Commercial 3d printers

ProX SLS 6100 3D Printer

The production-ready ProX® SLS 6100 features automated material handling and advanced 3D Sprint® software to deliver tough, high-resolution end-use parts and functional prototyping.

Production-Grade Materials

Produce tough, durable parts from a range of DuraForm® ProX production-grade nylon materials that have been optimized, validated and tested to ensure quality, with uniform 3D mechanical properties. The ProX SLS 6100 brings versatility to your applications, whether for functional prototyping or direct 3D production. Choose from industrial-grade, tough, impact and fatigue-resistant nylon 11 materials or strong, medical-grade, or flame-retardant capable nylon 12 thermoplastics, or filled nylons for advanced properties in terms of stiffness, temperature resistance, strength and surface finish.

ProX SLS 6100 Material Quality Control system

Unmatched Part Quality at High Throughput:

With faster build times than other SLS printers in its price point, high performance nesting and high density capability for a 25% larger build volume capacity, the ProX SLS 6100 delivers production quality parts in a fast and efficient process.

- Best surface finish

- Highest resolution and edge definition

- High accuracy and repeatability

- Uniform part properties

Predictive support through advanced 3D printing software increases uptime and SLS efficiency

Maximize Your Production with 3D Connect:

3D Connect™ Service provides a secure cloud-based connection to 3D Systems service for preventative support to enable better service, improved uptime and production assurance for your system. With 3D Connect Service, your system will automatically send alerts to 3D Systems' service team for immediate assistance in resolving printer-defined conditions or exceptions, solve problems remotely, pre-order parts, and schedule on-site services as required.

About this printer

-

Applications

-

Benefits

-

Tech Specs

Applications

- Impact and temperature resistant durable parts

- Covers, housings, enclosures

- Jigs and fixtures

- Reduced weight production parts

- Knobs, handles and other dashboard/interior parts

- Parts with snap fits and living hinges

- Machinery components

- Complex duct work

Benefits

- Manufacture strong end-use parts and functional prototypes faster

- Easily print any design without using supports or post-processing

- Integrated solution with expert application support

- Full automation of material handling frees valuable resource

- Streamline your workflow with automated production tools

- Lower cost of ownership with high throughput and material efficiency

- Smoothest surface finish, highest resolution and edge definition of any SLS system

Tech Specs

- Selective Laser Sintering (SLS) technology

- Max build envelope capacity (W x D x H): 15 x 13 x 18 in (381 x 330 x 460 mm)

- Broad range of production-grade nylon 11, nylon 12 and reinforced materials

- Consistent mechanical properties

- High production speed for its class of 2.

7 l per hour

7 l per hour - Streamlined production control, including 3D Sprint™ integrated additive manufacturing software, fully automated powder handling and optional 3D Connect capability

- Automated 3D part nesting

- Maximized build volume and density

-

Setting the New Standard in 3D Printing

Bring increased productivity and quality to your SLS production process with this exclusive additive manufacturing software with tools for file preparation, automatic 3D nesting, quality checks for pre-build verification, and efficient build planning,

-

A new level of management in 3D production

3D Connect Service provides a secure cloud-based connection to 3D Systems service teams for proactive and preventative support, enabling better service to improve uptime and deliver production assurance for your system.

-

3D printing with plastics offers many choices for engineering grade materials, elastomers and composites. Do you need flexibility? Strength? Bio-compatibility? More?

-

3D print with plastics to build almost anything - used for prototyping, manufacturing, anatomical models and more. Select a plastic material and 3D technology to deliver the characteristics you need.

Interested in purchasing this printer?

You must have JavaScript enabled to use this form.

