3D printing service near me

3D Printing | 3D Print Services

Find a 3D Printing Location

Print Functional Prototypes

You can use 3D printing for prototypes or one-of-a-kind items. Let The UPS Store® bring your ideas to life. We can even use your 3D CAD file.

Construct Manufacturing Jigs and Fixtures

We understand when you do your own manufacturing, jigs and fixtures are critical for insuring high-quality and efficiency during assembly and testing. Our 3D printer can create complex parts so you are not dependent on a CNC machine.

Create Custom Accessories

Want to design your own smartphone case or money clip? Most items that are smaller than a breadbox and can be made out of single color of plastic are perfect for 3D printing.

Build Architectural Models

You can work in just about any 3D architectural design program and then export to common 3D CAD file types. The finished product is ready to show off or you can sand and paint your building to give it just the right look.

3D Printing Services Expanded Across Nation

The UPS Store continues to expand 3D printing services nationwide to meet the growing demands of its small business customers. 3D printing now available at approximately 20 The UPS Store locations. Use the interactive map below to find a participating location near you, or check out the full list of all The UPS Store locations offering 3D printing services.

3D CAD and 3D Scanning Services

The UPS Store 3D print locations can now also offer you 3D CAD and 3D scanning services through HoneyPoint3D. Getting a custom 3D print has never been easier - you dream it, HoneyPoint3D designs it, The UPS Store prints it. Enjoy the HoneyPoint3D benefits of an easy quoting process, affordable and quality engineering, online viewing of your 3D files, and efficient turn-around times. Get your 3D CAD or scan quote today!

Netfabb® at The UPS Store®

Participating The UPS Store 3D print locations are utilizing Netfabb software for 3D print file preparation and customization. Services available at these locations include:

Services available at these locations include:

- File fixing

- Text labeling

- Logo labeling

- Cutting

Contact or visit these Netfabb locations to learn more about their advanced 3D offerings.

3D Printing Frequently Asked Questions

Here a few questions we frequently hear about 3D Printing.

Please feel free to contact your local The UPS Store for any other questions you may have

-

What is 3D printing?

-

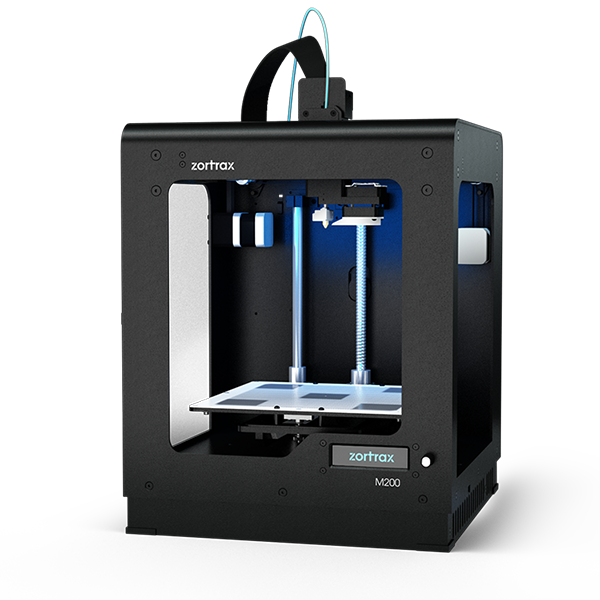

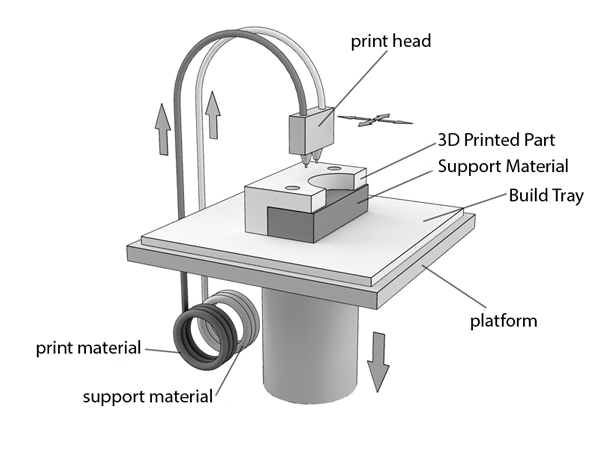

3D Printing is a manufacturing process that uses a digital file to create three-dimensional objects one layer at a time. We run a system that uses ABS plastic and soluble supports to create realistic prototypes and marketing models.

-

What kinds of things can I 3D print?

