3D printing contractors

COBOD announces distribution agreement with nidus3D

- COBOD announces distribution agreement with nidus3D (Ontario, Canada) to bring multifunctional construction robots based on 3D printing to Canada

- nidus3D recently built Canada’s first 3D printed multi-unit residential building, fully permitted for occupancy, and North America’s first 3D construction project to use real concrete

3D printing technology has transformed processes in medical, aerospace, and tool-making fields. Now, that same disruption is being brought to the construction sector, and nidus3D is at the forefront, paving the way for new builds to be achieved faster, more affordably, and with less waste, using COBOD technology.

As a testament to their ambitions, nidus3D has recently succeeded 3D printing Canada’s first multi-unit structure in real concrete using COBOD’s BOD2, the world’s best-selling 3D construction printer. The project is a first-of-its-kind consisting of four units each measuring 560 ft2 and is the first 3D printed home to obtain permission for occupancy in Canada. The 3D printed homes are expected to be available by Summer 2022 for individuals and couples seeking attainable housing.

“The opportunity to work with COBOD, world leader in 3DCP is incredible,” said Ian Arthur, President in nidus3D. “The BOD2 printer is an industry-leading construction printer that outstrips competitors in its versatility, scope, and durability. nidus3D is actively deploying 3D construction printing technology to lower building costs and expand access to resilient, efficient, and sustainable housing while complying with Canadian building standards.”

Commenting on signing nidus3D as a distributor, Philip Lund-Nielsen, Co-Founder & Head of Americas at COBOD International said, “We are proud to be partnering with nidus3D to bring our state-of-the-art 3D construction printing technology to Canada, further solidifying our position as the #1 supplier in North America. With their recent project, nidus3D successfully demonstrates how our technology can be applied to build faster, better, and cheaper as our partners learn to master the 3D printing technology. ”

”

Nidus3D reports to have multiple residential and non-residential buildings lined up for 2022 and 2023, these are subject to announcement at a later stage.

nidus3D used COBOD technology for their first 3D printed multi-unit residential building fully permitted for occupancy in Canada. Finished units will be provided to the market as long-term affordable rentals. The 3D printed homes are expected to be available by Summer 2022 for individuals and couples seeking attainable housing.About nidus3Dnidus3D is a strategic partner and distributor of COBOD BOD2 printers based out of Kingston, Ontario. With experience in construction, lean manufacturing, and public affairs, the team at nidus3D is actively deploying 3DCP (3D Construction Printing) technology to lower building costs and increase access to housing that is resilient, efficient, and sustainable, all while complying with Canadian building standards. Visit nidus3D.com for more information.

About COBOD InternationalCOBOD is the World’s leading supplier of 3D printers for the construction industry, with strategic investors GE Renewable Energy (USA) and PERI (Germany). COBOD’s mission is to disrupt the global construction industry through world-class multifunctional construction robots based on 3D printing systems. Faster. Better. Cheaper. The company 3D printed Europe’s first building in 2017. Subsequently the first 2- and 3-story buildings in Belgium and Germany were made with COBOD technology. The first villa in Dubai and the first buildings in Africa have also been done by COBOD 3D construction printers, like the first wind turbine bases.

COBOD’s mission is to disrupt the global construction industry through world-class multifunctional construction robots based on 3D printing systems. Faster. Better. Cheaper. The company 3D printed Europe’s first building in 2017. Subsequently the first 2- and 3-story buildings in Belgium and Germany were made with COBOD technology. The first villa in Dubai and the first buildings in Africa have also been done by COBOD 3D construction printers, like the first wind turbine bases.

COBOD has an open-source strategy, partnering with customers, academic institutions, and suppliers around the world. Its partners include GE (USA), CEMEX (Mexico), PERI (Germany), Holcim (Switzerland), Dar Al Arkan (Saudi Arabia), L&T Construction (India), and JGC (Japan). COBOD’s vision is to see buildings and concrete structures in every city around the world made by multifunctional construction robots. COBOD is headquartered in Denmark, employs of 90+ highly competent colleagues from 25 nationalities, and has a truly global presence in North- and Latin America, Europe, the Middle East, Africa, and Asia-Pacific.

Largest 3D printed building in Africa

- Power2Build finished their second and largest 3D printed building yet in Angola with the BOD2 construction printer.

- 140 m2 house printed 4,5 times faster than the first 3D printed building Power2Build made.

- D.fab concrete solution from COBOD International and CEMEX enabling cost-saving up to 90% – first shown in Angola, now spread all over the world.

- COBOD completely dominates the 3D construction printing market in Africa with the six 3D printed buildings, all done with COBOD technology.

Power2build have recently finished their largest 3D printed building with a COBOD BOD2 construction printer in Angola. The company has set out to transform the housing market and are pioneers aiming to solve affordable housing in Angola with 3D printed buildings.

The house is the second 3D printed residential building in Angola. It is a 140 m2 house that holds a suite, two bedrooms, three bathrooms, a dining room, and a living room. As the three bathrooms indicate, this is not a social housing project, but rather a house showcasing the design and architectural possibilities of 3D printed buildings.

As the three bathrooms indicate, this is not a social housing project, but rather a house showcasing the design and architectural possibilities of 3D printed buildings.

