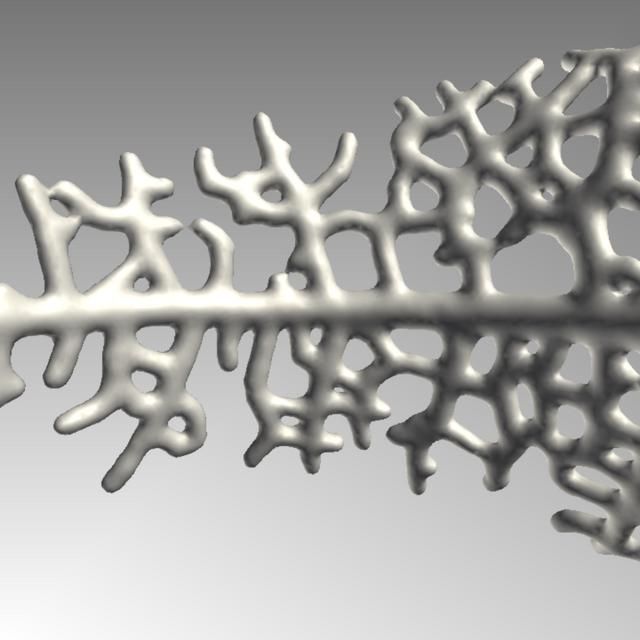

3D printed leaf spring

3D Printing Carbon PEEK Optimizes Vehicle Blade Spring for Good Comfort

3D Printing Carbon PEEK Optimizes Vehicle Blade Spring for Good Comfort

03.18.2021 | CC Collaborator | News

With the rapid development of science and technology, 3D printing materials have been proved to be important materials in automotive, aerospace and industrial applications. Recently, researchers have compared the leaf springs of Dodge SUV by using carbon PEEK printed in 3D. Their findings are summarized in "Design Optimization and Finite Element Analysis of Single-leaf Springs Based on 3D Printed Carbon PEEK".

(3D Printing of Carbon PEEK Material Parameters)

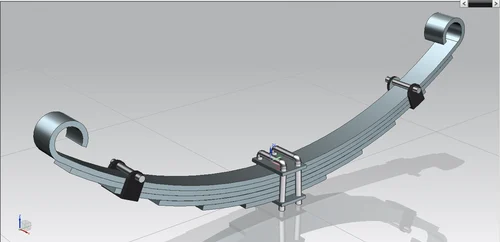

Leaf spring is a simple form of spring, commonly known as "balestra", which is usually used in automobile suspension. Vehicles must have good suspension system in order to achieve good driving and human comfort.

In previous studies, the main purpose is to determine the elastic strain energy and strength-weight ratio of composite-based leaf springs compared with steel. The purpose of this study is to explore the possibility and capability of additional material manufacturing in the process of developing leaf springs using carbon PEEK materials printed in 3D, and to analyze various parameters, such as:

Length

Thickness

Width

Fiber orientation

Fiber diameter

Percentage of volume fraction of fibre filler

Different load conditions

In this study, the properties of carbon PEEK, such as tensile strength, modulus, density and strength-weight ratio, were studied. The results show that compared with traditional steels, carbon PEEK has high elastic modulus in orientation, strength, corrosion resistance, good fatigue and adhesion.

Polyether ether ketone (PEEK) based polymer composites have controlled combinations of properties that can be achieved by 3D printing FFF (fused filament manufacturing) technology, making it possible to combine at least two different conventional materials. PEEK matrix materials play an important role in many fields because of their chemical-physical properties and light weight. In the automotive field, PEEK composites enable us to meet the requirements of strength and weight reduction. Polymer composites will not be corroded and used as coatings to create protective barriers.

PEEK matrix materials play an important role in many fields because of their chemical-physical properties and light weight. In the automotive field, PEEK composites enable us to meet the requirements of strength and weight reduction. Polymer composites will not be corroded and used as coatings to create protective barriers.

(a) Fiber orientation - 0 degrees; (b) Fiber orientation - 45 degrees; (c) Fiber

orientation - 90 degrees

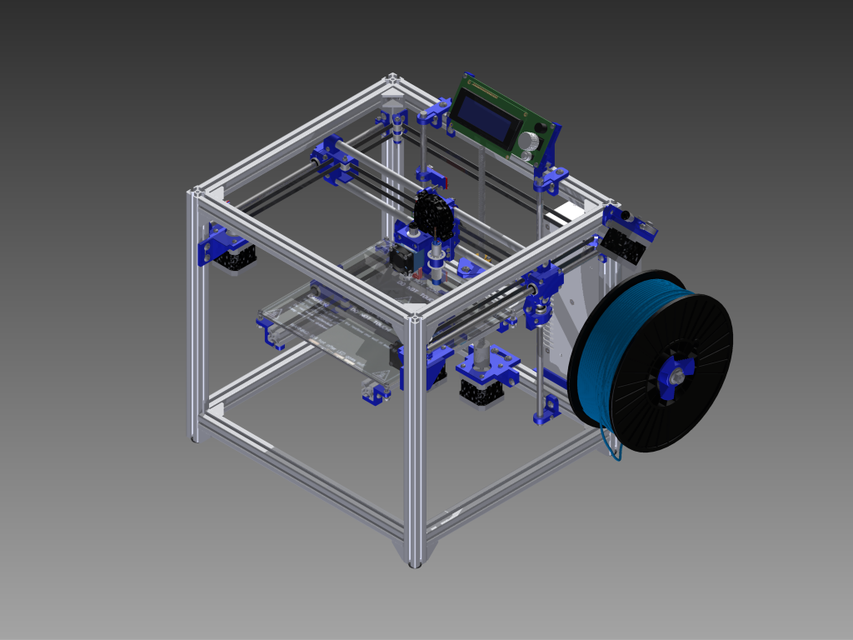

Researchers use custom 3D printers to produce parts, chassis to prevent excessive vibration, and chrome-plated interior parts. The movable extruder head equipped with induction heater can accurately locate the nozzle on the fixed heating bed and keep it at 250 C. The surface of the machine printing platform is galvanized and heated to 100 C.

