3D printer 10000

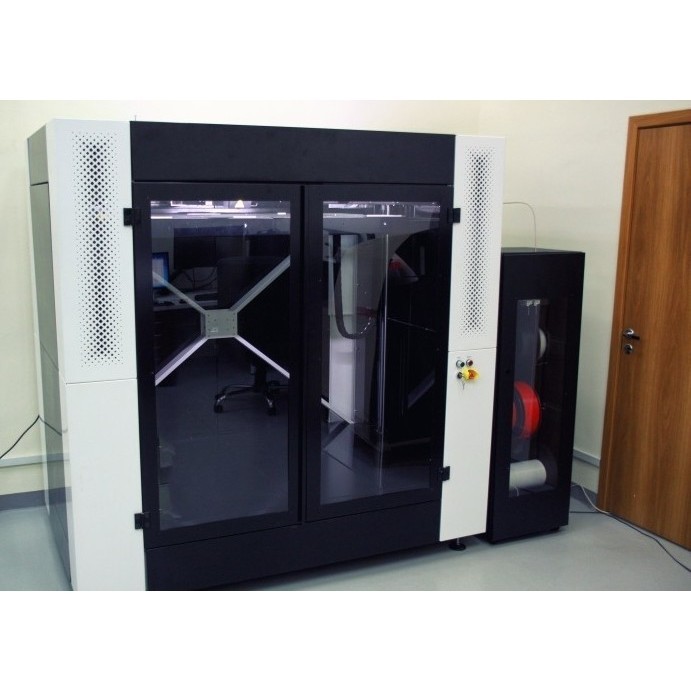

Commercial & Professional 3D Printer Buyer's Guide 2022 (Under $10,000)

Commercial 3D printers are changing how small businesses manufacture, how designers create and iterate, and how schools, healthcare professionals and engineers work.

These professional 3D printers, more expensive than standard desktop 3D printers but less than $10,000+ industrial 3D printers, allow small businesses to be more effective than ever in prototyping and improving their products.

This article focuses on highlighting the best commercial 3D printers, also known as prosumer 3D printers, production 3D printers, commercial grade 3D printers, or high end 3D printers, that are capable of producing professional-grade parts at decent scale, but cost less than $10,000. We therefore categorize commercial 3D printer price as up to $10,000, with no low end price provided it meets professional and small business 3D printer requirements.

What to expect in a commercial 3D printer?

Commercial grade 3D printers can take many forms: some need an FDM 3D printer that can 3D print PEEK or Ultem filaments, create extremely precise prototypes, or create multi-colored architectural models.

On the other hand, you may need a professional resin 3D printer to create ultra smooth resin prototypes for dental, aesthetic prototypes for items like sunglasses, and much more.

You may also be looking for a professional SLS 3D printer — though they often cost more than $10,000 — for high quality PA12 prototypes, functional parts, and various useful parts for engineers and designers.

Generally however, you should expect the following from a professional 3D printer:

- Commercial grade 3D printing performance: such as powerful heated chambers in FDM 3D printers for tougher material printing and systems for consistent and accurate printing.

- Wide material compatibility: with heated beds and extruders that can reach high temperatures for printing tougher filaments like Nylon, PC, PP, and perhaps even Ultem or PEEK.

- Fast printing and workflow: the best 3D printers for small businesses not only print quickly (at least twice the speed of desktop printers), but the entire workflow — from CAD software, to slicing, to printing, and then to iterating again — needs to be efficient for overall rapid prototyping.

- Very accurate: where resin 3D printers and SLS printers have advantages are in accuracy and surface finish. Resin printers can reach precisions that FDM printers cannot, so for precise and intricate models, such as characters for films or games, or wax molds for casting into precious metal jewelry, they’re ideal commercial 3D printers. SLS 3D printers require less post processing as they do not print with supports, making them ideal production 3D printers for ready-to-go prototypes made from Nylon.

- Large printing area: commercial 3D printers should have large enough build areas to support either large prototypes, or the printing of multiple small parts simultaneously, as a scalable production 3D printing system. 3D printers for commercial uses we recommend are typically larger for effective batch production 3D printing.

Our commercial 3D printer comparison sorts low to high price, making recommendations on the best 3D printer for business, for production, and many other 3D printers for different commercial uses.

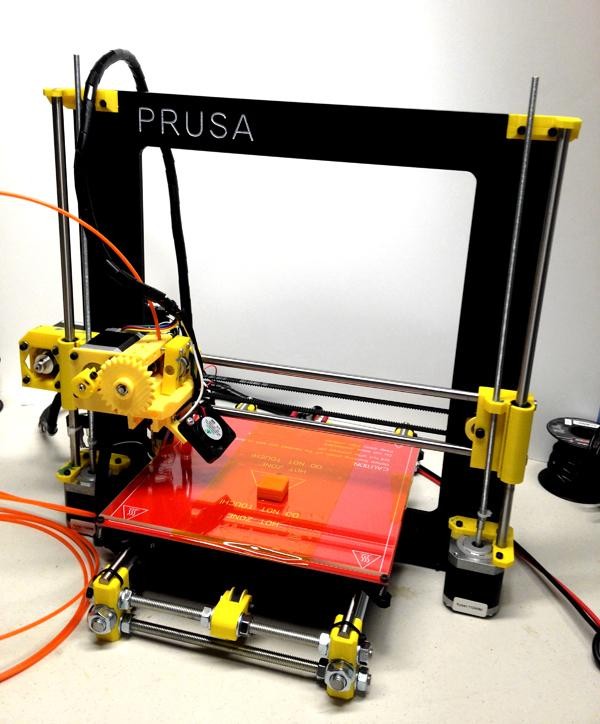

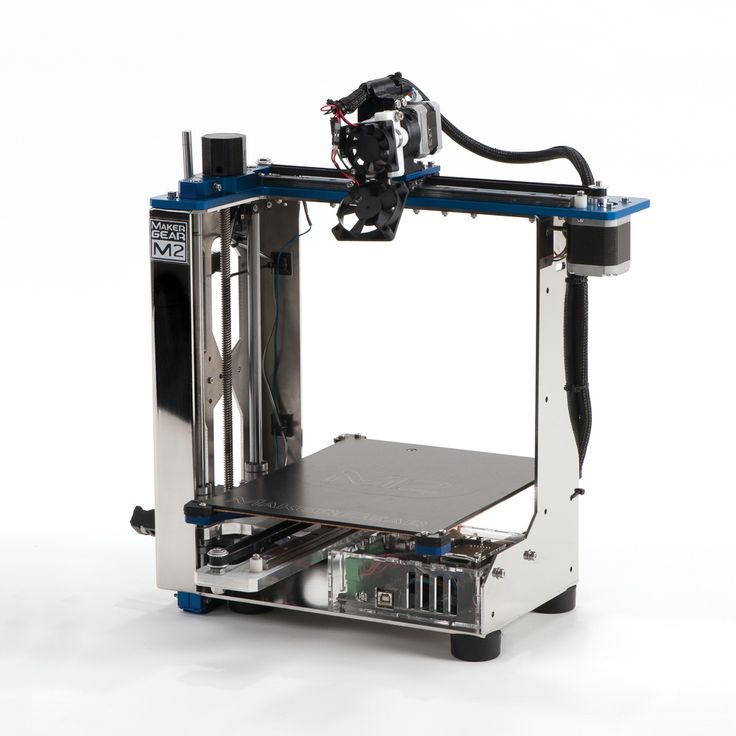

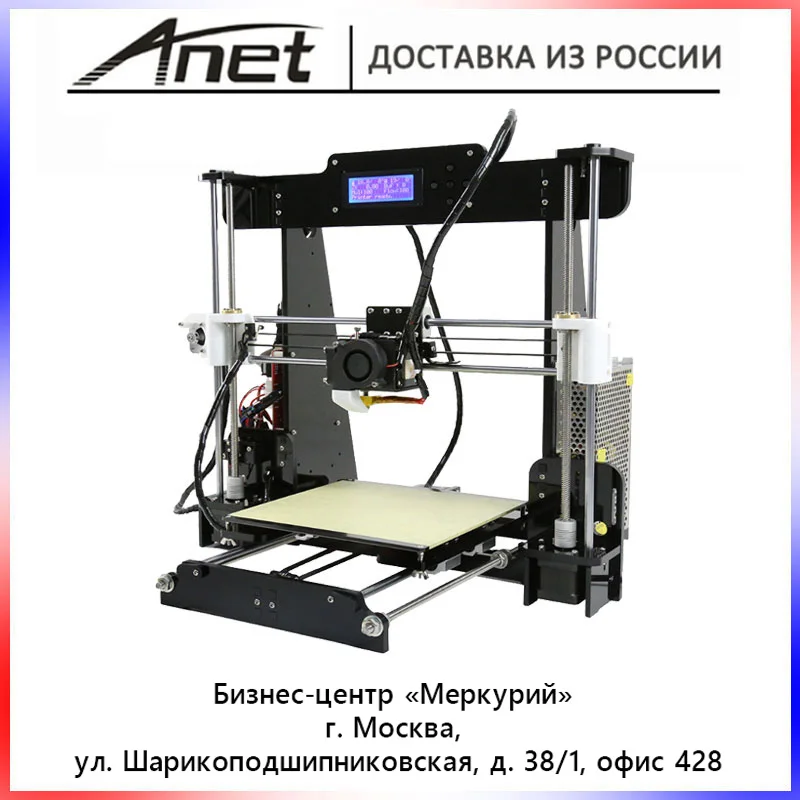

Prusa i3 MK3S+ — low cost commercial 3D printer for small businesses on a budget

- Price: $999 fully assembled — Available on Prusa Store here / $749 as a kit — Available on Prusa Store here

- Build volume: 250 x 210 x 210 mm

With a price of under $1,000 you’d expect the Prusa i3 MK3S to be limited to standard consumer uses like printing fun models from Thingiverse, or fun basic 3D printing projects. However, it excels far beyond this, functioning as one of the best 3D printers for small businesses if you’re on a tight budget.

It can’t compete with higher end 3D printers in some areas, like size of build area, but it’s a fantastic commercial 3D printer for standard size prototypes in materials like PETG, ASA, Nylon, PC, PP, HIPS, and carbon fiber filaments.

Prusa 3D printers are known for their reliability and with an above 200mm/s travel speed, it’s fairly quick for the price. These factors, combined with precise 50-micron minimum layer heights, make it a great overall commercial 3D printer for professional and precise prototype production.

For those looking for a larger 3D printer, a 3D printer for materials like PEEK, or more precise resin 3D printers, keep reading.

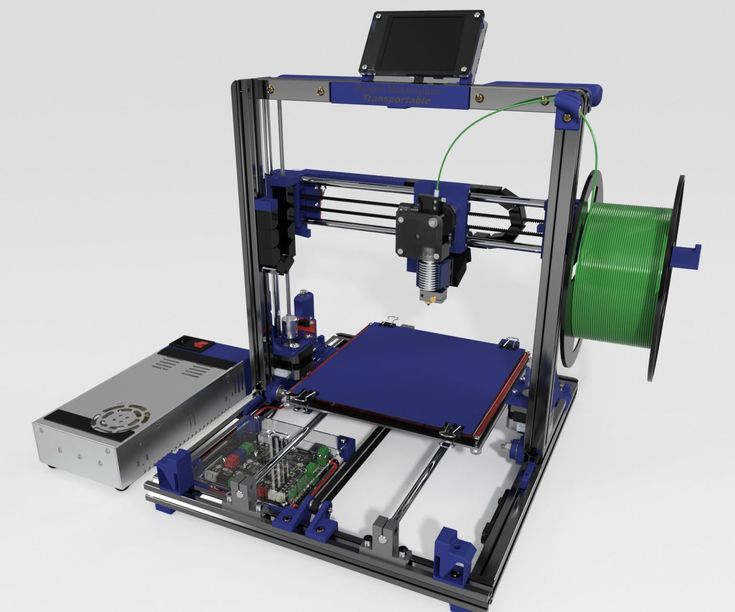

Ultimaker S3 — accurate commercial 3D printer for high quality prototypes

- Price: $4,080 — Available on Dynamism here / Available on Matterhackers here

- Build volume: 230 x 190 x 200 mm

The Ultimaker S3 follows the incredibly popular Ultimaker 3, and is an effective production 3D printer for small businesses and engineers capable of fantastic 20-micron resolutions. It can extrude composite filaments from either of its extruders, and can easily print soluble filaments with the dual extruder for easier post processing.

