3D print pla painting

Your Guide to Painting PLA 3D Prints

When it comes to painting PLA 3D prints, it’s not quite as simple as removing your part from the print bed and applying paint with a brush. Of course, you could do that, but the result would be sub-optimal and the paint might be inconsistent or chip off. For the best results painting PLA, there is a bit of prep work that needs to take place, including removing supports, smoothing the print surface, and priming. In this article, we provide a step-by-step beginner-friendly guide to painting PLA parts and explain why each post-processing step is important.

Recommended reading: PLA vs ABS: Which filament should one use?

Best paints for PLA

Before getting into how to prepare your 3D print for painting, let’s first talk about what types of paint work well with thermoplastics such as PLA. Fortunately, there are different options at your disposal, both in terms of paint type and application method.

As far as thermoplastic filaments go, PLA is one of the easiest to paint. With the right preparation and priming treatment, most types of paint will adhere to the material’s surface. Acrylic paint, enamels, and lacquers can all be used to finish a PLA print. When it comes to application, you can choose to paint using brushes or using spray paint.

Despite the fact that many paints work with PLA, the most popular options for painting PLA are acrylics and enamels. Let’s take a look:

Acrylic Paint

Acrylic paint is a water-based product made up of pigment particles, acrylic polymer binder, and water. The three materials form an emulsion which can be easily applied to surfaces. When the water in the paint evaporates, the paint becomes dry and stable.[1] Acrylics are known for being easy-to-use and are quick drying. When wet, they can be cleaned easily with water, but become permanent when dry. Acrylics are also highly versatile and adhere well to a wide range of substrates, including thermoplastics like PLA. In terms of appearance, acrylic paints have a matte finish.

In terms of appearance, acrylic paints have a matte finish.

Acrylic paints are safe and easy to work with when painting PLA 3D prints.

Enamel paint

Enamel paint is a category of solvent-based paints (oil-based paints) characterized by their glossy finish. Enamel paints are also known for creating a thin hard and stain-resistant shell, which can give products greater durability and weather resistance.[2] Like acrylics, enamel paints are sold as liquid (to be applied by brush) or in aerosol form (to be sprayed). Enamel paints typically dry slower than acrylic and can have a stronger smell due to the solvents in them.

Step One: Support Removal

Once you’ve removed your PLA part from the 3D printer, the first step is to remove any supports. (If your 3D model doesn't require any support structures and doesn’t need any cleanup, you can skip this step and head straight to step two.)

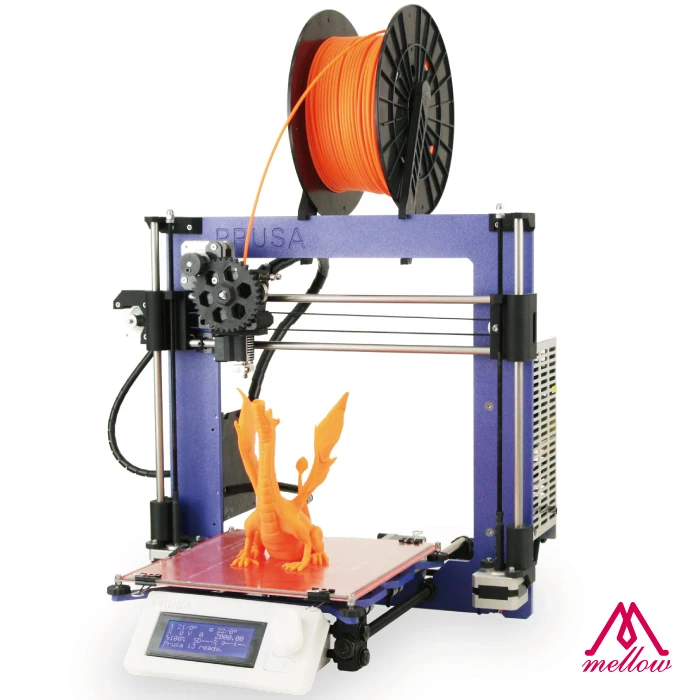

In the FDM 3D printing process, support structures ensure that certain design features—such as overhangs over 45 degrees or bridges—can be extruded successfully without succumbing to gravity. If supports are printed from the same material as your build (i.e. they are not soluble supports), they must be manually removed. In some cases, removal is as simple as breaking or cracking supports off by hand. This is easiest if the support structures are very low in density and are not well bonded to the surface of the PLA part.

If supports are printed from the same material as your build (i.e. they are not soluble supports), they must be manually removed. In some cases, removal is as simple as breaking or cracking supports off by hand. This is easiest if the support structures are very low in density and are not well bonded to the surface of the PLA part.

If your part has features that are at risk of breaking, however, we recommend using tools to assist in support removal, such as a knife, a pair of needle-nose pliers, or flush cutters. The aim, ultimately, is to remove the supports and leave as little trace as possible on the part surface. Working gently is the best way to remove supports while minimizing the risk of damage to the final model. You can also heat up the blade of a knife, which will soften the PLA and make it easier to pry the support away from the part surface.

We should note that build orientation and part design can greatly influence the support removal process. If turning your 3D model on its side on the print bed will reduce the number of supports required, the removal process will be significantly faster. Similarly, if you can tweak a design to remove a particularly challenging overhang, you will cut back on the amount of supports needed in the first place. Different types of support, such as tree supports, can also be easier to remove.

If turning your 3D model on its side on the print bed will reduce the number of supports required, the removal process will be significantly faster. Similarly, if you can tweak a design to remove a particularly challenging overhang, you will cut back on the amount of supports needed in the first place. Different types of support, such as tree supports, can also be easier to remove.

Gently remove supports by hand or using tools such as a knife, pliers, or flush cutters.

