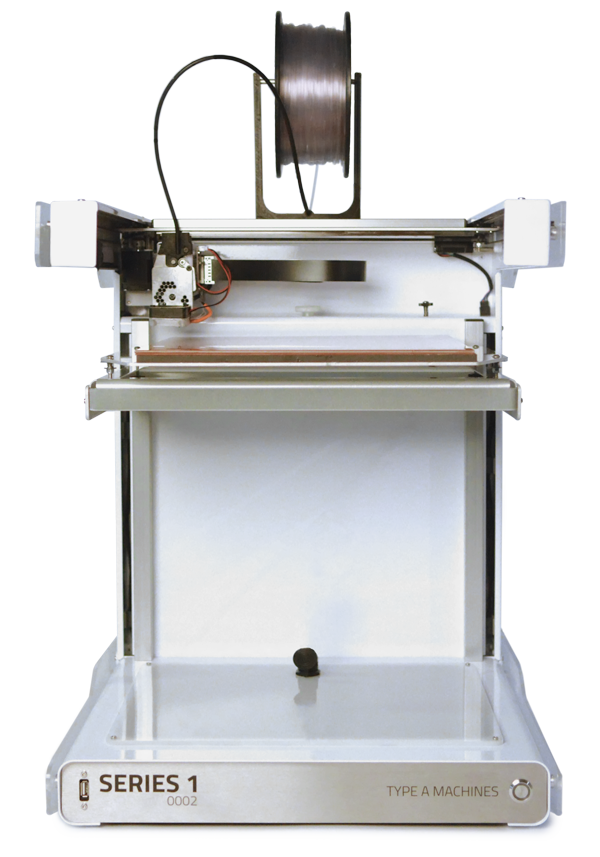

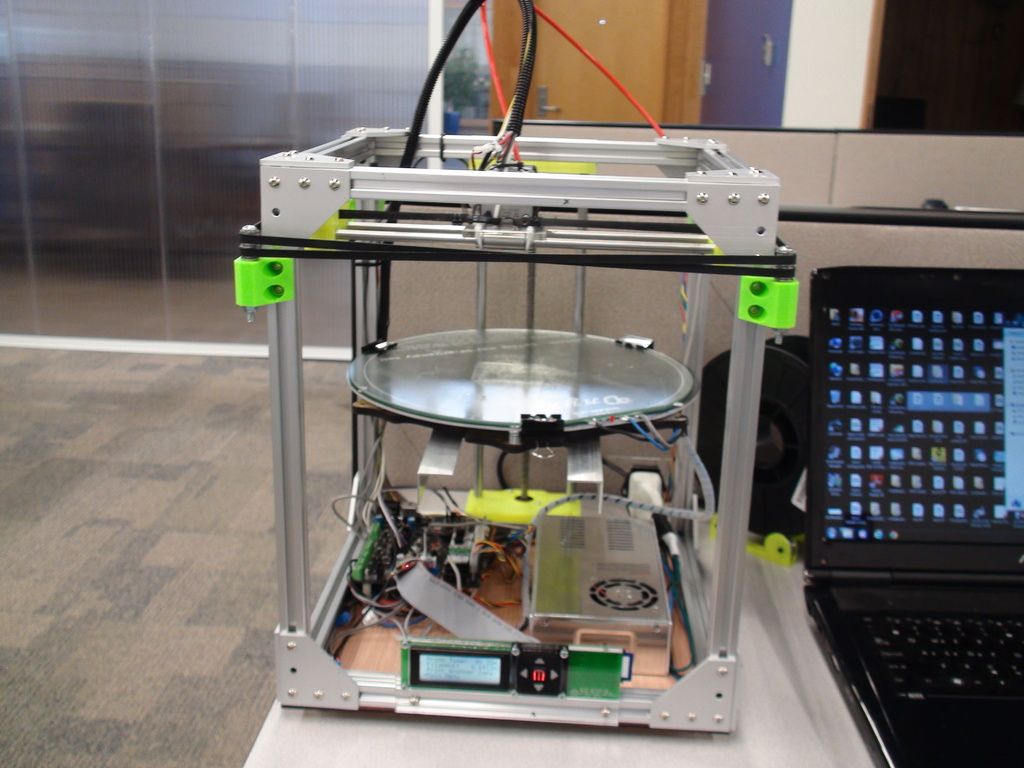

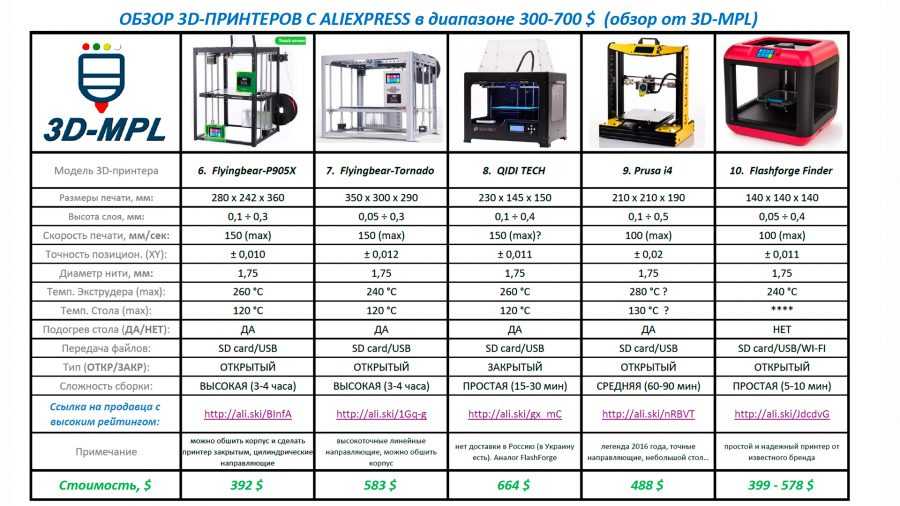

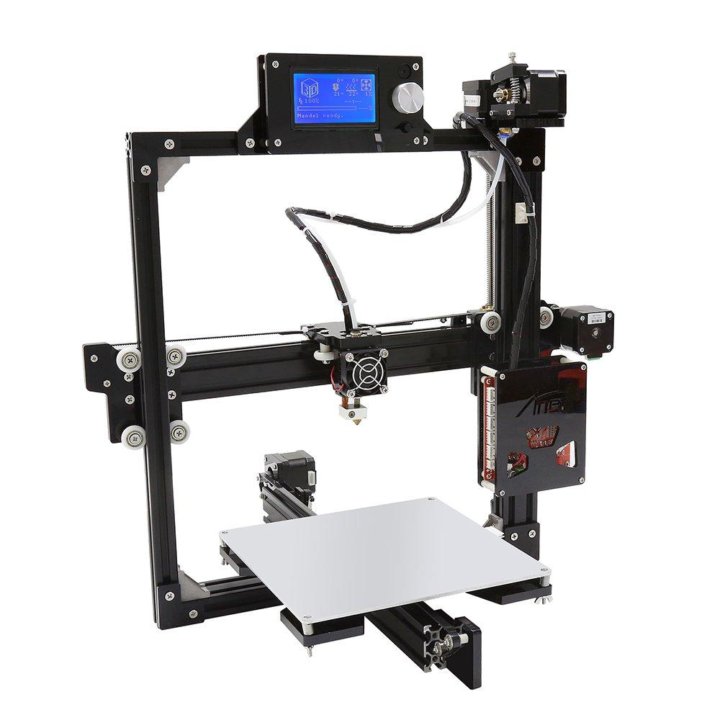

3D printer type a

Type A Machines Series 1 3D Printer Review 2022

4.6

See Price

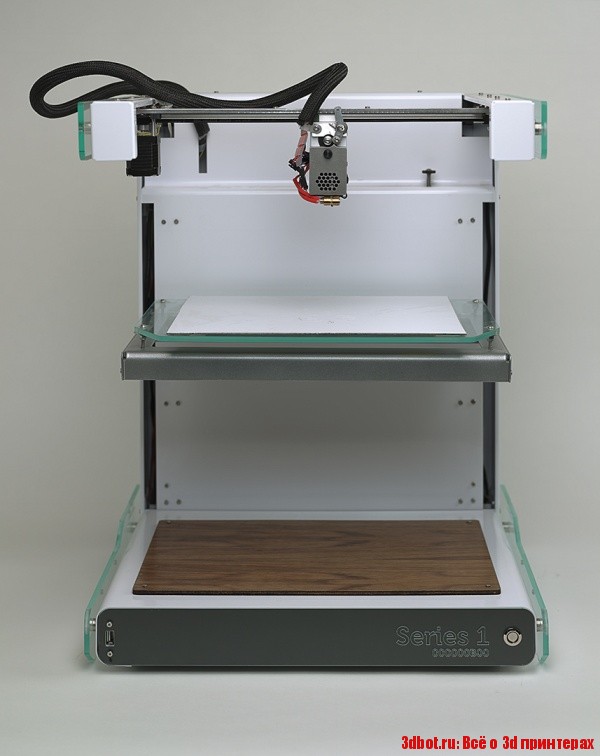

The Type A Machines Series 1 is one of those 3D printers that have benefited from the constant attention of its manufacturer, morphing from a functional, almost kit form level printer, into a sleek contemporary machine, the latest edition of which was launched in 2016 – the Series 1 Pro.

