Spider 3d scanner

Industrial 3D Scanner | Space Spider

| Scanner type | Handheld | Handheld | Handheld | Handheld | Desktop |

| 3D point accuracy Accuracy is the ability of a measurement to match the actual value of the quantity being measured. , up to | 0.05 mm | 0.1 mm | 0.1 mm | 0.1 mm | 0.01 mm |

| 3D resolution Resolution is the ability of a scanning system to resolve detail in the object that is being scanned. , up to | 0.1 mm | 0.2 mm | 0.5 mm | 0.2 mm | 0.029 mm |

| 3D accuracy over distance, up to | 0.05 mm + 0.3 mm/m | 0.1 mm + 0.3 mm/m | 0.1 mm + 0.3 mm/m | 0.1 mm + 0.3 mm/m | — |

| HD Mode | N/A | Yes | No | Yes | N/A |

| Hybrid geometry and texture tracking | Yes | Yes | No | Yes | N/A |

| Data processing algorithms | Geometry and texture based | Geometry and texture based | Geometry based | Geometry and texture based | Geometry based |

| Working distance | 0. | 0.4 – 1 m | 0.4 – 1 m | 0.35 – 1.2 m | — |

| Volume capture zone | 2,000 cm³ | 61,000 cm³ | 61,000 cm³ | 160,000 cm³ | 324 cm³ |

| Linear field of view, H×W @ closest range | 90 × 70 mm | 214 × 148 mm | 214 × 148 mm | 244 × 142 mm | — |

| Linear field of view, H×W @ furthest range | 180 × 140 mm | 536 × 371 mm | 536 × 371 mm | 838 × 488 mm | — |

| Angular field of view, H×W | 30 × 21° | 30 × 21° | 30 × 21° | 38.5 × 23° | — |

| Ability to capture texture | Yes | Yes | No | Yes | Yes |

| Texture resolution | 1.3 mp | 1.3 mp | — | 2.3 mp | 6.4 mp |

| Colors | 24 bpp | 24 bpp | — | 24 bpp | 24 bpp |

| 3D reconstruction rate for real-time fusion, up to | 7. 5 fps 5 fps | 16 fps | 16 fps | 22 fps | — |

| 3D reconstruction rate for 3D video recording, up to | 7.5 fps | 16 fps | 16 fps | 44 fps | — |

| 3D reconstruction rate for 3D video streaming, up to | — | — | — | 80 fps | — |

| Data acquisition speed, up to | 1 mln points/s | 18 mln points/s | 2 mln points/s | 35 mln points/s | 1 mln points/s |

| 3D exposure time | 0.0002 s | 0.0002 s | 0.0002 s | 0.0002 s | Customizable |

| 2D exposure time | 0.0002 s | 0.00035 s | 0.00035 s | 0.0002 s | Customizable |

| 3D light source | Blue LED | Flashbulb | Flashbulb | VCSEL | Blue LED |

| 2D light source | White 6 LED array | White 12 LED array | White 12 LED array | White 12 LED array | RGB LED |

| Position sensors | — | — | — | Built-in 9 DoF inertial system | — |

| Display/touchscreen | USB streaming through external computer | USB streaming through external computer | USB streaming through external computer | Integrated 5. 5" half HD, CTP. Optional Wi-Fi/Ethernet video streaming to external device 5" half HD, CTP. Optional Wi-Fi/Ethernet video streaming to external device | USB streaming through external computer |

| Multi-core processing | On external computer | On external computer | On external computer | Embedded processors: NVIDIA® Jetson™ TX2 Quad-core ARM® Cortex®-A57 MPCore Processor NVIDIA Maxwell™ 1 TFLOPS GPU with 256 NVIDIA® CUDA® Cores | On external computer |

| Interface | 1 × USB 2.0, USB 3.0 compatible | 1 × USB 2.0, USB 3.0 compatible | 1 × USB 2.0, USB 3.0 compatible | Wi-Fi, Ethernet, SD card | USB 3.0 |

