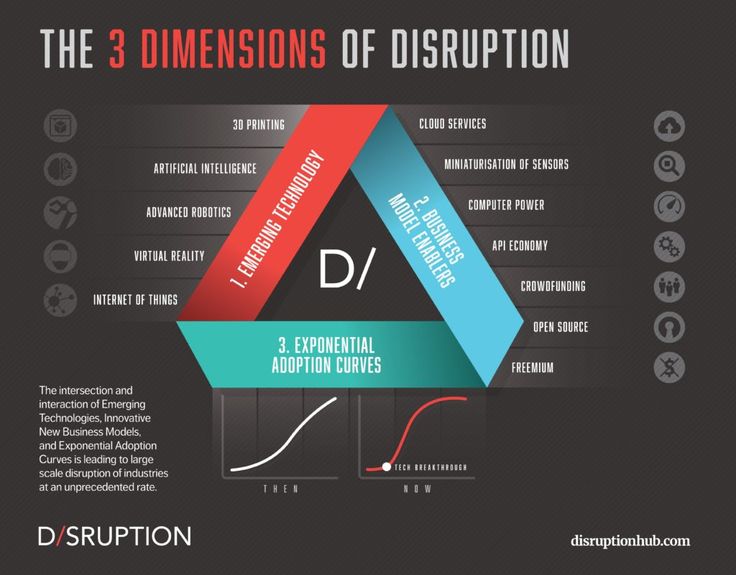

3D printing disruption

Three Companies Leading the Disruptive Innovation in 3D Printing | by Upen Singh

SCIENCE & FUTURE

And opening up large-scale investment opportunities.

Photo by Tom Claes on Unsplash3D printing is a disruptive innovation that is creating new markets and value networks. It is displacing established market-leading firms, products, and alliances, especially in healthcare, aerospace, and real estate.

According to Ark Investment Management, 3D printing will revolutionize manufacturing, growing at an annual rate of roughly 60% from $12 billion last year to $120 billion in 2025.

The management firm thinks that only 1% of the market has been penetrated today.

