3D printing portland maine

3D Printing Service Portland, ME | Instant Quotes Online

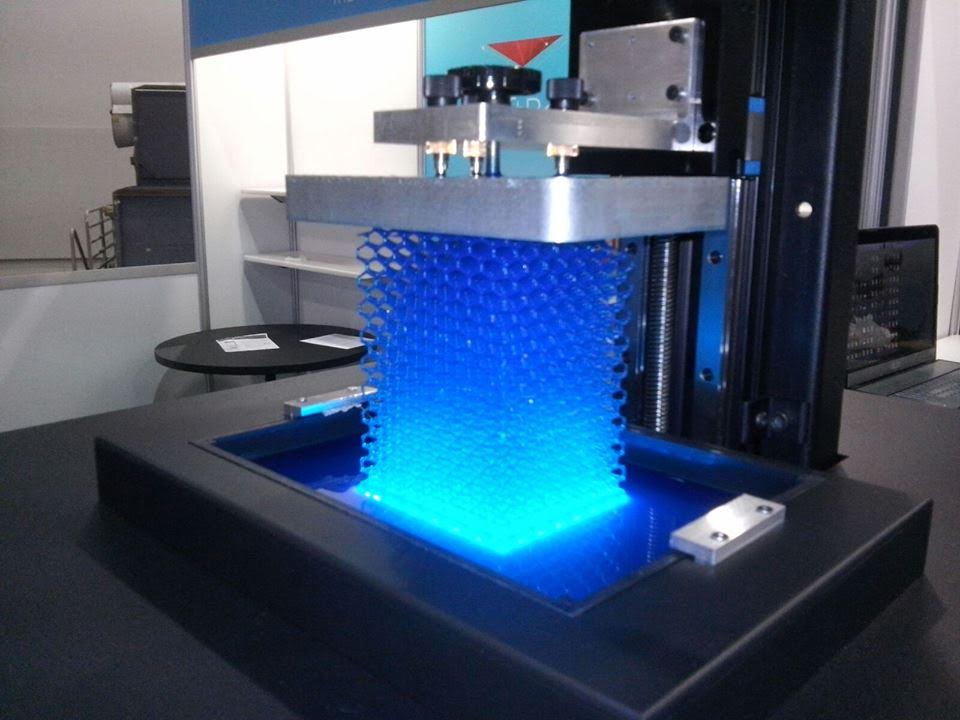

Our 3D printing capabilities

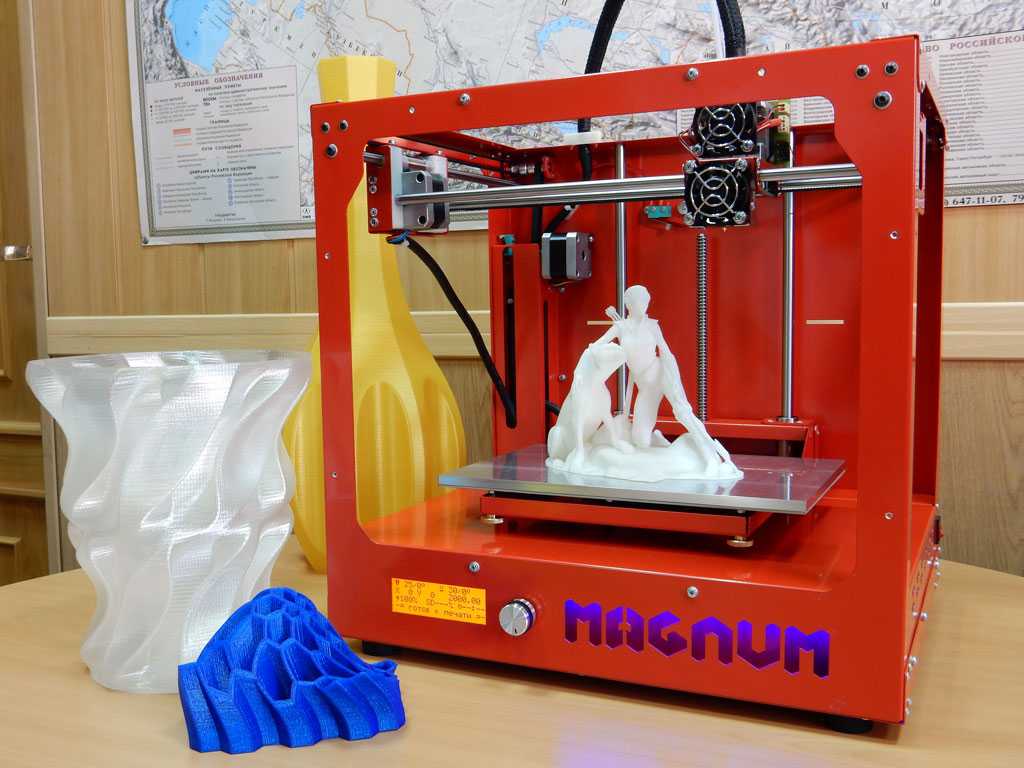

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