| Internal hard drive | — | — | — | 512 GB SSD | — |

| Supported OS | Windows 7, 8 or 10 x64 | Windows 7, 8 or 10 x64 | Windows 7, 8 or 10 x64 | Scanning: No computer required Data processing: Windows 7, 8, 10 x64 | Windows 10 x64 |

| Recommended computer requirements | Intel Core i7 or i9, 32 GB RAM, GPU with 2 GB VRAM | Intel Core i7 or i9, 64+ GB RAM, NVIDIA GPU with 8+ GB VRAM, CUDA 6. 0+ 0+ | Intel Core i7 or i9, 32 GB RAM, GPU with 2 GB VRAM | Intel Core i7 or i9, 64+ GB RAM, NVIDIA GPU with 8+ GB VRAM, CUDA 6.0+ | Intel Core i7 or i9, 64+ GB RAM, NVIDIA GPU with at least 3 GB VRAM, CUDA 3.5+ |

| Minimum computer requirements | Intel Core i5, i7 or i9, 18 GB RAM, GPU with 2 GB VRAM | HD: Intel Core i7 or i9, 32 GB RAM, NVIDIA GPU with CUDA 6.0+ and at least 2 GB VRAM SD: Intel Core i5, i7 or i9, 12 GB RAM, GPU with 2 GB VRAM | Intel Core i5, i7 or i9, 12 GB RAM, GPU with 2 GB VRAM | HD: Intel Core i7 or i9, 32 GB RAM, NVIDIA GPU with CUDA 6.0+ and at least 4 GB VRAM SD: Intel Core i5, i7 or i9, 32 GB RAM, GPU with 2 GB VRAMA computer is needed only for data processing. Scanning does not require a computer. | Intel Core i5, i7 or i9, 32GB RAM, GPU with 2 GB VRAM |

| 3D mesh | OBJ, PLY, WRL, STL, AOP, ASC, PTX, E57, XYZRGB |

| CAD | STEP, IGES, X_T |

| Measurements | CSV, DXF, XML |

| Power source | AC power or external battery pack | AC power or external battery pack | AC power or external battery pack | Built-in exchangeable battery, optional AC power | AC power |

| Dimensions, HxDxW | 190 × 140 × 130 mm | 262 × 158 × 63 mm | 262 × 158 × 63 mm | 231 × 162 × 230 mm | 290 x 290 x 340 mm |

| Weight | 0. 8 kg / 1.8 lb 8 kg / 1.8 lb | 0.9 kg / 2 lb | 0.9 kg / 2 lb | 2.6 kg / 5.7 lb | 12 kg / 26.7 lb |

Buy Handheld 3D Scanners and 3D Scanning Software at Best Price

3D scanning solutions

How Artec 3D is supporting Ukraine

Artec Leo Premium Pack

Ultimate 3D scanning pack that has everything you need: top-level handheld scanner, Calibration Kit, extended warranty, maintenance, software subscription, and then some.

Artec Leo

Our best 3D scanner, equipped with wireless technology and an inbuilt touch screen

Artec Eva

The ideal 3D scanning solution for making quick and accurate 3D models of medium-sized objects

