Ceramic 3d printing uk

3D Printing in technical Ceramics. Zirconia ZrO2 and Alumina Al2O3

3D Printing in our Ceramic materials gives your designs excellent temperature resistance, high strength and low conductivity.

Another recent addition to our 'Strong & Durable' and 'Fine Detail' service, our Ceramic 3D printing service gives you an ideal material where you need Strength, Smooth surface finish and excellent temperature resistance. Designs produced in Ceramic can have fine detail and the off white colour enhances temperature resistance when exposed to local heat sources.

We give you two ceramic options, our original Ceramic infused SLA and true real technical ceramics in Zirconia and Alumina.

Our ceramics are not the traditional pottery process and do not involve kiln firing.

Technical Ceramics. Zirconia and Alumina

Zirconia and Alumina give you a choice of 2 true technical ceramics offering superb material properties including very high operating temperatures, hardness and electrical insulation.

Alumina offers best extraordinary hardness, is bioinert and has excellent corrosion resistance. Example applications include burner jets, laboratory crucibles and it's high dielectric strength makes it ideal as an electrical insulator.

Zirconia gives you low thermal conductivity and its tribological properties (low friction) make it well suited for sliding components and some medical applications.

Technical Ceramics:

- Zirconia or Alumina ceramic built with LCM technology.

- Temperature Resistance of 1650°c. (Alumina)

- Typical accuracy +/- 0.1mm depending on design, geometry and build orientation.

- Build Volume - 81 x 51 x 156mm (Alumina)

- Build Volume - 75 x 47 x 146mm (Zirconia)

- Break away support structure.

Ceramic infused resin (SLA)

Our original Ceramic 3D Printing service, based on laser curing a Ceramic infused resin material via the Stereolithography (SLA) process. -6 [1/K]

-6 [1/K]

3D Printed Zirconia and Alumina Datasheet \ Design guide.

SLA Ceramic :

- SLA ceramic material built in 0.1mm layers.

- Temperature Resistance of 132°c. (270°c) HDT

- Density 1.7 g/cm³

- Tensile Modulus 10500Mpa (9800Mpa)

- Tensile Strength 68Mpa (80Mpa)

- Elongation at Break 1.1% (1.2%)

- Typical accuracy +/- 0.2mm depending on design, geometry and build orientation.

- Build Area - 500 x 500 x 590mm

- Break away support structure.

- Figures in brackets after a Thermal Postcure.

Cost option, please request pricing) - Revised 6th December 2018.

Cost option, please request pricing) - Revised 6th December 2018.

Ceramic 3d printing.

Ceramic nozzle, 3D printed for a factory production line application.

The design pictured was 3d printed in our ceramic material to take advantage of it's superior temperature resistance. The part delivers cooling air but works in very close proximity to a high temperature laser. The off white color means helps manage ambient in the environment.

3D Printed Ceramic Wave Guide.

Our Ceramic material offers excellent electrical properties for use as a substrate in wave guide applications, in the microwave spectrum of frequencies.

3D Printed Antenna in our Ceramic material.

Along with desirable electrical properties, our Ceramic material gives a smooth surface finish for metalisation processes.

See more of our work..

class="clearfix">

Find just the right material for your project with our Materials Wizard.