As we dive head-on into testing out the latest Series 1, we’ll be asking whether it is a vital improvement on its predecessors and whether the price tag is warranted.

| Printing Area | 305mm x 305mm x 305mm |

| Layer Resolution | 50 to 300 Microns |

| Supported Filament | PLA, PET, Nylon, ABS, flexible, TPD |

| Filament Diameter | 1.75mm |

| Extruders | 1 |

| Extruder Diameter | 0.4 mm |

Table of ContentsShow

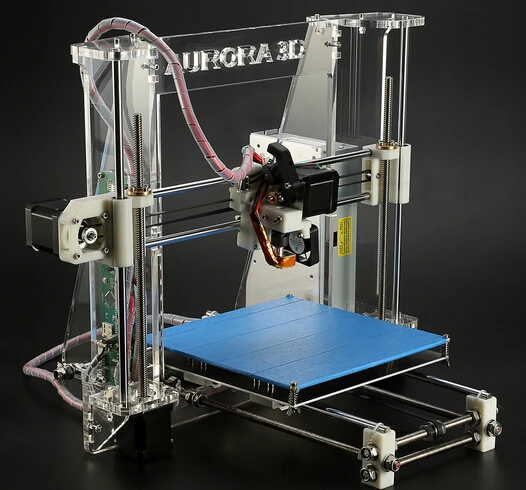

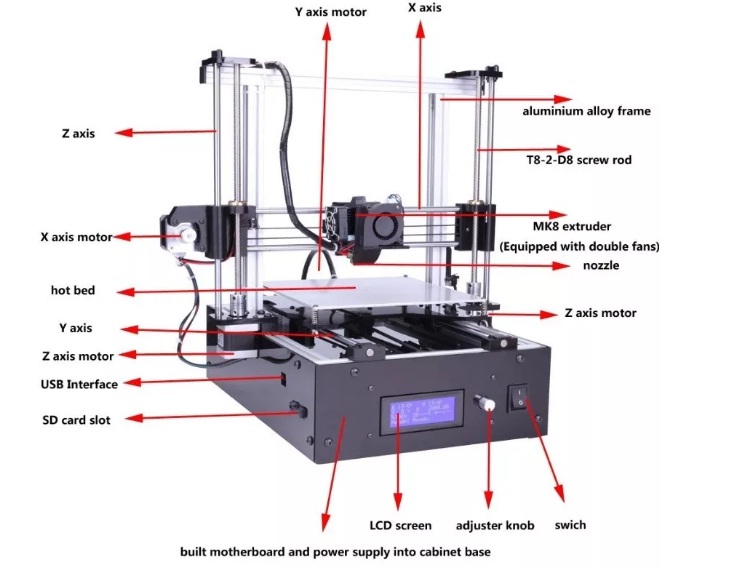

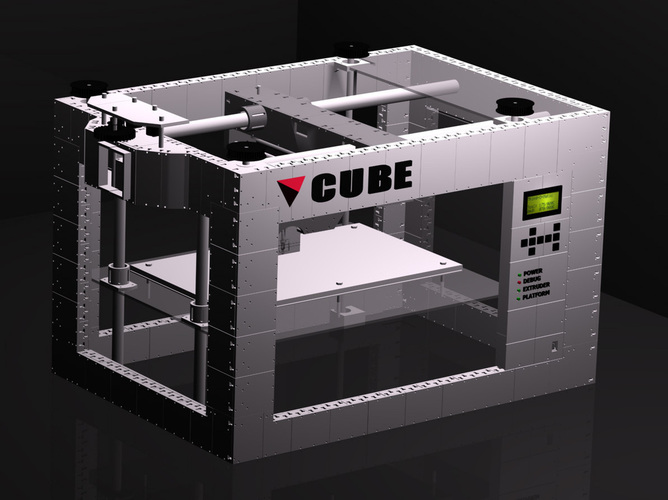

Design & Features

The Series 1 features a polished, nearly surgical design made of a clean aluminum and acrylic body supported by a precision laser cut CNC-milled folded metal chassis. The overall look is striking, to say the least, aided by the dominant white color scheme embellished by a few choice black parts notably the lower front panel adorned with a bold capitalized ”Series 1” logo. The Series 1 is one pretty device that marries both a kind of subdued industrial aesthetic with also Sci-Fi inspired contours and gilding.

The arrangement is quite the departure from the original iteration of this model that consisted of a naked wooden body and suffered from a couple of stability issues. The upgraded Series 1 appears to confine those problems to the past with a robust sideways U semi-open design borrowed from the second generation Series 1 (serial number 2xxx +) that weighs a solid 15 kg/50 lbs.

As for how this belle of the ball operates, it uses standard FDM technology with an XYZ cartesian design running on a linear guide NEMA 14 stepper motor for the X and Y axes, and a NEMA 17 stepper motor for the Z-axis, both with 1.8 degrees step angle and digitally interpolated 1/256th micro stepping as well as high-quality bearings.

These are powered by a primary BeagleBone Black (1GHz CPU, 512MB DDR3 RAM, 16GB SD drive) and a secondary RepRap Universal board with Allegro and Marlin-based firmware. Pretty standard stuff, but reliable nonetheless.

The build area is massive, running up to 305mm x 305mm x 305mm with a hypothetical build volume of 1728 square inches, placing it among the biggest in its size category. The heated bed itself is made of borosilicate glass and can reach temperatures up to 120 degrees Celsius in under 4 minutes while being readily removable and fitted with a BuildTak FlexPlate for added adhesion.

Type A Machines is aiming for enhanced stability and consistency in printing results with this fundamental upgrade – they state that manufacturing tolerances for the glass are less than a micron, which translates to one seriously flat surface.

The Series 1 sports a proprietary all-aluminum G2 extruder design at odds with the typical extruder configuration. It ostensibly decreases filament clogging and oozing problems by channeling filament through a single contained melt path.

This upgrade also signifies a longer life span for the extruder and hassle-free cleaning alongside more refined control of the printing process and temperatures up to 300 degrees Celsius. The design means parts like the hot end and nozzle are also modular given how simple they are to remove, clean, and even replace. A set of LEDs are also fitted to the print head to aid diagnostics.

With a nozzle diameter of 0.4 mm, the extruder can lay down resolutions between 50 and 300 microns for consistent results with the ability to go from 25 to 600 microns under the right circumstances. XY accuracy comes in at 6.57 microns, while Z-axis accuracy sits close at 6.25 microns. Overall print accuracy tallies in at around 100 microns.

The Series 1 is compatible with multiple types of PLA, PET, Nylon, ABS, flexible, carbon-based and TPD (NinjaFlex for example) materials. There’s no beating around the bush; the Series A is a versatile printer. The filament system is also open to third-party spools/cartridges in standard 1. 75 mm diameter.

75 mm diameter.

Depending on the Series 1 or Pro model, the printer comes with Wi-Fi, Ethernet, and USB-to-PC connectivity for across the board tethered and untethered access. Although the Series 1 has no onboard display, it does have a one-touch on/off button on the front panel.

As for software, the Type A Machines Series 1 uses a version of the Cura slicer configured specifically for Type A Machines printers that can read STL, OBJ, and AMF files with compatibility for Windows, Mac, and Ubuntu OS, alongside an onboard custom browser-based Series 1 Interface based on Octoprint that reads GCO and Gcode files.

Additional characteristics include a 1.3 megapixel onboard HD camera for the Pro model that can capture real-time video, produce still images, and time-lapse recordings.

Packaging & Assembly

Alongside the Series 1 printer, the package includes an accessory box (power cable, ethernet cable, palette knife, glue stick, antenna, ceramic screwdriver, wrench kit, 20ft PLA filament sample, business card for leveling), a hardware bag (spool holder kit, panel standoffs, and Allen keys), build platform, and side panels.

Installation is reasonably straightforward and involves installing the various acrylic side panels with bolts and spacers. Interestingly, these don’t just serve a cosmetic purpose but help with ventilation and stability during the printing process.

Next, the spool holder sits on an L bracket secured by bolts and the build plate is seated on standoffs and locked into place. Pressing down on the extruder lever then feeding the filament into the exposed hole is easy enough, and we didn’t encounter any snapping or bristling issues.

Calibration is a doddle thanks to a nifty Z height adjustment knob that does all the hard work for you. Of course, you’ll need to ensure the distance between the print head nozzle and the platform is just right yourself, but the knob helps greatly.

