3D printing policy

3-D Printing in Libraries: Policies & Best Practices

All libraries providing access to 3-D printers should adopt written policies governing the use of their 3-D printers. Such policies should:

- identify those eligible to use the library's 3-D printer;

- outline all rules and regulations concerning user access, fees, and training requirements;

- bar use of the library's 3-D printing facilities for illegal activities;

- include a statement informing users that all other library policies apply when using the library's 3-D printer or printing services, including policies addressing user behavior, acceptable use, cybersecurity, copyright, intellectual freedom and user privacy.

Policies can also include a specific provision requiring users to comply with all applicable laws, including laws governing copyright and the manufacture of regulated or illegal items.

Though policies, by necessity, must address concerns about access, potential misuse, and liability, policies should also reflect the library's commitment to learning and the exploration of ideas. A mission statement or statement of purpose should encourage users to learn about new technologies, exercise their imaginations, and assure their freedom to create, and design new projects within the parameters imposed by the technology.

Listed below are resources created by ALA and its members that provide guidance on developing effective policies and best practices for managing makerspaces and 3-D printers in libraries. We have also included other publications that offer both general information about 3-D printing as well as information about policy development for 3-D printers.

ALA's Office for Intellectual Freedom or ALA's Washington Office Public Policy staff can consult with individual libraries on policy development, depending on the questions or issues raised by the library.

August 2018 Update: Recently, the U.S. State Department entered into a settlement agreement that would have allowed Defense Distributed, a non-profit advocacy group, to post and make available downloadable instructions and templates for printing guns and gun parts on 3-D printers. On July 31, 2018, U.S. District Court Judge Robert Lasnik granted a temporary restraining order barring Defense Distributed from posting their files online. On Monday, August 27, Judge Lasnik issued an order reaffirming and extending the nationwide injunction barring the online dissemination of files for printing plastic weapons. The injunction will remain in place until the state attorney generals' case is resolved. (Attorney generals from 19 states and the District of Columbia have filed a lawsuit to set aside the settlement agreement or to prevent Defense Distributed from posting their files online.)

On July 31, 2018, U.S. District Court Judge Robert Lasnik granted a temporary restraining order barring Defense Distributed from posting their files online. On Monday, August 27, Judge Lasnik issued an order reaffirming and extending the nationwide injunction barring the online dissemination of files for printing plastic weapons. The injunction will remain in place until the state attorney generals' case is resolved. (Attorney generals from 19 states and the District of Columbia have filed a lawsuit to set aside the settlement agreement or to prevent Defense Distributed from posting their files online.)

Libraries should be aware that the settlement agreement allowing online distribution of the plans is not binding on libraries and does not confer a right to use those plans to create guns on library 3-D printers in violation of library policy or in violation of the applicable law regulating the manufacture or distribution of guns in the United States. This includes the law that makes it illegal to create, or assist in the creation, of a gun that is undetectable by x-ray machines or metal detectors.

These materials are not a legal opinion nor should they be regarded as legal advice. Readers should consult their own legal counsel for legal advice regarding their particular situation.

Resources for 3-D Printer Policy Development:

Progress in the Making: 3D Printing Policy Considerations through the Library Lens | ALA Office for Information Technology Policy (2015) (includes the sidebar "3D Printing, Intellectual Freedom and Library Values.") (2015)

Progress in the Making: An Introduction to 3-D Printing and Public Policy | ALA Office for Information Technology Policy (2014)

3D Printing in Libraries: A View from Within the American Library Association: Privacy, Intellectual Freedom and Ethical Policy Framework | Bulletin of the Association for Information Science and Technology (2015)

Copyright Considerations for Providing 3D Printing Services in the Library |Bulletin of the Association for Information Science and Technology (2015)

The Library's Legal Answers for Makerspaces, by Tomas Lipinski and Mary Minow | ALA Editions (2016)

Libraries Make Space For 3-D Printers; Rules Are Sure to Follow | NPR (April 2015)

3D Printers and Library Policy: Cool Technology Needs Rules Too | TechSoup for Libraries (2014)

3-D Printers: General Information

3-D Printers for Libraries, 2017 Edition, by Jason Griffey | Library Technology Reports

Progress in the Making: Librarians' Practical 3D Printing Questions Answered | ALA Office for Information Technology Policy (2016)

Toward A More Printed Union: Library 3D Printing Democratizes Creation | ALA Office for Information Technology Policy (2015)

Sample 3-D Printing Policies:

District of Columbia Public Library

Glen Carbon Centennial Library (IL)

Glen Ellyn Library (IL)

Jacksonville Public Library (FL)

Keene Public Library (NH)

Kirkwood Public Library (MO)

Meriden Public Library (CT)

Northbrook Public Library (IL)

Plano Public Library (TX)

Sacramento Public Library (CA)Idaho State University - Oboler Library

Michigan State University Libraries

Parkland College (IL)

Purdue University Libraries (IN)

University of Massachusetts - Amherst

University of Northern Iowa – Rod Library

3D Printer Policy » UF

- Research Services and Safety

- Occupational Safety & Risk Management

- Facility Support Services

- Service Animals in Labs

- 12 & 15 Passenger Van Policy

- 3D Printer Policy

- Asbestos Floor Tile Policy

- Asbestos Policy

- Basic Electrical Safety Policy

- Electrical Safety Policy

- Bicycles and Other Transportation Vehicles in University Buildings

- Biohazards Medical Monitoring Policy

- Biological Waste Disposal Policy

- Building Code Enforcement Policy

- Chain Saw Safety Policy

- Compressed Gas Cylinders Condensed Safety Rules

- Compressed Gas Cylinders Use and Storage

- Confined Space Entry Policy

- Contractor Health and Safety Requirement Policy

- Dive Boat Safety Policy – Responsibilities

- Drones & Unmanned Aircraft System Policy

- Electronics Reuse/Recycle

- Fall Protection Policy

- Feral Cats & Other Wild Animals Living on Campus Policy

- Golf Cart Policy

- Hazard Communication Policy

- Hazardous Energy Control (Lock out/Tag out) Policy

- Hearing Conservation Policy

- Heat Stress Policy

- Hot Work Safety Policy

- Hot Work Permit Request

- Hot Work Supervisor’s Role

- Indoor Environmental Quality Policy

- Lab Closeout Policy

- Lead Paint Policy

- Mercury Spills

- Minors in Research Laboratories, Clinics, or Animal Facilities

- Motorcycle, Scooter (Includes E-Scooters)/Moped, Segway and Bicycle Use by Employees: Personal Protective Equipment Policy