In the analysis of the parts, the researchers also found that the carbon fibers of the blades could be stretched in the tensile test, which also proved the validity of "zero fiber orientation".

Response Surface Methodology (RSM) and Analysis of Variance (ANOVA) enable the development of analytical regression models capable of predicting flexural and bending stresses. These are validated by the finite element results obtained by using various combinations of design parameters. As for the validation of the prediction model, the results of finite element analysis and regression analysis show good consistency with FEA results. Future work will demonstrate dynamic analysis and leaf spring behavior under dynamic loads.

These are validated by the finite element results obtained by using various combinations of design parameters. As for the validation of the prediction model, the results of finite element analysis and regression analysis show good consistency with FEA results. Future work will demonstrate dynamic analysis and leaf spring behavior under dynamic loads.

(a) Standard specimens on ARGO machine tools: (b) 3-D printed CPEK specimens.

(a) SEM micrographs at 200 um, (b) fibers at 45 degrees were evaluated by image fragment analysis.

Source from: https://creality3dpro.store/

3D Printed Springs - Smart Armor

- View Larger Image

3D printing has become a critical tool in product development and the increased availability of high-strength, dependable materials has enabled the use of 3D printing in areas that have not previously been possible. The open-minded thinking of the maker community has helped drive this advancement. Companies like Taulman and ColorFabb have made materials readily available for any fused filament fabrication (FFF) 3D printer that have strength, durability, and stiffness far above the basic PLA and ABS materials commonly used. One of these new materials is PET, a polyester based thermoplastic commonly used in water bottles for its chemical stability, strength, and durability. Taulman released T-Glase, a PETT variation of the basic material, and ColorFabb followed with XT, using a proprietary Eastman-Kodak formulation called Amphora. Both materials offer better strength and rigidity than PLA, hydrophobic properties, and ease of printing. I started using T-Glase to get away from ABS due to the fumes and the curling and warping that occurred in many of my prints, rendering some of them completely unusable. I added XT because of the opaque colors and found that it is the easiest printing material in my inventory.

The open-minded thinking of the maker community has helped drive this advancement. Companies like Taulman and ColorFabb have made materials readily available for any fused filament fabrication (FFF) 3D printer that have strength, durability, and stiffness far above the basic PLA and ABS materials commonly used. One of these new materials is PET, a polyester based thermoplastic commonly used in water bottles for its chemical stability, strength, and durability. Taulman released T-Glase, a PETT variation of the basic material, and ColorFabb followed with XT, using a proprietary Eastman-Kodak formulation called Amphora. Both materials offer better strength and rigidity than PLA, hydrophobic properties, and ease of printing. I started using T-Glase to get away from ABS due to the fumes and the curling and warping that occurred in many of my prints, rendering some of them completely unusable. I added XT because of the opaque colors and found that it is the easiest printing material in my inventory.

