Dentsply 3d printer

Primeprint | Dental 3D Printer

Interested in Primeprint?

Connect with us to learn more about Primeprint.

Contact us

About the Primeprint 3D Printing Solution

Expand your practice or lab with 3D printing

Primeprint Solution is a highly automated, end-to-end, medical grade 3D printing system for dentists and dental technicians who want to expand their treatment or service offerings. This smart hardware and software solution is designed for dental applications and can run the entire printing process, including post-processing. The high level of automation helps reduce handling times, allows for delegation, and enables a high level of productivity. Primeprint Solution enables the user to print biocompatible applications with reproducible and accurate results. 1

Why choose the DS Primeprint Solution?

A medical-grade 3D printing solution

Primeprint Solution is a simplified, highly automated, end-to-end 3D printing solution for producing medical applications, enabling users to expand their treatment and service offerings. It also helps reduce handling times and manual work, allowing you to aim at maximising productivity.

Designed with dental intelligence for excellence in your practice and lab

Dental Intelligence hardware and software enable the user to print biocompatible applications with reproducible and accurate results1. The intelligent material-handling concept was developed with the aim of safe and clean usage with RFID coding throughout the manufacturing process. By using the open, collaborative platform of cloud design services, dentists can request high-quality CADs, created by expert lab technicians, as ready-to-print files for 3D printing with Primeprint.

Procedures and treatment outcomes with a high level of safety

A quality process protocol supports a high level of safety based on medical device compliance and automatic case documentation for biocompatible applications. The unique Primeprint Box enables convenient and easy material handling without having direct contact with resins.

The unique Primeprint Box enables convenient and easy material handling without having direct contact with resins.

Ready-to-print files created for you by expert lab technicians

Primeprint becomes even easier to integrate into your practice by full delegating the CAD workflow to our design service, DS Core Create. DS Core Create provides you with easy access to ready-to-print designs created by expert lab technicians. With DS Core Create, you can decide whether you want to make the designs yourself or outsource the design workflow to a reliable and competent partner.

Features

RFID Tagging

Primeprint and Primeprint PPU automatically detect the material, without contact, thanks to RFID technology. The cartridge, material unit, and washing containers are equipped with RFID tags for fast handling and predictive maintenance.

DLP Light Engine

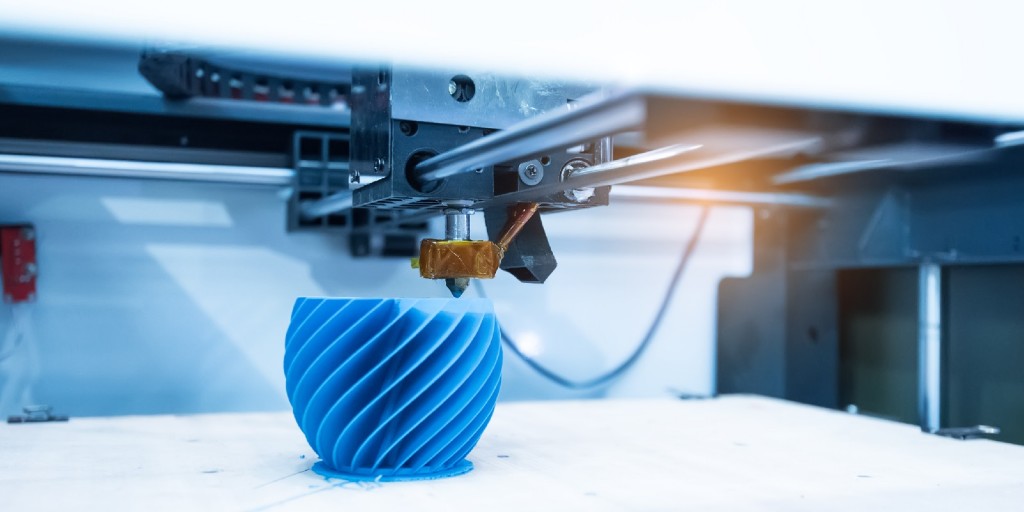

Primeprint uses digital light processing (DLP) technology, where resins are polymerised using UV light. The light projector hardens the resin layer by layer to deliver highly accurate printing results.

The light projector hardens the resin layer by layer to deliver highly accurate printing results.