- Natural Gas Leaks Policy

- Occupational Safety Forms

- Personal Protective Equipment

- Portable Power Tool Safety

- Powered Industrial Trucks (Forklifts)

- Q Fever/Coxiella burnetii in Sheep, Goats and Cattle Control Policy

- Recreational Use of the Lake Alice Watershed Policy

- Respiratory Protection Policy

- Shop Safety & Machine Guarding Policy

- Compressed Air Safety

- General Safety Rules

- Ladder Safety

- Machinery and Machine Guarding

- Materials Handling

- Shop Safety

- Woodworking Machine Guarding

- Student Shop Safety Policy

- Temporary Structures on Campus (Including Tents)

- Tractor & Roll Over Protection Structures (ROPS) Safety Policy

- Trenching and Excavation Policy

- Trenching and Excavation Safety Program

- Vaccination Policy for Research Personnel

OBJECTIVE

The objective of this policy is to establish health and safety requirements for using 3D printers in University of Florida facilities. The policy is presented in recognition of the continued expansion of 3D printer use by faculty, staff and students. Studies have indicated that 3D printers are capable of generating potentially harmful concentrations of ultrafine particles (UFP) and chemical vapors during the print process and through processes used following printing to treat the finished product.

The policy is presented in recognition of the continued expansion of 3D printer use by faculty, staff and students. Studies have indicated that 3D printers are capable of generating potentially harmful concentrations of ultrafine particles (UFP) and chemical vapors during the print process and through processes used following printing to treat the finished product.

AUTHORITY

By authority delegated from the University President, the Vice-President for Business Affairs is responsible for the safety of all University facilities. Under this authority, policies are developed to provide a safe teaching, research, service, housing and recreational environment.

Reference

Governor’s Executive Order Number 00-292; Occupational Safety and Health Act Sec 5 (General Duty Clause)

POLICY

The 3D Printer Policy establishes the minimum requirements necessary to allow for the safe use of 3D printers located in the University of Florida buildings. The policy covers all 3D printers, both department/program owned, and personal units used in campus buildings, including but not limited to those affiliated with the sciences, medicine, fine arts, performing arts, engineering, libraries and arts and craft studios.

RESPONSIBILITIES

Environmental Health and Safety (EH&S)

EH&S will be responsible for the review and approval of all 3D printer purchases.

Purchasing review will consider the type of printer, the type of print media to be used and the proposed location of the printer set-up before approval is granted.

EH&S may request the modification of a proposed printer location or the addition of improved exhaust ventilation before purchasing approval is granted.

EH&S has final authority over all safety issues and may immediately halt any operations or procedures it considers unsafe at any time at its discretion.

EH&S is available to perform air monitoring and hazard assessments upon request.

Principal Investigators (PI) and Managers with 3D printer oversight

The PI and 3D printer managers are responsible for enforcing the provisions of this policy including providing a set-up location meeting the ventilation requirements and for compliance with the training requirements.

Print supervisors are responsible for providing required personal protective equipment (PPE) and enforcing its correct use.

Users of 3D printers (Faculty, staff, students)

Individuals shall receive training in the correct and safe operation of the 3D printer including Hazard Communication (HAZCOM) training relevant to the media and other chemical products used in the printing process.

Required personal protective equipment shall be used.

No eating or drinking is allowed in areas where 3D printers are present.

PROCEDURES

3D printing at the University Florida includes the use of almost all currently available additive manufacturing technologies.

All 3D printing variations have the potential to produce health and safety hazards depending on the type of feedstock used and on the other processes involved in printing.

Whenever possible, printers certified to the ANSI/CAN/UL 2904 Standard, which tests and certifies printers for low emission rates, should be purchased.

Fused filament fabrication (FFF) represents one of the more popular types of 3D printing used at UF. This process typically uses a thermoplastic filament though other types of media can be used depending on the printer. Thermoplastic media generates ultrafine particulate (UFP), nanoparticles and volatile organic compounds (VOC) at varying concentrations regardless of which filament media is used. Recent studies have also found that formaldehyde can be produced by all types of filament media.

The amount of contaminant produced depends on the type of media used, the extruder nozzle temperature and on any additives present in the media.

Another popular type of 3D printing conducted on campus is stereolithography (SLA) which uses resins to produce the desired product. Chemicals in these resins can be irritants and sensitizers.

The following sections will serve to address the health and safety issues associated with 3D printers.

Print Media Types

Filament media can be found in numerous forms. The more commonly used filaments include polylactic acid (PLA), acrylonitrile butadiene styrene (ABS) and nylon. While all filament media types can be hazardous, PLA is generally considered the least hazardous of the group and should be used whenever possible.

The more commonly used filaments include polylactic acid (PLA), acrylonitrile butadiene styrene (ABS) and nylon. While all filament media types can be hazardous, PLA is generally considered the least hazardous of the group and should be used whenever possible.

Special ventilation considerations may be necessary when using other types of filament media or 3D printing processes.

Locations with 3D printers using combustible media such as powdered metals or carbon nanotubes must be reviewed and in compliance with fire safety and other health and safety requirements before the printer begins operation.

Ventilation

3D printers using PLA media exclusively may be set-up in a workspace having at least 4 air changes per hour.

The number of PLA printers in one location should be limited by the size of the space. One printer per standard office and no more than two printers for a standard classroom or workroom is allowable. Requests for the placement of multiple PLA printers in any space must be reviewed by EH&S before proceeding.