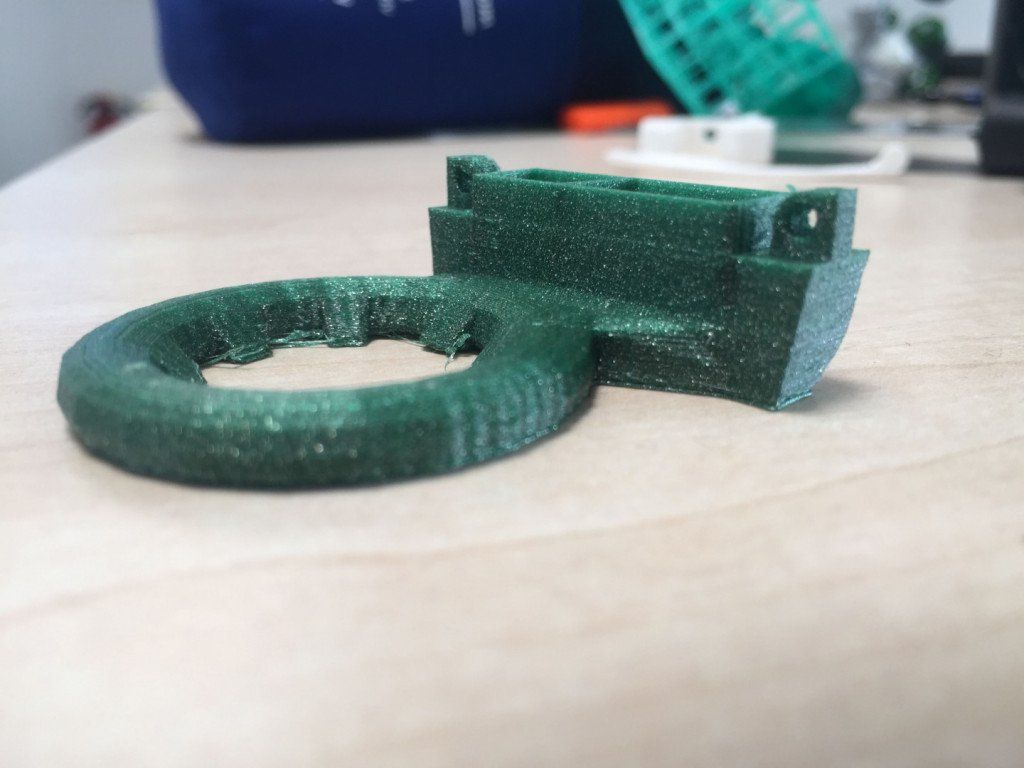

Several months ago I was contracted to help a local company solve a problem with one of their products. They needed to release a latch to open a spring-loaded drawer. It seems like a simple problem on the surface, but they also needed the system to run on a 3VDC battery with very low current draw. The solution they were using was a solenoid and due to the low voltage and current draw the solenoid did not generate enough mechanical force to overcome the friction between the latch and its mating catch. Compounding the problem was the available volume; the entire device is about the size of a smartphone and is abou5/8 of an inch thick. The area reserved for the mechanism, battery, and controller board is about 2.5 inches long and an inch wide. The battery and controller took up close to 2/3rds of that space, leaving only about an inch by inch by half-inch volume to work with. My initial solution was to use a miniature gear motor purchased from Pololu for a robotics project. This was coupled with a steel leaf spring with a formed latch feature. A cam on the motor pushed on a brass pin, in turn pushing the spring to release the catch. For a single prototype this worked very well, but when more than one was needed several problems became apparent; the most challenging being the difficulty of forming the integrated spring and latch. The hardened and tempered spring steel worked great for one unit but the cost and complexity of developing more than one was considerable.

A cam on the motor pushed on a brass pin, in turn pushing the spring to release the catch. For a single prototype this worked very well, but when more than one was needed several problems became apparent; the most challenging being the difficulty of forming the integrated spring and latch. The hardened and tempered spring steel worked great for one unit but the cost and complexity of developing more than one was considerable.

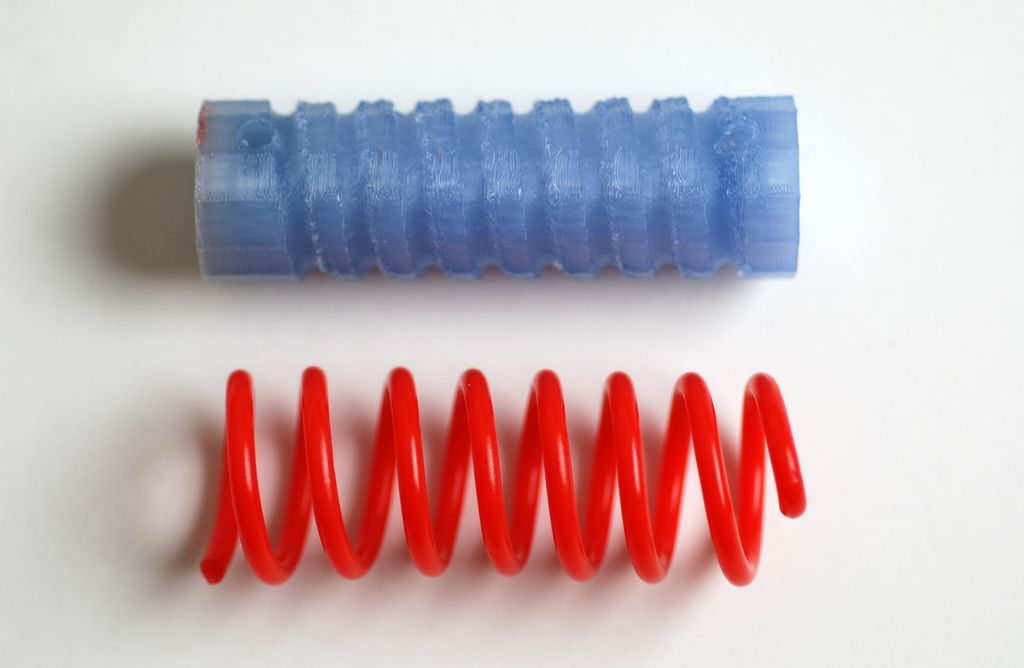

On a whim, I started looking at using T-Glase as a spring. I had noticed that when printed in thin, solid sections the material was flexible without breaking. A few trials later I had what would become the final prototype design. The latch, spring, and cam follower were integrated into a single 3D printable part.

The cam follower pin became a pivot pin and the Pololu motor was replaced with a smaller, cheaper planetary gearhead unit with lower current draw. The motor came with a 6-point spline interface, so a cam head was designed and printed to slip over the existing interface unit. The cam head provided another challenge; the first set of prints were made with PrintedSolid PET+ and have not been repeatable. The PET+ material provides many of the properties of ColorFabb XT but with a more rubbery, flexible characteristic. It was chosen only because it was what was in the printer at the time. Subsequent attempts with T-Glase and XT have failed to print without voids due to the thin areas on the part, or have not been able to hold the tolerances required to mate with the motor interface, requiring extensive hand finishing. In production, this will be an injection molded part; for now it isn’t a problem as I printed more than enough to cover the needs of the project.

The cam head provided another challenge; the first set of prints were made with PrintedSolid PET+ and have not been repeatable. The PET+ material provides many of the properties of ColorFabb XT but with a more rubbery, flexible characteristic. It was chosen only because it was what was in the printer at the time. Subsequent attempts with T-Glase and XT have failed to print without voids due to the thin areas on the part, or have not been able to hold the tolerances required to mate with the motor interface, requiring extensive hand finishing. In production, this will be an injection molded part; for now it isn’t a problem as I printed more than enough to cover the needs of the project.