Intelligent Material Management

For specific indications, Primeprint uses a distinct material. The cartridges are colour-coded for easy, contactless handling and intuitive operation. Primeprint also offers complete UV light protection. Thanks to the RFID tag, Primeprint automatically checks the inserted cartridge and fill level.

Active Coal Filter

The integrated active coal filter makes an external suction device redundant.

Robot Arm

Inside of the printer and the PPU, a robot arm moves the build plate to the respective process step without any manual work on your part.

Fast Printing

Primeprint quickly prints what you need for an optimised workflow.

Exact Lifetime Tracking

By using RFID tags and intelligent material management, Primeprint can predict any required maintenance.

Aluminum Build Plate

The building platform is equipped with highly reflective aluminum to ensure a maximum level of light efficiency and allow only low light absorption. Printed objects are securely attached to the build plate and securely transported with the Primeprint Box.

Printed objects are securely attached to the build plate and securely transported with the Primeprint Box.

Testimonials

For us dentists, Primeprint turns 3D printing into an efficient application for everyday use, and that’s also great for my patients. The workflow is simplified end to end so I can get very good results.“

Mike Skramstad, DDS, USA

I am more than enthusiastic about Primeprint, as it means 3D printing on a completely new level for our dental lab. The printer speed allows me to run multiple print jobs even during the day.”

Christian Schuchmann, Dental Technician, Germany

Discover more with DS Core

Primeprint Workflows

Learn more

Changing your dental practice with 3D printing

Learn more

Resources

Learn more

Thinking about getting a 3D printer? 6 benefits driving 3D printer adoption in dentistry

Learn more

Contact Us

Interested in learning more about Primeprint? Please complete the form below and one of our product specialists will be in touch.

I am a*

Please select Dental Assistant Dental Hygienist/Therapist Dental Laboratory Technician Dentist Dealer Channel Sales Office Staff/Front Desk Patient Other

Specialty

Please select NHS Clinics & Hospitals Dental Anaesthesia Endodontics Aesthetics & Plastic Surgery General Practice Implantology Oral and Maxillofacial Surgery Orthodontics Paediatric Dentistry Periodontics Prevention Prosthodontics

GDC Number

Comment*

Email*

Academic Title

Please select

Dr. Prof.

Prof. Dr.

Prof.

Prof. Dr.

Company*

Street

Postal Code & City*

Country*

Please select United Kingdom Ireland Jersey Guernsey Isle of Man

We would like to keep you informed with updates and offers from the Dentsply Sirona Group via email. Please tick the box if you are happy for us to do so. You can change your mind at any time. Simply adjust your email settings or unsubscribe from email marketing communications in your preference center.

load-icon

We are currently unable to process this time. Please try again later.

Please try again later.

*Required fields

Visit the Download Center to find Instructions for use, safety data sheets, eMDR documents, and more.

Go to Download Center

1. Reich S, Berndt S, Kühne CH, Herstell H. Accuracy of 3D-Printed Occlusal Devices of Different Volumes Using a Digital Light Processing Printer Appl. Sci. 2022, 12(3), 1576; https://doi.org/10.3390/app12031576

Berndt S, Herstell H, Raith S, Kühne CH, Reich S. Accuracy of 3D-Printed Master Cast Workflow Using a Digital Light Processing Printer. Appl. Sci. 2022, 12(5), 2619; https://doi.org/10.3390/app12052619

*DS Core currently supports automatic upload for devices connected to Sidexis 4.3.1, CEREC SW 5.2.3 and Connect SW 5.2.3.

Dentsply Sirona's Primeprint Cost + Price of Materials!

The latest pricing details about the Dentsply Sirona Primeprint.