Materials Wizard

3D Printed Materials

LATEST WORK

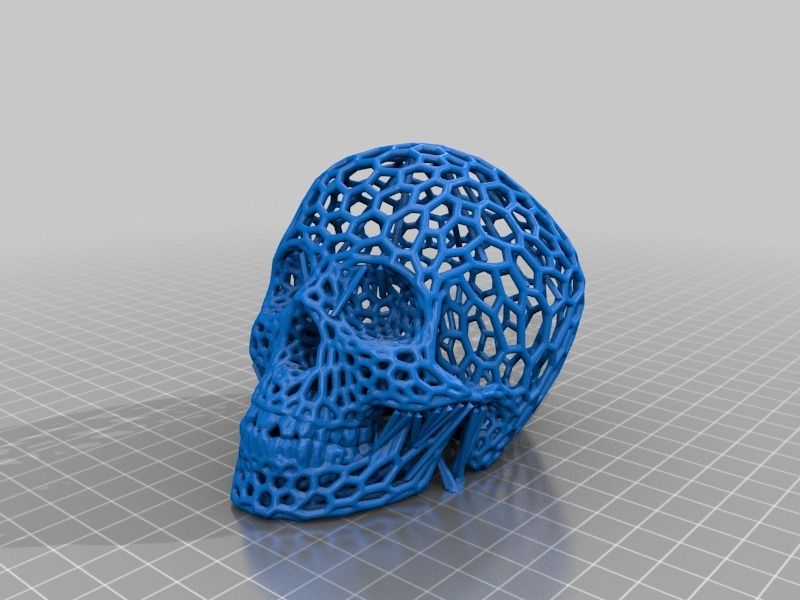

Example objects printed with our 3d printing services:

OUR CLIENTS SAY

"Great company for 3D prints in wide range of materials; good turn-around from quotation to delivery. Physically accurate product and great for sample evaluation prior to any production tooling investment."

Mark, Senior Development Manager.

Jul 2017

"Quick response to quotation request. Well packaged part, quick delivery. Very much appreciated as the part was used in a review meeting."

Philip, R&D Department.

LATEST NEWS

3D-Alchemy

FOLLOW US

3d printing applications for your organisation • 3D Matters

3D Printing Applications

Industry and Aerospace

The use of ceramic and metal materials in industry make 3D printing applications in these materials most interesting for the Aviation and Aerospace.

Certainly ceramics and metals have a wide variety of interesting mechanical, electrical, chemical, thermal and magnetic applications.

Moreover their material properties allow them to be very hard wearing, high strength and dimensional stable (low coefficient of thermal expansion). In conjunction such material qualities when combined with the ability to manufacture parts with complex geometries is attractive to engineers. Even more so given it can be done fast and without the cost of tooling.

There are many other 3D printing applications for this industry including; Dies and punches, Nozzles, Microwave Filters, Antennas, Electronic Connectors, Electrical Insulators, Rotary Blades and bespoke crucibles. Visit this page to read a case study on bespoke crucibles.

Case Study

Biomedical

It is without doubt 3D printing applications in healthcare have become a key area for development. In particular, one area of focus is in osterosteo-conduction and bone remodeling.

Calcium phosphates, such as hydroxyapatite or tricalcium phosphates, are the synthetic materials closest to bone. They are widely renowned in medical circles for their osteoconductive properties. Especially when the micropores size and porosity of interconnection are controlled. Due to the controlled porosity and being fully biocompatible they have minimal risk of rejection when implanted into the patient.

Other benefits include;

- Biocompatible

- Osteoconductor

- Good mechanical properties

- Medium-term resorbable

- Easy to stock and work with

Intervertebral Cages, Cranial Implants, Jawbone implants, Orbital Floor, Tibial Osteotomy Wedges, Eye ball socket are some examples of 3D printing applications for this industry.

Contact us for Case Study

Education and R&D Institutions

For Education and R&D 3D printing applications are endless. We have many customers doing some great work in this area. Consequently it is important we supply off-the-shelf and bespoke materials. These organisation's often require the ability to develop their own materials. Moreover our products are 'open platform' enabling customer material development programs and provide uninhibited R&D flexibility.

These organisation's often require the ability to develop their own materials. Moreover our products are 'open platform' enabling customer material development programs and provide uninhibited R&D flexibility.

For more information please contact us so that we can discuss your R&D objectives so that we can support your activity.

Case Study

Investment Casting

3D printing applications for ceramic materials is viable in the development & production of your customers parts for the investment casting process. Great examples include Ceramic cores and shells when produced in this way provide advantages such as:

- Increase complexity of parts without cost of tooling

- Easier to achieve more complex cores designs

- Flexibility of design

- Quick creation of new designs

- Better responsiveness and productivity

- Productivity increases

- Maintain the material properties as with traditional methods for wax and ceramics

- AM allows for greater control of the constraints applied to the application, for example, in core production.

More 3D printing applications for this industry include; wax patterns, crucibles filters, complex foundry cores and moulds.

Case Study

3D Jewellery and Luxury Goods

Additionally designers can utilise AM technology to explore new design opportunities; testing the level of detail and tolerances of a material whilst developing tactile forms and textures which are pleasing to the consumer.