Extensive testing with this design showed the longevity of the spring – over 20,000 latching cycles were recorded without a failure of the spring and with only a slight loss in stiffness. The first spring was printed with clear T-Glase and after about 12,000 cycles fine cracks were visible at the root of the leaf spring arm. Subsequent parts were made from black XT and show no such cracking. This may also be due to a slight lengthening of the leaf spring arm as well. The gray PET+ did not have enough stiffness to properly latch.

Subsequent parts were made from black XT and show no such cracking. This may also be due to a slight lengthening of the leaf spring arm as well. The gray PET+ did not have enough stiffness to properly latch.

The success of the design encouraged me to look further into replacing torsion and compression springs with 3D printed leaf-style springs. The same company came to me with another project; they wanted to use the same technology to make a firearm trigger lock. The idea was to allow the user to bypass the key lock with a control system using Bluetooth Low Energy (BLE), enabling the lock to be triggered between the locked and unlocked states based on proximity or a command signal from the user’s smartphone. As with the previous product, only a small volume was available. My customer wanted to modify an off-the-shelf lock and just integrate the BLE system while keeping the keyed operation so the user could choose between unlocking methods. The trigger lock presented a larger challenge as the force required to keep the lock dependably closed is relatively large – on the order of 4-5 lbf. In the key-only design this was accomplished with a compression spring. Due to the force limitation of the motor, a smaller force had to be used for prototyping with the assumption that the design would be changed to ensure proper retention of the lock. The prototype for this product involved replacing much of the volume occupied by the compression spring with the controller board and adding additional volume by extending the height of the unit. To fit the space and to provide optimal use of the available motor force, the linear spring and latch was replaced with a pivoting latch and an inward-curved leaf spring, as opposed to the outward curve used on the previous design. The inward curve provided a large increase in force, matching or exceeding that of the compression spring, in about the same space as the compression spring. This was too much for the motor to handle, so the force was reduced by changing the radius of the spring curve and the amount of deflection. Several trials were made until a balance between the available force from the motor equaled the force required to keep the lock latched during product development and initial user testing.

In the key-only design this was accomplished with a compression spring. Due to the force limitation of the motor, a smaller force had to be used for prototyping with the assumption that the design would be changed to ensure proper retention of the lock. The prototype for this product involved replacing much of the volume occupied by the compression spring with the controller board and adding additional volume by extending the height of the unit. To fit the space and to provide optimal use of the available motor force, the linear spring and latch was replaced with a pivoting latch and an inward-curved leaf spring, as opposed to the outward curve used on the previous design. The inward curve provided a large increase in force, matching or exceeding that of the compression spring, in about the same space as the compression spring. This was too much for the motor to handle, so the force was reduced by changing the radius of the spring curve and the amount of deflection. Several trials were made until a balance between the available force from the motor equaled the force required to keep the lock latched during product development and initial user testing.

A similar curved spring was used on a subsequent project. This third project was to develop a cabinet lock. The lock mechanism required the use of a serrated rod mounted to the cabinet door that interfaced with a spring-loaded locking unit mounted on the cabinet frame. When the door was closed, the rod slid into the locking unit and an internal latch caught one of the serrations on the probe. The desired size of the latching unit was cuboid and 1.25 inches on a side. As with the previous two projects, the restricted volume prompted the use of a small stroke spring. By integrating the spring into the latch slider, the part count was reduced and the assembly of this complex mechanism was simplified.

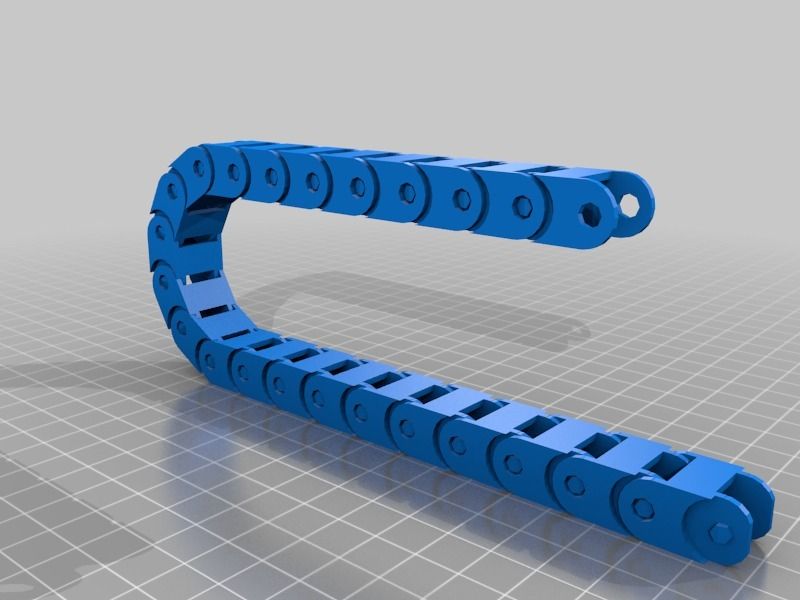

The key to utilizing 3D printed springs in production prototypes is to maintain the design to allow the printed spring to be replaced with a metallic spring with a minimum of redesign once the unit goes to production. Some products may be able to maintain the use of a plastic spring when the parts are being injection molded, but it will depend on the material used and the expected life of the part. For prototyping, 3D printed springs can enable rapid manufacturing of customized spring units and can integrate what may have been several separate and sometimes tiny parts into a single larger part. The technique can enable rapid testing and trials to enable the proper operational force to be determined; data that can be used later in the development cycle to properly size replacement metallic springs.

