3D printing for profit

How To Make Money With 3D Printing In 2023

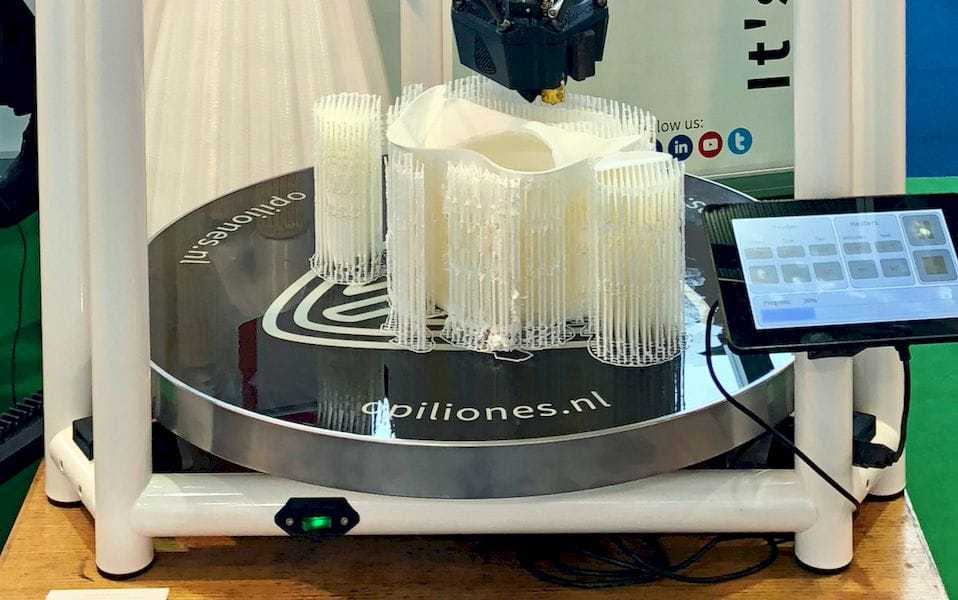

Above: The build size of the 3D printer will determine the size of the print/Source: Manufactur3DDid you know that to make money with 3D printing in 2023 you don’t need to pursue it full-time, instead it can also be a side hustle while you pursue other earning opportunities.

In one of our previous articles, we discussed the various 3D printing business opportunities you can pursue. However, these were full-time businesses, and the level of expertise, investment, time, and effort required for those ideas was prohibitively high.

We understand that not everyone wants to start a full-time 3D printing business in India in 2023, and you may be looking for side hustle opportunities. Side hustles are ideal for students, stay-at-home moms, working professionals, and even small businesses looking to add a new revenue stream.

So, in this article, we focus solely on side hustle ideas that help you make money with 3D printing.

Table of Contents

Can you really make money with a 3D Printer?

The straightforward answer is Yes! You can undoubtedly make money with a 3D printer or operating in the 3D printing industry in 2023.

How much money you ask? Well, that will depend on your level of knowledge and expertise in technology, as well as how much time you devote to this side hustle. In case you are looking to buy a 3D printer, then we have created a list of the best 3D printers for beginners in 2023 which you should definitely consider.

You can check out our list of some popular and some yet-to-be-popular ideas to make money and decide which one suits your routine.

Guide on how to make money with 3D printing in 2023

Sell Educational Models to Schools

Above: 3D printed educational models/Source: ZMorphOne of the best ways to make money with 3D printing in 2023 is to sell educational models to schools. It is now widely accepted that 3D printing is an excellent learning tool that is widely used in STEM education. But not all schools have the funds to purchase 3D printers, or have trained educators who can teach 3D printing to students. Instead of selling them 3D printers – which already most businesses are pursuing – you can persuade schools to purchase educational models.

But not all schools have the funds to purchase 3D printers, or have trained educators who can teach 3D printing to students. Instead of selling them 3D printers – which already most businesses are pursuing – you can persuade schools to purchase educational models.

All schools use standard medical or science models to teach students, and these are mostly outdated and even loosely mended together to keep from breaking apart. So, replacing their existing models and more interestingly, offering them new and unique 3D printed models to enhance the students’ understanding of concepts, ideas and topics, is significantly interesting to schools.

You will have to develop conceptual models and either design them yourself or get them designed and 3D printed. Once you have the sample models, you just need to go on a selling spree. If you secure an order, get them manufactured on-demand and deliver it to the school.

You can create 3D printed models of all human body bones, conceptual models to explain science, math, geography, history, and literally any subject that can be explained substantially well with models. Focus on developing products that not only help students but can also reduce the effort of educators to teach those concepts.

Focus on developing products that not only help students but can also reduce the effort of educators to teach those concepts.

3D Printer Reviewer

You can become a 3D printer reviewer if you are an expert in handling and using a 3D printer. You can contact manufacturers to obtain a 3D printer and write an exciting review of the 3D printer. This review can be posted on third-party blogs or even on your own YouTube channel. You can earn money from the manufacturer who wants his product reviewed by a third party or from the blog that will publish your content. This is one of the most straightforward ways to make money with 3D printing in 2023.

3D Printing YouTube Channel

This idea is closely related to the previous one about reviewing 3D printers. In addition to 3D printers, you can also review materials and software suites. No doubt a YouTube channel will require a considerable time to monetise, but as this is a side hustle, you won’t mind. All you have to do is post one video per 7 to 10 days. You may take a year to generate ad revenue but this idea certainly has a great long-term potential.

You may take a year to generate ad revenue but this idea certainly has a great long-term potential.

Invest in 3D Printing Stocks

Above: 3D printing stock trends/Source: Motley FoolIf you are a stock trader, you should look into 3D printing stocks. The market is undoubtedly young, but if you enjoy taking risks, you can certainly take a look at the stocks. Many companies have gone public in recent years, and if you want to take a chance, consider this option.

(Please keep in mind that this is not investment advice, and readers should make their own decisions about whether or not to invest. We are not responsible for any investment decisions made by reading this article.)

Consultancy

If you are a technology expert, why not put it to good use. You can start a consultancy business. This can easily be a side hustle, but with this idea, you can make a lot of money with 3D printing.

Globally, the rate of adoption of 3D printing technology remains slow. MSMEs believe that the capital investment is prohibitively expensive to even consider the technology. Though this is true to some extent, investing in 3D printers will provide benefits across the entire supply chain, as opposed to traditional machines, which only provide benefits in certain parts of the production.

MSMEs believe that the capital investment is prohibitively expensive to even consider the technology. Though this is true to some extent, investing in 3D printers will provide benefits across the entire supply chain, as opposed to traditional machines, which only provide benefits in certain parts of the production.

This is where the consultant can assist businesses in making better decisions about adopting 3D printing. You, as a consultant, can assist in answering questions like the need of the 3D printing technology for the business, whether the business really needs the technology, and, if so, how to implement the technology and more. Having someone at their side, will certainly help the MSMEs deal with technology sellers.