3D printers using ABS media or nylon may only be used in work areas having local exhaust ventilation or one pass air and at least six air changes per hour.

Printers should be fully enclosed and equipped with local exhaust ventilation or used within a fume hood whenever possible.

3D printers using other types of media, including but not limited to thermoplastics, photopolymers, high impact polystyrene, high density polyethylene, thermoplastic polyurethane (TPU), metal filament, biological media or other uncommon medias shall be reviewed by EH&S on a case by case basis with specific precautions required based on the hazards unique to the printing process.

General Safety

All printers must be installed according to the manufacturer’s requirements and according to NFPA 72 National Electric Code (current code requirements can be found at Building Codes Enforcement .)

Modifications to units that would void an existing certification (i. e. UL) are not allowed.

e. UL) are not allowed.

Safety Data Sheets (SDS) must be provided for all print feedstock and for any other chemical product used in the printing process. SDS must be readily accessible for review in the event of an emergency.

Printer extruder nozzles should be operated at the lowest temperature capable of producing the desired result.

Printer progress should be monitored remotely via camera or observation windows to minimize exposure concerns.

Keep 3D printers away from heavily trafficked areas.

Even if local exhaust ventilation is provided, there should be a waiting period in place to allow cool down and contaminant dissipation before opening the printer to access the finished product.

Safety interlock switches must be enabled and working properly during printer operation.

Operators must be protected from hot surfaces associated with the printers.

If UV light is used in the curing process, personal protective equipment and/or shielding must be utilized to protect personnel.

Training Requirements

All users working directly with a 3D printer and associated media are required to have hazard communication (HAZCOM) training covering any hazardous materials used in the process.

Completion of the training must be documented in writing with the records maintained by the manager of the printing operation.

Personal Protective Equipment (PPE) Requirements

Follow all PPE recommendations found in the Safety Data Sheet (SDS) for the specific printer media used.

Eye protection is required during any activity where airborne projectiles may be present (i.e. cutting off rough edges of a printed item).

For print processes using an alkaline bath to dissolve support material, an emergency eyewash will be required in the immediate vicinity of the work.

A handwash facility must also be available, particularly in areas where the media or processes used represent dermal hazards (i. e. resin printers).

e. resin printers).

A spill kit capable of neutralizing the caustic components of the alkaline bath shall also be provided.

Prohibitions

The use of a 3D printer to fabricate any item in whole or in part that is designed to be used as a weapon is prohibited.

A partial list of prohibited items includes:

- Firearms

- Knives

- Striking instruments

- Martial arts weapons

- Bow and arrow combinations

- Explosive devices

Additional Information

The National Institute of Occupational Safety and Health (NIOSH) has additional health and safety information for 3D printers at the following links:

3D Printing with Filaments: Health and Safety Questions to Ask (cdc.gov)

3D Printing with Metal Powders: Health and Safety Questions to Ask (cdc.gov)

3d printer in politics, quite unexpected and very creative.

top sellers

-

Bearing 604UU U604ZZ

U-bearing U604ZZ 604UU 4*13*4

35.

00 UAH

00 UAH -

Thermal mat for 3D printing 200 x 200 mm

3D printing thermal pad

150.00 UAH

-

Buy epo3d+ 3D printer

Epo3d+ Ukrainian FDM 3D printer on HIWIN rails. Thanks to reliable...

UAH 35,000.00

-

ABS granules

ABS granules for extrusion

400.00 UAH

-

PLA

PLA environmental plastic from Plexiwire.

100% advance payment....

100% advance payment.... UAH 375.00

-

Buy ABS plastic (ABS)

ABS plastic from Plexiwire. 100% prepayment. Free shipping...

UAH 220.00

-

Mini motor reducer 12v 100 rpm

high torque mini electric motor. Its size...

150.00 UAH

-

Nozzle for 3D printer 1.75 mm, for E3D and MK8 hotends

3D printer nozzle 1.75 mm 0.2/0.3/0.4/0.5

35.00 UAH

-

PETG plastic for 3D printer

PETG plastic from Plexiwire.

100% prepayment. Free...

100% prepayment. Free... UAH 360.00

-

SHF-20 shaft support

SHF-20 shaft support is used for CNC

60.00 UAH

-

A4988 stepper motor driver

35.00 UAH

-

Buy epo3d 3D printer

Ukrainian epo3d 3D printer built on the basis of modern kinematics...

UAH 18,000.00

All best sellers

Information

3d printer in politics, very unexpected and very creative.

Sierra Leone President Julius Maada Biot uses 3D printing in a very unexpected way, it informs people by transforming complex data into visual objects that are easier to understand.

Sierra Leone uses 3D printing to visualize its politics, turning complex shapes into an easy-to-understand printed model. The idea arose during a meeting at the State House, when President Julius Maada Biot discussed problems with education.

Biot has been president since April 2018, and in his first year in office, he focused on fighting corruption, stopping violence against women and girls, and providing free education to every child across the country.

During one particular meeting, he needed a way to easily show complex facts and figures, as there were no screens available. The Directorate of Science, Technology and Innovation (DSTI) at the State House came to the rescue and quickly turned data on the number of girls out of school in the country into a three-dimensional model.

This model was 3D printed and used to discuss the issue with the head of the UK Department for International Development, Mary Hunt.

“The fact that you can take the model and turn it over to see different aspects of the map from different angles makes you feel like you are there – in Kenem, Cabal or Bont – seeing the problems from the inside and you immediately get ideas – what needs to change,” Hunt said. “I was so impressed with the clarity and potential of the demonstration that I had to ask the President if I could take the model with me – as it is almost impossible to fully describe the problem in words.”

Should everyone use 3D printed models in meetings?

Officials in Sierra Leone also used 3D printed models to show children the distance between their home and their school, which delighted the children. This 3D model clearly showed how buses should be distributed and where roads should be built.

These 3d maps also led the Science, Technology and Innovation Directorate team to take action to create more schools in areas that needed them most.