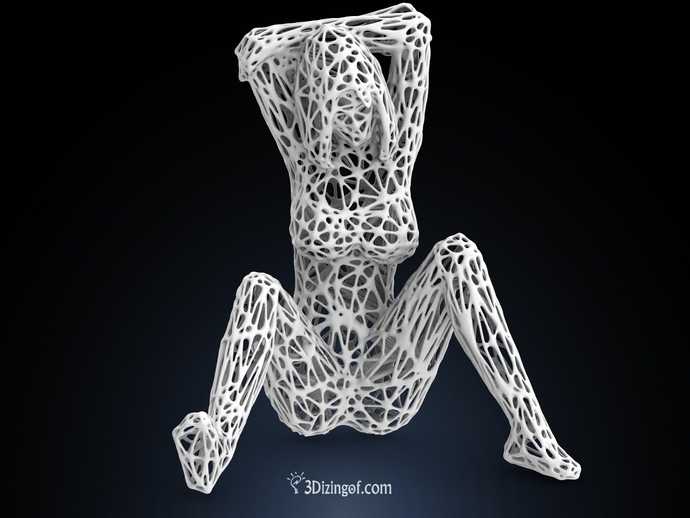

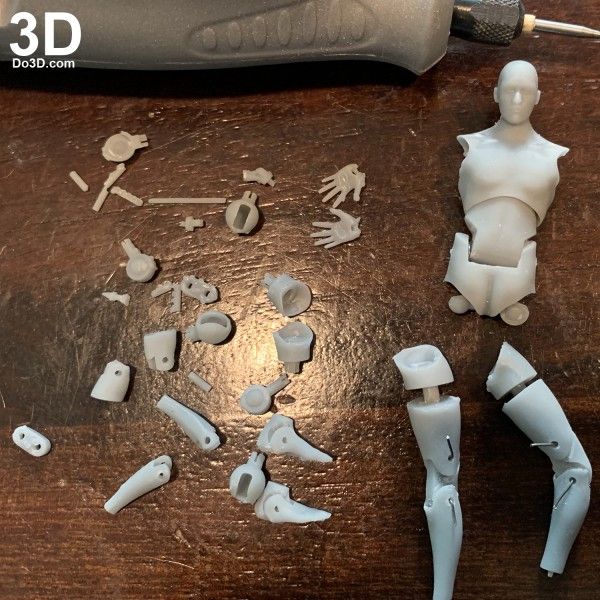

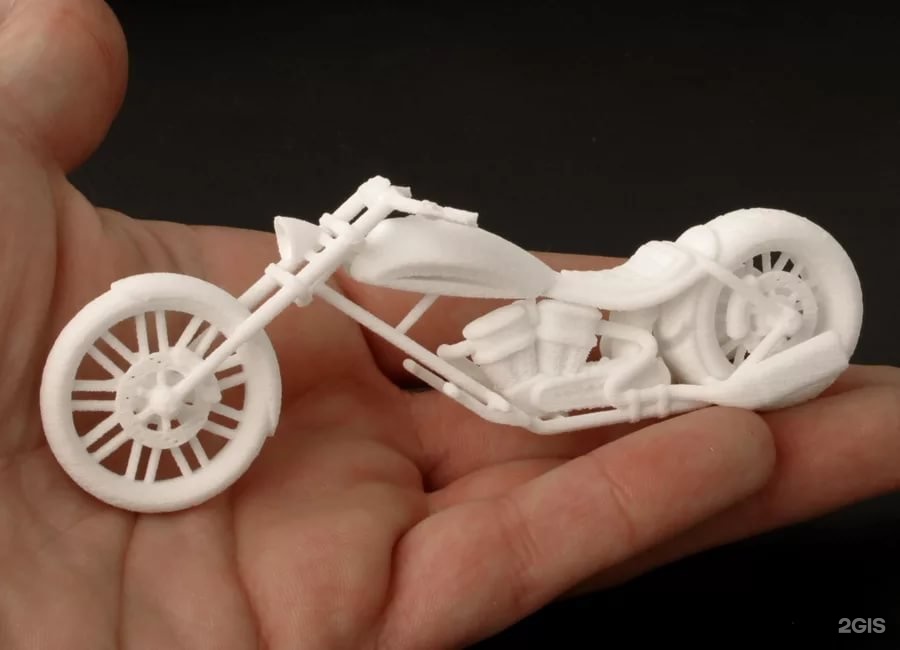

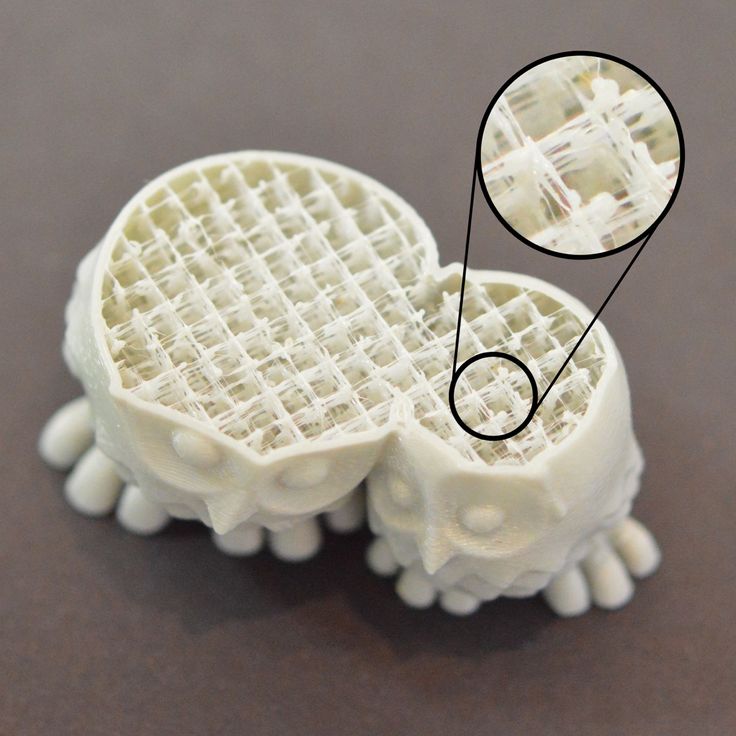

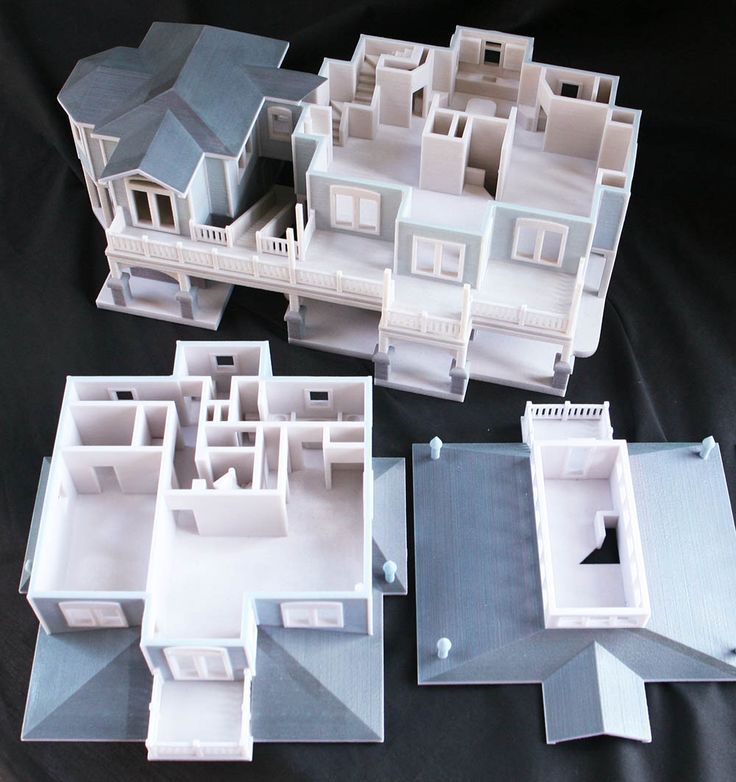

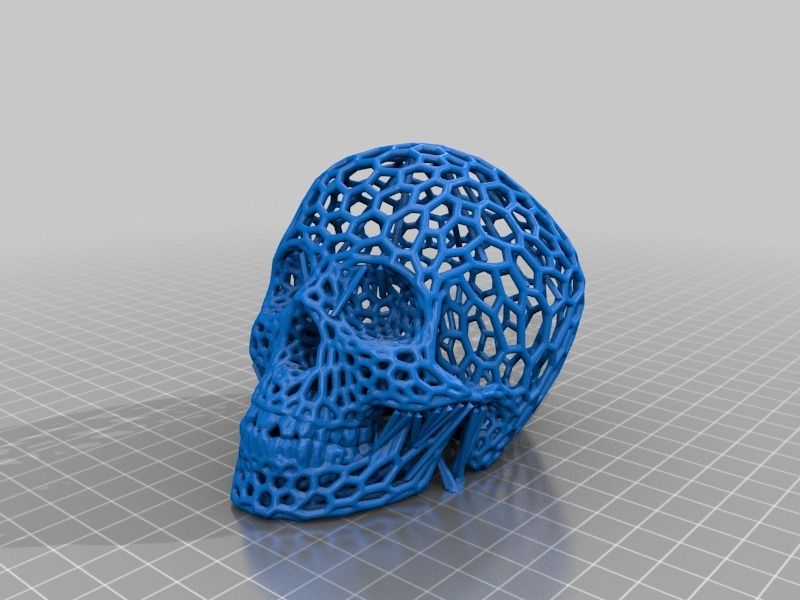

