3D printing jobs from home

3D Printing Jobs - Job Board

Looking for a job in the 3D printing industry? We’ve listed the latest engineering jobs on our job board.

All companiesCarbon3D systemsFilter by company

All countriesUnited StatesCanadaFilter by country

3D Systems

2 weeks ago

Print Process Engineer, Specialist

United States

Apply

3D Systems

3 weeks ago

Software Engineer

United States

Apply

3D Systems

1 month ago

Project Coordinator

United States

Apply

3D Systems

1 month ago

Engineering Technician - Austin, TX

United States

Apply

Carbon

1 month ago

Infrastructure Security Engineer

United States

Apply

3D Systems

1 month ago

Intermediate Biomedical Application Development Engineer

United States

Apply

3D Systems

1 month ago

Advanced Applications Engineer

United States

Apply

3D Systems

1 month ago

Materials Engineer

United States

Apply

3D Systems

1 month ago

3D Data Import Technician

United States

Apply

3D Systems

1 month ago

Senior Engineering Technician

United States

Apply

3D Systems

1 month ago

Entry Biomedical Engineer

United States

Apply

3D Systems

1 month ago

Vice President of Strategic Research

United States

Apply

3D Systems

1 month ago

Entry Biomedical Designer

United States

Apply

3D Systems

1 month ago

Principal Mechanical Engineer

United States

Apply

3D Systems

1 month ago

Computer System Validation (CSV) Quality Engineer

United States

Apply

3D Systems

2 months ago

Senior Software Quality Engineer

United States

Apply

3D Systems

2 months ago

Senior, Product Engineer

United States

Apply

3D Systems

2 months ago

Advanced Applications Engineer

United States

Apply

3D Systems

2 months ago

Senior Mechanical Engineer

United States

Apply

3D Systems

2 months ago

Materials Testing Scientist

United States

Apply

3D Systems

3 months ago

Senior Jetting and Printhead Engineer

United States

Apply

3D Systems

3 months ago

Senior Jetting and Printhead Engineer

United States

Apply

Carbon

3 months ago

Senior Software Engineer - Applications Team

United States

Apply

3D Systems

3 months ago

Process Development Engineer II - Seattle

United States

Apply

3D Systems

3 months ago

Process Development Engineer II - Seattle

United States

Apply

3D Systems

3 months ago

Procurement Specialist - Austin, Texas

United States

Apply

3D Systems

3 months ago

Procurement Specialist - Austin, Texas

United States

Apply

3D Systems

3 months ago

Bioengineer

United States

Apply

3D Systems

3 months ago

Bioengineer

United States

Apply

3D Systems

3 months ago

LAB Hardware & Software Technician

United States

Apply

3D Systems

3 months ago

Technical Writer II

United States

Apply

3D Systems

3 months ago

LAB Hardware & Software Technician

United States

Apply

3D Systems

3 months ago

Technical Writer II

United States

Apply

3D Systems

4 months ago

Senior Biomaterials Scientist

United States

Apply

3D Systems

4 months ago

Senior, Document Control Coordinator

United States

Apply

3D Systems

4 months ago

Controls Software Engineer

United States

Apply

3D Systems

4 months ago

Senior Embedded Software Firmware Engineer - Manchester, NH

United States

Apply

3D Systems

4 months ago

Senior, Software Dev Engrg

United States

Apply

3D Systems

5 months ago

Principal Laser Control Scientist

United States

Apply

3D Systems

5 months ago

Product Manager - Allevi

United States

Apply

3D Systems

5 months ago

Applications Engineer

United States

Apply

3D Systems

5 months ago

Entry BioMedical Designer

United States

Apply

3D Systems

5 months ago

Senior, Software Dev Engrg

United States

Apply

3D Systems

5 months ago

Mechanical Engineer - Austin, TX

United States

Apply

3D Systems

5 months ago

Software Engineer, Application Development

United States

Apply

3D Systems

5 months ago

Senior, Software Engineer Geometric Algorithms - Cary, NC

United States

Apply

3D Systems

5 months ago

Senior, Mechanical Engineer

United States

Apply

3D Systems

6 months ago

UI/UX Designer

United States

Apply

3D Systems

6 months ago

Senior, Software Dev Engrg

United States

Apply

3D Systems

6 months ago

Senior, Software Dev Engrg

United States

Apply

3D Systems

6 months ago

Engineer, CMF Medical Imaging

United States

Apply

3D Systems

6 months ago

Technician, CMF Medical Imaging

United States

Apply

3D Systems

6 months ago

Engineer, CMF Medical Imaging

United States

Apply

3D Systems

6 months ago

Technician, CMF Medical Imaging

United States

Apply

3D Systems

8 months ago

Biomaterials Scientist

United States

Apply

3D Systems

8 months ago

Supv BioCAD Engrg

United States

Apply

3D Systems

8 months ago

Document and Change Control Administrator

United States

Apply

3D Systems

8 months ago