Ultimaker created and develop Cura, the world’s most loved 3D slicer, but also offer more professional 3D printer software as part of their Enterprise packages for commercial 3D printing needs. These premium 3D printer options include the ability to open CAD files in Cura, unlimited storage of your parts in their digital parts library, as well as integrating 3D modeling software like SolidWorks and Autodesk Inventor into your workflow with their plugins. All these make for an efficient commercial 3D printing workflow for quick and effective iterating and part production.

All these make for an efficient commercial 3D printing workflow for quick and effective iterating and part production.

The touchscreen is easy to navigate, and WiFi connectivity makes it quick to access and print your files remotely in their digital library.

As a professional 3D printer, Ultimaker serve not just 3D printers for small businesses, but also huge clients like Volkswagen. The German multinational used Ultimaker 3D printers to produce over 1,000 parts, remarking on the productivity and ergonomics of Ultimaker’s printers.

The only factor affecting the Ultimaker S3’s usefulness as a full professional grade 3D printer is the build volume size, which could be larger. However, Ultimaker also offer the S5 for larger print needs, so read on for more information on this.

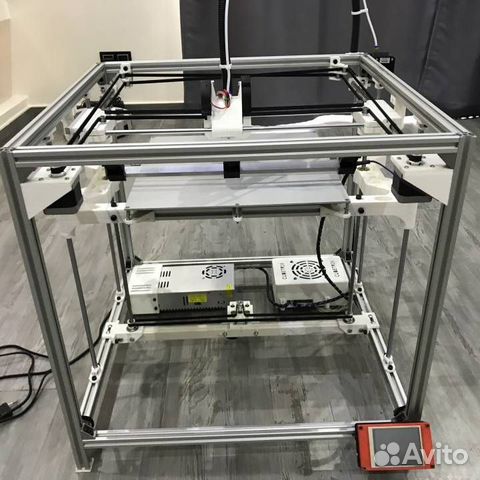

Ultimaker S5 — all-round excellent production 3D printer

- Price: $6,355 — Available on Dynamism here / Available on Matterhackers here

- Build volume: 330 x 240 x 300 mm

The Ultimaker S5 is the big brother of the already very powerful S3, and a commercial grade 3D printer for high quality engineering parts and accurate prototypes.

The main difference between the S3 and S5 is the larger print volume, a major improvement for those looking for a 3D printer for their small business capable of large prototype printing. It still features the same workflow options, dual extrusion, 20-micron layer heights, and trademark reliability and and precision.

However, you can also turn the S5 into a scalable production 3D printer with the Ultimaker’s S5 Pro Bundle for another few thousand dollars. This bundle adds both a spool holder and top filter. The material handler can hold up to six filament spools, and can automatically change them in and out for different uses as well as protecting filaments from moisture that would deteriorate print quality and protect them from dust, with the environment control filtering out fumes.

- The Ultimaker S5 Pro Bundle costs around $9,550 — Available on Dynamism here / Available on Matterhackers here

The Pro Bundle turns the S5 into the complete commericial 3D printer, able to print continuously, accurately, large parts — everything except super high grade material printing like PEEK and Ultem. The Ultimaker S5, alongside the S5 Pro Bundle with material holder and environment control add-ons.

The Ultimaker S5, alongside the S5 Pro Bundle with material holder and environment control add-ons.

Formlabs Form 3 — precise professional 3D printer for accurate resin parts

- Price: $3,499 — Available on Dynamism here

- Build volume: 145 x 145 x 185 mm

The Form 3 is sold as a professional quality 3D printer at desktop prices, building on the Form 2’s stellar reputation with incredible resolutions and able to create parts you can barely see the individual layer lines on.

Featuring their LFS (low force stereolithography) tech, layer spot clarity, as well as consistency, surface quality and better translucent material printing are some of the improvements made to the Form 3.

For production engineers looking for a workhorse production 3D printer that can go non-stop, the Form 3 is more than capable, with data on ongoing print performance constantly relayed and alerts if print performance changes so you can make alterations.

You can print in standard resins, or castable wax for jewelry casting, as well as specialized biocompatible commercial grade 3D printing resins for dental uses — which you should instead get the Form 3B for.

Their PreForm software makes preparing your prints easy, and if you’re looking to scale up to a 3D printing factory with multiple printers Formlabs have specialized consulting teams to help, and offer software for managing multiple 3D printers simultaneously.

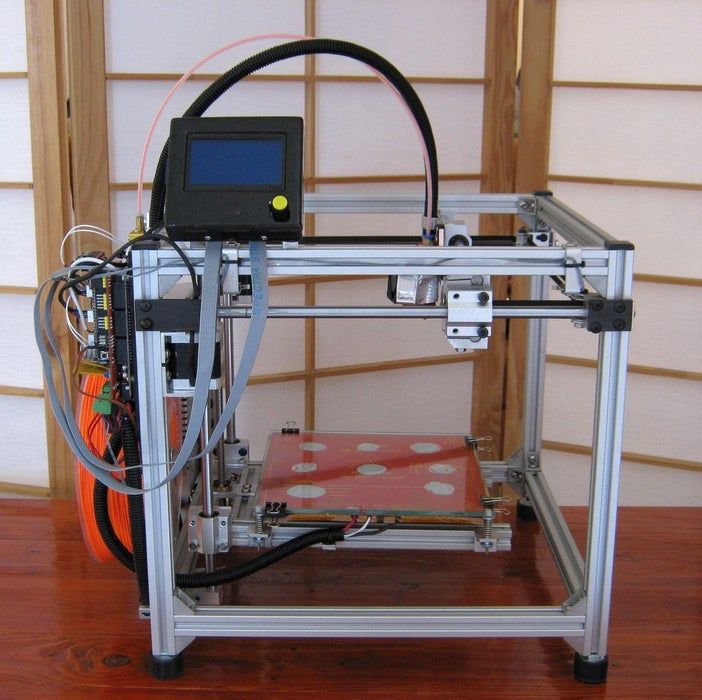

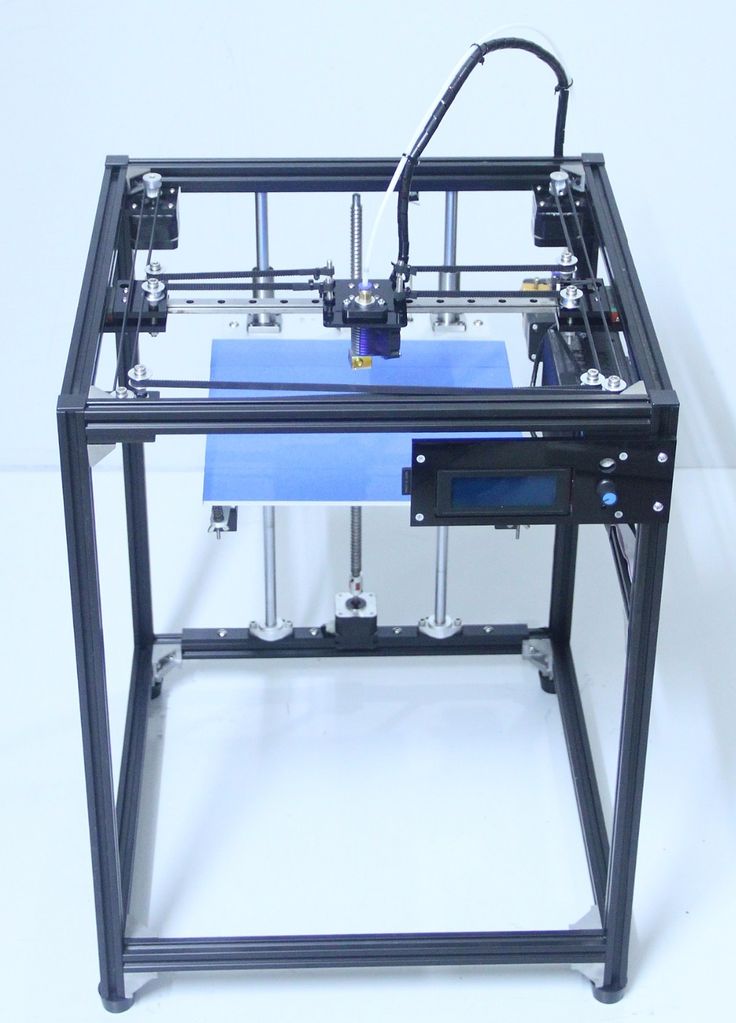

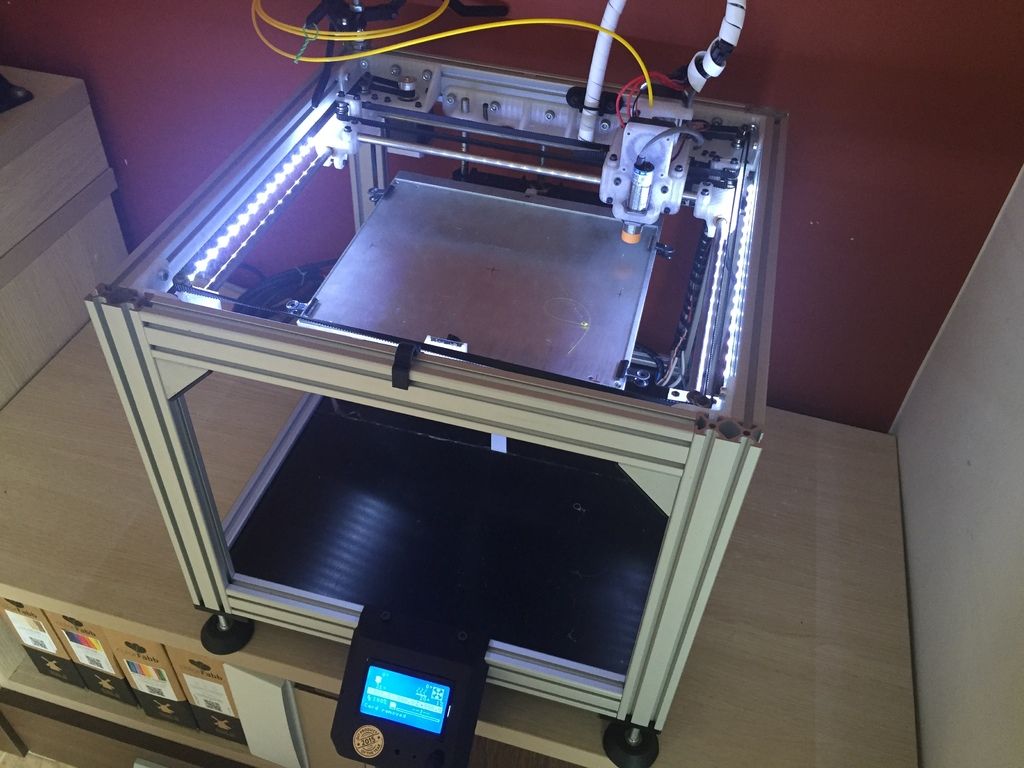

Raise3D Pro2 Plus — large production 3D printer for small businesses

- Price: $5,999 — Available on Dynamism here / Available on Matterhackers here

- Build volume: 305 x 305 x 605 mm

A true workhorse production 3D printer, the Raise3D Pro2 Plus can work 24/7 without much issue. Able to reach 300°C extruder temperatures, printing with filaments ranging from HIPS, ASA, PP, PVA, flexible filaments like TPU and TPE, Nylon, glass, carbon fiber, metal and wood filled filaments is no problem.

