3D printed frostmourne

Behold: The 1.3 Meter Tall, 3D Printed, World of Warcraft Frostmourne Sword - 3DPrint.com

If you are at all interested in massively multiplayer online role-playing games (MMORPGs), then you have likely wasted hours on end tethered to your PC playing World of Warcraft. In fact, close to 2% of every man, woman, and child (100 million people) on this planet have played the game, created in 2004 by Blizzard Entertainment, at some point in their lives.

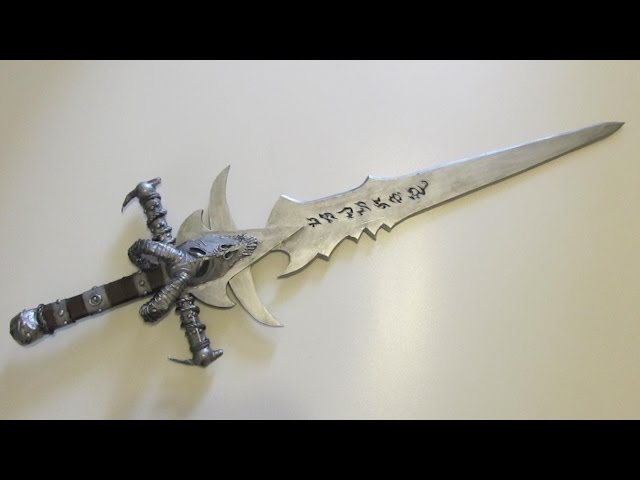

If you are an avid fan of the game, then you have also likely heard of Frostmourne. A giant runeblade which had the disembodied spirit of the Lich King attached to it, Frostmourne was eventually destroyed following the defeat of Arthas in the Icecrown Citadel. Now a gold replica of the hilt of Frostmourne is on display within the game.

Ok, that’s enough of me boring all of you who do not partake in this awesome game. Whether you are a fan of the game or not, one design and 3D print of Frostmourne is certain to blow you away. Kirby Downey and Elliott Viles, designers at My Mini Factory, worked together to create one of the coolest pieces I have ever seen.

They’ve designed and put together a 3D printed Frostmourne sword — that happens to be 1.3 meters tall.

The two worked together on this challenging project, which is printed in several pieces that snap together without the need for glue. While Downey designed the blade and the hilt joints using Solidworks, Viles worked on the skulls using Zbrush. When the skulls were complete Downey then merged the designs using Meshmixer, to make sure that he did not lose the scale and accuracy inherent within the models.

At this point it was time to print it all out, and see if it fit together like they had designed it to. They set the infill at 10% and printed at 0.2mm. The largest of the segments was the piece which included the main hilt and the ram’s head, measuring 217mm x 206mm x 120mm.

Certainly this isn’t just a weekend project. The sword, which measures a staggering 130cm x 40cm x 20cm when assembled, and weighs approximately 600 grams, took close to 50 hours to design, print, assemble, and paint. The painting and finishing work was done by Catherine Woods from My Mini Factory, and as you can see is simply amazing.

The painting and finishing work was done by Catherine Woods from My Mini Factory, and as you can see is simply amazing.

For those of you interested in trying to duplicate this incredible project, the design has been made available for free at My Mini Factory, or if you wish to purchase Frostmourne already printed and painted it is available for $499.

Let us know if you have tried printing this out. We would love to see your work posted in the 3D Printed Frostmourne forum tread on 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printed frostmourne • 3d printed wow • elliott viles • frostmourne • kirby downey • meshmixer • my mini factory • solidworks • world of warcraft • wow • ZBrush

Please enable JavaScript to view the comments powered by Disqus.

▷ frostmourne 3d models 【 STLFinder 】

Frostmourne

sketchfab

Frostmourne was the fearsome, rune-inscribed two-handed longsword of the Lich King. The runeblade originally belonged to Ner’zhul, who thrust it from the Frozen Throne, waiting for young Arthas Menethil to discover it on the continent of Northrend.

The runeblade originally belonged to Ner’zhul, who thrust it from the Frozen Throne, waiting for young Arthas Menethil to discover it on the continent of Northrend.

Frostmourne

sketchfab

hand paint with b3d and photoshop

Frostmourne

sketchfab

My own little version of Frostmourne from WoW

FrostMourne

thingiverse

An interpretation of the legendary sword FrostMourne, first seen in WarCraft 3 Instructions To print it out I recommend printing the stl that is split in half so that there is no support in unwanted. ..