Platform Manager - Jetting Technologies

United States

Apply

3D Systems

8 months ago

Entry BioCAD Tech

United States

Apply

3D Systems

8 months ago

Bioengineer

United States

Apply

3D Systems

8 months ago

Embedded Software Engineer

United States

Apply

3D Systems

8 months ago

Senior Engineering Technician

United States

Apply

3D Systems

8 months ago

Customer Project Engineer

United States

Apply

3D Systems

8 months ago

Mechanical Design Engineer

United States

Apply

3D Systems

9 months ago

Senior Quality Systems Specialist

United States

Apply

3D Systems

9 months ago

Senior, Electrical Engineering

United States

Apply

Carbon

9 months ago

Senior Technical Program Manager

Canada

Apply

Carbon

1 year ago

Firmware Engineer

Canada

Apply

Carbon

1 year ago

Staff Software Engineer - Applications Team

United States

Apply

3D Printing Jobs for October 2022

I want to Hire I want to Work

About 3D Printing3D printing is a process in which materials are successively joined and fused under computer control to form a 3D object. This is also called additive manufacturing is the act of making 3-D solid objects from a digital file. It is achieved using additive processes, which involves the laying down of successive layers of material until an object is created. Each layer can be seen as a thin slice horizontal cross-section of the final object.

With 3D printing, one can produce complex shapes using less materials than the traditional methods of manufacturing. 3D printing involves many different technologies, such as fused deposit modeling (FDM) or stereo-lithography (SLA).

From 45700 reviews, clients rate our 3D Printing Experts 4.9 out of 5 stars.

Learn more

Search Keyword

Where ?

My recent searches

Filter by:

Budget

Fixed Price Projects

Hourly Projects

Duration All DurationsLess than 1 week1 week to 4 weeks1 month to 3 months3 months to 6 monthsOver 6 months / OngoingUnspecified

Contests

Type

- Local Jobs

- Featured Jobs

- Recruiter Jobs

- Full Time Jobs

Skills

enter skills

Languages

enter languages

Add supports to 3D printer file for resin printing 6 days left

I am looking for someone to help me add supports to my files to ensure flawless prints with the photon mono printer.

3D Printing Rapid Prototyping

$8 / hr (Avg Bid)

$8 / hr Avg Bid

8 bids

Bid now

3d jewelry designer and 3d printing master 6 days left

3d jewelry designer and 3d printing master

3D Modelling 3D Printing 3D Rendering Graphic Design Product Design

$34 (Avg Bid)

$34 Avg Bid

14 bids

Bid now

Template job (for invite only) 5 days left

Template job so I can discuss with freelancers I invite.

3D CAD 3D Modelling 3D Printing

$827 (Avg Bid)

$827 Avg Bid

17 bids

Bid now

CAD Designer required for Lighting Product 2 days left

Looking for a designer who has: - Product design experience - Technical capabilities (CAD/Solidworks & 3D printing experience a must) - Artistic flare - A keen sense of style - Lighting experience is a huge plus - Electronics experience is a huge plus Being able to bring fresh ideas to the table is a crucial element to this job. Ability to translate concepts and design into a functional prototype. Position on a remote team available for the right person.

Ability to translate concepts and design into a functional prototype. Position on a remote team available for the right person.

3D Printing AutoCAD Manufacturing Design Product Design Solidworks

$32 / hr (Avg Bid)

NDA

$32 / hr Avg Bid

53 bids

Bid now

Correct surfaces in 3d files 1 day left

Hi! I have 3 drawings that were created in the past and that contain several surface issues. Due to that, I can't 3d print them. Check files Error1,2,3. I need a designer to correct these flaws and make them 3d-printable by my supplier. Here are pre-requisites: 1. All 3 drawings are attached. Have a look so you can be confident you can do it and so you can price accordengly. 2. I have OBJ and STL files only. I can't generate new files. 3. I want the final files to be OBJ, STL, and STEP extensions. 4. I'll release the milestone once I can 3d-print them PLEASE, only bid if you can do this kind of work. You've got to know basics of 3d-printing in order to be able to correct the files.

Due to that, I can't 3d print them. Check files Error1,2,3. I need a designer to correct these flaws and make them 3d-printable by my supplier. Here are pre-requisites: 1. All 3 drawings are attached. Have a look so you can be confident you can do it and so you can price accordengly. 2. I have OBJ and STL files only. I can't generate new files. 3. I want the final files to be OBJ, STL, and STEP extensions. 4. I'll release the milestone once I can 3d-print them PLEASE, only bid if you can do this kind of work. You've got to know basics of 3d-printing in order to be able to correct the files.