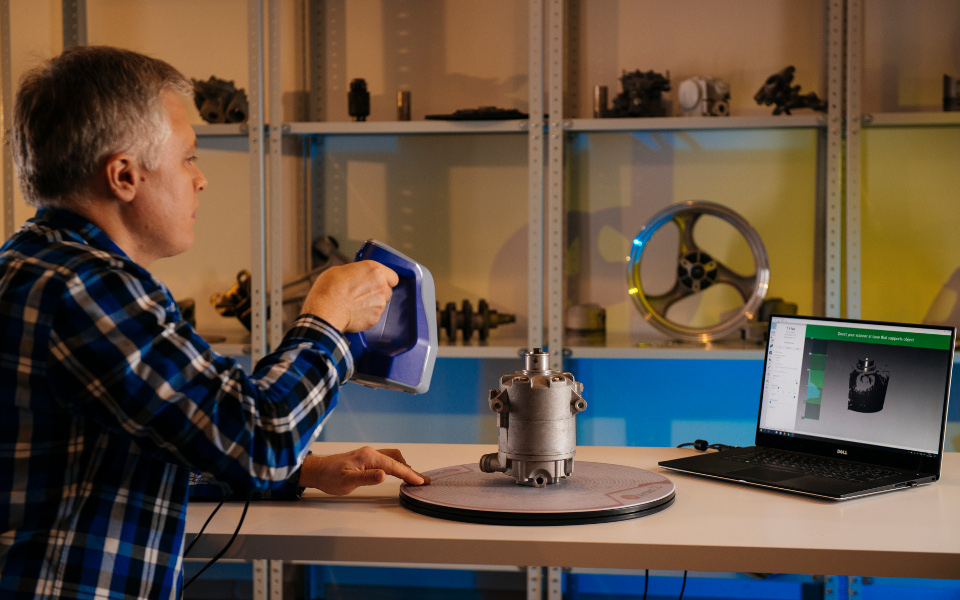

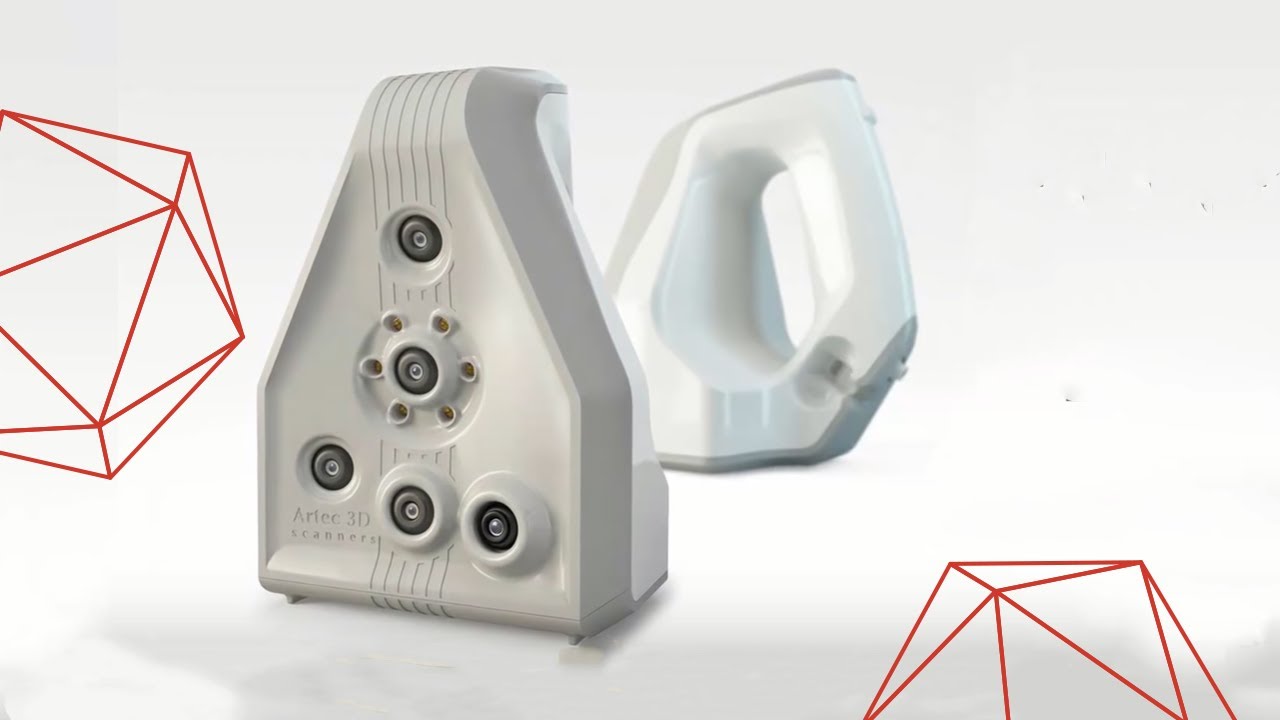

Artec Space Spider

A metrological 3D solution, perfect for capturing small objects for CAD applications and more

Artec Eva Lite

Entry level white light 3D scanner. Geometry tracking and capture only.