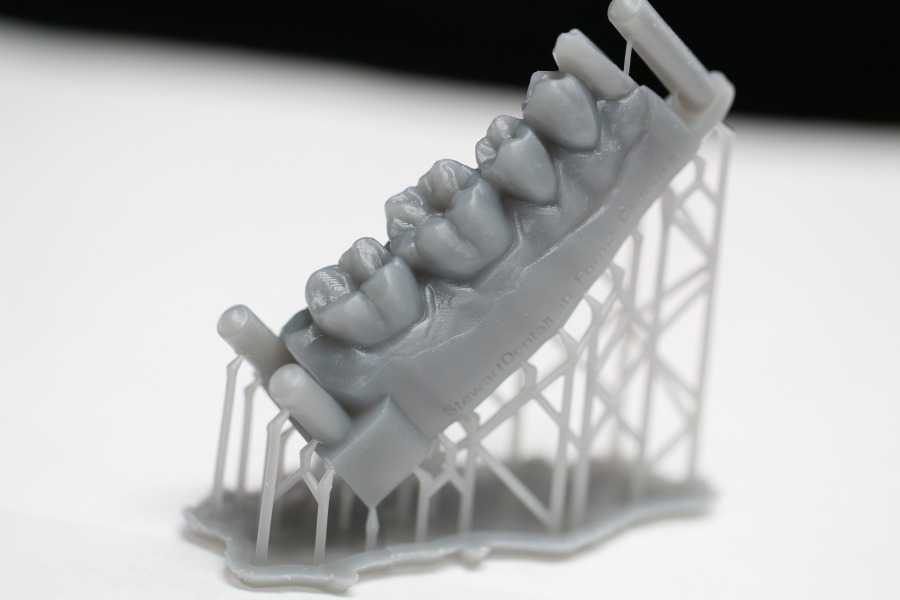

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc.

.

. -

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.9/5

Over 311 customers are satisfied with our 3D printing service.

“Much better than expected. Clean finish and accurate part. ”

“Perfect work, was exactly what I was looking for. Would definitely order again with confidence. ”

“All parts matched dimensions and the hub very dedicated to a satisfied customer.”

“Great print quality for the price and quick delivery!”