The 3D printer stands proudly on the president's desk and he said, "We need to make this quantum leap to catch up with the rest of the world using this kind of technology."

With 3D printing, we can visualize complex datasets and make them easier to understand. The 3D model easily shows peaks and troughs in the data and even overcomes language barriers when discussing a complex topic.

The President of Bio added: “All development decisions are actually based on the data we collect and we can actually play with the data in all its forms or in hard copy to help us make the right development decisions in Sierra Leone".

Video: https://www.youtube.com/watch?v=hOYbVCGwWks

Possibilities of 3D printing in small-scale production

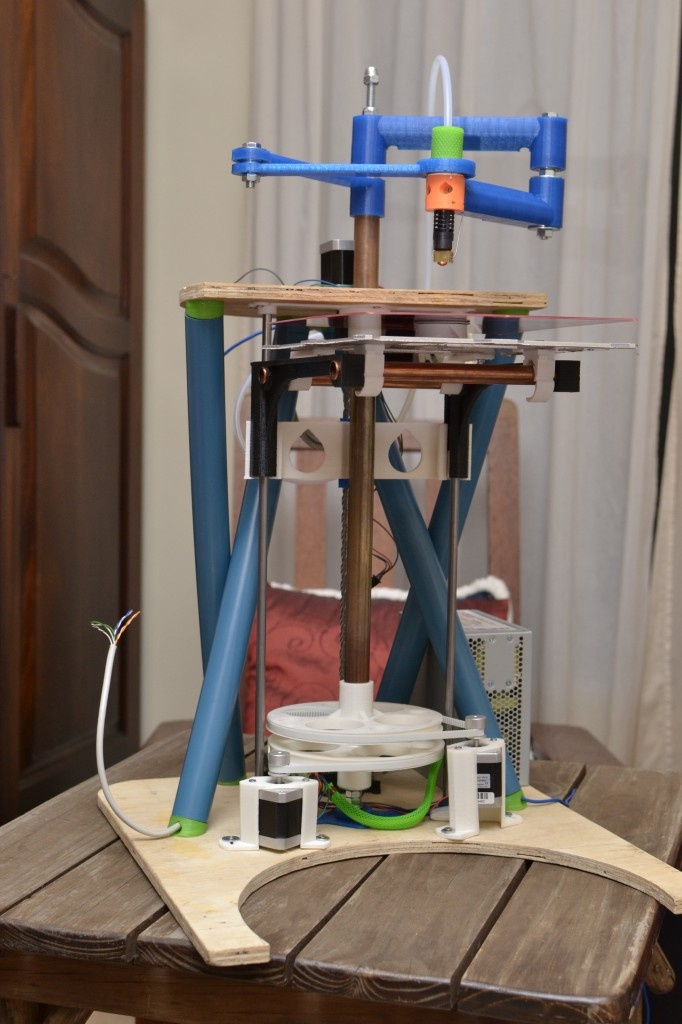

A bit of history

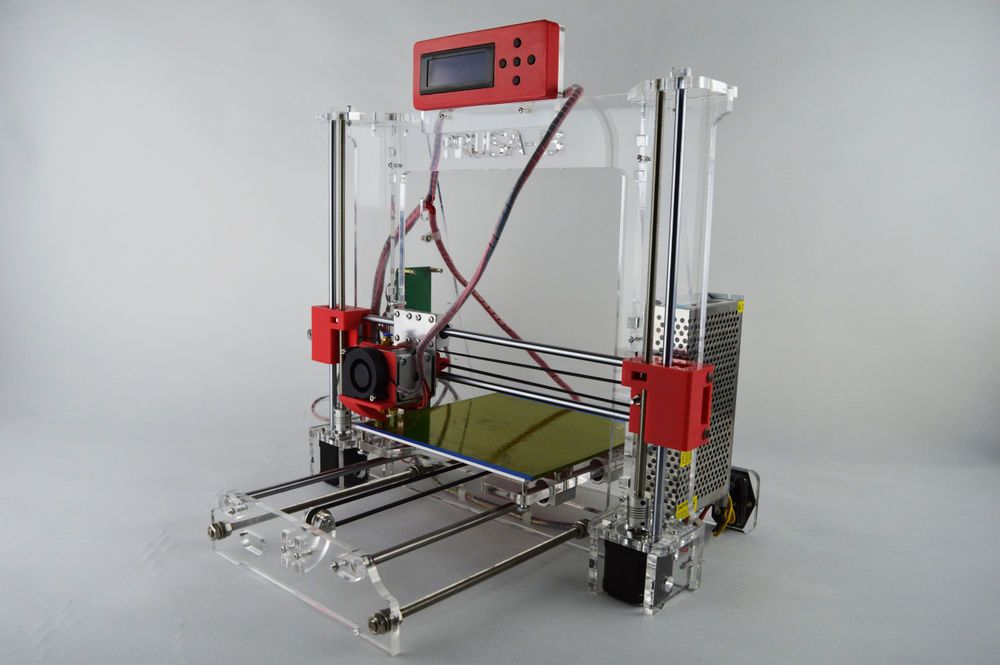

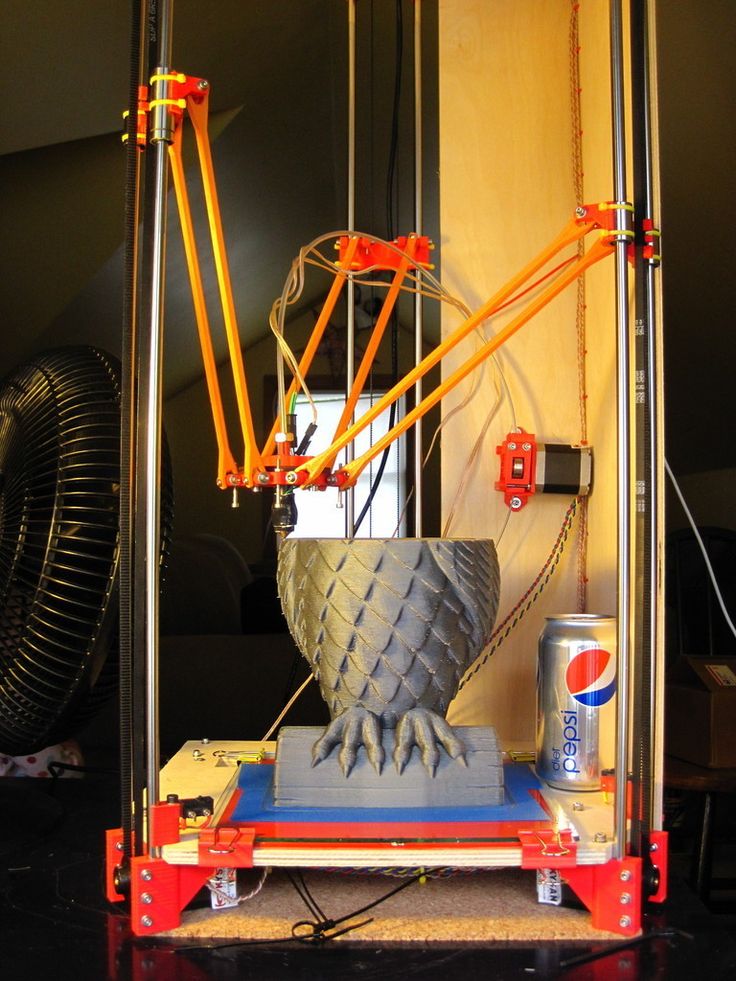

Modern desktop 3D printing began just over 10 years ago with the emergence of the RepRap enthusiast community. The goal of the project was to "self-copy", replicate the components of the 3D printers themselves. The task was to small-scale production of 3D printers on the 3D printers themselves. This idea was picked up and developed by the Czech engineer and entrepreneur Josef Prusa. He created the largest 3D printing farm to print plastic parts produced by his 3D printer factory. The total number of printers in his factory reaches 1000 pieces, this achievement was even registered in the Guinness Book of Records.

The task was to small-scale production of 3D printers on the 3D printers themselves. This idea was picked up and developed by the Czech engineer and entrepreneur Josef Prusa. He created the largest 3D printing farm to print plastic parts produced by his 3D printer factory. The total number of printers in his factory reaches 1000 pieces, this achievement was even registered in the Guinness Book of Records.

In this case, I would note Josef's marketing talent, because his company produces about 100 thousand printers a year and its production can hardly be called small-scale. However, he continues to print plastic components for his printers on them. Thus, their reliability is emphasized, because printing is part of the testing process, on the one hand, and on the other hand, it demonstrates to customers the quality of models made on a 3D printer. The effectiveness of this approach, from the point of view of the production itself, is negligible. One injection molding machine would do the job easily, saving a lot of space and electricity, and there would be no need for a large number of jobs.