Recommended reading: How to Remove Supports from 3D Prints

Step Two: Smoothing

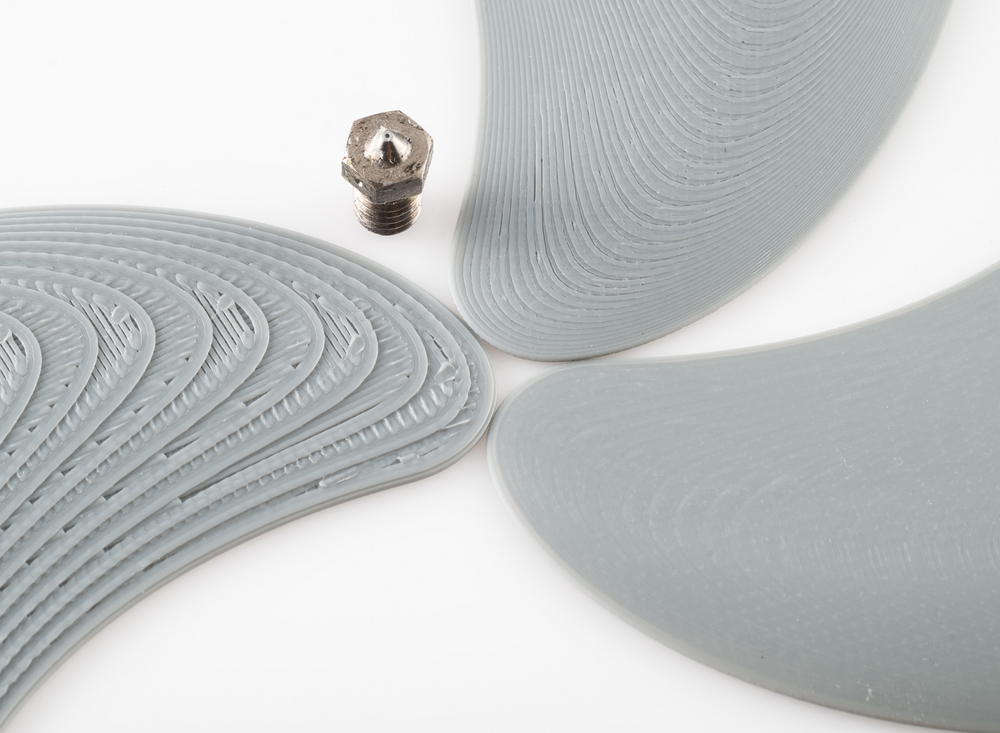

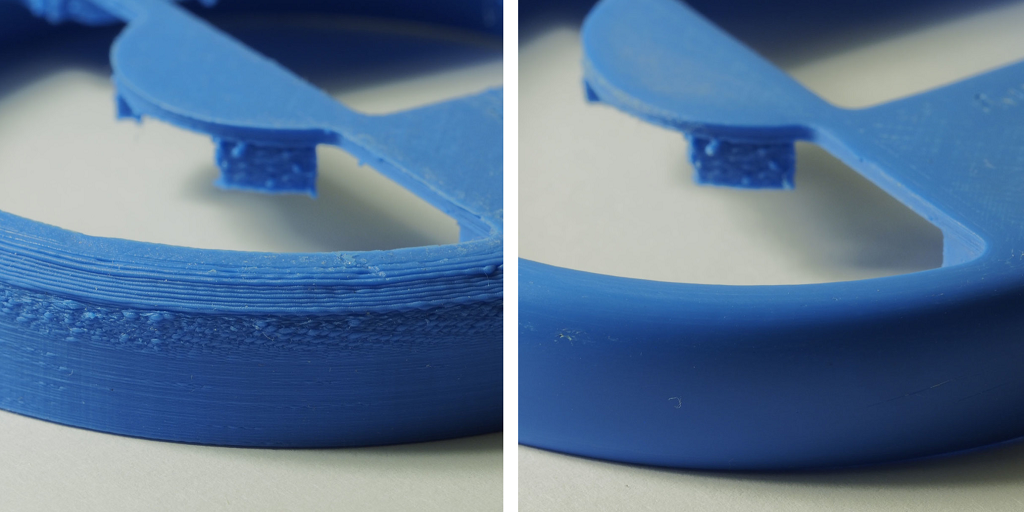

Once supports have been successfully removed from your printed model, it’s time to smooth out the part’s surface. The goal of this step is to remove any blemishes or surface defects leftover from supports as well as to flatten any prominent layer lines created by the filament extrusion process.

Sandpaper is the most popular method for smoothing PLA 3D prints: it’s cheap, safe, and is highly effective at removing surface inconsistencies. The one downside is that it can be time consuming. There are a number of different sanding mediums, including sanding blocks, sandpaper, and nail files. Sanding blocks are great for smoothing out larger parts with broader surface area; nail files are handy for smoothing out small details on PLA prints; and conventional sandpaper is pretty much suitable for everything.

The one downside is that it can be time consuming. There are a number of different sanding mediums, including sanding blocks, sandpaper, and nail files. Sanding blocks are great for smoothing out larger parts with broader surface area; nail files are handy for smoothing out small details on PLA prints; and conventional sandpaper is pretty much suitable for everything.

When smoothing a PLA 3D print, rub the sandpaper over the part’s surface in small circular motions—against the grain of the print. This will gradually remove the top layers of plastic and smooth any blemishes. If you have different types of sandpaper at your disposal, it is recommended to use a variety of different grit levels, starting with the coarsest sandpaper (lowest grit) and moving towards the finest sandpaper (highest grit). Many makers also finish the smoothing process with wet sandpaper. This is exactly what it sounds like: simply dampen a piece of fine-grit sandpaper and rub it over the 3D printed object. This step will not remove as much material as earlier sanding stages, but will result in a very smooth, polished surface.

This step will not remove as much material as earlier sanding stages, but will result in a very smooth, polished surface.

If time is a concern, you can use an electric sander. In this case, follow the same steps (starting with a lower grit sandpaper and moving to finer grit), but be sure not to sand one area for too long, as it can create a heat buildup that can soften and melt the PLA.[3] It is also a good idea to equip yourself with gloves and a mask when sanding PLA, and to work on an easy-to-clean surface. When sanding is complete, clean your work area and the 3D print to remove any PLA particles.

Recommended reading: Dissolving PLA: How to Melt PLA and Smooth 3D Prints

Step Three: Priming

While your 3D print should feel smooth to the touch after sanding, applying a primer will take it to the next level, evening out any remaining roughness or texture and filling in gaps. Primer also functions as a base layer and promotes better adhesion between the PLA surface and the paint. Priming is an essential step if you want your 3D print to have a professional painted finish.

Priming is an essential step if you want your 3D print to have a professional painted finish.

There are many different primers on the market, but primer filler (such as Rust-Oleum) is among the most recommended for finishing FDM 3D prints. Primer filler is sold as a spray, making it easy to apply. It also typically has a gray coloring, which provides a good neutral base for applying color later on. You can find primer fillers at your local hardware store.

To use an aerosol primer filler, it is important to mix the contents of the primer inside the can. Shaking the can vigorously can cause unwanted bubbles, so swirl the can for a few minutes instead. If in doubt, follow the instructions on the primer filler can.

For the best coverage, suspend your 3D model in the air and spray the primer from a distance of 25-30 cm. Spray the primer in steady motions across the model, from left to right and up and down. This will ensure that the primer is being applied evenly and is covering the whole print surface. You also want to avoid spraying too much at one time, because this can cause pooling or dripping. Finally, be sure to work in a well ventilated space using the proper protective equipment.

You also want to avoid spraying too much at one time, because this can cause pooling or dripping. Finally, be sure to work in a well ventilated space using the proper protective equipment.

When the first coat of primer is complete, let it dry. If needed, you can go back in with your sandpaper for any touch ups. Typically, PLA 3D prints require at least two coats of primer before painting gets underway. Before applying your first coat of paint, make sure the primer is completely dry (this can take about 40 minutes).

Step Four: Painting 3D Prints

Once your print has been sanded and primed, it is ready to be painted. In this step, you have some choices to make. For starters, you have to choose the type of paint you want to work with. As we saw earlier, some of the best paints for PLA are acrylics and enamel paints. You also have to choose which application method you will use: spray painting or hand painting.

Spray painting 3D prints results in a uniform, smooth finish.

Spray Painting

Spray painting is a good option for achieving a uniform, smooth surface finish. It is also good for parts that require tighter tolerances or good dimensional accuracy because it adds color in thin layers with less buildup than hand painting. Be sure to follow instructions on the spray paint you are using (i.e. in terms of shaking the can and storage).

For the best results spray painting your 3D print, hang your print using a thin wire in a well ventilated area. This will enable you to spray the entire print’s surface without missing any spots. Similar to applying the primer, move the spray can continuously, back and forth and up and down, with wide strokes that cover the entirety of the print. This will ensure that the paint is applied evenly and to the entire print.[4]

Once the first coat is complete, wait 15 to 20 minutes before applying a second coat. Repeat this until the desired saturation and finish is achieved. At this point, leave the painted 3D print for at least 24 hours before applying any varnish or polishing coatings. And don’t forget to wear protective equipment, like gloves, goggles, and mask when spray painting.

At this point, leave the painted 3D print for at least 24 hours before applying any varnish or polishing coatings. And don’t forget to wear protective equipment, like gloves, goggles, and mask when spray painting.