Power2build is working with COBOD’s 3D printing technology to significantly reduce the housing shortage in Angola. The 3D printing technology is an innovative method that allows construction of affordable and high-quality housing in the region in a faster and more competitive way.

Power2Build printed Angola’s first 3D printed building – a 53 m2 house. This was an incredible milestone, marking the beginning of a revolution, as the house was the world’s first 3D printed house in real concrete (defined by particle size above 8 mm).

While the first house was printed in 48 hours, the second house with 140 m2 was printed in 30 hours. This equates to a 4,5 times improvement in productivity. In addition to this, the team was able to both do the printing, and the water and electrical installations at the same time.

Ricardo Almeida, CEO from Power2Build said: “We are very proud of our progress; people were questioning if we couldn’t print bigger. We have now printed a 2,6 times bigger house and in about 2/3 of the time compared to the first house. We improved the speed of execution remarkably, but still believe there is room for improvement. In the future we will only become better at mastering this technology. We are getting more efficient by the day and closer to achieving our vision to deliver better housing at affordable prices to Angolan families.”

Angola was the first country in the world that printed with the D.fab solution from COBOD International and CEMEX, making printing of real concrete possible. The solution has since been used in projects in a.o. Japan, Malaysia, Saudi Arabia, Ireland and Canada.The 3D printed house was done with the D.fab material solution, a ground-breaking additive mix developed by COBOD and CEMEX, that enables printing with real concrete, leading to cost-savings of up to 90% compared to printing with mortars. D.fab enables the usage of 99% locally available materials and only 1% Magic Mix supplied by COBOD. 3D printing with real concrete is a genuine step change in the industry of 3D construction printing and serves as a prominent gateway to properly commercializing the technology.

D.fab enables the usage of 99% locally available materials and only 1% Magic Mix supplied by COBOD. 3D printing with real concrete is a genuine step change in the industry of 3D construction printing and serves as a prominent gateway to properly commercializing the technology.

Commenting on the successful build of the house, Henrik Lund-Nielsen, Founder & General Manager of COBOD International said: “We are proud to have made the technology for this project. Power2Build have increased their speed of execution tremendously compared to their first and now second project. This is a great example of how we and our customers are continuously improving the technology and can build faster, better, and cheaper as our customers and partners become experts at mastering the 3D printing technology.”

COBOD International’s 3D construction printing technology is dominating the market in Africa, which so far has six 3D printed buildings all done with COBOD technology. The company was the first (and only) to print in Malawi, Madagascar, Kenya, and Angola, two of which are schools and four residentials. Later this year COBOD’s customer 14trees will begin printing a double-digit number of houses in Kilifi in Kenya.

Later this year COBOD’s customer 14trees will begin printing a double-digit number of houses in Kilifi in Kenya.

World leader in 3D construction printing solutions with +50 printers sold world-wide.

COBOD’s mission is to build smarter through multifunctional construction robots based on 3D printing technology and COBOD’s vision is to automate minimum 50% of construction processes on building sites. All leading to better, faster, cheaper and more sustainable construction than conventional concrete. We constantly strive to reduce the co2 footprint of 3D printed concrete.

COBOD’s 3D printers made Europe’s first building in 2017. Subsequently our printers made the first 2- and 3-story buildings in Europe (Belgium & Germany), North America (US & Canada) and India. Also, the first 3D printed villa in Dubai and buildings in Africa have been done by COBOD 3D construction printers, just like the first wind turbine bases.

Also, the first 3D printed villa in Dubai and buildings in Africa have been done by COBOD 3D construction printers, just like the first wind turbine bases.

COBOD has an open-source material strategy, partnering with customers, academic institutions, and suppliers around the world.

COBOD is privately owned by General Electric, CEMEX, Holcim and PERI as key shareholders, and our partners further include Dar Al Arkan (Saudi Arabia), L&T Construction (India), JGC (Japan), Siam Cement (Thailand) and Orascom (Egypt).

COBOD is headquartered in Denmark with regional offices and competence centers in Florida and Malaysia. Our team consists of +100 passionate pioneers from 25 nationalities and through our installed base of printers, we have a truly global presence in North- and Latin America, Europe, the Middle East, Africa, and Asia-Pacific.

Video of Power2Build house: https://youtu.be/zRKVQ6SNLlI

3D printers in construction: prospects for application

At first glance, 3D printing structures seem to be some kind of shell of a half-finished building. But upon closer examination, you will not find even a brick. Layers of material seem to build up one on top of the other - this is how a complex structure is created. It's a futuristic world of 3D printing where robotic arms automatically layer and compress layers of concrete or plastic or any other material into a foundation and build a structure.

But upon closer examination, you will not find even a brick. Layers of material seem to build up one on top of the other - this is how a complex structure is created. It's a futuristic world of 3D printing where robotic arms automatically layer and compress layers of concrete or plastic or any other material into a foundation and build a structure.

This method of construction is quite niche today - only a few prototypes of 3D houses and offices have been printed in the world. However, this technology represents an exciting and potentially powerful solution to building change.

What is 3D printing in construction, what is the potential, and will we be working on 3D printed projects in the near future?

- What is 3d printing in construction?

- 3D printers in construction: how is it done?

