3D printing service providers in india

3D Printing service in India

Pan India Supply Delivery Of Small Batch Production Part

We make cost effective and Low Volume production 3D Printing, We are supplying 3D printed parts across India with our Pan India Network

Get Quote

Explore Our Material

+15

Unique engineering & Bio compatible materials

10

industries Served

5 to 5000

Parts can be produced per day

OVERVIEW

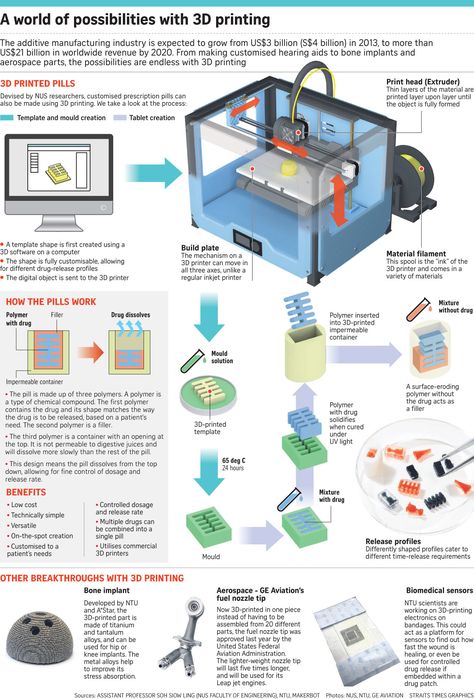

PRECISE3DM is India’s largest 3D printing service provider transforming Indian manufacturing Industries with its Digital Manufacturing solution. We use 3D Printing technology to manufacture end use parts that can be manufactured without involving tools or mould. We 3D print complex parts at low cost with fine geometrics directly from CAD Design. We manufacture your complex parts in a rapid Phase, You don’t have to wait for months. Our technology can manufacture the components in days, since we don’t use year old manufacturing methods. Our parts have exceptional strength, smooth finish, balanced weight, extreme accuracy compared to the manually fabricated parts.

KEY FEATURES

Our DM service is Ultra-Fast & Affordable, with same-day prototyping and low volume production without making any tool.

An alternative to traditional injection molding that enables designs to go straight from CAD to manufacturing without tooling or delay

We use 3Dsdsystems resin materials that are production and indirect production- grade and certified bio compatible and rapid prototyping materials.

The 3D printer is installed at technology partner locations in more than five places to cater to low volume production 3D printing service to pan India customers.

Traditional design restrictions do not apply anymore. Design complexity does not come at an additional cost during the production process with additive manufacturing techniques.

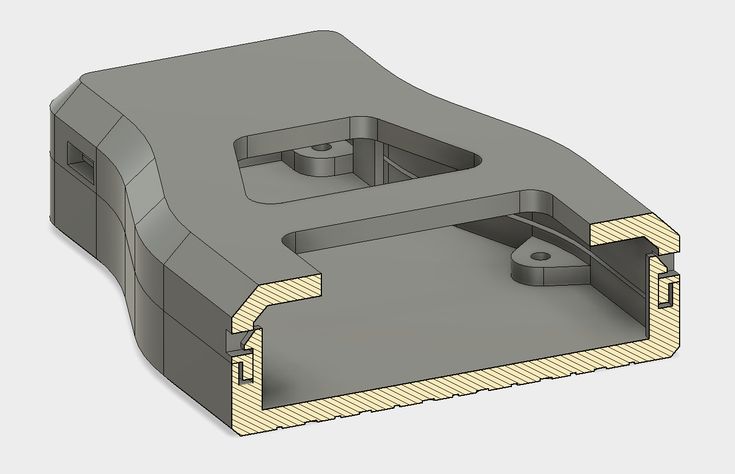

MATERIALS

We use high quality resins from 3D systems for our 3D printing service, The required components that are segmented into production grade, Indirect production and prototyping materials. Direct production materials are used to provide highly durable end use parts like thermoplastic and rubber, with six sigma certifications. We use Industry's best indirect production castable materials that are unique and most suitable for master prototype wax patterns to produce direct end use parts. Prototyping materials that we use have versatile properties that are essential for functional fitments, testing, and other prototyping applications.