For instance it allows for design validation and quick product development. Furthermore the use of zirconia and/or alumina in combination with diamonds, silver and/or gold. Refer to our case study below to see how.

Other 3D printing applications for this industry; Rings, pendants, sculptures.

Case Study

Investment idea: 3D Systems because 3D printing

Mikhail Gorodilov

makes money on investments

Author profile

expected growth in demand in this area.

Growth potential and duration: 20. 5% for 14 months; 54% over 4 years; 11% per year for 15 years.

5% for 14 months; 54% over 4 years; 11% per year for 15 years.

Why stocks might go up: 3D printing has a great future.

How we act: we take shares now at $32.34.

When creating the material, sources were used that are inaccessible to users from the Russian Federation. We hope you know what to do.

Our thoughts are based on an analysis of the company's business and the personal experience of our investors, but remember: it is not a fact that an investment idea will work as we expect. Everything we write is forecasts and hypotheses, not a call to action. Rely on our thoughts or not - it's up to you.

And what about the author's forecasts

Research, such as this and this, suggests that the accuracy of target price predictions is low. And this is normal: there are always too many surprises on the stock exchange and accurate forecasts are rarely realized. If the situation were reversed, then funds based on computer algorithms would show results better than people, but alas, they work worse.

Therefore, we do not try to build complex models. The profit forecast in the article is the author's expectations. We indicate this forecast for reference: as with the investment idea as a whole, readers decide for themselves whether to trust the author and focus on the forecast or not.

We love, appreciate,

Investment edition

How the company earns

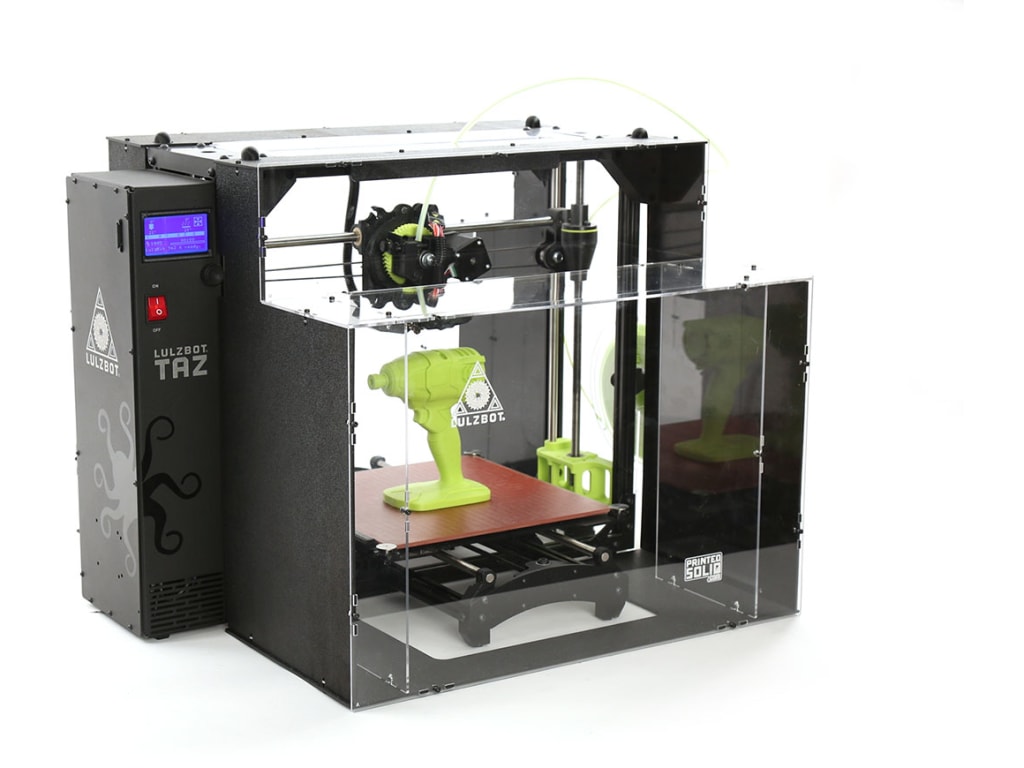

DDD makes 3D printers and provides services in this area. You can see what the company's printers look like on its website, but for the most part, these are printers for the corporate sector.

According to the annual report, the company's revenue is divided into the following segments.