For prototyping, 3D printed springs can enable rapid manufacturing of customized spring units and can integrate what may have been several separate and sometimes tiny parts into a single larger part. The technique can enable rapid testing and trials to enable the proper operational force to be determined; data that can be used later in the development cycle to properly size replacement metallic springs.

For more information on the products described here, please visit see the Smart Armor Product Page.

Protect What Matters by Locking it Up with Smart Armor!

-Ben Hudson

STL file axial scx10 ii ar44 leaf spring attachment・3D printer model to download・Cults

axial scx24 c10 dropbed

1.88 €

Accessories 24th scale 1/24

1.88 €

scx24 jeep drop bed

1. 88 €

88 €

rc4wd mojave cab flatbed 12.3wb

€23.48

Best 3D Printer Files in the Gadget Category

Porta Chiavi, keychain Shark

Free

Coffee cup box!

€1.20

Propeller keychain

Free

Tom's Samsung Galaxy S9+ in Case Car Holder for Brodit ProClip Mount System

Free

Pen and ink bottle (work pen)

1.90 €

Owl eyes only - wall key holder

Free

STRONGMAN - WALL KEY HOLDER

1,33 €

Automatic Hammer Bot

Free

Bestsellers in the Gadget category

Revolver Colt SAA Peacemaker Fully functional BB 6mm primer pistol 1:1 scale

4. 99 €

99 €

Flexi Duck Print in place Multiparts

€3.29 -25% 2.46€

AP15 REINFORCED L. UPGRADE

6,50 €

Igloo housing for Bambu P1P

4 €

DIY Arduino Robot Arm with smartphone control

1 €

Storage 9mm 100x fits in container for cartridges 7.62 NATO

7.04 €

Application to turn your photo into 10 types of jewelry

3,50 €

5.56 / .223 100x storage fits in 7.62 NATO cartridge case

7.04 €

Candy Gat - 3D printed gun PEZ

4. 69 €

69 €

Dice box with mechanical rotating top

3.71 €

CAT IN A BOX - WALL HANGER FOR KEYS

0,99 €

G17- DD17 Frame with rails

6.50 €

Keyfob application

€3.50

Pawprint Heart Fidget Spinner, printed on the spot, keychain,

1.17 €

JEEP WRANGLER PEN HOLDER - 3-IN-1

1.85 €

App to turn a photo into a bobble head

3.50 €

💖 Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so support us in maintaining the activities of and creating future developments is very simple. Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via Ko-Fi here 💜.

-

INVITE YOUR FRIENDS: Invite your friends, discover the platform and the great 3D files shared by the community!

3D printers in construction: prospects for application

At first glance, 3D printing structures seem to be some kind of shell of a half-finished building. But upon closer examination, you will not find even a brick. Layers of material seem to build up one on top of the other - this is how a complex structure is created. It's a futuristic world of 3D printing where robotic arms automatically layer and compress layers of concrete or plastic or any other material into a foundation and build a structure.

This method of construction is quite niche today - only a few prototypes of 3D houses and offices have been printed in the world. However, this technology represents an exciting and potentially powerful solution for building change.

What is 3D printing in construction, what is the potential, and will we be working on 3D printed projects in the near future?

- What is 3d printing in construction?

- 3D printers in construction: how is it done?

- 5 examples of innovation

- How can 3d printed projects help construction companies?

- 3D printing distribution

- Civil engineering 3D printing

- Wiki House technology - an open source project for 3D printing: what is behind the concept

- Reverse side of medal

- How 3D printing can be integrated into construction

- About PlanRadar

3D printing in construction - what kind of technology?

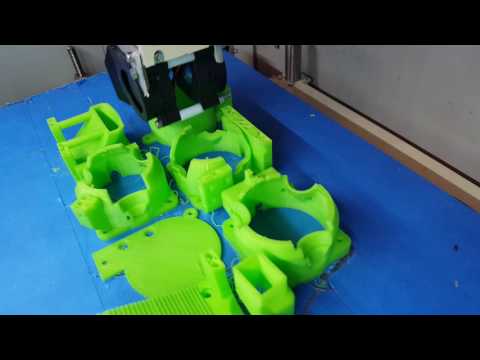

3D printing for construction uses both a 3D printer that has a robotic “crane-arm” that builds structures right on the construction site, and the creation of certain elements by printers at the factory, which are already assembled into a structure on site.

The concept of 3D printing is not new: it first appeared in the 80s. But it has only been in the last decade that this technology has been improved enough (and the cost has been reduced significantly) that it has become a real mainstream.