- 5 examples of innovation

- How can 3d printed projects help construction companies?

- 3D printing distribution

- 3D printing in civil engineering

- Wiki House technology - an open source project for 3D printing: what is behind the concept

- Reverse side of the coin

- How can 3D printing be integrated into construction

- About PlanRadar

3D printing in construction - what kind of technology?

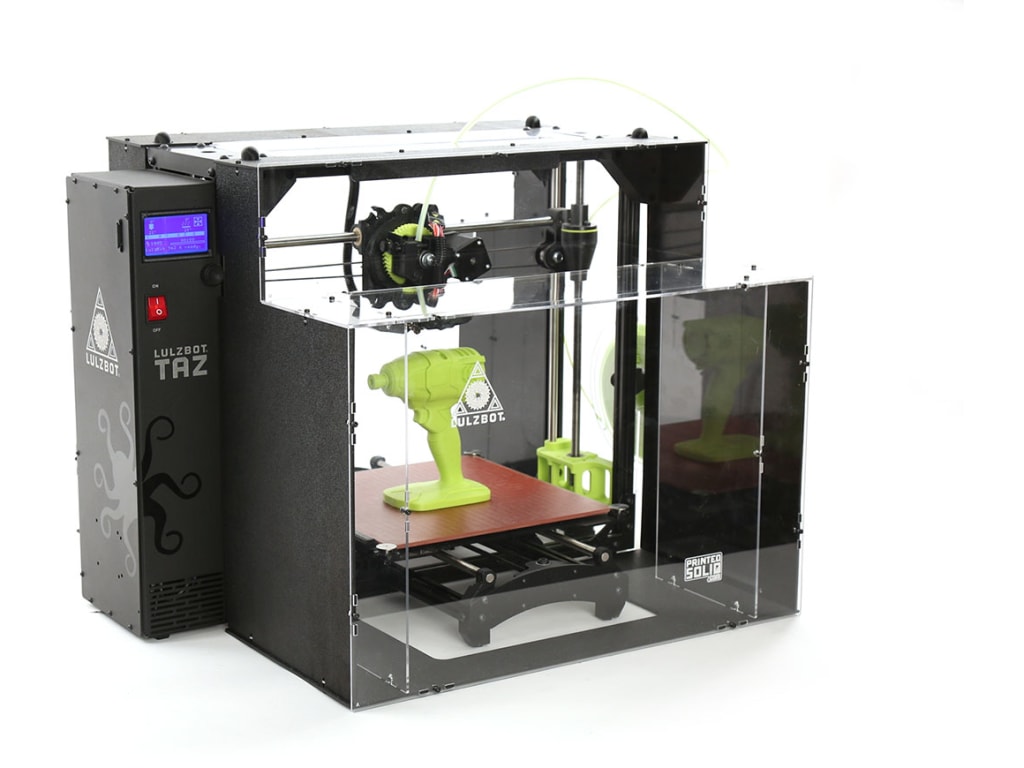

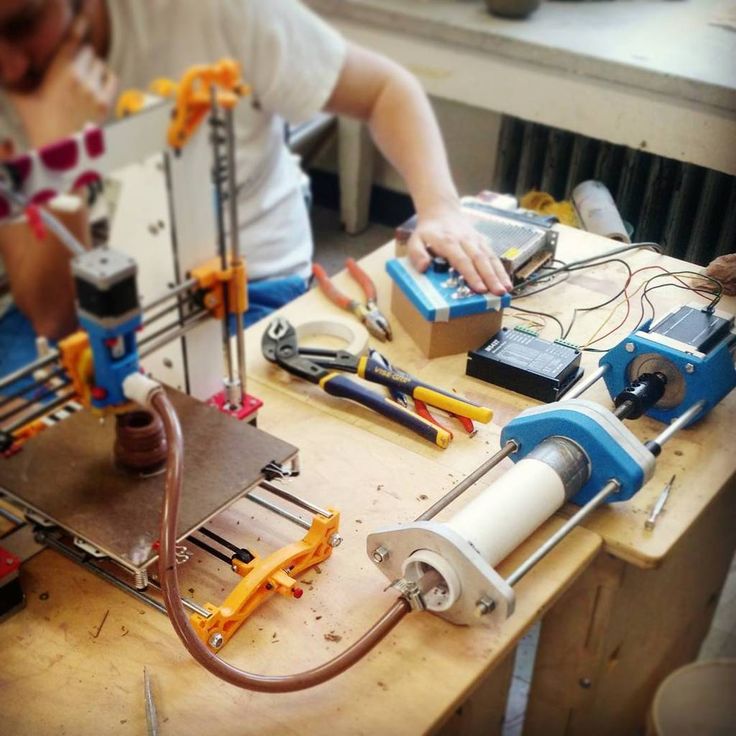

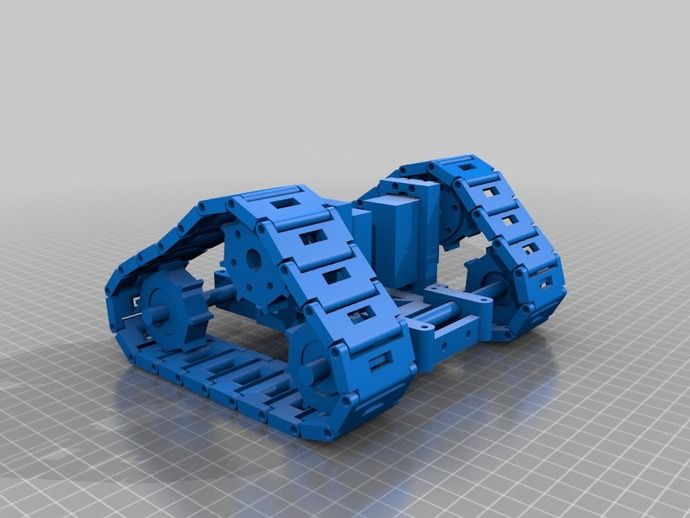

3D printing for construction uses both a 3D printer that has a robotic “crane-arm” that builds structures right on the construction site, and the creation of certain elements by printers at the factory, which are already assembled into a structure on site.

The concept of 3D printing is not new: it first appeared in the 80s. But it's only in the last decade that this technology has been improved enough (and the cost significantly reduced) to become a real mainstream.

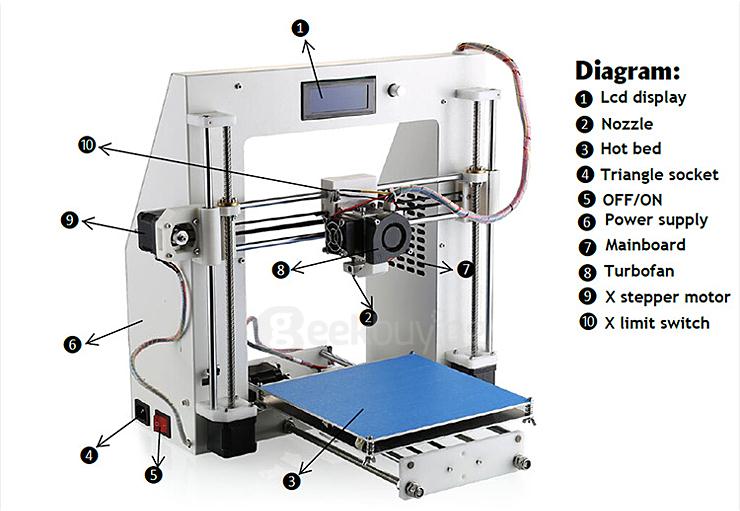

3D printers are not much different from conventional inkjet office printers. The software tells the printer about the dimensions of the final product. And then the printer starts to output the material to the platform according to the plan. 3D printers often use liquid metals, plastics, cement, and variations of various materials that, when cooled and dried, form a structure.

In a 3D construction printer, the CAD or BIM programs tell the device what to print, and the machine begins layering the material according to the design plan.

3D printers in construction: how do they work?

3D printing concept - The printer extrudes a defined liquid mixture in layers, level by level, creating a design based on a 3D model. The prepared mix of concrete, filler, plasticizer and other components is loaded into the hopper of the device and fed to the print head. The mixture is applied to the surface of the site or to the previous printed layers. This is how most 3D printers work. Among them, there are three types of devices for 3D printing:

The mixture is applied to the surface of the site or to the previous printed layers. This is how most 3D printers work. Among them, there are three types of devices for 3D printing:

Robotic printer