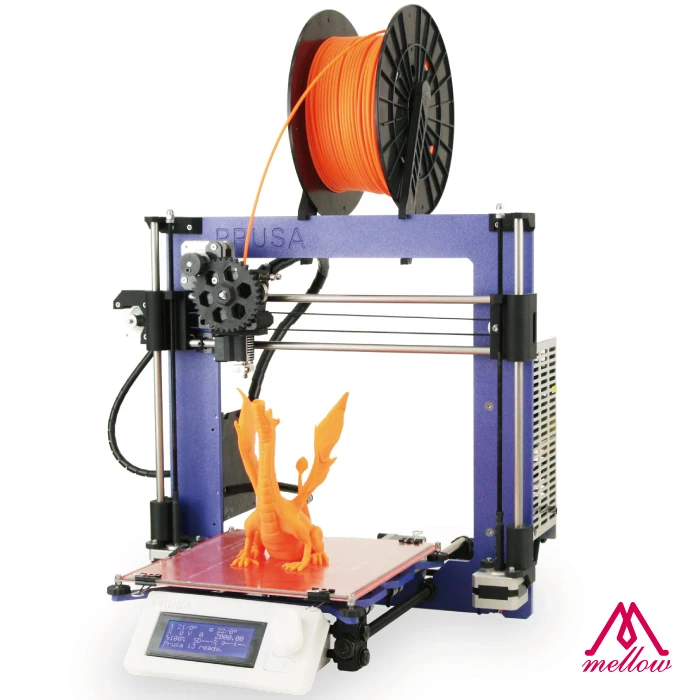

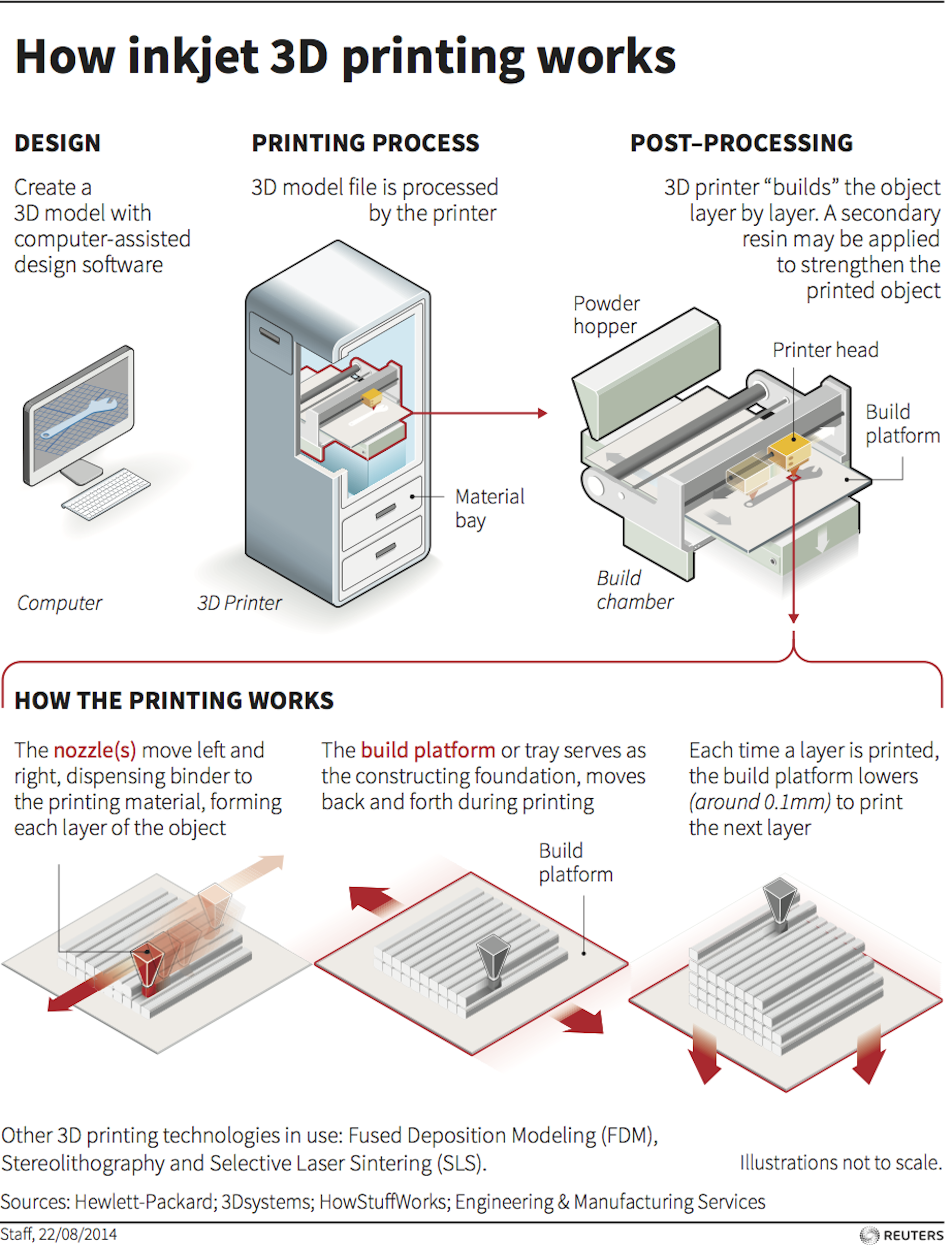

3D printing is a form of additive manufacturing that builds objects layer-by-layer, as opposed to traditional subtractive manufacturing that removes material from larger blocks. This means — for the first time, we can build from the ground up, layer by layer using AI to design every single part — from size, quantity to aesthetics.

We are able to create parts that traditional manufacturing cannot make. “This is really disruptive for healthcare and aerospace markets,” explains Tasha Keeney, CFA, and Analyst at ARK Investment Management.

3D printing can be used to create complex, low-volume parts. For instance, we can scan a human body and print the required implant that is specifically designed for the patient, without the need to shave off the patient’s bone.

Let’s take a look at the three 3D printing companies that are currently leading the way —

This company is the global leader in digital manufacturing services, including 3D printing, CNC (computer numerical control) machining, injection molding, and sheet metal fabrication.

It does rapid manufacturing of low-volume custom parts for prototyping and short-run production. Medical devices, electronics, appliances, automotive, and consumer products use these parts.