3D Scanning

Above: 3D scanning a high precision part for reverse engineering with a portable scanner/Source: Manufactur3DWith the introduction of 3D printing, reverse engineering has gained renewed interest and momentum. Because of the ease with which any type of object can be 3D printed, many industries are now scanning obsolete or old machine parts and having them 3D printed.

There are several ways to profit from 3D scanning. All you need is a scanner, which will undoubtedly be an investment, but you can also purchase smaller handheld scanners and provide scanning services.

Finding work through online freelancing jobs is the best approach. Several websites list available jobs, and you can also inquire directly with companies about contracting work. Once you’ve identified a few potential clients, you can start scanning and creating digital files.

Rent out your 3D printer or 3D Pen

In 2023, this is the best way to make money with 3D printing. If you have a 3D printer and/or a 3D Pen that you are not using, consider renting it out. Connecting with schools can earn you a quick buck by renting it to them during their science fairs, lab days, or any other special day. You can also rent it out to an engineering student for his academic project or to a local manufacturer. Additionally, you can even get resourceful and look for unique customers, such as families who want to have fun on weekends, parents that home-school their kids, and so on.

Sell digital 3D models

Above: You can buy and sell 3D models on sites like Gambody/Source: GambodyThis is a great online side hustle and easy way to make money with 3D printing. The only prerequisite is that you need to be proficient in designing for 3D printing. If you are, then you can try to search for trends and cash in on them by creating relevant 3D models.

You can also unique create models for household or office products like home décor. You can sell them on online 3D model repositories. Some designers also create designs for household parts that regularly break and can be replaced with 3D printed spare parts But this has to be done carefully to ensure you are not infringing on any copyrighted/trademarked designs.

Sell Personalised Products

The world is approaching a time when people are more inclined to purchase personalised products. Most customers are tired of mass-produced products that do not reflect their individuality. So, for such customers, you can design and 3D print personalised one-of-a-kind products that make them feel special. You can take user input on shape, size, texture, colour, geometry, and much more in account while creating such a unique product.

You can take user input on shape, size, texture, colour, geometry, and much more in account while creating such a unique product.

Selling such personalized products can help you make money with 3D printing, and it does not have to be a full-time job. It’s a great side hustle.

How to Get Started?

The answer on how to get started will depend on what you wish to accomplish. To get started you will need a CAD designing software (Read: Best CAD software for 3D printing), a 3D printer to print parts (Read: Factors to Consider When Buying a 3D Printer), 3D Scanner, registration on e-commerce sites or your very own website to sell online, and intrinsic knowledge of the technology. You may not necessarily need all the equipmentIn some cases, you may need all the equipment.

Once you choose which idea you want to pursue, you can buy the equipment and start your side hustle right away.

Full-time Business Ideas

If you are interested in getting into full-time 3D printing business then you can check out our dedicated article on the different 3D Printing Business Opportunities. To know the popular business ideas for providing 3D printing services, do read our article on the topic. But remember that starting a business is not as easy as it sounds. If you wish to know how to start a 3D printing business in India in 2023, then you do check out our detailed article which covers all aspects of running a business.

To know the popular business ideas for providing 3D printing services, do read our article on the topic. But remember that starting a business is not as easy as it sounds. If you wish to know how to start a 3D printing business in India in 2023, then you do check out our detailed article which covers all aspects of running a business.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D printing. which publishes the latest 3D printing news, insights and analysis from all around the world. Visit our 3D Printing Education page to read more such informative articles. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter.

11 Ways to Make Money 3D Printing in 2023 – Clever Creations

Our site is reader-supported. When you buy via the affiliate links on this site, we will receive a commission at no cost to you. All opinions remain our own. Learn more

All opinions remain our own. Learn more

Ever wondered about turning your 3D printing hobby into a profitable business venture? We’re here to tell you that there are several ways to make money with 3D printing even as a beginner.

In this guide, we’ll examine the best ways how to make money with a 3D printer, which 3D printing services are most in-demand right now, and what you need to know about running a 3D printing business before you get started.

Best ways to make money with a 3D Printer in 2023

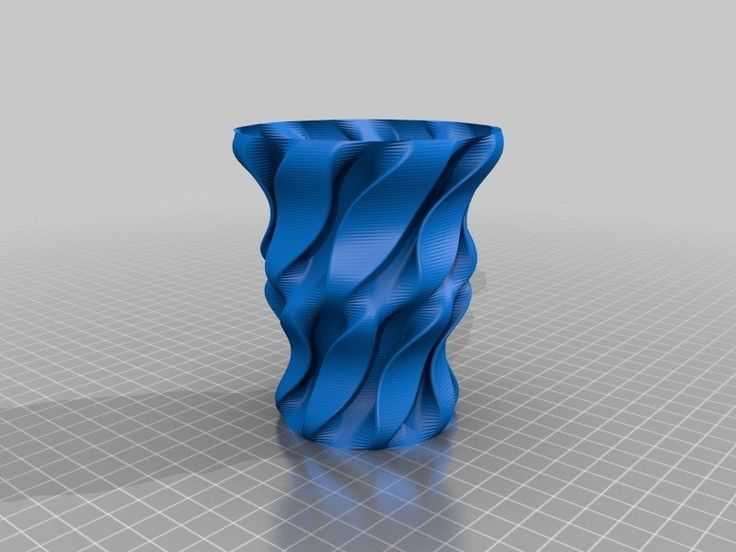

1. Design and sell 3D prints

If you want to design, print, and sell your own 3D printed items, there are a few different ways to do it. For example, you’ll need to decide if you want to stick with a set of specific designs or if you want to work on commission.

Personalized or custom items mean you have to make a new 3D model for every order. Offering only pre-designed items allows you to make items ahead of time and ship them out as needed.

There is a market for nearly every type of 3D print you can create, so choose the types of items you enjoy making. After you have decided that, figure out where the customers for those items like to shop so that you can offer your products there.

What can I make and sell with a 3D printer?