Artec Ray

Long range laser scanner for digitizing large objects, such as airplanes or buildings.

Artec Micro

The perfect metrology-grade desktop 3D scanner for quality inspection, jewelry and dentistry.

Artec Metrology Kit: Entry

Optical coordinate measuring system for inspection and engineering. Accuracy up to 4 microns.

Artec Metrology Kit: Professional

Optical coordinate measuring system for inspection and engineering. Accuracy up to 2 microns.

Upgrade Eva Lite to Eva

Get the full power of Eva’s color tracking and capture features.

Upgrade

Special offers

Educational packages

Artec handheld 3D scanners available at lower prices for classroom use

View more info

Geomagic Design X bundle

An all-in-one reverse engineering solution with Artec Studio and 3D engineering software

View more info

Geomagic for SOLIDWORKS bundles

Export your 3D scans directly to SOLIDWORKS and make manufacture-ready 3D models

View more info

Geomagic Freeform bundles

A winning combination for hands-on organic product design and manufacturing

View more info

Geomagic Control X bundles

An outstanding combo for extensive quality control with easy data capture and analysis

View more info

Geomagic Wrap bundles

A great solution for comprehensive exact surfacing with an extensive toolbox

View more info

Artec software

Artec Studio 17 Trial

An easy way to get started. Try Artec Studio for 30 days at no cost.

Try Artec Studio for 30 days at no cost.

See all plans

Artec Cloud

Annual, renewed automatically every year

See all plans

200 GB

12 months from date of payment

See all plans

12 months from date of payment

See all plans

Geomagic software

Geomagic for SOLIDWORKS

An ideal scan-to-CAD solution for a seamless workflow in SOLIDWORKS.

Geomagic Design X

Optimal reverse engineering software for fast conversion of 3D scan data into CAD models.

Geomagic Control X Professional

A powerful metrology solution with an advanced set of tools for a flexible workflow.

Geomagic Wrap

A versatile solution with an extensive toolbox, perfect for exact surfacing.

Optional equipment

Leo Calibration Kit

Recalibrate your Artec Leo in your own time, and in your own environment, to ensure its accuracy always stays at its highest.

Artec Turntable

A smart turntable for effortless 3D scanning of small objects with Artec Space Spider.

Smart battery charger (Leo)

High-performance and intelligently designed to deliver maximum charges, while extending battery lifespan to the fullest.

Smart Li-Ion battery (Leo)

Keep an extra battery handy and give yourself up to 6 hours more scanning freedom wherever your project takes you.

Eva/Spider battery pack

Scan anywhere for up to 6 hours non-stop. Includes a pouch, a charger, and a power cable for connecting the battery to the 3D scanner.

Artec Eva hard case

Designed with Eva’s measurements in mind, this hard case will keep it safe during storage and transportation.

Space Spider calibration kit

This kit is there to make sure the accuracy of your Space Spider remains at its highest at all times, even after a sudden jolt!

Battery pack cable

Got a field scanning job lined up but your dog has chewed the cable of your Eva/Space Spider battery pack? Order a replacement in just a few clicks!

Power supply for battery pack

No matter what extra accessory you may need, Artec 3D has you covered. Order this native power supply unit to charge your Eva/Space Spider battery pack the fastest and safest way possible!

Order this native power supply unit to charge your Eva/Space Spider battery pack the fastest and safest way possible!

Eva/Spider USB cable

A fully tested cable featuring the connector needed for your Artec scanner.

Eva/Spider power supply

1.8 m power supply developed exclusively for Artec 3D scanners for stable performance

Artec USB Kit

Maximize your Artec Eva or Space Spider’s FPS rate with a USB 3.1 to Thunderbolt 3 adapter and add a 5 m extension to your scanner’s USB cord for scanning over longer distances.