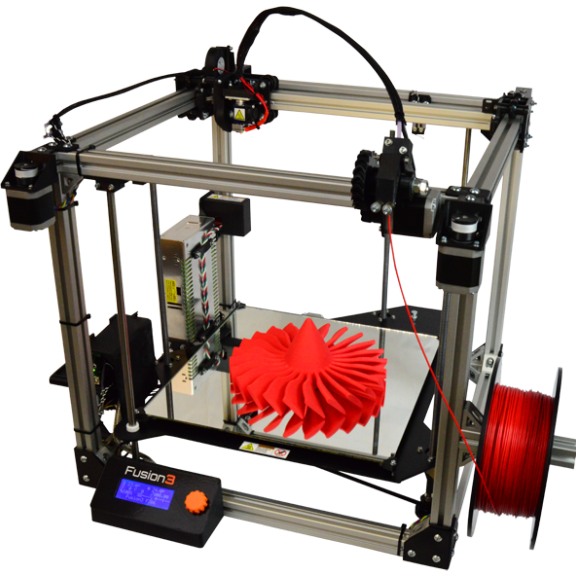

Dentsply Sirona officially launched the Primeprint last week in their virtual event. One thing that was missing was the price of the 3D printer and the resin materials. Something everyone was eagerly waiting to learn about.

This is the most highly automated printer in the market with a focus on ensuring validated workflows that precisely and consistently produce medical-grade results.

Thanks to the excellent Dentsply Sirona ANZ team, we have more details we can share with you.

The Cost of the Primeprint by Dentsply Sirona

In Australia & New Zealand, the Primeprint will come as a package including: (Primeprint packages will vary in other countries due to different dealers being able to only sell certain product lines so check with your local dealer.)

- Primeprint 3D printer

- Primeprint Post-Processing Unit (PPU)

- Primeprint material unit VAT x 2

- Primeprint Curing Carrier x 3

- Washing containers x 2

- Resin cartridges x 3

- inLab CAD SW 22 full package (included for free, usually ~20K NZD)

- Computer to run the software

- Nitrogen Gas Bottle with Regulator and Hose

- DS Core Light + DS Core Care Warranty for 3 Years.

Total Cost: $64,989.00 NZD

(approx. ~40k USD)

In the USA it is said the Primeprint package is around $30,000 USD

Each region offers different inclusions with the printer package

This means that Primeprint is priced at the very premium range of the market.

In this particular ANZ package there are a few things to note:

- A few extra curing lightboxes are included. This means while you are post-processing one job, you can start another case. You need at least two light boxes to do this.

- Two material VATS are included. These material vats are sealed and will completely preserve any resin. You can leave material in the VAT for extended periods of time with no issue.

- The entire system works on RFID tags. The Primeprint will know how much resin is in each cartridge and how much is in the VAT.

- 3 resin material cartridges are included.

What's with the Nitrogen Tank?

- The Primeprint PPU requires nitrogen for curing the printing products.

It can't be used without it.

It can't be used without it. - A nitrogen tank is included in the package

- This bottle can be easily exchanged once empty for a new one

- What is the point of nitrogen? During curing nitrogen gas is used to 'push out' all the oxygen in the chamber which prevents discolouring and makes sure the material properties are preserved.

- This ensures a fully cured surface with no excess monomer at all on the medical device.

- Using nitrogen in curing is not new or specific for the Primeprint. In fact, it is accepted as the gold standard in the dental printing industry

Primeprint Printing Materials

All materials used in the Primeprint are validated. The company states it is not a 'closed' system per se but a validated one. The Primeprint will release with a number of printing resins outlined below and more resins will be released in the future. Not all resins will be Dentsply Sirona but the key is they are validated for the system before release.

Primeprint will not work with any other resin that is not validated. You cannot fill a cartridge with another resin for example, as everything is confirmed using RFID tags. You cannot trick the system into printing another resin.

Resins included on launch:

- Primeprint Tray - custom tray material

- Primeprint Model - model material

- Primeprint Model T - model material that can be used for thermoforming (hence the T)

- Can be used with Sure Smile to print models at the different aligner stages and then vacuum-form aligners

- Primeprint Guide - surgical guides

- Primeprint Splint - splints and night guards

- Primeprint Cast - cast material that can be burnt out for lab processes

- Primeprint Temp - temp restorations, available in A1, A2 and A3

Coming soon - Lucitone denture printing materials, denture try-in material and aligner materials.

Printer Material Costs

Primeprint resins will be sold as material cartridges.

The cost of these cartridges is either ~286 USD or ~670 USD per cartridge

Tray and Model resins are the cheaper ones.

Surgical guide, splint and temp restoration resins are the more expensive ones.

The company says the cost per appliance when utilising these cartridge's is a few dollars.

DS Core - Care

We have covered DS Core - Care in details in our last post. But here are some additional details

- DS Core Care is Dentsply Sirona’s new integrated equipment support and services package.