Read also: New technologies in construction 2021

5 innovative examples of 3D printing

To date, only a few 3D printing projects have been implemented in the construction industry. Here are five of the most impressive and promising projects:

Dubai City Hall Office Building, UAE

1. Dubai City Hall Office Building, UAE

3D printed building. The office block built in the UAE is 9,5 meter high building with an area of 640 m2.

An Apis Cor 3D printer moved around an open-air construction site with a crane and erected different parts of the structure.

2. Office of the Future, UAE

Office of the Future, UAE

Another impressive 3D printed building in the UAE, the Office of the Future is a unique, fairly large structure that currently houses a temporary headquarters organization Dubai Future Foundation.

For this building, the elements were not created on site and were printed in 17 days, while the building itself was assembled in 48 hours.

3. WinSun 3D Printer Homes, China

WinSun 3D Printer Homes, China

WinSun 3D Printing Company of China has also applied factory-built 3D printers to build residential buildings. The company has created several house projects, including a small multi-storey building. All construction details can be printed quickly and cheaply and then quickly assembled on the construction site.

The company calculated that it would cost as little as $161,000 to build and print their five-story building.

4. 3D printed license plate at Lewis Grand Hotel, Philippines

3D printed license plate at Lewis Grand Hotel, Philippines

When planning a trip to the Philippines, consider staying at the Lewis Grand Hotel in Angeles City , Pampanga, where visitors will be greeted with the world's first 3D printed hotel suite. The hotel room was designed by Lewis Jakich, hotel owner and materials engineer, in collaboration with 3D printing specialist Anthony Rudenko. They created a massive 3D printer that prints sand and concrete based on volcanic ash. The room was printed in 100 hours.

The hotel room was designed by Lewis Jakich, hotel owner and materials engineer, in collaboration with 3D printing specialist Anthony Rudenko. They created a massive 3D printer that prints sand and concrete based on volcanic ash. The room was printed in 100 hours.