Contact us

how to assemble a 3D scanner from scrap materials and digitize reality — T&P

The first 3D printers that cost less than a gaming computer have become a mandatory attribute of almost any hackspace or fablab (laboratory of technical creativity and electronic art). Now 3D scanners have joined them. MIPT student and employee of the Polytechnic Museum Daniil Velovaty himself assembled a three-dimensional scanner from a laser, a webcam, and scrap materials.

As part of the special project Phystech. Reader" he told T&P about the future of reality scanning.

As part of the special project Phystech. Reader" he told T&P about the future of reality scanning.

Daniil Velovaty

It was easy to get used to 3D printers: I drew the desired detail or figure on the computer, loaded it into the printer, and a few hours later I took its embodiment in plastic. Yes, what about plastic, they are already printing in metal, and even in organic matter: they recently printed a living liver. No wonder you want to go further. The next step is scanning. Oddly enough, but before the advent of 3D printers, there was no great need to transfer a real object to the digital world: the creators of games and films simply hired artists who drew whatever was needed. The need for scanners arose only when it was important to convey the relief and shape of an object with very high accuracy. At the same time, neither the duration of the scan nor the cost were often completely unimportant. This is how the first representatives of 3D scanners appeared: lidars.

Lidar (from English Light Detection and Ranging) is an expensive but very accurate device. It allows you to build 3D models of objects with an accuracy of millimeters, the size of which can be compared with the size of a building. From the decoding of the abbreviation LIDAR, it follows that it is any rangefinder that measures distance using light. An incredible number of devices fall under this description. But most often, devices like this are called lidars:

A special system of mirrors is placed inside the device. A phase laser rangefinder is installed here, which measures the distance using a laser, and two mirrors serve to deflect the laser beam in two planes. Thus, the ray runs through a certain sector of space and builds its 3D model. As you might guess, the speed of such a scanner depends on the speed of the rangefinder and the speed of rotation of the mirrors. And since all this is quite complex equipment that requires fine tuning, it costs quite a lot of money. It is much more profitable to order a scan than to buy the device itself. Moreover, you still need to figure out how to use it.

It is much more profitable to order a scan than to buy the device itself. Moreover, you still need to figure out how to use it.

As industrial devices were, to put it mildly, beyond the reach of the average consumer, and the need to scan reality grew, cheap desktop and handheld 3D scanners appeared. The former, as a rule, have a turntable on which the object under study is placed. A few minutes after the start of the scan, we will get the finished model. Of course, the scan quality and the size of the scanned area are incomparable with lidars, but they cost several orders of magnitude cheaper. It is to this class of devices that the scanner we developed belongs. The main problem with these scanners is that the object to be scanned must fit on a turntable, which greatly limits the scope. Another significant disadvantage of these scanners is the incompleteness of scanning and blind spots. If, for example, you try to scan a vase, the scanner will only see its outer part, and not the cavity inside.

The second type of scanners are handheld 3D scanners. They need to be moved around the object by hand, but they build a model with the help of cameras. The operation algorithm of such scanners is much more complicated, they are more expensive, and the quality of the result is worse, but they allow you to scan large objects and spend less time on it. They look something like this:

One of the main advantages of such a scanner is that it is not limited by the scanning area. We can scan, for example, a person's face without having to place their head on a turntable. With a certain diligence, even an entire room can be scanned, if only the positioning accuracy allows it. To improve accuracy, you can stick special marks that the scanner finds and uses as reference points. Actually, in the photo above, this is what was done. This approach limits the scanning area, but, unfortunately, here either the sheep are safe or the wolves are full.

In our lab, we decided to create a cheap 3D scanner with an accuracy comparable to that of 3D printing. This was our first serious project, so we made mistakes, misunderstood a lot, and learned even more along the way. We first built a simple laser rangefinder using a laser pointer and a webcam. To understand how a 2D camera can measure distance, you have to use your imagination. Imagine a thread stretched in the air, along which a spider is crawling. If we stand close to the rope, we see how the spider is crawling straight towards us (not a very pleasant sight). And if now we shine a lamp on this whole structure from the side, we will see a shadow on the floor. Since the light comes from the side, the projection of the spider will move along the projection of the thread. By measuring the distance from the beginning of the thread's shadow to the spider's shadow, we can calculate how far the spider has crawled by multiplying by some factor, because we are creating a contraction mapping.