-

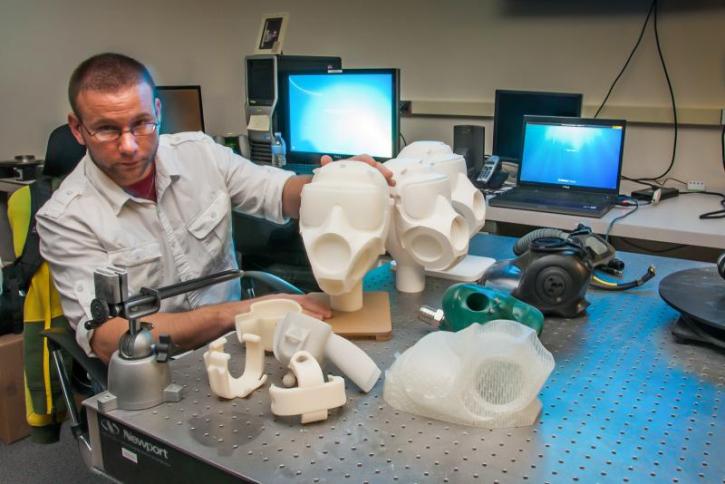

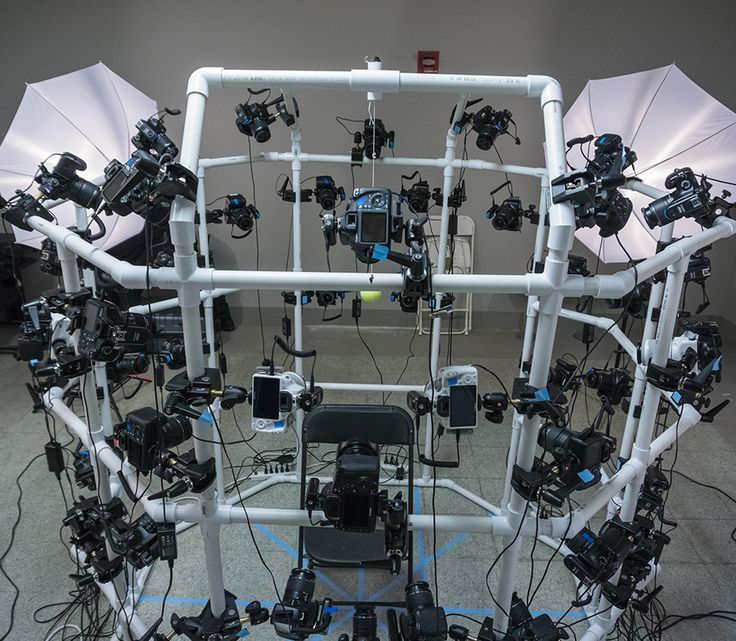

Small business owners and aspiring entrepreneurs will have the opportunity to print prototypes as part of the new product development process. With this printer, The UPS Store locations will be equipped to produce items like engineering parts, functional prototypes, acting props, architectural models, fixtures for cameras, lights and cables.

-

How long does it take to print?

-

The time it takes to print an object will depend on the complexity of the design. A simple object may take 4-5 hours, while a complex object may take 24 hours.

-

Which UPS Store locations are offering 3D printing?

-

The UPS Store is in the process of rolling out nearly 100 3D printing locations across the country. Visit /print/3d-printing/locations for more information.

3D Printing in 3 Steps (Yes, Only 3!)

3D Printing in 3 Steps (Yes, Only 3!) | Staples.comby Kevin Ackerman, Staples® Contributing Writer

Since it gives computer users the ability to produce tangible objects in a variety of materials and colors right from their desktop, 3D printing seems as if it would be technically complicated (or just magical). But in reality, it’s not all that different from printing in two dimensions on paper.

To produce a printed page, all computer users need is a document, a computer and access to a printer — and, of course, ink and paper. Likewise, printing in 3D only requires three similar things. Sure, the technologies differ, but that’s the basic gist, as these three steps explain.

Likewise, printing in 3D only requires three similar things. Sure, the technologies differ, but that’s the basic gist, as these three steps explain.

Step 1: Develop a Concept

If you were to open a document file on your computer, hit some random keys on your keyboard and press Print, you’d have a paper printout — though it wouldn’t make much sense. With 3D printing, you can’t make a shape that easily, not even a poor one, so it’s worth beginning the process by putting some thought into your object.

Start by knowing what you’d like to print in three dimensions. If you don’t have an idea or concept, there are plenty of free suggestions online to get you started. Web sites like Thingiverse.com offer a library of pre-designed objects that you can print with any 3D printer to gain experience. Or you can be inspired by people who are already using 3D printing technology.

Phoenix-based sculptor Kevin Caron uses 3D printing to refine his artwork before making full-sized versions. "Mostly what I'm doing is proof of concept designs. You know, will it stand up, does it look right and are the proportions correct on it?” he says.

