3D printing groningen

3D Printing Service Groningen | Instant Quotes Online

Our 3D printing capabilities

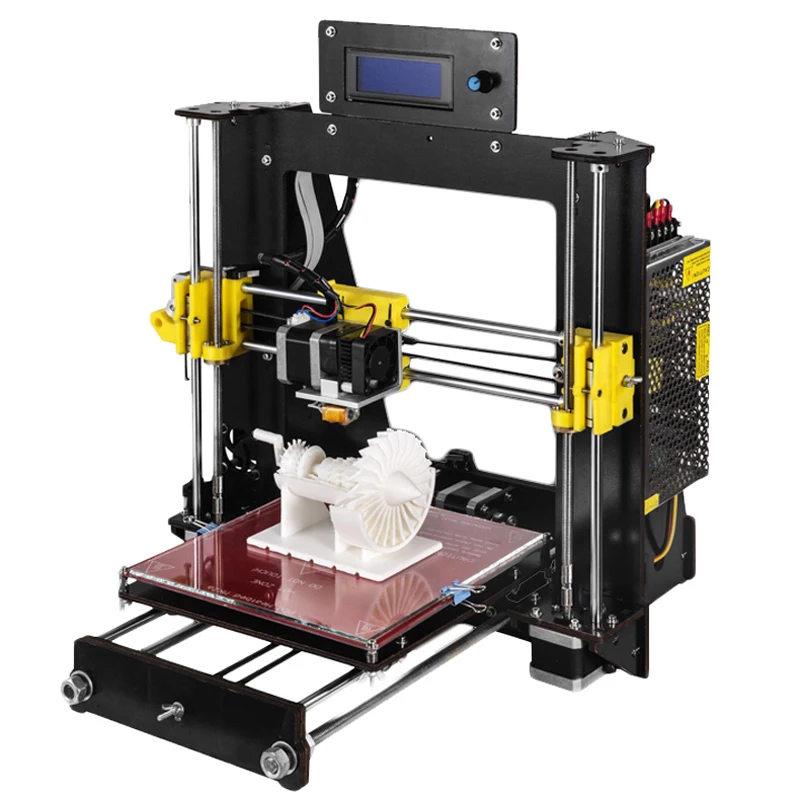

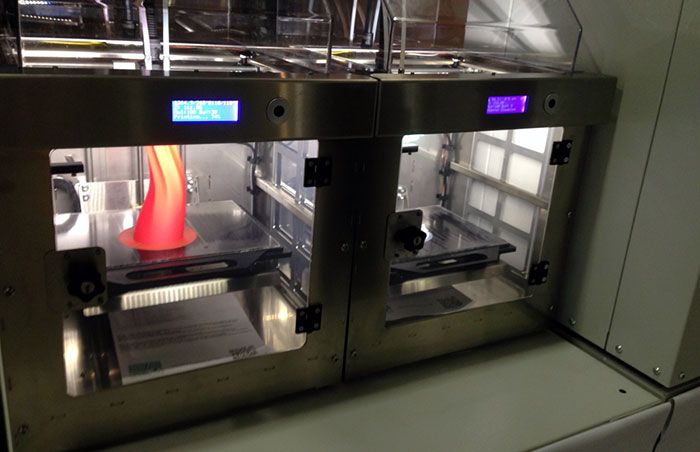

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

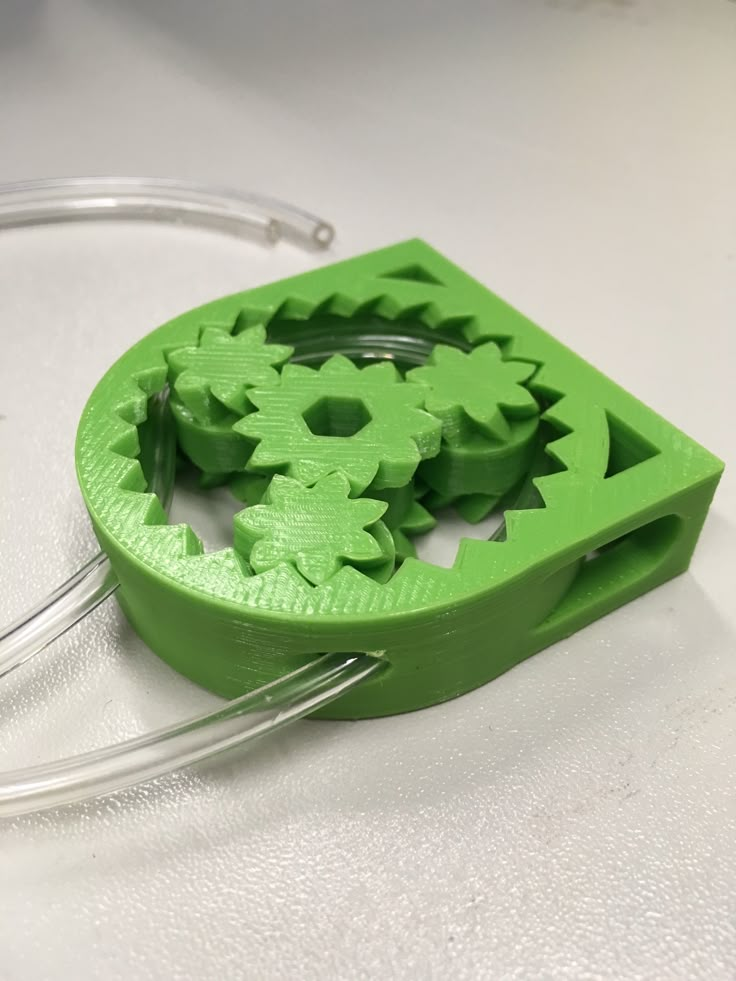

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

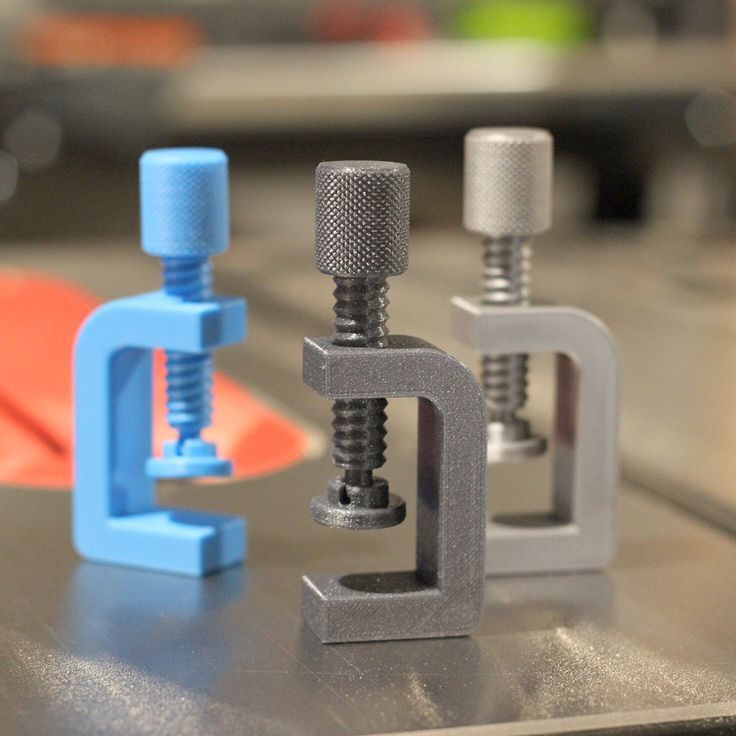

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc.

.

. -

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.9/5

Over 237 customers are satisfied with our 3D printing service.

“Great 3d printing for a low price. Highly recommended.”

“The prints fit perfectly as replacement parts. ”

“Duidelijke communicatie, zeer snelle oplevering van het project en goede kwaliteit. Zeer tevreden en voor toekomstige projecten zal ik zeker weer deze service gebruiken. ”

“Once again, perfect! Thank you very much!”

“Realy great and helpful. My stl file consists out of multiple parts. (I was not aware of that) So it was more work, then expected but I got it quick and great quality.”

“Good quality prints. After order was already placed it was possible to change a color of an orderded part. Very good service!”

“Extremely well printed. There was a Bug in my Design but the Seller tried to print it more times. very fast communication good service and extremely well printed. Thanks A lot, i will be coming back for other projects!”

“Great print, thanks for re-doing it (second part). After some mild sanding to get rid of some rough edges I slotted the part into place and it worked excellently. ”

”

“The supplier was communicative and helpful!”

“As expected. Leaflet with extra info over material included. Received part before predicted delivery date”

“Great service. They were fast in communication and with the delivery of the model. The model was smooth and detailed. I will surely work with their service more often.”

“Sehr guter und kompetenter Service! Nur zu empfehlen.”

“Best 3dhub I have used yet. Fast communication, fast printing and the guy really knows what he is doing. His services sure is worth the money.”

“super dit! mijn eerste keer dat ik iets laat 3D printen maar het gaat echt heel makkelijk en snel. ga ik zeker vaker doen!”

“Excelent service as allways, hub reprinted my model at better settings when they found that the resulting part wasn't sturdy enough. To me that shows a keen eye for and a strong dedication to delivering quality!”