First Name

Last Name

Business Email

Company

Country -- Select Country --AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua & BarbudaArgentinaArmeniaArubaAscension IslandAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia & HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBritish Virgin IslandsBruneiBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCanary IslandsCape VerdeCaribbean NetherlandsCayman IslandsCentral African RepublicCeuta & MelillaChadChileChinaChristmas IslandClipperton IslandCocos (Keeling) IslandsColombiaComorosCongo - BrazzavilleCongo - KinshasaCook IslandsCosta RicaCroatiaCuraçaoCyprusCzechiaCôte d’IvoireDenmarkDiego GarciaDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard & McDonald IslandsHondurasHong Kong SAR ChinaHungaryIcelandIndiaIndonesiaIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKosovoKuwaitKyrgyzstanLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacao SAR ChinaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmar (Burma)NamibiaNauruNepalNetherlandsNetherlands AntillesNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorthern Mariana IslandsNorth MacedoniaNorwayOmanOutlying OceaniaPakistanPalauPalestinian TerritoriesPanamaPapua New GuineaParaguayPeruPhilippinesPitcairn IslandsPolandPortugalPuerto RicoQatarRomaniaRussiaRwandaRéunionSamoaSan MarinoSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint MaartenSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia & South Sandwich IslandsSouth KoreaSouth SudanSpainSri LankaRepublic of Sudan (North Sudan)St. BarthélemySt. HelenaSt. Kitts & NevisSt. LuciaSt. MartinSt. Pierre & MiquelonSt. Vincent & GrenadinesSurinameSvalbard & Jan MayenSwedenSwitzerlandSão Tomé & PríncipeTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad & TobagoTristan da CunhaTunisiaTurkeyTurkmenistanTurks & Caicos IslandsTuvaluU.S. Outlying IslandsU.S. Virgin IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamWallis & FutunaWestern SaharaYemenZambiaZimbabweÅland Islands

BarthélemySt. HelenaSt. Kitts & NevisSt. LuciaSt. MartinSt. Pierre & MiquelonSt. Vincent & GrenadinesSurinameSvalbard & Jan MayenSwedenSwitzerlandSão Tomé & PríncipeTaiwanTajikistanTanzaniaThailandTimor-LesteTogoTokelauTongaTrinidad & TobagoTristan da CunhaTunisiaTurkeyTurkmenistanTurks & Caicos IslandsTuvaluU.S. Outlying IslandsU.S. Virgin IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican CityVenezuelaVietnamWallis & FutunaWestern SaharaYemenZambiaZimbabweÅland Islands