Hand Painting

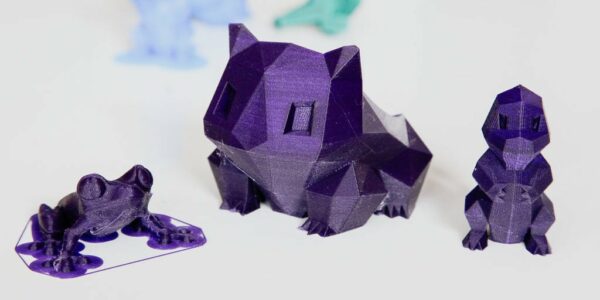

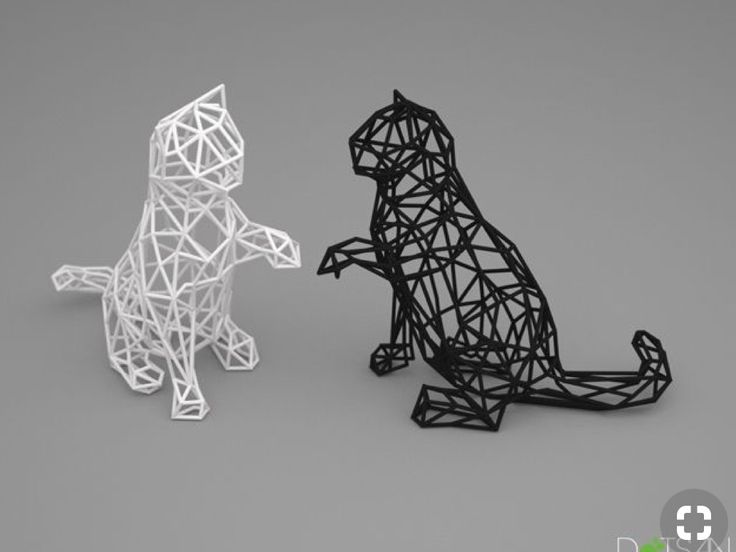

Hand painting is usually the best choice for 3D prints that require fine details, such as toys or miniature models. Use good quality brushes and paint to coat your 3D print in the colors of your choosing. When the base layers of paint are dry (it might take several even coats to get the opacity and consistency you want), go in with finer paint brushes to add detail. If possible, start by using the lightest colors and progress to using the darkest colors.

If you are painting using brushes, it is best to work with acrylic paint. This type of paint is easy to work with and is among the most affordable. Note that cheaper acrylic paints might not have the best coverage and may require more coats than a better quality paint.

Clear Coat

When you are happy with the appearance of the color paint, there is the optional step of adding a clear coat to your print. The clear coat is a transparent layer that protects the surface of the paint and can modify the finish. For example, if you have painted your print with matte acrylics, you can apply a glossy clear coat for a shinier finish. The clear coat can also be applied by brush or sprayed using the same techniques we discussed for painting.

Key Takeaways

Painting is a reliable way to make your 3D prints look more professional, whether you are making a product design prototype, a decoration for your home, or a functional part. Achieving a high-quality paint job, however, takes some time and effort. Here are some of our key takeaways for painting PLA 3D prints:

Acrylic and enamel paints are the two best options for painting PLA 3D prints.

Before painting, it is essential to remove supports and smooth the print’s surface using sandpaper.

Priming ensures that the print surface is sealed and smooth. It also helps the final coats of paint to adhere to the plastic material.

For smooth uniform coats of paint, spray paint is recommended. Hand painting is best for adding small details.

Hang or mount your 3D print to paint every angle and to ensure even coats. This will also help the paint to dry uniformly without any blotches.

When post-processing and painting PLA, make sure to work in a well-ventilated space and to use the proper protective equipment, such as mask and gloves.

References

[1] https://www.liquitex.com/us/knowledge/what-is-acrylic-paint/

[2] https://acrylgiessen.com/en/enamel-vs-acrylic/

[3] https://www.makerbot.com/professional/post-processing/sanding/

[4] https://www.makerbot.com/professional/post-processing/painting/

How to paint PLA 3D printed parts?

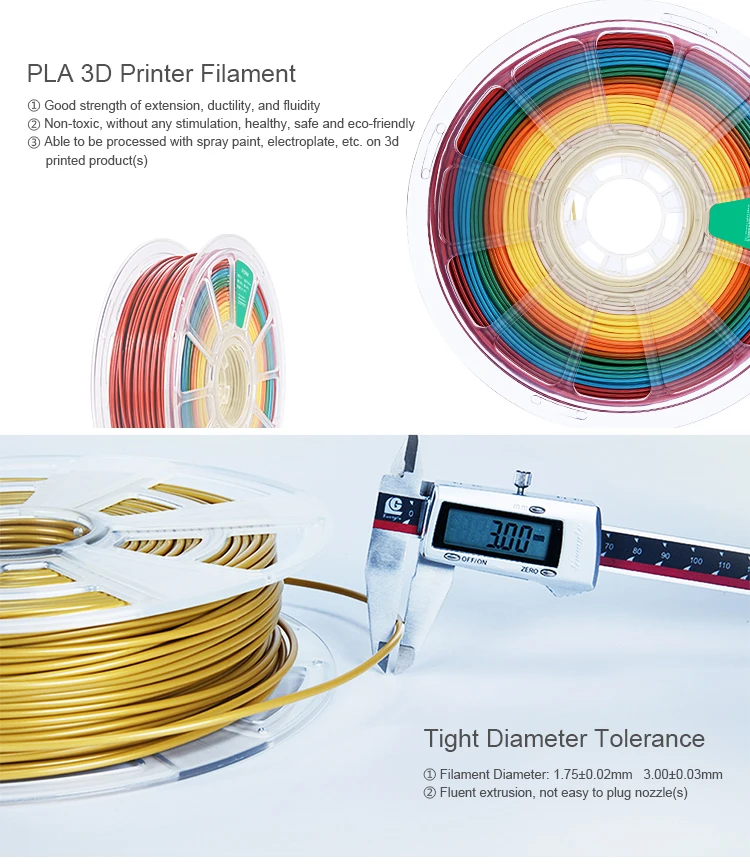

PLA is one of the most widely used materials for 3D printing because of its good mechanical properties and ease of printing. Despite the fact that there is a very wide range of colors available for PLA, many times we have to paint the printed parts to give them different finishes according to the purpose of our project.

Despite the fact that there is a very wide range of colors available for PLA, many times we have to paint the printed parts to give them different finishes according to the purpose of our project.

Today, in Bitfab, we show you how to paint the PLA printed parts.

How to prepare the part for painting

If you are going to paint a part printed on PLA it is because you want to give it a special finish. To achieve this, we must first start with a part that has a good print quality, which is essential to achieve a good finish after painting. We will never get a properly painted part from a badly printed part

In Bitfab we have several articles where we help you to diagnose problems in your prints and give you tips to improve the quality of finishes:

- How does the orientation affect the quality of the part?

- Guide to solve the most common problems in your prints

In these articles we show you how you can make the parts you print come out as good as possible, so as to minimize the post-processing needed before painting them.

Once we have a good quality part, it is very likely that we will want to give it some kind of treatment to improve its finish even more and get as smooth a surface as possible, thus eliminating the layer lines. For this we have several possible solutions, the most common being:

- Traditional sanding to remove layers using abrasive materials

- Coating our part with a resin, making the layers invisible

- Chemical polishing with a solvent (not recommended)

We’ll tell you a little bit about each of these methods so that you know how to post-process your part in the most convenient way.

Traditional sanding

A very simple way to improve the surface quality of our parts is by sanding. We can use a multitude of tools, from typical sandpaper to precision tools such as a Dremel type multi-tool such as the Dremel 3000 we use.

Some very interesting tools for these cases can be modeling files. There are many shapes and sizes, and they will help you sand the smallest parts and access the nooks and crannies of any model.

We recommend this Amazon set that is very complete and affordable.