“I've ordered self designed Parts that were used as edge protection. We needed the parts soft and flexible so we ordered these in tpu. Parts arrived our site and were like we expected. would definitely order again.”

Parts arrived our site and were like we expected. would definitely order again.”

“Thanks! Delivery was fast and print as expected. Color matches my car's dashboard perfectly. ”

“Fast and very good work. Thank you very much!”

“Schon das zweite mal bestellt, alles bestens! :)”

“Binnen één uur zelfs aan de deur afgeleverd”

“( Dutch below) Very high print-quality, amazing finish and very competing price, and the communication / flexibility of the handler was very customer-success oriented. -- Erg hoge printkwaliteit, mooie afwerking, goede prijs, en communcatie vanuit owner was just great, keeping me in the loop regarding planning.”

“Easy to do business with, good communication, fast delivery and perfect quality. Recommended!”

“Great first experience with 3D printing for me. Next time I need something printed I know who to go to! :) ”

“Again great job. If you need parts quickly and good quality.? ”

“Nice print, in less than 24 hours (I picked it up). ”

”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near Groningen

Emden Assen Groningen

Hoogeveen Hengelo Enschede

Zwolle Deventer Münster

Oldenburg

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

3D Printing Service Near You

44 3D Printing Services are currently ready to take your order and deliver custom parts to Groningen, Groningen, Netherlands. Through our platform, you can order 3D printed prototypes, replacement parts and many other custom projects without any minimal size or quantity requirements. If you have an idea of what technology, material or application suits your order, use filters to narrow down the search. You can also explore vendors’ portfolios with printed examples and customer ratings for a full perspective on their experience with different types of parts.

Through our platform, you can order 3D printed prototypes, replacement parts and many other custom projects without any minimal size or quantity requirements. If you have an idea of what technology, material or application suits your order, use filters to narrow down the search. You can also explore vendors’ portfolios with printed examples and customer ratings for a full perspective on their experience with different types of parts.