“Bed quality, speed, and service I’ve seen for PLA. Even sent me a time lapse!”

“Again, exactly the quality expected. Very pleased.”

“Excellent print, good communication and a speedy manufacture, and over a holiday weekend!”

“Exceeded expectations Spot on prototype looking forward to ordering revisions”

“He handled the order quickly, the parts fit and look great.”

“excellent work; I like the little keychain figurine a lot.”

“I like this hub, they are fast and professional ”

“The prints were as I wanted. Great advice in choosing the materials. ”

“Communication was excellent and parts came back as ordered”

“Very impressed overall by the service and quality. ”

”

“Thanks for the quick service and great quality!”

“Extremely fast service - especially given the number of units - and no compromise in quality. Excellent communication as always.”

“Very happy with the large print that came out. Hub offered to create custom changes to make sure no warping happened during printing. Parts came out very consistent and accurate. ”

“Great! No problems and was exactly what I expected and ordered!”

“Frew consistently delivers extremely high quality prints. I highly recommend his services”

“Beautiful print, received it in such a short period of time, I was actually shocked - looked fantastic in my model. ”

“Parts are neatly printed and arrived on time. Awesome job!”

“Awesome service, quick turn around. I have already ordered from this hub multiple times and will order again!”

“Great service, super fast, great quality. ”

“Service was fantastic, upgrade advice was a very nice touch, great knowledge.”

“Great Customer service! Responded promptly and clearly! Completed printed parts extremely fast and shipped right away while keeping me updated along the way. Recommend 100%”

Recommend 100%”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near Portland, ME

Lewiston, ME Portland, ME Dover, NH

Portsmouth, NH Bangor, ME Haverhill, MA

Methuen Town, MA Lawrence, MA Peabody, MA

Manchester, NH

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

Maine 3D printing services at STEAMfruit

Maine 3D printing services at STEAMfruit

Michael Vickery, owner of the 3D printing service company ‘STEAMfruit’, photographed by Portland Headshot

Prototyping, Design, and 3D Modeling with STEAMfruit

Michael’s studio, where he provides 3D printing services, is just down the hall from my own, and Tina has seen him at Engine for years. But it was only recently, during the Mill Project that we took some time to stop by and see some of the amazing things that he’s doing at STEAMfruit.

But it was only recently, during the Mill Project that we took some time to stop by and see some of the amazing things that he’s doing at STEAMfruit.

Building 15 Suite 212

MON-FRI 9AM-5PM

www.steamfruit.com

Who are you and where are you from?

I am Michael Vickery, a native Mainer, currently residing in Saco with my wife & partner, Laura, our teenagers, Max and Pearl, assorted dogs and cats. I am a life-long artist/designer/maker with a well-rounded background in art & design, various print production processes, operation & production management, AV/IT/tech, blown glass production, 3D modeling & animation, simulation, carpentry, ceramics, and more.

Tell me a little about your business?

STEAMfruit has established and quickly secured a place in the nascent digital manufacturing landscape. Our primary focus is product design, rapid prototyping, and reverse engineering utilizing the latest in Computer Aided Design (CAD), 3D Printing, and 3D scanning technologies, among others. I get asked about our name a lot— “STEAM”, as most educators know, is an acronym for Science, Technology, Engineering, Art, Mathematics, all of which are employed toward achieving an ultimate design/product, or the “fruit” of our labor.

I get asked about our name a lot— “STEAM”, as most educators know, is an acronym for Science, Technology, Engineering, Art, Mathematics, all of which are employed toward achieving an ultimate design/product, or the “fruit” of our labor.

Individuals and businesses with problems to solve, or product ideas for doing so, often don’t take that next step into design and prototyping because it is historically time-consuming and expensive. We minimize both of those barriers by providing consulting, design, and rapid prototyping services so that you can have a proof-of-concept in your hands within days vs. weeks, months, or even years. At our core we are about solving problems with beautiful design, all the while identifying efficiencies in processes, and manufacturing.

We’re building partnerships with local industrial/product designers, tool & mold makers, manufacturers, and suppliers in order to provide complete “art to part” services quickly, effectively, efficiently, and economically.

We provide high-end design and functional prototyping services that catalyze traditional manufacturing toward the new paradigm of agile manufacturing— faster and more effective design iteration, accurate functional prototypes, reduced tool & mold costs, short-run production, one-offs, all leveraging the existing local service and supply chain. Basically we help you get your beautiful product ideas to market fast and economically.