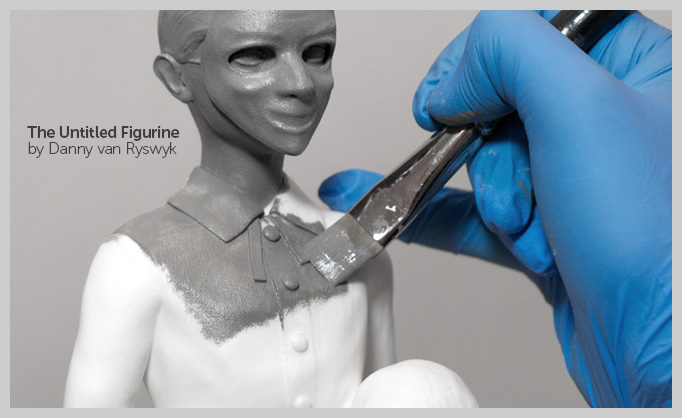

Using resins to improve the finish

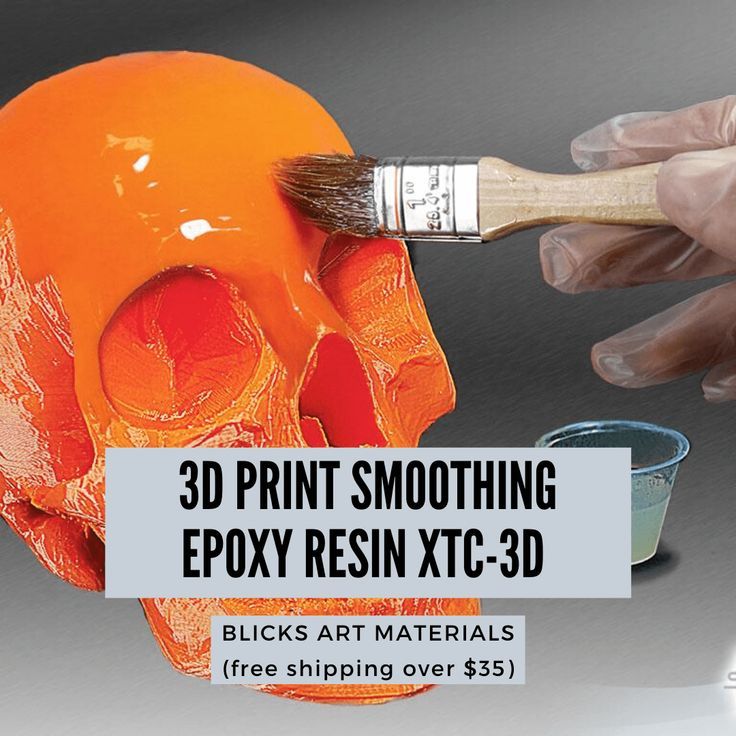

There are many resins specifically designed for improving the finish of 3D printed parts. One of the best known because of its quality is the XTC-3D brand.

It is a two-component resin very similar to the typical epoxy resins that we can find in chemical stores. In this case, its composition is designed to have the appropriate density and viscosity for this purpose, being sufficiently viscous to be able to apply well, but not too viscous to be able to penetrate the gaps in our part.

The results, as you can see, are quite good.

Use of solvents for PLA

An old trick that has always been used on ABS printed parts is to use acetone, either by liquid application with a brush or steam application, to smooth their surface. This type of “experiment” is in itself a risky task since it reminds you that you are using a liquid with very high solvent power (enough to dissolve the polymer itself).

In the case of PLA, acetone does not work (or at least does not work for the vast majority of PLA) and we must use a different solvent. The most commonly used is dichloromethane or methylene chloride.

We have used it at Bitfab, and we cannot deny that you get extraordinary results with a correct application, but it is absolutely essential to take very strict security measures. We are professionals and we have the appropriate means. Acetone is a product that can be dangerous, but dichloromethane is, in many aspects, much more hazardous to health.

We only recommend this method if you have the appropriate facilities and the necessary safety equipment.

Which paint to use?

Now that we have a quality model and we have applied the treatment we believe convenient, the time has come to paint it.

PLA, depending on its formulation, can be a little “exquisite” with the paints you use on it. It is possible that certain types of paint do not adhere to PLA, so it is advisable to always use a good primer first to ensure good adhesion.

Primer is basically a paint specially designed to adhere to almost any surface, creating, once dry, a surface to which any other paint can adhere without any problem. There are many types of primer with different characteristics but for most situations a multi-purpose spray primer will do the trick and come out cheap.

The usual strategy is:

- Sand or resin down to an acceptable finish

- Prime and let dry

- Check the finish

- Repeat

In this way we will be adding coats of primer and improving the finish, although usually a couple of coats is enough if we are not looking for an extremely perfect finish.

The next thing is to choose the type of paint, although if you have applied a primer almost any type of paint will be valid. If we want to paint with a brush we can choose acrylic paint like the one used to paint miniatures, such as these of the famous Vallejo brand:

Another alternative is to use acrylic spray paint, which is more suitable if we simply want to paint our part in one color quickly and evenly. In this section there are lots of brands, models and colors.

In this section there are lots of brands, models and colors.

Our favorites are Montana spray paints (maybe harder to get in the US or in the UK). Although it is a brand that comes from the world of graffiti, it has developed a very wide professional range with industrial paints, special paints, body fillers, primers…

Conclusions

In this article we have taught you the principles of how to prepare your model for painting, choosing between:

- Sanding

- Resin application

- Chemical smoothing

Then all you have to do is prime and paint and you’re ready to show your part to everyone and leave them with their mouths open.

PLA print settings | How to choose modes for PLA filament

PLA plastic filament is used in FDM 3D printers. This is a truly amazing material that is environmentally friendly and non-toxic. During printing, it does not “stink”, but emits a light aroma of popcorn. The thing is that it is made on the basis of natural plant materials - corn, potatoes, cane, etc.

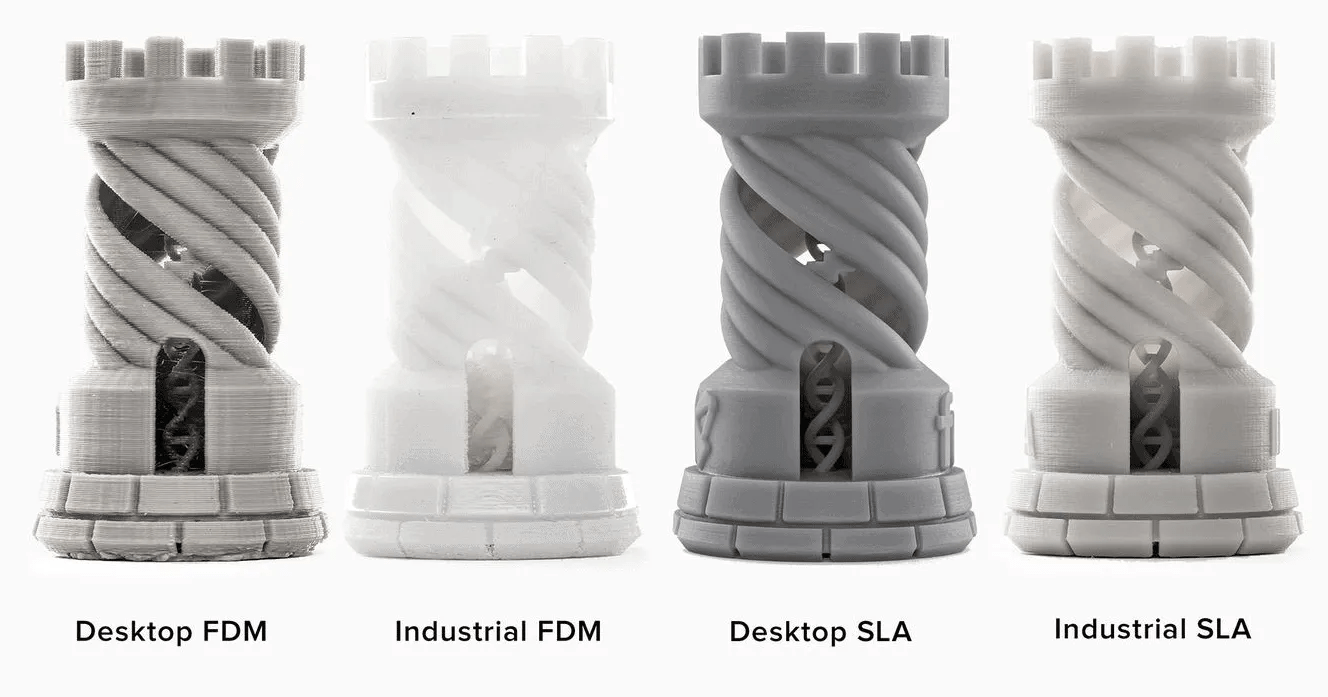

If you compare PLA with ABS, it turns out that the former is harder, and therefore the process of applying the next layer will be slower. But this has a positive effect on the result of printing, because the products are smoother. However, this imposes its own characteristics on the print settings, the choice of which should be guided by the characteristics of the material.

