 3D printer go hand-in-hand. Typically, a garage workshop is an ideal location for your 3D printer. A garage can be well ventilated and has a large volume, keeping VOC and UFP concentrations low. Plus you can choose not to stay in it while the 3D printer is in operation.

Plus you can choose not to stay in it while the 3D printer is in operation.

If you’re planning on using the printer in your living room or bedroom, an enclosure and a good ventilation system is a must. You must also be careful not to place the 3D printer near the kid’s area. Other than risking damaging your 3D prints, you do not want to risk their long-term health either with PETG or ABS filament.

Recommended:

PETG vs ABS: Which Filament Should You Use?

Air purifier

An air purifier is a great device to filter out unwanted toxic particles from the air. They are a must-have if you’re planning on printing indoors. Not only do these purifiers filter out the harmful VOCs, but they also remove any smell and provide clean air in your workspace. The most crucial element in these purifiers are their filters, so let’s look at the two common types of filters used.

HEPA filters

HEPA stands for High-Efficiency Particulate Air filter. The HEPA filter is theoretically designed to remove almost 99. 97% of air particles with a size of 0.3 microns. These filters have a MERV rating corresponding to the particle size they can filter out. You should get a HEPA filter with a MERV rating of 17 or above, as these are the effective ones against the 3D printer’s UFPs.

97% of air particles with a size of 0.3 microns. These filters have a MERV rating corresponding to the particle size they can filter out. You should get a HEPA filter with a MERV rating of 17 or above, as these are the effective ones against the 3D printer’s UFPs.

Carbon filters

Carbon Filters use activated carbon to filter out particles. Unlike HEPA filters, the carbon filters process the foul-smelling chemicals and essentially eliminate any odors or harmful fumes in the atmosphere.

These filters are primarily used in conjunction with the HEPA filters. The HEPA filters capture any dust, chemicals, or pollen in the air, and the carbon filters process this air to be as clean as possible.

Our pick

The Levoit Core 300 air purifier is one of the cheapest yet most effective air purifiers available on the market right now. It features both HEPA and carbon filters and can filter out VOCs, UFPs, dust, toxins, smoke, and pet hair. It operates almost silently at a noise level of just 24 dB.

Combine this with a sleek-looking design and a small size; this air purifier is an excellent match for any small-to-medium-sized 3D printing workspace.

LEVOIT Air Purifier for Home Allergies Pets Hair in Bedroom, h23 True...

76,273 Reviews

Check PriceWindow fan

In the end, there is no more straightforward solution than getting a window fan. Window fans are a great way to keep the air flowing in the room and ensure sufficient ventilation in the workspace. When mounted in a window opening, the fan ensures that there is sufficient fresh air coming in to prevent VOCs and ultrafine particles from building up in the room.

Comfort Zone CZ310R 9" 3-Speed, 3-Function, Expandable, Reversible...

10,811 Reviews

Check PriceFAQ

Are 3D printers safe for pets?

3D printers are generally safe to use around pets. There are no known direct effects on their health. However, some pets may be more vulnerable to certain VOCs and may even experience nauseating symptoms.

There is also the danger of hotends, the heated bed, and moving parts of the 3D printers. Your pet might not be aware of the danger of these components and get injured by being too curious. It is best to take adequate precautions while operating your printer around pets.

Does a 3D printer smell?

While a 3D printer by itself does not smell, it is the plastic filament that smells when melted. The strength of the smell partly depends on the type of filament you use. Printing with ABS creates a strong smell, whereas PLA fumes are barely noticeable.

How to filter 3D printer fumes?

To properly filter printer fumes you can use an enclosed 3D printer, add an aftermarket enclosure to your 3D printer, or add an air purifier with both HEPA and carbon filters.

Maintaining sufficient ventilation in your room is a good addition as well. This removes leftover fumes, eliminates foul smells, and carries in fresh air.

Conclusion

3D printing is a great hobby and a fun one at that. However, to enjoy it fully and stress-free, you need to take certain precautions. While we cannot wholly avoid fumes, we can very well limit them and save ourselves from some headaches.

However, to enjoy it fully and stress-free, you need to take certain precautions. While we cannot wholly avoid fumes, we can very well limit them and save ourselves from some headaches.

A well-ventilated workspace, an air purifier, and a 3D printer with an enclosure are all things you can integrate into your setup to keep yourself safe from toxic and harmful 3D printing fumes. While you can never avoid all possible risks, these are enough to make a worry-free experience.

When none of these options are realistic for you, then sticking to PLA filament is the safest thing you can do.