"Mostly what I'm doing is proof of concept designs. You know, will it stand up, does it look right and are the proportions correct on it?” he says.

And Chris Considine, CEO and founder of Los Angeles–based CXC Simulations, uses 3D printing to prototype custom-designed parts for racing simulators that are so realistic, they are used by professional race car drivers. "We need 3D orienting to see if the part feels exactly how we want it to feel,” he says.” We went through about 30 versions before we found the one that was perfect for us. Other than 3D printing, there’s truly no way you could have done that without building it over and over again."

Step 2: Hop on a Computer

Once you know what you want to produce, it’s time to sit down at a computer and make it happen. 3D prints are most commonly generated from an STL or .stl file. Standing for “stereolithography” (what 3D printing was named when it was first invented), this file format is to 3D printing what the . doc file is to document output.

doc file is to document output.

To open and manipulate an STL file, you’ll need computer-aided design (CAD) software. For decades, these programs have been used by everyone from architects to product designers, so there are many kinds of CAD software available.

SketchUp is a free modeling program designed to be straightforward and allow anyone to create three-dimensional renderings, whether simple or complicated. Likewise, Tinkercad keeps the design process easy by providing just three simple tools. It also runs in a Web browser and offers step-by-step design lessons to demonstrate how easy 3D printing can be.

Meanwhile, programs like AutoCAD are favored by many experienced professionals, having been used in the design and prototyping of millions of products throughout the years.

To run these programs, you don’t need a particularly powerful computer. Caron uses an HP desktop machine to create his digital sculptures. "It's not a big screaming gaming computer by any means,” he says. "It's just a small office computer and it handles the CAD program just fine.”

"It's just a small office computer and it handles the CAD program just fine.”

Step 3: Get Access to a 3D Printer

Most people assume they need to own a 3D printer to produce digitally rendered objects, but that isn’t true. Sure, owning a desktop 3D printer can put your designs within arm’s reach. But driving across town to pick up your objects at a Staples 3D printing service location or having them delivered by mail can be just as convenient for some businesses.

For example, Caron owns a CubeX™ commercial 3D printer. With the ability to print objects up to the size of a basketball, this device produces designs in plastic and in more than 4,000 different colors. He’s also used print-on-demand services to produce sculptures that he couldn’t make on his office’s machine.

"They’re breathtaking when you see them,” he says of the two acrylic sculptures. "The detail that I could view on the computer came out in the print — it just blew me away. ” Caron is planning to scale his designs down and turn them into jewelry to sell. "I've gotten one back in a polished glass and it's stunning. You can’t tell it from gold other than by the weight."

” Caron is planning to scale his designs down and turn them into jewelry to sell. "I've gotten one back in a polished glass and it's stunning. You can’t tell it from gold other than by the weight."

If you are interested in using 3D printing but need help with these steps, visit one of our stores that offers 3D printing services (currently in Los Angeles and New York City). There, we can help you with all the steps, from getting in touch with designers to actual 3D printing. You can even get in our 3D printing photo booth and have your face put on a figurine.

Go from Concept to Reality

Some businesses would argue that 3D printing, whether it’s done in the office or at an outside service, is worth its weight in gold. "I can go from concept in my head to holding the part in sometimes as quickly as an hour,” says Considine. "It’s a very powerful thing for an engineer to have. It's liberating."

Related Articles

7 Things You Didn't Know About 3D Printing

In the ever-expanding universe of 3D printing, no one knows it all. Though the technology has been around since the 1980s, it’s only recently... Read more

Though the technology has been around since the 1980s, it’s only recently... Read more

8 Tips from MakerBot for Making Better 3D-Printed Objects for Your Small Business

Both an art and a science, 3D printing is actually easy to do, but difficult to master. The experts at MakerBot have seen... Read more

Carrie Mae Rose

Does mankind’s destiny lie in the stars? Artist Carrie Mae Rose thinks so. Her show... Read more

3D printing to order in Nizhny Novgorod, the cost of services

The cost of printing on a 3d printer allows you to use the service not only for commercial and state enterprises, but also for individuals - innovative production technologies have become widely available. Prototyping of 3d models is the reading of information from a computer program by special equipment and translation into a real object by successive building up layer by layer until the formation of a finished product. ProPlast-NN LLC carries out 3d printing to order - the price of is calculated individually depending on the size of the object, the number of samples ordered, the material from which they will be made and the method of prototyping.

Prototyping of 3d models is the reading of information from a computer program by special equipment and translation into a real object by successive building up layer by layer until the formation of a finished product. ProPlast-NN LLC carries out 3d printing to order - the price of is calculated individually depending on the size of the object, the number of samples ordered, the material from which they will be made and the method of prototyping.