Printing

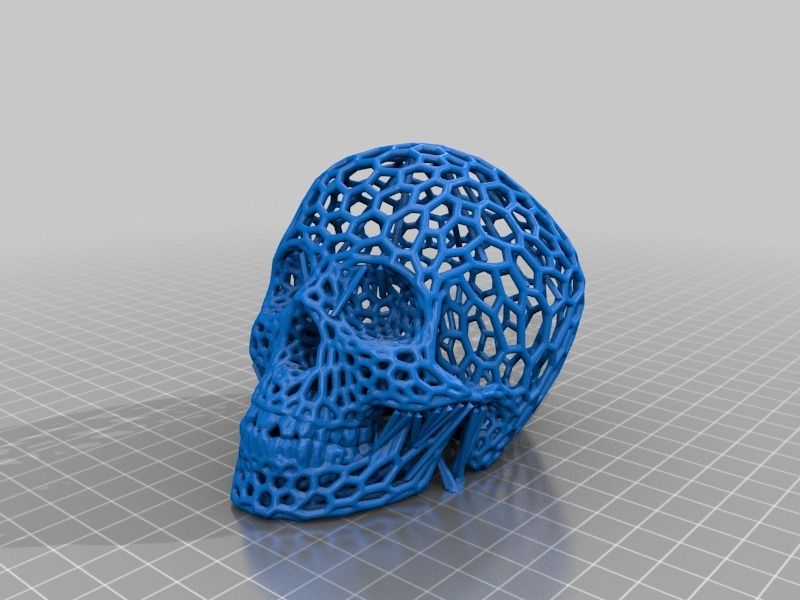

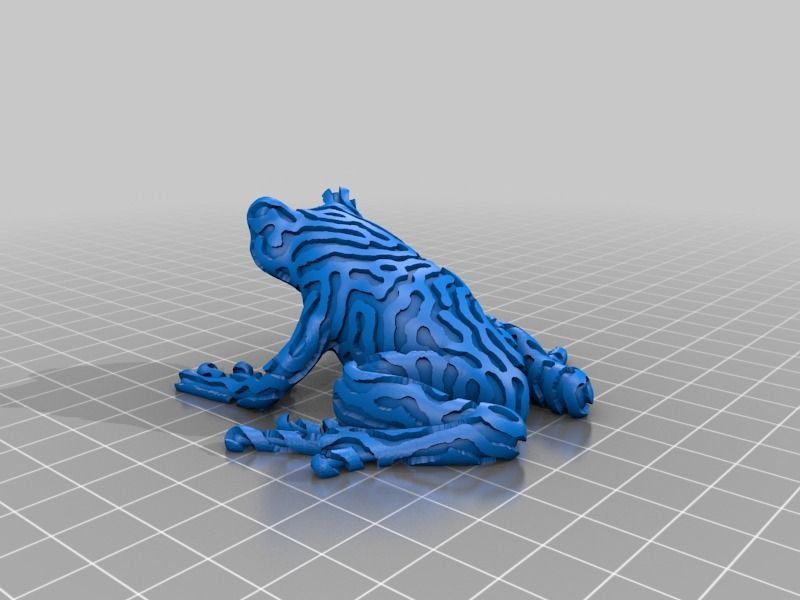

Across the board, the quality of the prints was always there regardless of the type of material including flexible filaments. We did face a few issues with the test print with the first layer crushed into the build plate, but a quick recalibration sorted this out immediately. From here and across a dozen various tests, the Series A didn’t fail us once.

From here and across a dozen various tests, the Series A didn’t fail us once.

From a visual point of view, the Series 1 is such a smooth workhorse from the almost choreographed movements of the extruder to the near-silent operational levels. Not once were we bothered by noise levels or janky jitters.

Support

Type A Machines sadly shut its doors in early 2018, handing over support duties to Solid State Printers, which services the Series 1/Series 1 Pro alongside selling replacement parts and the like. As such, no customer support team exists to offer troubleshooting guidance or advice. Users are therefore very much on their own or must lean on 3D printing communities scattered across the internet.

Point of sale warranties may offer refund clauses, but chances of actually picking up a Series 1 are pretty slim, to begin with, given the quality of the device and the numerous awards it garnered before Type A Machines shut down.

Verdict

Beyond being one of the most stylish mid form factor prosumer printers out there, the Type A Machines Series 1 is nothing short of an excellent and clever investment, if you can get your hands on one.

The design, build, and quality of the parts work in unison to produce outstanding prints while equally allowing room for modular upgrades and improvements that make the Series 1 somewhat future proof.

Types of 3D Printers, 3D Printing Materials, and Applications

Skip to Main Content

3D printing or additive manufacturing (AM) technologies create three-dimensional parts from computer-aided design (CAD) models by successively adding material layer by layer until physical part is created.

While 3D printing technologies have been around since the 1980s, recent advances in machinery, materials, and software have made 3D printing accessible to a wider range of businesses, enabling more and more companies to use tools previously limited to a few high-tech industries.

Today, professional, low-cost desktop and benchtop 3D printers accelerate innovation and support businesses in various industries including engineering, manufacturing, dentistry, healthcare, education, entertainment, jewelry, and audiology.

All 3D printing processes start with a CAD model that is sent to software to prepare the design. Depending on the technology, the 3D printer might produce the part layer by layer by solidifying resin or sintering powder. The parts are then removed from the printer and post-processed for the specific application.

See how to go from design to 3D print with the Form 3 SLA 3D printer. This 5-minute video covers the basics of how to use the Form 3, from the software and materials to printing and post-processing.

3D printers create parts from three-dimensional models, the mathematical representations of any three-dimensional surface created using computer-aided design (CAD) software or developed from 3D scan data. The design is then exported as an STL or OBJ file readable by print preparation software.

3D printers include software to specify print settings and slice the digital model into layers that represent horizontal cross-sections of the part. Adjustable printing settings include orientation, support structures (if needed), layer height, and material. Once setup is complete, the software sends the instructions to the printer via a wireless or cable connection.

Once setup is complete, the software sends the instructions to the printer via a wireless or cable connection.

Some 3D printers use a laser to cure liquid resin into hardened plastic, others fuse small particles of polymer powder at high temperatures to build parts. Most 3D printers can run unattended until the print is complete, and modern systems automatically refill the material required for the parts from cartridges.

With Formlabs 3D printers, an online Dashboard allows you to remotely manage printers, materials, and teams.

Depending on the technology and the material, the printed parts may require rinsing in isopropyl alcohol (IPA) to remove any uncured resin from their surface, post-curing to stabilize mechanical properties, manual work to remove support structures, or cleaning with compressed air or a media blaster to remove excess powder. Some of these processes can be automated with accessories.

3D printed parts can be used directly or post-processed for specific applications and the required finish by machining, priming, painting, fastening or joining. Often, 3D printing also serves as an intermediate step alongside conventional manufacturing methods, such as positives for investment casting jewelry and dental appliances, or molds for custom parts.

Often, 3D printing also serves as an intermediate step alongside conventional manufacturing methods, such as positives for investment casting jewelry and dental appliances, or molds for custom parts.

The three most established types of 3D printers for plastics parts are stereolithography (SLA), selective laser sintering (SLS), and fused deposition modeling (FDM). Formlabs offers two professional 3D printing technologies, SLA and SLS, bringing these powerful and accessible industrial fabrication tools into the creative hands of professionals around the world.

Stereolithography was the world’s first 3D printing technology, invented in the 1980s, and is still one of the most popular technologies for professionals. SLA 3D printers use a laser to cure liquid resin into hardened plastic in a process called photopolymerization.

SLA resin 3D printers have become vastly popular for their ability to produce high-accuracy, isotropic, and watertight prototypes and parts in a range of advanced materials with fine features and smooth surface finish. SLA resin formulations offer a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

SLA resin formulations offer a wide range of optical, mechanical, and thermal properties to match those of standard, engineering, and industrial thermoplastics.

Resin 3D printing a great option for highly detailed prototypes requiring tight tolerances and smooth surfaces, such as molds, patterns, and functional parts. SLA 3D printers are widely used in a range of industries from engineering and product design to manufacturing, dentistry, jewelry, model making, and education.

- Rapid prototyping

- Functional prototyping

- Concept modeling

- Short-run production

- Dental applications

- Jewelry prototyping and casting

Learn More About SLA 3D Printers

Stereolithography (SLA) 3D printing uses a laser to cure liquid photopolymer resin into solid isotropic parts.

SLA parts have sharp edges, a smooth surface finish, and minimal visible layer lines.

Selective laser sintering (SLS) 3D printers use a high-power laser to sinter small particles of polymer powder into a solid structure. The unfused powder supports the part during printing and eliminates the need for dedicated support structures. This makes SLS ideal for complex geometries, including interior features, undercuts, thin walls, and negative features. Parts produced with SLS printing have excellent mechanical characteristics, with strength resembling that of injection-molded parts.

The unfused powder supports the part during printing and eliminates the need for dedicated support structures. This makes SLS ideal for complex geometries, including interior features, undercuts, thin walls, and negative features. Parts produced with SLS printing have excellent mechanical characteristics, with strength resembling that of injection-molded parts.

The most common material for selective laser sintering is nylon, a popular engineering thermoplastic with excellent mechanical properties. Nylon is lightweight, strong, and flexible, as well as stable against impact, chemicals, heat, UV light, water, and dirt.

The combination of low cost per part, high productivity, and established materials make SLS a popular choice among engineers for functional prototyping, and a cost-effective alternative to injection molding for limited-run or bridge manufacturing.

- Functional prototyping

- End-use parts

- Short-run, bridge, or custom manufacturing

Learn More About SLS 3D Printers

SLS 3D printers use a high-powered laser to fuse small particles of polymer powder.

SLS parts have a slightly rough surface finish, but almost no visible layer lines.