MATERIAL GENERAL KEY FEATURES

Direct Production Grade

Bio Compatibility

Excellent Flammability Resistance

Excellent Print Quality

Long Term Environmental Stability

Eight Years Indoor One Year Outdoor Stability

Thermoplastic Behaviours For SnapFit

Withstand UV And Humidity

Rigid High Strength Plastic

Thermoplastic Nature

HOW IT WORKS

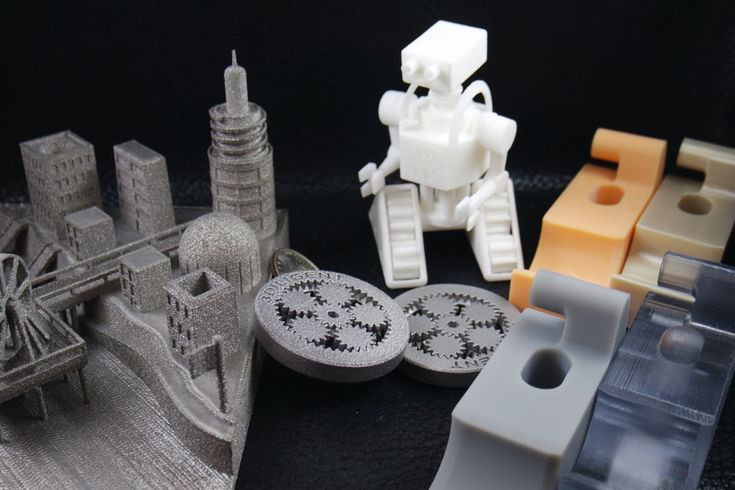

IMAGE GALLERY

Ear buds

Nut bolt

Jewellery

EngineeringPart

VIDEO GALLERY

CASE STUDY

What is Geomagic For Solidworks 2023 and Top 7 key features?

February 1, 2023 3D Inspections

READ MORE

Key reasons why should you choose Freescan UE 11 3D Portable 3D scanner in India

February 1, 2023 3D Inspections

READ MORE

3D scanning service in India 2023, why should you consider Precise3DM for your 3d scanning requirement in India?

February 1, 2023 3D Inspections

READ MORE

Why is Geomagic Design X better than any other reverse engineering software in the market?

February 1, 2023 3D Inspections

READ MORE

3D Scanning Applications for the EV industry 2023

July 20, 2021 3D Inspections

READ MORE

Vikram Movie uses 3D printing and 3D scanning technology for making Prop guns for movie scenes

June 3, 2022 3D Scanning service

READ MORE

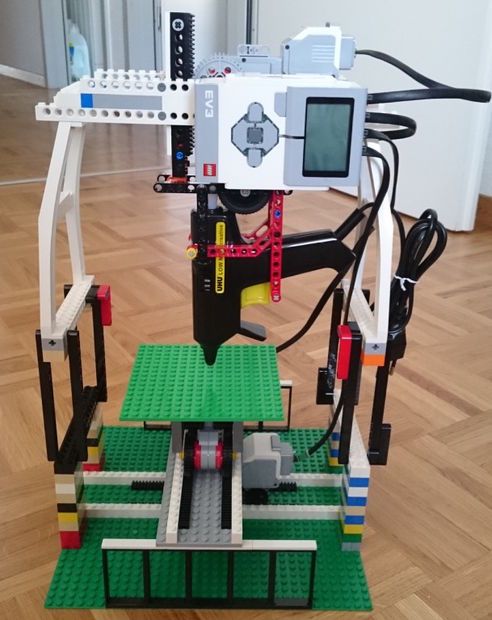

What is a digital manufacturing Lab and how is it useful in the Education industry?

mar 17 , 2022 3D Scanning

READ MORE

Are you an abroad client looking for a 3d scanning service in India? see how we help a French manufacturer

March 30, 2022 3D Scanning

READ MORE

3D Scanning Service in India: A Guide for International Clients

April 22, 2022 3D Inspections

READ MORE

FAQs

Is 3D printing as strong as injection molding?

We Precise3DM equipped with four Figure 4 offers some materials that are as strong as injection molded parts. Some of these materials provide tensile strength as high as 80 Mpa after proper post processing.

Some of these materials provide tensile strength as high as 80 Mpa after proper post processing.

How can I avail 3D printing services in India?

We at Precise3Dm provide 3d printing services all over India. To use the services, you can contact us through our website or call any Precise3dm technical representatives.

What is the part size that you can do 3d printing and low volume production?

For general 3d printing, we can have a build volume of 300x300x500mm, and for low volume production, the build volume is 124.8 x 70.2 x 346 mm.

What technology do you use for 3d printing and low volume production?