3D printing capabilities for low volume production

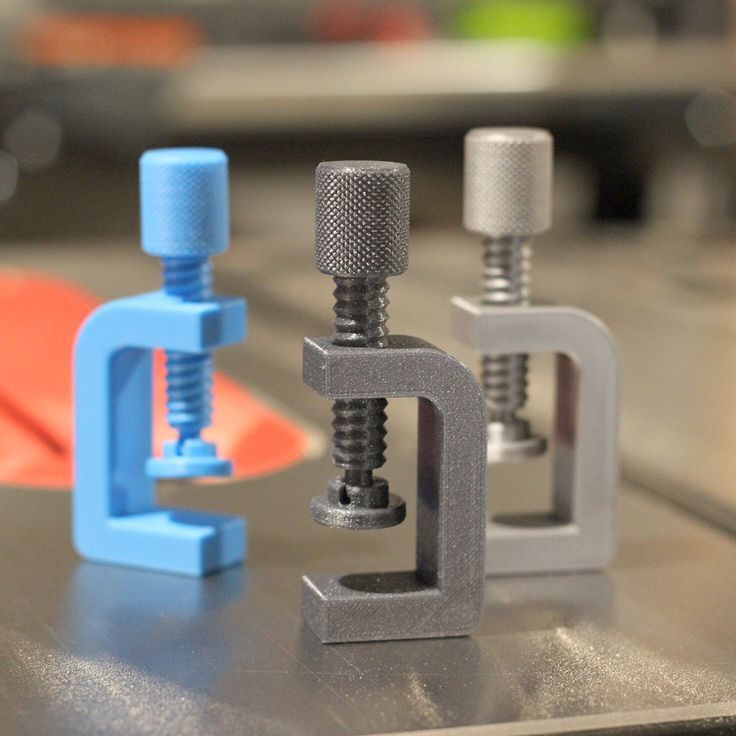

So what are the possibilities of desktop 3D printing for small-scale production? I note right away that this article is about desktop 3D printers. I will not consider industrial systems in it, since they are in a different price category, both for the equipment itself and for printing materials.

To begin with, it is worth talking about what can be produced on 3D printers. Usually we are talking about small plastic elements, plugs, clamps, housings, holders and other similar elements. The choice is to order a mold or 3D print these elements. It is easy to make such a choice by calculating the cost of the mold, the cost of products obtained on an injection molding machine and the cost of printing the same product on a 3D printer of the required circulation. You need to understand how many units of production per unit of time you need to produce and, accordingly, how many and which 3D printers will be needed for this task. Having made such an initial analysis and having previously understood that 3D printing is what suits you, you should carefully start choosing equipment.

Having made such an initial analysis and having previously understood that 3D printing is what suits you, you should carefully start choosing equipment.

If you already know what you will print, the choice becomes easier. If you plan to produce models with different tasks in the future, then before buying, you should carefully analyze the possible options. The main factor influencing the choice of equipment is the presence or absence of certain functionality in future models. The printer should print with materials that will ensure the functionality of your products. For example, a future part must withstand a certain heating or cooling temperature, be strong, rigid, wear and shock resistant, or, conversely, soft, rubber-like, elastic, flexible. The more versatile a 3D printer is, the more expensive it is. Indeed, for printing various types of plastic, printers are equipped with closed chambers, interchangeable extruders, perforated platforms, feed mechanisms with adjustable filament pressure, etc.