Their tagline is “Manufacturing. Accelerated.”

This company is based in Minnesota, US with manufacturing facilities in Japan and several locations in Europe.

Vicki Holt is the president and CEO of this company. Holt had just taken this lead right after the company went public. She successfully let the company to $459 million in revenues in 2019, representing a 17-percent compounded annual growth rate over her tenure.

She mentioned that US manufacturers are in the “very early innings” of responding to an over-dependence on Chinese sources of manufacture, and Protolabs is helping them create resiliency solutions.

Trade prices of recent 5 years for ProtoLabs, Inc (PRLB). Taken from Yahoo Finance on Feb 2, 2021.This company is the global leader for 3D measurement, imaging, and realization technology. They develop and market computer-aided devices and software for the 3D Metrology, AEC (Architecture, Engineering & Construction), and Public Safety Analytics markets.

Their products enable customers to quickly and easily measure their world and then use that data to make smarter decisions faster.

Headquartered in Florida, they have locations in the Americas, Europe, and Asia.

This company which was founded in 1981 has now become a global leader in the manufacture of 3D measurement technology. Currently, Michael Burger is the president and CEO.

Trade prices of recent 5 years for Faro Technologies, Inc (FARO). Taken from Yahoo Finance on Feb 2, 2021.This company is the global leader in making 3D printers, and the 3D printing of plastic parts is manufacturing parts that will make flights lighter, reduce complexity, and simplify production.

Engineers use Stratasys systems to model complex geometries in a wide range of thermoplastic materials. Currently, this company manufactures in-office prototyping and direct digital manufacturing systems for automotive, aerospace, industrial, recreational, electronic, medical, and consumer products.

“3D printing is the only technology that can actually print, create, and manufacture a geometry without any limitations in geometry in comparison to the current way of manufacturing,” says Andy Middleton, president of Stratasys in Europe.

People no longer have to base their design on the limitations of manufacturing. In addition to the regular materials like plastic, 3D printing can also be done with aluminum, titanium, and different alloys.

This company was founded in the US in 1989 and now is headquartered in Israel. It has 8 facilities in North America. Yoav Zeif is the CEO.

Trade prices of recent 5 years for Stratasys Ltd. (SSYS). Taken from Yahoo Finance on Feb 2, 2021.The massively disruptive innovation of 3D printing will shift markets in many ways. Guaranteed revolutionary changes in healthcare, transportation, and real estate due to this innovation have already opened up large-scale investment opportunities, which is in its early states now.

Upen Singh writes about people, progress, and the future. He is interested in making lives better.

Having traveled over to 25 countries he is always seeking new adventures to learn from and share. He has an M.A. in Developmental Economics from West Virginia University.

He has an M.A. in Developmental Economics from West Virginia University.

He lives in Thailand, Nepal, and the United States, constantly traveling. He is currently involved in a village development project called Metta Valley in far-west Nepal.

10 ways 3D Printing will disrupt traditional manufacturing

Additive manufacturing technology has evolved dramatically since the days when we were all creating 3D printed novelty cartoon characters and watching with wonder as television painted a rather sci-fi image of a future with 3D printing at the heart of the home. In recent years, 3D printing has indeed become democratised, and even if not an integral part of everyday home life, ordinary people are able to afford this technology. However, the domestic market is already slowing and, by comparison, the development of 3D printing as a manufacturing technology is gargantuan. Particularly applicable to industries where innovation and complex components are commonplace – such as aerospace, automotive and medical markets – additive manufacturing has been embraced, not only for rapid prototyping but also with an eye to serial production. There is seemingly no end to the limits to which this on-demand manufacturing technology can be pushed. We take a look below at some of the predictions for the future of 3D printing.

There is seemingly no end to the limits to which this on-demand manufacturing technology can be pushed. We take a look below at some of the predictions for the future of 3D printing.

The majority of 3D printing is currently used for rapid prototyping during the development phase of production, where the 3D printed component is used as a sample rather than a final, functional solution. Higher quality output, improved materials and bespoke finishes will move the market towards using the technology for serial production. We are already seeing the adoption of additive manufacturing technology in areas where cost- and weight-reduction are paramount and where fast response times provide a competitive edge. There is no reason for larger scale manufacturers not to look to 3D printing for the same benefits. GE Aviation used 3D printing to take a nozzle for a jet engine from an almost impossibly intricate build made up of 20 separate pieces, to a single-piece 3D printed in a nickel alloy, weighing 25% less than their usual nozzle and five times more durable. Their former head of engineering describes the manufacturing technology as ‘an engineer’s dream’.