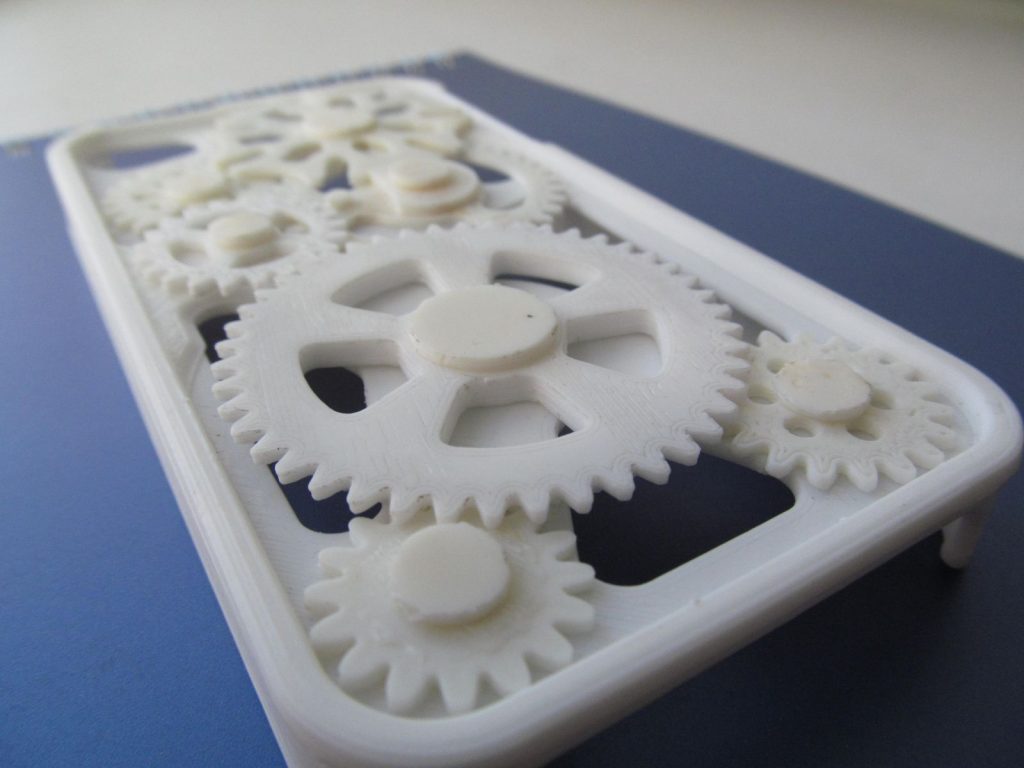

In terms of the things to 3D print and sell, your products can be anything from planters to phone cases to home décor items. Ideally, the products you sell line up with your own passions while still being in high demand from your target audience.

Some of the most popular things to make and sell are:

- (D&D) miniatures. 3D printed miniatures are very popular at the moment. Unlike store-bought miniatures, these can be fully customized to your customers’ liking. You can also paint the miniatures before shipping them out, but many customers don’t mind painting minis for themselves, or they leave them unpainted altogether. When doing this, we recommend you use a resin 3D printer for miniatures.

- Jewelry. 3D printed jewelry can be sold at a high mark-up and for more money than other items, but there is a lot of competition in this niche on sites like Etsy. For 3D printing jewelry, a resin 3D printer (or even a high resolution 4K+ resin 3D printer) is ideal.

Image: xfanta via MyMiniFactory

There is a lot of demand for 3D printed jewelry- Cosplay items. Creating and selling cosplay items can be a profitable endeavor. 3D printing helmets, 3D printing armor, or all kinds of other props are valid ways of making money with a 3D printer.

- Planters. Attractive self-watering planters aren’t always easy to find in retail stores. That is one of the reasons why they are popular things to 3D print.

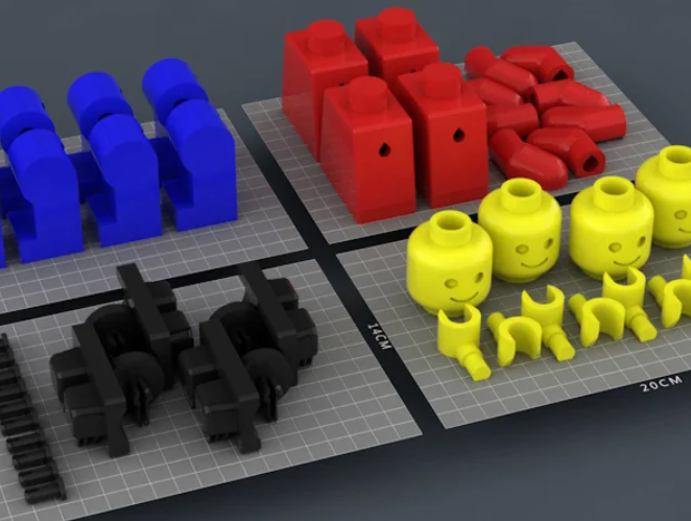

- Toys. Toys are easy to make on FDM printers and barely need any post-processing.

These are just a few examples, but the list is practically endless. Think key chains, customized shoes, personalized crafts, or other one-off items. You can sell designs of others (if the copyright license allows), or create your own designs and your own products.

You can sell designs of others (if the copyright license allows), or create your own designs and your own products.

Where to sell 3D prints?

There are many platforms you can use to sell your 3D printed items and make money with a 3D printer, both online and offline. Most sellers choose a few different platforms for selling to reach a variety of markets and audiences, as well as to bring in more money.

While it’s important to not limit yourself to one sales channel, you should also be careful not to spread yourself too thin.

Offline

You have several choices for selling your 3D printed items in person. Events like craft fairs, trade shows, garage sales, and festivals can all give you the opportunity to show off your 3D prints and gain customers. If you have access to electricity at the event, setting up your printer in your booth can be an easy way to attract people to your table.

You can also put your 3D printed items into consignment shops or set up a display in local businesses. This gives your 3D printing business local exposure without committing to a storefront.

This gives your 3D printing business local exposure without committing to a storefront.

Online

To reach a large and varied global market with your 3D printed items, you should sell online. You should ideally have your own online store at some point. In the meantime, there are several eCommerce platforms that can help you get started:

- Etsy

- eBay

- Amazon

- Fiverr

2. Start a local 3D printing business

Starting a local 3D printing business is one of the quickest ways to get customers and generate sales. You can manufacture custom parts, tools, and necessities for other local businesses. This is especially true if you live around several factories or plants. You can reach out to your local bakery about cookie cutters, or make trophies or awards for events.

Recommended:

The 5 Best 3D Printers for Making Cookie Cutters

The list goes on. You will be surprised by how much you can contribute to your local community once you just start asking. If you are wondering how to make money with a 3D printer, this option offers you lots of potential.

If you are wondering how to make money with a 3D printer, this option offers you lots of potential.

While opening your own business sounds complicated, it’s a rather straightforward process. You should contact your local authorities or city council to double-check the ordinances. You may find that you won’t need any permits or zoning updates to run it from your house. That depends on where you live and how your local laws are set up.

What do you need to start a 3D printing business?