As well as the huge build volume and wide material compatibility, the Raise3D Pro2 Plus also offers great precision, with up to 0.01 mm layer heights and 5-micron repeatability. You can change the nozzle out to a smaller or larger one depending on whether your project favors speed or precision.

The large 7-inch touchscreen simplifies your workflow and makes it easy to switch settings or choose your model to print — made easier by Raise3D’s visual model selection previewer. And, if during printing you run into any problems with the power or any other error, the printer can resume from whenever it was stopped without issue.

Marking itself as one of the best 3D printer for business uses, it has some of the largest print areas, as well as an aerospace grade build plate offering excellent adhesion, durability, and preventing warping that can affect or ruin prints — as well as making prints easy to remove. It’s all fully enclosed, so you can effectively maintain and control the chamber temperature to minimize warping and prevent fumes from spreading.

If you want the workhorse benefits of the Raise3D Pro2 Plus, but don’t need the extra Z-axis height building, you can save a couple thousand dollars by going with their standard Pro2 model instead, with a 300mm maximum print height instead of the Pro2 Plus’ 605mm.

Intamsys Funmat HT Enhanced — professional 3D printer for PEEK & Ultem printing

- Price: $7,500 — Available on Matterhackers here

- Build volume: 260 x 260 x 260 mm

For those looking for a specialized PEEK and Ultem 3D printer, the Intamsys Funmat HT Enhanced is the best professional 3D printer for PEEK that’s in most small business’s budget. Costing $6,000 rather than the $20,000+ commonly seen among commercial 3D printers for PEEK, the Intamsys Funmat HT is a great entry-level production 3D printer.

With 90°C constant chamber temperatures, a 160°C heated build plate, and 450°C maximum extruder temperatures from its all-metal hot end, printing PEEK, PEKK, PPSU and Ultem are no problem. However, if you want to use it for printing PEEK as well as more standard plastics you can also do that, with interchangeable nozzles for different printing plastics like PLA and ABS, PC, Nylon, ASA, and more.

Therefore, the Intamsys Funmat HT is a great entry-level production 3D printer for high performance polymer printing. It can automatically level itself with its four advanced drivers offering great precision, and the industrial build platform quality and design features PEI film and glass ceramic materials for great durability and minimal deformation during printing — as well as being safe to use with biocompatible materials like PEEK that may be used to print medical or dental parts.

It can automatically level itself with its four advanced drivers offering great precision, and the industrial build platform quality and design features PEI film and glass ceramic materials for great durability and minimal deformation during printing — as well as being safe to use with biocompatible materials like PEEK that may be used to print medical or dental parts.

With PEEK’s extensive use in medical parts, electrical engineering, aerospace, dental, Ultem’s industrial uses, and PPSU’s medical applications, the Intamsys Funmat HT capitalizes on 3D printing’s fastest growing material segment, but at a low price. Intamsys sell their own Ultem and PEEK filaments, and overall, the Funmat HT Enhanced is one of the best 3D printers for small businesses looking to print high performance plastics to either create parts for other companies, or iterate in-house.The Intamsys Funmat HT Enhanced is an ideal professional 3D printer for PEEK without breaking the bank.

Some other articles you may be interested in:

- The best 3D printers for small business

- Best PEEK 3D printers

- Best industrial 3D printers

- Best 3D printers under $2,000

- Best metal 3D printers

The Best 3D Printers in October 2022 (For Every Price)

With so many 3D printers available, from different price ranges to different technologies entirely, it can be difficult to pick the best 3D printer for you.

We’re here to help: we continuously update this best 3D printer guide with the latest 3D printer reviews, and we’ve tested over a dozen 3D printers on this site to create this buyer’s guide.

If you’re in a rush, here’s our 3 top picks:

BUDGET OPTION

Creality Ender 3 V2

Reliable low-cost 3D printer

Easily upgradable with a wide range of printable or purchasable upgrades

Improved print bed for better adhesion

Available at:

Creality hereAmazon hereRESIN PICK

Anycubic Photon Mono X

High-quality mid-range resin 3D printer

Fast 60mm/h resin printing

Powerful 4K LCD screen for precise details and miniatures

Available at:

Anycubic hereAmazon herePREMIUM PICK

Prusa i3 MK3S+

Gold standard in DIY FDM 3D printing

Super reliable workhorse

Upgradable to print 5 colors simultaneously

Available at:

Prusa hereWhat makes a good 3D printer?

We used the following criteria, along with our hands-on experience, to make our top picks:

- Print quality: resolutions, accuracy and consistency

- Build volume: not a problem if you just want to print miniatures, but bigger can be better

- Reliability: especially important in cheap printers, we picked durable printers that work reliably

- Versatility: from the range of materials you can print, to any extras such as a dual extruder, enclosure, and more

- Easy to use: easy assembly, simple and intuitive to set up, and straightforward slicer software

We’ve split our recommended picks into different categories to help you find the best 3D printer based on your needs.

Then, below we have our full product reviews of each printer with the full details, and where to get the best price.

The Best 3D Printers in 2022 – Reviews

Best under $300: FDM — Creality Ender 3 V2, Anycubic Kobra

Best under $300: Resin — Anycubic Photon Mono 4K, Elegoo Mars 2 Pro / Mars 3

Best for kids — Toybox 3D printer

Best for $500: FDM — Anycubic Vyper, Prusa Mini, Creality Ender 3 S1 Pro

Best large-format resin printer — Anycubic Mono X, Elegoo Saturn S

Best large-format FDM — Creality Ender 5 Plus

Best FDM 3D printer for $1000 — Prusa i3 MK3S+

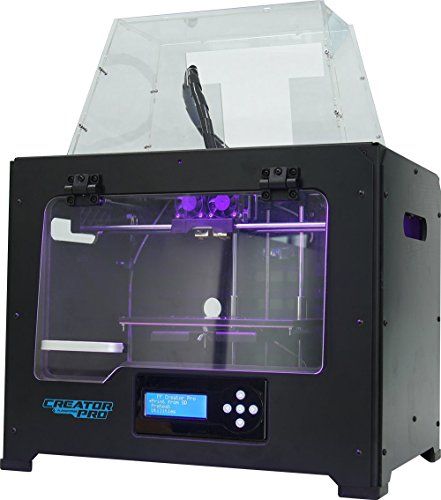

Best dual extruder under $1000 — Flashforge Creator Pro 2, Sovol SV04

Best 3-in-1 3D printer, CNC, laser — Snapmaker 2.0 AT

Professional resin printers — Prusa SL1S Speed, Formlabs Form 3

Professional FDM — Ultimaker S3, S5

Here’s the full list:

| 3D printer | Price | Best place to buy | Alternative |

|---|---|---|---|

| Creality Ender 3 V2 | $279 | Creality Store here | Amazon here |

| Anycubic Photon Mono 4K | $219 | Anycubic here | Amazon here |

| Elegoo Mars 2 Pro / 3 | $250-$350 | Elegoo here | Amazon here |

| Toybox | $299 | Toybox here | |

| Anycubic Kobra | $299 | Anycubic here | Amazon here |

| Prusa Mini | $350 | Prusa Store here | |

| Anycubic Vyper | $359 | Anycubic Store here | Amazon here |

| Creality Ender 3 S1 Pro | $479 | Creality Store here | Amazon here |

| Anycubic Mono X | $449 | Anycubic here | Amazon here |

| Elegoo Saturn S | $549 | Elegoo here | Amazon here |

| Sovol SV04 | $539 | Sovol 3D here | |

| Ender 5 Plus | $579 | Creality Store here | Amazon here |

| Prusa i3 MK3S+ | $749 / $999 | Prusa (DIY) here | Prusa (built) here |

| Flashforge Creator Pro 2 | $649 | Flashforge here | Amazon here |

Snapmaker 2. 0 AT 0 AT | $1,199-$1,799 | Snapmaker here | Amazon here |

| Prusa SL1S Speed | $1,999 | Prusa Store here | |

| Formlabs Form 3 | $3,499 | Dynamism here | |

| Ultimaker S3 | $4,030 | Dynamism here | Matterhackers here |

| Ultimaker S5 | $5,995 | Dynamism here | Matterhackers here |

Best Under $300

For new and experienced makers alike, finding the best 3D printer without breaking the bank is important.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

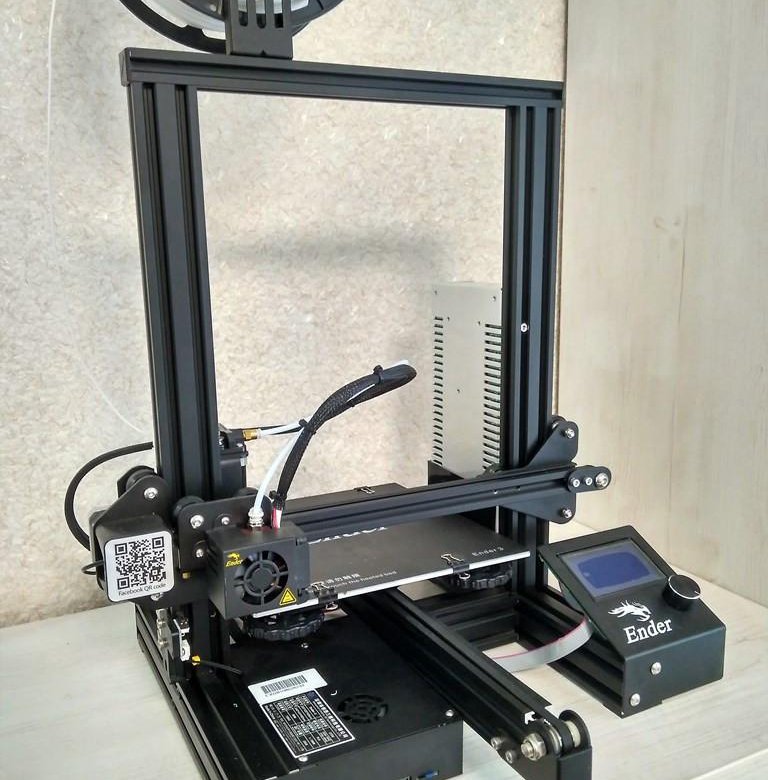

Creality Ender 3 V2 — best 3D printer for the price

- Price: Check price at Creality Official Store here / Available on Amazon here

- Build volume: 220 x 220 x 250 mm

One of the leading 3D printers for $200, the Creality Ender 3 V2 is a very powerful machine for the price. It can be assembled in under an hour, and also features a heated bed.

It can be assembled in under an hour, and also features a heated bed.

An affordable workhorse 3D printer, the Ender 3 V2 is known for its reliability, churning out part after part without issue. The open printing area means it isn’t ideal for tougher filaments like ABS or Nylon, but as a PLA 3D printer it works well.

The Ender 3 V2 features a number of small but useful improvements on the best-selling Ender 3. The print volume is the same, but the print bed is now carborundum glass mounted on an aluminum bed, improving adhesion and making removing finished prints easier than on the previous magnetic bed. The HD screen is better than the original LCD interface, a small but pleasant quality-of-life improvement.