Sort byDistanceLowest PriceBest Rating

Category

Location

International

Technology

AnyAnyfdmslsslalpddup

Product Application

AnyAnyPrototypeHD PrototypeJewelryDentalMulti-colorMetalMiniatures

MaterialSelect allUnselect all

(taulman) PCTPE3D Color-inkjet PLA8K Resin304 Stainless Steel316L Steel PlasticA2 Tool SteelABSABS+ABS-CFABS-ESD7 (Static dissipative)ABS-M30ABS-RABS-like ResinABSiASAASA-CFAccura ClearVueAccura e-StoneAgilusAlumideAluminaAlumina ZirconiaAluminium AlSi10MgAluminium Alloy AlSi12Aluminium NitrideAluminum PLAAmphora HT5300Antero 800NA (PEKK)Antero 840CN03 (PEKK-ESD)Anti-Microbial PLA (Purement)Bio-based TPUBio-compatible (MED610)BioMed-ResinBiocompatible ABS (ABS-M30i)Biocompatible PC (PC-ISO)BlueCast CR3ABlueCast LSBlueCast OriginalBlueCast X-FiligreeBlueCast X-OneBlueCast X5BlueCast X10Brass PLABrick PLABronze PLACF-TPUCPE (co-polyester)CPE+Carbon FiberCastForm PSCastable ResinCastable Wax 40 ResinCeramic FilamentCeramic ResinChameleon PLA (Thermochromic)ClearBiomedResinCobalt-Chrome (CoCr)Color-Blending PLAColorFabb XT CF20 (PET-G)Color KitColorfabb HTConductive PLACopperCopper PLACordieriteCrystalFlex (SBR)Cyanate Ester (CE)D2 Tool SteelDURABIODental LT ResinDental Non-Castable ResinDental SG ResinDigital ABSDraft ResinDuraForm EXDuraForm FlexDuraForm GFDuraForm HSTDuraForm PA PlasticDuraForm® ProX™ PA PlasticDurable (PP-like) ResinDurusE-GumEPU 40 (polyurethane elastomer)ESD-Safe PCESD-Safe PETGESD-Safe PLAESD-Safe PVDFESD-safe PEKKElastic Resin (Soft and flexible)Elixir PLA (Extra Shiny)FLEX (Elastic TPE)FPU 50 (Flexible Polyurethane)FR-ABS (Flame Retardant)FabProElasticFabProFlexibleFabPro JewelCastFabProProtoFabProToughFiberglassFlexfill 98A TPUFlexible ResinFoaming PLAFormfutura ApolloXFormfutura FlexiFilFormfutura TitanXFull-color plastic (VisiJet C4 Spectrum)Full-color sandstone (VisiJet PXL)Fused SilicaGlass-reinforced NylonGlass-reinforced ResinGreen-TECGreen-TEC Pro CarbonGreen-TecProGrey Pro Resinh23 Tool SteelHD GlassHIPSHPLA-CFHP PA-12HSHT FiberglassHTPET+Heat Treatable PLA (HTPLA)High Reactive ResinHigh Temp ResinHigh Temperature (RGD525)HydroxyapatiteIglidur I150Impact PLAInconel 625 Ni625Inconel 718Innofil Pro1Jewelry Wax (Solidscape 3Z Model)Kevlar-reinforced nylon LaserForm A6LaserForm Ni718LaserForm™ Ti Gr. 1²LaserForm™ Ti Gr. 5²LaserForm™ Ti Gr. 23²Liqcreate Clear ImpactLiqcreate Composite-XLiqcreate Flexible-XLiqcreate Strong-XLiqcreate Tough-XMagnetic Iron PLAMaraging SteelMarble PETGMarble PLAMatte Fiber HTPLAMatte PLANanoceramic ResinNonOilenNylonNylon-CFNylon 6/69Nylon GF30OnyxOnyx ESDOnyx FROnyx FR-APA-12 with Glass BeadsPA-CFPA11 NylonPA12 NylonPA 2200PA Cast NylonPC-ABSPC-ABS with Carbon FiberPC-ASAPC-CFPC-PBTPCTGPEEKPEEK-CFPEI-CFPEKKPETPET-CFPETG PETG (Recycled)PETG-CFPETG MattePETT (T-glass)PLAPLA+PLA++PLA-CFPLA-RecycledPLA/PHAPLA 3D870 (APLA)PLA FlexPLA NX-2PLATECPOM (Delrin)PP-CFPPSF/PPSU (Heat and chemical resistant)PRO HSPRO HTPSUPVAPVDF (PolyvinylideneFluoride)PaperPolyCastPolyMax PLAPolySmooth™ (PVB)PolyamidePolycarbonate (PC)PolyphenyleneSulfidePolypropele-GF-30PolypropylenePrecise PLAPrintaMent PURE (matt)Raptor PLAResinRigid 10K ResinRigid 4000 ResinRigid Polyurethane (RPU)Rigid opaque ResinRigurRiziumSTRubber-like (TPU)Rubber-like ResinSBSST-130Silicon NitrideSilicone ResinSilicoreSomos 201Somos EvoLVe 128Somos NeXtSomos WaterShed XC 11122Stainless Steel 17-4 PHStainless Steel 316LStainless Steel 420 Bronze InfusedStandard acrylic ResinSteel PETGStoneFil PLAStrong ResinTPCTPE SEBS 95ATPU 60DTPU 70DTPU 95ATPU Shore 45-56 ATPU Shore 79ATPU powderTR250 ResinTango (Rubber-like material)Titanium (Ti6Al4V)Titanium Ti64Tough3000Tough PLATough ResinTranslucent RigidTricalcium PhosphateTungsten Fill PLAULTEM(PEI) 1010 CGULTEM(PEI) 9085 CGUV Color Сhanging PLAUltem (PEI) 1010Ultem (PEI) 9085Urethane Methacrylate (UMA)VeroVisiJet CE-BKVisiJet CE ElastomericVisiJet CR-CLVisiJet CR-WTVisiJet FTX CastVisiJet FTX resinVisiJet M2 ElastomericVisiJet M2 RigidVisiJet M3VisiJet M3 DentcastVisiJet M5VisiJet SL ClearVisiJet SL e-StoneVisiJet® EX200VisiJet® HR200VisiJet® SR200Visijet CE-NTVisijet CF-BKWaterClear ResinWax-like ResinWax Filament (MoldLay)Wood PLAZ-ABSZ-ASA ProZ-ESDZ-GLASSZ-HIPSZ-PCABSZ-PETGZ-PLAZ-PLA ProZ-ULTRATZirconia 3YZirconia 8YZortrax Basic ResinZortrax Resin PRObronzeFill - PLA/PHA + fine bronze colorFabb-XT (Amphora AM1800)copperFill - PLA/PHA + fine copper corkFill - PLA/PHA + fine cork fibrecoPLAiglidur I180nGen-CFnGen Amphora AM3300 (PET-G)nGen FLEXwoodFill - PLA/PHA + fine pinewood zp130 Powder