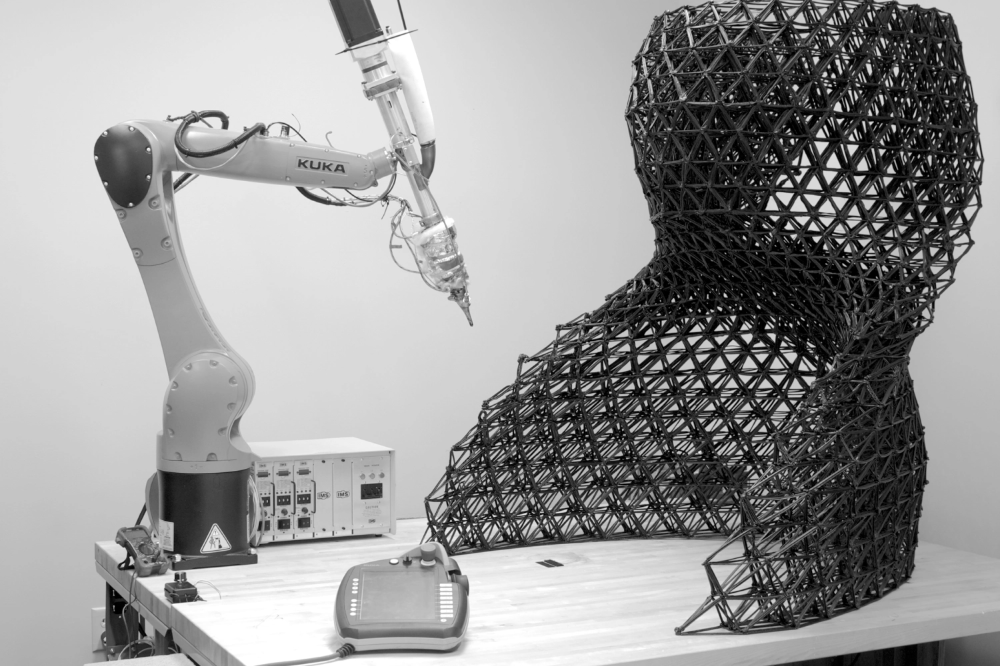

3d printing and prototyping - the latest technologies in practice

The combination of computer technology with production allows you to multiply the speed of production, reduce the cost of creating the necessary items. Volumetric printing is developing at a rapid pace, from the realm of fantasy, it has become a familiar production process, which can be carried out using various methods. Order 3d printing in Nizhny Novgorod for one model or batch of products, just call Pro Plast-NN LLC at the numbers listed on the site. The customer will receive a three-dimensional plastic part, made with a high degree of accuracy according to the drawings or based on a real analogue. Small-scale production of products by 3D printing and prototyping is possible.

The customer will receive a three-dimensional plastic part, made with a high degree of accuracy according to the drawings or based on a real analogue. Small-scale production of products by 3D printing and prototyping is possible.