If you’re going to be spending $200 on a 3D printer, you can’t expect the quality to be flawless. If you want a Creality 3D printer and you have an extra $200 – upgrade to the Ender 3 S1 Pro, which also features on this ranking.

Read more: comparing the Ender 3, Ender 3 Pro, Ender V2 and S1

Anycubic Photon Mono 4K

- Price: Check price at Anycubic Official here / Amazon here

- Build Volume: 165 x 132 x 80 mm

- Bed Leveling: Manual

- LCD: 6.

23” 4K monochrome LCD

23” 4K monochrome LCD - XY Resolution: 35 microns

- Filament Compatibility: Resin

- Connectivity: USB

The Anycubic Photon Mono 4K is a major upgrade on the standard Photon Mono, retaining the simplicity of the original while pumping up the XY resolution from 50 to 35 microns to put it in line with the pricier Mars Elegoo 3.

This major shift comes courtesy of a pivot to a 6.23″ LCD pushing 3,840 x 2,400 pixels. Although the 165 x 132 x 80 mm tails behind the Mars 3’s 143 x 90 x 165 mm, it still offers ample space for most resin-based home projects and then some.

The 1-2 second cure time remains identical to the original Mono, but you’re effectively able to produce the same prints in the same time frame but at a higher overall quality. Elsewhere, the 4K jumps to a new 15-LED matrix parallel light source that allows for more uniform light distribution, resulting in richer details.

So why opt for the Anycubic Photon Mono 4K over the Elegoo Mars 3? While the Mars 3 offers a sleeker overall printing experience, the Anycubic Photon Mono 4K just about keeps in pure specifications and print quality, all for $80 less.

If you’re after that sweet spot between spending as little as possible but still want a reliable, quality resin 3D printer, the Anycubic Photon Mono 4K hits the mark.

Elegoo Mars 2 Pro / Mars 3

BUDGET PICK

Elegoo Mars 2 Pro

Print Volume: 129 x 80 x 160 mm

Screen size: 6.08″ 2K Monochrome LCD

XY Resolution: 50 microns

Speed: 30-50 mm/h

Cleaning/Curing: Elegoo Mercury Plus/X

Available at:

Elegoo hereAmazon herePREMIUM PICK

Elegoo Mars 3

Print Volume: 143 x 90 x 175 mm

Screen resolution: 6. 6″ 4K LCD

6″ 4K LCD

XY Resolution: 35 microns

Speed: 1.5-3 seconds per layer

Cleaning/Curing: Elegoo Mercury Plus/X

Available at:

Elegoo hereMatterhackers hereAmazon hereWe were very impressed when we tried out the Elegoo Mars 2 Pro – especially for such a low price. It was easy to set up and get started, and the surface finish on our prints was fantastic.

However, you can upgrade from the Mars 2 Pro’s 2K screen to the Mars 3’s 4K screen if your budget can stretch that far, offering crisper details and ultra-fast 1.5-second layer curing.A dinosaur model we 3D printed on the Elegoo Mars 2 Pro

The Elegoo Mars 2 Pro’s quality is great, and should be more than enough to print good-looking miniatures and models. The Mars 3 is not a necessity, but if you do want to overhaul the resolution and quality, go for the Mars 3.

The Mars 3 also has a larger build area: 143 x 90 x 165 mm, vs the Mars 2 Pro’s 129 x 90 x 150 mm. You can print 15mm taller models, and you have 14mm on the X-axis for printing more miniature models at the same time.Clank video game 3D print on the Elegoo Mars 2 Pro.

For XY resolution, the Mars 3 clocks in at 35 microns, an improvement on the Mars 2 Pro’s 50 microns. However, both are very well-made, with robust parts and CNC machined aluminum bodies.

So, if you’re fine with the 2K LCD screen, smaller build area and slightly slower print speed, then the Mars 2 Pro is a great budget pick. But if you want those extra upgrades, go for the Mars 3 – or even the Mars 3 Pro. The Mars 3 also comes with a year’s free ChiTuBox Pro, which usually costs $150+.

Read more: our review of the Elegoo Mars 2 Pro

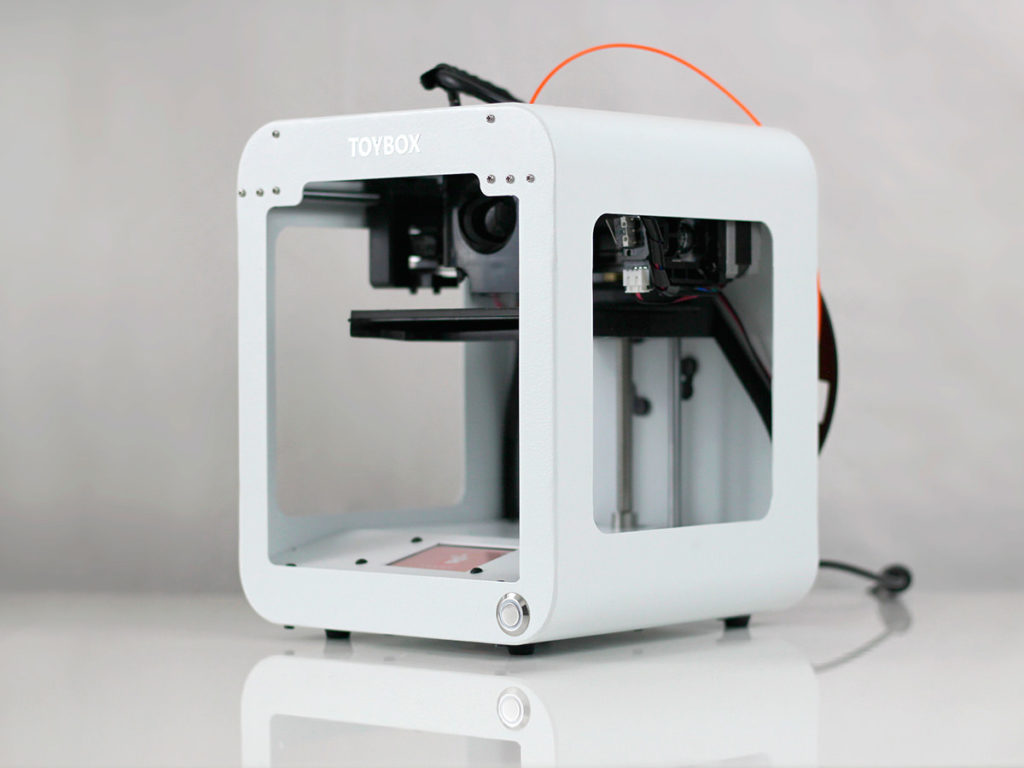

Toybox: Best For Kids & Complete Beginners

- Price: $299 – Available at Toybox Official store here

- Build volume: 70 x 80 x 90 mm

The Toybox isn’t your high-tech, workhorse 3D printer to start a business with, but it is one of the simplest and most accessible 3D printers we’ve ever tested – ideal for kids and beginners.

The build volume is small – just 70 x 80 x 90 mm, but if you have modest 3D printing goals to print miniatures and other fun characters, it’s a great choice.

Toybox have partnered with numerous big players to bring you a huge range of free models you can 3D print too, from Batman and Wonder Woman, to fun 3D printable dragons, tanks, cars, and so much more.A fun seal we 3D printed with the Toybox.

For kids it’s super safe: it only prints low-temperature PLA, and any hot parts are kept well away from prying hands. You get small spools of many different color filaments to print away with – affectionately called 3D printer “food” by Toybox – and we found it to be reliable yet super accessible.

If you’re brand new and want a hassle-free run, or want to get your kids into 3D printing cheaply, the Toybox is great.

The full review: Toybox 3D printer review

For beginners: the best 3D printers for beginnersGetting the Toybox set up.

Anycubic Kobra – best under $300

- Price: Check price at Anycubic here / Amazon here

- Build Volume: 220 x 220 x 250 mm

- Bed Leveling: Yes, LeviQ automatic bed leveling

- Build Platform: PEI-coated spring steel heated bed

- Filament Compatibility: PLA / ABS / PETG / TPU

- Connectivity: USB, SD Card

The Anycubic Kobra delivers incredible value for the asking price, with a spec sheet that reads like one for a printer twice its price. We were lucky enough to review the Kobra, and despite some minor slicer issues, we were thoroughly impressed with Anycubic’s latest entry-level printer.

Standout features include Anycubic’s in-house developed LeviQ automatic bed leveling and homing system, a PEI-coated spring steel heated bed, a direct drive extruder, and one of the sharpest touch screen UI’s we’ve seen at the price point. It’s frankly baffling to see these types of features on a printer costing less than $300.An owl we 3D printed on the Anycubic Kobra during our test.

It’s frankly baffling to see these types of features on a printer costing less than $300.An owl we 3D printed on the Anycubic Kobra during our test.

The Anycubic Kobra’s budget appeal also extends to the quality of the prints. With a bit of software wrangling, the Kobra is capable of fantastic prints for the price, and the bang-on average 220 x 220 x 250 mm build volume should cover all your everyday 3D printing needs.

A layer thickness range of 50 to 300 microns and print speeds pushing up to 180 mm/s have you covered for everything from sharp, detailed prints through to quick, functional parts.

Overall, the Anycubic Kobra is an affordable printer that stands out for taking some of the more frustrating and time-consuming aspects of the hobby out of the picture so that you can concentrate on the actual printing.

If you’re a first-timer looking for a gentle introduction to 3D printing, the Anycubic Kobra is arguably the best option out there currently.

And if the build volume isn’t enough, upgrade to either the Kobra Plus or Kobra Max:

- Kobra Plus: 300 x 300 x 350 mm build area – Available here

- Kobra Max: 400 x 400 x 450 mm build area – Available here

Read the full review: Anycubic Kobra review and test

Best Under $500

Prusa Mini – Best Premium-Budget Printer

- Price: $350 – Available at Prusa Official here

- Build Volume: 180 x 180 x 180 mm

- Bed Leveling: Yes, SuperPINDA probe

- Build Platform: Removable magnetic spring steel sheets

- Filament Compatibility: PLA, PETG, ASA, ABS, Flex

- Connectivity: USB, Ethernet

With the Prusa Mini, the company leverages all the Prusa i3 MK3S+’s usability and specs into a comparatively affordable printer. The Prusa Mini’s price is entry-level, only marginally higher than you’d pay for the ever-popular Ender 3 and Anycubic Kobra.

The Prusa Mini’s price is entry-level, only marginally higher than you’d pay for the ever-popular Ender 3 and Anycubic Kobra.

It’s a sophisticated 3D printer that focuses on simplicity. It features automatic mesh bed leveling courtesy of a superb SuperPINDA probe, a classy PEI-coated spring steel removable bed, and instructions that are as clear and user-friendly as they come.

The Prusa Mini also pairs well with a broader range of materials than your standard budget printer, covering PLA and ABS along with PETG, ASA, HIPS, and produces decent results with demanding exotics like PC blends and CF-PETG.

However, for all the Mini’s fantastic attributes, it’s abundantly clear where Prusa trimmed the fat, with a rather measly 180 x 180 x 180 build volume.

For the average maker, especially first-timers, the Mini’s build volume should be more than enough for most common print projects. However, if you want to print large models, or large terrain areas for miniatures, opt for an Ender 5 Plus.

Volume aside, the Prusa Mini is a solid premium-budget option for those buying a first printer and even more experienced makers looking to add to their printer line-up.