5. Two-story mansion in Beckum, Germany

Two-story mansion in Beckum, Germany

The first 3D-printed residential building with an area of about 80 square meters - the brainchild of the German construction company PERI GmbH and the architectural design bureau MENSE-KORTE ingenieure + architecture. A BOD2 3D printer was used to print one square meter of double wall cladding in 5 minutes. The building is a structure with three-layer hollow walls filled with insulating mass. Installation of hollow pipes and connections during printing was carried out manually.

3D printing in construction seems really impressive, but what are the real benefits of such technology?

How can 3D printed designs be useful for construction companies?

Proponents of 3D printing houses and commercial offices point to several advantages of this construction method:

- Zero waste construction

In the UK, almost a third of the waste comes from the construction industry. According to the Transparency Market Research Group, the construction industry worldwide will produce 2.2 billion tons of construction waste by 2025. And although most of the waste is related to the demolition of buildings, the construction sites themselves produce a lot of waste.

According to the Transparency Market Research Group, the construction industry worldwide will produce 2.2 billion tons of construction waste by 2025. And although most of the waste is related to the demolition of buildings, the construction sites themselves produce a lot of waste.

Conversely, 3D printing can reduce waste to almost zero. A 3D printer uses a well-defined amount of material that is required to print a design - no more, no less. This can be a big savings.

- Reduced energy consumption

3D printing in construction encourages the use of locally available materials and natural ingredients. This practice can reduce energy costs in transportation, construction and manufacturing, as most local materials require less energy to process or install. If traditional materials with toxic chemical impurities are replaced with natural ones, then the toxicity of the entire construction can be reduced. In addition, local materials are often better suited to local climates and can reduce a building's heating or cooling load, which also reduces construction costs.

- Save time and money

As with AI in construction, a 3D printer can run 24 hours a day, 7 days a week. This means construction projects have the potential to be completed much faster and a number of low-skilled labor costs can be avoided. What's more, 3D printing eliminates the need for temporary structures, such as formwork and scaffolding, that are commonly used in traditional construction. Studies of 3D printed concrete structures have shown a significant reduction in formwork requirements, reducing costs by 35-60%.

- Can realize unusual design shapes

One of the most attractive characteristics of 3D printers is their ability to create complex and unusual design designs, including a single, unique one. Since the job of a 3D printer is to layer the material, they can be programmed into absolutely any unusual shape that would be much more difficult to create with traditional techniques.

- Minimize human error and improve safety

The published injury statistics at the workplace by the American agency BLS in 2020 indicates that construction is one of the most traumatic areas and a high incidence of diseases. Every day, about 5333 workers die on the construction site. And with the advent of 3D printing, the number of work injuries and fatalities will obviously decrease, as it makes construction more programmable and automated. Robotic construction requires standardized, accurate and complete digital building information, making this technology more accurate and efficient, with minimal rework due to human error or any information inconsistencies. The usual problems with materials and components that need to be stored somewhere, protected from damage are leveled out, problems with installation and work in progress due to damage also disappear - 3D elements are created as they are built, they do not need to be moved and stored.

- Exploring new markets

The use of a 3D printer also allows construction companies to enter new market sectors that were previously inaccessible to them. And for start-up companies, having a 3D printer will be a competitive advantage. What's more, 3D printing is a brilliant way to elevate or improve the reputation of a construction company's brand among those who believe that concrete production has an impact on the planet's environment.

Distribution of structural 3D printing

3D printing for structural reinforcement, small scale components and structural steel could revolutionize design, construction and space exploration. In addition, the European Space Agency (ESA) believes that using 3D printed metals to create high-quality complex shapes can significantly reduce their cost, and they will become very common.

ESA has developed a project with the European Commission to improve the printing of metal components that can be used in space. In total, 28 European partners have united for the joint project AMAZE (Additive Manufacturing Aiming Towards Zero - layer-by-layer 3D printing for zero waste from production and efficient production of high-tech metal products).

In total, 28 European partners have united for the joint project AMAZE (Additive Manufacturing Aiming Towards Zero - layer-by-layer 3D printing for zero waste from production and efficient production of high-tech metal products).

Almost everything can be designed on a computer, so AMAZE plans to install a 3D printer on board the spacecraft, and as soon as an astronaut needs any part, a tool, he can simply print it.

Structural 3D printing

Civil engineering 3D printing

Civil engineering 3D printing has been gaining popularity over the past decade, as has the aerospace and biomedical industries. This revolutionary manufacturing technique is based on its unique ability to create any geometric shape without any formal restrictions, minimizing waste but increasing productivity and results. The construction industry's push towards automation has recently reached important milestones, including the creation of the first structures using robotic "arms" and 3D printing technology.

The use of 3D printing in the creation of structural elements from polymer materials, concrete and metals is becoming more common.

These civil engineering technicians can create freeform and innovative architectural designs using CAD-integrated software.

However, despite considerable research in the aerospace and bioengineering industries to evaluate and analyze this mechanism, there is still a lack of understanding of its use, the impact of 3D printed materials in civil structures, both in terms of material properties and structural response.

Imperial College London

Read also: Best Building Apps in 2021

WIKI HOUSE - 3D printing in construction: what is the concept behind

Wiki House is an innovative project created by a small group of architects in London in 2011 . It offers an open source digital house design system that allows users to create, upload and share designs and print their own houses.