We use DLP (Digital Light Projection) technology for low volume production. It has high print speeds that make it possible to print multiple parts in a realistic time frame

It has high print speeds that make it possible to print multiple parts in a realistic time frame

How long do you take to 3D Print my part?

Print time depends on the size and complexity of the part. To get an exact estimate of the time required to print your file, we would need a .stl file. You can directly upload your file on our website and get an estimate for time and cost as well.

My part is rubber. Do you print rubber-like material?

Yes!! We print rubber as well as many other production materials like bio-compatible materials and flexible materials. Our materials can effectively match the properties of some of the most used materials in production.

Per day how many parts can you print?

We use DLP (Digital Light Projection) technology for low volume production. It has high print speeds that make it possible to print multiple parts in a realistic time frame

It has high print speeds that make it possible to print multiple parts in a realistic time frame

How do you increase the strength of a 3D-printed part?

The strength of 3D printed parts can be increased by utilizing some post-processing measures like curing, for which we have special equipment. After curing, the properties of the material changes to some extent giving more strength to the materials

Best 3D Printing Services in Bangalore

1. What is 3D printing and how does it work?

3D printing Bangalore is the process of creating a three-dimensional, physical object from a digital model. 3D printing service is sometimes referred to as “additive manufacturing,” although this term is used more frequently within the manufacturing industry to describe online 3D printing’s role in the industrial process.

3D printing in Bangalore begins with a 3D CAD model that is sliced into fine layers. The software turns these layers into instructions for your 3D printer, which deposits material layer by layer until the model is replicated. Excess material is removed post-process, leaving the user with a complete physical object. The software and materials that are used vary depending on the user’s intended application for the product.

2. What materials can be used in 3d printing?

Below are the materials used for 3D Printing in Bangalore:

ABS

ABS is a low-cost material, great for printing tough and durable parts that can withstand high temperatures while 3D Printing online.

Flexible

Flexible filaments, commonly referred to as TPE or TPU, are known for their elasticity allowing the material to easily stretch and bend for 3D Printing in Bangalore.

PLA

PLA is the go-to material for most users due to its ease-of-use, dimensional accuracy, and low cost.

HIPS

HIPS is a lightweight material most commonly used as a dissolvable support structure for ABS models in online 3D Printing India.

PETG

PET and PETG filaments are known for their ease of printability, smooth surface finish, and water resistance.

Nylon

Nylon is a tough and semi-flexible material that offers high impact and abrasion resistance. It is an ideal choice for printing durable parts.

Carbon Fiber Filled

Carbon fiber filaments contain short fibers that are infused into a PLA or ABS base material to help increase strength and stiffness.

ASA

ASA is a common alternative to ABS and is great for outdoor applications due to its high UV, temperature, and impact resistance for 3D Printing in India.

Polycarbonate

Polycarbonate is known for its strength and durability. It has very high heat and impact resistance making it an ideal choice for tough environments.

Polypropylene

Polypropylene is great for high-cycle, low strength applications due to its fatigue resistance, semi-flexible, and lightweight characteristics.

Metal Filled

Metal filled filaments are made by mixing a fine metal powder into a base material, providing a unique metallic finish, and added weight.

Wood Filled

Wood filaments combine a PLA base material with cork, wood dust, or other derivatives, giving the models a real wooden look and feel.

PVA

PVA is commonly known for its ability to be dissolved in water and is often used as a support material for complex prints in 3D Printing Bangalore.

3. Is 3D printing the future?

In short, Yes. 3D printing in Bangalore provides the design freedom to experiment with more effective and efficient part shapes, with fewer potential points of failure improving the management of a sensitive thermal environment. As product development cycles shrink across every industry, these capabilities give manufacturers a level of design, production, and supply chain flexibility previously unobtainable.

4. Why is 3D printing not popular?

3D printing Bangalore is an upcoming technology, and it is already a part of INDUSTRY 4.0 . But on par we have to accept the fact that it is not commonly used except for the industrialists down the lane. According to us, a few reasons for its reduced popularity:

- 3D printers are costly ones but a one time investment.

- Basic CAD knowledge is necessary for working with 3D printing in Bangalore.

- Above all there are no predetermined properties for the printer materials i.e., we do not know the performance of 3D printed materials

- Any breakage caused by the whole component has to be replaced . It cannot be repaired unlike steel components.