..

Frostmourne

sketchfab

Frostmourne from Warcraft. ...Hope you enjoy :) Check more at www.Youtube.com/c/Jerzkusart

Frostmourne

grabcad

The edge this sword is made by surface

Frostmourne

thingiverse

Frostmourne

Frostmourne

grabcad

The edge this sword is made by surface

Frostmourne

sketchfab

“Whomsoever takes up this blade shall wield power eternal. Just as the blade rends flesh, so must power scar the spirit.” —The inscription on Frostmourne’s pedestal The sword is based on the one that can be found in games from Warcraft universe such...

Just as the blade rends flesh, so must power scar the spirit.” —The inscription on Frostmourne’s pedestal The sword is based on the one that can be found in games from Warcraft universe such...

Frostmourne

sketchfab

No description provided.

Frostmourne

sketchfab

A weapon from World of Warcraft

Frostmourne

thingiverse

Frostmourne from World of Warcraft with a base.

Frostmourne untextured

sketchfab

No description provided.

Frostmourne Keychain

thingiverse

Frostmourne Keychain

Frostmourne Sword

sketchfab

Frostmourne Sword in the rock. This is one of my Lick King’s project fanmade. Therefore, there is only have the sword, the other will be done soon. I made this with pbr material by substance painter. I know there still have many mistake, hope you...

Frostmourne sword

myminifactory

3d model of Arthas' sword Frostmourne, from World of Warcraft videogame. ...The model tagged as frostmourne keychain includes a ring so it can be used as a badge/keychain

...The model tagged as frostmourne keychain includes a ring so it can be used as a badge/keychain

Lego Frostmourne

thingiverse

My friend asked me to make a Frostmourne for his lego Lich King. So i made it! ... I use HotCheeseSoup Frostmourne model for this.

Cherry MX - Frostmourne KeyCap

thingiverse

Cherry MX key for WOW

Wallmount for Frostmourne

thingiverse

Wallmount for holding your Frostmourne. ... Holes are 4,5mm so should be fine for most of your 6mm wall plugs

Now with bottom piece to keep tip of your blade straight

... Holes are 4,5mm so should be fine for most of your 6mm wall plugs

Now with bottom piece to keep tip of your blade straight

Frostmourne Rune Ring

thingiverse

"Whomsoever takes up this b̶l̶a̶d̶e̶ ring shall wield power eternal" Sized to fit my size 12.5 finger, but should be adjustable to any size. ...A ring size chart has been included.

Tinkercad skeleton Frostmourne

thingiverse

Frostmourne from World of Warcraft for the tinkercad skeleton model. This thing was made with Tinkercad. ...Edit it online https://www.tinkercad.com/things/iXIro24RJYx

Frostmourne wall mount

thingiverse

Here comes a wall mount for the Frostmourne-sword from World of Warcraft, you can find here:

https://www. thingiverse.com/thing:2952596

It's a remix, I used the bottom parts of this thing:

https://www.thingiverse.com/thing:2952596

I modified...

thingiverse.com/thing:2952596

It's a remix, I used the bottom parts of this thing:

https://www.thingiverse.com/thing:2952596

I modified...

Frostmourne Chain Fob

thingiverse

I made this into a key chain thingy.

Wall Holder For Frostmourne

thingiverse

My own holder for frostmourne

Frostmourne Wall Mount

thingiverse

I made this wall mount for my full size frostmourne from:

https://www. myminifactory.com/object/3d-print-frostmourne-from-warcraft-4156

I designed this in F360 with a scetch I made in Adobe Illustrator.

I printed the two main parts with the...

myminifactory.com/object/3d-print-frostmourne-from-warcraft-4156

I designed this in F360 with a scetch I made in Adobe Illustrator.

I printed the two main parts with the...

Frostmourne (World of Warcraft)

sketchfab

Probably the most iconic weapon of the game. ...I personally really love this one.

World of Warcraft Frostmourne

thingiverse

Stampa della Frostmourne di World of Warcraft. Per cosplay si consiglia infill del 15-20% per maggiore resistenza, ma è possibile stamparla come esposizione anche al 5%. File originali:...

Cut up Frostmourne

thingiverse

I wanted a full scale model, but my print bed isn't nearly big enough. Hooray for Puzzlecut! The cuts aren't NEARLY that large; I set them to -0.4 to illustrate the cut locations. In the .scad and .stl file they're set to -0.01, but that's of course...