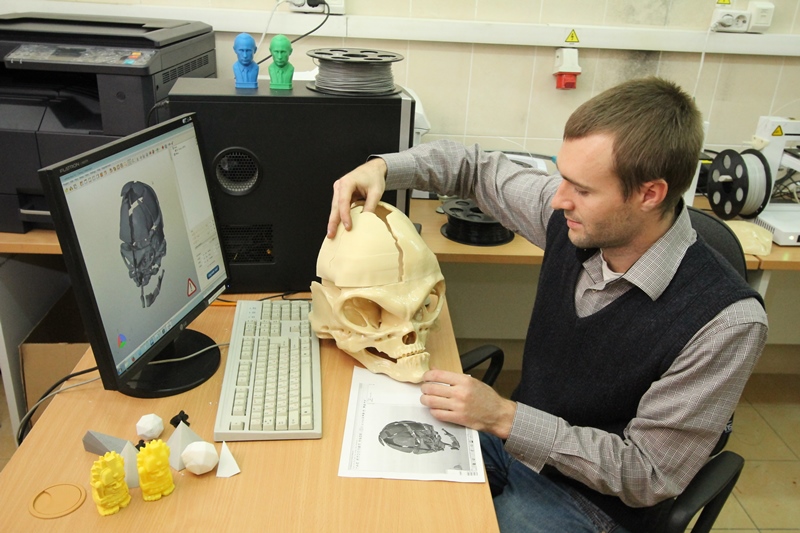

Where the created 3d models and prototypes are used

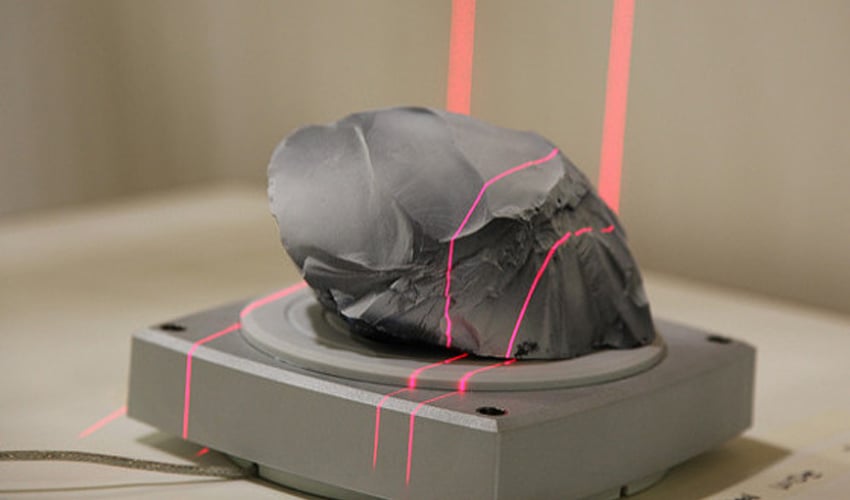

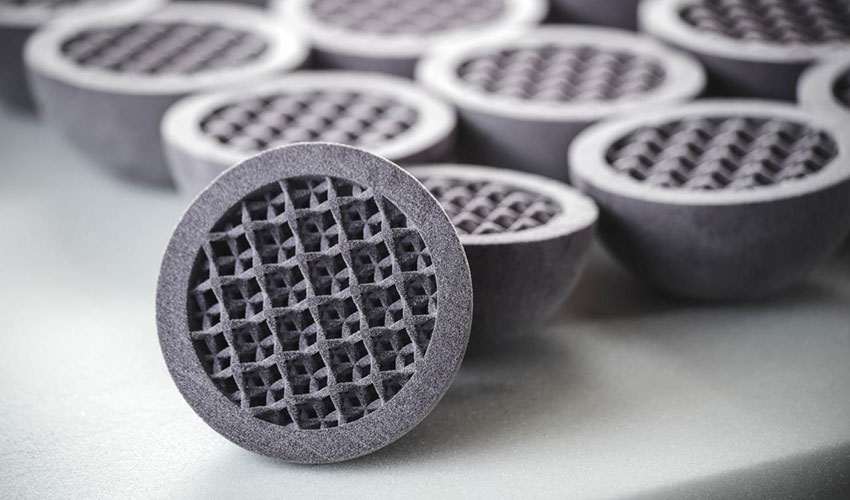

Prototyping on 3d printers allows you to quickly and at low cost get a sample of the desired part from a polymer material, made with a high degree of accuracy, without roughness or distortion. Depending on the technology used and the material from which the sample is made, the product acquires high-tech properties: ideal shape, strength, plasticity, temperature stability. Models have found application in many areas, so they make custom 3d printing companies of different specializations:

- medicine;

- automotive;

- serial industrial production: mechanical engineering, instrumentation, metallurgy;

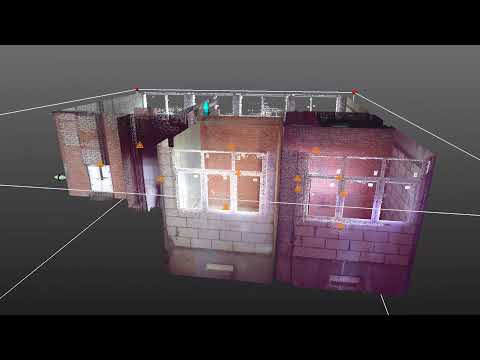

- architecture - when creating models of buildings and complexes;

- design;

- souvenir production.

How 3d prototyping is carried out

The basis for prototyping is a 3d image of an object, compiled by a computer program with three-dimensional modeling functions. 3d custom prototyping is performed with high accuracy of transferring an image into a physical object using one of several possible methods:

- FDM (Fused Deposition Modeling). A moving molten polymer thread forms an object of complex geometric shape in layers, which can subsequently withstand high mechanical and thermal loads.

- SLS (Eng. Selective Laser Sintering). This is the sintering of a powder in a container under the targeted action of a laser beam.

- MJM (from the English. Multi Jet Modeling - modeling with many nozzles). Multi-nozzle 3d printer prototyping , applying molten material with multiple inkjet heads, based on the principle of laser printer.

- LOM (from the English Laminated Object Manufacturing - the production of an object by lamination).

Bonding layer by layer of thin films, as is done with lamination. After reaching the desired volume with a laser tool, an object of the desired shape is cut out of the mass.