5. Limited raw materials, not all material can be 3d printed with 3D Printing Bangalore.

5. Is 3D printing time consuming?

The quantity of parts being produced also has an impact on the amount of time it takes to complete a 3D printing Bangalore job. However, the reduction in print time is not as greatly reduced for more complex parts with short layers as the actual printing process is still fairly time-consuming.

However, the reduction in print time is not as greatly reduced for more complex parts with short layers as the actual printing process is still fairly time-consuming.

6. How popular is 3D printing in Bangalore?

With the help of 3D Printing Bangalore, you can print anything from electronics to jewellery just sitting at home. Yes, that is what 3d printing service does! It has been in use in the industrial setting for almost 30 years and now it is advancing towards consumer as well as small scale-oriented businesses in Bangalore.

7. What can 3D printers make?

There’s much more on the list of applications for 3D printing in Bangalore, all happening now in myriad industries using a variety of innovative technologies and materials. Think dentistry, eyewear, prosthetics, furniture design, archaeology, palaeontology, and forensic sciences, to name just a few. And you can be sure that the creative and diverse uses for 3D printing Bangalore will continue to grow — and continue to improve the way we live and work.

8. Is nylon good for 3D printing?

Yes. When it comes to 3D printing materials, Nylon has to be mentioned as one of the most popular materials for professional users. This can be attributed in large part to its popularity outside of 3D printing Bangalore. Nylon has a wide range of applications thanks to its unique properties and the benefits of 3D printing in Bangalore mean that parts can be made on the fly easily and inexpensively.

9. Is there a Limitation to what shapes you can 3D print?

No limits in terms of shapes, but no information on manufacturability. One of the principal advantages of 3D Printing Bangalore is that it is possible to imagine all shapes without the limits of the constraints of the plastics industry, such as undercuts, hollowness, respect for thicknesses, etc.

10. How can Makenica help me?

Makenica offers 3D Printing services in India with which it is possible to print complex geometric shapes and interlocking parts that require no assembly. It is also possible to produce single objects, in small quantities, at low cost and fast delivery. This technology of 3D Printing Bangalore at Makenica also helps in the reduction of production-related material loss.

It is also possible to produce single objects, in small quantities, at low cost and fast delivery. This technology of 3D Printing Bangalore at Makenica also helps in the reduction of production-related material loss.

11. Why to Choose Our 3D Printing Service in Bangalore?

Here are the reasons why 3D Printing Bangalore with Makenica is popular:

- Flexible Design

- Rapid Prototyping

- Print on Demand

- Strong and Lightweight Parts

- Fast Design and Production

- Minimising Waste

- Cost Effective

- Ease of Access

- Environmentally Friendly

- Advanced Equipment

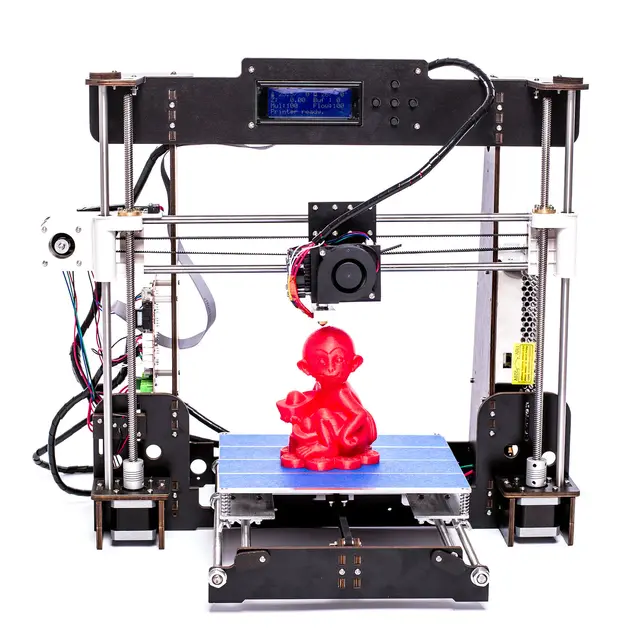

12. What types of 3D printers are there?

The seven different types of 3D printers used for 3D Printing in Bangalore are:

Fused deposition modelling (FDM)

Stereolithography(SLA)

Digital Light Processing(DLP)

Selective Laser Sintering (SLS)

Selective laser melting (SLM)

Laminated object manufacturing (LOM)

Digital Beam Melting (EBM)

13. Which Cities Makenica Service in India ?

Which Cities Makenica Service in India ?