PLA plastic specifications

PLA plastic for 3D printers has a number of key characteristics. Depending on the brand, the properties may vary slightly. However, this material is characterized by:

- strength and rigidity;

- translucency and even transparency;

- wide range of colors;

- smooth, detailed finished models and shiny surface.

PLA turns out to be easier to work with, ideal for those new to 3D printing as it doesn't warp or shrink like ABS. But it is less heat-resistant and already at 70 degrees it can begin to deform.

The most important layer in FDM 3D printing will always be the first layer. It must be fixed on the desktop to avoid further deformation. In this regard, PLA plastic is less demanding in comparison with ABS. But many use special substrates, blue tape or glue stick. You can print simply on glass, especially if the 3D printer is equipped with a heated table. The optimum temperature in this case will be 70 degrees, although in some cases, it has been experimentally established that the best results are achieved on a cold table.

The second point - it is important to correctly set the height of the extruder. The nozzle should be at such a height that a standard sheet can easily pass between it and the work table.

The nozzle should be at such a height that a standard sheet can easily pass between it and the work table.

Next, you need to decide on the standard set of settings:

- temperature;

- layer thickness;

- table temperature (if heated).

Another important point to get the best print result from PLA is to use the blower at full power. So the plastic will be cooled in time and not deformed.

As with ABS, print performance will be derived empirically. For example, the temperature will be set to 200 degrees and then raised or lowered by 5 degrees until the best option is found, in which the layers will perfectly hold together, have time to freeze and not swim.

And the average print settings for PLA are as follows:0026

, nevertheless, is still guided by the recommendations . Add to this experienced developments and the best printing result will not be long in coming.

Add to this experienced developments and the best printing result will not be long in coming.

Material comparison:

Poor +

Satisfactory + +

normally + +

Good + + +

excellent + + + +

|

| ABS HIPS FLEX | + + + + | + + + + + | + + | + + | + + + | + + | + + + + | ||

| Light fur. Processing | + + + + | + + | + + | + | + | + + | + + + | |||

| Durability on the street | + + | + | + + | + + + 9003 | + + + | + + + | + + | + | Thermal resistance | + + + | + + | + + + | + + + + | + + | + 9002 + | + + + + | + + + + | + | + + | + + + | + 9,0000033 |

| Proceeds | + + + | + + | + | + + + | + + + + + . | + + | ||||

| Oil resistance | + + + | + + + | + + | -40°С to +70°С | -40°С to +100С | -35°С to +85°С | ~190°С fusion temperature -10°C to +30°C |

Simplify3D PLA print settings

Below are the recommended print settings for PLA plastic and job preparation in the Simplify3D slicer.

Main parameters: printer print area - 200x200x210 mm, nozzle diameter - 0.3 mm. *These values need to be changed for your printer.

Translation of the Simplify3D slice and parameters of the Simplify3D slider is presented by the link - follow

9000 9000 9000 9000

Plastic Plastic Plastic for 3D Princes. Plastic post-processing after 3D printing ABS, PLA, Nylon, Petg

Plastic post-processing after 3D printing ABS, PLA, Nylon, Petg

Contents:

- Post-processing of FDM parts

- Remove supports

- Removal of soluble supports when printing with a 3D printer with two extruders

- Sanding plastic 3D printed products

- Application of Acetone in ABS plastic processing

- Filling irregularities in ABS plastics

- ABS/PLA polishing

- Priming and painting 3D printed products

- Acetone Baths for ABS Products

- Chemical solvent baths

- Using epoxy to finish prints

Hello everyone, Friends! With you 3DTool!

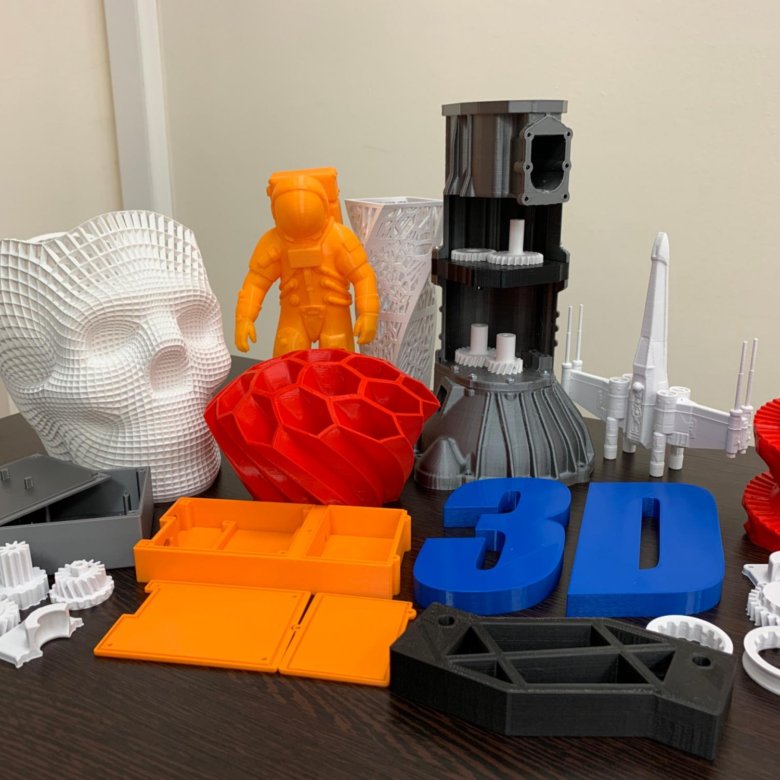

With the FDM 3D printing of the , plastic parts of any geometric shape can be quickly and economically produced. Finished parts show visually the lines of the layers they were printed on, making post-processing an important consideration if a smooth surface is required. Some post-processing techniques can also increase the strength of finished products by helping to reduce their anisotropic properties.

This article will discuss the most common post-processing techniques in FDM 3D printing .

Catalog of FDM 3D printers

Post-processing of FDM parts

This picture above (from left to right) shows the post-processed parts FDM :

- gap filling

- raw

- sanded

- polished

- painted

- epoxy coated

Remove supports

Support removal is typically the first step in post-processing for any 3D printing technologies if the part requires support for precision manufacturing. Supports can usually be divided into 2 categories: standard and instant .

Unlike other post-processing methods discussed in this article, support removal is a requirement and does not result in improved surface quality.