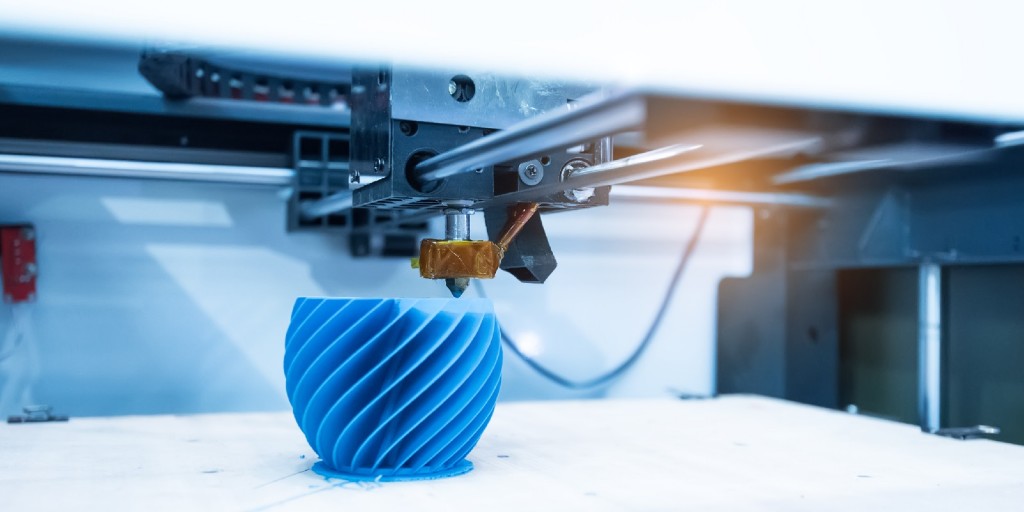

3D printers are not much different from conventional inkjet office printers. The software tells the printer about the dimensions of the final product. And then the printer starts to output the material to the platform according to the plan. 3D printers often use liquid metals, plastics, cement, and variations of different materials that, when cooled and dried, form a structure.

In a construction 3D printer, the CAD or BIM programs tell the device what to print, and the machine starts layering the material according to the design plan.

3D printers in construction: how do they work?

3D printing concept - The printer extrudes a defined liquid mixture in layers, level by level, creating a design based on a 3D model. The prepared mix of concrete, filler, plasticizer and other components is loaded into the hopper of the device and fed to the print head. The mixture is applied to the surface of the site or to the previous printed layers. This is how most 3D printers work. Among them, there are three types of devices for 3D printing:

The prepared mix of concrete, filler, plasticizer and other components is loaded into the hopper of the device and fed to the print head. The mixture is applied to the surface of the site or to the previous printed layers. This is how most 3D printers work. Among them, there are three types of devices for 3D printing:

Robotic printer

Read also: New technologies in construction 2021

5 innovative examples of 3D printing

To date, only a few 3D printing projects have been implemented in the construction industry. Here are five of the most impressive and promising projects:

Dubai City Hall Office Building, UAE

1. Dubai City Hall Office Building, UAE

3D printed building. The office block built in the UAE is 9,5 meter high building with an area of 640 m2.

An Apis Cor 3D printer moved around an open-air construction site with a crane and erected various parts of the structure.

2. Office of the Future, UAE

Office of the Future, UAE

Another impressive 3D printed building in the UAE, the Office of the Future is a unique, fairly large structure that currently houses a temporary headquarters organization Dubai Future Foundation.

For this building, the elements were not created on site and were printed in 17 days, while the building itself was assembled in 48 hours.

3. WinSun 3D Printer Homes, China

WinSun 3D Printer Homes, China

WinSun 3D Printing Company in China has also applied factory-built 3D printers to build residential buildings. The company has created several house projects, including a small multi-storey building. All construction details can be printed quickly and cheaply and then quickly assembled on the construction site.

The company calculated that it could cost as little as $161,000 to build and print their five-story building.

4. Lewis Grand Hotel, Philippines 3D printed number

Lewis Grand Hotel, Philippines 3D printed number

When planning a trip to the Philippines, consider staying at the Lewis Grand Hotel in Angeles City , Pampanga, where visitors will be greeted with the world's first 3D printed hotel suite. The hotel room was designed by Lewis Jakich, hotel owner and materials engineer, in collaboration with 3D printing specialist Anthony Rudenko. They created a massive 3D printer that prints sand and concrete based on volcanic ash. The room was printed in 100 hours.

The hotel room was designed by Lewis Jakich, hotel owner and materials engineer, in collaboration with 3D printing specialist Anthony Rudenko. They created a massive 3D printer that prints sand and concrete based on volcanic ash. The room was printed in 100 hours.

5. Two-story mansion in Beckum, Germany

Two-story mansion in Beckum, Germany

The first 3D-printed residential building with an area of about 80 square meters - the brainchild of the German construction company PERI GmbH and the architectural design bureau MENSE-KORTE ingenieure + architecture. A BOD2 3D printer was used to print one square meter of double wall cladding in 5 minutes. The building is a structure with three-layer hollow walls filled with insulating mass. Installation of hollow pipes and connections during printing was carried out manually.

3D printing in construction seems really impressive, but what are the real benefits of such technology?

How can 3D printed designs help construction companies?

Proponents of 3D printing houses and commercial offices point to several advantages of this construction method:

- Zero waste construction

In the UK, almost a third of the waste comes from the construction industry. According to the Transparency Market Research Group, the construction industry worldwide will produce 2.2 billion tons of construction waste by 2025. And although most of the waste is related to the demolition of buildings, the construction sites themselves produce a lot of waste.

According to the Transparency Market Research Group, the construction industry worldwide will produce 2.2 billion tons of construction waste by 2025. And although most of the waste is related to the demolition of buildings, the construction sites themselves produce a lot of waste.

Conversely, 3D printing can reduce waste to almost zero. A 3D printer uses a well-defined amount of material that is required to print a design - no more, no less. This can be a big savings.

- Reduced energy consumption

3D printing in construction encourages the use of locally available materials and natural ingredients. This practice can reduce energy costs in transportation, construction and manufacturing, as most local materials require less energy to process or install. If traditional materials with toxic chemical impurities are replaced with natural ones, then the toxicity of the entire construction can be reduced. In addition, local materials are often better suited to local climates and can reduce a building's heating or cooling load, which also reduces construction costs.