Makenica, with a significant presence, is the country's greatest pool of 3D Printing expertise, with competent professionals. Makenica has five facilities in Bangalore, with headquarters in the United States. This broad reach has enabled us to provide excellent service to a large customer base. The online 3D Printing services available at Makenica range from personalised to one-of-a-kind bespoke solutions. Each customer is guided on their route to quality production by our team of specialists.

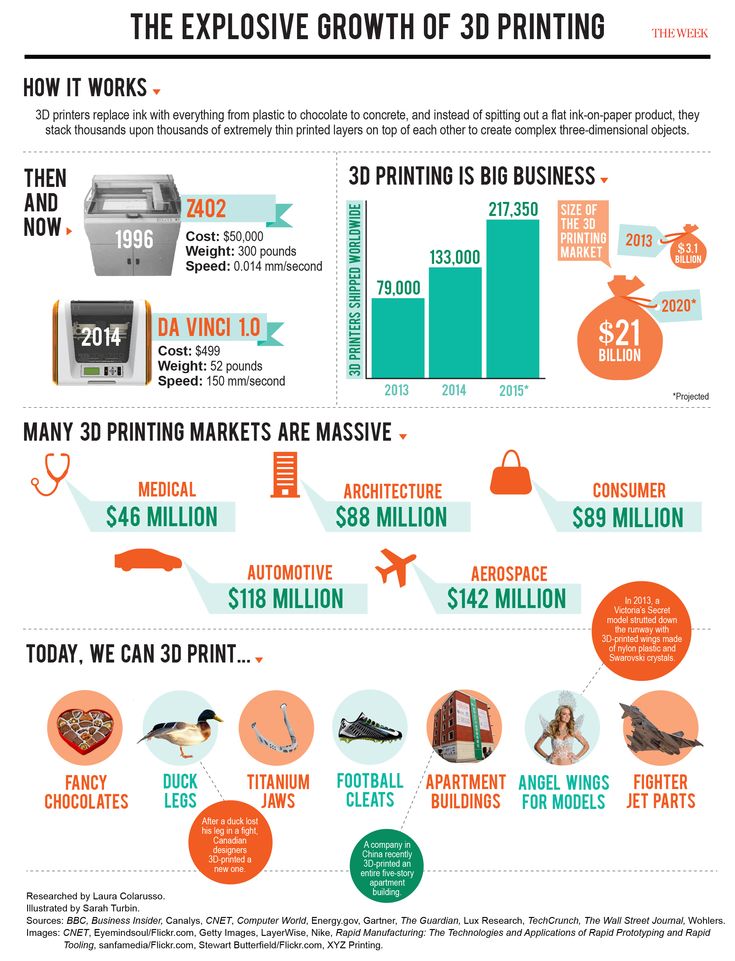

Development of the 3D printing industry. Projects and investments

Miscellaneous

+7 926 604 54 63

address

Ara phone is a "constructor" of modules inserted into a metal frame. 3D printing technology has been expanding rapidly over the past few years. It not only replaces traditional production methods, but also allows you to achieve results that are unattainable by other means. Surprisingly, explosive growth occurs with relatively little R&D funding. Of course, there are several large manufacturers of 3D printers that invest tens of millions of dollars in new developments, but these amounts are much less than those invested in other technologies.

It not only replaces traditional production methods, but also allows you to achieve results that are unattainable by other means. Surprisingly, explosive growth occurs with relatively little R&D funding. Of course, there are several large manufacturers of 3D printers that invest tens of millions of dollars in new developments, but these amounts are much less than those invested in other technologies.

Start-up companies, many of which received money to develop production through crowdfunding, have made 3D printing accessible to enthusiasts and innovative small businesses. But even more impressive results should be expected after large international companies with billions in R&D budgets enter the scene.

How are large companies using additive technologies and 3D printing, and what should we expect from some of them in the near future?

Google Inc. is one of the giants that have shown interest in projects based on 3D printing technologies. One of the first such projects was Project Ara , carried out in collaboration with 3D Systems . The idea is to mass-produce 3D-printed modules for the Apa smartphone, which Google plans to launch on the market early next year.

One of the first such projects was Project Ara , carried out in collaboration with 3D Systems . The idea is to mass-produce 3D-printed modules for the Apa smartphone, which Google plans to launch on the market early next year.