Ender 3 S1 Pro

- Price: Check latest price at Creality here / Amazon here

- Build volume: 220 x 220 x 270 mm

- Minimum layer height: 0.05mm

- Bed leveling: Automatic

- Max extruder temperature: 300°C

We highly recommend the standard Ender 3 or Ender 3 V2 for a very low-cost FDM kit, but if you want premium features for a couple hundred bucks extra, the Ender 3 S1 Pro is one of the best printers under $500.

We were really impressed with the quality when we printed out some test prints during our Ender 3 S1 3D printer review.

The build volume is mostly the same (270 mm vs 250 mm on z-height) as the standard Ender 3, but the S1 Pro has an all-metal and direct drive extruder, versus the Ender 3’s PTFE bowden extruder. This makes it much easier to print flexibles like TPU, and reduces filament jamming from the generally higher quality extruder.We 3D printed a cat…for our cat…on the Ender 3 S1 Pro.

This makes it much easier to print flexibles like TPU, and reduces filament jamming from the generally higher quality extruder.We 3D printed a cat…for our cat…on the Ender 3 S1 Pro.

The S1 Pro can also handle up to 300°C temperatures, so high-temp Nylon and other filaments are no problem – a rarity at under $500. The Ender 3 standard runs up to 255°C, and the Ender 3 S1 (not Pro) can handle 260°C.

Another major advantage is the auto-bed leveling. While you can buy a CRTouch or BLTouch for the Ender 3, it’s a hassle and a time sink, so the Ender 3 S1 and S1 Pro coming with this is a big plus.

The z-axis is also generally sturdier and of higher quality for more reliable and precise printing, and if you do intend to print fine details, the Ender 3 S1 range goes down to 0.05mm layer heights, versus the 0.1mm on the other Ender 3 printers.

Read the full review: Ender 3 S1 Pro review and test

Anycubic Vyper

- Price: Best price on Anycubic Store / Also Available on Amazon

- Build volume: 245 x 245 x 260 mm

We were impressed with the Anycubic Vyper when we tested it last month. The build volume is impressive, and slightly larger than you’d expect for this price range — yet the printer is compact, and fits on most desktops.

The build volume is impressive, and slightly larger than you’d expect for this price range — yet the printer is compact, and fits on most desktops.

The auto leveling makes life easier and can be done via 1 click, and the Vyper also automatically adjusts your nozzle height for optimum printing. The spring steel magnetic platform makes it easy to remove prints, and its magnetism means you can remove the entire plate, remove your model in a more convenient place, and then click it back into place for your next print.One of the torture tests we 3D printed – an XYZ cube, which came out crisply.

Though we kept it at the standard 50-60mm/s during our test, Anycubic highlight how the Vyper’s innovative new double fan system lets you print at up to 100mm/s without creating issues. Still, if you’re going to use your printer as a speed demon, be careful when printing very small models.

The large 4.3-inch touchscreen makes printing a breeze, and the layout is intuitive and simple to operate. It doesn’t have WiFi connectivity, but it’s very easy to move models from Cura to the SD card and print them on the Vyper. Overall, it’s a good compact 3D printer for home makers.

It doesn’t have WiFi connectivity, but it’s very easy to move models from Cura to the SD card and print them on the Vyper. Overall, it’s a good compact 3D printer for home makers.

You can read more about the Vyper in our Anycubic Vyper review

Best Large-Format Resin

Anycubic Mono X

- Price: Check price at Anycubic Official Store here / Available on Amazon here

- Build volume: 192 x 120 x 245 mm

The Mono X is a big upgrade on Anycubic’s lower priced LCD printers. This home 3D printer can print intricate tabletop or D&D models in fantastic detail, and is one of the best 3D printers for miniatures. It prints at a very respectable 60mm/h.

The 4K screen makes for incredibly precise layers for the price, and in fact you’ll barely be able to see any visible layer lines if you use more accurate print settings. Additionally, the upgraded double linear Z-axis improves stability, further improving performance.

The 3.5” touchscreen makes it easy to operated, and the Mono X works over via WiFi or USB/SD. Overall, it’s one of the best 3D printers for resin molds and models under $1,000, and a great 3D printer for resin.

Elegoo Saturn S – Best Large Resin 3D Printer

- Price: Check latest price at Elegoo here / Amazon here

- Build Volume: 196 x 122 x 210 mm

- Bed Leveling: Manual

- LCD: 9.1-inch 4K HD Monochrome

- XY Resolution: 48 microns

- Filament Compatibility: Resin

- Connectivity: USB

The Elegoo Saturn S is a new-look upgrade on the standard Saturn, bring it in line with larger resin competitors like the Anycubic Mono X series.

Compared to the standard Saturn, build volume jumps from 192 x 120 x 200 mm to 196 x 122 x 210 mm.

This is a slight increase, but these numbers position the Saturn S as one of the larger format printers priced under $500 – ideal for printing batches of your favorite high-detail figurines.

Elsewhere, the Saturn S 4K screen refines the XY resolution to 48 microns, offering a slight jump in fine detail over the Saturn’s 50 microns. You could spend a further $200 on the Photon Mono X 6K to drop to 34 microns. Still, the differences at this scale are virtually indistinguishable to anyone but the most discerning makers.

When compared with the Anycubic Mono X (not the 6K version), they have similar 4K screens and resolutions, with the Saturn S having a 4mm larger X-axis, and the Mono X with a 35mm larger Z-height. So if you want to print taller models, go with the Mono X.

They’re of similar speeds, and have similar connectivity via USB – so it’s mostly down to what you plan to print: do you want to print wider, or taller? For wider, go with the Saturn S, for taller, the Mono X. And for a 6K screen, go for a Mono X 6K.

Best Large-Format FDM

Ender 5 Plus – Best Large-Format 3D Printer Under $1,000

- Price: Check price at Creality Official here / Amazon here

- Build Volume: 350 x 350 x 400 mm

- Bed Leveling: Yes, BLTouch auto-bed leveling probe

- Build Platform: Glass heated bed

- Filament Compatibility: PLA, ABS, TPU, Composite-Filled

- Connectivity: SD Card, Browser Interface

The real highlight of the Ender 5 Plus is the 350 x 350 x 400 mm build volume – far above the average found on sub-$1000 printers.

So much real estate opens the door for far more ambitious hobbyist prints – cosplay items and accessories, batch printing smaller parts, large vases or household pieces, and any other projects that benefit from the extra space.

As the most premium of the entry-level Ender line-up, it also throws in a few quality-of-life improvements, notably BLTouch-powered automatic bed leveling, which blazes through normally fiddly calibration. It also features a quality removable tempered glass plate, filament runout sensor, and a sharp 4.3″ touchscreen.

Beyond these, the Ender 5 Plus is a functional printer much like the Ender 3, with few extra bells and whistles. A possible downside for some but a genuine benefit for others as the Ender 5 Plus offers a solid foundation ripe for upgrades and tinkering.

All-metal extruder, direct drive system, enclosure, mainboard, all-metal hot end, and countless 3D printed upgrades are all possible add-ons to transform a solid printer into an exceptional one capable of handling all manner of exotic and abrasive filaments.

Some mods are more daunting than others, but the Ender 5 Plus popularity means there’s an in-depth guide, tutorial, and video available for every upgrade to walk you through every step, courtesy of an engaged and active community.

Best FDM 3D Printer For $1000

Prusa i3 MK3S+

- Price: $749 as a kit — Available on the Prusa store here / $999 fully assembled — Available on the Prusa store here

- Build volume: 250 x 210 x 200 mm

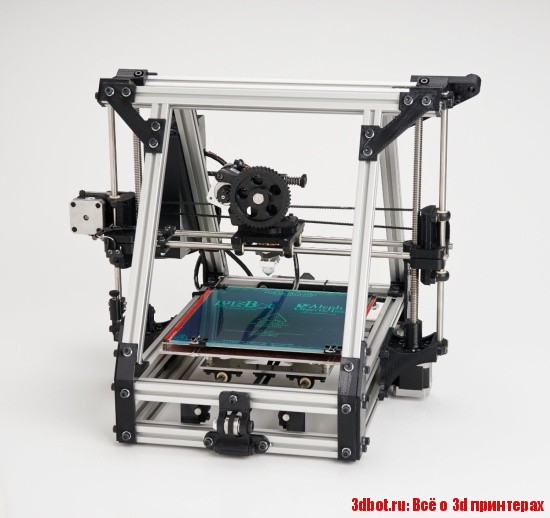

Literally the gold standard of desktop FDM kits, Josef Prusa has sold over 100,000 of his 3D printers over the years. Known as the premier 3D printer to emerge from the RepRap movement, the Prusa i3 MK3S+ is packed with features that make it a great 3D printer for both makers as well as businesses.

The MK3S+, released at the tail end of 2020, features a number of small yet beneficial improvements over the MK3S. The new SuperPINDA probe allows for fully-automatic mesh bed leveling, with other improvements including easier to mount bearings on the Y-axis that provide better support.

The new SuperPINDA probe allows for fully-automatic mesh bed leveling, with other improvements including easier to mount bearings on the Y-axis that provide better support.

You get there bed surface options for spring steel sheets – smooth, textured or satin – covering various different material printing and making finished prints easier to remove than ever. The Prusa can print almost anything, with an extruder temperature up to 300°C possible — so even filaments like Polycarbonate are no issue.

If you want to print multi-color parts, you can upgrade your Prusa i3 MK3S+ with Prusa’s multi-material upgrade 2.0 kit, allowing you to print five colors or materials simultaneously, for $300. Moreover, the high-quality Bondtech gears and E3D nozzle within their custom-designed extruder make for great quality prints as well as top workhorse-like reliability. It’s also a fast 3D printer, able to travel and print up to 200mm/s.

- You can purchase the Multi Material Upgrade Kit here.

You can buy your own Prusa 3D printer online for $999 for a ready-made printer, or save a couple of hundred dollars and assemble it yourself. Overall, it’s one of the top 3D printers for $1,000, and one of the best 3D printer kits around.

Best Dual Extruders Under $1000

Sovol SV04: Best Low-cost IDEX 3D Printer

- Price: $539 — Available at Sovol store here

- Build volume: 300 x 300 x 400 mm

If you want a dual extruder 3D printer, and don’t want to pay more than a thousand bucks, then there’s only two games in town: the Sovol SV04 and the Flashforge Creator Pro 2.

The main difference is the Sovol SV04’s much larger build volume: it’s the same as the Creality CR-10, at 300 x 300 x 400 mm. This lets you print large objects with multi-colors, or even two fairly large models at the time using the IDEX dual extrusion features.

We tested the Sovol SV04 for a few days while reviewing it, and managed to print some really cool multi-colored 3D prints like the frog and cube shown below.

We also printed some great plant pots for some flowers and a cactus using the Copy Mode feature, with each extruder printing a plant pot simultaneously for double the productivity.

To be short: if you want a dual extruder 3D printer with a large build volume that works well, go for the Sovol SV04. The IDEX is a really handy addition (the Sovol SV02 isn’t IDEX) for quickly making multiple parts.

But, if you don’t mind having the smaller build volume, and instead prefer the enclosed build chamber to better print materials like ABS and Nylon, then go for the Flashforge Creator Pro 2.

Flashforge Creator Pro 2

- Price: Check price at Flashforge Official store here / Available on Amazon here

- Build volume: 200 x 145 x 150 mm

The Flashforge Creator Pro 2 is one of the best desktop 3D printers on the market for dual extrusion. This makes the Flashforge Creator Pro ideal for low-cost multi-material or color printing.

The Creator Pro 2’s main upgrade on the original Creator Pro is it now features an IDEX 3D printer system, meaning that the two extruders can move independently on the Y-axis rather than being locked together.