3D Modelling 3D Printing 3ds Max CAD/CAM

$32 (Avg Bid)

$32 Avg Bid

34 bids

Bid now

3D modelling of bottles & Packaging 1 day left

We want to get 3D model of some bottles & Packaging for ecommerce website

3D Animation 3D Modelling 3D Printing 3D Rendering Solidworks

$87 (Avg Bid)

$87 Avg Bid

51 bids

Bid now

Bulk Ornaments 1 hour left

I have the STL files and specs, I just need more printing capacity than I currently have. Each ornament is about 3 inches around, 3.5mm thick, and uses 5 grams of filament with .16mm layer lines and 80% infill. Looking for a cost per unit or bulk price for 100.

Each ornament is about 3 inches around, 3.5mm thick, and uses 5 grams of filament with .16mm layer lines and 80% infill. Looking for a cost per unit or bulk price for 100.

3D Printing 3D Rendering

$101 (Avg Bid)

$101 Avg Bid

15 bids

Bid now

Top 3D Printing Community Articles

- Entrepreneurship

Q Fortune hired a 3D Artist to render an animal helmet and camera rig

- Entrepreneurship

Kate collaborated with a 3D artist on Freelancer to create her invention.

- Design

A breakdown of the mechanical properties that define common engineering materials such as steel, carbon fiber, polycarbonate, copper and more.

Advantages and disadvantages. How 3D printing affects business and our lives - Trade on vc.ru

What is 3D printing?

745 views

3D printing is a process in which a digital model is turned into a tangible, solid three-dimensional object, usually by applying many successive thin layers of material. 3D printing has become popular so quickly because it makes manufacturing accessible to more people than ever before. This is partly due to the price (the starting price for a basic 3D printer is around $300) and the small size of the printers compared to traditional manufacturing.

How does it work?

First, the virtual design of the object is done. This design will work like a blueprint for a 3D printer. Virtual design is done using computer-aided design (CAD) software, a type of software that can produce accurate drawings and technical illustrations. A virtual design can also be created using a 3D scanner, which creates a copy of an existing object by photographing it from different angles.

Virtual design is done using computer-aided design (CAD) software, a type of software that can produce accurate drawings and technical illustrations. A virtual design can also be created using a 3D scanner, which creates a copy of an existing object by photographing it from different angles.

CAD software for creating a 3D model

Once the virtual model has been created, it must be prepared for printing. This is done by splitting the model into many layers using a process called slicing. When slicing, the model is cut into hundreds or even thousands of thin horizontal layers using special software.

Slicing the 3D model

After the model has been cut, the slices are ready to be loaded onto the 3D printer. This is done using a USB cable or Wi-Fi connection to move the sliced model from the computer to the 3D printer. When the file is loaded onto the 3D printer, it reads each piece of the model and prints it layer by layer.

How are things printed?

The 3D printer will begin printing layers of material in a process known as material extrusion. Depending on the type of 3D printer and the material used, there are several methods for material extrusion.

Depending on the type of 3D printer and the material used, there are several methods for material extrusion.

3D printer nozzle.

Most commonly, a 3D printer has a nozzle that ejects a semi-liquid material such as molten plastic, metal, or cement. The extrusion nozzle can move both horizontally and vertically as it precisely places the material following the pattern of the digital model layer by layer.

This process is repeated until the 3D printer has reproduced each layer of the extruded digital model.

What kind of things can be done with 3D printers?

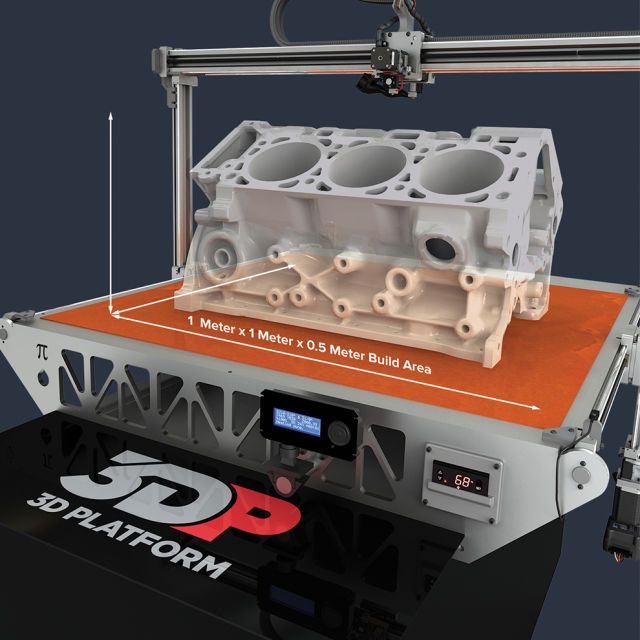

Almost anything you can imagine can be turned into a 3D printed design. 3D printers are helping designers, engineers, and even ordinary people create complex objects in ways that previous manufacturing methods were not capable of.

3D printers are being used to create toys, phone cases, tools, clothes, tables, lamps, pottery, art, and even cars.