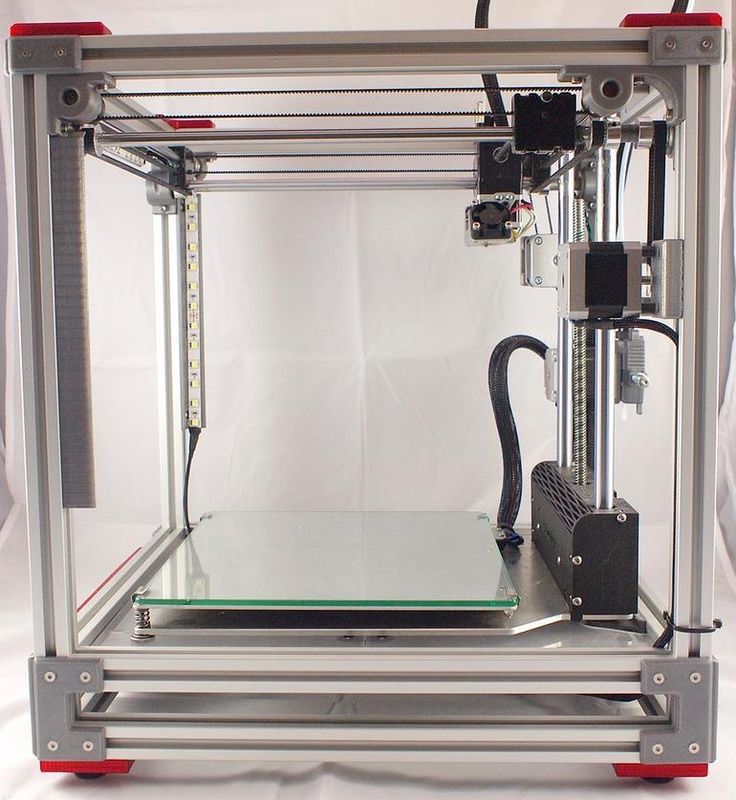

Removing supports mechanically is necessary when printing with a 3D printer with a single extruder (for example, PICASO Designer X, Hercules 2018, Zenit, Prusa i3 Steel Bizon) When using 3D printers with two extruders, as a rule, the supporting part of the product is made of special soluble materials.

Catalog of 3D printers with two extruders

Left to right. Original printing with support, poor support removal and quality support removal.

Tools and materials you will need for this job:

- Pliers

- Set with small tools (eg watchmaker's set).

Support Removal Process: The support material can usually be removed from the finished model without much effort. Cleaning of the substrate material in hard-to-reach places (for example, in holes) can be done using an awl and pliers. Properly positioned support structures and proper print orientation can greatly reduce the impact of the support material on the aesthetics of the final result.

Properly positioned support structures and proper print orientation can greatly reduce the impact of the support material on the aesthetics of the final result.

Plus

- The overall geometry of the part does not change

- Fast on time

Cons

- Does not remove visible layer lines, streaks or smudges on print surface

- If support structures leave excess material or marks behind, the accuracy and appearance of the part will be reduced

Soluble support removal when printing with a 3D printer with two extruders

As we said earlier, the removal of supports printed from soluble materials is done differently than manually, mechanically, so the use of 2 or more extruder printers is preferable. (e.g. PICASO Designer X PRO, Raise3D PRO2)

Catalog of 3D printers with two extruders

Tools and materials you will need for this job:

- Solvent safe container

- Thinner

- Ultrasonic cleaner (optional)

Process : the final model is placed in a bath with an appropriate solvent (for example, for PVA plastic it will be ordinary water, for material HIPS it will be D-limonene ) until the support material dissolves. Support is usually printed with:

Support is usually printed with:

- HIPS (in conjunction with ABS )

- PVA (in conjunction with PLA )

Glass storage containers such as jars are excellent receptacles for diluting limonene. For dissolution in water, any non-porous container will do. For prints using HIPS/ABS bath with a 1:1 ratio of limonene to isopropyl alcohol works very well for quick support removal. Many other support materials such as PVA (used with PLA ) are water soluble.

Helpful Hint: Speed up the dissolution time of the support material by using an ultrasonic bath and changing the solution as soon as it becomes saturated with plastic dissolved in itself. Using a warm (not hot) solvent will also speed up the dissolution time if you don't have an ultrasonic cleaner available.

Catalog of ultrasonic baths

Pros

- Great for complex geometries where standard support removal would be impossible without damaging the base model.

- This results in a smooth surface where the support structure is in contact with the base piece.

Cons

- Improper dissolution of the material can lead to discoloration and deformation of the entire part.

- Does not remove visible layer lines, streaks or spots on part surface

- May cause small spots or holes in the final print if soluble material gets on the object during printing

-

Sanding plastic 3D prints

Sanded brown ABS plastic part

Tools and materials you will need for this job:

- Sandpaper up to 1000

- Rags

- Toothbrush

- Soap

- Face mask

Sanding Process: After the supports have been removed or dissolved, sanding can be performed to smooth the part and remove any visible stains or traces of the supports. The initial grit size of the sandpaper depends on the layer height and print quality.

The initial grit size of the sandpaper depends on the layer height and print quality.

For layers with a height of 0.2 mm or less, or if there are no spots left on the part after printing, sanding can be started with a paper grain of - 150.

If there are visible spots or the object was printed at a layer height of 0.3 mm or more, start sanding with 100 grit paper.

purity. The print should be cleaned with a toothbrush in soapy water and then with a rag, between sanding gradations to prevent dust build-up and " sintering ". Your FDM parts can be sanded down to 5000 grit to achieve a shiny part surface.

Helpful Hint:

Always sand evenly over the entire surface of the part in small circular motions. Of course, it is more convenient to sand perpendicular or even parallel to the print layers, but this can lead to indentations in the model. If the part becomes discolored or if there are many small scratches after sanding, you can use a blow dryer. With it, you gently heat the part, thereby softening the surface a little and visible unnecessary defects will weaken or disappear altogether.

With it, you gently heat the part, thereby softening the surface a little and visible unnecessary defects will weaken or disappear altogether.

Pros

- With this method, you get an extremely smooth surface

- This method facilitates additional post-processing (such as painting, polishing, or epoxy coating)

Cons

- Not recommended for thin wall prints as this may damage part

- Difficult for surfaces with difficult geometries and fine details

- Can affect overall print accuracy if sanding is done too aggressively and too much material is removed

Acetone for ABS plastic

Two white printed halves made of ABS bonded with plastic diluted in acetone.

Tools and materials you will need for this job:

- Acetone

- Cotton buds or brush

Machining process: When the size of the finished part exceeds the maximum size of the 3D printer's camera, the model often has to be broken into smaller parts and reassembled later by gluing. For PLA and other materials, bonding can be done using the appropriate adhesive (selection of adhesive will depend on the plastic) . For ABS plastic, multi-piece assemblies can be glued with acetone. The mating surfaces should be lightly moistened with acetone and held firmly together or, if possible, clamped until most of the acetone has evaporated. At this point, the two parts of your model will stick together.

For PLA and other materials, bonding can be done using the appropriate adhesive (selection of adhesive will depend on the plastic) . For ABS plastic, multi-piece assemblies can be glued with acetone. The mating surfaces should be lightly moistened with acetone and held firmly together or, if possible, clamped until most of the acetone has evaporated. At this point, the two parts of your model will stick together.

Helpful Hint: increasing the contact area with acetone will increase the strength of the joint. This can be done by including block connections in the design.

Pros

- Acetone will not discolor the surface of the part like other adhesives

- After drying, the seam will exhibit ABS properties, making further processing easier and more uniform

Cons

- The bond formed by this cold welding is not as strong as a solid impression

- Excessive use of acetone can lead to aggressive dissolution of the part and adversely affect the final result and tolerances

-

Filling irregularities in ABS plastics

The gray ABS model had voids after sanding. The surface became smooth.

The surface became smooth.

Tools and materials you will need:

- Epoxy (for small voids only)

- Automotive Putty (large voids and joints)

- ABS plastic and acetone (for small voids only and for ABS parts only)

Process: After sanding or removing soluble backings, gaps often appear in the print. During printing, gaps are sometimes formed, and often this pattern is unavoidable. Small gaps and voids can be easily filled with epoxy and no further treatment is required. Large gaps, or gouges, left from attaching model assembly parts can be successfully filled with automotive putty, which will require additional sanding after drying.

The putty gives excellent results and can be easily sanded and painted after it has fully cured. The connection will be strong, and will not weaken the plastic. Conversely, autofiller parts tend to be stronger than native plastic.

Gaps in ABS printing can also be filled by making a slurry of ABS filament and acetone ( ABS juice or ABS juice ) that chemically reacts with the part and penetrates any surface voids. A ratio of 1 to 2 between ABS and acetone is recommended. This method will not significantly affect the cleanliness of the surface around the gap if properly applied.