FDM/FFF solutions

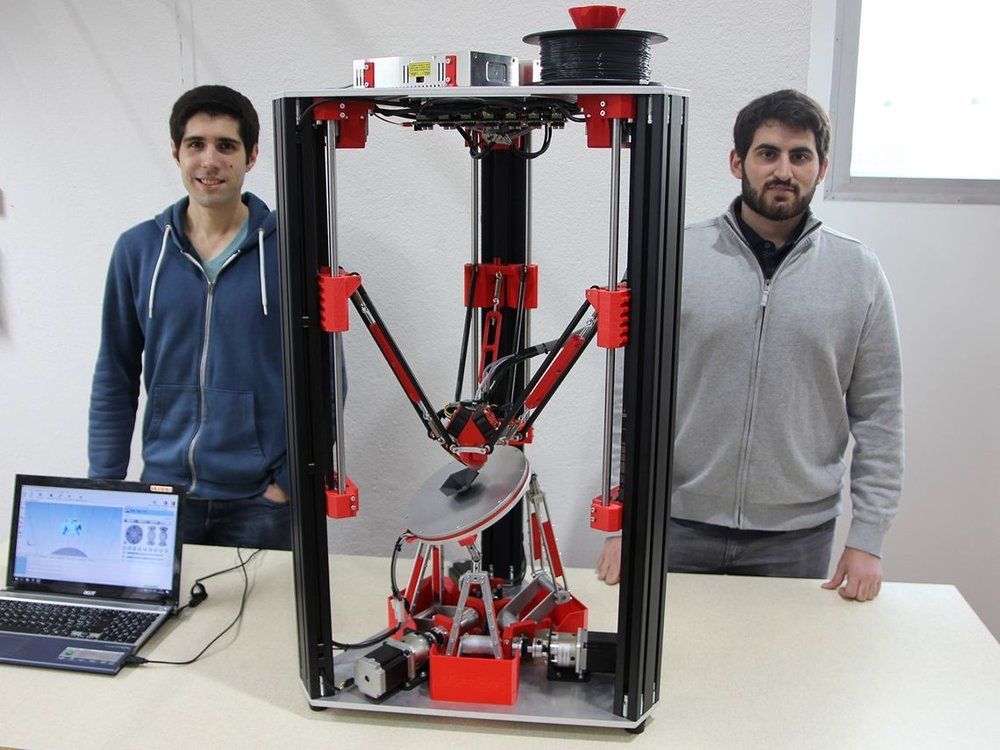

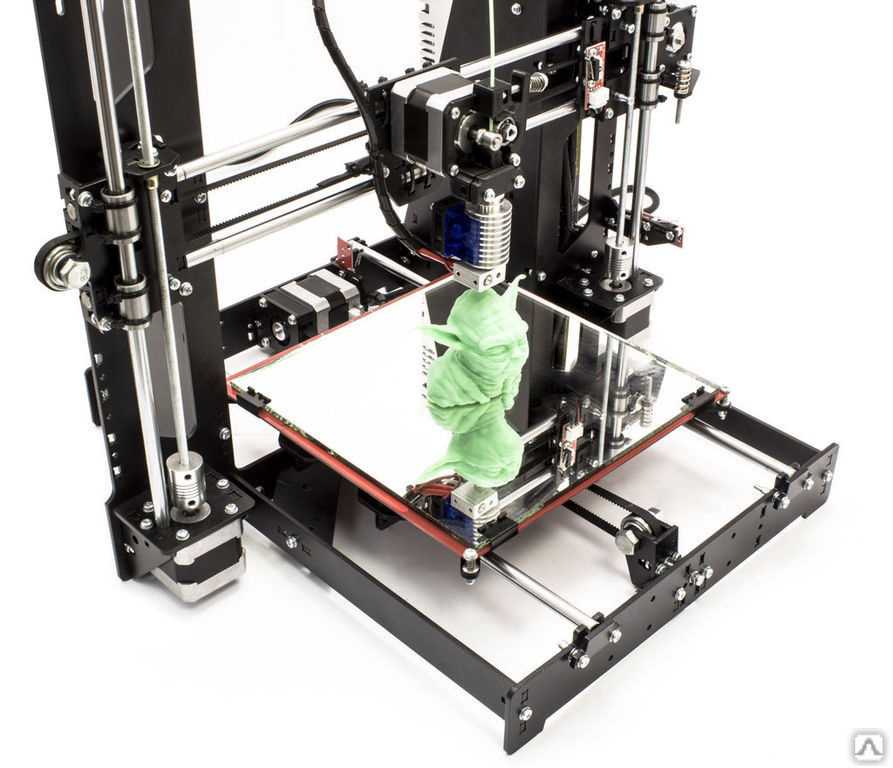

This is the FDM/FFF printing technology most commonly used today for small-scale production. Let's look at a few technological solutions that manufacturers offer.

The most affordable and suitable for printing simple models from plastics such as PLA or PETG is a solution based on budget printers such as Creality Ender-3. These are very simple models that are installed on racks.

Pictured is a 3D printing farm in Creality3D

Among the advantages of this solution: the ability to quickly deploy it in almost any suitable place, quickly increase the number of printers to increase the productivity of the farm. Of the minuses: the impossibility of printing with engineering plastics, the need to manually remove models, as well as the impossibility of remote monitoring and control over printing.