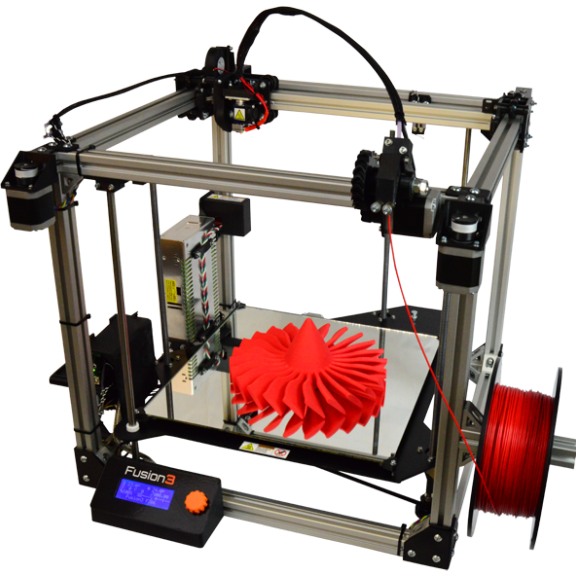

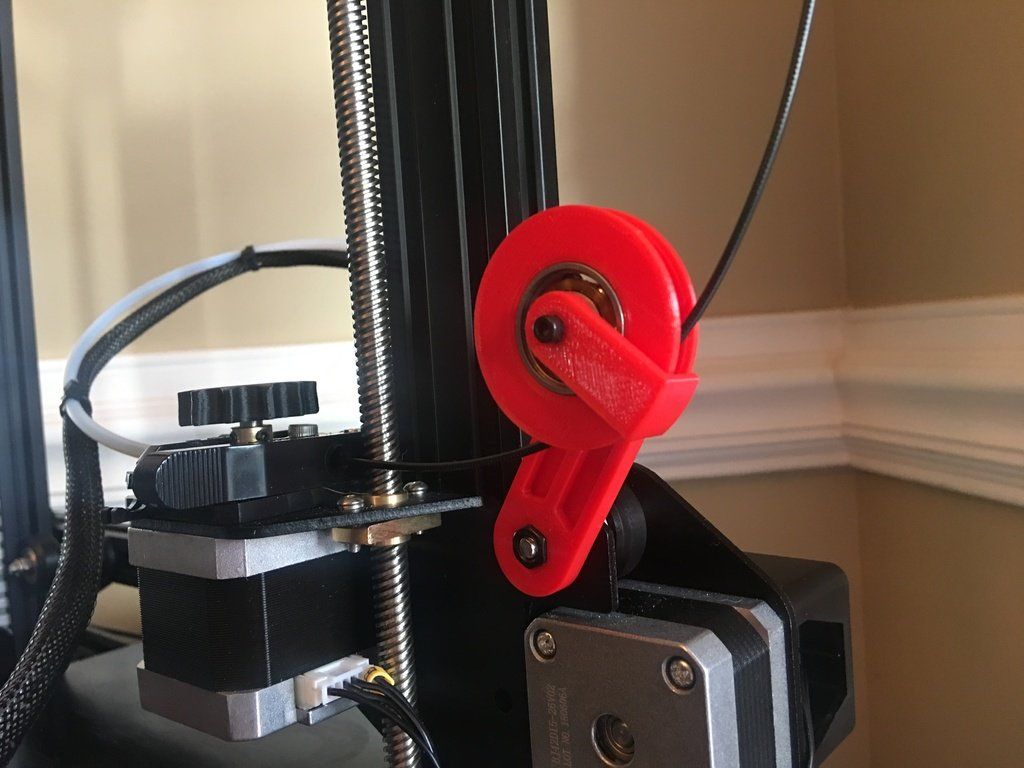

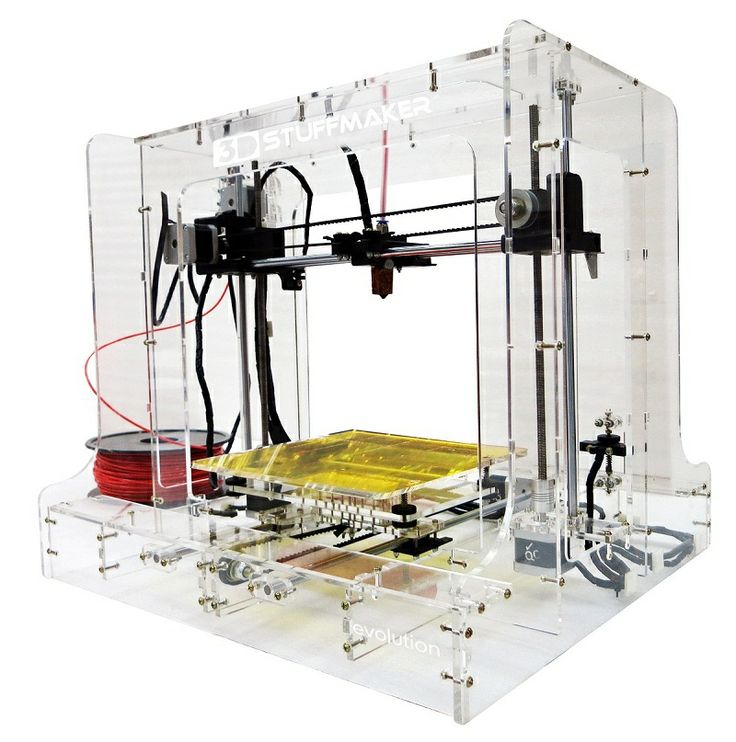

3D printer

It goes without saying that if you want to start your own 3D printing business, you need a 3D printer. In this case, it should be a reliable 3D printer that you are already familiar with and have a stock of spare parts for.

You don’t want to start taking requests from customers and have to cancel their orders a week later. Things like this happen when you’re waiting on a replacement part or because something basic went wrong and you don’t know how to fix it. Be prepared with basic troubleshooting knowledge of your machine and backup components before you start.

You don’t need a top-of-the-line printer to offer your 3D printing services. However, you should aim to have a properly working and time-efficient one. Every minute that you spend re-leveling your build plate because your printer falls out of alignment is a minute that you have to account for through higher printing fees or lost maintenance costs.

Going with a 3D printer under $1000, like the reliable Prusa i3 MK3S, is a good way to save yourself time.

On the other hand, if you decide to go with a budget 3D printer, like the Ender 3 V2, you can make use of the many Ender 3 upgrades that turn it into a more time-efficient machine. One example of this is the BLtouch leveling sensor, which removes the need for manually leveling the build plate.

Business website

You need a website to inform your potential customers about your 3D printing business and to capture leads. You should have this set up by a professional web designer if possible. This will be your main touchpoint for customers to interact with your brand. As such, you want it to look good and reputable to bring in those early clients.

As such, you want it to look good and reputable to bring in those early clients.

You should also contract a graphic designer. They will make your logo, company palette, and other branding materials. Your web designer will need them to keep your website design on-brand.

Some web designers can do both (and vice versa). Just be sure that they have a strong foundation in branding if you choose to use one person for everything.

You can go as basic or complex as you would like with your final website design. It depends on what types of services you plan to offer and how much of the pre-purchase and buying phase you want to happen online.

Premium add-ons like an online store, quote generator, appointment scheduling app, and other tools add value to your end customer. They will cost you more money in upfront design charges since they may require adding a web developer to your project as well.

3. Design and build prototypes

Using your 3D printer to design and build your own (or someone else’s) product prototypes is a great way to monetize your machine. For other people’s prototypes, you can charge them for designing and building them. For your own prototype, you can send it into production and have your own product line thanks to your 3D printer.

For other people’s prototypes, you can charge them for designing and building them. For your own prototype, you can send it into production and have your own product line thanks to your 3D printer.