Goods - 61.2%. A variety of printers: for plastic, for metal, for ceramics, and so on. Specialized software for scanning, design and virtual simulations for the medical sector. The segment's gross margin is 31.6% of its revenue.

Services - 38.8%. Technical support and training services for the company's clients. Production services for the company's customers - from prototyping to more complex projects. Specialized services for the medical sector: surgical planning, printing devices and instruments, building anatomical models, and more. The segment's gross margin is 52.7% of its revenue.

Production services for the company's customers - from prototyping to more complex projects. Specialized services for the medical sector: surgical planning, printing devices and instruments, building anatomical models, and more. The segment's gross margin is 52.7% of its revenue.

The report lacks detail: it would be useful to know what types of printers the company has - ceramic or metal, how much revenue they generate, and what is the structure of revenue by customer type. We know that the company serves clients from almost every possible industry: everyone always needs to print something large.

Company revenue by country and region:

- Americas - 50.25%. The US accounts for 49.47% of the company's total revenue.

- Europe, Middle East and Africa - 38.34%.

- Asia Pacific - 11.41%.

The company is unprofitable.

Revenue and profit for the last 12 months in billions of dollars, total margin as a percentage of revenue. Source: Macrotrends

Source: Macrotrends Arguments in favor of the company

Dropped. The company's shares have fallen in price by 41.57% since February of this year: from $55.35 to $32.34. The fall was quite strong and perhaps we can pick up stocks in anticipation of a rebound.

Something about a fast growing market. DDD's target market for 3D printing and related solutions and products is expected to increase from $15 billion in 2021 to $37.2 billion in 2026. More recently, DDD acquired Volumetric Biotechnologies, a biomaterial printing company, perhaps from this, those who believe that soon the missing organs for transplantation can be mass-produced on printers will run into the DDD shares.

The company has not the largest capitalization - 4.05 billion dollars. It is possible that its shares will be easy to pump for retail investors because they read somewhere that "the sector is very promising."

Prose of the market. In general, the company has something to hope for without speculation. In the Proto Labs idea, we have already discussed the good prospects for companies related to R&D and small-scale production due to the expected increase in corporate sector investment around the world in the renewal of fixed assets. And 3D printing is needed primarily for creating prototypes and a small number of parts.

In the Proto Labs idea, we have already discussed the good prospects for companies related to R&D and small-scale production due to the expected increase in corporate sector investment around the world in the renewal of fixed assets. And 3D printing is needed primarily for creating prototypes and a small number of parts.

DDD could also benefit from Biden's infrastructure package, which is about to become a reality. This will stimulate the industry and contribute to the demand for DDD solutions: it will increase the wear and tear of the equipment of manufacturing companies and increase their need to invest in the business.

Life has become better. In the latest report, DDD showed progress: the loss ratio of its business is declining - and profit may not be far off. This can attract investors from among banks and funds into shares.

Can buy. DDD has 35 years of additive manufacturing experience with solutions for all industries, from dentistry and surgery to jewelry and high-tech manufacturing. Given all of the above, it may well be bought by some large industrial conglomerate.

Given all of the above, it may well be bought by some large industrial conglomerate.

What can get in the way

Expensive. The company has a P/S of about 6.55, which is not very low. And if we take into account the unprofitability of the company and the fact that its revenue has not been growing particularly actively in recent years, you can even decide that the company is expensive.

Unprofitable. The company has been on the market for a long time, but it has no profit. Loss will contribute to the volatility of these stocks. Yes, and there is always the possibility of bankruptcy, even taking into account the fact that DDD's accounting is quite accurate: it has enough money to close all urgent debts.

Not all at once. Waves of investor interest in the field of 3D printing periodically give way to disappointment when it suddenly turns out that not every individual user can print their own house yet.