Medicine is also finding new ways to use 3D printing to help patients. Physicians can now print 3D medical models that are so accurate that surgeons can essentially test-run a patient's 3D model before actually operating on that patient. 3D printed models are also being used to create less expensive, stronger and more suitable prostheses for people who have lost limbs.

Physicians can now print 3D medical models that are so accurate that surgeons can essentially test-run a patient's 3D model before actually operating on that patient. 3D printed models are also being used to create less expensive, stronger and more suitable prostheses for people who have lost limbs.

7 benefits of 3D printing:

1. Cost optimization

Less equipment, material and labor costs.

Cost optimization is important for every business. One of the benefits is that when using 3D printing, operating costs, labor costs and material costs combined are lower than large-scale production.

Cost of the machine

The cost of operating the machine plays a very small role in the total cost of the production process. The energy required to create parts in an industrial environment can be expensive, but the ability to design and build complex parts and products in one step provides an increased level of efficiency and saves time. Thus, the cost of operating the machines is offset by the savings gained from speed.

Labor costs

The good thing about 3D printing is that labor costs are low. Compared to traditional manufacturing, where different people may be required to work on several different machines, or a production line is required to fully assemble a product. The printer will require an operator to start the mechanism and start the automated process of creating the loaded design. Consequently, labor costs are significantly lower than in traditional production.

Material costs

The range of materials for 3D printers used for 3D printing is growing every day, and in recent years this has made it possible to optimize the final cost of the product even better.

Less transport costs

One of the biggest benefits of 3D printing is that it reduces the distance the product will have to travel. Because 3D printers can create a product from start to finish, this allows designers to design a product in one country and email it to another country to prepare for production. There is no need for prototypes to be moved from factory to factory to complete the process. This makes 3D printing an industry that can be created around the world without leaving a trace. Thus, there is a reduction in sea, air and road transport.

There is no need for prototypes to be moved from factory to factory to complete the process. This makes 3D printing an industry that can be created around the world without leaving a trace. Thus, there is a reduction in sea, air and road transport.

2. Less waste.

The traditional manufacturing process is basically a subtractive process in which raw materials are lost and reused over and over again, resulting in high costs and waste. The advantage of 3D printing is a unique way of creating a product with minimal waste, the so-called additive manufacturing. While more traditional methods involve waste that can be reused or recycled, it still takes time and effort to determine how and when this waste will be used. High volume 3D printers do it themselves.

Thermoplastic materials, for example, can be melted, solidified (cooled to become solid), melted again, solidified again, and so on. Thus, production "waste" can be reused.

3. Time Reduction

We live in a rapidly changing world where everything is for yesterday and this is where 3D printing can really make a difference. One of the big advantages is that parts and products can be produced much faster than using traditional methods. Complex designs can be created as a CAD model and then turned into reality in just a few hours. This embodies design ideas in a way that can be quickly tested and developed in a short amount of time. Whereas traditional methods can take weeks or months to get from design to prototype to production.

One of the big advantages is that parts and products can be produced much faster than using traditional methods. Complex designs can be created as a CAD model and then turned into reality in just a few hours. This embodies design ideas in a way that can be quickly tested and developed in a short amount of time. Whereas traditional methods can take weeks or months to get from design to prototype to production.

4. Competitive advantage

Businesses can create better, better, and more advanced products in a shorter amount of time, which provides a competitive advantage. It also allows you to develop products at an early stage, prototyping faster, which means the product will be invented, ready for production and market sooner. The ability to create a life-size prototype allows designers to think differently about the products they are developing.

The product is often left to the imagination. This increases the risk of losing information somewhere during the connection, which at some point can lead to serious problems. It is this natural value that will make it possible to speak with your partners, investors and clients in the same language. After all, you can not only talk about a product that will be produced in some time on the other side of the world, but also touch it. The probability that the produced product will not be able to satisfy the needs and agreements, will be expensive is quite high, which means it should be described as best as possible from the very beginning. One of the benefits of 3D printing is that it allows you to quickly create a concept that people can physically hold in their hands, eliminating any fear or misunderstanding. While this may only be a prototype and still open to change, it does at least give an idea of what the end result will look like, offering a more accurate representation than a description.

It is this natural value that will make it possible to speak with your partners, investors and clients in the same language. After all, you can not only talk about a product that will be produced in some time on the other side of the world, but also touch it. The probability that the produced product will not be able to satisfy the needs and agreements, will be expensive is quite high, which means it should be described as best as possible from the very beginning. One of the benefits of 3D printing is that it allows you to quickly create a concept that people can physically hold in their hands, eliminating any fear or misunderstanding. While this may only be a prototype and still open to change, it does at least give an idea of what the end result will look like, offering a more accurate representation than a description.