Tip : If gaps are visible on FDM parts before sanding, fill them with epoxy and then sand once until dry. This will greatly reduce the overall time required to achieve a smooth surface.

Pros

- Epoxy resins are easy to sand and prime, making the surface easy to paint

- ABS juice will be the same color as your part, as long as you use the same filament by color and manufacturer. Therefore, there will be no discoloration of the surface

Cons

- Auto putty or other polyester epoxy will dry opaque resulting in discolored spots on the print

- Requires additional sanding to achieve uniform coverage

- Can affect overall print accuracy if sanding is done too aggressively and too much material is removed

ABS and PLA polishing

ABS Plastics Catalog

Catalog of PLA plastics

Tools and supplies you will need

- Polish

- Sandpaper

- Nonwoven wipe

- Toothbrush

- Microfibre cloth or polishing pad

Process: Plastic polish can be applied after sanding to give standard filaments such as ABS and PLA a glossy finish. After the part has been sanded to 1000 grit, wipe off any excess dust from the Non-woven » cloth, then clean it in a bath of warm water with a toothbrush.

After the part has been sanded to 1000 grit, wipe off any excess dust from the Non-woven » cloth, then clean it in a bath of warm water with a toothbrush.

Allow the piece to dry completely and buff it with a buffing pad, or by hand with a microfiber cloth and a jewelry polish designed specifically for plastic and synthetics that provides a long lasting shine.

Other plastic polishes, such as car headlight polishes, work on the same principle, but some may contain chemicals that can damage the original material.

Tip: For polishing small parts, attach the polishing pad to the Variable Speed Drill (or other rotating tool such as a drill) . Bench grinders equipped with a polishing wheel can be used for larger, stronger prints, but don't polish too long in the same place. This can cause the plastic to melt due to friction.

Pros

- Polishing is applied without the use of any solvents that can deform the part and change the accuracy tolerances.

- When properly ground and polished, the part will give the impression of a mirror finish, imitating plastic injection molding

- Plastic polish and cleaner are very economical, making this method quite profitable for a quality finish

Cons

- The part must be carefully sanded before polishing if a mirror finish is required. This may affect tolerances

- Primer/paint may not adhere to surface after polishing and you will need additional products

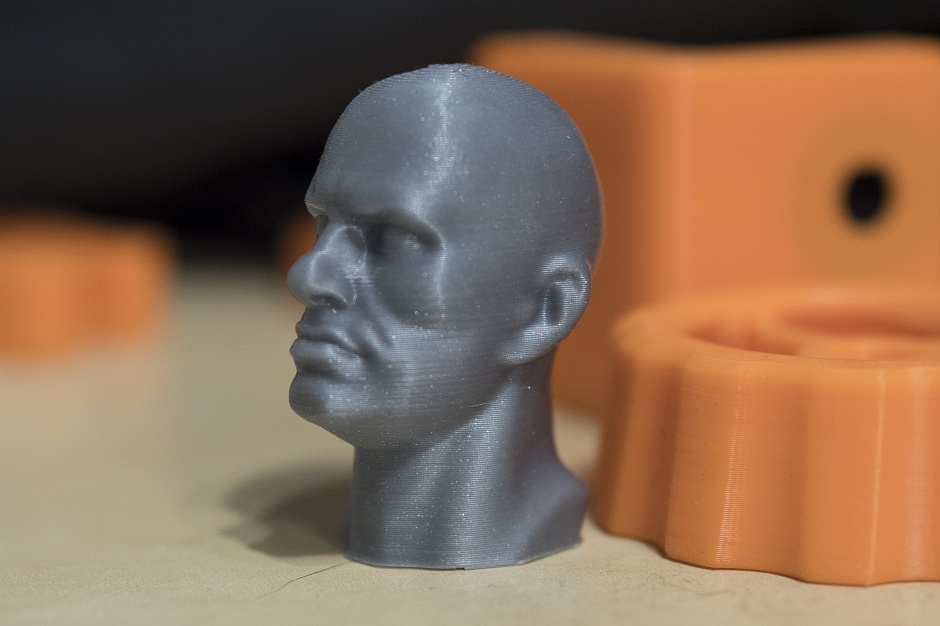

Priming and painting 3D printed products

White PLA part spray painted gray

Tools and materials you will need:

- Non-woven cloth

- Toothbrush

- Sandpaper

- Aerosol Acrylic Primer

- Polishing agents

- Masking tape (only if using multiple colors)

- Gloves and petal mask

Finishing process: after the part is properly sanded (up to 500 grit sandpaper is required at this stage) , the print can be primed. The primer should be applied in two coats using an aerosol can.

The primer should be applied in two coats using an aerosol can.

An aerosol primer designed for painting models will provide an even coverage and be thin enough not to darken the part before painting.

A thick primer, such as one available at the hardware store, may stick together and require more sanding.

Apply the first coat in short, quick strokes at a distance of about 15 - 20 cm from the part to avoid the formation of a thick layer of primer. Let the primer dry and sand down any imperfections with 9 grit sandpaper.0824 500. Apply the final coat of primer with light, quick strokes.

Once the primer is complete, painting can begin. Painting can be done with acrylic paints and artist's brushes, but using an airbrush or spray can give a smoother surface.

Hardware store spray paint tends to be thicker and harder to control, so it's best to use paints made specifically for painting models.

The primed surface should be sanded and polished (sanding and polishing sticks used in nail salons are ideal for this application) and then cleaned with a non-woven cloth.

Paint over the model using very light layers; the first few layers will look translucent. Once the paint has developed an opaque coat of (usually after 2-4 coats) of , allow the model to dry for 30 minutes to allow the paint to set. Carefully polish the paint layer with nail sticks.

Multi-colour models can be painted with masking tape. Once all layers of paint are ready, remove the tape and buff the paint using polish paper. Polishing paper such as 3M or Zona can be purchased in a variety of grit sizes. You can buy it in a pack in many online stores. It will give the paint a shine that cannot be achieved in any other way.

Helpful Hint: Do not shake the can when using spray paint! The goal is to mix the pigment or primer, shaking the propellants will cause bubbles to form in the aerosol. Instead, rotate the jar for 2-3 minutes. The stirring ball should roll, not rattle.

Pros

- Professional results with attention to detail

- Excellent appearance of the final product, regardless of the material/color in which the object was originally printed

Cons

- Paint and primer will increase the volume of the model, which will change the tolerances and can cause problems if the part is part of the assembly

- Buying a high quality spray paint or airbrush is not cheap

Acetone baths for ABS products

Smoothed black model of a petal with a spherical surface made of ABS plastic after an acetone bath.

Tools and materials you will need:

- Non-woven cloth

- Sealed container

- Thinner

- Paper towels

- Aluminum foil (or other solvent resistant material)

- Face mask and chemical resistant gloves

Process: Line the chosen container with paper towels along the bottom and, if possible, up the sides. It is very important that the steam does not disturb the chamber itself. The chamber may be sealed.

It is recommended to use glass and metal containers.

Pour in enough solvent to dampen but not drown the paper towels. This will also help them stick to the side walls of the container.

Acetone is well known for its ability to smooth out ABS parts. For PLA, smoothing is possible with various solvents, they work well, but as a rule, with PLA, it is more difficult to get a smooth surface, unlike ABS.

IMPORTANT! When working with any solvent, please follow the safety regulations for the chemical and always follow the appropriate safety precautions !

A small "raft" of aluminum foil or other solvent-resistant material should be placed in the middle of a lined paper towel container.

Next, place your part on this raft (either side selected as the bottom on the raft) and close the lid of the container.

Steam polishing can vary in duration, so check the print periodically. Heat can be used to increase polishing speed, but care must be taken to prevent the buildup of potentially explosive fumes.