Additionally we maintain a consumer-facing service— 3D selfies; in particular, personalized wedding cake toppers. We perform an actual 3D scan of the individual or couple, edit and process the resulting 3D digital model, then 3D print it in one of a variety of available materials, and apply a finish according to the customer’s desire.

What made you choose the mill for your business?

I love the eclectic community within the mill as well as the energy that continues to build around Biddeford’s renaissance, or “Biddesance” as it’s come to be known. There’s an exciting and inspirational vibe going on that is energizing. It’s also very central to my network of partners. We have a complete Maine-based design and manufacturing ecosystem within a 5-mile radius.

There’s an exciting and inspirational vibe going on that is energizing. It’s also very central to my network of partners. We have a complete Maine-based design and manufacturing ecosystem within a 5-mile radius.

How long have you been doing this?

Not quite two years.

What makes your business interesting to you?

It is a culmination of nearly everything I’ve endeavored to do. It incorporates many different processes and technologies that fascinate me. Also, no two projects are alike. A love to share the enthusiasm and “ah-ha” moments with clients as we work through their projects toward a tangible solution. I thrive on creative and technical challenges, solving problems.

I especially enjoy forming new partnerships and business relationships with the people and businesses of the area and exploring how our specialties can mesh or compliment one another.

What makes you stand out from others in the same industry?

I run a nimble and responsive lab that focuses on building relationships with clients and gaining a thorough understanding of their needs and challenges. I approach everything with one eye on design, the other on function— whether it be a peanut butter sandwich or a complex mechanism. There is this accepted mantra that “form follows function” that often minimizes the importance of design and the human interface.

I approach everything with one eye on design, the other on function— whether it be a peanut butter sandwich or a complex mechanism. There is this accepted mantra that “form follows function” that often minimizes the importance of design and the human interface.

I strive to maintain balance in that mixture. I also bring a lot of experience with processes, production, materials, and systems to the table. Not to mention, I am obsessively detail and quality oriented.

The Mill Project

The Mill Project is a joint partnership project between Portland Headshot, a brand of Peter Greeno Photography, and the Pepperell Mill Campus, redeveloping Biddeford’s historic mill campus.

See more more about the project and it’s stories at:

THE MILL PROJECT

Or sign up for the newsletter at:

Pepperell Mill Campus

Previous All Blogs Next

Portland-based Hilos creates sustainable 3D printed shoes - see how it's done

now, yes, shoes today printed on a 3D printer. And it's being done right here in downtown Portland by a company called Hilos, which won Best in Show at Austin's South by Southwest last spring.

It goes something like this: A computer-generated shoe design is sent to a 3D printer the size of a small car, specifically a Hewlett Packard MJF 5200. The nearly 2,000-pound printer runs all night to create about a dozen pairs of shoes (shoe insole and heel) . Local designers collect all the details and send the shoes directly to the buyer. Shoes are made only after an order has been placed. nine0007

3D printing technology allows Hilos to produce shoes on demand, helping to reduce overproduction, a major problem in the fashion industry.

“With our newly developed shoe molds specially adapted for 3D printing, we can go from idea to reality on the market in just 90 days. Traditionally, brands need 18 months,” said Elias Stahl, CEO and co-founder of Hilos. “With the speed and flexibility of this technology, we can significantly lower entry barriers while increasing a more sustainable outcome for the industry.” nine0007

“With the speed and flexibility of this technology, we can significantly lower entry barriers while increasing a more sustainable outcome for the industry.” nine0007

Shoes are also notorious for being thrown into landfills and beaches. Hilos shoes are therefore specially designed to be recyclable at the end of their life. The company encourages customers to send old pairs for recycling. The bonus for this is a 15% discount on your next purchase at Hilos.

“The real beauty of this design, in my opinion, is that it is also fully rounded,” said Gaia Giladi, co-founder and chief creative officer of Hilos. nine0007

“3D printing allows us to create the internal channels you see here,” Giladi said, pointing to a hole in the sole of one of the shoes. “You can assemble the shoe in a whole new way by cutting through the upper without glue so you can easily cut through the wire, skin the platform and completely recycle every component. You can't do that with traditional production. "

"

Giladi and Stahl hope to make their mark on the industry by collaborating with other brands. Hilos recently partnered with Helm Boots, an Austin-based men's shoe company, to create a custom design using Hilos' 3D printing technology.