Test the market

Understanding whether a model will succeed requires a lot of research, especially when it comes to traditional production methods. However, prototyping with 3D printing will allow businesses to get feedback from potential buyers and investors like never before. The product can be customized and changed right up to the very last minute, which traditional production methods do not offer. This means that 3D printing offers a unique and valuable way to determine if a product has the potential to go to market and be successful at the same time.

However, prototyping with 3D printing will allow businesses to get feedback from potential buyers and investors like never before. The product can be customized and changed right up to the very last minute, which traditional production methods do not offer. This means that 3D printing offers a unique and valuable way to determine if a product has the potential to go to market and be successful at the same time.

5. Error reduction

When it comes to designing parts and products, designers must consider efficiency. The production of many parts and products requires a large number of steps using traditional production methods. Therefore, each step can lead to an error with the risk of restart, which will lead to problems with the overall production process. A one-step manufacturing process is more advantageous.

There are many industries that have a long and drawn out production process. Where some of the steps are to create a CAD model and then develop a prototype which may require adjustments before it is finally sent to final production. This is a process that takes a lot of time, and none of the steps can be skipped, since they all play a role in the production process. However, one of the advantages of 3D printing is that it creates a product in one step, without interaction with operators during this process. You just need to finalize the design and upload it to the printer. This eliminates dependency on a range of manufacturing processes and enhances control over the final product.

This is a process that takes a lot of time, and none of the steps can be skipped, since they all play a role in the production process. However, one of the advantages of 3D printing is that it creates a product in one step, without interaction with operators during this process. You just need to finalize the design and upload it to the printer. This eliminates dependency on a range of manufacturing processes and enhances control over the final product.

In the traditional manufacturing process, failed prototypes cost time and money. With every wrong prototype you have to go back to the drawing board and there is no guarantee that it will be right the second time around. Even small adjustments have a significant financial and time impact on the entire process. This is where 3D printing can eliminate risk, as designs can be tested by creating a production-ready prototype before proceeding to final creation. This helps build confidence in the design before investment is made and extra money is paid out to take it to the next level of mass market production.

6. Privacy

Continuous prototyping and production on our own 3D printer ensures that designs never leave the company's premises, protecting your intellectual property. No third parties can ever claim your innovations. Every innovative design is kept in-house, so you don't have to worry about privacy anymore.

7. Custom Made

The freedom to design is one of the great benefits of 3D printing. Because 3D printing is ideal for one-off production and the creation of individual parts in a single process, this means you can take advantage of the opportunity for customization. Therefore, many industries such as medicine and dentistry are using 3D printing and design because of the ability to create customized implants and aids. In fact, sports equipment can be created specifically for athletes, and thus individual details can be created in a way that has never been done before.

Traditional methods relied on shapes and cutting, making the tuning process very labor intensive. In contrast, customizing 3D printed products can have improved structural integrity, make complex changes, and change parts to meet specific requirements. This setup gives 3D printing endless possibilities.

In contrast, customizing 3D printed products can have improved structural integrity, make complex changes, and change parts to meet specific requirements. This setup gives 3D printing endless possibilities.

Disadvantages of 3D printing:

1. Initial cost of the printer

You need to buy a 3D printer, and even though the return on investment will be fast and high, the initial investment must be made.

2. Post-processing

A 3D printed object in most cases requires some post-processing.

3. Print time

When it comes to producing many objects, 3D printers are slow compared to other manufacturing technologies. Aside from mass production, another disadvantage is the long print times for single prints. Depending on the size and quality of the printer, printing can take anywhere from a few hours to a few days, but if the printer fails when it's almost finished printing, you'll have to start over. However, by making sure the 3D model and print file are well designed and cut, and the printer is set up correctly, you can almost guarantee that the print will be perfect.

4. Special skills are required to work with 3D models.

Once you have purchased a printer, you must learn how to create and modify 3D models. 3D modeling is a skill that takes a lot of time and effort to fully master, a process of trial and error. But once you learn how to use the program, you can print whatever comes to your mind.

5. Job Loss in Manufacturing

As we mentioned in the Benefits of 3D Printing, this technology allows you to create product designs and prototypes in a matter of hours because it only takes one step. This eliminates many steps that are used in traditional manufacturing. Due to this, no large labor costs are required. Thus, the introduction of 3D printing can lead to a reduction in manufacturing jobs. For countries that rely on large numbers of low-skill jobs, job cuts in manufacturing can have a big impact on the economy. However, it is likely that robotics will have a much greater impact here.

Conclusion

For any business, their customers are the key to success, so customer satisfaction becomes an important part of their strategy. By staying ahead of the competition and giving customers what they want, industrial 3D printers have changed the way businesses deliver exactly what they need. Customer expectations have changed because they want to receive goods quickly and efficiently.

By staying ahead of the competition and giving customers what they want, industrial 3D printers have changed the way businesses deliver exactly what they need. Customer expectations have changed because they want to receive goods quickly and efficiently.