This was our first serious project, so we made mistakes, misunderstood a lot, and learned even more along the way. We first built a simple laser rangefinder using a laser pointer and a webcam. To understand how a 2D camera can measure distance, you have to use your imagination. Imagine a thread stretched in the air, along which a spider is crawling. If we stand close to the rope, we see how the spider is crawling straight towards us (not a very pleasant sight). And if now we shine a lamp on this whole structure from the side, we will see a shadow on the floor. Since the light comes from the side, the projection of the spider will move along the projection of the thread. By measuring the distance from the beginning of the thread's shadow to the spider's shadow, we can calculate how far the spider has crawled by multiplying by some factor, because we are creating a contraction mapping.

Our scanner works in much the same way. Only instead of a thread - a laser beam, and instead of a screen with a shadow - a camera. Just as a spider moves along a thread, a spot moves along the laser beam, which occurs when this beam encounters an obstacle. Having found the position of the spot in the photograph, we can determine the distance to the object on which this spot is located. In words, it is difficult. It looks simpler in the picture:

Just as a spider moves along a thread, a spot moves along the laser beam, which occurs when this beam encounters an obstacle. Having found the position of the spot in the photograph, we can determine the distance to the object on which this spot is located. In words, it is difficult. It looks simpler in the picture:

The farther the wall, the closer to the dotted line will be the pfc point on the camera matrix

But such a rangefinder measures the distance to a single point, and this takes a very long time. Therefore, we put a lens on the laser, which turns the laser spot into a laser line. Now we measure the distance to hundreds of points at once (after all, a line can be represented as a set of points), it remains to build a system that allows this line to go through the entire object, and for this we need a turntable on which the object is placed.

The scanner itself is assembled from plywood pieces that have been laser cut. To rotate the table, a stepper motor is used, which is controlled by a board developed by us. It also controls the brightness of the laser and backlight.

It also controls the brightness of the laser and backlight.