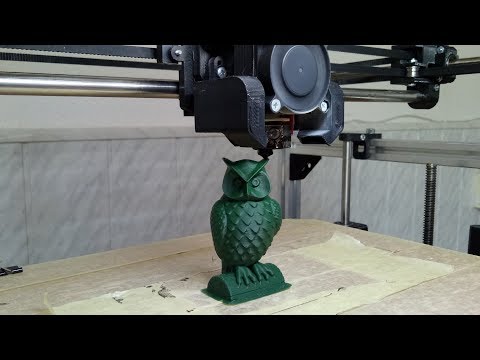

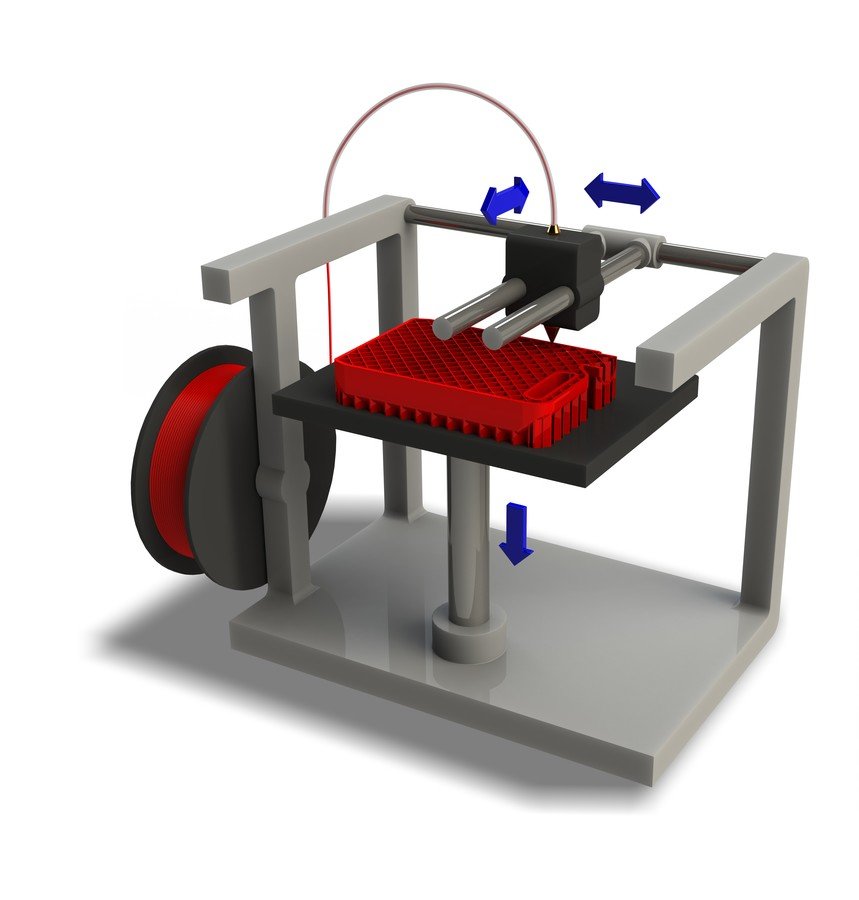

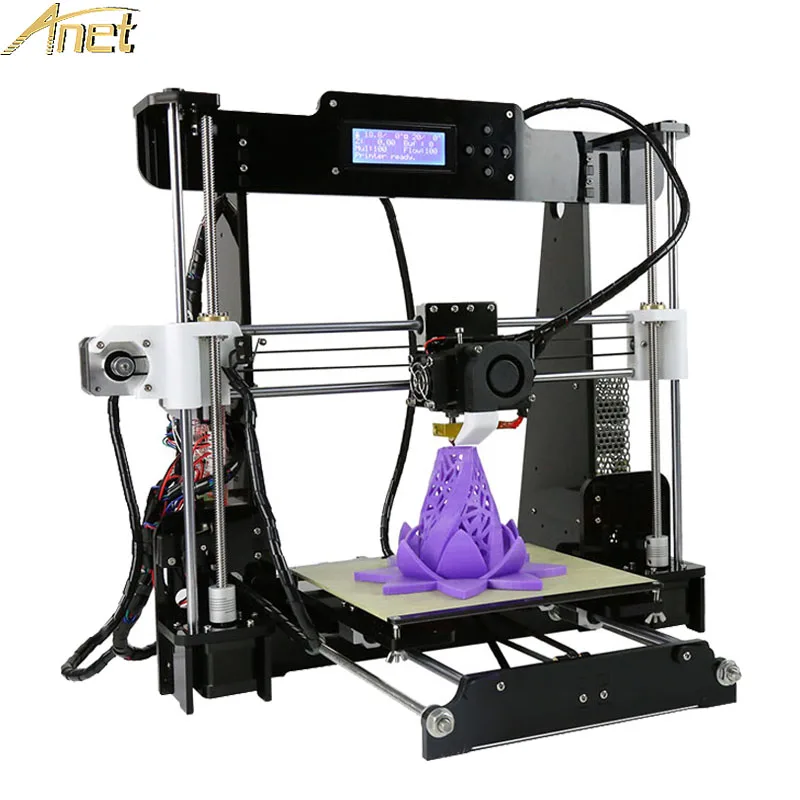

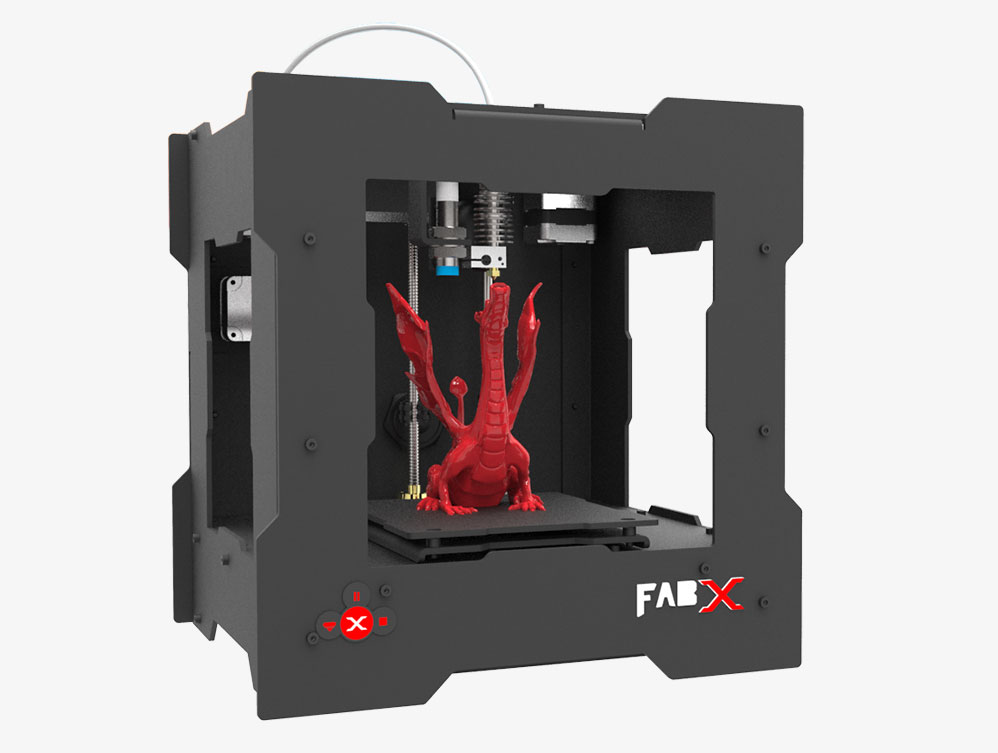

Fused deposition modeling (FDM), also known as fused filament fabrication (FFF), is the most widely used type of 3D printing at the consumer level. FDM 3D printers work by extruding thermoplastic filaments, such as ABS (Acrylonitrile Butadiene Styrene), PLA (Polylactic Acid), through a heated nozzle, melting the material and applying the plastic layer by layer to a build platform. Each layer is laid down one at a time until the part is complete.

FDM 3D printers are well-suited for basic proof-of-concept models, as well as quick and low-cost prototyping of simple parts, such as parts that might typically be machined. However, FDM has the lowest resolution and accuracy when compared to SLA or SLS and is not the best option for printing complex designs or parts with intricate features. Higher-quality finishes may be obtained through chemical and mechanical polishing processes. Industrial FDM 3D printers use soluble supports to mitigate some of these issues and offer a wider range of engineering thermoplastics, but they also come at a steep price.

- Basic proof-of-concept models

- Simple prototyping

Learn More About FDM 3D Printers

FDM 3D printers build parts by melting and extruding thermoplastic filament, which a printer nozzle deposits layer by layer in the build area.

FDM parts tend to have visible layer lines and might show inaccuracies around complex features.

Having trouble finding the best 3D printing process for your needs? In this video guide, we compare FDM, SLA, and SLS technologies, the most popular types of 3D printers, across the most important buying considerations.

Each 3D printing process has its own benefits and limitations that make them more suitable for certain applications. This video compares the functional and visual characteristics of FDM, SLA, and SLS printers 3D printers to help you identify the solution that best matches your requirements.

Do you need custom parts or prototypes fast? Compared to outsourcing to service providers or using traditional tools like machining, having a 3D printer in-house can save weeks of lead time. In this video, we compare the speed of FDM, SLA, and SLS 3D printing processes.

In this video, we compare the speed of FDM, SLA, and SLS 3D printing processes.

Comparing the cost of different 3D printers goes beyond sticker prices—these won’t tell you the full story of how much a 3D printed part will cost. Learn the three factors you need to consider for cost and how they compare across FDM, SLA, and SLS 3D printing technologies.

As additive manufacturing processes build objects by adding material layer by layer, they offer a unique set of advantages over traditional subtractive and formative manufacturing processes.

With traditional manufacturing processes, it can take weeks or months to receive a part. 3D printing turns CAD models into physical parts within a few hours, producing parts and assemblies from one-off concept models to functional prototypes and even small production runs for testing. This allows designers and engineers to develop ideas faster, and helps companies to bring products more quickly to the market.

Engineers at the AMRC turned to 3D printing to rapidly produce 500 high-precision drilling caps used in drilling trials for Airbus, cutting the lead time from weeks to only three days.

With 3D printing, there’s no need for the costly tooling and setup associated with injection molding or machining; the same equipment can be used from prototyping to production to create parts with different geometries. As 3D printing becomes increasingly capable of producing functional end-use parts, it can complement or replace traditional manufacturing methods for a growing range of applications in low- to mid-volumes.

Pankl Racing Systems substituted machined jigs and fixtures with 3D printed parts, decreasing costs by 80-90 percent that resulted in $150,000 in savings.

From shoes to clothes and bicycles, we’re surrounded by products made in limited, uniform sizes as businesses strive to standardize products to make them economical to manufacture. With 3D printing, only the digital design needs to be changed to tailor each product to the customer without additional tooling costs. This transformation first started to gain a foothold in industries where custom fit is essential, such medicine and dentistry, but as 3D printing becomes more affordable, it’s increasingly being used to mass customize consumer products.

Gillette's Razor Maker™ gives consumers the power to create and order customized 3D printed razor handles, with the choice of 48 different designs (and counting), a variety of colors, and the option to add custom text.

3D printing can create complex shapes and parts, such as overhangs, microchannels, and organic shapes, that would be costly or even impossible to produce with traditional manufacturing methods. This provides the opportunity to consolidate assemblies into less individual parts to reduce weight, alleviate weak joints, and cut down on assembly time, unleashing new possibilities for design and engineering.

Nervous System launched the first-ever 3D printed ceramic jewelry line, consisting of intricate designs that would be impossible to manufacture using any other ceramic technique.