The benefits of 3D printing are wide and varied. Many industries are starting to incorporate 3D printing into their processes in an attempt to capitalize on the technology in a variety of ways. This is a technology that has grown significantly in recent years and will continue to grow as it continues to improve on what it has to offer. When you consider all the advantages of 3D printing, it becomes obvious that it will soon become a technology that will overtake traditional methods. It's just a matter of time.

It is the ability to print complex shapes and interlocking parts without the need for any assembly that makes 3D printing so unique. It is possible to create small complex shapes at very low cost and in a short amount of time. The ability to design and manufacture objects of various shapes without the need for special tools provides businesses with a higher level of flexibility when it comes to manufacturing and helps reduce costs. The strength of 3D printing is that it promotes innovation and is ideal for on-demand customization. This gives businesses the ability to design and build products like never before. A process that allows the imagination to be free because there are almost no boundaries. It can bring old designs back to life for a number of industries where parts are obsolete.

The ability to design and manufacture objects of various shapes without the need for special tools provides businesses with a higher level of flexibility when it comes to manufacturing and helps reduce costs. The strength of 3D printing is that it promotes innovation and is ideal for on-demand customization. This gives businesses the ability to design and build products like never before. A process that allows the imagination to be free because there are almost no boundaries. It can bring old designs back to life for a number of industries where parts are obsolete.

3D printing is a rapidly growing industry with great potential for the future. We have just begun to understand how 3D printed objects can make our lives easier, more convenient, safer and healthier. And because 3D printing is advancing as fast as people can come up with new designs to print, it may not be long before we live in a world where you can 3D print your lunch, a tailored shirt, or repair parts. everyday items. all without leaving your own home.

all without leaving your own home.

The Fialan team will help you realize your wildest projects and ideas.

Regardless of the scale and specification - the savings in purchasing in China not only a 3D printer, but also equipment for such niches as medicine, CNC, cafes and bars, warehouse equipment and many others will cost you up to 30% cheaper compared to the domestic market.

You can learn more about profitability and get professional advice at the link: equipment for business.

Also, please call +38 (044) 290‑76‑11

home use, examples of printing and work, opportunities in everyday life, education and commercial purposes

3D printer is a device that processes a three-dimensional computer model and on the basis of the received data builds a three-dimensional object. Most often, objects are created by layer-by-layer fusing of plastic or solidification of a special resin.

Regardless of the technology used, the printer is excellent for making solid products with complex shapes. Thanks to this, three-dimensional modeling is used in a variety of areas: from the production of souvenirs to the construction of buildings.

Thanks to this, three-dimensional modeling is used in a variety of areas: from the production of souvenirs to the construction of buildings.

Anyone who is interested in 3D printers should familiarize themselves with the real situations of its use. Ordinary users will expand their horizons, and potential entrepreneurs will see interesting opportunities for creating a business.

Where the 3D printer is used

As already noted, 3D printers produce three-dimensional products using special computer models as a basis. This method of production has the following advantages:

- creation of objects of any shape and complexity;

- high speed;

- small amount of scrap;

- a wide range of materials, from metallized plastics to foodstuffs.

Important! 3D printing reduces production costs and significantly speeds up the workflow.

Home and household use

Initially, printers were rather complex and expensive technical devices used only by scientists and specialists. Nowadays, anyone can purchase a printer, as there are many manufacturers (both domestic and foreign) on the market.

Nowadays, anyone can purchase a printer, as there are many manufacturers (both domestic and foreign) on the market.

Thanks to the availability of 3D modeling, the production of various items directly at home is actively developing. The most common products are:

- toys;

- souvenirs and gifts;

- small parts for automobiles, electronics and household appliances;

- furniture fittings;

- cases for smartphones;

- kitchen utensils;

- all kinds of decorations and crafts.

Attention! If desired, the owner of a 3D printer can start a business without leaving home. The production of the aforementioned unique souvenirs or cases is a very profitable business.

In the aerospace industry

It turns out that 3D printers can print more than just toys and small parts. The aerospace and aircraft industries are already taking advantage of 3D printing. Thus, the world-famous Boeing company and the American corporation Lockheed Martin have already begun to create engine parts and load-bearing structural elements. Items are made from all-metal materials using laser sintering technology.

Thus, the world-famous Boeing company and the American corporation Lockheed Martin have already begun to create engine parts and load-bearing structural elements. Items are made from all-metal materials using laser sintering technology.

In and for space

3D modeling could become a very important technology in the space industry. For example, SpaceX presented the Dragon v2 spacecraft, which uses printed parts in its engine.

The use of 3D printing is not limited to the ground industry: in 2016, NASA sent a special 3D printer to the ISS that can work in zero gravity. With its help, various tests can be carried out, but more importantly, astronauts can independently create the items they need without waiting for the ship to arrive from Earth.