« 3D Systems and Google create a high performance, high quality, full color, fully automated printer designed to print thousands of modules for Ara per day,” says Weston Twigg, an analyst at Pacific Crest Securities . - The printer is expected to be 50 times faster than existing counterparts. This printer, regardless of the success of the Project Ara , will enable 3D printing to significantly increase its value to the manufacturing industry.”

This isn't Google's only 3D printing initiative. A few weeks ago it became known about the initiative of Google and 3D printing service provider Shapeways for the free distribution of bracelets, which, according to the authors of the idea, should make programming an attractive activity for women.

General Electric

General Electric invests heavily in 3D printing technology. So, in May of this year, it became known about the plans of G E to build a plant in India, where a modern 3D printer will be used to produce both plastic and metal products. The company is investing about two hundred million dollars in this project. The plant will start producing products at the end of 2014.

General Electric 's investment in additive manufacturing is expected to be a role model for competing industrial giants.

Miscellaneous

Printing jewelry on a 3D printer - an overview of the most interesting models

The times when 3D printing of jewelry seemed like something fantastic is over. Today, more and more designers are using 3D equipment to bring their ideas to life. Some printers work with filament, others use powder, and still others print with liquid resin or wax. 3D printed jewelry looks and feels exactly like traditionally molded pieces.

Highlights

White and black Gemino & Orbis Nylon earrings printed with SLS nylon resin. The material has a very light weight, which makes the jewelry comfortable, ideal for everyday wear. An interesting design will organically fit into both a classic and a shocking image.

3D printed wedding rings. Original custom-made symbols of eternal love accurately convey the details that are important for the newlyweds. With a unique asymmetrical line and elegant twists, Ray's ring will appeal to fans of the original designs. For lovers of clean, minimalist silhouettes, the Clio is the way to go. For connoisseurs of unconventional solutions, the Amar diamond ring will suit, the design of which forms a loose knot of two lines that merge, symbolizing an unbreakable union.

Gorgeous 3D printed face jewelry by Iris van Herpen. Cellchemy 3D printed jewelry designs look like a mask and the way it sits on the face of the wearer looks like something otherworldly. The wire masks are printed with a high resolution multi-material printer. Each part of the mask, custom-designed for a specific runway model, was created using a generative design process after a 3D scan of her face.

The wire masks are printed with a high resolution multi-material printer. Each part of the mask, custom-designed for a specific runway model, was created using a generative design process after a 3D scan of her face.

Guinness World Record-listed diamond ring. India's major 3D printing service provider Imaginarium helped Kotti Shrikant win the Guinness World Record for having the most diamonds set in a single ring. The process of developing a masterpiece called "Divine - 7801 Brahma Vajra Kamalam" went through several iterations. The design team chose the Himalayan camellia flower, which strikes the perfect balance between traditional and contemporary forms. Computer-aided design (CAD) was then used to calculate the number of diamonds. Imaginarium managed to make petals of gold and helped to set the intended number of stones.

18K Gold Charm 3D print by Elizabeth Landis. The spectacular pendant reminds of natural harmony and succinctly complements the luxurious look. Honeycombs are formed into an openwork pattern, and the figure of a bee symbolizes wisdom, diligence, purity.

Frog Ring 3D Gold Plated Brass Object by Peter Donders. The designer rejects classical forms and traditional solutions. He uses 3D printing to revolutionize the jewelry industry, be it in the areas of jewelry making or designing finishes. The frog ring emphasizes the grace, sense of humor of the fair sex.

A charming decoration that can effectively complement a creative look.

"Opposites" collection by Francesca Paolin "spring-summer 2015", printed in polyamide. The MA in Fashion Design from Domus Academy channeled her creativity into creating body jewelry from alternative materials using 3D technology. The author drew inspiration for the development of the collection from ancient history and culture.

Solar nylon bracelet. The Septem brand offers unique fashion items from designers around the world. All products are made on 3D printers. The customer can choose their favorite materials, colors, sizes from the list. The original bracelet attracts with its futuristic design and adds creativity to the image.

N-E-R-V-O-U-S necklace is a 3D printed necklace made up of 175 unique pieces. It is a 21st century piece of jewelry designed and manufactured using methods that did not exist until recently. The necklace is built in layers of durable yet flexible nylon using selective laser sintering technology. The design comes out of the printer fully assembled. The necklace attaches simply and securely with a hidden magnetic clasp.

Plumeria Nylon Earrings have a matte texture, ideal for original, bold looks. You can choose any color from 12 possible. Earrings with a floral pattern will appeal not only to young fashionistas, but also to elegant ladies.