- More than just extended warranty. Includes a customer support portal (self support) and an annual preventative service - not always included in extended warranty with other products.

- This care package looks after you from all different aspects, more refined package.

- DS Core Care - is only for PRIMEPRINT customers for now.

Eventually all Dentsply Sirona customers will be able to access DS Core Care. E.g. at this stage not Primescan, Sidexis etc.

Eventually all Dentsply Sirona customers will be able to access DS Core Care. E.g. at this stage not Primescan, Sidexis etc. - DS Core is a subscription service - which in NZ is being bundled for free with Primeprint for the first 3 years.

- Multiple packages depending on how much cloud storage you need. Currently DS Core Light is ~18 USD per month - 1 TB of cloud storage data

- You can upgrade cloud storage size anytime - up to 15 TB of cloud storage data

- First three years of DS Core Care and DS Core Light is included with a Primeprint purchase

DS Core - Create

Updated Primeprint Specifications

From our last post, we have answered some of the questions we had:

1

Price: ~40k USD for entire package2

Print platform size: 134 x 76x 150mm (w x d x h)3

Resolution: Partial information - 70-micron pixel size4

Software: inLab CAD and CAM SW 225

Print Speed: 30-40 min for a model on high res settings6

Available Resins: closed system with model, splint, surgical guide and provisional resin at this stage. No denture or permanent restoration resins at this stage.

No denture or permanent restoration resins at this stage.7

Accuracy: 46 microns for ortho casts according to the literature they presented8

Printer dimensions: Primeprint: 530mm x 515mm x 670mm (W x D x H) with a weight of 41kg. Post Processing Unit: 730mm x 550mm x 680mm (W x D x H) with a weight of 45kg.9

The Primeprint requires a nitrogen gas supply (included).

That's all the latest info we know about the Primeprint.

What do you think about the value of the Primeprint package?

Leave your comments below.

90,000 dental 3D printer - Primeprint - DentSply MailleferAdd to the Favorite folder

Add more detailed information on the DentSply Maillefer

Technology

Description

Why choose Primeprint Solution? Medical Grade 3D Printing Solution Primeprint Solution is a simplified, highly automated, end-to-end 3D printing solution for medical application manufacturing, allowing users to expand their range of treatments and services. It also helps reduce processing time and manual labor, allowing you to aim for maximum productivity. Developed with an intelligent dental approach to achieve excellence in your practice and laboratory RFID tags Primeprint and Primeprint PPU automatically detect the material, without contact, thanks to RFID technology. Cartridge, material block and flush containers are equipped with RFID tags for fast processing and predictive maintenance. DLP Light Engine Primeprint uses Digital Light Processing (DLP) technology to polymerize resins using ultraviolet light. The light projector cures the resin layer by layer, producing highly accurate print results. Intelligent material management For specific indications, Primeprint uses a separate material. The cartridges are color-coded for easy, touch-free handling and intuitive operation. Primeprint also provides full UV protection. Thanks to the RFID tag, Primeprint automatically checks the inserted cartridge and fill level. Active carbon filter An integrated active carbon filter makes an external suction device unnecessary.

It also helps reduce processing time and manual labor, allowing you to aim for maximum productivity. Developed with an intelligent dental approach to achieve excellence in your practice and laboratory RFID tags Primeprint and Primeprint PPU automatically detect the material, without contact, thanks to RFID technology. Cartridge, material block and flush containers are equipped with RFID tags for fast processing and predictive maintenance. DLP Light Engine Primeprint uses Digital Light Processing (DLP) technology to polymerize resins using ultraviolet light. The light projector cures the resin layer by layer, producing highly accurate print results. Intelligent material management For specific indications, Primeprint uses a separate material. The cartridges are color-coded for easy, touch-free handling and intuitive operation. Primeprint also provides full UV protection. Thanks to the RFID tag, Primeprint automatically checks the inserted cartridge and fill level. Active carbon filter An integrated active carbon filter makes an external suction device unnecessary. robot arm Inside the printer and PPU, a robotic arm moves the print plate to the appropriate step in the process without any manual work on your part. Fast Print Primeprint quickly prints what you need to streamline your workflow. Accurate life tracking Through the use of RFID tags and intelligent material management, Primeprint can predict any maintenance needed.

robot arm Inside the printer and PPU, a robotic arm moves the print plate to the appropriate step in the process without any manual work on your part. Fast Print Primeprint quickly prints what you need to streamline your workflow. Accurate life tracking Through the use of RFID tags and intelligent material management, Primeprint can predict any maintenance needed.