In architecture

Creating three-dimensional objects is an ideal technology for architecture, because with the help of mock-ups, designers and engineers can see the embodiment of an invented object as accurately as possible. Of course, architectural models have been used before, but printing on a printer greatly simplifies and speeds up the process of developing buildings.

Of course, architectural models have been used before, but printing on a printer greatly simplifies and speeds up the process of developing buildings.

Pistol manufacturing and weapon printing examples

Like many technologies, 3D printing is used for more than just a good cause. Even the simplest printers make it possible to make a functional plastic gun - if it collapses from a single shot, it can still be extremely dangerous.

Some experts believe that people should be able to defend themselves. Thus, the organization Defense Distributed posted on the Internet three-dimensional models of a single-shot Liberator pistol. Subsequently, the company developed parts for the AR-15 rifle and the Kalashnikov assault rifle, which will allow people to assemble weapons from a minimum of parts and materials.

Attention! Many countries have banned the production and circulation of printed weapons, but it is extremely difficult to control this area.

Clothing

Fashion designers have also noticed the benefits of 3D modeling. Some materials (for example, nylon) are quite suitable for creating clothes, and the finished product will take on an unusual shape and at the same time be quite strong and elastic.

Continuum Fashion has already presented some of the pieces that have been a hit at fashion shows. Ready-made clothes can even be purchased online. Of course, now such things look too eccentric and are clearly not intended for everyday wear, but experts believe that in the near future people will print clothes right at home.

Examples of works in art

Many famous sculptures, bas-reliefs, architectural feats can only be seen in the largest museums in the world or directly in a particular city. If you wish, you can purchase a replica, but such figures are usually very expensive and are not sold everywhere.

A 3D printer will come to the aid of art connoisseurs: you just need to load a model into the device, which will be scanned by museum workers.

Help! This method is useful for the study or conservation of the object itself, since 3D scanning and modeling allows copies to be made with a high degree of accuracy.

3D printing in medicine

Three-dimensional modeling is one of the most promising new technologies that are used in medicine. In some areas (for example, in dentistry), 3D printing has already been put on stream, in other areas its development is a matter of the near future.

Surgical preparation

3D modeling allows you to carefully prepare for operations. 3D scanners provide the most accurate image of the required area of the body, after which a copy is printed from a computer model and it is calculated how to operate this place.

Prosthetics

Printed objects are in high demand in prosthetics, as 3D printing allows the production of prostheses of the most complex shape and takes into account all the individual features of the body.

The Swedish company Arcam produces a wide variety of prostheses, including all-metal objects, using printers. They are used both in more conventional limb prosthetics and for bone or joint replacement.

Dentistry

Dental prostheses, crowns, aligners (plastic braces) are exactly the items that a 3D printer for dentistry is best suited to create. Align Technology has developed a method in which the oral cavity is first scanned and then a custom prosthesis or brace is created. For production, liquid resin solidification technology is used, so the finished products have the highest degree of accuracy.

Products

Many people have heard of 3D food printers that can produce food in the most bizarre shapes. Indeed, 3D printers can easily print with hot chocolate, dough, sugar syrup and other semi-liquid products (even minced meat!).

One of these devices was developed by Foodini - the printer uses any paste-like product. Unlike conventional printers, food models do not cope well with the heat treatment of food, but this problem will most likely be eliminated soon.

Unlike conventional printers, food models do not cope well with the heat treatment of food, but this problem will most likely be eliminated soon.

Characters

Making and collecting figurines of famous people, movie, game and comic book characters is an important hobby for many people. Three-dimensional modeling makes it easy to print the most accurate copy even on a simple home printer, so that anyone can collect an extensive collection of characters.

Home Robots

Arduino electronic components have allowed many craftsmen to equip a smart home system or greatly facilitate the process of many household chores. The problem is that not all people are well versed in programming, electronics and soldering.

Scientists in Massachusetts are working on a printer that will create simple household robots. The user will need to set the desired functions and select a design, after which the system will print all the necessary details. A ready-made robot, for example, will be able to dust cabinets or monitor the stove in the kitchen.

A ready-made robot, for example, will be able to dust cabinets or monitor the stove in the kitchen.

Musical instruments

Another promising branch of 3D modeling. Professional musicians will tell you that really valuable instruments take years to develop and last for decades, so a hastily printed part cannot replace them.

In fact, some parts can be printed on a printer: the neck or body is made of wood plastic, so they are in no way inferior to the originals. In terms of decoration, plastic definitely surpasses familiar materials: the shape and design of musical instruments can be the most unexpected.

Shoes

Shoes, like clothes, can be easily 3D printed. An important advantage of such products is full compliance with the anatomical features of the owner (size and shape of the foot).

The printer prints both women's and men's shoes. So far, fashionable shoes flaunt only on the catwalks, but in the future they may well go into mass production.