1²LaserForm™ Ti Gr. 5²LaserForm™ Ti Gr. 23²Liqcreate Clear ImpactLiqcreate Composite-XLiqcreate Flexible-XLiqcreate Strong-XLiqcreate Tough-XMagnetic Iron PLAMaraging SteelMarble PETGMarble PLAMatte Fiber HTPLAMatte PLANanoceramic ResinNonOilenNylonNylon-CFNylon 6/69Nylon GF30OnyxOnyx ESDOnyx FROnyx FR-APA-12 with Glass BeadsPA-CFPA11 NylonPA12 NylonPA 2200PA Cast NylonPC-ABSPC-ABS with Carbon FiberPC-ASAPC-CFPC-PBTPCTGPEEKPEEK-CFPEI-CFPEKKPETPET-CFPETG PETG (Recycled)PETG-CFPETG MattePETT (T-glass)PLAPLA+PLA++PLA-CFPLA-RecycledPLA/PHAPLA 3D870 (APLA)PLA FlexPLA NX-2PLATECPOM (Delrin)PP-CFPPSF/PPSU (Heat and chemical resistant)PRO HSPRO HTPSUPVAPVDF (PolyvinylideneFluoride)PaperPolyCastPolyMax PLAPolySmooth™ (PVB)PolyamidePolycarbonate (PC)PolyphenyleneSulfidePolypropele-GF-30PolypropylenePrecise PLAPrintaMent PURE (matt)Raptor PLAResinRigid 10K ResinRigid 4000 ResinRigid Polyurethane (RPU)Rigid opaque ResinRigurRiziumSTRubber-like (TPU)Rubber-like ResinSBSST-130Silicon NitrideSilicone ResinSilicoreSomos 201Somos EvoLVe 128Somos NeXtSomos WaterShed XC 11122Stainless Steel 17-4 PHStainless Steel 316LStainless Steel 420 Bronze InfusedStandard acrylic ResinSteel PETGStoneFil PLAStrong ResinTPCTPE SEBS 95ATPU 60DTPU 70DTPU 95ATPU Shore 45-56 ATPU Shore 79ATPU powderTR250 ResinTango (Rubber-like material)Titanium (Ti6Al4V)Titanium Ti64Tough3000Tough PLATough ResinTranslucent RigidTricalcium PhosphateTungsten Fill PLAULTEM(PEI) 1010 CGULTEM(PEI) 9085 CGUV Color Сhanging PLAUltem (PEI) 1010Ultem (PEI) 9085Urethane Methacrylate (UMA)VeroVisiJet CE-BKVisiJet CE ElastomericVisiJet CR-CLVisiJet CR-WTVisiJet FTX CastVisiJet FTX resinVisiJet M2 ElastomericVisiJet M2 RigidVisiJet M3VisiJet M3 DentcastVisiJet M5VisiJet SL ClearVisiJet SL e-StoneVisiJet® EX200VisiJet® HR200VisiJet® SR200Visijet CE-NTVisijet CF-BKWaterClear ResinWax-like ResinWax Filament (MoldLay)Wood PLAZ-ABSZ-ASA ProZ-ESDZ-GLASSZ-HIPSZ-PCABSZ-PETGZ-PLAZ-PLA ProZ-ULTRATZirconia 3YZirconia 8YZortrax Basic ResinZortrax Resin PRObronzeFill - PLA/PHA + fine bronze colorFabb-XT (Amphora AM1800)copperFill - PLA/PHA + fine copper corkFill - PLA/PHA + fine cork fibrecoPLAiglidur I180nGen-CFnGen Amphora AM3300 (PET-G)nGen FLEXwoodFill - PLA/PHA + fine pinewood zp130 Powder

Sort by

AnyDistanceLowest PriceBest Rating

Upload files to compare instant quotes from local 3D printing services

Upload filesor contact us directly to get a volume discount.

If you’re looking to get something 3D printed and delivered to Groningen, Groningen, Netherlands, you’re in the right place. All companies that provide prototyping and printing near you are listed above.

How much does it cost to 3D print my parts?

To check out the pricing instantly, choose a vendor and hit the “Instant order” button. From a 3D model file such as STL, PLY, OBJ or 3MF we are able to calculate the price automatically. If you aren’t sure which vendor to choose, you can “Get instant quote” at the very bottom of the page with the list of all available 3D printing bureaus.

What if I don’t have a 3D file?

3D printing starts from a model, so it is necessary to have a file. Fortunately, many companies that provide additive manufacturing can help you design the parts. For more complex modeling tasks, consider hiring a professional 3D designer.

How do I choose a vendor?

Treatstock aims for transparent workflow between 3D printing companies and customers for great results. To make sure you have all the information needed to choose your manufacturing partner, we include a list of vendor’s machines and customer ratings for each service provider. The full list of their capabilities is included on their business page as well.

To make sure you have all the information needed to choose your manufacturing partner, we include a list of vendor’s machines and customer ratings for each service provider. The full list of their capabilities is included on their business page as well.

How does it work?

- Upload a 3D file to instant order;

- Select specifications and fill in the delivery details;

- Finalize the order process;

- Monitor progress in your Purchases;

- Get your custom parts delivered to your door.

Our support team is always available for assistance. To learn more about 3D printing technologies, visit our manufacturing guide. And the material guides will help you find out more about all available manufacturing mediums.

Printing locations

- Amsterdam

- Utrecht

- Maastricht

- Delft

- Rotterdam

Product Application

- Prototype

- HD Prototype

- Jewelry

- Dental

- Multi-color

- Metal

- Miniatures

Materials

- PLA

- ABS

- Nylon

- Wood PLA

- ASA

- Resin

- Rubber-like (TPU)

- PA12 Nylon

- PETG

Technology

- FDM (Fused Deposition Modeling)

- DMLS (Direct Metal Laser Sintering)

- SLS (Selective Laser Sintering)

- PolyJet and PolyJetMatrix

- SLA (Stereolithography)

- CJP (ColorJet Printing)

- DLP (Digital Light Processing)

- DUP (LCD-based Direct UV Printing)

Our site uses cookies. By continuing to use our site you are agreeing to our Privacy Policy

By continuing to use our site you are agreeing to our Privacy Policy

or

Forgot password?

Remember Me

By using this Service, you agree to our Terms and that you have read our Privacy Policy, including our Cookie use.