4. Rent out your 3D printer

Many people love the idea of 3D printing but don’t have the time, space, or money to buy their own printer. Or sometimes they just need the occasional niche print and don’t think it’s worth it to buy their own machine.

That’s where you and your 3D printer rental services come in! You can charge customers a fee for a printing service where you print their models on your printer. Doing this during your 3D printer’s usual downtime lets you make money 3D printing in moments where you don’t need to use the machine for yourself.

This seems like one of the easier options on this list to try. However, print on demand does have some complicated elements to consider. You have to be properly compensated for all time and materials involved.

That includes the cost of your time spent leveling and maintaining the printer (as well as the cost of wear and tear on your machine from additional usage). Keeping in mind the 3D printer’s electricity usage and other 3D printer costs is important too.

For your 3D printing service, you also need to consider if you will honor requests for certain colors of filament, what types of filament potential customers can order, and if you will also include services for post-processing for a fee.

Image: Mtar Einbern via MyMiniFactory

Post-processing can also include painting5. Sell digital 3D models

If you’re a skilled modeler, sculptor, or drafter, you can forgo the necessity for physical products and sell your 3D model files online. This option is more of a passive income business model that can work beside or be independent of a physical product line.

Selling digital files like 3D models lets you make money on one product several times without having to make the item more than once. It becomes even more efficient if the digital files you sell are existing assets from another project that weren’t used anymore and would otherwise have no value.

It becomes even more efficient if the digital files you sell are existing assets from another project that weren’t used anymore and would otherwise have no value.

While you won’t be making money in large sums per sale for 3D models, they can still earn a higher lifetime revenue than a print and sell option of the same model. Digital files simply sell with more regularity than physical objects and have no production cost associated with each extra copy sold.

Where to sell 3D model files

The first place you should consider selling your 3D models is on your own website. If you already have one of those for your local 3D printing business, excellent. If not, start looking for a web designer ASAP.

Third-party platforms charge fees to use their services. Having your own eCommerce site ensures that you get a larger percentage of profit from each sale and increase the money you make 3D printing. The downside to this is that you have to build your audience and website traffic yourself. Most third-party eCommerce platforms bring their audience to you.

Most third-party eCommerce platforms bring their audience to you.

Some of the best places to sell your 3D models are:

- Etsy

- MyMiniFactory

- CGTrader

- Cults3D

Image: DarkFigurines via MyMiniFactory

3D models are loaded into a slicer program to generate instructions for the 3D printer6. Start a YouTube channel

You can use your 3D printing knowledge to set up your own YouTube channel. Build your audience by posting cool and helpful 3D printing YouTube videos to your channel.

It is possible for you to earn revenue from ads, donations, affiliate programs, and brand sponsorships. If you get a large enough following, companies might also send you free products to review.

You most likely won’t make a full-time living from YouTube (especially at first). However, if you grow it as one of several monetization strategies, it can be helpful. It’s a great way to push potential customers to your website or online shop. It can also help develop your name as a knowledgeable person in the industry.

It’s a great way to push potential customers to your website or online shop. It can also help develop your name as a knowledgeable person in the industry.

7. Start a blog

You can use a blog to write 3D printer-related content and share your knowledge with others. Like YouTube, you can monetize the content on your blog through ads, affiliate programs, and paid sponsorships. Having a blog gives you more control over the creative process. You also make a lot more from ads on your website than YouTube pre-roll ads.

You can also use your blog as a way to bring readers to your website where you sell your prints, 3D model files, and other products. Your blog content acts as a verification that you know what you’re talking about on the subject of 3D printing.

It shows that you can be looked at as a trusted source. This is called brand authority, and it makes it much easier to convert an audience member into a customer when they already trust what you’re saying.

8. Repair things in your household

A 3D printer is a great tool to have around when something in your house breaks. With basic computer-aided design (CAD) knowledge and (free) 3D modeling software, you can design replacement parts for broken appliances, furniture, and so on.

Normally when something breaks, you have to order a new part from the manufacturer. You potentially have to replace the entire thing if the manufacturer can’t help you. By doing basic repairs, 3D printing your own replacement parts, and keeping your old belongings in functional shape, a 3D printer helps you save money over time.

9. Repair 3D printers for others

There is no denying that 3D printers can be a bit temperamental sometimes. They have a large number of parts to make them operate the way they should. If someone is new to 3D printing or never learned what most of those components are meant to do, they will struggle to fix it when something goes wrong.

Put your technical 3D printer knowledge to good use and offer to fix broken printers for a fee. Most people will be happy to spend money to let someone more capable deal with it. You get paid work from a person who was likely never going to use your 3D printing services or buy your products.

10. Flip broken 3D printers

If a 3D printer is broken badly enough that the owner doesn’t want to fix it, you can still salvage it by fixing it up. After you have repaired it, you can then resell it for a profit. You can also keep it for spare parts for another 3D printer and sell that one afterward.

11. Offer 3D printing courses

If you’ve been 3D printing for a while, you probably know quite a bit about the subject. Consider using that knowledge to create an online course or series of online courses that teach new 3D printing enthusiasts the basics.

It will be a big initial investment of your time to plan the course, film it, edit it, compile it, and market it. However, you can continue to sell the course for years to come while doing little to no maintenance work on it.

However, you can continue to sell the course for years to come while doing little to no maintenance work on it.

You can host the course through an online learning platform like:

- Skillshare

- Udemy

- Domestika

- Teachable

You can also host it through your website if you have one (and use your blog to help market it.)

Frequently asked questions

Can you make money with 3D printing?

Yes, there are many ways you can start making money with a 3D printer. Selling 3D prints (like phone cases) or offering 3D printing services are some of the most popular methods, but there are many more you can choose from.

Is it legal to sell 3D prints?

As long as you follow the copyright license on any 3D model you use, you are legally allowed to sell 3D prints of the model. For any models you design yourself, you are the license holder, so you can use the models freely.

If any of the models depict copyrighted or trademarked content, that overrules the designer’s license. For example, if someone designed a 3D model of a well-known cartoon character, they still cannot sell prints of it because the character is not their intellectual property.

Image: edoyola via MyMiniFactory

Always check whether the objects you 3D print are copyrighted or notIs 3D printing a good side hustle?

Yes, 3D printing is a great side hustle if you already know a lot about the subject. If you are brand new to 3D printing and are trying to jump into starting a business with it from day one, it might be a frustrating experience.

Taking some time to learn your 3D printer, understand the settings, and be able to troubleshoot the most common issues are going to be very helpful in the long run. It will also ensure that you don’t guarantee your 3D printing service to someone before you are able to render it.

3D printing is also not much different than beginning any other side business. Starting a 3D print store or print-on-demand service requires niche market research, marketing, social media skills, and some understanding of business management. Those are all skills anyone can and should learn to increase how much money they make with their side business.

Starting a 3D print store or print-on-demand service requires niche market research, marketing, social media skills, and some understanding of business management. Those are all skills anyone can and should learn to increase how much money they make with their side business.