Hooray for Puzzlecut! The cuts aren't NEARLY that large; I set them to -0.4 to illustrate the cut locations. In the .scad and .stl file they're set to -0.01, but that's of course...

World of Warcraft Frostmourne

thingiverse

Fantastica spada del Lich King stampa realizzata da 140cm Per cosplay si consiglia infill 15-20% sul pezzo centrale per via delle corna sottili, ma si può stampare anche al 5% se volete usarla come oggetto da esporre. ... File originali presi su: ...

World of Warcraft Frostmourne

sketchfab

World of Warcraft Frostmourne

What do 3D printers print with?

3D printing is based on the technology of layer-by-layer growth of solid objects from various materials. Volumetric models are printed from plastic, concrete, hydrogel, metal, and even living cells and chocolate. In this article, we will provide a brief overview of the most popular 3D printing materials .

Volumetric models are printed from plastic, concrete, hydrogel, metal, and even living cells and chocolate. In this article, we will provide a brief overview of the most popular 3D printing materials .

ABC plastic

ABS plastic is known as acrylonitrile butadiene styrene. This is one of the best consumables for 3D printing. Such plastic is odorless, non-toxic, impact-resistant and elastic. The melting temperature of ABC plastic is from 240°C to 248°C. It is available for retail sale in the form of a powder or thin plastic threads wound on bobbins.

ABS plastic 3D models are durable, but do not tolerate direct sunlight. With the help of such plastic, only opaque models can be obtained.

3D printing ABS resin

Acrylic

Acrylic is used in 3D printing to create transparent models. When using acrylic, the following features must be taken into account: this material requires a higher melting point than ABS plastic, and it cools and hardens very quickly. A lot of small air bubbles appear in heated acrylic, which can cause visual distortions of the finished product.

A lot of small air bubbles appear in heated acrylic, which can cause visual distortions of the finished product.

Products printed with acrylic

Concrete

Test samples of 3D printers for concrete printing are currently being made. These are huge printing devices that painstakingly, layer by layer, “print” construction details and structures from concrete. Such a 3D printer can “print” a residential two-story house with a total area of 230 m2 in just 20 hours.

An improved grade of concrete is used for 3D printing, the formula of which is 95% coincides with the formula of ordinary concrete.

Products printed with concrete

Hydrogel

Scientists from the University of Illinois (USA) printed biorobots 5-10 mm long using a 3D printer and hydrogel. Cardiac tissue cells were placed on the surface of the biorobots, which spread over the hydrogel and began to contract, setting the robot in motion. Such hydrogel robots are capable of moving at a speed of 236 micrometers per second. In the future, they will be launched into the human body to detect and neutralize tumors and toxins, as well as to transport drugs to their destination.

Such hydrogel robots are capable of moving at a speed of 236 micrometers per second. In the future, they will be launched into the human body to detect and neutralize tumors and toxins, as well as to transport drugs to their destination.

3D printed hydrogel biorobots

Paper

Some 3D printers use plain A4 paper as the print media. Since paper is an affordable and inexpensive material, paper models are also inexpensive and accessible to users. Such models are printed in layers, with each subsequent layer of paper cut out by the printer and pasted onto the previous one. Paper models print quickly, but lack durability or aesthetics. They are ideal for rapid prototyping of a computer project.

3D printed paper

Gypsum

Gypsum materials are widely used in modern 3D printing. Models made of gypsum are short-lived, but have a very low cost. Such models are ideal for making objects intended for presentations. They can be shown as a sample to customers and clients, they will perfectly convey the shape, structure and size of the original product. Since plaster models are highly resistant to heat, they are used as casting samples.

They can be shown as a sample to customers and clients, they will perfectly convey the shape, structure and size of the original product. Since plaster models are highly resistant to heat, they are used as casting samples.

3D printed plaster model

Wood fiber

Inventor Kai Parthi has developed a special wood fiber for 3D printing. The fiber consists of wood and a polymer and is similar in properties to polyactide (PLA). The combined material allows you to get durable and solid models that look like wooden products and have the smell of freshly sawn wood. Currently, the innovative material is only used in self-replicating RepRap printers.

3D printed wood fiber model

Ice

In 2006, two Canadian professors received a grant to develop 3D printing technology for ice figures. For three years, they learned how to create small ice objects using 3D printers. Printing takes place at a temperature of -22°C, water and methyl ether heated to a temperature of 20°C are used as consumables.

Printing takes place at a temperature of -22°C, water and methyl ether heated to a temperature of 20°C are used as consumables.