Preparations

Another important area related to medicine. In the production of medicines, it is necessary to observe a strict dosage of the components and mix them in the correct proportions.

Organovo uses a special gel material that allows for very precise joining of preparations. This technology is not very suitable for mass production, however, it will find its application in the creation of products intended for a particular person.

In mechanical engineering

Many car parts can be easily printed on a printer: for example, Formula 1 already uses printed components in its cars. The American company Local Motors has released a car at all, the body of which is completely made of printed parts.

In fact, the mass production of auto parts is still too expensive. 3D printing is more effective for creating machine parts that have long been discontinued.

Help! Before the manufacture of many machines and mechanisms, specialists manually create prototypes of these products.

Printing prototypes on a printer is much more convenient and faster.

Customization

With the help of a 3D printer, you can transform the look of ordinary things beyond recognition. Wicker lampshades for lamps, a futuristic bicycle frame - all this is guaranteed to attract attention, since there are simply no analogues of our own production.

If you use different decor (paints, varnish), then the thing can look like a fantastic concept from the future, or like an old fancy product - it's up to you.

Furniture

3D printers make it possible to produce furniture that is almost indistinguishable from the real thing. The fact is that a special plastic is used for printing, which includes micro-sawdust. So, the material Laywoo-D3 even has the smell of wood, and the printed product is easily processed, painted and varnished.

Designer Joris Laarman has made some improvements to the design of the printers so that his design can easily print metal and create all sorts of openwork pieces for furniture.

Jewelery

3D modeling is actively used to create jewelry pieces with particularly complex shapes. Some devices can immediately print precious metals, while other printers make a copy of the jewelry.

The fact is that before the production of a ring, brooch or necklace, jewelers first manually create a wax model and only then cast the product on it. Jewelry 3D printers have made it possible to significantly speed up and reduce the cost of this process. To create models, a special material is used, similar to jewelry wax, and among the devices, masters usually choose Soldscape T76, Objet260 Connex, etc. With the help of 3D construction printers, you can simplify the process of building buildings, reduce waste and reduce labor costs.

Experts have not yet created an ideal device for 3D printing of buildings and structures, but work on it is being carried out in two directions at once. So, the Chinese company Winsun has released a huge printer (6 x 10 x 40 m), which applies a special solution in layers and creates a floor, walls with all the holes and niches for communications. The main disadvantage of this device is its immobility (the finished building must be transported to another place).

The main disadvantage of this device is its immobility (the finished building must be transported to another place).

In contrast, Spanish scientists are working on small robotic printers that attach to prefabricated building elements and create new parts of the structure. Which of these technologies will be more effective and expedient, time will tell.

In school education

3D modeling technologies provide a unique opportunity to study a wide variety of fields of knowledge and school subjects. Simple 3D printers for schools can be used to equip any educational institution (both older groups of kindergartens and university departments).

Help! Modern devices are very efficient, do not emit harmful substances, are relatively easy to set up and have a low cost.

The use of 3D printing will increase students' interest in the subject, develop their design and design skills, visually show the course of certain processes (Imagine that a section of an internal combustion engine, a femur or a three-dimensional model of a sulfuric acid molecule is printed in a lesson) .

3D printers are some of the most innovative and amazing devices created in recent years. More recently, they were available only to scientists, and now anyone can purchase a budget machine. With a minimum investment, users can create a variety of products and objects, design new objects, come up with a unique design for familiar things.

In industry, the scope of 3D printers is even more amazing: it seems that they can make everything from food and clothes to cars and buildings. It seems that in the near future the printer will become a common device that is in every home (like a TV or a refrigerator), and most industrial products will be printed. In the end, the printer can even print another one of the same printer, and then the circle of production will be closed.

In fact, such scenarios are best reserved for science fiction films. Three-dimensional modeling has a number of serious drawbacks, due to which mass printing production becomes completely unprofitable. Not all printers can connect various plastics, work with different colors and temperatures. When using expensive machines, the cost of a printed product will be tens and hundreds of times higher than the cost of an item made in a conventional factory. It is more expedient to use 3D printing for the production of unique things or products where high form accuracy is important (for example, in prosthetics).

Not all printers can connect various plastics, work with different colors and temperatures. When using expensive machines, the cost of a printed product will be tens and hundreds of times higher than the cost of an item made in a conventional factory. It is more expedient to use 3D printing for the production of unique things or products where high form accuracy is important (for example, in prosthetics).

Even if the technical and economic shortcomings of modern printers are corrected over time, mass printing of things still does not bode well. Demand for manufactured goods will plummet and the entire world economy will collapse. In addition, it is not clear how to resolve the issue of copying unique products (in the current realities, the owner or copyright holder receives funds for the use of copyright or patent).

Finally, 3D modeling can be used for undesirable purposes (for example, for the production of weapons). If every person at home has a machine on which to print a gun, this is unlikely to lead to something good.