Bonding layer by layer of thin films, as is done with lamination. After reaching the desired volume with a laser tool, an object of the desired shape is cut out of the mass. - SLM (from English Selective Laser Melting - selective laser melting). Selective fusion of metal with a targeted laser beam, resulting in a solid object.

- EBM (from the English Electron Beam Melting - electron beam melting). Creation of a product from a powder that is melted by a directed electron beam.

- STL (from English stereolithography - stereolithography). Purposeful formation of a solid object by a laser beam directed into a container with liquid polymer rubber.

Benefits of 3d printing and prototyping

What are the advantages and benefits for a customer who decides to order 3D printing with printer?

Before launching a new product into mass production, an enterprise can purchase a prototype, test it, make changes to avoid errors in the design development of the product, and reduce the cost of production.

If a private or public enterprise needs to produce a small batch of products, it is more profitable for him to apply for a small-scale prototyping service than to carry out design and engineering development and testing of prototypes, reconfigure production, use labor resources and equipment. Printing on a 3D printer at affordable prices will save businesses a significant amount, reduce production costs.

The desired samples can be obtained in a short period, regardless of the degree of complexity of the object being created. Typically, the prototyping process lasts from one to ten days, depending on the specifics of the chosen manufacturing method. You can place an order for 3D printing at Pro Plast-NN LLC - we will answer your questions, calculate the cost, conclude an agreement and print products in a short time.

The cost of 3d printing on the printer is low, which allows customers to reduce their own costs for design development, testing and sample production. LLC "Pro Plast-NN" makes high-quality 3D printing - the price is calculated by managers individually, depending on the volume, complexity of the work, the chosen manufacturing method and the material from which the sample is printed.

LLC "Pro Plast-NN" makes high-quality 3D printing - the price is calculated by managers individually, depending on the volume, complexity of the work, the chosen manufacturing method and the material from which the sample is printed.

The cost of prototyping and creating 3d models

Answer to question how much it costs to print on a 3d printer depends primarily on the number of ordered products, the material from which the product is made, the size of the object, and the technology of its manufacture.

The company "Pro Plast-NN" has the possibility of small-scale production of parts - we can produce a whole batch of products. The cost of a single sample is higher than products produced in batches.

Pro Plast-NN LLC offers 3D printing in Nizhny Novgorod at prices below market prices. Many businesses and individuals who once applied for the service prints on a 3d printer to order become our regular customers - we guarantee the quality of the resulting products, fast production speed, meeting deadlines.

How a 10-year-old schoolboy learned to make money from his hobby - 3D printing

Continuation of the story from

Interview

Interview

Ekaterina Garanina-Karpova

RB.RU media correspondent

Ekaterina Garanina-Karpova

Tikhon Nazarov is only 10 years old, but he already has his own business: he prints 3D figures to order and sells them through Instagram. True, now the Sobiraykin project is on pause: parents want Tikhon to try something else, besides, there are a lot of tests at school.

A schoolboy told Rusbase about how it all started and what he is saving money for, why he wants to get into Yandex and shake hands with Nikolai Drozdov.

Ekaterina Garanina-Karpova

“Dad suggested making money on 3D printing”

— Tell us about yourself.

Tikhon: My name is Tikhon, I am 10 years old. I was born and live in Moscow, I study in the fourth grade. I like to collect Lego and play computer games.

— How did the business start?

Tikhon: Once my dad and I went to the Kalibr Technopark, where we visited a 3D printing company. There were a lot of cool details and figures - it inspired me. I was interested in making them. And the fact that you can earn money on this, dad suggested.

At first we made Lego models and sold them. At some point, I felt sorry for giving away the kits - and it was decided to switch to models using the 3D printing method. They started Instagram, made a post there and sold the first craft.

Pavel: We ordered a logo from Fiverr for $5, a business card layout for another $5 and decided to start with an Instagram store as the simplest format.

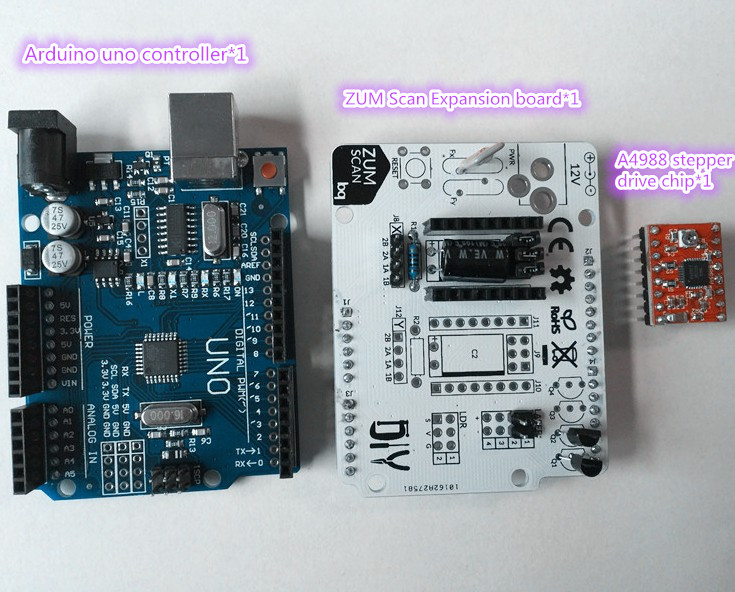

Tikhon: I took courses in 3D printing and modeling.