Ice-printed figure

Metal powder

No plastic can replace metal with its pleasant soft sheen and high strength. Therefore, 3D printing often uses powder from light and precious metals: copper, aluminum, their alloys, as well as gold and silver. However, metal models do not have sufficient chemical resistance and have high thermal conductivity, so fiberglass and ceramic inclusions are added to the metal powder for printing.

3D printed metal powder jewelry

Nylon

Nylon printing has a lot in common with ABS printing. The exceptions are the higher printing temperature (about 320°C), high water absorption capacity, longer curing time, the need to evacuate the extruder due to the toxicity of the nylon components. Nylon is a rather slippery material, for its use it is necessary to equip the extruder with spikes. Despite these shortcomings, nylon is successfully used in 3D printing, since parts from this material are not as rigid as those made from ABS plastic, and sliding hinges can be used for them.

Despite these shortcomings, nylon is successfully used in 3D printing, since parts from this material are not as rigid as those made from ABS plastic, and sliding hinges can be used for them.

Nylon thread for 3D print

Nylon products printed by a 3D printer

Polycaprolactone (PCL)

Polycaprolactone closely close to biodegradable polyester. It is one of the most popular consumables for 3D printing. It has a low melting point, hardens quickly, provides excellent mechanical properties to finished products, easily decomposes in the human body, and is harmless to humans. In addition, it can be used in several 3D printing technologies at once: SLS, ZCorp and FDM.

Polycaprolactone for 3D printer

Polycarbonate (PC)

Polycarbonate is a hard plastic that is able to maintain its physical properties at extremely high and extremely low temperatures. It has high opacity, has a high melting point, and is suitable for extrusion processing. At the same time, its synthesis is associated with a number of difficulties and is not environmentally friendly. Used to print heavy duty models in several 3D printing technologies: SLS, LOM and FDM.

It has high opacity, has a high melting point, and is suitable for extrusion processing. At the same time, its synthesis is associated with a number of difficulties and is not environmentally friendly. Used to print heavy duty models in several 3D printing technologies: SLS, LOM and FDM.

Polylactide (PLA)

Polylactide is the most biocompatible and environmentally friendly material for 3D printers. It is made from the remains of biomass, sugar beet or corn silage. Having a lot of positive properties, polylactide has two significant drawbacks. Firstly, the models made from it are short-lived and gradually decompose under the influence of heat and light. Secondly, the production cost of polylactide is very high, which means that the cost of models will be much higher than similar models made from other materials. Used in 3D printing technologies: SLS and FDM.

Polylactide filament and 3D printed products with polylactide

Polypropylene (PP)

Polypropylene is the lightest of all plastics in existence today. Compared to HDPE, it melts worse and resists abrasion better. At the same time, it is vulnerable to active oxygen and deforms at low temperatures.

Compared to HDPE, it melts worse and resists abrasion better. At the same time, it is vulnerable to active oxygen and deforms at low temperatures.

3D printing polypropylene

Polyphenylsulfone (PPSU)

This material came to 3D printing from the aircraft industry. It practically does not burn, is characterized by heat resistance, high hardness. It resembles ordinary glass, but surpasses it in strength. Used in 3D printing technologies: SLS and FDM.

High density polyethylene (HDPE)

This is the most common type of plastic in the world, from which PET bottles, canisters, pipes, films, bags, etc. are made. In 3D printing, low-density polyethylene is the unsurpassed leader. This material can be used in any 3D printing technology.

3D printed polyethylene shoes

Chocolate

British scientists presented to the public the first chocolate 3D printer that prints any chocolate figures ordered by the operator. The printer applies each next layer of chocolate on top of the previous one. Due to the ability of chocolate to quickly solidify and harden when cooled, the printing process is quite fast. In the near future, such printers will be in demand in confectionery and restaurants.

The printer applies each next layer of chocolate on top of the previous one. Due to the ability of chocolate to quickly solidify and harden when cooled, the printing process is quite fast. In the near future, such printers will be in demand in confectionery and restaurants.

Chocolate printer in action

Other materials

There are 3D printers that are designed to print with clay mixtures, lime powder, living organic food, and many amazing materials. One can only guess what materials for 3D printing will be used in the near future.

history, application, perspectives - Miscellaneous - Blog

3D printing is a massive revolution in the world of physical things. Today it covers all spheres of human activity and continues to develop rapidly.

3D printer - additive device (from English Additive - “addition, admixture”), capable of recreating any object by layer-by-layer reproduction according to a 3D model.