If you still have any questions or would like to add something, let us know in the comments below.

3 main dangers of a 3d printer that you didn’t even think about

Most people who use household appliances don’t even think that their use can cause real harm to health, not to mention the use of production equipment at home, which includes even the most simple 3D printer

Danger #1 - VOCs

VOCs are volatile organic compounds. This is a group of chemical compounds that, when evaporated, can cause significant harm to health and the environment. These VOCs are plentiful in print filaments. In the process of printing, the hot end of the printer heats up the plastic and VOCs begin to evaporate from it, extremely actively, then evaporation continues on the hot table until the product has completely cooled down. Many sources say that printing with PLA filament is absolutely safe - it is an environmentally friendly material made from corn. In fact, PLA plastic is even more toxic than, for example, ABS when heated to the same temperature, but PLA plastic is printed at a lower temperature and therefore less VOCs are released.

This is a group of chemical compounds that, when evaporated, can cause significant harm to health and the environment. These VOCs are plentiful in print filaments. In the process of printing, the hot end of the printer heats up the plastic and VOCs begin to evaporate from it, extremely actively, then evaporation continues on the hot table until the product has completely cooled down. Many sources say that printing with PLA filament is absolutely safe - it is an environmentally friendly material made from corn. In fact, PLA plastic is even more toxic than, for example, ABS when heated to the same temperature, but PLA plastic is printed at a lower temperature and therefore less VOCs are released.

Hazard #2 - Microplastics

It turns out that the printing process releases not only volatile organic compounds into the air, but particulate matter that can damage the human respiratory system. These hard particles are called in another way "microplastics". They are essentially particles of plastic 100 nanometers or smaller. They fly freely in the air, are inhaled by humans and settle inside us. This problem has not been thoroughly studied yet, since it appeared in the last 10-15 years, but the negative impact of microplastics on all systems and organs of living beings has been proven.

They fly freely in the air, are inhaled by humans and settle inside us. This problem has not been thoroughly studied yet, since it appeared in the last 10-15 years, but the negative impact of microplastics on all systems and organs of living beings has been proven.

Hazard #3 - Fire

A 3D printer is such a specific device that includes heat, moving parts, flammable plastics, and long, continuous operation. Almost everyone who has ever printed massive parts with print times over 12 hours has left their printers unattended for hours or even overnight. To date, there have been cases of fire in 3D printers during operation. The main problem is overheating of the structural elements and the microprocessor.

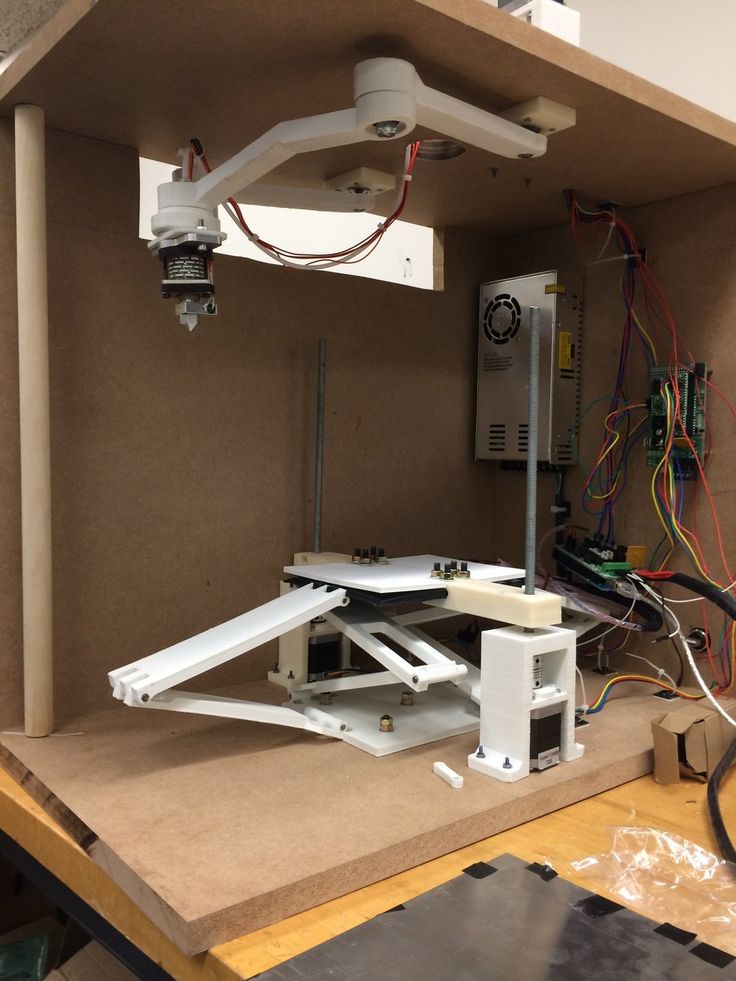

One answer to all questions

Experts who deal with this problem recommend equipping 3D printers, especially if they are used at home, with cases with an air cleaning system, visual control and remote power off.