- Save time and money

As with AI in construction, a 3D printer can run 24 hours a day, 7 days a week. This means construction projects have the potential to be completed much faster and a number of low-skilled labor costs can be avoided. What's more, 3D printing eliminates the need for temporary structures, such as formwork and scaffolding, that are commonly used in traditional construction. Studies of 3D printed concrete structures have shown a significant reduction in formwork requirements, reducing costs by 35-60%.

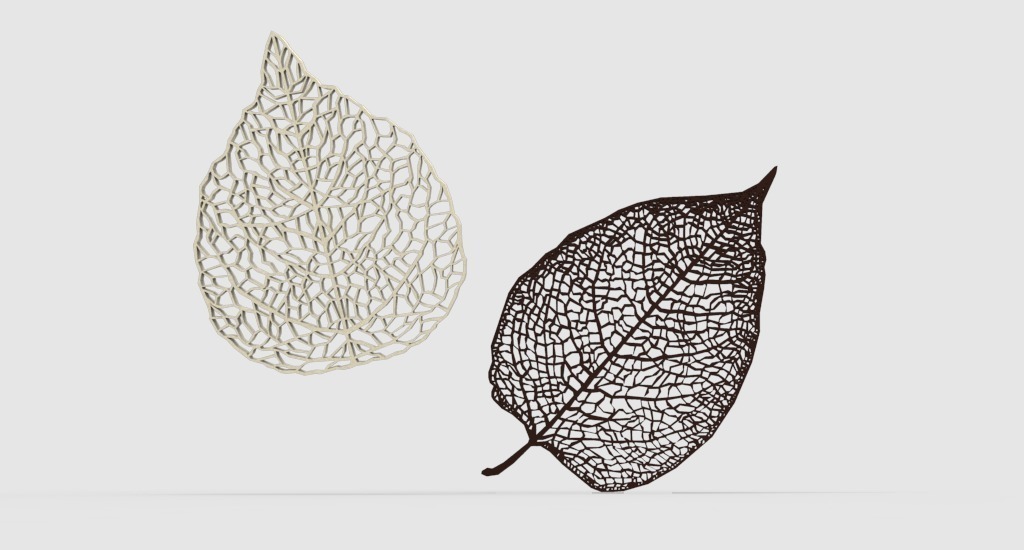

- Can realize unusual design shapes

One of the most attractive characteristics of 3D printers is their ability to create complex and unusual design designs, including the only one that is unique. Since the job of a 3D printer is to layer the material, they can be programmed into absolutely any unusual shape that would be much more difficult to create with traditional techniques.

- Minimize human error and improve safety

The published injury statistics at the workplace by the American agency BLS in 2020 indicates that construction is one of the most traumatic areas and a high incidence of diseases. Every day, about 5333 workers die on the construction site. And with the advent of 3D printing, the number of work injuries and fatalities will obviously decrease, as it makes construction more programmable and automated. Robotic construction requires standardized, accurate and complete digital building information, making this technology more accurate and efficient, with minimal rework due to human error or any information inconsistencies. The usual problems with materials and components that need to be stored somewhere, protected from damage are leveled out, problems with installation and work in progress due to damage also disappear - 3D elements are created as they are built, they do not need to be moved and stored.

- Exploring new markets

The use of a 3D printer also allows construction companies to enter new market sectors that were previously inaccessible to them. And for start-up companies, having a 3D printer will be a competitive advantage. What's more, 3D printing is a brilliant way to elevate or improve the reputation of a construction company's brand among those who believe that concrete production has an impact on the planet's environment.

Distribution of structural 3D printing

3D printing for structural reinforcement, small scale components and structural steel could revolutionize design, construction and space exploration. In addition, the European Space Agency (ESA) believes that using 3D printed metals to create high-quality complex shapes can significantly reduce their cost, and they will become very common.

ESA has developed a project with the European Commission to improve the printing of metal components that can be used in space. In total, 28 European partners have united for the joint project AMAZE (Additive Manufacturing Aiming Towards Zero - layer-by-layer 3D printing for zero waste from production and efficient production of high-tech metal products).

In total, 28 European partners have united for the joint project AMAZE (Additive Manufacturing Aiming Towards Zero - layer-by-layer 3D printing for zero waste from production and efficient production of high-tech metal products).

Almost everything can be designed on a computer, so AMAZE plans to install a 3D printer on board the spacecraft, and as soon as an astronaut needs any part, a tool, he can simply print it.

Structural 3D printing

Civil engineering 3D printing

Civil engineering 3D printing has been gaining popularity over the past decade, as has the aerospace and biomedical industries. This revolutionary manufacturing technique is based on its unique ability to create any geometric shape without any formal restrictions, minimizing waste but increasing productivity and results. The construction industry's push towards automation has recently reached important milestones, including the creation of the first structures using robotic "arms" and 3D printing technology.

The use of 3D printing in the creation of structural elements from polymer materials, concrete and metals is becoming more common.

These civil engineering technicians can create freeform and innovative architectural designs using CAD-integrated software.

However, despite considerable research in the aerospace and bioengineering industries to evaluate and analyze this mechanism, there is still a lack of understanding of its use, the impact of 3D printed materials in civil structures, both in terms of material properties and structural response.

Imperial College London

Read also: Best Building Apps in 2021

WIKI HOUSE - 3D printing in construction: what is the concept behind

Wiki House is an innovative project created by a small group of architects in London in 2011 . It offers an open source digital house design system that allows users to create, upload and share designs and print their own houses.