Digital Print Pioneer • Interior+Design

Design

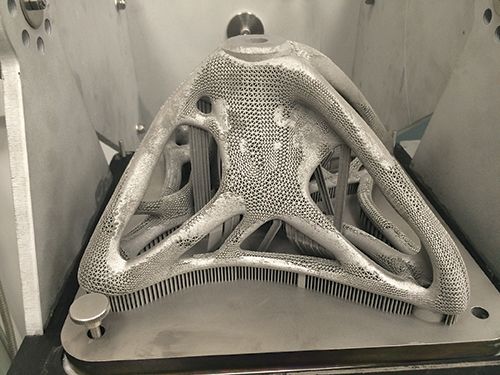

Joris Laarman (b. 1979) belongs to a new generation of experiential designers. Their weapon is technology, their goal is to design the future. By changing materials and making things more difficult, Larman and his studio tinker with artisans, bring in scientists, and deal with engineers to perfect the product. The hobby of Joris Larman is 3D printing and robotic metal printing using manual labor. The work is very diverse - from one-of-a-kind furniture to museum installations, films and master classes at universities around the world.

3D printed Makerchairs series.

Joris Laarman Lab was born in 2004 with the help of documentary filmmaker Anita Star. Anita and Joris grew up in the Dutch countryside and built their own careers. Larman graduated summa cum laude from the Eindhoven Design Academy in 2003, becoming famous for his famous Heatwave project, an openwork radiator published by Droogdesign (today manufactured by Jaga). Vitra and Flos soon became clients of the young studio Joris Laarman Lab. In 2011, the Wall Street Journal named Joris Larman Design Innovator of the Year. Interest in digital printing led to a series of classes with students from the famous Architectural Association in London, the Rietveld Academy in Amsterdam, and at his alma mater, the Design Academy in Eindhoven.

Nebula ceiling light for Flos.

In 2015, in collaboration with MX3D, Joris built a bridge in Amsterdam: the most complex rigid metal structures were bent by robots. Using the same method, he created an aluminum chair and an incredible bronze butterfly screen. A monolithic piece of metal turns into a porous form like a sponge, as if woven from the smallest molecules. The elements are combined with each other using laser sintering technology, which allows to achieve the strength of the seat. “In 2014, we put a welding machine on a manipulator. This was just the beginning - then we could create an object just two centimeters from the floor, ”says the designer. — The Butterfly screen is already a two-meter object. Sells screen New York Friedman Benda Gallery.

A monolithic piece of metal turns into a porous form like a sponge, as if woven from the smallest molecules. The elements are combined with each other using laser sintering technology, which allows to achieve the strength of the seat. “In 2014, we put a welding machine on a manipulator. This was just the beginning - then we could create an object just two centimeters from the floor, ”says the designer. — The Butterfly screen is already a two-meter object. Sells screen New York Friedman Benda Gallery.

“I strongly believe in the future of both digital manufacturing and local crafts”

Heat wave radiator. Droogdesign/Jaga. 2003.

Bookshelf Branch. 2010. Design Museum Groningen, The Netherlands.

Table Bone. 2010. Aluminum.

Vortex rack. Aluminum.

Chair Aluminum Gradient. From the collection of the Vitra Design Museum.

From the collection of the Vitra Design Museum.

Chair Aluminum Gradient. Fragment. From the collection of the Vitra Design Museum.

Forest table. Kukje Gallery, Korea.

Starlings table. From the collection of the Museum of Decorative Arts, Paris, France.

Joris Laarman Lab's groundbreaking works are widely acclaimed, exhibited in many exhibitions around the world, and can be found in the permanent collections of more than 30 major international museums, including the Museum of Modern Art in New York, the Georges Pompidou Center in Paris and Rijksmuseum in Amsterdam.

Author:

Natalya Timasheva

Photo:

provided by the press service of the designershare:

FB TW OK

#Museum of decorative art (Musée des Arts Décratifs)

#Design Academy Eindhoven

#Netherlands

#designer

#Joris Laarman

#3D printing

#Name

#Musee des Arts décoratifs

#Academy of Design in Eindhoven (Design Academy Eindhoven)

#Netherlands

#Designer

#Joris Larman)

#3D-PEACH

#Name : smart carrycot Snoo Yves Beara

Design Now Design NowAmazing things that can be printed on a 3D printer - Articles - Arrivo

"What we need to build a house - draw, we will live" - today this phrase has become a reality. Everyone is happy with the progress in 3D printing: archaeologists are copying mummies, NASA specialists are growing artificial meat, birds are moving into high-tech birdhouses, and designers are bringing to life the most daring shoes that girls have ever worn. We offer you to get acquainted with the latest innovations and trends in 3D printing.

Everyone is happy with the progress in 3D printing: archaeologists are copying mummies, NASA specialists are growing artificial meat, birds are moving into high-tech birdhouses, and designers are bringing to life the most daring shoes that girls have ever worn. We offer you to get acquainted with the latest innovations and trends in 3D printing.

Pistol

Owners of 3D printers can get their hands on a weapon by downloading a few files from the Defense Distributed website. The printed pistols look like weapons from science fiction films, but are not yet as reliable as real ones. However, progress does not stand still - last year, Solid Concepts printed the world's first 3D metal gun.

SLR camera

French designer Leo Marius managed to print a SLR camera. The author of the invention did not fail to share it with the world - today anyone who does not spare $30 to download files from Marius' website and 15 hours to assemble the camera can become the owner of the unique Open Reflex "reflex camera".

Marius did not dare to create a 3D printed lens, and the Japanese Yuki Suzuki was not afraid of this either. He made the lens out of clear acrylic. The pictures taken on this camera can hardly be called high-quality, but Suzuki did not seek to please the capricious fans of Canons and Nikons - he was primarily guided by scientific interest.

Waterproof bikini and futuristic shoes

Advanced designers have also learned how to customize the 3D printer to suit their needs. Special software today allows you to quickly make clothes, taking into account the individual parameters of a person. Using new technologies, designers from Continuum, for example, have already managed to create a waterproof nylon bikini.

It is quite possible that 3D outfits will soon become a trend, but so far only celebrities risk flaunting futuristic dresses, and even then very extravagant ones.

Last year, Lady Gaga appeared in public in a black dress printed on a 3D printer by Materialize. Flashed in a printed dress and "Queen of Burlesque" Dita Von Teese. At the same time, the dress for Dita was made according to the drawings of the medieval mathematician Fibonacci and consisted of 17 different parts.

Flashed in a printed dress and "Queen of Burlesque" Dita Von Teese. At the same time, the dress for Dita was made according to the drawings of the medieval mathematician Fibonacci and consisted of 17 different parts.