3d printer housing It is easiest to make a simple housing from a structural profile, you must remember that such a housing must be airtight, since microplastics and VOCs can penetrate through the smallest cracks. The case must be equipped with exhaust ventilation and several layers of HEPA filters at the outlet, ideally a carbon filter, this will increase the level of microplastic cleaning. Taking the air duct outside is also an option, but there is a possibility of a drop in temperature inside the case, which will affect print quality.

The case must be equipped with exhaust ventilation and several layers of HEPA filters at the outlet, ideally a carbon filter, this will increase the level of microplastic cleaning. Taking the air duct outside is also an option, but there is a possibility of a drop in temperature inside the case, which will affect print quality.

If you still don’t change your mind about leaving printers unattended, equip the housing with a simple webcam with remote access via the Internet, this will allow you to periodically keep an eye on the situation and take the necessary measures if something happens.

Housing 3d printer Well, to control the work, it is necessary to equip the printer's power supply system with a remotely controlled relay or socket that can be de-energized remotely via the Internet. This not tricky gadget will not only provide security, but also save money, if the model suddenly fell off, and printing continues, then the printer can be turned off from the smartphone.

And of course it is useful to keep the printer clean, regularly clean the motherboard and motor drivers from soap and microplastics. Part 2 Consumables

In the first article, we talked about the dangers that await the owner of the printer if the device is used improperly. Let's imagine a situation where a person received an electric shock due to the open body of the device or inadvertently touched a heated extruder, receiving an unpleasant burn. These events will clearly indicate the culprit of the incident, his negligence and disregard for safety requirements. They cannot be completely eliminated, but the likelihood of their occurrence can be seriously reduced by following the manufacturer's instructions and common sense.

However, when working with a 3D printer, we inevitably expose ourselves to the risk of another property, which is much more difficult to deal with: inhalation of harmful substances released during the melting of consumables.

Let's make a reservation right away - in this material we do not set ourselves the goal of describing all possible consumables. Despite the expansion of the range, the main raw materials for the FDM printer are still two types of plastic: ABS and PLA. In addition to them, other filaments will be mentioned in the article, however, we will focus on these polymers. So, let's try to understand together how dangerous printing consumables are. First, a few terms.

Despite the expansion of the range, the main raw materials for the FDM printer are still two types of plastic: ABS and PLA. In addition to them, other filaments will be mentioned in the article, however, we will focus on these polymers. So, let's try to understand together how dangerous printing consumables are. First, a few terms.

ABS (acrylonitrile butadiene styrene, ABS) is an opaque thermoplastic material made from acrylonitrile, 1,3-butadiene and styrene monomers. Hard and strong even at low temperatures, it has good resistance to heat, chemicals and is easy to process.

PLA (polylactide, PLA) is a polyester based on lactic acid. Plants are used as its basis: corn or sugar cane.

Plastics are not hazardous at normal room temperature. A huge number of things are made from ABS, including cases of household appliances, stationery and children's toys. Polylactide is used for the manufacture of disposable tableware, medical products and other items with a short service life.

In Russia, plastic products are certified or declared (depending on the type of product) for compliance with safety requirements upon release. In our country, these requirements are spelled out in GOSTs or the Technical Regulations of the Customs Union. For example, there are TR “On the safety of toys”, “On the safety of packaging”, and so on, where, among other things, the standards for the content of residual chemicals are prescribed.

A certificate or declaration guarantees that the items in question are safe under normal use, which is why most plastic toys are made of ABS plastic. The main problems begin when the polymers are heated and melted. Surely everyone is familiar with the unpleasant smell of melting plastic. This smell indicates the release of various chemicals into the air, not all of which are harmless.

So, let's try to figure out what are the dangers of heated plastic?

1. Harmful fumes of the starting material

During melting, part of the polymer inevitably passes into a gaseous state and mixes with air. The type of starting material depends on the plastic. Due to the fact that natural ingredients are used to make PLA, it is considered to be biocompatible and safe for humans when melted. But in fact, there are practically no laboratory studies confirming this fact.