When removing the part from the chamber, try not to touch it at all, leaving it on the raft and removing it from the container. Any points of contact with the part will generate surface defects because the outer shell will be half dissolved. Allow parts to dry completely before use.

NOTE . Many aerosol and/or spray solvents are flammable/explosive and solvent vapors can be harmful to human health. Be especially careful when heating solvents and always work in a well ventilated area.

Pros

- Smooths out many small spots and reduces layer lines present in the print without any additional work

- Creates a very smooth "shell" around part

- A very fast method that can be implemented with improvised means

Cons

- Doesn't heal gaps or completely mask layer height

- The dithering process "dissolves" the outer shell of the print, and therefore the tolerances are greatly affected

- Negatively affects print strength due to changes in material properties

Chemical solvent baths

Tools and supplies you will need:

- Solvent safe container

- Thinner

- Hook or small screw

- Wire

- Drying rod or stand

- Face mask and chemical resistant gloves

Process: Make sure the container you are using is wide enough and deep enough to hold the part and solvent. Fill the container with the appropriate amount of solvent, taking care to minimize splashing. As with steam smoothing, acetone should be used to dip the ABS.

Fill the container with the appropriate amount of solvent, taking care to minimize splashing. As with steam smoothing, acetone should be used to dip the ABS.

PLA is sufficiently resistant to solvents, so it may take several passes to achieve the desired result.

Prepare the part for dipping by screwing an eye hook or small screw into an inconspicuous surface of the imprint. Pass the wire through the eye of the hook or around the screw so you can lower your piece into the wire bath. If the wire is too thin, you won't be able to submerge the part in the solvent.

Once the part is prepared, quickly immerse the entire object in the solvent for no more than a few seconds using wire. Pull out the print and attach it to a wire over a dryer rod or rack to allow the solvent to completely evaporate from the surface. The part should be gently shaken after you remove it to facilitate drying and avoid solvent build-up in depressions on the surface.

Helpful Hint: If the part has an opaque whitish color after drying, it can be hung over a solvent bath for a while so that the evaporating vapors slightly dissolve the surface. This will restore the color of the print and provide a glossy outer layer.

This will restore the color of the print and provide a glossy outer layer.

Pros

- Print surface smoothes much faster than steam polishing

- Produces much less fumes than other solvent polishing methods and is safer

Cons

- Very aggressively smoothes the surface of the part, so the tolerances deviate greatly from the specified

- Immersion too long can lead to complete deformation of the part and a significant change in material properties

Using epoxy to finish prints

The part is sanded and coated with epoxy resin.

Tools and supplies you will need:

- Two-component epoxy (such as XTC-3D)

- Foam applicator

- Brushes

- Mixing container

- Sandpaper 1000 grit or higher

Process : After the print has been sanded (sanding first will give better end results) , completely clean it with a non-woven cloth.

Mix the correct ratio of resin and hardener as directed in the resin instructions. Make no mistake about the proportions. Epoxies are exothermic when mixed, so glass containers and containers composed of low melting point materials should be avoided.

Containers specifically designed for mixing epoxy resins are recommended. The wrong ratio will lengthen the drying time and the epoxy may never be able to fully cure, resulting in a disastrous and sticky part.

Mix resin and hardener thoroughly according to instructions. Stir gently to minimize air bubbles. The faster the epoxy dries, the better. Most epoxies have a working dry time of only 10-15 minutes, so do your post-processing in the proper order.

Apply the first coat of epoxy using a foam applicator and try to minimize resin buildup on recessed surfaces or other details of the print. Once your part is sufficiently covered with resin, allow it to fully cure according to the manufacturer's instructions. One coat may be enough to smooth the detail, but for optimum appearance, the print should be lightly sanded with fine sandpaper (1 000 grit or higher) . Remove dust with a non-woven cloth and apply a second coat of epoxy in the same manner.

One coat may be enough to smooth the detail, but for optimum appearance, the print should be lightly sanded with fine sandpaper (1 000 grit or higher) . Remove dust with a non-woven cloth and apply a second coat of epoxy in the same manner.

Pros

- A very thin coat of epoxy will not significantly affect part tolerances (unless the part has been sanded first)

- Resin provides an outer protective sheath around the part

Cons

- The layer lines will still be visible, they are under the "smooth" shell

- Applying too much epoxy can cause surface dripping and over-smoothing of print details

Tools and supplies you will need:

- Plating solution. It can be prepared by mixing a metal salt with acid and water, but if the proportions are not accurate, it will be difficult to get a professional result.

Buying a ready-made solution guarantees that there are no problems with plating.

Buying a ready-made solution guarantees that there are no problems with plating. - Sacrificial anode. The anode material must match the metal of the plating solution, so if copper sulfate is used in the solution, then a copper anode should be used. You can use any item made of metal plating (copper wire, for example), or you can purchase a thin strip of metal plating that is made specifically for electroplating.

- Conductive paint or acetone and graphite. The print surface must be conductive for coating, which can be achieved with conductive paint or a 1:1 solution of graphite and acetone. Conductive ink will work on any printed material, but a solution of acetone and graphite will only work on ABS.

- Power Rectifier - A battery can be used instead of a rectifier, but a battery is not as efficient and will not deliver results as quickly and consistently as a rectifier. A rectifier is also a safer option. It can simply be turned off to stop the current flow during electroplating.

- Conductive screw or eyelet

- Non-conductive vessel

- Lead set

- Non-conductive gloves and goggles.

Electrophoresis solutions are acids and can cause eye damage if splashed, so appropriate goggles are required. Also, these solutions can irritate the skin and conduct a charge when used. Therefore, non-conductive gloves should always be used.

Process: metal plating can be electroplated at home or in a professional workshop. Proper plating requires a deep knowledge of materials, and what you can do at home has certain limitations compared to what can be done in a professional workshop.

For a better finish and a wider range of plating options, including chrome plating, a workshop would be the best option. For clarity, the copper plating process will be described below.

At home, galvanization can be done using copper or nickel plate. It is imperative that the surface of the print to be processed is as smooth as possible before coating; any unevenness and visible lines of the layers will start to stand out after coating.

Prepare a cleaned and sanded print. By coating the plastic with a thin layer of high quality conductive paint or a solution of acetone and graphite (if made of ABS) . Allow the conductive coating to dry completely and sand if necessary to ensure a smooth finish. It is extremely important to minimize contact with the print or wear gloves as the sebum on your fingers will interfere with the coating process.

Insert a screw or hook with an eye into an inconspicuous surface of the part, similar to dipping in solvent.

Attach to one of the rectifier leads. This will serve as the cathode. The connection must be made to the negative terminal of the rectifier. Connect the copper anode to the positive terminal of the rectifier using the second power wire and fill the container with enough electroplating solution so that the imprint and the copper anode are completely hidden. Turn on the power rectifier. After the rectifier is turned on, make sure that the part does not touch the anode in any way.

IMPORTANT! Be very careful at this stage. After the part is lowered into the bath and the system is energized, any contact with the solution, anode or cathode may result in personal injury !

Set the power supply rectifier to 1-3 volts. After that, the metallization process will begin until the part is completely covered with metal. Voltage may be increased to reduce coating time, but should not exceed 5 volts. Simply turn off the straightener and remove the print after a satisfactory finish has been applied. Dry the print with microfiber towels. Coat the part with a special varnish for metal after drying. This will protect it from corrosion.

Pros

- The metal shell increases the strength of the plastic part, which greatly expands the possibilities of its application and use

- The outer metal coating is very thin so if properly applied, tolerances of 9 can be held tightly0012

- Creates a beautiful surface that, if done correctly, will not look like a 3D printed object

Cons

- It is usually very expensive to do this at a professional level, and home plating requires a fair amount of professional processing equipment

- Electroplating at home can cause electric shock if not followed

Well, that's all we have! We hope this article was useful for you!

Order 3D printer or FDM consumables , you can