The kit does not require any special knowledge and training and can be created in 1 day. Elements are digitally cut from ordinary sheet material, like plywood, using a CNC machine. And it's much faster, less costly, and doesn't require the involvement of experts, as in conventional traditional construction.

Elements are digitally cut from ordinary sheet material, like plywood, using a CNC machine. And it's much faster, less costly, and doesn't require the involvement of experts, as in conventional traditional construction.

A standard two bedroom house can be built for less than £50,000 and additional components such as cladding, insulation, windows and more can be added to the main frame of the structure. The first house that was built on the basis of the open source Wiki House technology was a two-story building. The 3D printed house was presented at the London Design Festival in 2014.

The Wiki House movement was spearheaded by Alastair Parvin, whose TED presentation "Architecture for People, Built by People" talked about the promise of 3D printing in construction. The creator of this project believes that Wiki House can help solve the housing problem, especially in emergency situations such as earthquakes (there is already evidence that 3D-printed houses can withstand shocks up to magnitude 8).

In the future, this could become a real alternative to low-cost houses, while allowing the customer to control the design of the project.

3D building built using Wiki House

Will 3D printing be the sustainable future of building?

3D printing has the potential to revolutionize the supply chain and structure through a new method of design and manufacturing. According to the study, 3D printing can help the construction industry become more economical, more efficient and greener.

Saxon University of Applied Sciences scientists Ivo Kotman and Neils Faber claim that 3D printing technology will be a "game changer". They explored the possibilities of 3D printing concrete, and their conclusions are:

- 3D printing shortens the supply chain and the overall design process. 3D printing right on the job site eliminates time-consuming steps in the design process. The architects, engineers, contractors, clients, and executives who normally have to be actively involved in a project are no longer needed in 3D printing.

Since all tasks can be combined in one figure of the architect, who uses the modeling method and reproduces the exact holistic designs.

Since all tasks can be combined in one figure of the architect, who uses the modeling method and reproduces the exact holistic designs. - Pipe fitting and electrical wiring become easier and more efficient. Heating systems, insulation, plumbing and electricity all require the laborious on-site installation of conventional construction. However, in 3D printing, some of these features can be incorporated into the 3D printing process. Cavity wall printing is less resource intensive, improves insulation, and allows the use of 3D-printed hot or cold water channels. Moreover, the need for on-site installation is eliminated, which directly affects the reduction of waste.

- The best logistics. 3D printing eliminates 3 logistics and shipping issues. Firstly, many materials and elements often deteriorate upon delivery, and if everything is printed on site, then damage is minimized

Secondly, in order to withstand transportation, the parts must be with increased technical characteristics, which by default increases the cost of them, and therefore the entire project. 3D printing right on the construction site will help to avoid such additional costs.

3D printing right on the construction site will help to avoid such additional costs.

- Creation of individual house designs available to the general market. Usually, building a house with the involvement of an architect is an expensive pleasure for most consumers. But with concrete 3D printing, you don't have to worry about the chosen shape, it won't cost more. In fact, this means that in the future more people will be able to buy houses of their own design, according to their individual needs

Reverse side of the coin

While 3D printing is definitely attractive, it's still important to look at it impartially, removing some of the promotional stimulus. Skeptics note several disadvantages of this technology.

Skeptics note several disadvantages of this technology.

- Research and development costs

Most construction companies operate with relatively low profitability. To start using 3D printing everywhere, significant investments will be required.

- Will consumers see this as a marketing ploy?

3D printed houses, offices, shops and other infrastructure are often impressive. But do most people really want to live or work in one? For most people, brick houses are much more familiar and attractive. Other technologies such as prefabricated houses also seemed like an attractive technology of the future some time ago, but have not been widely adopted, despite the fact that in many cases they were cheaper than traditional ones.

- Difficulty integrating with other components

3D printers can create unique and interesting designs. However, if you need a building that will use different materials or different elements that will not be suitable for 3D printing, then it will be a challenge to include a 3D printer for the building process.

- Skilled labor shortage

With the current problem of a shortage of skilled labor in the construction sector as a whole, 3D printing will require an even larger set of specialized knowledge and skills, which will have to be selected from an already small niche of candidates. So finding specialists to work in 3D printing for construction may be another difficult task in the future.

- Construction quality control

Weather conditions can slow down the traditional building process, but things are even worse for 3D printing. The environmental factor for commercial construction may reduce the demand for 3D printing. What's more, quality control can be a much more serious task, requiring constant monitoring of the process by real people at the construction site.

- No standards and regulations

Despite the regular mention of 3D printing in the media, it still has not had a significant impact on the construction sector. There is an obvious liability issue when using these printers, even more so than human liability when doing some construction work. And quite a few other ambiguities regarding this technology. So until norms and standards are established, as well as rules in this area, 3D printing is unlikely to become mainstream in the construction industry.

There is an obvious liability issue when using these printers, even more so than human liability when doing some construction work. And quite a few other ambiguities regarding this technology. So until norms and standards are established, as well as rules in this area, 3D printing is unlikely to become mainstream in the construction industry.

Read also: New technologies in construction 2021

How can 3D printing be integrated with construction?

At the moment there is strong evidence that 3D printing is worthy of attention and can be applied in the construction segment, and most likely that this technology will be used more in the coming years. True, it is not known how widely these devices will be used on the construction site, or whether they will remain only a tool for the manufacture of block elements for prefabricated structures. But for certain projects, it is reasonable to assume that 3D printers and this technology in construction will be a must-have tool in the arsenal of builders.