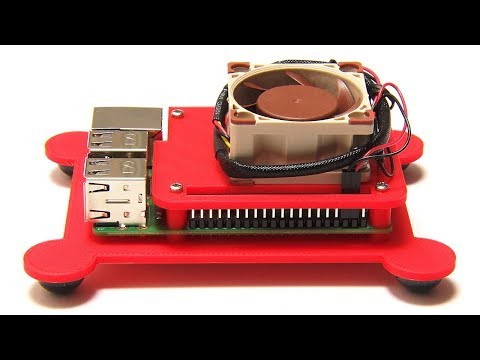

Pavel: These are courses in robotics where children get acquainted with a 3D printer, various types of plastics and learn how to model. When they master simple things, the design stage begins on Arduino - a designer with microcircuits; then programming. As a result, the guys make their own project, where they need to model the body, print it out, assemble the circuit and program, for example, a tank, car or robot.

Tikhon and Pavel Nazarovs

Read more about the young heroes at the link — How do customers find out about Sobiraykin?

Tikhon: From Instagram. It seems to me that they find us by hashtags.

It seems to me that they find us by hashtags.

Pavel: Tikhon and I tried to experiment with promotion, but it didn't work. Recommendations and hashtags mostly work.

— How long does it take to make one part?

Tikhon: The last thing I printed was a rocket-constructor of several parts. The production time depends on the quality, printing speed and filling of the part. It may not work the first time, you have to retype.

Pavel: A small key fob takes about an hour to print on a non-professional printer, like we do at home (the Nazarovs have Wanhao Duplicator i3 Mini. - Note). A model of several parts can be printed for a day.

— How many orders are there in a month?

Tikhon: First there was one order, then more and more. Now the number is decreasing.

Pavel: We took a time out and are not actively promoting Sobiraykin. We decided to think about what else Tikhon wants to do.

We decided to think about what else Tikhon wants to do.

“I learned to negotiate with adult buyers”

— The most unusual order?

Tikhon: Three-in-one stand for iPhone, Apple Watch and Earpods made of glow-in-the-dark plastic. The order was made for almost six months, since it was necessary to correct the connectors in the modeling program and retype everything, and then refine it.

Pavel: Then Tikhon saved up and bought his own 3D printer: the selection of settings was very long, so it took so much time to order.

— How do your parents help you in business?

A schoolboy from Tyumen makes a business on cakes with an unusual design Tikhon: I remember we had the biggest project: modeling and printing 130 medals for a fitness center and children's swimming competitions. ..

..

Pavel: The whole family, including Tikhon's sister, three-year-old Maya, helped to knit ribbons for the medal.

— What have you learned from business?

Tikhon: Work with a 3D printer and negotiate with people you don't know.

Pavel: … And those who ask for a discount. And I myself found out what Instagram is: we figured it out together with Tikhon. I think my son knows more about social media than I do. Learned a lot about 3D printing.

People have a fear of the new, especially the adult generation. And technology is evolving at a faster pace. Adults often perceive not knowing new things as something bad.

— Is it difficult for you to negotiate with people who are two or three times older than you?

Tikhon: I don't look at age.

Medals for a fitness club

“I’m saving for a car and future business”

— Tikhon, please tell us what you spend the money on.

Tikhon: My goal is to save up for a car. And this is how I distribute them: part for myself, part for a bank card and another part for a future business.

— How is your day structured?

Tikhon: Frankly speaking, lately there is almost no free time: there are tests at school, for which you have to prepare. I get up at 6-7 am, go to bed at 10 pm. I spend most of my time at school, on Tuesdays, Wednesdays and Fridays I go to sports - swimming and rock climbing.

— Do they know about your hobby at school? Maybe classmates are interested?

Tikhon: They don't ask. I don't think they are particularly interested.

— Have you already thought about what you will do after school?

Tikhon: I'm interested in mechanics. In the future I want to design cars. This is useful: I don't want an expensive sports car, I don't like everything expensive. I like economical cars, something like UAZ or Lada. Many do not appreciate them, but, in my opinion, they are good cars.