Product development is an iterative process that requires multiple rounds of testing, evaluation, and refinement. Finding and fixing design flaws early can help companies avoid costly revisions and tooling changes down the road. With 3D printing, engineers can thoroughly test prototypes that look and perform like final products, reducing the risks of usability and manufacturability issues before moving into production.

With 3D printing, engineers can thoroughly test prototypes that look and perform like final products, reducing the risks of usability and manufacturability issues before moving into production.

The developers of Plaato, an optically clear airlock for homebrewing, 3D printed 1,000 prototypes to fine tune their design before investing in expensive tooling.

3D printing accelerates innovation and supports businesses across a wide range of industries, including engineering, manufacturing, dentistry, healthcare, education, entertainment, jewelry, audiology, and more.

Rapid prototyping with 3D printing empowers engineers and product designers to turn ideas into realistic proofs of concept, advance these concepts to high-fidelity prototypes that look and work like final products, and guide products through a series of validation stages toward mass production.

Applications:

- Rapid prototyping

- Communication models

- Manufacturing validation

Learn More

Manufacturers automate production processes and streamline workflows by prototyping tooling and directly 3D printing custom tools, molds, and manufacturing aids at far lower costs and lead times than with traditional manufacturing. This reduces manufacturing costs and defects, increases quality, speeds up assembly, and maximizes labor effectiveness.

This reduces manufacturing costs and defects, increases quality, speeds up assembly, and maximizes labor effectiveness.

Applications:

- Jig and fixtures

- Tooling

- Molding (injection molding, thermoforming, silicone molding, overmolding)

- Metal casting

- Short run production

- Mass customization

Learn More

3D printers are multifunctional tools for immersive learning and advanced research. They can encourage creativity and expose students to professional-level technology while supporting STEAM curricula across science, engineering, art, and design.

Applications:

- Models for STEAM curricula

- Fab labs and makerspaces

- Custom research setups

Learn More

Affordable, professional-grade desktop 3D printing helps doctors deliver treatments and devices customized to better serve each unique individual, opening the door to high-impact medical applications while saving organizations significant time and costs from the lab to the operating room.

Applications:

- Anatomical models for surgical planning

- Medical devices and surgical instruments

- Insoles and orthotics

Learn More

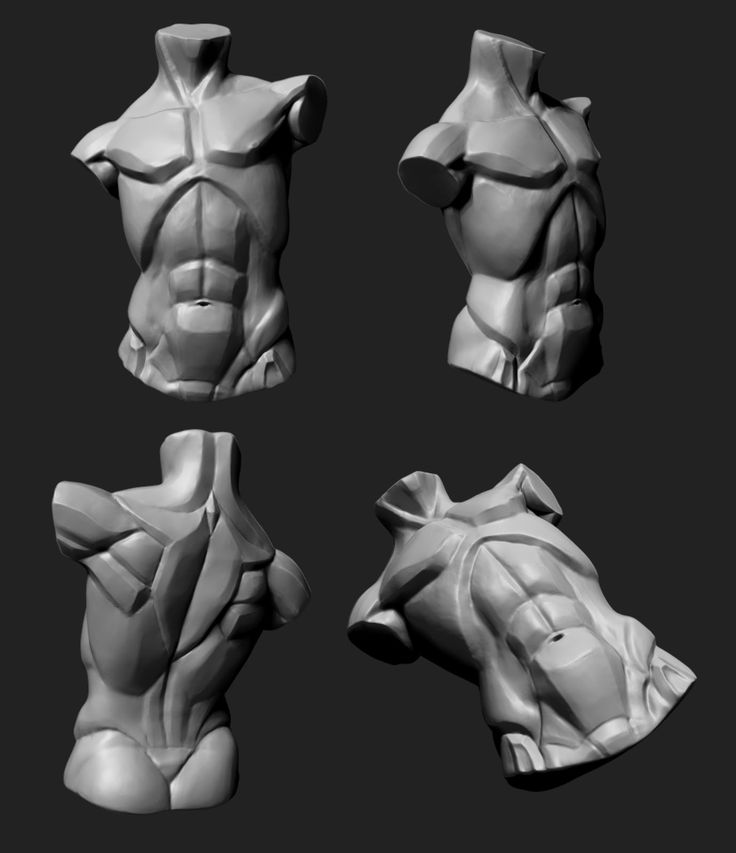

High definition physical models are widely used in sculpting, character modeling, and prop making. 3D printed parts have starred in stop-motion films, video games, bespoke costumes, and even special effects for blockbuster movies.

Applications:

- Hyper-realistic sculptures

- Character models

- Props

Learn More

Jewelry professionals use CAD and 3D printing to rapidly prototype designs, fit clients, and produce large batches of ready-to-cast pieces. Digital tools allow for the creation of consistent, sharply detailed pieces without the tediousness and variability of wax carving.

Applications:

- Lost-wax casting (investment casting)

- Fitting pieces

- Master patterns for rubber molding

Learn More

Hearing specialists and ear mold labs use digital workflows and 3D printing to manufacture higher quality custom ear products more consistently, and at higher volumes for applications like behind-the-ear hearing aids, hearing protection, and custom earplugs and earbuds.

Applications:

- Soft silicone ear molds

- Custom earbuds

Learn More

The market for 3D printing materials is wide and ever-growing, with printers for everything from plastics to metals, and even food and live tissue in development. Formlabs offers the following range of photopolymer materials for the desktop.

Standard 3D printing materials provide high resolution, fine features, and a smooth surface finish ideal for rapid prototyping, product development, and general modeling applications.

These materials are available in Black, White, and Grey with a matte finish and opaque appearance, Clear for any parts requiring translucency, and as a Color Kit to match almost any custom color.

Explore Standard Materials

3D printing materials for engineering, manufacturing, and product design are formulated to provide advanced functionality, withstand extensive testing, perform under stress, and remain stable over time.

Engineering materials are ideal for 3D printing strong, precise concept models and prototypes to rapidly iterating through designs, assess form and fit, and optimize manufacturing processes.

Explore Engineering Materials

Medical resins empower hospitals to create patient-specific parts in a day at the point of care and support R&D for medical devices. These resins are formulated for 3D printing anatomical models, medical device and device components, and surgical planning and implant sizing tools.

Explore Jewelry Materials

Jewelry resins are formulated to capture breathtaking detail and create custom jewelry cost-effectively. These resins are ideal for jewelry prototyping and casting jewelry, as well as vulcanized rubber and RTV molding.

Explore Jewelry Materials

Specialty Resins push the limits of 3D printing, featuring advanced materials with unique mechanical properties that expand what’s possible with in-house fabrication on our stereolithography 3D printers.

Explore Specialty Materials

In recent years, high-resolution industrial 3D printers have become more affordable, intuitive, and reliable. As a result, the technology is now accessible to more businesses. Read our in-depth guide about 3D printer costs, or try our interactive tool to see if this technology makes economic sense your business.

Calculate Your Savings

New to 3D printing? Explore our guides to learn about the key terms and specific characteristics of 3D printing to find the best solution for your business.

For further questions,

Explore 3D Printing Resources

What types of 3D printers are there? 3D printing technologies

This article does not pretend to be scientific, but rather a small introduction to 3D printing "for dummies".

What exactly do we mean by the concept of 3D printing?

In the early 1980s, new methods for the production of parts began to develop, based not on the removal of material, as in traditional machining technologies, but on the layer-by-layer production of a product according to a three-dimensional model obtained in CAD by adding materials in the form of plastic, ceramic, metal powders. and their bundles by thermal, diffusion or adhesive methods. And what does this mean in practice? That it became possible to create physical objects in a completely new way.

and their bundles by thermal, diffusion or adhesive methods. And what does this mean in practice? That it became possible to create physical objects in a completely new way.

The first to patent this technology back in 1984 was Chuck Hull, who also created 3D Systems in 1986, which is still one of the industry leaders. The first commercial 3D printer, the 3D Systems SLA-1, was introduced in 1987.

Thus, we smoothly approach the story of the first and perhaps the most promising 3D printing technology today, namely photopolymer resin printing. Initially, this technology was called SLA, but over time, this name has become not entirely correct.

Photopolymer printing

The essence of photopolymer 3D printing is that a liquid photopolymer resin solidifies under the influence of light and forms a 3D model. Initially, a laser acted as a light source, and the technology was called SLA or stereolithography.

Despite the apparent simplicity, 3D Systems has spent more than 10 years to bring to market the first full-fledged commercial product. This required a shift in other technological products, such as solid-state lasers, which use a solid-state substance as an active medium.

This required a shift in other technological products, such as solid-state lasers, which use a solid-state substance as an active medium.

Without going deep into the technological wilds, we can say that about 25 years of gradual development of this technology passed until 2013-2014, when SLA 3D printers cost hundreds of thousands of dollars and were available only to large companies, where they were also used very limitedly due to the high cost as equipment and materials.

Created in 2011, a startup called FormLabs reimagined Chuck Hull's ideas and developed the first desktop SLA 3D printer, which began selling for up to $3,000. Thus, it made it possible for a wide range of users to get involved in 3D printing. Over the years, FormLabs has delivered tens of thousands of its printers to market, avoided being taken over by larger players, and became the first 3D printing unicorn to be worth over $1 billion. This story was one of two turning points in the breakthrough made by 3D printing technology in recent years. But other companies also did not stand still and very soon realized that a laser as a light source for illuminating a photopolymer resin is not the only solution, and they proposed another way to form a model, which was called DLP (Digital Light Processing) .

But other companies also did not stand still and very soon realized that a laser as a light source for illuminating a photopolymer resin is not the only solution, and they proposed another way to form a model, which was called DLP (Digital Light Processing) .