The type of starting material depends on the plastic. Due to the fact that natural ingredients are used to make PLA, it is considered to be biocompatible and safe for humans when melted. But in fact, there are practically no laboratory studies confirming this fact.

ABS plastic is a petroleum-based material, which already implies increased toxicity when heated. Unfortunately, the standards for the content of acrylonitrile butadiene styrene in the air in our country have not yet been released. GN 2.1.6.1338-03 “Maximum Permissible Concentrations (MACs) of Pollutants in the Atmospheric Air of Populated Areas” mentions acrylonitrile butadiene styrene dust, but it can be obtained at home only by grinding a plastic product, and not by printing.

Is ABS plastic safe? We asked an expert to answer this question.

Denis Cherepovich, head of Alfa-filament:

“ABS (acrylonitrile butadiene styrene) is a copolymer of acrylonitrile with butadiene and styrene. From the name it is clear that three monomer substances are used in the production of this polymer. Accordingly, these three monomers may be present in residual amounts in the total bulk of the polymer. All, absolutely all, without exception, manufacturing plants have strict output control on the content of residual monomers. This data can be found in the hygiene certificates for ABS granules.

From the name it is clear that three monomer substances are used in the production of this polymer. Accordingly, these three monomers may be present in residual amounts in the total bulk of the polymer. All, absolutely all, without exception, manufacturing plants have strict output control on the content of residual monomers. This data can be found in the hygiene certificates for ABS granules.

During printing, heating of the polymer in the nozzle causes it to melt and, accordingly, a certain amount of residual monomers is released from the plastic mass. I note right away that not all of the mass of residual monomers enters the air during melting.

Next, I will make a small reference to normative documents and concepts in order to freely use the data in the future and not cause questions from readers.

Maximum allowable concentration of a hazardous substance. This parameter shows the maximum concentration of a substance in the air, which does NOT have harmful effects and does NOT lead to the development of pathologies and diseases in the human body. There are quite a lot of MPC values for different living conditions, I will give further MPC of substances in the working area of enterprises (MPC). The data are taken from the normative legal document "Maximum Permissible Concentrations (MPC) of harmful substances in the air of the working area GN 2.2.5.1313-03", approved by the Chief State Sanitary Doctor of the Russian Federation on April 27, 2003.

There are quite a lot of MPC values for different living conditions, I will give further MPC of substances in the working area of enterprises (MPC). The data are taken from the normative legal document "Maximum Permissible Concentrations (MPC) of harmful substances in the air of the working area GN 2.2.5.1313-03", approved by the Chief State Sanitary Doctor of the Russian Federation on April 27, 2003.

MPCrz - the maximum concentration of substances in the air of the working area, with which, with an 8-hour working day and 40 working hours a week, no harmful changes occur in the human body.

Hazard class - conditional value, designed for quick classification of substances according to the degree of danger:

1st class - extremely dangerous

2nd class - highly dangerous

3rd class - moderately dangerous

4th class - low hazard

5th class - practically non-hazardous.

Let's analyze what kind of substances can be contained in ABS plastic and what are their properties:

Butadiene - a gas with a characteristic unpleasant odor, hazard class 4, MPCrz = 100 mg/m3. This gas is practically not dangerous to the body.

This gas is practically not dangerous to the body.

Styrene - MPCrz = 30 mg/m3, hazard class 2. Colorless liquid with a pungent odor, practically insoluble in water, volatile. Causes complex lesions of the nervous system, irritation of the mucous membranes.

And finally, the most dangerous substance:

Acrylonitrile is a volatile liquid with a strong almond odor, hazard class 2, MPC = 0.5 mg/m3. When ingested, it causes headache, dizziness, weakness, nausea, vomiting, sweating, lowering body temperature, convulsions, loss of consciousness, death. Soluble in water.

Next, I propose to calculate how much ABS plastic needs to be printed as much as possible in order to reach the MPC value of the most dangerous monomer, acrylonitrile, in air.

Let's conditionally take an average working room with a window and a door, area 10 m2, ceiling height 2.5 m. Air volume in such a room is approximately 25 m3. The average rate of natural ventilation of the premises, according to building codes and regulations, is at least 30 m3 / hour, i. e. in our 25 m3 room with a window, a door and normal natural ventilation, all the air is changed in about an hour. We also take this hour for further calculation.

e. in our 25 m3 room with a window, a door and normal natural ventilation, all the air is changed in about an hour. We also take this hour for further calculation.