How long does it take to start making money with a 3D printer?

That depends on a few different factors. If you are trying a few of our suggestions on how to make money with a 3D printer, your chances of quickly connecting with new customers are higher than if you only stick to one method or sales platform.

How quickly people buy from or contract you also depends on having things like:

- A professional-looking website

- Clean and effective copy on your website and product listings

- High-quality pictures of your products

- Well-defined policies for shipping, returns, customization, etc.

- Good pricing (that doesn’t mean fighting to be the lowest)

- Accurate market research and a good strategy for your business

Not all of these factors have to be a slam-dunk every time. Online shops with terrible pictures make sales every day, while some with professional product photography do not. People stumble onto products by accident every day, even if their marketing strategy is abysmal. These are just some things that may color your timeline for profitability.

Online shops with terrible pictures make sales every day, while some with professional product photography do not. People stumble onto products by accident every day, even if their marketing strategy is abysmal. These are just some things that may color your timeline for profitability.

How long does it take to learn 3D printing?

If you have a plug-and-play 3D printer that is designed to set up and start 3D printing almost instantly (note that these are usually the more expensive machines on the market), you can start getting serviceable prints within a day.

Cheaper and more hands-on 3D printer models have a steeper learning curve and take more time to become adept with. Many of the tasks that plug-and-play printers do automatically are manual on budget printers. It will likely take you a few days to start producing quality parts. It will take a few months to have a firm understanding of all the 3D printer’s elements.

As far as being able to make your own 3D models, those skills are considerably more time-consuming to learn. You can make very basic models within a day or so by following tutorials. However, it can take months or even years to become a skilled designer who creates original and aesthetically pleasing 3D models.

You can make very basic models within a day or so by following tutorials. However, it can take months or even years to become a skilled designer who creates original and aesthetically pleasing 3D models.

Do you need a license to 3D print?

Anyone with access to a 3D printer can print 3D models for non-commercial uses. However, the rules are slightly different when you intend to sell the finished product. Any models used need to have a commercial use license.

That means only choosing ready-made models online that have the proper license. You can also contact the designer to inquire about obtaining commercial rights. Many designers are willing to charge you a licensing fee in those situations, but some will still refuse. It’s important to be respectful either way.

What software do I need?

To start 3D printing, you need a 3D modeling program and a slicer program. The 3D modeling software lets you create 3D models to print, while your slicer turns your models into lines of code that your 3D printer can read.

For help picking out a 3D modeling program, we have an in-depth comparison between the best free modeling software options.

Is 3D printing expensive?

The expenses of 3D printing depend on several factors. These include what type of material you use, what type of 3D printer you have, if you keep your printer well-maintained, and how you store your materials.

Paying attention during 3D model slicing and set up can cut down costly or wasteful mistakes. Keeping your 3D printer clean and lubricated extends the life of its parts. Storing your filaments or 3D printer resins away from moisture and light will extend its working life and help you save money.

Conclusion

There are several options to make money 3D printing, which means there is something suitable for everyone. Do you make money with a 3D printer? What do you find most challenging about running a 3D printing business or side hustle? Let us know in the comments!

1. Best ways to make money with a 3D Printer in 2023

Best ways to make money with a 3D Printer in 2023

2. Frequently asked questions

3. Conclusion

3D Printing Trends That Could Boost Profits in 2022

By TY Yap / 12/07/2022 20/12/2022 / 3d printers, Market trends, New arrivals, Printers, Printer / 5 min read

3D printing is becoming popular these days because it takes the printing process to the next level. It has become an integral part of many industries and is loved by designers for the value it provides as an efficient way to prototype new products. Given the growing popularity of 3D printing, this article will highlight industry trends that will increase profits in 2022.

Content

3D printing market potential

Popular 3D printed items in 2022

Bottom line

3D printing market potential

is expected to grow at a compound annual growth rate (CAGR) of 22. 1% between 2021 and 2030. In addition to these optimistic trends, specialist firms in the industry have also predicted a CAGR of 27% for the 3D printing market, reaching a market turnover of $115 billion by 2030.

1% between 2021 and 2030. In addition to these optimistic trends, specialist firms in the industry have also predicted a CAGR of 27% for the 3D printing market, reaching a market turnover of $115 billion by 2030.

This rapid growth is mainly due to the increased use of 3D printing in prototyping, tooling and design in the manufacturing and industrial fields. This is due to the growing demand and more flexible features offered by various modern 3D printers.

In addition, the expansion of 3D printing applications in many other areas such as healthcare, consumer products and education is likely to become an even greater driver of the 3D printing industry. And as 3D printers become more affordable and widely available, their use is no longer limited to the traditional manufacturing sector, but is slowly expanding to include home and home use.

Popular 3D printed items in 2022

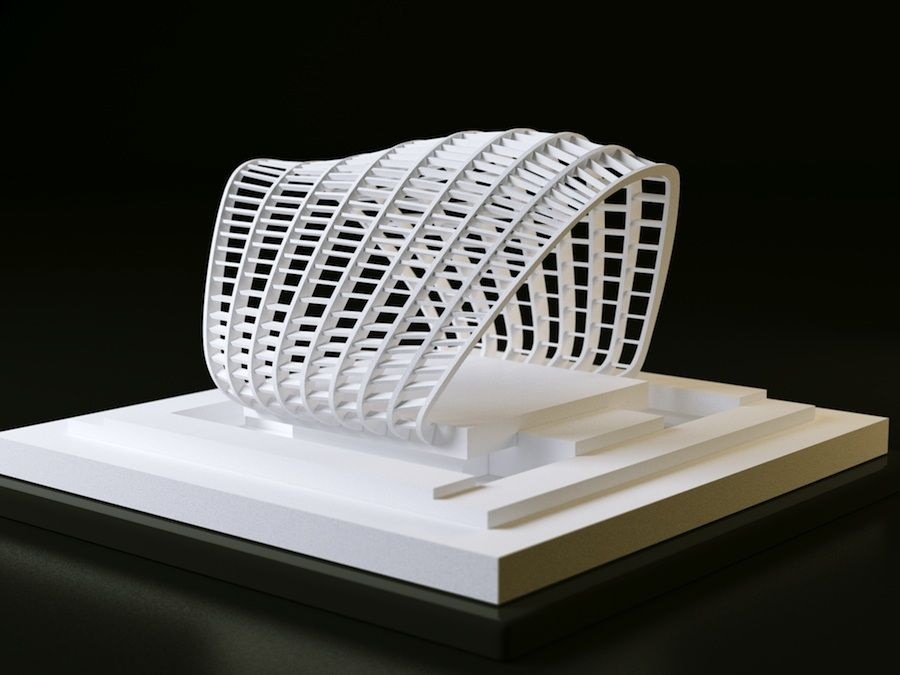

Industrial products

The development of industrial products 3D printing is mainly driven by the growth of the metal 3D printing industry, with a CAGR of 22. 9% from 2021 to 2030 with a market value of $22.6 billion .