This opens up possibilities for both duplication 3D printing (printing two identical parts at the same time), and mirror modes (printing mirrored parts like two opposing shoe soles), greatly improving efficiency. This comes at the cost of some X-axis size, down to 200mm.

The Creator Pro 2 is an accurate 3D printer, with a minimum layer height of 0.05mm. Its closest alternative is the Sovol SV04, a similar-priced IDEX printer, but whereas the Sovol has a larger build volume, the Creator Pro has a sturdily built enclosure for better heat control.

Overall, it’s another terrific 3D printer, and a safe and reliable printer for the price.

Best 3-in-1 3D Printer, CNC and Laser

Snapmaker 2.0 AT (A250T and A350T): Best 3-in-1 3D Printer

- Price: $1,199 to $1,799 — Best price on Snapmaker Store here / Also Available on Amazon here

- Build volumes: up to 320 x 350 x 330 mm

The Snapmaker 3D printers aren’t just 3D printers – you can switch the extruder module out and switch in the CNC carver, or the laser engraver module in just a few minutes and get working.

The 3D printer module stands on its own as high-quality – we were surprised by just how reliable, accurate, and effective it was when we tested it. It doesn’t feel like you lose anything on the 3D printing side when you add on the other options. The metal structure and linear rails are sturdy, retaining precision even on the largest A350T we tested.

You can 3D print all major hobbyist filaments like PLA, flexible filaments like TPU, and ABS. The smartphone-shaped touchscreen makes it really easy to operate, and the WiFi connectivity saves you hassle from constantly plugging in SD cards or USBs.

You get a range of premium features — auto-leveling, filament run-out detection, dynamic print speeds via the intelligent software –generally making your 3D printing experience more pleasant and productive.The three sizes of the Snapmaker 2.0 options.The 3D printer head accurately printed the precise details of this vase.

By default you get the weaker 1600mW cutting module which we still managed to laser engrave with nicely, as well as cutting through thin and soft wood (though it takes a lot longer than specialized lasers).

However, you can purchase the 10W high power laser for an extra $399, which can engrave anodized aluminum (check out our wolf engraving below), and comfortably cut through acrylic and wood – we cut out an entire rhino puzzle from black acrylic in under 15 minutes.

You can carve soft and hard woods, as well as carbon fiber sheets and acrylics. We also used the 4-axis CNC module to carve chess pieces from epoxy blocks, and the bit can comfortably carve most woods and similar materials.

We cut chess pieces using the v-bit carver, and the 4-axis rotary module add-on (this costs an extra few hundred bucks though) which lets you carve into cylindrical blocks like a lathe to create detailed characters. Snapmaker Luban software handles the four axes well, and it’s a very well-designed software and slicer generally (vs buggier 3D software like Revopoint’s RevoScan).A lion the Snapmaker CNC toolhead carved. We also carved a knight chess piece that came out smoothly.

Read our full review: our Snapmaker 2. 0 3D printer review

0 3D printer review

For more on CNC: read our Snapmaker 2.0 CNC and laser review

If you want to engrave contrasting images, you can use the laser engraver. It can engrave on woods, as well as leather, fabrics and acrylic. We engraved a few cylinder-shaped blocks to test the 4-axis engraving module, as well as using the laser cutter to cut through a thin piece of wood to make this gift box.

We recommend also purchasing the enclosure to improve your printing experience and keeping you safer — and you may want to also pick up some extras for CNC. Their wide range of extras and goodies are on their site, which you can visit here.

If you’re considering the newest A250T or A350T vs the standard Snapmaker 2.0, the newer version is upgraded for a faster and quieter 3D printing experience generally, with a newly designed 3D printing module as well as more intelligent fan speed adjustments and a more powerful power module. There’s even rumors of a dual extruder module coming soon.

Best Professional Resin Printers

Prusa SL1S Speed

- Price: $1,999 — Available on Prusa Store here

- Build volume: 127 x 80 x 150 mm

The SL1S Speed is an upgrade on the original SL1, featuring 25% larger build volume, even more improvements to part quality, and more speed than ever.

One of the fastest resin printers around, the SL1S Speed cures layers in 1.4 seconds, and can fill the entire 150mm-high build chamber in just 3 hours. The high-resolution mono 5.96-inch LCD panel accurately cures layers of resin with the UV LED array, with even very small parts retaining their quality and intricacy.

Another major benefit is Prusa’s commitment to open source — all Prusa printers are open source, and are compatible with third-party resins, though Prusa also sell their own high-quality materials. And being a Prusa 3D printer, naturally it’s reliable and durable.

We recommend you also pick up Prusa’s wash and cure machine for post-processing your resin models. It washes, dries and cures your prints after the printing process, and costs an additional $599.

It washes, dries and cures your prints after the printing process, and costs an additional $599.

Formlabs Form 3

- Price: $3,499 — Available on Dynamism Store here

- Build volume: 145 x 145 x 185 mm

Retailing at $3,499, Formlabs’ Form 3 has become the resin 3D printer. It’s popular in both the dental and 3D printed jewelry markets due to its tremendous accuracy and for being significantly faster than traditional methods. The upgraded Form 3 has a number of improvements on the Form 2, including new LFS technologies and what Formlabs call a new Light Processing Unit which improves the surface finish of prints.

- The Formlabs 3B can also be purchased here / The Formlabs 3L can also be purchased here

The build volume hasn’t drastically increased in the newer Form 3 (just 10mm taller Z axis), but it now boasts incredible 25 micron accuracy. You can buy Formlabs resins, or there are a number of third-party resins compatible with the Form 3 which we’ve linked below.

- For Formlabs official resin: you can buy 1 liter here

- For third-party resins (may result in loss of quality of print): 1 liter here for significantly cheaper, or 500ml here

Best Professional FDM Printers

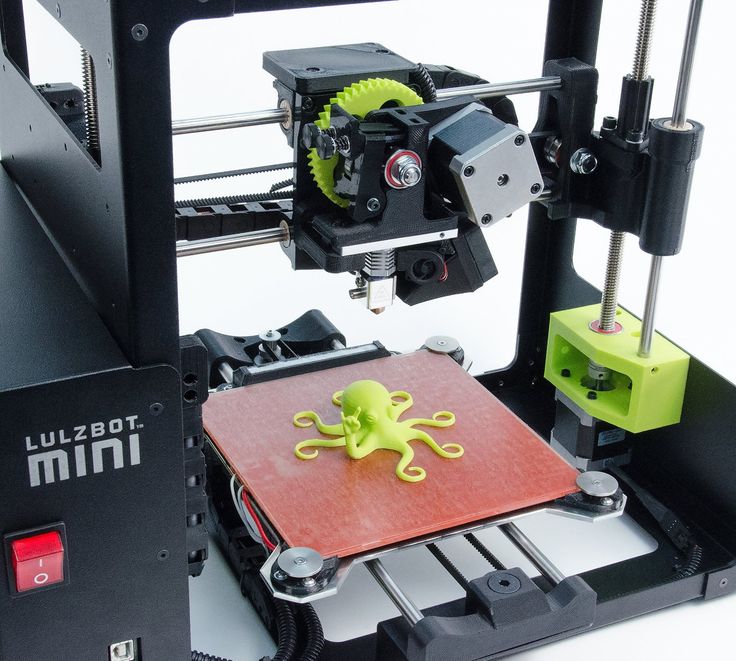

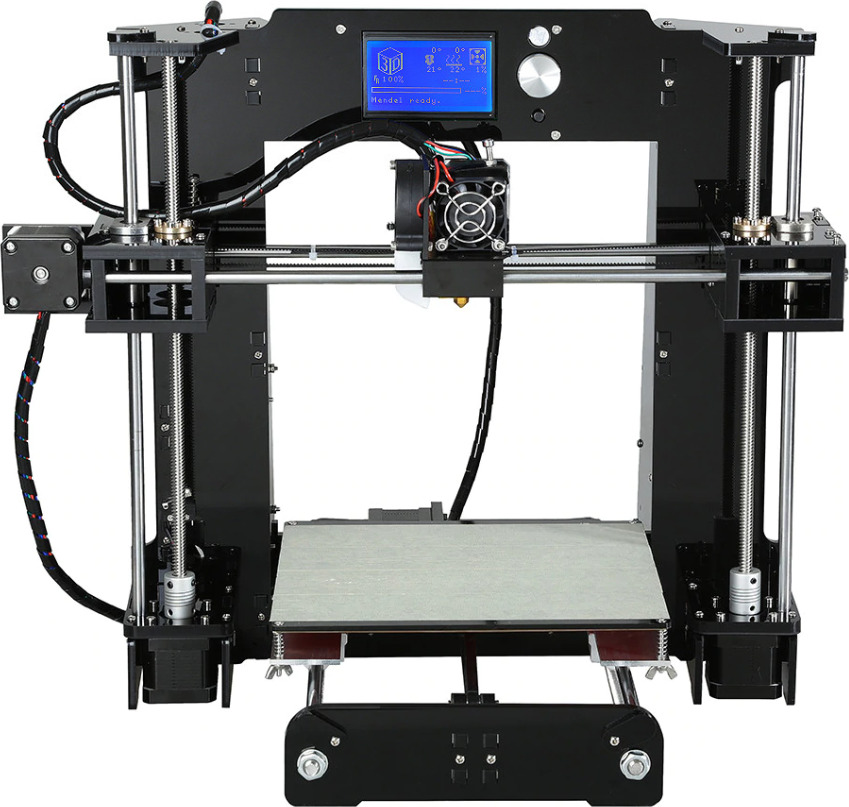

Ultimaker S3

- Price: $4,080 — Available on Dynamism Store here / Available on Matterhackers here

- Build volume: 230 x 190 x 200 mm

Dutch manufacturer Ultimaker have released some of the best 3D printers of the last few years. With a dual extruder and accuracy up to 20 microns, the Ultimaker S3 is a great 3D printer for rapid prototyping, and is used by small businesses, designers, and makers worldwide.

In addition, the Ultimaker S3 has a very decent 230 x 190 x 200 mm build volume, and includes a built-in camera for remotely monitoring your prints. You can connect to the printer via WiFi, USB or Ethernet very simply. Moreover, the Ultimaker S3 has an auto-leveling system for prints to make sure printing goes smoothly.

If you’re looking for the best 3D printer in terms of accuracy, ease of use, and equipment, and don’t mind spending upwards of $4,000, the Ultimaker S3 is the printer for you.

Ultimaker S5

- Price: $5,995 — Available on Dynamism Store here / Available on Matterhackers here

- Build volume: 330 x 240 x 300 mm

Compared with the excellent S3, the S5 is more expensive, moving away from the desktop 3D printer price range, but features a number of improvements and new features designed to make the Ultimaker S5 a more viable manufacturing method for prototypes and small batch production.

Featuring a larger 330 x 240 x 300 mm maximum build size, this is certainly an advantage over the Ultimaker 3. This makes it a better 3D printer for larger prototypes, shown as the Ultimaker S5 has already been used in companies such as Volkswagen. Ultimaker have earned a tremendous reputation over the years for creating great machines, and we feel the S5 is no different.

Buyer’s Guide – Things to Consider When Buying a 3D Printer

Which type of 3D printer do you want? And which materials do you want to print?

Different technologies do different things. For accurate minis for D&D, go for a resin 3D printer (MSLA / LCD) – they can print with much finer resolutions and smoother surface areas. But for a simpler setup and generally more relaxed experience (no curing, no chemicals) with stronger prints, go for an FDM printer.

Within this, you need to decide which material – filament or resin – best suits your needs.