Their former head of engineering describes the manufacturing technology as ‘an engineer’s dream’.

Although the actual printing process in additive manufacturing is automated, the level of human intervention in both the setup and finishing of production is still disproportionally high. A shift towards better simulation software and smarter tools will allow 3D printing to be better integrated into the automated production processes.

3. SustainabilityWhilst additive manufacturing is, by its very nature, less wasteful than existing subtractive processes, we are likely to see a further shift towards energy efficiency and recycled or reusable media. The University of Louisville have found a process that will transform the 8 million tons of soybean husk produced every year during the processing of soy, into micro and nano scale fibres that can be used for fibre composites and thermoplastic packaging products in 3D printing.

Image source: enablingthefuture.org

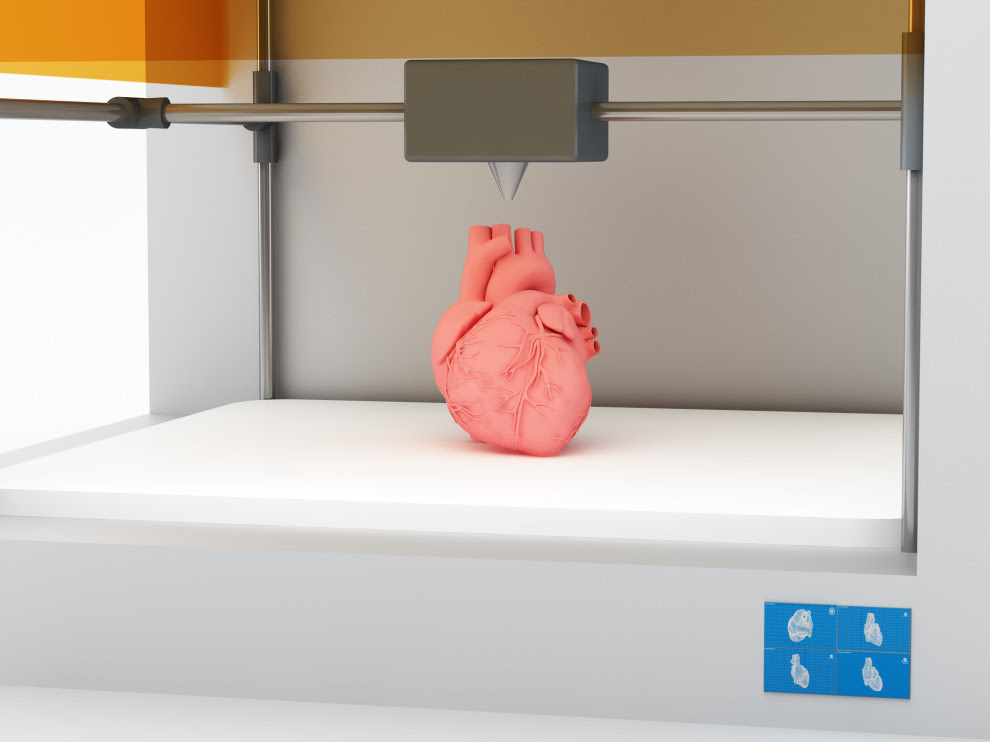

4. Customised prosthetics and organs for healthcareWhilst 3D printed prosthetics are already starting to gain wide acceptance, we’ve not seen much uptake as yet in bioprinting. The 3D printing of tissues and organs will become commonplace as the technology matures and people become more comfortable with the concept. e-NABLE is a global community of volunteers who use their domestic 3D printers to make free prosthetic limbs for children and adults who have lost limbs through war, natural disasters and accidents. Their open-source designs mean that just about anyone with access to additive manufacturing technology can get involved.