“We came to Portland to start this company because Portland is the shoe capital of the US,” Stahl said.

At the same time, Stahl also acknowledges that Portland is at the crossroads of footwear and technology, where many well-known companies are based. nine0007

“With 3D Systems and HP and Autodesk located here, there is an incredible technology base and product experience that we think will change the retail landscape,” he said.

Hilos makes everything from strappy sandals and clogs to mules and chunky heels. Prices range from $175 to $375.

Source: nine

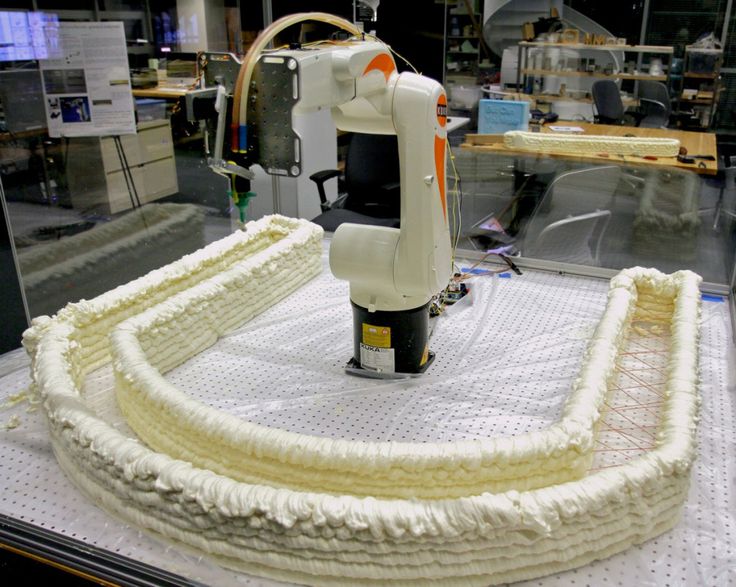

Subscribe to the author $2.8 million to develop a technique for 3D printing tooling for the manufacture of wind turbine blades. The university intends to print forms on a large-format 3D printer and use recyclable composite materials with cellulose fillers. nine0007

The university intends to print forms on a large-format 3D printer and use recyclable composite materials with cellulose fillers. nine0007

According to the press service of the university, the project is aimed at reducing the cost and speeding up production processes, since at present the cost of a set of large-sized molding equipment for manufacturing blades can reach ten million dollars, and a full production cycle often takes up to one and a half years.

“The large molds will be printed on the world's largest resin 3D printer, installed at the university's Center for Advanced Structures and Composites, using recyclable biopolymers reinforced with wood products. Our team estimates that the combination of advanced additive technologies and bio-based raw materials can help reduce the cost of creating new blades by 25-50% and reduce the lead time by six months. The spent materials can be recycled and reused,” commented Habib Dager, head of the Center for Advanced Structures and Composites. nine0007

nine0007

The developers believe that the use of biopolymers with fillers of cellulose micro- and nanofibers will make it possible to obtain products with mechanical characteristics at the level of aluminum and at the same time achieve significant savings: if a pound of high-quality ABS plastic costs more than $5, then composite bio-raw materials will cost about at two dollars. In addition, the team plans to integrate heating elements into 3D printed molds using Oak Ridge National Laboratory (ORNL) work to better control surface temperatures, and will also participate in ORNL’s research on additive manufacturing blades using continuous fiber-reinforced polymers. . nine0007

In the fall of 2019, the University of Maine set three records at once by printing a one-piece hull of a seven-meter boat on Ingersoll's large-format hybrid additive-subtractive press. The same equipment is planned to be used in the new project.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at news@3Dtoday. ru

ru

wind generator energy UMaine Ingersoll

Follow author

Follow

Don't want

4

Article comments

More interesting articles

eight

Follow author

Follow

Don't want

With Kings3D stereolithography 3D printers, Qiuping has become a leading enterprise...

Read more

five

Subscribe to the author

Subscribe

Don't want

Establishment of the center will help improve the quality and reduce the cost of engineering products.