The kit does not require any special knowledge and training and can be created in 1 day. Elements are digitally cut from ordinary sheet material, like plywood, using a CNC machine. And it's much faster, less costly, and doesn't require the involvement of experts, as in conventional traditional construction.

Elements are digitally cut from ordinary sheet material, like plywood, using a CNC machine. And it's much faster, less costly, and doesn't require the involvement of experts, as in conventional traditional construction.

A standard two bedroom house can be built for less than £50,000 and additional components such as cladding, insulation, windows and more can be added to the main frame of the structure. The first house that was built on the basis of the open source Wiki House technology was a two-story building. The 3D printed house was presented at the London Design Festival in 2014.

The Wiki House movement was spearheaded by Alastair Parvin, whose TED presentation "Architecture for People, Built by People" talked about the promise of 3D printing in construction. The creator of this project believes that Wiki House can help solve the housing problem, especially in emergency situations such as earthquakes (there is already evidence that 3D-printed houses can withstand shocks up to magnitude 8).

In the future, this could become a real alternative to low-cost houses, while allowing the customer to control the design of the project.

3D building built using Wiki House

Will 3D printing be the sustainable future of building?

3D printing has the potential to revolutionize the supply chain and structure through a new method of design and manufacturing. According to the study, 3D printing can help the construction industry become more economical, more efficient and greener.

Saxon University of Applied Sciences scientists Ivo Kotman and Neils Faber claim that 3D printing technology will be a "game changer". They explored the possibilities of 3D printing concrete, and their conclusions are:

- 3D printing shortens the supply chain and the entire design process. 3D printing right on the job site eliminates time-consuming steps in the design process. The architects, engineers, contractors, clients, and executives who normally have to be actively involved in a project are no longer needed in 3D printing.

Since all tasks can be combined in one figure of the architect, who uses the modeling method and reproduces the exact holistic designs.

Since all tasks can be combined in one figure of the architect, who uses the modeling method and reproduces the exact holistic designs. - Pipe fitting and electrical wiring become easier and more efficient. Heating systems, insulation, plumbing and electricity all require the laborious on-site installation of conventional construction. However, in 3D printing, some of these features can be incorporated into the 3D printing process. Cavity wall printing is less resource intensive, improves insulation, and allows the use of 3D-printed hot or cold water channels. Moreover, the need for on-site installation is eliminated, which directly affects the reduction of waste.

- The best logistics. 3D printing eliminates 3 logistics and shipping issues. Firstly, a lot of materials and elements often deteriorate upon delivery, and if everything is printed on site, then damage is minimized

Secondly, in order to withstand transportation, the parts must be with increased technical characteristics, which by default increases the cost of them, and therefore the entire project. 3D printing right on the construction site will help to avoid such additional costs.

3D printing right on the construction site will help to avoid such additional costs.

- Creation of individual house designs available to the general market. Usually, building a house with the involvement of an architect is an expensive pleasure for most consumers. But with concrete 3D printing, you don't have to worry about the chosen shape, it won't cost more. In fact, this means that in the future, more people will be able to buy houses of their own design, according to their individual needs

Reverse side of the coin

While 3D printing is definitely attractive, it's still important to look at it impartially, removing some of the promotional stimulus. Skeptics note several disadvantages of this technology.

- Research and development costs

Most construction companies operate with relatively low profitability. To start using 3D printing everywhere, significant investments will be required.

- Will consumers see this as a marketing ploy?

3D printed houses, offices, shops and other infrastructure are often impressive. But do most people really want to live or work in one? For most people, brick houses are much more familiar and attractive. Other technologies such as prefabricated houses also seemed like an attractive technology of the future for some time, but have not been widely adopted, despite the fact that in many cases they were cheaper than traditional ones.

- Difficulty integrating with other components

3D printers can create unique and interesting designs. However, if you need a building that will use different materials or different elements that will not be suitable for 3D printing, then it will be a challenge to include a 3D printer for the building process.

- Skilled labor shortage

With the current problem of a shortage of skilled labor in the construction sector as a whole, 3D printing will require an even larger set of specialized knowledge and skills, which will have to be selected from an already small niche of candidates. So finding specialists to work in 3D printing for construction may be another difficult task in the future.

- Construction quality control

Weather conditions can slow down the traditional building process, but things are even worse for 3D printing. The environmental factor for commercial construction may reduce the demand for 3D printing. What's more, quality control can be a much more serious task, requiring constant monitoring of the process by real people at the construction site.

- No standards and regulations

Despite the regular mention of 3D printing in the media, it still has not had a significant impact on the construction sector. There is an obvious liability issue when using these printers, even more so than human liability when doing some construction work. And quite a few other ambiguities regarding this technology. So until norms and standards are established, as well as rules in this area, 3D printing is unlikely to become mainstream in the construction industry.

There is an obvious liability issue when using these printers, even more so than human liability when doing some construction work. And quite a few other ambiguities regarding this technology. So until norms and standards are established, as well as rules in this area, 3D printing is unlikely to become mainstream in the construction industry.

Read also: New technologies in construction 2021

How can 3D printing be integrated with construction?