Without going into technical details, it is important to note that the advantage of this technology lies in higher productivity due to the illumination of the entire layer at once, in contrast to the laser, which must physically illuminate the entire model, so it must be constantly moved. With a simple example, it is very easy to explain what this means. Suppose you need to print a ring, this task on printers of both technologies will take about the same time, but if you need to print 10 rings at once, DLP technology will take advantage. That is, with a DLP printer, you will print 10 rings in the same time as one, while an SLA printer will spend a certain time drawing each of the rings, although this will make it possible to achieve better quality.

A few numbers...

The Form2 SLA printer takes 11 hours and 22 minutes to print 55 models.

As a result, 12.4 minutes for one ring .

And the Uniz Slash Plus 3D printer, which is based on DLP technology, will spend only 3 hours 51 minutes printing 6 rings, it turns out one ring in 3.8 minutes .

DLP technology gained some popularity and began to compete with traditional SLA, but did not become a breakthrough, when suddenly a new revolution happened - LCD 3D printers appeared on the scene.

The principle of formation is even simpler, a powerful LED lamp, enhanced by a lens system, shines on an LCD matrix, which projects the desired image onto a polymer bath, where a 3D model is formed.

The creation of this technology in 2016 made it possible to reduce the price of a 3D printer by 10 times compared to the FormLabs Form 2 printer that was the hit of that time, the price for budget LCD 3D printers started from $300. This drastic cost reduction has greatly expanded the customer base and has given home users and small print studios the opportunity to try this technology for their needs.

This drastic cost reduction has greatly expanded the customer base and has given home users and small print studios the opportunity to try this technology for their needs.

What is its advantage over others, besides the price itself?

LCD, as well as DLP printers, illuminate the layer immediately, this gives them an advantage in performance, although at first users were faced with not very high quality of the models themselves. But with the advent of 3D printers with a 2K LCD matrix in 2019, and then a little later 4K, this problem was solved, and LCD printers today are superior both in speed and in the minimum layer thickness of their older brothers.

Vivid examples of 2K resolution printers are models - Elegoo Mars, Anycubic Photon S, Wanhao GR1, Phrozen Shuffle Lite, Phrozen Shuffle 2019, Phrozen Shuffle XL 2019, Phrozen Sonic, 4K - Phrozen Shuffle 4K, Phrozen Transform.

The introduction of 8K sensors in the near future, as well as the use of special monochrome sensors that increase print speed, will make this technology dominant in the 3D printer market.

PHOTOPOLYMER 3D PRINTING TECHNOLOGIES:

I hope I was able to convey to you the essence of the differences between these technologies, but now, in fact, I want to tell you why SLA / DLP / LCD 3D printing is most often chosen. Here it is immediately worth dividing printers into industrial and desktop.

industrial 3D printers are mainly used for large-scale prototyping, as well as small-scale production and mold making. With a sufficiently high productivity and good quality of the final products, this equipment is used in the automotive industry, aerospace industry, and also for printing massive objects, such as this mammoth bone, printed by Materialize in cooperation with the Belgian Royal Institute of Natural Sciences in Brussels.

Desktop SLA/DLP/LCD printers are widely used, primarily in such areas as dentistry, jewelry, ship and aircraft modeling, as well as the manufacture of unique gifts and souvenirs. You can read more about this in our articles on these topics.

You can read more about this in our articles on these topics.

The use of a 3D printer in dentistry

3D printing in prototyping

The use of a 3D printer in jewelry

3D printing in small-scale production

High detail and high-quality finish makes this 3D printing technology an excellent tool for solving numerous problems that previously had to be solved in much more time-consuming and expensive ways in the areas of activity that I mentioned above.

Photopolymer printing on a 3D printer in dentistry.

Photopolymer 3D printing in jewelry. On the right is a 3D printed master model of the bracelet.

Photopolymer printing for prototyping

3D Resin Printing Souvenirs

FDM 3D Printing Development Path

The second father of 3D printing can be safely called S. Scott Crump, who at 19In 1988, he patented FDM (Fused Deposition Modeling) technology, and in 1989, together with his wife, he created Stratasys, which is still one of the main companies in the industry.

Scott Crump, who at 19In 1988, he patented FDM (Fused Deposition Modeling) technology, and in 1989, together with his wife, he created Stratasys, which is still one of the main companies in the industry.

The abbreviation FFF (Fused Filament Fabrication) is also often used for this technology, but this should not mislead you. The essence of the technologies is the same, but the names are different in order to avoid patent disputes.

So, what, in fact, was invented. The essence of the idea was that a plastic thread is fed into an extruder, where it melts at a high temperature and forms a model in layers through a small nozzle.

Based on this invention, Stratasys began to produce industrial 3D printers, which were mainly used as well as the first SLA machines in the automotive industry, aerospace industry, and with the advent of various durable plastics such as polycarbonate (PC), polyetheretherketone (PEEK), polyetherimide (PEI, Ultem), polyphenylsulfone (PPSF/PPSU), and for functional prototyping. This technology did not become widespread until more than 20 years later, the RepRap (Replicating Rapid Prototyper) project, a self-replicating mechanism for rapid prototyping, appeared.

This technology did not become widespread until more than 20 years later, the RepRap (Replicating Rapid Prototyper) project, a self-replicating mechanism for rapid prototyping, appeared.

The original idea was to create a 3D printer that another 3D printer could print, in this photo all the plastic parts of the "child" are printed on the "parent". In fact, something completely different happened - a group of enthusiasts were able to create a budget 3D printer for home or office use. The idea was quickly picked up by three geeks from New York, who created the MakerBot company and began commercial production of desktop FDM 3D printers. This was the second turning point in the modern history of 3D printing.

The cost of printers was about $1000, and this price became quite acceptable for many enthusiasts, technologists, engineers and students who are passionate about the idea of 3D printing.

In 2013, MakerBot was taken over by Stratasys for a record $400 million. The result of all this was that the world received a very interesting technology for creating physical objects. A huge advantage of FDM technology is its cheapness and a large selection of printing materials, which began to appear in large quantities after the start of the spread of 3D printing. FDM printers primarily spread among home users, who began numerous experiments with printing at home, you can read more about this in the article 3D printing as a hobby.

The result of all this was that the world received a very interesting technology for creating physical objects. A huge advantage of FDM technology is its cheapness and a large selection of printing materials, which began to appear in large quantities after the start of the spread of 3D printing. FDM printers primarily spread among home users, who began numerous experiments with printing at home, you can read more about this in the article 3D printing as a hobby.

In addition, FDM printing has found its main professional application - prototyping. With the introduction of 3D printing into this process, it will never be the same again. Prototyping has become significantly cheaper and faster, and this made it possible to try many more ideas from engineers to create the highest quality and thoughtful products, more about this can also be found in the article 3D printing in prototyping. There are also active efforts to introduce FDM 3D printing into small-scale production, and this story took an unexpected turn during the COVID-19 epidemic. when doctors urgently needed to produce parts for ventilators, as well as mask holders for doctors who are forced to wear them all day.

when doctors urgently needed to produce parts for ventilators, as well as mask holders for doctors who are forced to wear them all day.

FDM 3D printing was able to fully demonstrate its main advantages compared to classical production, namely the speed of modeling a new model and launching it into series in the shortest possible time, less than one day.

Another major advantage of FDM printing is the wide choice of materials, ranging from biodegradable PLA plastic to materials such as PEEK, which can be sterilized at high temperature and pressure.

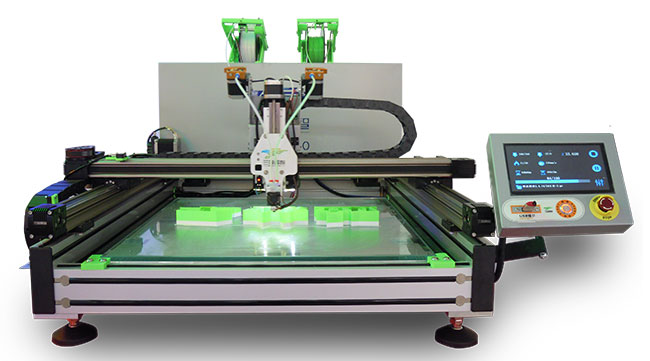

In the near future, we expect the widespread introduction of so-called "3D printing farms", which will be able to implement the concept of "flexible production", the essence of which is that such a farm can produce any available product, and not specialize in the manufacture of any specific products. , as happens in a classic production. Today it can be spare parts for old models of railway cars, and tomorrow it can be medical mask holders or souvenir cups for competition winners or plastic end caps for furniture.

In the meantime, let's continue our story about the different types of 3D printing that arose in parallel with the development of the two mainstream technologies that I have already talked about. Many engineers and entrepreneurs in different countries and companies have realized that it is possible to start using the principles of 3D printing using other materials and ways of forming models, and this is what they came up with.

Other 3D printing

SLM (Selective Laser Melting) - selective laser melting, also known as DMLM and LPBF. The principle of 3D printing here is that, under the influence of a powerful laser, metal powder melts and forms a 3D model. This allows you to create models of complex shapes and high strength, most of all this technology has been used in aerospace and medicine. A rocket is not a mass product, and some elements are much more convenient and more profitable to print on a 3D printer than to mill or cast.

Pictured above is the world's largest printed rocket engine. It was printed on the SLM 800 printer by SLM Solutions for the British aerospace company Orbex. The engine is manufactured as an all-metal nickel alloy product. SLM 3DSLM 3D printing has reduced time by 90% and costs by 50% compared to CNC machines.

It was printed on the SLM 800 printer by SLM Solutions for the British aerospace company Orbex. The engine is manufactured as an all-metal nickel alloy product. SLM 3DSLM 3D printing has reduced time by 90% and costs by 50% compared to CNC machines.

In medicine, metal 3D printing has begun to be used to create individual titanium implants made directly for a particular patient, which significantly increases the chances of recovery.

EBM (Electron Beam Melting) - electron beam melting. This is a technology similar to SLS/DMLS, only here the object is formed by melting a metal powder with an electron beam in a vacuum.