According to the hygiene certificates of Russian manufacturers of conventional ABS, the content of residual acrylonitrile in the granulate is no more than 0.001%. For foreign manufacturers (Samsung, LG, Kumho, Ineos, etc.), these figures are even lower. In food and medical ABS plastics, this value is almost zero.

Now, having all the data, we can calculate how much ABS plastic needs to be processed/printed per hour in our room in order to reach the MPC of acrylonitrile equal to 0.5 mg/m3 (we make all calculations in terms of 1 hour, because do not forget that in 1 hour all the air in the room changes):

1) MPC = 0.5 mg / m3 multiply by the volume of the room 25 m3:

0.5 x 25 = 12.5

12.5 mg of gaseous acrylonitrile is the maximum allowed in our room

2) Next, we find what is the mass of ABS plastic contains 12. 5 mg of acrylonitrile:

5 mg of acrylonitrile:

12.5 / 0.001% = 12.5 / 0.00001 = 1,250,000 mg, which is equal to 1250 g or 1.25 kg

Thus, we conclude: to achieve MPC of acrylonitrile in a room with a volume of 25m3, we need to process / print 1.25 kg of ABS plastic per hour, which is absolutely unrealistic.

Also, do not forget that in order to predict the most pessimistic scenario, we took into account many conventions: ABS is the most common and contains the maximum possible amount of acrylonitrile, all the monomer was released into the air during printing, the operator is constantly indoors, the ventilation in the room is only natural .

I hope that the calculation principle has been explained clearly, and exactly the same principle the reader will be able to calculate the "dangerous print speeds" of PLA, HIPS, SAN, MABS, PEEK, ASA, POM and other polymers.

In conclusion, I would like to once again assure users of the safety of FDM technology and wish them good luck in all their endeavors. ”

”

2. Decomposition of the substance into monomers

Another danger is the decomposition of a part of the plastic into toxic components when heated and melted.

Irina Nikitina, Head of the Occupational Safety Control Department of the Federal State Budgetary Institution TsNMVL, an expert in special assessment of working conditions:

“The process of heating or melting plastics releases extremely toxic gases into the environment. Much depends on the type of active substance. In the solid state, plastics are relatively safe, but when melted, they can partially decompose into components, or oxidize and form other chemicals.

Let's take ABS plastic, that is, acrylonitrile butadiene styrene. It is a strong and resistant polymer used in many industries. Non-toxic under normal conditions. At present, there are no maximum permissible indicators regulating the concentration of this substance in the atmospheric air and the air of the working area in Russian state standards. However, the monomers that make it up are well known - these are acrylonitrile, butadiene, styrene (the very name of ABS plastic is formed from the initial letters of the names of the monomers). At a temperature of about 400ºС, acrylonitrile butadiene styrene partially decomposes into these monomers.

However, the monomers that make it up are well known - these are acrylonitrile, butadiene, styrene (the very name of ABS plastic is formed from the initial letters of the names of the monomers). At a temperature of about 400ºС, acrylonitrile butadiene styrene partially decomposes into these monomers.

When released into the air, styrene can cause both acute reactions and chronic diseases of the liver, kidneys, and circulatory system. Butadiene-1,3 has a general toxic and irritating effect. Vapors of poisonous acrylonitrile are 20 times more toxic than styrene, signs of poisoning are headaches, weakness, sleep disturbances, memory loss, and general fatigue.

At elevated concentrations of these substances in the air, a person may experience a sharp and unpleasant odor. For example, the smell of styrene partially resembles acetone and alcohol.

To determine the exact concentration of a harmful substance released into the atmosphere, it is necessary to use chemical analysis methods and special equipment, such as gas analyzers. Therefore, regardless of whether a specific type of polymer is in the regulatory documents or not, it is necessary to follow simple rules: work in rooms with a ventilation system or good ventilation, install a local suction and pay attention to pungent odors. If any appear, it is better not to risk it, but to leave the room and ventilate the room.

Therefore, regardless of whether a specific type of polymer is in the regulatory documents or not, it is necessary to follow simple rules: work in rooms with a ventilation system or good ventilation, install a local suction and pay attention to pungent odors. If any appear, it is better not to risk it, but to leave the room and ventilate the room.

It must be remembered that in industrial enterprises, the employer monitors and is responsible for working conditions, while when working at home, all potential dangers fall on the shoulders of the owner and household members.