For many PLA filament works just fine as it doesn’t really warp, doesn’t require a heated bed or enclosure (but is still good if you have the choice), comes in a wide variety of colors and blends (even conductive, or glow in the dark!), and it’s cheap.

ABS is tougher despite being just as cheap, and still comes in a wide range of colors – but it can warp and crack if not printed under the right conditions, and requires a heated bed and chamber. Some consider PETG to be a happy medium: it’s great for adhesion and super tough – but its stickiness makes it difficult to print overhangs and supports.

Some consider PETG to be a happy medium: it’s great for adhesion and super tough – but its stickiness makes it difficult to print overhangs and supports.

For resins, you don’t have the same range of options as you would with FDM, in materials or colors. There are a few color options, but most use standard resins – though companies like Formlabs have developed dental, jewelry casting, tough ABS-like resins, and a few other types.

What size models do you want to print?

Don’t waste your money on an enormous 3D printer if you just want to print miniatures, but also don’t skimp on a smaller machine if you want to print huge cosplay swords.

Think about what you want to print right now – and what you might want to print in the future. With good 3D printers starting in the $300 price range, it can be an expensive decision to get wrong. Also consider the size of your workspace – 3D printers are deceptively big and you need to make sure it’ll fit.

Also, resin 3D printers typically have smaller build volumes than FDM printers, so if size matters, go FDM.

What do you want to 3D print generally?

Beyond size, think about exactly what you want to 3D print for your projects. If you’re not as fussed about perfect quality, go for a printer with high top speeds (delta 3D printers are generally better for this) – especially if you’re printing cubes and similar shapes that don’t have details.

But, if you want high-resolution, pick printers that can handle lower layer heights and take smaller nozzle sizes – or resin printers with the most precise XY resolutions.

For high-temperature filaments, either get an enclosed 3D printer like the Creator Pro 2, or buy an enclosure for your printer – Creality sell their own enclosures, and there are popular DIY projects for the Prusa and other best-selling printers.

If you want to print PC, Nylon, carbon-fiber mixes, and other abrasive blends, you’ll need a printer with a hot end that can handle these temperatures – either go for a Prusa or higher-spec printer, or buy a hot end upgrade kit.

And if you want to print flexible filaments like TPU, opt for a 3D printer that’s either a direct drive 3D printer, or has a direct drive kit like the Ender 3 range – though while you can use a Bowden extruder, it requires a lot more oversight to prevent issues coming up.

Do you want an easy 3D printing experience?

While you shouldn’t be discouraged if you’re a beginner, we recommend you pick 3D printers with features such as auto-leveling, WiFi connectivity, filament run-out sensors and print resume functions, and easy-to-use software and touchscreens to save you hassle if you’re newer or less technical.

Self-leveling is a nice extra that saves you manually re-leveling the printer every few prints, and should guarantee you crisp prints rather than janky blemish-full messes.

WiFi connectivity saves you from taking SD cards back and forth from your laptop to your 3D printer for every print, and is generally a nice addition to have that boosts print productivity.

Filament run-out sensors and print resume features (in case of a power cut or similar) are fairly ubiquitous now – even most entry-level 3D printers have them. But they can be a lifesaver, especially if you lose power during the latter stages of a 24-hour or longer print of a large prototype or cosplay costume piece.

For easy-to-use software, Cura should have you covered for the slicer, but some 3D printers have more intuitive interfaces than others. Most now have touchscreens (though turnable knobs on printers like the Enders and Prusas are fine), and we particularly liked the Snapmaker’s easy-to-use touchscreen interface and design.

Go for a trusted brand and model if buying on the cheap side

There are hordes of low-cost 3D printers in the $160-$300 range. Most aren’t that reliable, and we recommend sticking with FDM kits like the Ender 3 range, Anycubic entry-level printers, and Elegoo or Anycubic resin printers for lower price printers that actually work well.

The last thing you want to do is get burned and left with an expensive brick. Opt for a highly-reputed printer with large communities and active forums, in case you run into trouble – we recommend these here.

Do you want to print in multiple colors?

For fully multi-colored prints – as in, colored by the pixel (or voxel in 3D) – you’re going to struggle. XYZ made a full-color 3D printer a few years back but the colors looked washed out and it cost $3,500.

But you can get multi-color prints from a few other ways. You can pick a dual extruder 3D printer and print with two colors, or use a filament splicer like a Palette to print with up to four different colors simultaneously.

Color options for resin LCD or MSLA printers are very limited, unfortunately. To get multi-color resin prints, you mostly need to rely on post-processing.

FAQs

Which are the best 3D printer brands?

The best 3D printer brands for low-cost printers include Creality, Prusa, Anycubic and Elegoo for FDM and LCD printers.

For mid-range 3D printers, Prusa make the fantastic i3 MK3S+, and other brands such as Flashforge, Dremel, Qidi Tech, Formlabs, Ultimaker, Makerbot and Raise3D are highly-reputed.

In professional ($10,000+ price ranges) 3D printing, brands like Markforged, Desktop Metal, Carbon 3D, Stratasys and 3D Systems are widely adopted.

Which is the best 3D printer right now?

The Ender 3 range (including V2 and S1) are some of the best 3D printers for FDM kits, with Anycubic’s Mono range and Elegoo Mars dominating the low-cost resin market.

Prusa 3D printers are some of the best 3D printers under $1,000, with brands like Ultimaker manufacturing some of the best prosumer 3D printers for small businesses and prototyping.

If you enjoyed this article, you may also enjoy:

- Our guide to the best 3D pens

- Our ranking of the best 3D scanners

- Our ranking of the best 3D printers for beginners

- Our ranking of the best SLS 3D printers

- Our ranking of the best FDM 3D printers

- Our ranking of the best resin 3D printers

- 3D printer deals

Top 20 Inexpensive 3D Printers ($199 to $1000)

3DPrintStory Reviews Top 20 Inexpensive 3D Printers ($199 to $1000)

Just 10 years ago, a 3D printer cost over $100,000. Today, you can easily find a cheap 3D printer for under $200. This is amazing.

Today, you can easily find a cheap 3D printer for under $200. This is amazing.

Naturally, the lower the price, the more restrictions. Some of the printers on our list will not have a heated bed and the workspace will be small. Naturally, the quality of most of the models presented below cannot compete with more expensive counterparts.

But with a little patience and diligence, it is quite possible to achieve high-quality 3D printing on a printer that costs half the price of a flagship smartphone. And it's really cool!

Important note : All 3D printers in this top are supplied assembled by the manufacturer. If you have free time and want to spend less money, you can buy DIY kits and assemble the 3D printer yourself according to the instructions.

List of the best cheap 3D printers in the price range from $ 200 to $ 1000

| 3D Printer | Material Material | Working space (mm) | Price | 459 |

|---|---|---|---|

| Flashforge Finder | PLA | 140 x 140 x 140 | 499 |

XYZPRINING DA vinci jr. 1.0 Pro 1.0 Pro | PLA | 150 x 150 x 150 | 499 |

| XYZprinting da Vinci Jr. Mix 2.0 | PLA | 150 x 150 x 150 | 599 |

| Printrbot Simple | |||

| Dremel Idea Builder | PLA | 230 x 150 x 140 | 899 |

| Printrbot Simple Pro | PLA | 200 x 150 x 200 | 999 |

| Prusa i3 MK2 | PLA, ABS, exotic | 250 x 210 x 20022 | |

In the article we are considering unfinished, but high -quality 3D printers from AM etc.

If you want to buy them, even if you live in large cities such as Kyiv, Moscow, St. Petersburg, Minsk, it may turn out that these models will not be in the online stores of your city, or they may be with a decent mark-up relative to the cost that indicated in the article.

Since most of them are European / American, it is possible that they will not be in stores at all.

Therefore, before making a choice, I recommend looking directly at eBay, Amazon, Aliexpress, etc. - many sellers on these planforms deliver to the CIS countries within 1-4 weeks on average.

It is especially worth monitoring these platforms during the discount period - Black Friday or Chinese New Year (Aliexpress or Gearbest) - prices on such days can be 2 or more times lower than usual and it is worth waiting for a few weeks.

Monoprice MP Select Mini ($199)

Probably the best 3D printer on our list. Why? Because the Monoprice MP Select Mini is an impressive development with a thoughtful, compact design at a very low price. This model has a quick-change steel material feed wheel, a cooler for cooling the nozzle, a color LCD screen, a heated table, plus the ability to transfer models for 3D printing via microSD or USB.

The heated bed and wide temperature range of the extruder are especially pleasing, because for such a small price you get the opportunity to print in different materials: from ABS B to PLA or exotic materials like conductive PLA plastic, wood, metal-based composites and PVA.

For those who are worried about the lack of a guarantee - for such a price it is possible without it. This model is upgradeable. For example, you can install a new nozzle, change the table and add WiFi connectivity.

Small working space - 120 x 120 x 120 mm. Over time, this will definitely not be enough for you.

Specifications of cheap 3D printer Monoprice MP Select Mini

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 120 x 120 x 120 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- 3D printing speed: 55 mm/s;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.75 mm;

- Control panel on 3D printer: yes;

- Connection: SD card, USB.

Back to the list of 3D printers

M3D Micro Retail ($249)

The M3D Micro 3D printer hit the market thanks to Kickstarter. This model was presented with an incredible price of $349.

This model was presented with an incredible price of $349.

The working space of the M3D Micro is 109 x 113 x 166 mm. There are several body color options. The company has implemented "Micro Motion Technology" - a set of innovative solutions - thanks to which you get excellent quality 3D printing at a small price.

Today, this inexpensive 3D printer already costs even less than the price announced on Kickstarter. You can buy it for $249 with a 12 month warranty. By the way, it is already possible to pre-order the next "pro" version.

Specifications of cheap 3D printer M3D Micro Retail

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 116 x 109 x 113 mm;

- Minimum layer height: 50 microns;

- Maximum layer height: 350 microns;

- Number of extruders: 1;

- XY accuracy: 15 microns;

- Open Source: no;

- 3D printing speed: 55 mm/s;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: no;

- Connection: USB.

Back to 3D printer list

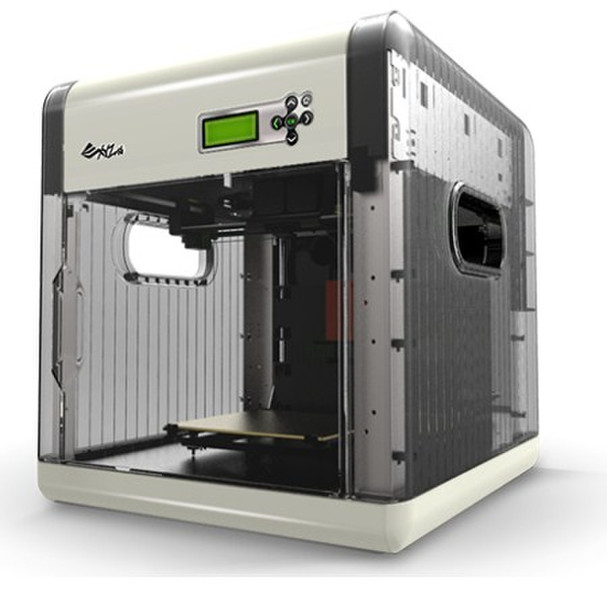

XYZprinting da Vinci Mini ($289)

Da Vinci Mini is a successful attempt to make the 3D printer user-friendly. This model has only one button and 5 multi-colored indicators that reflect the current status of 3D printing. In addition, this affordable 3D printer is WiFi capable so you can control it over a network in your home, office or lab.

Unfortunately, you can only use the manufacturer's own 3D materials. On average, they cost 20% more than usual. However, the company also argues that the materials used (PLA) will be 100% non-toxic.