This is useful: I don't want an expensive sports car, I don't like everything expensive. I like economical cars, something like UAZ or Lada. Many do not appreciate them, but, in my opinion, they are good cars.

— Do you see yourself as a leader in a large company?

Tikhon: No. I would like to have my own business.

- Which famous person would you like to shake hands with?

Tikhon: Steve Jobs, Nikolai Drozdov and Dmitry Nagiev. Nikolai Drozdov is such a calm person and knows a lot about nature. And I just like Nagiyev.

iPad stand

“Let your child try more different activities”

— Pavel, in one interview you said that you had a career guidance problem and you want your children to avoid it…

Pavel: Yes, at one time I was faced with the fact that I did not know what I wanted to do and what I liked. I found myself after 30 years: it was something like a rebirth. I want to show Tikhon a wide range of occupations and professions that he might like. My task as a parent is to listen to the wishes of the child, observe him and let him try new things.

Recently Tikhon saw on the Internet how card tricks are shown: they bought a magician's set. I am trying to make sure that Tikhon knows what to do next by the end of school.

Children copy their parents. The coolest thing is to communicate with the child about everything and treat him like an adult.

Read on the topic: 19-year-old e-sportsman who earns tens of thousands of dollars — There are parents who think that spending time at the computer is bad. You work in IT. Are you comfortable with the fact that Tikhon plays computer games?

Pavel: It depends on what you mean by “time at the computer”. I was advised a podcast by child psychologist Dmitry Zitser, thanks to which I rethought a lot for myself in education. Many consider gadgets to be evil, but this is because we ourselves did not have them in childhood. Tikhon has recently become interested in CS:GO. On the one hand, this is sticking, on the other hand, communication. He learns to communicate, develops the speed of reaction. You need to talk with the child, share feelings, observe him.

I was advised a podcast by child psychologist Dmitry Zitser, thanks to which I rethought a lot for myself in education. Many consider gadgets to be evil, but this is because we ourselves did not have them in childhood. Tikhon has recently become interested in CS:GO. On the one hand, this is sticking, on the other hand, communication. He learns to communicate, develops the speed of reaction. You need to talk with the child, share feelings, observe him.

Tikhon: The main thing there is strategy and attention. But I don’t follow esports, I just know that there are championships.

— Is own business a good option to instill in children the value of money and a love of work?

Pavel: The main thing is not to overload with knowledge. The simplest thing is to show by personal example, because children copy our behavior.

Tikhon Nazarov

“There are no good entrepreneurship courses for children even in Moscow”

— You went to the Kidstart school of business thinking. Did this help in the development of Sobiraykin?

Did this help in the development of Sobiraykin?

Pavel : The project just started with a search for financial literacy and business thinking courses. I started looking for something for Tikhon two years ago, when he was eight. It turned out that all such courses - even in Moscow! - Only for high school students. It's a pity: children could come up with something of their own from a young age. My generation had a template - to finish school, go to university, find a job... I tell Tikhon that all this is not necessary, the main thing is that he should do what brings pleasure, for which I would like to get up in the morning.

This summer we visited Skolkovo for the first time: I contacted Ilya Chekh, the founder of the Motorika company, on Facebook, told about Tikhon, and asked if he could come and see the production. Ilya showed how dentures are made and painted. We liked everything, and this year we would like to come up with a practice for Tikhon for the summer.

The Sobiraykin project is already a year old, and it has quickly gained momentum. But now I want Tikhon to see how many other opportunities are nearby. No, we are not closing Sobiraykin, we just put it on pause.

— Tikhon, are there companies where you would like to go on an excursion?

Tikhon: To Yandex. See how the program gives everything: answers, links... educational platform for tutors

My child wants to become a programmer. What do I need to do now?

How to teach generation Z so that school years are not in vain

- 3D printing

- Business

- RB Interview

- Russia

- Technology

- Teenagers

- RB Young

Found a typo? Select the text and press Ctrl + Enter

Related materials

- one Do you want to build a 3D printing business? Here's what to know

- 2 95% cheaper: what is the effectiveness of 3D printing for modern business

- 3 MPEI will print airplanes: young scientists presented an innovative 3D printer

- four 3D common sense: why do companies introduce additive technologies?

- 5 Create what no one has created.

How are the 3D printing championships

How are the 3D printing championships

CAPABILITIES

December 01, 2022

Starta VC Pitch Contest

December 01, 2022

Patenting of inventions and (or) utility models in the Russian Federation

December 02, 2022

Winter startup weekend

All possibilities

Stories

Compilation: Top 10 Most Popular AI Image Generators

Speakers

How to transfer money to Europe from Russia in 2022?

Speakers

9 promising business ideas after the departure of foreign companies

Archive rb.