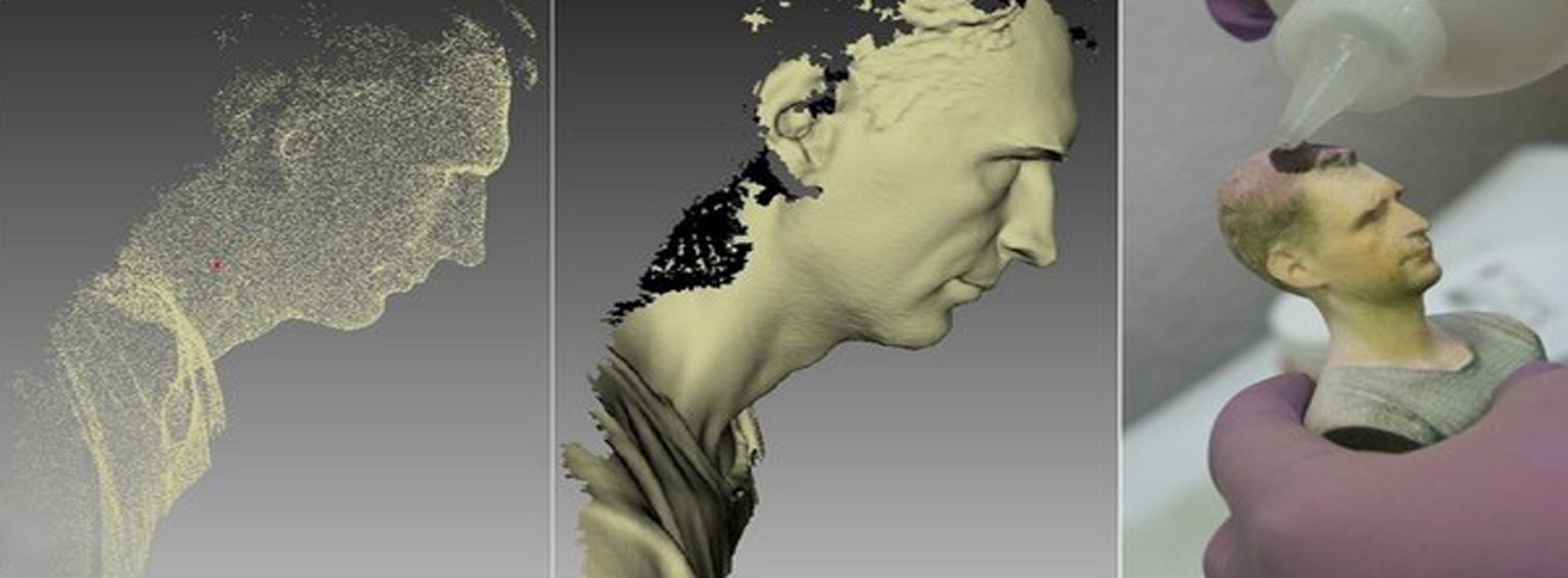

The image from the camera is processed on a computer; a Java program was written for this. After scanning is completed, the program generates a so-called point cloud, which, using another program, are combined into a full-fledged model. This model can already be printed on a 3D printer, that is, a copy of a real object can be obtained.

Don't miss the next lecture:

Theory and practice

Tags

#3D printers

#MIPT

#technologies

-

10 061

scanning - 3D scanning technology news and reviews

Until recently, 3D printers seemed to print small details for several hours. Modern 3D scanners make it possible to quickly and easily obtain three-dimensional images of real objects and convert them into digital 3D models. Subsequently, the received content can be used for everything, including as a model for 3D printing.

Thanks to modern technology, scientists are able to recreate the faces of people who lived on Earth thousands of years ago. To do this, they need a skull, a tomography machine and a 3D modeling program. Earlier, we have already talked in detail about the achievements of scientists in this area - we showed how the astronomer Nicolaus Copernicus, the Egyptian Queen Nefertiti and Pharaoh Tutankhamun looked at one time. Recently, scientists have reached the pharaoh Ramesses II, who is considered one of the most powerful rulers of ancient Egypt. Having studied the skull, they created a model of his head and superimposed on it the details of his appearance, which are mentioned in ancient documents. As a result, they got a man whose appearance meets all the standards of beauty of the ancient Egyptian era. Let's find out how scientists recreated the appearance of Ramesses II and look at the images - what beautiful features are we talking about?

Read more In Australia, there are Narakort Caves - a national park, inside which there are many fossils of ancient animals. At the moment, scientists know about the existence of 26 caves, but there may be hidden tunnels between them. Most likely, inside them lie the remains of animals that scientists have not yet had a chance to study. To find hidden passages, Australian students launched the CaveX project, which developed 15 research robots. Among them, they chose the mechanism that is best suited for exploring the cave - it is a robot in the form of a spider with six limbs. It is believed that this design will allow it not to damage the surface of a historically important site. The robot will be equipped to create a 3D map of the cave, but what exactly can it find inside?

At the moment, scientists know about the existence of 26 caves, but there may be hidden tunnels between them. Most likely, inside them lie the remains of animals that scientists have not yet had a chance to study. To find hidden passages, Australian students launched the CaveX project, which developed 15 research robots. Among them, they chose the mechanism that is best suited for exploring the cave - it is a robot in the form of a spider with six limbs. It is believed that this design will allow it not to damage the surface of a historically important site. The robot will be equipped to create a 3D map of the cave, but what exactly can it find inside?