At the moment there is strong evidence that 3D printing is worthy of attention and can be applied in the construction segment, and most likely that this technology will be used more in the coming years. True, it is not known how widely these devices will be used on the construction site, or whether they will remain only a tool for the manufacture of block elements for prefabricated structures. But for certain projects, it is reasonable to assume that 3D printers and this technology in construction will be a must-have tool in the arsenal of builders.

ABOUT PLANRADAR

PlanRadar was founded in 2013 and provides an innovative mobile software solution for construction and real estate. Our app is available on all iOS, Android and Windows devices and has already helped over 13,000 customers digitize their workflow in over 55 countries. Find out more about the app here.

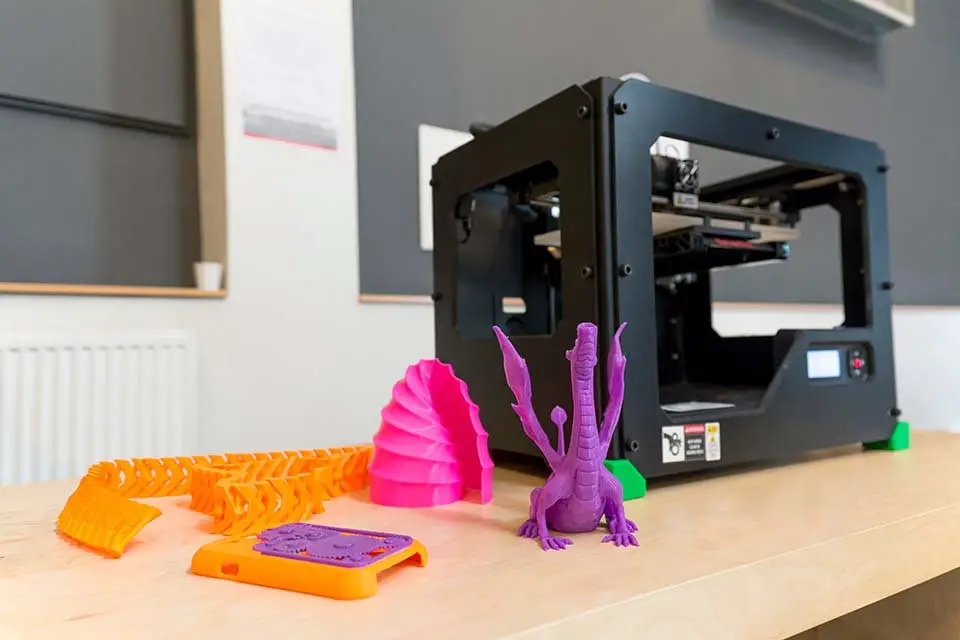

How to earn money with a 3D printer. Company's stats “3Dplast – a maker of plastic for 3D friend”

In this stat, let's look at the basic idea of how exactly work can be done.

3 D other items for sale

The most logical thing you can do is to sell items that are made with the help of a 3D printer. Knowing about the feasibility of 3D-druk, but not dreaming of possession, the custodians want to take objects, which they can only find in their fantasies, or on armchairs. I joke for whom vikonavtsiv. You can sell your services to help your own site, through social media, on marketplaces and in any other way that is convenient for you.

In Ukraine, you can combine more of these functions on the Prom.ua platform, for example. І add to a new profile on facebook/or instagram, in the field of your target audience.

Vzagalі cool, like you have an idea of what kind of product, like, what to name, “pіde”. Then choose the appropriate material, put your choice on the line, paint your working logo, and voila.

For example, 18-fold cotton Grant Gabrielson invented personalized molds for pouring chocolate for his clients using PLA or PP. Varto is cheap, even more demanding, easy to fight.

Your advantage can become stronger and more specialized trade, which you need, in the presence of strong competitors. For example, fans of cosplay will need different details for their costumes - if you know and trust you, you can become their main supplier of cosplays. The same is true for other souls - fans of the Dawn Wars, Marvel and DC comics, the whole world of Warhammer and so on.

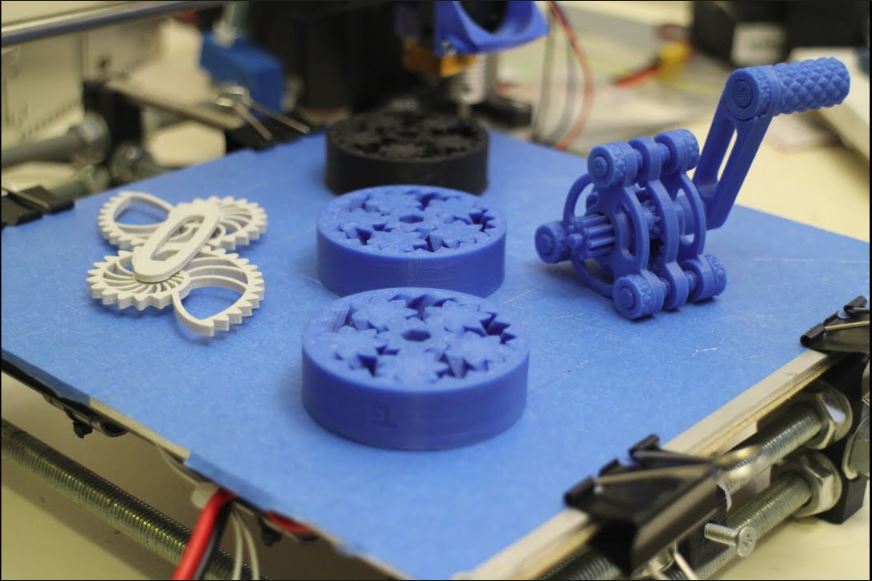

Schwiedke Prototype

Request a service so you can contact professionals in the field of architecture, design, engineering and life. 3D-friend allows you to create large-scale prototypes for different purposes:

3D-friend allows you to create large-scale prototypes for different purposes:

- demonstration of goods, objects and projects;

- presentation to investors;

- re-verification of the principle dії аbo vzagalі pratsezdatnostі probable product.

Why is it one of the most advanced methods of 3D imaging, because the FDM method has no other advantages in the field of swidish prototyping before any other technologies.

- 3D-friend allows you to prototype quickly and at low cost.

- Decreasing the amount of pardon in the design of the robe.

- Item 1 means that it is easy to generate a small number of options for outdoor use with small spaces - not available.

- Allows you to create prototypes of more folding end products.

For example, 3D-drugs will be ideal solutions for architects and engineers, who need to show their creativity – architecture or construction. Now I don’t need a check for a month, while fakhivtsy manually prepare layouts - finish every few days up to a week or two, so that I can take a 3D model.

Home-made products

The only way to earn money is to enter the home-made and hand-made market.

The most obvious butt - interior items "for the old times" can be broken for a few days and undoubtedly cost less, even if the master of the sprat was robbed.

You can work everything that your imagination suggests and that is requested by customers - a vase, lamps, lamps, household items, interior items.

For example, you can work fashion accessories for designers, as long as you know about them or you know how to make propositions for them. Or embellish for the quiet, who are looking for non-standard and individual options.

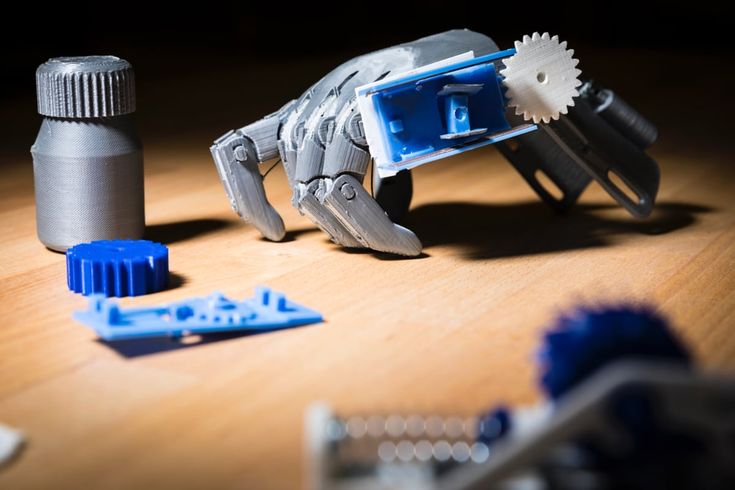

Work as a contractor

In the European Union, Great Britain and the USA, a number of service marketplaces are being established, as if they are signing an affiliate program for 3D printers. Seeing this is obvious - the company will take the contractor, you will take the appointment. Koristuvachi go to their site, publish those who need to abuse - the platform for spreading the word. Similar services can be found in Russia.

Koristuvachi go to their site, publish those who need to abuse - the platform for spreading the word. Similar services can be found in Russia.

There are no such Maidans in Ukraine. I would like to promote the great gravity of the 3D market to a friend with our own partner programs. You can learn to wash them and become a contractor for vikonanny zamovlen.

Services “close” to a 3D friend

Really, to get to the market of a 3D friend, don’t obligatory buy yourself a 3D printer. You can buy a 3D-scanner and apply a highly specialized service 3D-scanning of the scanners, so you can help yourself. Abo help tim who give merit to the friend of the big figures of people for their photographs.

It is also possible to draw 3D models and sell them without intermediary or on specialized maidanchiks.

Before we talk, you can expand the software for 3D-friends - also required, but you need the skills.

Soup spoon

Thus, the 3D-druk market is actively developing and continuing its activity. But it’s hard to think that in this sphere everyone is “smeared with honey” and pennies flow like water.

But it’s hard to think that in this sphere everyone is “smeared with honey” and pennies flow like water.

Remember, there is nowhere without marketing. Like a daily business. If you just buy a 3D printer and keep checking customers - it doesn't work.

As a matter of fact, it is necessary to pay attention to the fact that you are with clients, with some pracciuvatimete. Apply mi pointed at the article. As a client, discuss with them the prospect of spying, and just start.

I do not immediately. Try to spoil everything - you can spend money and you can earn money. Understand that your business will be profitable.

Another obvious "spoon of dog" in 3D-druk, with which the novelties stick together, the most obvious looking details. Mayzhe zheden material does not give an ideal surface and details may be post-finishing. Also, to add parameters to each other on the level of the details - pardons in the whole process contribute to the whole result.

Ale, the quality of ready-made products is the key to proof and practice.