9% from 2021 to 2030 with a market value of $22.6 billion .

Metal 3D printing applications are centered around manufacturing processes such as prototyping, tooling, and creating functional parts for the automotive, aerospace, defense, healthcare, consumer electronics, and construction industries. The Asia-Pacific region is the market that is expected to grow the most over the next 5-10 years, given the industrial and construction needs of emerging markets.

The growth of the 3D metalworking industry is largely due to the fact that the 3D printing process is much faster than the traditional production of parts. This is especially true for some unique items made to specification, such as custom made gears and shafts. 3D printing offers both flexible and customized industry solutions as the designs, sizes and shapes to be printed can be easily customized with the appropriate software.

And of course, while metal printers may require a large initial investment, metal 3D printers these days start at a much more economical price, but are still capable of promising high durability and high performance.

Fortunately, for those businesses that may find it difficult to make an initial investment, there is a good alternative to getting into the industrial goods 3D printing business. That is, by hiring a 3D printing service to have your desired 3D printed products delivered straight to your door. Such highly specialized options often provide not only flexibility in terms of metal 3D printing material, but also versatility in terms of 3D printing technologies.

Medical products

The dental industry is the most prominent specialization in the field of medicine that uses 3D printing technology. 3D printers are used to produce various dentures. The dental 3D printing market is expected to more than double within five years, to $7.9 billion in 2027 from the current estimated market size of $3.1 billion.

Three major factors that have contributed to this growth include: the rise of cosmetic dentistry in line with rising global disposable income, the growing concerns of tooth loss among an aging world population, and the fact that 3D printing in dentistry can help improve overall speed, performance and quality of denture equipment.

The current average market price for a dental 3D printer is typically around $3,000 per set according to industry experts. However, in the wholesale world, costs are affected not only by volume, but also by the launch of innovative, low-cost technologies, such as the introduction of LCD-based 3D printers. Wholesale dental-grade LCD 3D printers can cost as little as half the average market price, or even well below that.

3D printed dentureFashion & Accessories

The exclusivity and customization of 3D printing make it a good alternative for the fashion industry. Among all kinds of fashion products, jewelry stands out as the most suitable item for 3D printing, partly due to the rapid growth of the jewelry market worldwide, with a CAGR of 12.1% between 2019 and 2026. But it is also related to that 3D printers meet the needs of jewelry designers.

Through the use of computer-aided design software, 3D printers can significantly reduce the reliance on the labor-intensive manual process of creating complex jewelry designs. In addition, the precision 3D printing technology ensures optimal precision and detail, which meets the requirements of such jewelry production technologies as engraving and filigree. All in all, this means that 3D printing has made jewelry manufacturing more cost-effective and offers an efficient and time-saving solution to the needs of designers.

In addition, the precision 3D printing technology ensures optimal precision and detail, which meets the requirements of such jewelry production technologies as engraving and filigree. All in all, this means that 3D printing has made jewelry manufacturing more cost-effective and offers an efficient and time-saving solution to the needs of designers.

Similar to dental 3D printers, resin printers are most suitable for jewelry 3D printing, and the advent of liquid crystal 3D printing technology has opened up more opportunities for low-cost jewelry 3D printers, for example, this model which is similar to the one in the picture below.

Bottom Line

Overall, 3D printers offer a unique solution for many industries around the world, and this will drive the growth of the market for 3D printing machines and services. For those interested in entering this market, there are three key products to look out for in order to gain a competitive edge: Industrial, Medical, and Fashion. And the good news is that advances in 3D printing technology have reduced investment opportunities, especially at the wholesale level, making 3D printers more affordable for businesses large and small alike. Those interested in capitalizing on this growing market can take a closer look at these factors or check out the range of 3D printing machines available on Alibaba.com.

And the good news is that advances in 3D printing technology have reduced investment opportunities, especially at the wholesale level, making 3D printers more affordable for businesses large and small alike. Those interested in capitalizing on this growing market can take a closer look at these factors or check out the range of 3D printing machines available on Alibaba.com.

3D printing for fun and profit: a serious hobby is growing up

InoSMI materials contain assessments of foreign media only and do not reflect the position of the InoSMI editors

This year at the Maker Faire inventions exhibition in the 3D printing category, 76 exhibits were presented, and two booths dedicated to this technology were constantly crowded with visitors. They picked up and examined cubes, spherical lattices, bracelets and bright figures linked together. At the same time, guests constantly asked: “Is this a three-dimensional printing?”, although the answer was invariably in the affirmative.

Adrianne Jeffries

This year's Maker Faire featured 76 exhibits in the 3D printing category, with two 3D printing booths filled with visitors. They picked up and examined cubes linked together, spherical lattices, bracelets and bright figures. At the same time, guests constantly asked: “Is this a three-dimensional printing?”, although the answer was invariably in the affirmative. "It's going to be a parent with a baby in their arms and the baby's mouth is barely open, and then I look at the parent and their mouth is open too," says Elisa Richardson of 3D printing company Shapeways.

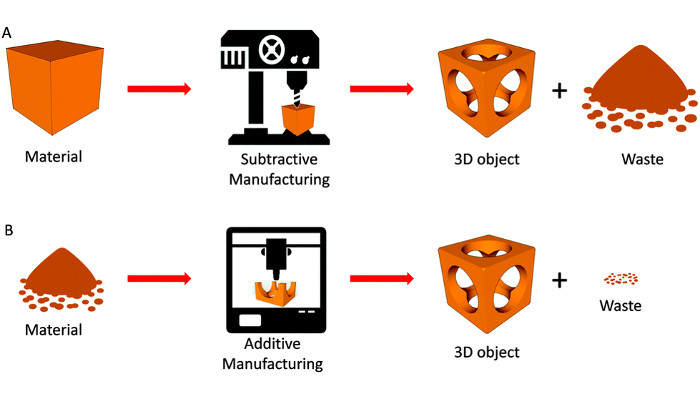

The term "3D printing" refers to a series of technologies for the layer-by-layer creation of a solid object based on a virtual three-dimensional model. These technologies are rapidly becoming cheaper and more accessible. In colloquial speech, 3D printing has two definitions. Definition one: a revolutionary movement in which the workers will become the owners of the means of production. Definition two: an innovative technology that, in its most impressive form, makes it possible to produce knick-knacks that could easily pass for Chinese products.

Definition two: an innovative technology that, in its most impressive form, makes it possible to produce knick-knacks that could easily pass for Chinese products.

Wired Editor-in-Chief Chris Anderson yesterday published a book called Makers: The New Industrial Revolution. It focuses on 3D printing. “Machines are turning into push-button presses,” Anderson said during his talk at the show, pointing to a slick, microwave-shaped 3D printer on stage. What kind of world will they create?