SLS (Selective Laser Sintering) is selective laser sintering, another very interesting technology. The model formation process here is the same as in SLM, but instead of metal powder, polyamide or nylon powder is used. This makes it possible to form very strong, wear-resistant products of complex shapes, which, first of all, can be used as functional prototypes of future metal or durable plastic products.

SLS Printed Engine Manifold

SLS printed furniture

MJF (Multi Jet Fusion) is an original technology developed by HP that essentially repeats the principle of SLS, but does not use a laser. This gives the printer a certain performance advantage over laser technology, as it bakes the layer immediately, just as it does with LCD 3D printers, which we wrote about in detail earlier in this article. Being one of the world's technology giants, HP quickly broke into the small 3D printing market and quickly took a large share in the industrial equipment segment, unfortunately, as of 2020, HP has not started shipping its 3D printers to the Russian market.

Surgical instrument and cylinder block printed on MJF printer

PolyJet is a technology similar to conventional inkjet printing. Liquid polymer is fired through many tiny nozzles onto the surface of the printing platform, after which they are cured using ultraviolet radiation. Using this technology, you can create high-quality full-color layouts and prototypes with the highest level of detail and finish quality comparable to industrial serial samples. Unfortunately, the high cost of equipment and materials does not allow a wider implementation of this technology.

Liquid polymer is fired through many tiny nozzles onto the surface of the printing platform, after which they are cured using ultraviolet radiation. Using this technology, you can create high-quality full-color layouts and prototypes with the highest level of detail and finish quality comparable to industrial serial samples. Unfortunately, the high cost of equipment and materials does not allow a wider implementation of this technology.

MJM (Multi Jet Modeling) is a multi-jet modeling technology similar to PolyJet, but wax can also be used as a material. The technology was developed by 3D Systems, therefore, for reasons of patent protection, it has a different name. Wax printing is widely used in the jewelry business for making individual models to order and creating master models. There are also specialized printers from SolidScape that print with a two-component wax for subsequent melting of the support material in hot water.

CJP (Color Jet Printing) is a technology, the essence of which is layer-by-layer gluing and coloring of powder based on gypsum or plastic. With this technology, you can create full-color products, and this is most often used for printing architectural models and figures of people. The cost of printing in this case is lower than with PolyJet technology, which gives more opportunities for its wider use.

With this technology, you can create full-color products, and this is most often used for printing architectural models and figures of people. The cost of printing in this case is lower than with PolyJet technology, which gives more opportunities for its wider use.

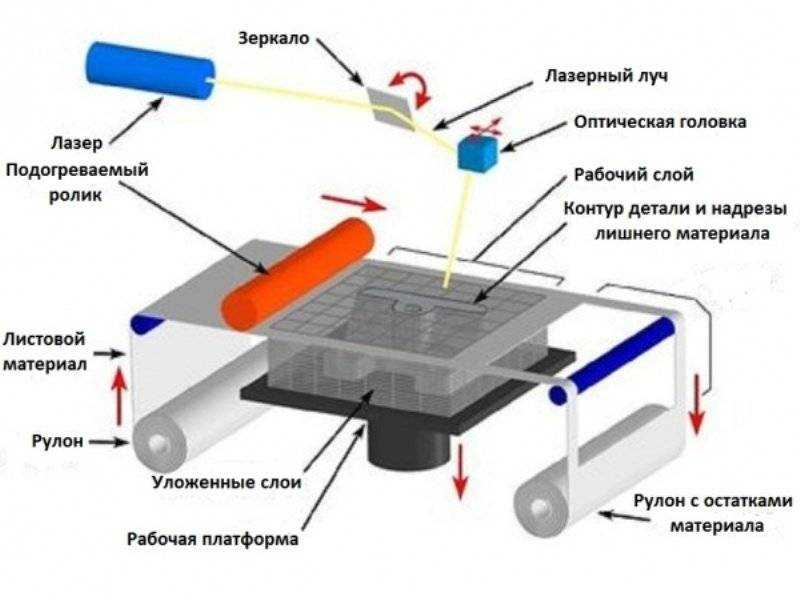

LOM (Laminated object manufacturing) - a technology similar to CJP, but here the building materials are paper, each sheet of which is glued to the previous one, painted with an inkjet printer and perforated. This gives a full color 3D model and is also well suited for architectural and decorative models.

Another technology with great prospects is the combined technology of metal 3D printing, which combines 3 stages of creating a model: printing on an FDM printer with a special composite thread, where metal and polymer are mixed in certain proportions, melting the polymer and baking the metal model. Based on this technology, the American companies DeskTop Metal and MarkForged have already created their commercial models of 3D printers and started selling them both in America and Europe, but so far the technology is very crude and does not guarantee good quality of finished products. But its huge advantage is the significantly lower price of both printers and finished products. These systems have not yet been delivered to Russia, so we are waiting for the opportunity to independently evaluate their quality and effectiveness. In the next few years, this technology may become the most popular of all possible 3D printing methods.

But its huge advantage is the significantly lower price of both printers and finished products. These systems have not yet been delivered to Russia, so we are waiting for the opportunity to independently evaluate their quality and effectiveness. In the next few years, this technology may become the most popular of all possible 3D printing methods.

Studio System+ by Desktop Metal

How it works:

3D printing with ceramics is also a promising direction in various industries. There are a number of companies that produce equipment that prints ceramic models. Various manufacturers use the already mentioned DLP and SLA for this, as a slightly adapted multi-jet simulation technology Ceramic binder jetting (CBJ) . This seal is used in dentistry, jewelry, as well as to create high-quality prototypes with the necessary functional properties. Also, on the basis of FDM printers, printers are being created that print with clay to create ceramic products in a new way. For example, the Italian company WASP has been offering such systems for several years based on its delta printers that print with plastic filament.

For example, the Italian company WASP has been offering such systems for several years based on its delta printers that print with plastic filament.

Construction 3D printers essentially also use the same construction principle as in FDM printers, only liquid concrete is applied instead of a molten filament. This makes it possible to build the walls of a 100 square meter house in about 3 days, which is significantly faster than standard construction methods and, in addition, it makes it possible to create objects of complex shapes. Of course, this direction is promising, but today it has not been widely used, although in China construction 3D printers were used to quickly build autonomous blocks for self-isolation of patients with mild coronavirus, who did not get a place in hospitals, but they were at home dangerous. An interesting fact is that the most promising housing project on Mars is also recognized as a 3D printing method.

House printed by an Irkutsk company in Dubai in 3 days

Coronavirus boxes in China. 15 rooms were made in 1 day.

15 rooms were made in 1 day.

Food 3D printing is another way to use FDM technology, only here the material is edible raw materials. Chocolate printers are the most widely used. The tempered chocolate enters the extruder and forms a 3D model in layers through the nozzle. Because chocolate, unlike plastic, is a very delicate material, so it is not so easy to print with it, although it makes it possible to quickly create customized culinary masterpieces or desserts of unusual shapes. In addition to chocolate, it is possible to print using puree, dough or jam. This technology is still at an early stage of development, and perhaps in the near future we will see more advanced equipment that can be used more widely. One of the representatives of 3D printers for printing chocolate is Choc Creator.

And last but not least, the kind of 3D printing that has very high hopes for the future is 3D bioprinting . At its core, this is a layer-by-layer printing, where living cells act as a material. This is a relatively new type of 3D printing, the first experiments were carried out in 2000 by bioengineer Thomas Boland, who modified conventional desktop printers to print DNA fragments. For 20 years, this industry has stepped far forward, and now, in addition to prototypes of human organs, implants, vascular tubes, heart valves, auricles, cartilage, bone tissue and skin for subsequent transplantation are successfully printed. This type of printing has been successfully used to create "simulators" for doctors, on which they can rehearse operations or for students for live practice. And, of course, one of the main purposes of bioprinting is to print functioning internal organs for transplantation from the patient's biomaterial. So far, this direction is at the stage of development and testing and is not fully used to treat patients, but a large number of successful experiments have already been carried out. Like the heart seal by Israeli scientists in 2019year, while very tiny in size, but the main thing is that it is able to perform its functions.

This is a relatively new type of 3D printing, the first experiments were carried out in 2000 by bioengineer Thomas Boland, who modified conventional desktop printers to print DNA fragments. For 20 years, this industry has stepped far forward, and now, in addition to prototypes of human organs, implants, vascular tubes, heart valves, auricles, cartilage, bone tissue and skin for subsequent transplantation are successfully printed. This type of printing has been successfully used to create "simulators" for doctors, on which they can rehearse operations or for students for live practice. And, of course, one of the main purposes of bioprinting is to print functioning internal organs for transplantation from the patient's biomaterial. So far, this direction is at the stage of development and testing and is not fully used to treat patients, but a large number of successful experiments have already been carried out. Like the heart seal by Israeli scientists in 2019year, while very tiny in size, but the main thing is that it is able to perform its functions. Also, bioprinting has great prospects in the experimental testing of medicines produced by pharmaceutical companies.

Also, bioprinting has great prospects in the experimental testing of medicines produced by pharmaceutical companies.

Of course, I did not manage to cover all 3D printing technologies in this article, but even if you are not a technical expert, you can get a first idea of 3D printing, its various technologies and methods of application. If you are interested in the use of 3D printing in your work or hobby, please contact the specialists of our company and we will always be happy to advise you further.

Alexander Kornweitz

3D Printing Market Expert

3D Printer Types, Materials & More

Affordable, reliable Formlabs 3D printers for office and workshop use set the industry standard for professional 3D printing for businesses around the world. Scale your prototyping and manufacturing with cost-effective, high-resolution models and print-quality industrial 3D printers.