---

This is an automatic translation. (view original in English)

Catalogs

No catalogs are available for this product.

See all DENTSPLY MAILLEFER catalogs

Visit the DENTSPLY MAILLEFER website for more information

*Prices are pre-tax, exclude delivery charges and customs duties, and do not include additional charges for installation or activation options. Prices are indicative and may vary depending on country, commodity prices and exchange rates.

Read article - New study shows 3D printing is more accurate than milling for dental crowns

Researchers at Japan's Tohoku University Graduate School of Dentistry have found that 3D photopolymer printing is a more efficient technology for making dental crowns than conventional milling.

In their study, dentists made crowns by 3D printing and milling. After several rounds of testing, the team stated that the 3D printed models had "higher accuracy" and "fewer minor discrepancies" than milled specimens, so they see photopolymer printing as a more "promising technology" for creating permanent crowns.

Color maps of common deviations in the crowns of molars.

Is it time to stop milling ?

As the wear resistance and color stability of dental materials continue to improve, dentists are choosing milled composite dental crowns over traditional metal restorations. By using patient modeling and impression software, custom implants can be fabricated without using a ceramic block milling machine.

According to the team from Tohoku University, the technology faces challenges such as cutter wear and waste of excess material. The researchers also point out that milling often forces dentists to adhere to stringent preparation requirements, and even when they adhere to them, grooves can form on the internal surfaces of crowns, resulting in an imperfect fit for the patient.

At the same time, there is more and more research and development in the field of dental resins for 3D printing, including those with high strength and suitable for the growth of restorations with different occlusal loads. The team appreciates the technology's potential for creating models, prosthetic bases and splints.

STL model files used to detect deviations between milled crowns.

Tests with 3 D - printed crowns

Initial results showed a significant difference between the crowns obtained on the router with a difference of 100-200 µm. At the same time, printed models showed higher accuracy. The deviation was more pronounced in the milled parts, with a "certain internal groove" observed, which they attributed to the brittleness of the base material of the crowns.

At the same time, printed models showed higher accuracy. The deviation was more pronounced in the milled parts, with a "certain internal groove" observed, which they attributed to the brittleness of the base material of the crowns.

Interestingly, a 3D printer resolution of 62 µm gives less shoulder accuracy than a milled crown. But this was enough to create accurate models, while milling produced grooves on the inner surface of the crowns, which can lead to a poor fit and are a "technical limitation".

Although a team of Japanese researchers concluded that DLP 3D printing is superior to milling for crown fabrication, further research is needed on various systems and parameters. In addition, more research is needed on the fracture resistance and biocompatibility of 3D printed implants, which they believe can now be used to restore sharp teeth such as incisors.

Dental restorations printed with Saremco CROWNTEC resin.

Dental printers 3 D -p As the researchers pointed out, 3D printing is already being used in the manufacture of dentures, and new materials continue to emerge that expand the application of the technology.

This year, 3D Systems agreed with Saremco to use CROWNTEC resins for fabricating crowns on NextDent 5100 3D printers.

This year, 3D Systems agreed with Saremco to use CROWNTEC resins for fabricating crowns on NextDent 5100 3D printers. Before that, Desktop Health launched an Einstein 3D printer and Flexcera Smile Ultra+ resin. They are designed to produce high-strength, aesthetically pleasing dentures. The printer works on DLP technology, similar to Desktop Metal ETEC systems. Productivity is enhanced by HyperPrint technology, which provides a 50% increase in speed.

Most recently, Dentsply Sirona has also expanded its portfolio with a Primeprint 3D printer and post-processing equipment for the production of dental implants. The newly introduced 385 nm wavelength printer is designed to enable dentists to easily create accurate models, guides, temporary crowns or splints.

Taiwanese company Phrozen, which has already gained fame in the mid-range LCD 3D printer market for high precision and product stability, has also focused on the development of dental 3D printers. Among them are the Phrozen Sonic 4K 2022 and Phrozen Sonic XL 4K 2022 models.