5. MetalMetal printers will become cheaper, with better tolerances and higher quality finishes, which will, in turn, create a greater uptake in the market. One of the fastest growing segments of the additive manufacturing market, 3D printing in metal is already widely used for the rapid prototyping of components. However, because 3D printing can facilitate the production of parts with internal structures and shapes that cannot be machined, this is a potential game changer and could drive the push to serial production of metal components. One of the world’s largest metal 3D printing machines is already making entire rockets for NASA to be trialled in space during the coming year.

However, because 3D printing can facilitate the production of parts with internal structures and shapes that cannot be machined, this is a potential game changer and could drive the push to serial production of metal components. One of the world’s largest metal 3D printing machines is already making entire rockets for NASA to be trialled in space during the coming year.

Bespoke medication is the goal of 3D printing in the pharmaceutical sector. This would enable manufacturers to combine multiple prescriptions into a single pill which is then printed on demand, saving billions in healthcare – not to mention saving lives. There are some drugs on the market which are already produced through additive manufacturing, an example being Spritam, an epilepsy drug and the first 3D printed medicine to be approved by the FDA. The main benefit currently is that the dosage can be customised for the recipient so that the dosage is accurate in a way that mass-produced drugs are not.

Image source: bigrep.com

7. Modular and bespoke vehicles3D printing in the automotive industry is mostly used for product development and rapid prototyping. In the future, we can expect to see more and more cars with 3D printed parts, allowing for bespoke customisation of vehicles. We’re not going to see fully 3D printed vehicles in the general marketplace just yet because the technology is not ready to replace the current processes involved in volume production of vehicles, but the potential is there. However, that’s not to say that it isn’t currently feasible; NERA is the first 3D printed e-motorbike, with all parts except for the electronics produced through additive manufacturing.

8. Composite materialsComposites are lightweight, strong materials usually found in industries such as aerospace, automotive, and oil and gas. Their production is costly in terms of labour and resource, but material development is allowing more of these to be 3D printed with the potential to scale the process up to larger volumes. This could make lighter, stronger components available for serial production and reduce costs.

This could make lighter, stronger components available for serial production and reduce costs.

There are already examples of some 3D printed homes, but as the cost savings, flexibility and efficiency of on-site printing become increasingly attractive to both architects and the construction industry, we can expect to see more homes produced through additive manufacturing in the coming years. As innovative architects around the world tussle to out-do one another, this project by SQ4D claims to be the world’s largest 3D printed home at 1900 square feet, only taking 48 hours to print over an eight-day period.

10. 3D fashionWhilst much of the innovation and development in the world of additive manufacturing is based around manufacturing technology in engineering settings, not all 3D printing is destined for industry. The possibilities that 3D printing opens up is also catching the eye of fashion designers. With the ability to grow a fabric 3-dimensionally and define the characteristics of that garment – flexibility, waterproofing, opacity – not only can clothing become aesthetically novel, but also functionally smart too. These dresses from ThreeASFOUR were designed as a point of crossover between biomimicry and fashion.

These dresses from ThreeASFOUR were designed as a point of crossover between biomimicry and fashion.

3D printer 'The Beast' - a breakthrough in Russian 3D printing!