Industry Leading LFS Desktop 3D Printer

(Low Force Stereolithography)

Learn More About Form 3

First Affordable High Volume Resin 3D Printer

Learn More About Form 3L

Scalable multi-printer solution

Industrial power of selective laser sintering in your workshop

Explore Fuse 1 computer-aided design (CAD), by sequentially adding material layer by layer.

Although 3D printing technologies have been around since the 1980s, only recent advances in machinery, materials and software have opened up the possibilities of 3D printing to a wider range of companies - previously only a few high-tech industries used such tools.

Today, affordable professional desktop and workshop 3D printers make it easier for businesses across industries to innovate. Such industries include engineering, manufacturing, dentistry, healthcare, education, entertainment, jewelry, and audiology.

Any 3D printing process begins with the creation of a CAD model, which is exported to software to prepare the design for printing. Depending on the technology used in the 3D printer, models are made layer by layer by curing a photopolymer resin or by sintering a powder. The models are then removed from the printer and post-processed depending on the intended use.

Depending on the technology used in the 3D printer, models are made layer by layer by curing a photopolymer resin or by sintering a powder. The models are then removed from the printer and post-processed depending on the intended use.

3D printers create objects from 3D models, mathematical representations of 3D surfaces created using computer-aided design (CAD) software from 3D scan data. The design is then exported to an STL or OBJ file, which is read by the 3D printing software.

3D printers come with software for setting print parameters and the ability to analyze the digital model in layers, which are horizontal sections of the printed object. Customizable print options include model orientation, support structures (if required), layer height setting, and resin type. Once the settings are complete, the software sends instructions to the printer via a wireless or cable connection.

Some 3D printers use a laser to turn liquid photopolymer resin into hardened plastic, others create objects by sintering small particles of polymer powder at high temperatures. Most 3D printers can perform the printing process without an operator, and modern systems automatically refill the material needed to create objects from cartridges.

Most 3D printers can perform the printing process without an operator, and modern systems automatically refill the material needed to create objects from cartridges.

Depending on the technology and material, printed models may require rinsing with isopropyl alcohol (IPA) to remove uncured polymers from their surface, final polymerization to stabilize mechanical properties, manual processing to remove supporting structures, or cleaning with compressed air or an appropriate apparatus to remove excess powder. Some of these processes can be automated with accessories.

3D printed objects can be used immediately or after post-processing and necessary finishing by machining, decorating, painting, fastening or joining. Often 3D printing also serves as an intermediate step, being used in combination with traditional manufacturing methods such as casting blanks for jewelry and dental prostheses, or molds for custom products.

Can't find the 3D printing technology that best suits your needs? In this video tutorial, we compare Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS) technologies in terms of the top factors to consider when purchasing.

Each 3D printing technology has its own advantages and disadvantages, making them better suited for different applications. In this video, we compare the functional and visual performance of Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS) 3D printers so you can find the solution that best suits your needs.

Do you need to produce custom models or prototypes quickly? Compared to hiring a third party or using traditional methods such as machining, having your own 3D printer cuts lead time by weeks. In this video, we compare print speeds using 3D printing technologies such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

3D printer cost comparison goes beyond labeled prices, which do not give you an idea of the actual cost of a 3D printed model. Learn about the three factors to consider to learn about costs when using 3D printing technologies such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

With traditional manufacturing processes, a model can take weeks or months to complete. 3D printing turns CAD models into physical objects within a few hours: in this way, products and their combinations can be created based on one-time conceptual models, as well as functional prototypes, and even small production runs can be tested. This enables developers and engineers to develop ideas faster and helps companies bring products to market faster.

3D printing eliminates the need for expensive injection molding or machining tools and equipment; the same equipment can be used to create parts of various geometries, from prototyping to production. As 3D printing becomes more relevant in the production of functional end products, it can complement or replace traditional manufacturing methods for a growing range of small to medium volume products.

From shoes and clothing to bicycles, we are surrounded by uniformity as businesses strive to standardize products and make production more economical. 3D printing allows you to change only the digital design and adapt each product to the client's requirements without additional equipment costs. Because of this, 3D printing has found its way into industries where custom fit is key, such as medicine and dentistry, but as 3D printing becomes more accessible, it is increasingly being used to mass-modify consumer products.

3D printing allows you to change only the digital design and adapt each product to the client's requirements without additional equipment costs. Because of this, 3D printing has found its way into industries where custom fit is key, such as medicine and dentistry, but as 3D printing becomes more accessible, it is increasingly being used to mass-modify consumer products.

3D printing can create complex shapes such as overhangs, microchannels and organic shapes that would be expensive or even impossible to produce with traditional manufacturing methods. This makes it possible to form combinations from fewer individual parts, reduce weight, reduce the number of weak joints and reduce assembly time, which opens up new possibilities in the field of design and construction.

Product development is a cyclical process consisting of several stages of testing, evaluation and adjustment. Finding and fixing flaws in templates early on can help companies avoid costly redesigns and additional tooling during the manufacturing process. With 3D printing, engineers can thoroughly test prototypes that look and work like final products before they go into production, and reduce the risks associated with usability and manufacturing complexity.

With 3D printing, engineers can thoroughly test prototypes that look and work like final products before they go into production, and reduce the risks associated with usability and manufacturing complexity.

By creating the necessary prototypes and 3D printing special tools, molds and production aids, manufacturing companies can automate production and optimize workflows at a much lower cost and in much faster time than traditional manufacturing. Thus, production costs are reduced and defects are prevented, quality is improved, assembly is accelerated and labor productivity is increased.

Digital Dentistry reduces the risks and uncertainties associated with human error, enabling consistent quality and accuracy at every step of the workflow, and improving the quality of patient care. 3D printers can produce a range of high quality custom products at low cost, providing exceptional fit and reproducible results.

3D printers are versatile tools for creating immersive learning and research environments. They stimulate creativity and introduce students to professional-level technology, enabling the implementation of the STEAM method in the fields of science, technology, art and design.

They stimulate creativity and introduce students to professional-level technology, enabling the implementation of the STEAM method in the fields of science, technology, art and design.

Affordable, professional-grade desktop 3D printing helps clinicians create medical devices that meet the needs of each individual and increase the effectiveness of treatment. At the same time, the organization significantly reduces time and money costs: from laboratories to operating rooms.

High-resolution printed physical models are widely used in digital sculpting, 3D character modeling and prop making. 3D-printed models have been featured in animated films, video game characters, theatrical costumes, and even special effects for blockbuster films.

Professional jewelers use the power of CAD and 3D printing to rapidly prototype, customize jewelry to customer specifications and produce large batches of castings. Digital tools allow you to create dense, highly detailed models without the tedious, error-prone production of stencils.

Formlabs offers two professional 3D printing technologies: stereolithography and selective laser sintering, making these powerful and user-friendly industrial production tools available to creative professionals around the world.

Stereolithographic (SLA) 3D printing uses a laser to turn liquid photopolymer resin into solid isotropic models.

The most common method is inverted stereolithography, in which a platform is lowered into a reservoir of polymer, leaving only a thin layer of liquid between the platform and the bottom of the reservoir. The galvanometers direct the laser through a transparent window under the resin tank to obtain a 3D cross section and selectively cure the resins. The model is formed from successive layers less than a hundred microns thick. If necessary, the protruding parts are supported by support structures attached to the platform. When the layer is completed, the model is lifted from the bottom of the tank to allow fresh polymer to flow under it, and the platform is lowered again. The process is repeated until the print is complete.

The process is repeated until the print is complete.

-

rapid prototyping;

-

functional prototyping;

-

concept modeling;

-

small-scale production;

-

manufacture of dental products;

-

Jewelry prototype making and casting

rapid prototyping;

functional prototyping;

concept modeling;

small-scale production;

manufacture of dental products;

jewelry prototyping and casting

Learn more about stereolithographic 3D printing

Selective laser sintering (SLS) 3D printers use a powerful laser to sinter small particles of polymer powder into a solid structure.

A thin layer of powder is applied to the top of the platform inside the build chamber and the printer preheats the powder to just below the melting point of the feedstock. The laser scans the cross section of the 3D model and forms a solid object by mechanically fusing the particles. The unsprayed powder supports the model during printing and eliminates the need for special support structures. The platform is lowered into the build chamber one layer, typically 50-200 microns thick, and the recoater applies a new layer of powder from above. The laser then scans the next slice of the model and the process is repeated for each layer until the model is complete.

The unsprayed powder supports the model during printing and eliminates the need for special support structures. The platform is lowered into the build chamber one layer, typically 50-200 microns thick, and the recoater applies a new layer of powder from above. The laser then scans the next slice of the model and the process is repeated for each layer until the model is complete.

-

functional prototyping;

-

production of final models;

-

small-scale production and customization.

functional prototyping;

production of final models;

small-scale production and custom-made products.

Learn more about selective laser sintering

The market for 3D printing materials is broad and growing: printers are being used to print everything from plastics to metals, and even potentially food and living tissue. Formlabs offers the following range of photopolymer materials for desktop 3D printing.

Standard 3D printing materials provide high print resolution, excellent model performance and a smooth surface, ideal for rapid prototyping, product development and simulation.

Standard resins are available as Black, White, Gray resins for a matte finish and opacity, Clear for translucent prints, and a Color Kit to match virtually any color.

View standard 3D printing resins

These are 3D printing materials for engineering, manufacturing and product design. They offer advanced functionality, withstand numerous test tests, work under stressful conditions and do not lose strength over time.

Engineering resins are ideal for 3D printing strong and accurate concept models and prototypes to quickly evaluate design quality, shape and fit, and optimize manufacturing processes.

Explore Engineering Resins

Dental Resins are empowering dental labs and dental practices to quickly, cost-effectively, and outsource a range of dental products, from dental models to biocompatible surgical guides, splints and orthodontic models of thermoformed retainers and aligners.

Explore dental resins

Jewelry resins are designed to enhance detail and cost-effectively create custom jewelry.