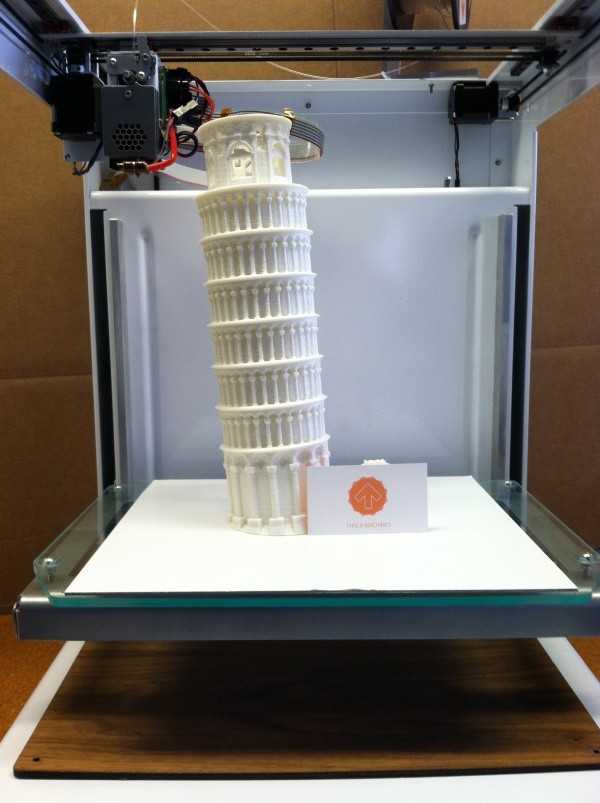

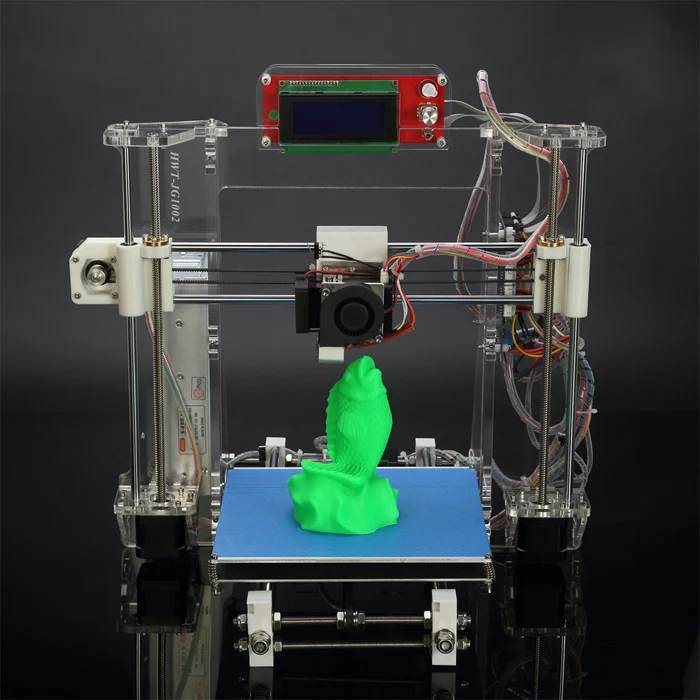

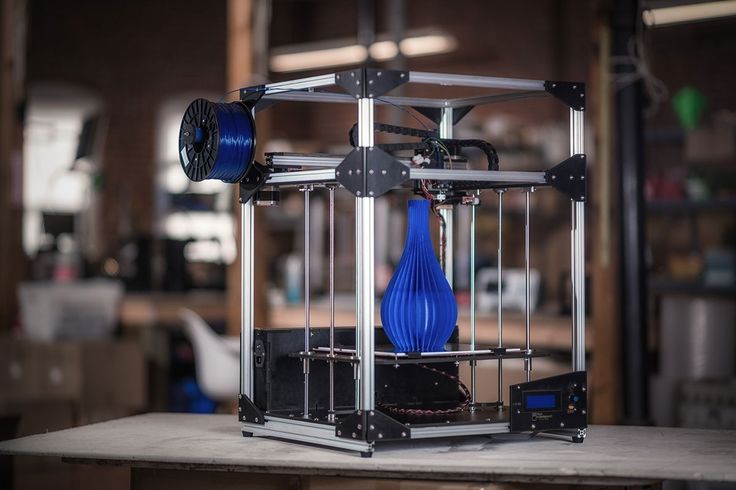

The next level of organization of small-scale production is a farm of printers that can cope with the most diverse tasks. For example, a farm built on the basis of Raise3D Pro2 3D printers. Each such printer is equipped with two extruders, a closed camera and a built-in webcam for remote monitoring. On such printers, you can easily change the "manufactured" models. Today it can be simple plugs made of PLA plastic, and tomorrow it will be complex models made of carbon fiber or nylon gears. The disadvantages include only the high cost of equipment and the remaining need to shoot finished models manually.

For example, a farm built on the basis of Raise3D Pro2 3D printers. Each such printer is equipped with two extruders, a closed camera and a built-in webcam for remote monitoring. On such printers, you can easily change the "manufactured" models. Today it can be simple plugs made of PLA plastic, and tomorrow it will be complex models made of carbon fiber or nylon gears. The disadvantages include only the high cost of equipment and the remaining need to shoot finished models manually.

Pictured is a 3D printing farm at 2050.AT

Another option for such a solution is a farm based on printers with two independent IDEX type extruders. In the photo below you can see a similar farm based on Raise3D E2 printers. The solution has the added benefit of increasing productivity: each printer can print two identical models at the same time instead of one. The disadvantages remain the same: the need to shoot models manually and the rather high cost of the printers themselves. The benefits are the same plus increased performance.

The benefits are the same plus increased performance.

Pictured is a 3D printing farm at 3D.RU

If for the previous solutions small-scale production is one of the possible applications, then the printer, which will be discussed further, is created specifically for this task. The TierTime X5 is a mini conveyor with 12 interchangeable pads for long, uninterrupted printing. After the printing of the model or models is completed, the platform moves off the platform, and a new one takes its place, after which printing can continue. In this case, both the same and different models can be printed. The printer also maintains a print queue, different employees can send jobs to it, and they will be executed as they arrive. Models from the sites will still have to be removed manually, so it’s too early to talk about full automation. Of the minuses, it is worth noting the high cost of equipment and its low productivity. For comparable money, you can buy up to 10 printers of the same level, but their performance will be 10 times greater. True, they will take up much more space, and it is much more difficult to monitor 10 printers than one. But at the same time, one must take into account that if one of the 10 printers breaks down, you still have 9 more. If the only printer breaks, you are left without your equipment for an indefinite period of time, depending on the timing of the repair.