3D printing

Subscribe to the author

Subscribe

Don't want

5

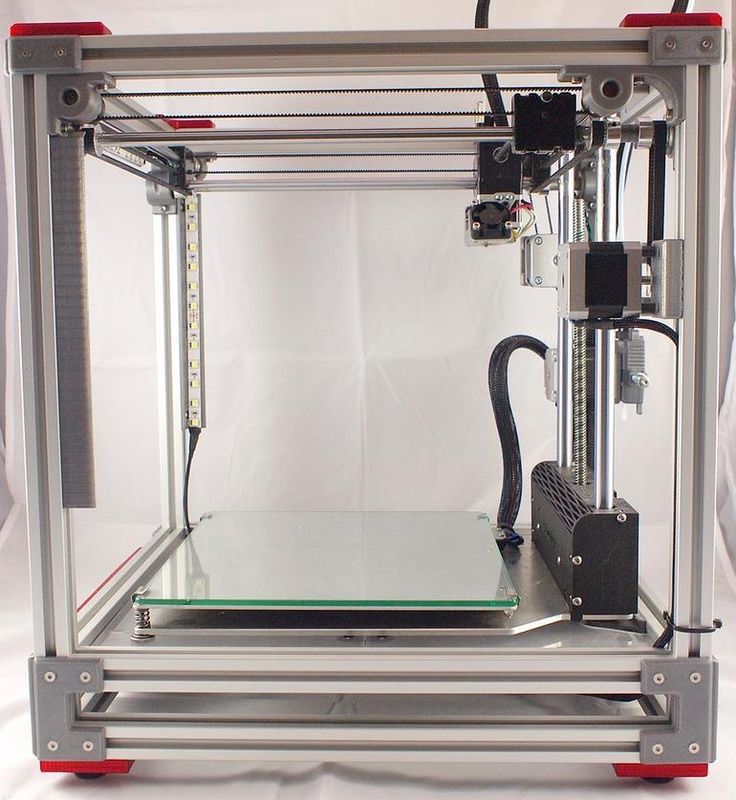

In the Russian 3D printing market, you can find dozens of different 3D printers with different characteristics. Of particular note is the domestic 3D printer Zver.

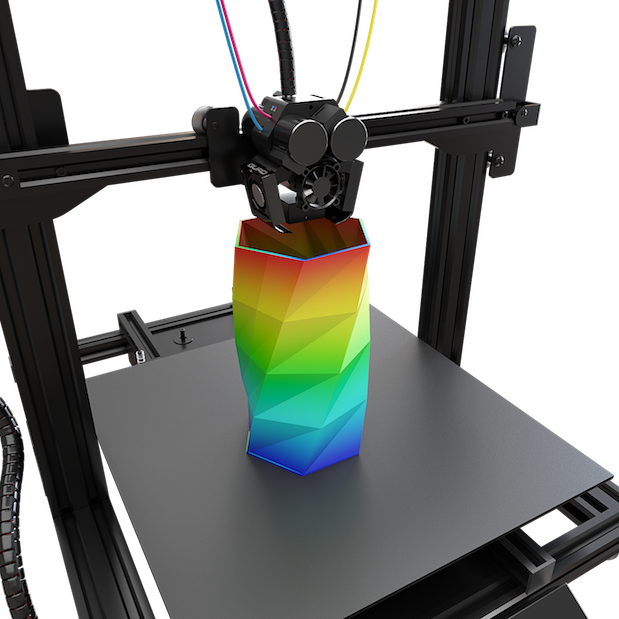

Designed by the best engineers in the country, the "Beast" outperforms its competitors many times over. Its extended print area is truly impressive, with a working area of 450mm x 530mm x 750mm. This greatly simplifies the printing of large objects, since with such characteristics no gluing of parts is required, the print object itself is solid and more reliable in use. What makes this printer different from others is the movement of the extruders on rails, which gives high precision and quality to the print. "The Beast" is a closed structure, which is equipped with an advanced two-zone heating table. This allows you to significantly reduce energy costs in cases where printing on the entire table is not required. Table heating up to 120 degrees is achieved in less than 4 minutes.

"The Beast" is a closed structure, which is equipped with an advanced two-zone heating table. This allows you to significantly reduce energy costs in cases where printing on the entire table is not required. Table heating up to 120 degrees is achieved in less than 4 minutes.

"The Beast" is one of the few printers on the market that has two extruders with nozzle adjustment from 0.3 mm to 1.2 mm. Depending on the purpose of the object, the specialist selects the required diameter. A large nozzle will provide fast printing of a large object with a low degree of detail, and a small one can create miniature products with a drawing of every little thing. The presence of two extruders allows you to print either two different colors of the same material, or use the main and supporting material to create a more accurate model. Unlike the first model of the Zver 3D printer, the second model is equipped with auto-calibration, which greatly facilitates work and simplifies printer management. Sending for printing is carried out both with the help of a computer and via micro-SD.

Sending for printing is carried out both with the help of a computer and via micro-SD.

Zver 3D printer works on FDM printing technology using various types of materials - ABS, PLA, PVA, Hips. Thanks to two extruders, the owner of the "Beast" can use two materials at the same time, which allows you to create sophisticated and exclusive items.

"The Beast" is an excellent analogue of foreign 3D printers. Taking into account the current situation in the world, Russia is starting an active policy of import substitution, actively supporting Russian manufacturers of industrial equipment and specialists in new technologies. The new Russian 3D printer does not differ in print quality from its foreign counterparts, but its price is an order of magnitude lower, since it does not depend on the exchange rate and political events affecting the country's economy.