According to 2021 data, the most unsafe places on our planet are the Gaza Strip, Sudan and Somalia. It is believed that tourists who have gone to these places may never return, because there is a high chance of being killed or captured. But crime is almost everywhere - to be convinced of this, it is enough to look at the criminal report. Unfortunately, some criminals cannot be arrested even if there is video from surveillance cameras and even the testimony of witnesses. On the recordings, the faces of thieves and murderers are often blurred, and people cannot remember the special features of the criminals. In order to improve the accuracy of recognizing violators of law and order, scientists decided to create their 3D models so that eyewitnesses could view them from different angles. It is impossible to explain the whole essence of the idea of the researchers in one paragraph, so let's delve into the details.

Unfortunately, some criminals cannot be arrested even if there is video from surveillance cameras and even the testimony of witnesses. On the recordings, the faces of thieves and murderers are often blurred, and people cannot remember the special features of the criminals. In order to improve the accuracy of recognizing violators of law and order, scientists decided to create their 3D models so that eyewitnesses could view them from different angles. It is impossible to explain the whole essence of the idea of the researchers in one paragraph, so let's delve into the details.

The collection of the Dutch Postal Museum in The Hague (Netherlands) has a chest containing 300-year-old letters. In those days, there were no envelopes, so to protect letters from prying eyes, the authors folded the paper in the most cunning ways. Sometimes they made cuts, holes and glues to make the letter as difficult to open as possible. So, if the paper was damaged, the recipient could immediately guess that someone had already read his letter. The chest with letters was found only in 1926, so opening the letters without damaging them seemed an impossible task. Indeed, over time, the paper becomes fragile and any attempt to open it could damage it. However, recently scientists decided to study them using a special X-ray, which is used for dental purposes. It turned out that with the help of this device you can read letters without even opening them. Now I will tell you how this is possible.

The chest with letters was found only in 1926, so opening the letters without damaging them seemed an impossible task. Indeed, over time, the paper becomes fragile and any attempt to open it could damage it. However, recently scientists decided to study them using a special X-ray, which is used for dental purposes. It turned out that with the help of this device you can read letters without even opening them. Now I will tell you how this is possible.

Have you seen films in which the spy first takes a photo of the key he needs, and then returns again with a duplicate that appears from nowhere? This is usually the plot of films for a robbery: a potential thief does not want to steal the key, so as not to expose himself, quickly photographs it so that make a duplicate of the key according to photo and then return to complete the plan. It would seem that this is something from the level of "hacking a power plant and leaving the whole city without electricity. " But experts are now warning that criminals can indeed use 3D printing technology to break into your home or open a safe. All they need for this is a photo of the keys to the house.

" But experts are now warning that criminals can indeed use 3D printing technology to break into your home or open a safe. All they need for this is a photo of the keys to the house.

The devastating flames that raged in the 850-year-old cathedral in Paris have been brought under control. The cathedral burned down almost to the ground and will be "closed for restoration", which will require an indescribable amount of money and, according to experts, will take 40-50 years. Donations for the restoration of the famous Notre Dame Cathedral come from all over the world, but there is something else that will help restore the cathedral to its former glory: a 3D map, digitized 3D scans of the building.

Read more Scientists from the Howard Hughes Medical Institute have improved the method of fluorescence microscopy in such a way that now it can be used to capture in high resolution the dynamic processes occurring in a living organism. The scientists shared the results of their work in the scientific journal Science, and an example of the visualization of dynamic processes, which was filming the movement of immune cells in a fish embryo, was presented in an article in the journal Nature.

Scientists from Tel Aviv University and Ben Gurion University, with the support of their Canadian and Chinese colleagues, were able to solve the problem of inaccurate reading of objects by 3D laser scanners. The method turned out to be very inexpensive, but effective.

Read morePeriodically, we tell you about the various developments of the Disney Research laboratory, which employs dozens of highly qualified specialists in various fields of science. This time, Disney engineers have presented a revolutionary technology for reconstructing a 3D model of a human jaw from photographs or video footage. In the foreseeable future, this technology can be used to create realistic 3D images of people in films, cartoons and video games.

Read more We have repeatedly told you about the process of 3D printing of biological tissues and even human organs on the pages of our website. Science over the past few years has stepped far forward in this area and is not going to give up its positions.