Specifications of cheap 3D printer XYZprinting da Vinci Mini

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 150 x 150 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: no;

- Heated table: no;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: yes;

- Connection: USB, WiFi.

Back to 3D printer list

Monoprice Maker Select V2($299)

The next cheap 3D printer with a good reputation is the Monoprice Maker Select V2.

This model is an analogue of the Wanhao Duplicator i3, which, in turn, borrowed the design from the Prusa i3. But this does not affect the quality, as the Monoprice Maker Select V2 is easy to use and gives excellent 3D printing results.

Monoprice Maker Select V2 design feature is that the power supply and control panel are placed outside the 3D printer. The working space of this model is 200 x 200 x 180 mm. And this is really a good indicator for the money.

Specifications of cheap 3D printer Monoprice Maker Select V2

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 200 x 200 x 180 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: software;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: yes;

- Connection: USB, SD card.

Back to the list of 3D printers

New Matter MOD-t ($299)

New Matter is a young startup that offers a 3D printer MOD-t - An interesting design with a minimalistic design. This cheap 3D printer is WiFi enabled so you can manage print settings and print from your computer, tablet or smartphone. The working space is 150 x 150 x 125 mm. Thanks to the case, the noise during its operation is reduced. But the most interesting and attractive thing about MOD-t is the price. Only $299. In general, this is an interesting, high-quality model.

Specifications of cheap 3D printer New Matter MOD-t

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 100 x 125 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: no;

- Connection: USB, WiFi.

Back to the list of 3D printers

Printrbot Play ($399)

The Printbot Play is a very popular budget 3D printer that is often used in education. This inexpensive, reliable model, which is almost entirely made of metal.

The working space is 100 x 100 x 130 mm. Printbot Play has an extruder manufactured by the company itself - Alu Extruder v2. The body is made of powder coated steel and aluminium. SD slot provided.

You can upgrade the basic design of the Printrbot Play with a heated stand or increase the Y-axis stroke.

Back to 3D Printer List

Wanhao Duplicator i3 Plus ($459)

The Wanhao Duplicator i3 Plus is an upgraded version of the popular Wanhao Duplicator i3 (which in turn is based on the Prusa i3).

The main features of this cheap 3D printer are a large working space of 200 x 200 x 180 mm, a steel frame, electronics integrated into the design itself (previously it was taken out separately), a slot for a full-size SD card and a touchscreen display for control.

Wanhao Duplicator i3 Plus Cheap 3D Printer Specifications

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 200 x 200 x 180 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: design and software;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.75 mm;

- Control panel on 3D printer: yes;

- Connection: USB, SD card.

Back to the list of 3D printers

Flashforge Finder ($499)

FlashForge Finder is one of the newest 3D printers on our list. This affordable 3D printer offers an average working space of 140 x 140 x 140mm.

This Finder features a transparent sidewall design so you can view the 3D printing process from any angle. A color display is installed, it is possible to transfer data via WiFi network. The printer comes with some supplies and a USB flash drive, so you can start 3D printing almost immediately.

Specifications of cheap 3D printer FlashForge Finder

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 140 x 140 x 140 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- XY accuracy: 11 microns;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: yes;

- Connection: USB, WiFi.

Back to 3D printer list

XYZprinting da Vinci Jr. 1.0 Pro ($499)

What's so special about the da Vinci Jr. 1.0 pro? This is a new model from XYZPrinting, which includes many advanced features, such as support for printing materials from other manufacturers and increased speed of 3D printing.

Also features an auto-calibration mechanism, a closed chamber with a unique cooling system, and a 0.3mm nozzle option for high-quality printing of fine model details. All in all, this is a great 3D printer with a lot of useful features and at a low price.

Specifications for cheap 3D printer da Vinci Jr. 1.0 Pro

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 150 x 150 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: yes;

- Connection: USB, SD card.

Back to 3D printer list

XYZprinting da Vinci Jr. Mix 2.0 ($599)

XYZprinting provides a wide range of low cost 3D printers. And paying attention to each model is quite difficult, although many of them are very interesting.

XYZprinting da Vinci Jr. Mix 2.0 stands out because it can print with two different materials and mix them to create multi-colored models. This dual-color 3D printing technology is rare in this price range ($500 to $1,000), so if you're interested in experimenting with multicolor printing, XYZprinting da Vinci Jr. Mix 2.0 is a great choice.

However, there is a drawback. This 3D printer is not compatible with materials from other manufacturers, so you will have to buy special materials from XYZprinting (as we mentioned above, they cost 20% more, but are not toxic).

Specifications of cheap 3D printer XYZprinting da Vinci Jr.

Mix 2.0

Mix 2.0 - Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 150 x 150 mm;

- Minimum layer height: 200 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: no;

- Heated table: no;

- Nozzle diameter: 1.75 mm;

- Control panel on 3D printer: yes;

- Connection: USB, SD card, WiFi.

Back to 3D printer list

Printrbot Simple ($599)

Printrbot Simple is the flagship of the Printbot empire. This model has a great open design with a solid aluminum frame and a working space of 150 x 150 x 150mm. This inexpensive 3D printer comes fully assembled at a very good price. As you need and want to experiment, you can add a heated table and expand the workspace in the horizontal plane.

Specifications of cheap 3D printer Printrbot Simple

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 150 x 150 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- 3D printing speed: 80 mm/s;

- Open Source: design and software;

- Compatible with materials from other manufacturers: yes;

- Heated table: optional;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: no;

- Connection: USB.

Back to the list of 3D printers

UP mini 2 ($599)

The UP mini 2 is a low cost 3D printer that packs in impressive design and functionality. For starters, it has a touch screen panel and the ability to connect via WiFi.

But the most interesting is further. Implemented power failure protection system. 3D printing will continue after the emergency stop. Built-in HEPA air filtration system. Automatic detection of the height of the extruder nozzle. A separate, closed container for the material, thanks to which it does not deteriorate under the influence of moisture from the environment.

Great 3D printer for a small price. The only thing that upsets me a little is the small working space - 120 x 120 x 120 mm.

Specifications of cheap UP mini 2 3D printer

- Printer type: FDM;

- 3D printing materials: PLA, ABS;

- Working space: 120 x 120 x 120 mm;

- Minimum layer height: 150 microns;

- Maximum layer height: 350 microns;

- Number of extruders: 1;

- Open source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: yes;

- Connection: USB, WiFi.

Back to 3D Printer List

Monoprice Maker Select Ultimate ($699)

The Monoprice Maker Select Ultimate is an extraordinary beast that combines elements from two leaders in the world of 3D printing - Zortax and Ultimaker. The Monoprice Maker has an aluminum perforated printing table, which was offered in the Zortax M200 (thanks to this table, the grip of the base of the model with the table is much better), and the software part is almost identical to Ultimaker 2 (very user-friendly interface and functionality).

This model uses a "Bowden extruder", i.e. the feed units and nozzle are separated, unlike the direct feed. This improves reliability and reduces the likelihood of 3D printing errors (although, most likely, it was necessary to sacrifice printing speed, as the weight of the printing unit increases). Given the cost, this is a good model, the analogues of which are much more expensive.

Specifications of cheap UP mini 2 3D printer

- Printer type: FDM;

- 3D printing materials: PLA, ABS, exotic;

- Working space: 200 x 200 x 175 mm;

- Minimum layer height: 20 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.75 mm;

- Control panel on 3D printer: yes;

- Connection: USB, SD card.

Back to the list of 3D printers

Robo C2 ($799)

The Robo C2 is a small 3D printer with tons of connectivity options. Using a specialized application, you can monitor the status of 3D printing from your smartphone or tablet. It can be connected to a Chromebook. Thanks to the built-in slicing program, you do not need to install additional printing software.

Probably the most impressive is the integration with Amazon Alexa. Users can stop, cancel and check the status of 3D printing in real time using voice commands.

What does this inexpensive 3D printer offer? Working space 127 x 127 x 150 mm. The 3D printing speed is 300 mm/s and the resolution is 20 microns. There is a built-in 3.5'' color touch screen, a system for monitoring the amount of remaining material for printing, automatic calibration and a removable self-aligning print platform. The only drawback is that the table is not heated, so you have to use PLA plastic.

Specifications of cheap 3D printer Robo C2

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 127 x 127 x 150 mm;

- Minimum layer height: 20 microns;

- Number of extruders: 1;

- Open Source: software;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.75 mm;

- Control panel on 3D printer: yes;

- Connection: USB, WiFi.

Back to the list of 3D printers

Wanhao Duplicator 4S ($829)

The Duplicator 4S has 2 extruders. It's essentially a copy of the MakerBot Replicator. Behind the steel body is the MK10 material feed mechanism, which is currently the easiest to use and most sought after in the market for 3D printer components.

It's essentially a copy of the MakerBot Replicator. Behind the steel body is the MK10 material feed mechanism, which is currently the easiest to use and most sought after in the market for 3D printer components.

One of the features of this model is a high-precision material feed wheel, which ensures the same filament feed speed. The Duplicator 4S is equipped with a 0.4mm precision nozzle.

Specifications of cheap 3D printer Duplicator 4S

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 225 x 145 x 150 mm;

- Minimum layer height: 100 microns;

- Maximum layer height: 500 microns;

- Number of extruders: 2;

- XY accuracy: 11 microns;

- 3D printing speed: 40 mm/s;

- Open Source: software;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 0.4 mm;

- Control panel on 3D printer: yes;

- Connection: USB, SD card.

Back to the list of 3D printers

Polar 3D Printer ($899)

Polar 3D belongs to a separate category of 3D printers in this top, since this model implements the polar coordinate system. This causes the table to rotate and the print head to move up, down, right, and left.

Thanks to the polar coordinate system, this 3D printer is powered by two stepper motors, so it consumes less power. In addition, it turned out to realize a larger size of the working area: 203 (table diameter) x 152 (Z coordinate) mm.

Nominal price $899, but there are special discounts for educational institutions. The discounted price is only $599.

Specifications of cheap 3D printer Polar 3D

- Printer type: FDM;

- Materials for 3D printing: PLA;

- Working space: 203 (table diameter) x 152 (Z-coordinate) mm;

- Minimum layer height: 50 microns;

- Maximum layer height: 400 microns;

- Number of extruders: 1;

- 3D printing speed: 40 mm/s;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: no;

- Connection: USB, WiFi, SD card.

Back to 3D printer list

FlashForge Creator Pro ($899)

You've probably heard of this 3D printer. FlashForge Creator Pro is very similar to Makerbot Replicator 2X. This inexpensive 3D printer has 2 extruders, it has a steel closed case.

Other features include a table sizing system, and a guide screw that makes the guide system more stable and durable. The design is nothing special, but this model has earned positive reviews from the 3D community due to its reliability, versatility and ease of use.

Specifications of cheap 3D printer FlashForge Creator Pro

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 225 x 145 x 150 mm;

- Minimum layer height: 100 microns;

- Maximum layer height: 500 microns;

- Number of extruders: 2;

- XY accuracy: 11 microns;

- 3D printing speed: 40-100 mm/s;

- Open Source: design and software;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: yes;

- Connection: USB, SD card.

Back to 3D Printer List

Dremel Idea Builder ($899)

The Idea Builder is plug and play. This 3D printer is designed by Dremel. It has a color touch screen display. Sufficiently large working space - 230 x 150 x 140 mm. Unfortunately, the table is not heated. On the other hand, since only PLA plastics can be used, this model is great for classrooms and teaching labs.

Specifications of cheap 3D printer Dremel Idea Builder

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 230 x 150 x 140 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;