The Zver 3D printer can be used in various sectors, from architecture to industry. The characteristics of the printer (especially its large print area) impress specialists, it is rightfully called the leader of modern 3D printing.

Follow author

Follow

Don't want

5

More interesting articles

eighteen

Follow author

Follow

Don't want to

The use of 3D printers in construction is becoming commonplace. This year was no exception, even...

Read more

ten

Subscribe to the author

Subscribe

Don't want

Introduction

So, good day to all! This is my second post...

Read more

261

Follow author

Subscribe

Don't want

I continue the series of articles started with the part devoted to polymers.

This part will be devoted to...

Read more

3D printing - a breakthrough in medical technology uMEDp

3D printing is definitely the technology of the year.

With the help of 3D printers, this technology has penetrated many different areas of life. 3D printers are used to create accessories, dishes, designer models and even weapons. Printers for private use and professional tools are already on the market. And recently there has also been a trend in the use of this technology in medicine.

Both experts and non-specialists agree that 3D printing is quite capable of changing the life of society, as people with its help get the opportunity to actually create things that are necessary in everyday life. 3D printing may not be a common feature of everyday life for a long time, but in medicine this technology has already begun to make breakthroughs.

According to Ashkhen Hovsepyan, director of SIU System, the official distributor of the American corporation 3D Systems: “Medicine is one of the most important and most promising areas for the development of 3D technologies. 3D printing can be used in transplantology, traumatology, prosthetics, plastic surgery, dentistry and many other areas.”

3D printing can be used in transplantology, traumatology, prosthetics, plastic surgery, dentistry and many other areas.”

3D technologies in modern medicine are used in different ways - some are used partially so that they can be modified for various tasks, and some technologies have fully entered the workflow.

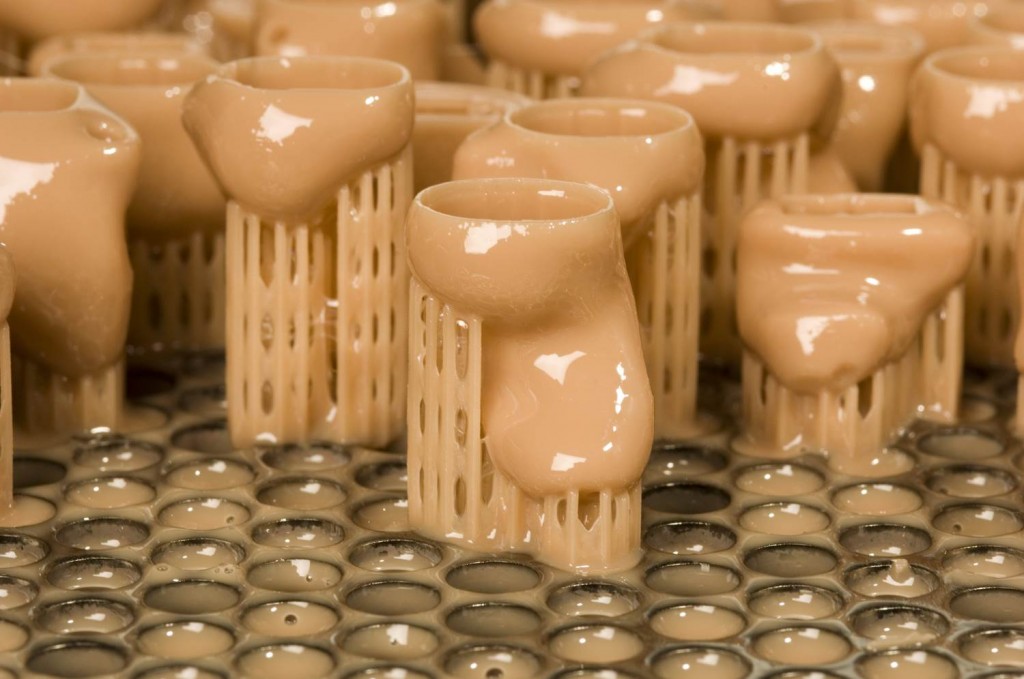

Dentistry

3D technologies are used most actively in this area. Align Technology introduced 3D printed aligners to the market back in 1999. Mouthguards are a convenient alternative to braces that do not cause any inconvenience, as they are transparent and therefore invisible on the teeth. The company currently produces over 650,000 caps per day. To create a cap, the patient's jaw is scanned in all angles. Then individual mouthguards are created - they have to be printed again every two weeks, since changes have occurred in the dentition during this time.