Let's give an example from foreign practice. A study conducted in 2016 by a group of scientists from the Illinois Institute of Technology confirmed that the threat of releasing harmful substances into the air does not come from printers, but from consumables. More than 10 types of filament were tested by the Institute staff. The results showed that the level of harmful particles and vapors depends mainly on the filament material, and not on the type of printer.

When using ABS plastic, traces of styrene, a substance that is dangerous and carcinogenic, were found in the air. Nylon-based materials exuded caprolactam, less harmful than styrene, but also capable of causing poisoning. Polylactide released a harmless substance called lactide into the air. At the same time, nothing is reported about the concentrations of substances.

3. Ultrafine particles (nanoparticles)

Another risk factor is associated with ultrafine particles (nanoparticles) with a diameter of less than 1 micron, which are released in large quantities during 3D printing. These particles can penetrate directly into the alveoli of the lungs and the epidermis, causing various respiratory disorders and allergic reactions. Inhalation of toxic nanoparticles can cause lung pathologies in humans, such as bronchitis, tracheitis, and asthma. At the same time, the risk index for ABS is 3 to 30 times higher than for PLA. In tests conducted by Italian scientists Fabrizio Merlo and Stefano Mazzoni, it turned out that the time for which the content of nanoparticles in the air returns to normal levels is from 10 to 30 minutes after the end of the 3D printing process.

How can this be dealt with and the risks minimized? First, filtering. A number of devices are already using high efficiency (HEPA) filters that can purify the air before it leaves the 3D printer. Of course, this is not a panacea. Some ultrafine particles are as small as 15 nm, while HEPA filters typically have a bandwidth of 300 nm.

An additional barrier is also the closed housing of the device, which partially traps harmful fumes. It is these two factors that can contribute to protection against the overwhelming number of nanoparticles. According to the latest study from the Illinois Institute of Technology, a closed chamber 3D printer reduced UPF emissions by 74%, and an additional HEPA filter helped to increase this figure to 9one%.

Scientists also advise to work in well-ventilated rooms: it is ideal to use a ventilation system that can change the entire volume of air in the room three times per hour. This means that a 100 m3 room would require a ventilation system capable of handling 300 m3 of air per hour.

4. Other substances and impurities that are released when using plastic

The results of a study by Fabrizio Merlot and Stefano Mazzoni, already mentioned by us, showed that during the melting and mixing of plastic, fumes of many toxic substances are released, among which, for example, ammonia, cyanuric acid, phenol and benzene.

The presence of specific substances depends on the thread, or rather on the polymer of which it is composed. Both the filament itself and the plastic must have documents confirming the composition of the material and the residual content of impurities. Often these are the same certificates of conformity that we wrote about at the beginning of the article.

Plastics produced abroad have their own safety certificates. For example, the Alfa-filament company uses granules for the manufacture of ABS filament, which have food and biocompatible approvals from the FDA - the US Food and Drug Administration. However, regardless of the country of manufacture, the plastic manufacturer is obliged to have such documents and make them available to potential buyers.

Unfortunately counterfeit filament is not uncommon in the world market. In low-quality materials, the amount of harmful substances is many times higher than the established norms. For example, poisonous hydrocyanide was found in one type of Chinese ABS plastic. Therefore, before purchasing consumables for 3D printing, make sure the seller is reliable and, if necessary, ask him to provide documents confirming the safety of the filament.

But do not despair, because the problem of counterfeit filament is still more relevant for the world market than for the domestic one. The largest Russian companies guarantee the quality of their own products and often post all permits on their own websites, and sometimes conduct independent tests of their products. So, in 2015, the Russian manufacturer of consumables REC, with the help of an accredited testing laboratory, carried out its own measurements of the concentration of chemicals in the air during 3D printing with its own filament. In total, 5 types of plastic were used: ABS, PLA, FLEX, RUBBER, HIPS.

In total, 5 types of plastic were used: ABS, PLA, FLEX, RUBBER, HIPS.

It turned out that HIPS, FLEX and RUBBER filament do not emit toxic substances at all during printing. When printing PLA plastic, acetone is formed, ABS plastic exuded vinyl chloride, however, in no case were values even close to the MPC of the air in the working area recorded.

To summarize, how to protect yourself from the harmful effects of plastic fumes:

1. Use a ventilation system. In particular, the researchers advise working in well-ventilated areas: it would be ideal to use a ventilation system that can change the entire volume of air in the room three times per hour. If there is no ventilation, open windows and try to be as little as possible in the same room as the printing printer.

2. Pay attention to smells. A strong odor indicates an increase in the concentration of the active substance. Take extra precautions or leave the room altogether.

3.