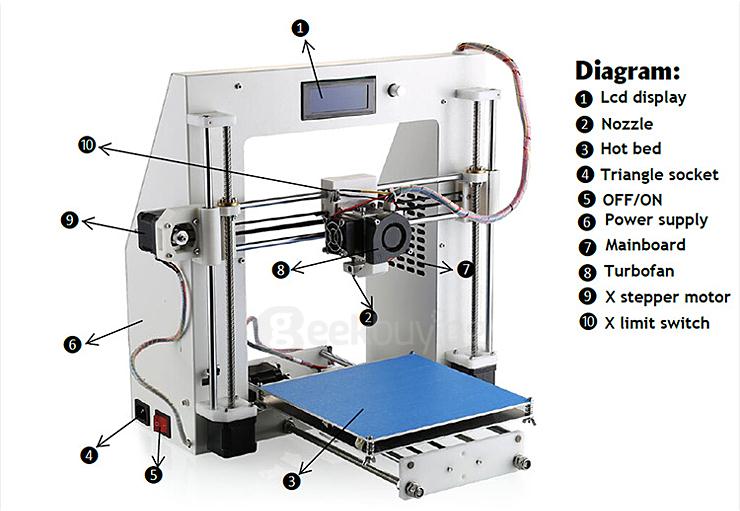

3D printing technology is still quite raw and needs significant improvement: there are problems with a large number of defects, temperature control. So DDD will remain in the position of such a risky startup for some time to come, the technology of which has not yet been fully mastered. This must be understood and accepted in order not to be surprised by the volatility of these stocks.

Hot time puts its test. The company has production and assets around the world, and more than half of its sales are made outside the United States. This means that logistical problems, as well as an increase in the cost of labor and raw materials, will be reflected in its reporting. Well, the permanent threat of a new quarantine must also be taken into account: as the experience of 2020 showed, the DDD business does not respond well to a decrease in industrial activity in the world.

As a result

Shares can be taken now at $32.34. And then there are three options:

- wait until shares are worth $39.

I think we will reach this level in the next 14 months;

I think we will reach this level in the next 14 months; - wait until the stock is worth $50. Here, you may have to wait 4 years for 3D printing to become widespread;

- hold shares for 15 years to see the company become IBM from the world of 3D printing.

But still, it should be remembered that this idea is very volatile. So don't invest in these stocks unless you're ready for the storm.

UK government to invest $25 million to build 3D printing center

Siemens 3D printer for gas turbine parts production costs of difficult-to-manufacture products. According to the minister, the state will allocate 15.3 million pounds (about $25 million) for this, the BBC reported.