According to A. Hovsepyan: “Many people are embarrassed to wear braces: such constructions look unaesthetic. Clients prefer to stay with a malocclusion for life, so mouthguards are ideal for these people. Some Moscow dentists are already using this method to create a Hollywood smile.”

Clients prefer to stay with a malocclusion for life, so mouthguards are ideal for these people. Some Moscow dentists are already using this method to create a Hollywood smile.”

With the help of 3D printers, it is also possible to create an impression of the jaw and teeth much cheaper, easier and faster. This approach is used, for example, at the Moscow State University of Medicine and Dentistry. There, students are already being taught the use of 3D technologies in dentistry using specially purchased equipment.

Hearing aids

Widex has been using proprietary hearing technology since 2012. First, liquid silicone is injected into the auricle, on the basis of which an impression is created. The 3D impression model is then processed on a 3D scanner and reproduced by a 3D printer. The hearing aid is inserted into the model and the result is a miniature and precise ITE.

In'Tech took a different approach. In 2001, they started working with the Viper SLA printer. It allows you to make a shell for hearing devices that can be inserted inside the ear. The sheath accuracy can be adjusted within a millimeter.

It allows you to make a shell for hearing devices that can be inserted inside the ear. The sheath accuracy can be adjusted within a millimeter.

Transplantology

What once seemed like science fiction is now becoming a reality - 3D printing can create organ parts for transplants. In 2012, a Belgian woman was first transplanted with a jaw created in this way. Although there is no talk of creating a complete organ yet - 3D printing, of course, is not able to recreate full-fledged kidneys, heart valves or a liver.

However, a 3D printer is quite capable of replacing parts and components of the body. In the United States, exoskeleton elements have already been printed on a 3D printer for a two-year-old girl Emma, who suffers from arthrogripposis. This is a disease of the musculoskeletal system, in which the joints and muscles are underdeveloped, and deformity and contraction of the limbs occur. But the auxiliary exoskeleton helped the child move his arms, which means he could draw and play. In 2013, scientists have already created a whole exoskeleton for the girl Amanda Boxtel (Amanda Boxtel), who, due to paralysis after a fall on skis, could not walk for 22 years.

In 2013, scientists have already created a whole exoskeleton for the girl Amanda Boxtel (Amanda Boxtel), who, due to paralysis after a fall on skis, could not walk for 22 years.

“The developers of 3D Systems have been able to put a woman on her feet. Her spine, lower legs and thighs were 3D scanned, after which a complete exoskeleton was printed. Amanda was able to get up and move around on her own again. Control units and complex mechanical drives provided by EksoBionics specialists were combined with elements printed on a 3D printer,” says Hovsepyan.

Russian science does not lag behind American colleagues. In 2013, a private laboratory for biotechnical research "3D Bioprinting Solutions" was opened on the basis of Skolkovo - here the methods of three-dimensional organ bioprinting are studied from all sides. In addition to titanium implants, 3D printing can also create bone models that are as similar in structure to real ones as possible. Such technology would make transplant operations safer and easier.

Oncology

Can 3D printing help people with cancer? Scientists expect to use 3D models not only for rehabilitation after surgery, but also to prevent the development of tumors. There are already examples of this from practice: the patient had the left side of his face completely removed due to a malignant tumor. But 3D printing has helped surgeons implant a facial prosthesis that allows patients to eat properly.

The prospect of cancer prevention with 3D technology is just beginning to develop. In DNA, there is a sequence of G-quadruplex molecules that cannot be depicted in two-dimensional space. Scientists from the University of Alabama have created a model of such a molecule on a 3D printer. This model is expected to help understand how to influence such molecules in order to stop the division of cancer cells in the pancreas.

Prosthetics

Customized prostheses that take into account all the characteristics of the patient - not the exclusive prerogative of 3D printing, but much cheaper.