Read also: Arguments against innovation

Anderson and his co-speaker Bre Pettis, who founded MakerBot Industries and has become a charismatic leader and main face of the 3D printing movement, say the world has a bright future ahead of it, thanks to the nascent 3D printing industry. These people belong to the category of optimists who believe that 3D printing is a revolutionary technology that will have an impact on the world as huge as the Internet has had on publishing.

The creative technical community fully shares this sentiment. This syndicate of entrepreneurs and thinkers combines artisanal production with high technology. The exhibits on display at this year's Maker Faire offer a glimpse of what 3D printing could be and how far it still has a long way to go.

Hype

Last month, research firm Gartner called 3D printing a "peak of over-expectation" in its annual report on the hype and hype of new technologies. If 3D printing follows the path of other revolutionary technologies, such as the Internet, then it will not create any turning point in history and disappoint its early fans. As Gartner points out, 3D printing will enter a streak of relative obscurity, but it will continue to evolve and eventually reach the level of mass-produced industries.

And in the 3D printing booth, some innovative start-ups showed their faces. "In 10 years, a 3D printer will be in every home," said engineer Craig Broady of Formlabs. This Cambridge-based 3D printing startup has raised a $1.4 million investment to launch its new $100,000 project, scheduled to launch in 22 days.

This Cambridge-based 3D printing startup has raised a $1.4 million investment to launch its new $100,000 project, scheduled to launch in 22 days.

Also related: This is not science, but evil

Most 3D printers use a technique called fusion modeling, where plastic is heated and laid in layers through a die. This means that the object melts until it is completely made. Formlabs has developed a printer it calls the FORM 1. It uses lasers and liquid polymer to print objects with a precision that the new industry has never known. The company demonstrated the printer in action using a magnifying glass as it made an exquisite replica of the Eiffel Tower.

Whether it's a world-changing revolutionary breakthrough or a simple innovation, 3D printing is something people admire. Visitors to the show crowded the Formlabs booth, looking at the company's orange printers, touching the 3D-printed chess pieces, and asking questions about the Eiffel Tower. Brody pulled his iPhone out of his pocket to check how many people are supporting the company's new project: more than 700. "Designers can prototype parts, and kids, of course, make toys," he said. “These things can be used for anything.”

"Designers can prototype parts, and kids, of course, make toys," he said. “These things can be used for anything.”

The 3D printing revolution was first announced at the turn of the century. Then the price of machines capable of printing plastic objects from computer models began to drop from hundreds to tens of thousands. A little over six years ago, when the cheapest 3D printer cost $25,000, Gizmag dreamed that 3D printing would "slowly seep into local shops that make designs in front of you, and then into homes where models can be made." will download on the Internet, and then make what you want.

The 3D printing industry seems to be moving too fast today. A home printer today can be purchased for less than $500. Product quality is rapidly improving, object sizes are increasing, as are the number of 3D printing companies, and the number of articles on the subject in 2012 is already twice what it was in the past. Here is just one typical headline that appeared on the pages of the Telegraph: "3D printing: a technology that could transform the world. "

"

See also: World Innovation Ranking 2012

Despite technical advances, 3D printers still cannot reproduce objects with moving parts. Most of the start-up 3D printing companies and lone artisans at the show were displaying rather primitive products, such as logos, jagged figures, as well as the wonders of geometry. Afinia, an aspiring design company, has printed several Halloween ghost figurines. Weistek, which claims to be China's first 3D printing company, showed off Buddha and dragon figurines and a tiny bowl of noodles.

The kids enjoyed printing toy sharks with the MakerBot printer - the process takes 36 minutes but is still cool. But it seems that most of the visitors did not understand the meaning of what they saw. “Yes, we don’t have a 3D printer,” one dad grumbled at his kids. “And we just have to cut out paper figures.”

More than a toy, but not yet a revolution

In April 2011, the Dutch company Shapeways held a small informal gathering in New York to celebrate the opening of their office. The office was so new that it hadn't been furnished yet. Instead, the company lined two white tables with samples of designers whose creations Shapeways printed on its mid-range presses and then shipped to customers. Since the company is in the manufacturing business itself, its 3D printed objects seemed to be the most beautiful and the most complex of all in the industry.

The office was so new that it hadn't been furnished yet. Instead, the company lined two white tables with samples of designers whose creations Shapeways printed on its mid-range presses and then shipped to customers. Since the company is in the manufacturing business itself, its 3D printed objects seemed to be the most beautiful and the most complex of all in the industry.

But when rumors about how 3D printing will change the world went through the roof, the pace of its spread became less than impressive. At the time, Shapeways printed mostly white geometric sculptures, ornate bracelets, nasty-looking earrings, nonsensical designs, and solid-color figurines that looked like walking springs because of their visible lines.

Also Related: Intellectual Property - A New World of Rights and Royalties

A year and a half later, the Shapeways product line looked very different.

Today the company manufactures products in 30 different materials, including silver, stainless steel and glazed ceramics. One of Shapeways' most popular merchandise is Sad Little Keanu Reeves. This is a tiny figurine of an actor in a blazer and jeans, made of sandstone. His face and hands are of a completely natural color, the fingers are separated, the texture of the hair is emphasized. At the exhibition, the company showed a lighter, sunglasses, and a detailed replica of the cat Nyan, floating on an 8-bit rainbow.

One of Shapeways' most popular merchandise is Sad Little Keanu Reeves. This is a tiny figurine of an actor in a blazer and jeans, made of sandstone. His face and hands are of a completely natural color, the fingers are separated, the texture of the hair is emphasized. At the exhibition, the company showed a lighter, sunglasses, and a detailed replica of the cat Nyan, floating on an 8-bit rainbow.

How did Shapeways improve their products so much? Printers have gotten better and better, says marketing director Carine Carmy. In addition, post-print technologies and modeling principles have been improved. The software is also getting better and better, she notes.

Shapeways has several machines in New York and a factory in the Netherlands. In addition, this month she will open a factory in Long Island City. When it comes to making products out of more durable materials such as ceramics and metal, Shapeways is partnering with 3D Systems, which makes a wide range of printers from desktop to industrial. Last year, 3D Systems bought the very first manufacturer of such printers, Z Corp, and is also improving its own machines and technologies.

Last year, 3D Systems bought the very first manufacturer of such printers, Z Corp, and is also improving its own machines and technologies.

See also: Eastern Europe - hidden hub of innovation

Now that Shapeways is printing ready-to-ship products, it's easier to appreciate the economic power of 3D printing. For example, a designer jeweler can now use 3D printing marketplaces such as Shapeways, Sculpteo, i.materialise to take on-demand orders without having to fill a box full of them. “I think 3D printing as a science fiction technology has reached its peak,” Carmi says. “But 3D printing as a revolutionary breakthrough – here, I think we are at the very beginning.”

As for desktop home printers, they are also constantly improving. "I don't think there will be any slowdown here," MakerBot spokesman Andrew Pelkey said in a letter. “Let's say the layering algorithm we developed for the new MakerWare software generates a toolpath that has very few filament retractions.