Designers have not forgotten about the part of the wardrobe so beloved by women, like shoes - in this genre, a 3D printer can work real miracles. For example, Sebastian Errazuriz printed a unique collection called "12 Shoes for 12 Lovers", dedicated to his apparently difficult relationships with women. Among the gems of the collection are shoes called "Gold Digger Allison", "Snow Queen Sofia", "Soldier Jane Barbara" and "Crybaby Alexander".

Sweets

Replacing traditional plastic cartridges with melted chocolate, you can create endless possibilities for creating desserts. Chocedge has created exclusive 3D printers that can print any pattern in chocolate, including your own photo. If chocolate is too traditional for you, you can try unusual sweets from Cubify.

Meanwhile, Modern Meadow is hard at work building a printer that can print a steak. To do this, scientists use sophisticated technology, including the cultivation of stem cells.

The 3D printed food project is being funded by the space agency NASA, which believes it will be possible to feed astronauts in this way in the near future.

Researchers also assure that the day is not far off when modern technologies will allow even pizza to be printed. To do this, they say, it is simply necessary to increase the number of cartridges in the printer by adding dough, cheese and other necessary ingredients.

The rights to this article belong to arrivo.ru.

Acoustic guitar

The world's first 3D printed acoustic guitar was Scott Summit, who claims that his creation is even superior to hand-assembled instruments. New Zealander Olaf Digel followed in his footsteps, creating a whole line of so-called ODD guitars, among which there is even an instrument in the form of a web with spiders crawling inside.

3D printing is not limited to guitars. So, an employee of the MIT Media Lab, Amit Zoran, managed to print a real flute, and the German company EOS created a 3D model of a violin based on a polymer. But innovative instruments still sound much worse than traditional ones.

James Bond car

The creators of the latest James Bond film, Skyfall Coordinates, regretted actually blowing up the legendary 1960 Aston Martin DB5 special agent car, and printed a 1:3 scaled down version of it on a 3D printer.

It is the 3D printed version that explodes on the screen at the climax of the film.

A complete car can also be printed on a 3D printer. This is how all 50 parts of Urbee 2 were created, which is capable of accelerating to 112 km / h and driving up to 64 km on electric power alone. At the same time, the streamlined body of the machine significantly reduces fuel consumption. In 2015, the creators of the hybrid are going to drive more than 4,000 km on it, spending only 38 liters of fuel.

Prostheses and human organs

In 2011, Richard Wang, who lost 4 fingers while working in the workshop, 3D printed his own prosthesis. Subsequently, Richard began to design prosthetic hands called Robohand and even created the world's first 3D prosthetic laboratory in Sudan, where he helps disabled children.

The use of 3D printers in medicine promises to become even more useful over time - Chinese scientists have already learned how to print prototypes of human organs. True, they “live” for no more than 4 months and are devoid of blood vessels. However, according to researchers, it will be possible to “print” full-fledged organs in 15-20 years.

Turntable

Amanda Gassey created a turntable using a 3D printer. You can't listen to classic vinyl records on it, but Amanda also came up with a special program that converts any sound file into 3D format. The sound quality of such records leaves much to be desired, so the creation can be considered rather as a design refinement.

Bicycle

Why reinvent the wheel - it's better to print it on a 3D printer, EADS decided. The AirBike created in this way impresses with its characteristics. Firstly, it is 65% lighter than its classic aluminum counterparts, and secondly, it is no less durable than them.

Birdhouse

Coming into contact with such a brilliant creation of our time as a 3D printer, one cannot help but share it with the smaller brothers. Recently, MakerBot held a competition for the best printed birdhouse. The owners of 3D printers did not stint on ideas for birdhouses: many creations were sent to the competition in all possible styles - from classic to high-tech. The winner was Eric Darwoodle, who built a real cozy villa for some lucky bird.

Lamp

Thanks to the development of Materialize, everyone can create their own unique lamp. If you do not believe in your design abilities, you can simply choose one of the copies available on the Internet and print it on your own 3D printer or order it for home delivery. Such lamps are able to turn any room into a forest from Avatar, casting the thinnest shadows on the ceiling. Designers from Nervous system assure that each lamp they create with a leaf pattern is unique, just like plants in nature.

Such lamps are able to turn any room into a forest from Avatar, casting the thinnest shadows on the ceiling. Designers from Nervous system assure that each lamp they create with a leaf pattern is unique, just like plants in nature.

Mummy

While the real mummy of the Egyptian emperor Tutankhamen rests in his homeland, in New York they recreated its exact copy using a 3D printer. Materialize, which created the reproduction, used CT scan data. The copy is made from photopolymer resin applied layer by layer. Makeup artists helped to fully match its counterpart to the 3D printed version of Tutankhamun.

The rights to this article belong to arrivo.ru.

3D children's drawings

The Crayon creatures site offers everyone the opportunity to bring children's drawings to life by printing them out in 3D. The idea is good because it makes getting a new toy dependent on the development of children's artistic skills. Who knows, maybe, having such a motivation, one day your child will learn to draw no worse than Van Gogh or Picasso.

Toys for adults

Using a 3D printer, you can create toys not only for children, but also for adults. So, the site Maker love offers a free and quite diverse design of sex products. If you have a 3D printer, you can download and print any copy you like here, and do it in a size that is limited only by your imagination.

Gadget Accessories

Gadget fans will love 3D printed accessories too. Printers today can print a case for an iPhone or iPad. If you want something extraordinary, you can turn to designer creations. So, SaGa design has developed an unusual stand for a tablet, which is an atlas supporting the gadget.

Art objects and sculptures

A lacy skull, a puppet horse or a futuristic bouquet of flowers - the possibilities of 3D printing are limited only by the imagination of the author of the art object. Many designers have already turned to this genre, and some of them have managed to create real masterpieces of our time with the help of a 3D printer.

For example, Josh Hacker is making headway towards lace skulls. According to him, he sets as his task "the embodiment of the architecture of the imagination." And Mikaella Janse van Vuuren printed out a three-dimensional image of her drawing of a puppet horse with movable wings and functional joints.

Jewelry

Jewelry created using the possibilities of 3D printing, although not precious, is undeniably unique. The American design studio Nervous System has 3D printed flexible jewelry, consisting of hundreds of small fragments connected by miniature hinges. To create such decorations, fragments are combined in a special graphic editor into the final three-dimensional model, which is then compressed to a small size and sent to print.