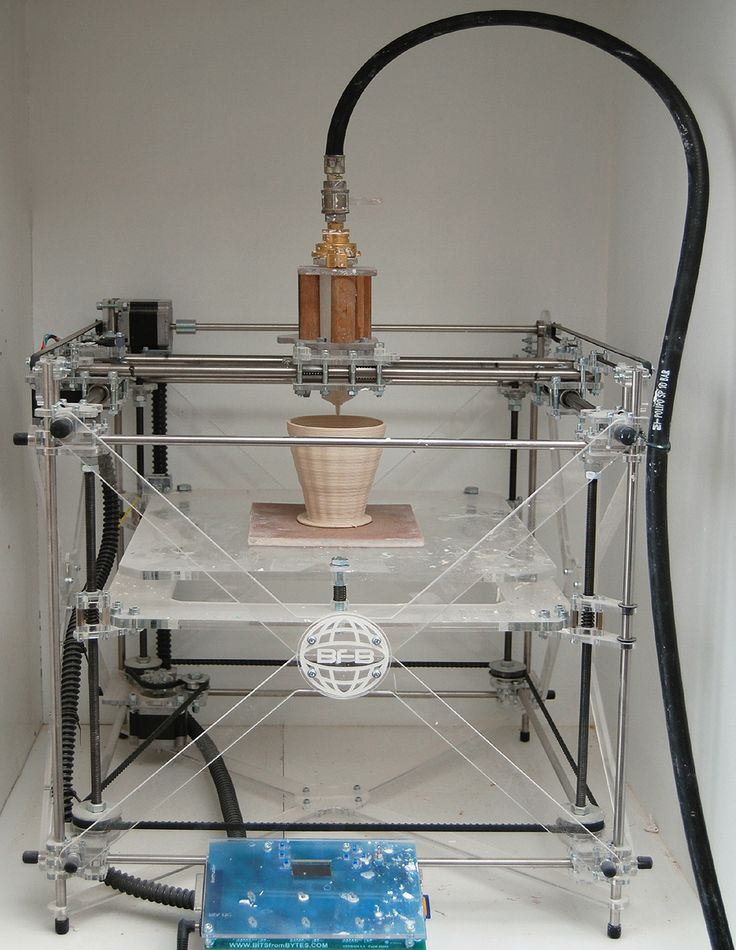

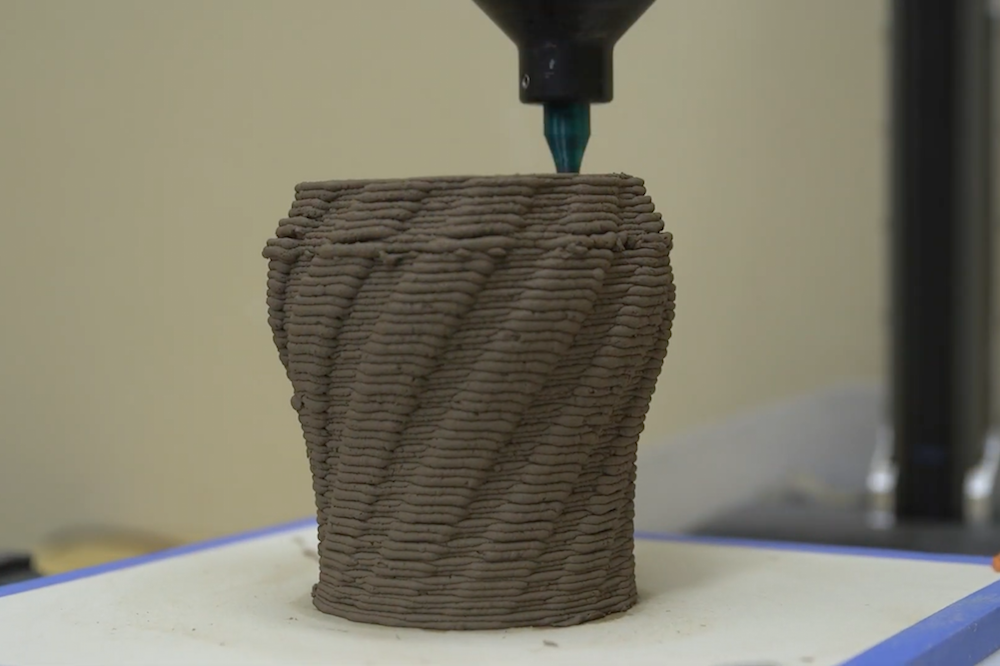

3D printing technology is the build-up of material on an object layer by layer. Historically, production has consisted not of layering, but of removing material, most often by cutting or drilling parts. The UK 3D Printing Center will be located in Coventry next to the Manufacturing Technology Center (MTC), which is funded by both public and private funds and supports new manufacturing technologies.

The 3D Printing Center will, among other things, develop new components for jet engines, an industry in which the UK is a major player thanks to Rolls-Royce's leadership position. Its creation will also support the automotive and medical industries. However, the aerospace industry will still receive the main benefit - state investment is made as part of the authorities' strategy aimed at supporting this sector, writes the Financial Times. The strategy calls for £2bn ($3.3bn) from the government and industry to go into research to build the next generation of passenger aircraft.

The government will also provide £15 million to a new aerospace center at MTC that will develop technologies for new materials such as carbon fiber reinforced plastics for aircraft fuselage and wing parts.

The companies will invest an amount equal to the government allocation. As a result, a total of 60 million pounds ($98 million) will go to finance both projects. The money will also be used for vocational training and advanced training for 1,000 engineers.

The UK aerospace industry is the second largest in the world in terms of revenue after the US.

The 3D printing center is due to open in 2015. The government will "feel free" to support the success of British manufacturers, Osborne said.

3D printing technology is beginning to be used more and more in production. At the end of last year, the German Siemens announced that from January it would use it to produce spare parts for gas turbines. This will allow it to speed up the repair work (in some cases, for example, when repairing propulsion systems - from 44 weeks to four) and reduce costs.

Siemens will be one of the first industrial companies in the world to apply 3D printing to everyday metal production. Meanwhile, a number of the largest industrial companies, from EADS to General Electric, are also preparing to introduce this technology into production; the latter said last year that it plans to produce jet fuel injectors in this way.

In July 2013, the US space agency NASA announced that it had successfully tested a 3D printed engine part for a rocket engine.