The past: a brief history of 3D printing

The history of 3D printing begins in the mid-twentieth century, in the 1950s, when the American Charles Hull tried to implement the first additive technology - stereolithography.

The closest relatives of 3D printers appeared in Japan in the early 1980s thanks to the work of Dr. Hideo Kodama, who developed a device for rapid layer-by-layer printing of prototypes of physical objects.

In 1986, Charles Hull finally received a patent for his invention and founded the 3D System Corporation, which is today the leader in 3D printing.

In 1988, mass production of stereolithographic (SLT) printers was launched, which created objects from digital blanks. The material was an acrylic-based liquid substance, which turned into plastic under the action of laser beams.

By the early nineties, 3D models were being created by a new generation of printers using laser sintering technology. Then the term "3D printing" appeared. If earlier the product was "grown" from liquid acrylic, then by that time it was already made from powder under the influence of a laser.

If earlier the product was "grown" from liquid acrylic, then by that time it was already made from powder under the influence of a laser.

In the early 2000s, a real revolution in 3D printing took place: the market split into two directions - high-tech expensive systems and devices available to a wide category of consumers. Both are rapidly developing, actively taking root in all spheres of human life.

Present: 3D printing applications

Medical

One of the fastest growing areas of 3D printing is medicine. In 2011, there was a triumph in regenerative medicine: a printer filled with biogel with stem cells “printed” a human kidney in 3 hours. Although organ transplantation is still far away, scientists are already developing technologies for transplanting blood vessels grown using 3D printing, abdominal organs, and skin.

Today, all over the world, including Russia, 3D-printed elements of the human skeleton - bones, joints, teeth - are successfully implanted. In the Research Institute of Traumatology and Orthopedics of St. Petersburg, endoprosthesis replacement of lost limbs and joints is successfully used, and in the Novosibirsk Research Institute. N.Ya. Tsivyan perform operations to replace the cranial bones using additive technologies, returning children and adults to a full life.

In the Research Institute of Traumatology and Orthopedics of St. Petersburg, endoprosthesis replacement of lost limbs and joints is successfully used, and in the Novosibirsk Research Institute. N.Ya. Tsivyan perform operations to replace the cranial bones using additive technologies, returning children and adults to a full life.

Construction

Building with 3D printing is a serious competitor to traditional approaches. The United Arab Emirates, Thailand, China and Russia are already using state-of-the-art mobile printers to print homes right on site.

The printing method is the same as in other areas of application - extrusion layer by layer (production by forcing a viscous material through forming holes). Cement, construction debris, used building materials, fiberglass, etc. are used as materials. The technology works on the principle of a construction crane that erects walls from a mixture of concrete and binder materials.

If we talk about the rationality of this construction method, then the cost of materials and work time are several times lower, and the absence of foremen and teams reduces the financial costs of human labor. Moreover, this technology provides housing for people with extremely low incomes.

Moreover, this technology provides housing for people with extremely low incomes.

It is difficult to overestimate the prospects for the rapid construction of economical housing of original architectural forms both in overpopulated cities and in hard-to-reach corners of the planet.

Byt

Printers with 3D printing technology are gradually mastering the production of food, clothing, shoes, unique souvenirs, toys, furniture - everything that people use in everyday life.

To print a wide range of household products, a person only needs a printer and various materials for it.

3D food printer fills with ingredient cartridges and prepares the most delicious multi-ingredient dishes from recipes stored on a memory card.

3D printed clothes and shoes have already been shown at fashion shows. Very soon it will be possible to buy patterns and print dresses and jeans for yourself without leaving your home. Unique decorative additions can be printed to the finished product to give individuality to the factory product.

The Future: 3D Printing Perspectives

3D printing technology will soon make it possible to create elements for building research bases on the Moon and Mars. NASA has already successfully tested 3D-printed titanium nozzles for rocket engines.

Prospects for the development of nearby planets dictate a reduction in the cost of transporting cargo and materials. So, NASA experts called the use of 3D printing in space the only option for the possible development of the planets. Landing pads, monolithic structures and roads can be printed on the Moon from local soil, and on Mars from basalt and regolith. Moreover, in the subpolar regions of Mars, water and low temperatures will help build habitable "Martian igloos" - multi-layered ice shelters from radiation and winds.

Also in the future it will be possible to reproduce another printer, spare parts and cartridges for it on a 3D printer. Self-reproducing printers will be a new round and at the same time the logical conclusion of the 3D revolution.