True, they will take up much more space, and it is much more difficult to monitor 10 printers than one. But at the same time, one must take into account that if one of the 10 printers breaks down, you still have 9 more. If the only printer breaks, you are left without your equipment for an indefinite period of time, depending on the timing of the repair.

Another printer option designed specifically for low volume production is the Creality3D CR-30 PrintMill ribbon type model. This printer is created on the principle of a conveyor belt, models can be printed endlessly and fall into the box themselves, you just have to remember to change the plastic. Human participation is minimal, but due to the complex design, where printing is carried out at an angle of 45 ° C, there are many restrictions on the geometry of models, the location of supports and other nuances. But on the other hand, this is the most automated process of all possible today, especially given the modest budget for the purchase.

In an effort to fully automate small-scale production, manufacturers and builders of 3D printing factories or small-scale production add various equipment. In particular, to automate the removal of models, cobots (collaborative robots) are used, which are programmed to remove the platform along with the printed model and install a new printing platform, after which printing resumes. This is an insanely expensive solution that doesn't really improve productivity, and can only be justified in countries with incredibly high wages.

Pictured is a VooDoo Manufacturing 3D printing truss

Another possible solution for the complete automation of the small-scale production process using 3D printing was presented by the Latvian company Mass Portal. She created a portal system for this task. The printers are installed in a rack, where the manipulator arm removes the platforms with finished models and transfers them to a special storage rack. Such a solution almost completely automates the entire process, but its cost is so high, and the system itself is so cumbersome that it is not worth talking about its effectiveness for a wide range of tasks.

Such a solution almost completely automates the entire process, but its cost is so high, and the system itself is so cumbersome that it is not worth talking about its effectiveness for a wide range of tasks.

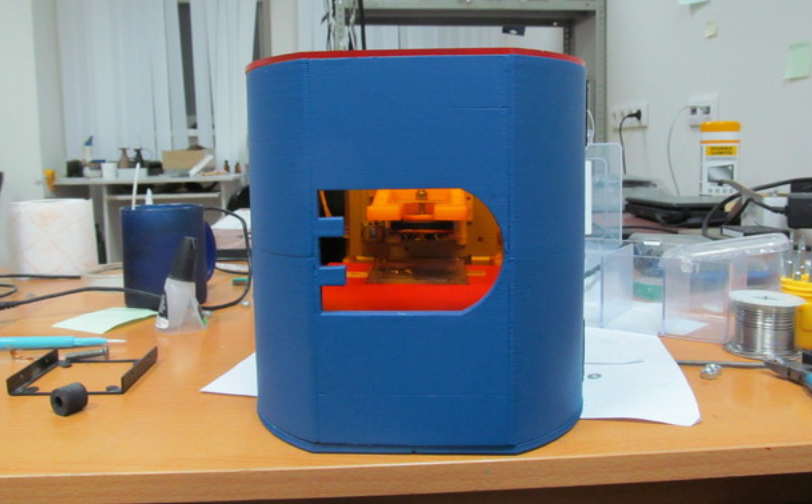

Photopolymer Solutions

All solutions discussed earlier in this article were created on the basis of FDM / FFF technology, which involves printing using molten plastic filament. But recently, photopolymer 3D printers are gaining more popularity, which print on the principle of forming a model from a liquid photopolymer. From the point of view of small-scale production, this technology has a number of advantages. First of all, performance. The technology allows you to illuminate the entire layer at once - in this way the printer spends the same time printing one or any other number of models that fit into the construction area. If earlier desktop photopolymer printers had modest pad sizes and, accordingly, their production potential was not very high, then this year a number of models with a large print area and high detail were introduced, for example, the Phrozen Sonic Mega 8K printer model.

Printing models on the photo lasted 3.5 hours. It is not difficult to calculate the performance of a printer. In this case, even one printer is a mini-factory and is capable of solving serious production problems. It is also important to note that unlike FDM/FFF printers, all photoresin 3D printers are inherently universal - you can print on them with any resins available on the market or even those that will appear in the future.

Not surprisingly, the creators of 3D printing trusses were inspired by the huge opportunities that were opening up, and many small-scale productions were created based on such equipment. For example, the British company Photocentric has opened the largest such center in Europe based on its LC Magna model. It came in handy during the pandemic, when it was necessary to urgently establish the production of elements necessary for the treatment of patients, for example, replaceable valves for ventilators.

Unfortunately, it is also not complete without significant disadvantages, but let's talk about everything in order. First of all, this is the process of post-processing of printed models, which consists of washing the models in alcohol and subsequent illumination in a UV camera. Without these procedures, the model will not acquire the final quality. These processes cannot be automated, they require a lot of labor, and this must be taken into account when choosing equipment. In addition, it should be taken into account that the cost of photopolymer resin is on average 3 times more than plastic for 3D printing, and, accordingly, the cost of the resulting products will be higher. Another factor to consider is the need for special preparation of the installation site for printers, the availability of high-quality ventilation and the possibility of waste disposal.

First of all, this is the process of post-processing of printed models, which consists of washing the models in alcohol and subsequent illumination in a UV camera. Without these procedures, the model will not acquire the final quality. These processes cannot be automated, they require a lot of labor, and this must be taken into account when choosing equipment. In addition, it should be taken into account that the cost of photopolymer resin is on average 3 times more than plastic for 3D printing, and, accordingly, the cost of the resulting products will be higher. Another factor to consider is the need for special preparation of the installation site for printers, the availability of high-quality ventilation and the possibility of waste disposal.

Totals

In summary, even a single 3D printer is a suitable solution for small-scale production. 3D printing is ideal for small-scale production. The main thing is to choose the right equipment, calculate its payback period and the cost of the final product.