House

Dutch architect Janjap Reissenaars from Universe Architecture is going to build an entire building using a 3D printer. As conceived by the author, the printer will create sections of the building (6 by 9 meters in size) from sand and a binder. The final material promises to be stronger than cement. Although the building will still need to be reinforced with concrete, this is the world's first project to build an entire building using a 3D printer.

The final material promises to be stronger than cement. Although the building will still need to be reinforced with concrete, this is the world's first project to build an entire building using a 3D printer.

Furniture

By 3D printing a house, you can create furniture for it in the same way. There are already tables, chairs and even beds that have been made using 3D printing. Basically, such furniture is created from individual parts, but recently BigRep created a printer that can print whole furniture. The dimensions of such furniture are quite standard.

The machine can work with nylon, plastic and Laywood, which looks like real wood.

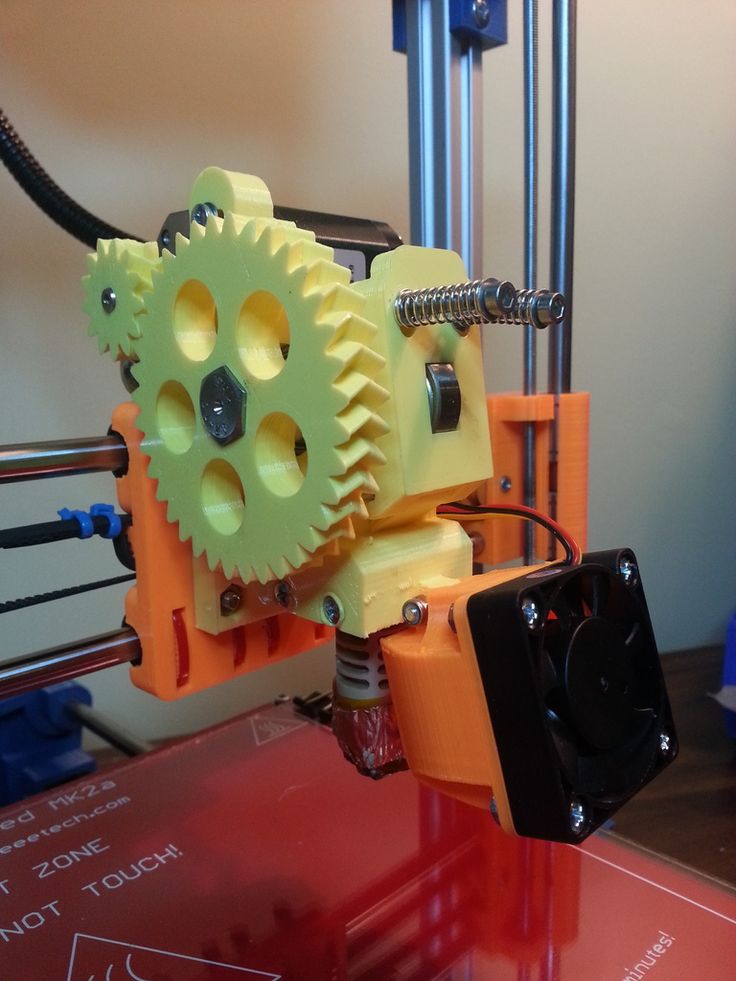

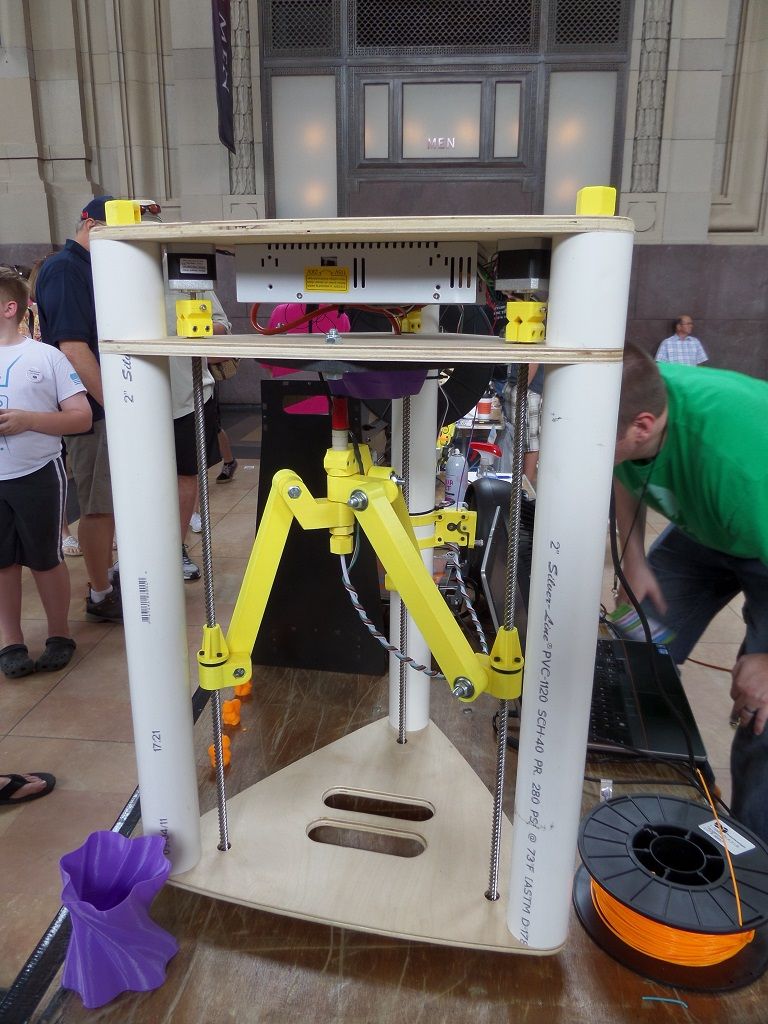

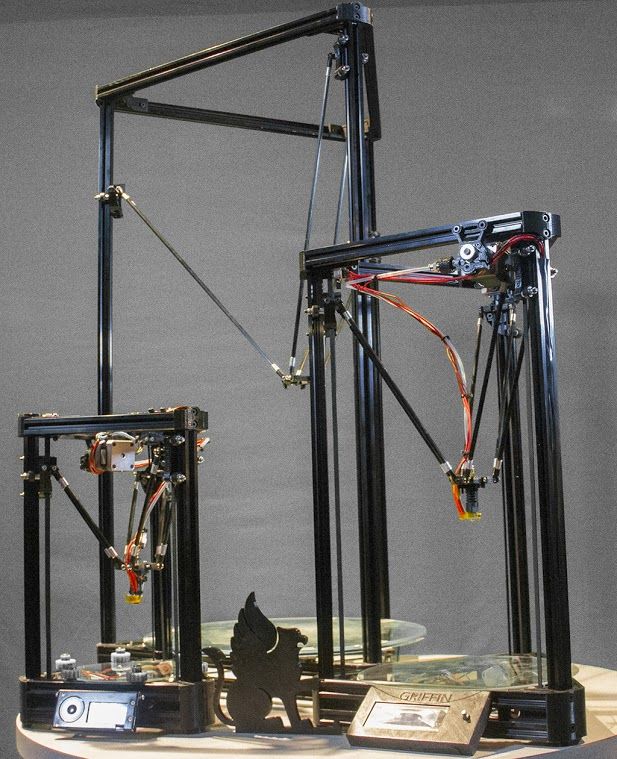

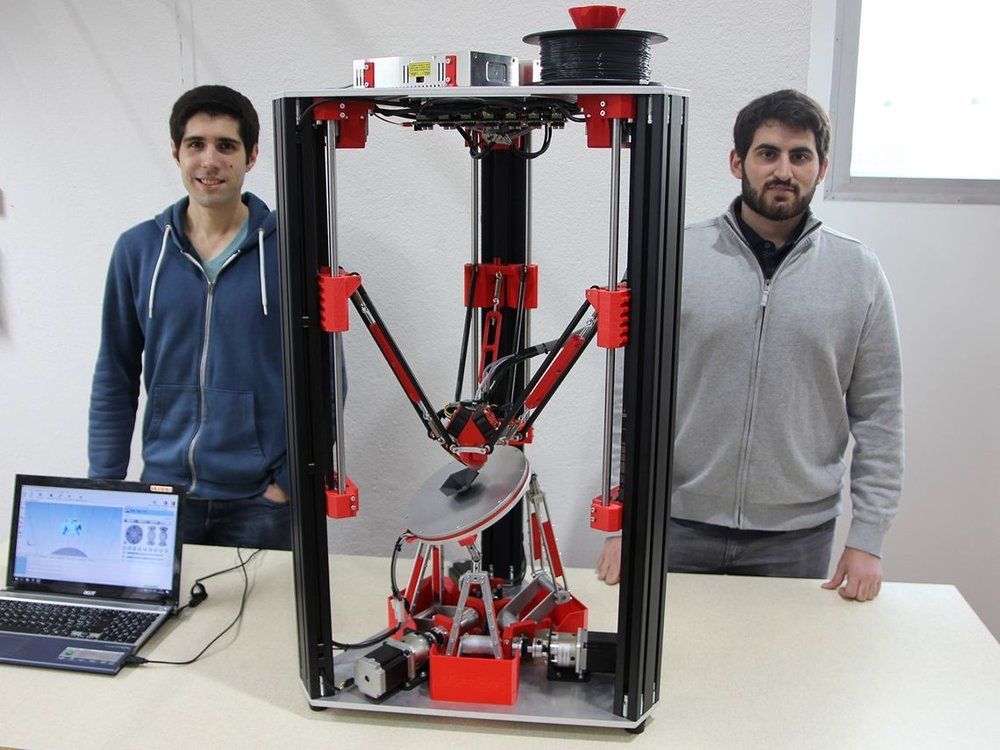

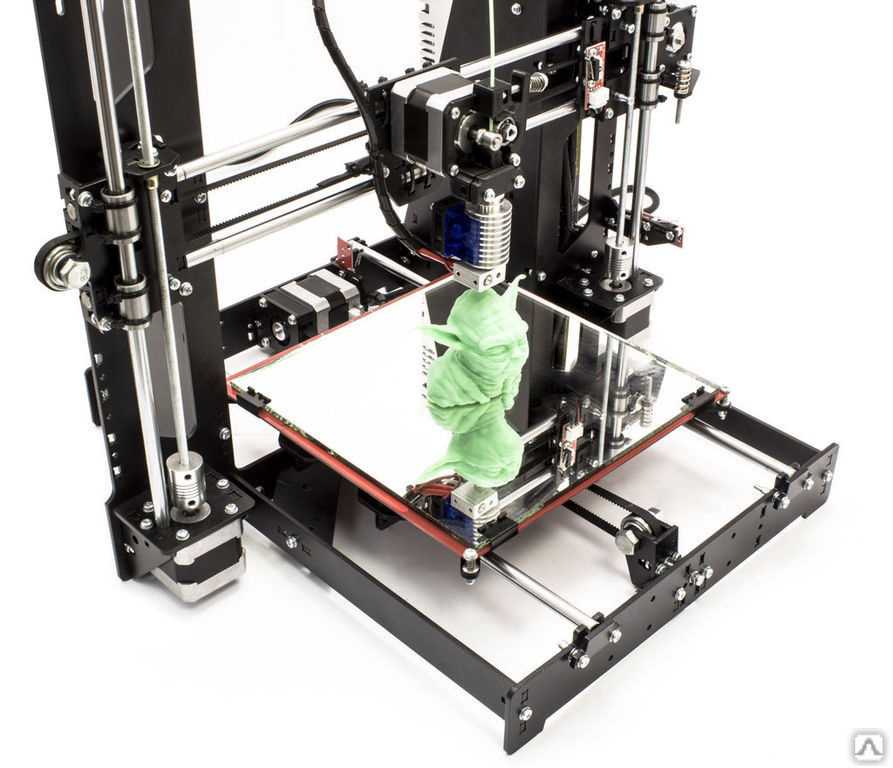

3D printer

The RepRap 3D printer is unique in that it can print itself. Nevertheless, it still does not reproduce all of its own parts, and the final assembly must still be carried out by a person. The creators of RepRap believe that the universal self-replicating 3D printer can eventually be used in the production of small household items.