State -- Select State --Buenos AiresCatamarcaChacoChubutCiudad Autónoma de Buenos AiresCórdobaCorrientesEntre RíosFormosaJujuyLa PampaLa RiojaMendozaMisionesNeuquénRío NegroSaltaSan JuanSan LuisSanta CruzSanta FeSantiago del EsteroTierra del FuegoTucumánAustralian Capital TerritoryNew South WalesNorthern TerritoryQueenslandSouth AustraliaTasmaniaVictoriaWestern AustraliaBurgenlandKärntenNiederösterreichOberösterreichSalzburgSteiermarkTirolVorarlbergWienAcreAlagoasAmapáAmazonasBahiaCearáDistrito FederalEspírito SantoGoiásMaranhãoMato GrossoMato Grosso do SulMinas GeraisParáParaíbaParanáPernambucoPiauíRio de JaneiroRio Grande do NorteRio Grande do SulRondôniaRoraimaSanta CatarinaSão PauloSergipeTocantinsAlbertaBritish ColumbiaManitobaNew BrunswickNewfoundland and LabradorNorthwest TerritoriesNova ScotiaNunavutOntarioPrince Edward IslandQuebecSaskatchewanYukon TerritoriesAisén del General Carlos Ibañez del CampoAntofagastaAraucaníaArica y ParinacotaAtacamaBío-BíoCoquimboLibertador General Bernardo O'HigginsLos LagosLos RíosMagallanesMauleRegión Metropolitana de SantiagoTarapacáValparaísoAnhuiBeijingChinese TaipeiChongqingFujianGansuGuangdongGuangxiGuizhouHainanHebeiHeilongjiangHenanHong KongHubeiHunanJiangsuJiangxiJilinLiaoningMacaoNei MongolNingxiaQinghaiShaanxiShandongShanghaiShanxiSichuanTianjinXinjiangXizangYunnanZhejiangÎle-de-FranceOccitanieAuvergne-Rhône-AlpesBourgogne-Franche-ComtéBretagneCentre-Val de LoireCorseGrand EstHauts-de-FranceJuraNormandieNouvelle-AquitainePays de la LoireProvence-Alpes-Côte d'AzurBaden-WürttembergBayernBerlinBrandenburgBremenHamburgHessenMecklenburg-VorpommernNiedersachsenNordrhein-WestfalenRheinland-PfalzSaarlandSachsenSachsen-AnhaltSchleswig-HolsteinThüringenAndaman and Nicobar IslandsAndhra PradeshArunachal PradeshAssamBiharChandigarhChhattisgarhDadra and Nagar HaveliDaman and DiuDelhiGoaGujaratHaryanaHimachal PradeshJammu and KashmirJharkhandKarnatakaKeralaLakshadweepMadhya PradeshMaharashtraManipurMeghalayaMizoramNagalandOdishaPuducherryPunjabRajasthanSikkimTamil NaduTripuraUttar PradeshUttarakhandWest BengalCarlowCavanClareCorkDonegalDublinGalwayKerryKildareKilkennyLaoisLeitrimLimerickLongfordLouthMayoMeathMonaghanOffalyRoscommonSligoTipperaryWaterfordWestmeathWexfordWicklowAgrigentoAlessandriaAnconaAostaArezzoAscoli PicenoAstiAvellinoBariBarletta-Andria-TraniBellunoBeneventoBergamoBiellaBolognaBolzanoBresciaBrindisiCagliariCaltanissettaCampobassoCarbonia-IglesiasCasertaCataniaCatanzaroChietiComoCosenzaCremonaCrotoneCuneoEnnaFermoFerraraFirenzeFoggiaForlì-CesenaFrosinoneGenovaGoriziaGrossetoImperiaIserniaLa SpeziaL'AquilaLatinaLecceLeccoLivornoLodiLuccaMacerataMantovaMassa - CarraraMateraMedio CampidanoMessinaMilanoModenaMonza e BrianzaNapoliNovaraNuoroOgliastraOlbia-TempioOristanoPadovaPalermoParmaPaviaPerugiaPesaro e UrbinoPescaraPiacenzaPisaPistoiaPordenonePotenzaPratoRagusaRavennaReggio CalabriaReggio EmiliaRietiRiminiRomaRovigoSalernoSassariSavonaSienaSondrioSiracusaTarantoTeramoTerniTrapaniTrentoTrevisoTriesteTorinoUdineVareseVeneziaVerbano-Cusio-OssolaVercelliVeronaVibo ValentiaVicenzaViterboAichiAkitaAomoriChibaEhimeFukuiFukuokaFukushimaGifuGunmaHiroshimaHokkaidoHyogoIbarakiIshikawaIwateKagawaKagoshimaKanagawaKochiKumamotoKyotoMieMiyagiMiyazakiNaganoNagasakiNaraNiigataOitaOkayamaOkinawaOsakaSagaSaitamaShigaShimaneShizuokaTochigiTokushimaTokyoTottoriToyamaWakayamaYamagataYamaguchiYamanashiBusanDaeguDaejeonGangwonGwangjuGyeonggiIncheonJejuNorth ChungcheongNorth GyeongsangNorth JeollaSeoulSouth ChungcheongSouth GyeongsangSouth JeollaUlsanJohorKedahKelantanMelakaNegeri SembilanPahangPerakPerlisPulau PinangSabahSarawakSelangorTerengganuWilayah Persekutuan Kuala LumpurWilayah Persekutuan LabuanWilayah Persekutuan PutrajayaAguascalientesBaja CaliforniaBaja California SurCampecheChiapasChihuahuaCoahuilaColimaDurangoFederal DistrictGuanajuatoGuerreroHidalgoJaliscoMexico StateMichoacánMorelosNayaritNuevo LeónOaxacaPueblaQuerétaroQuintana RooSan Luis PotosíSinaloaSonoraTabascoTamaulipasTlaxcalaVeracruzYucatánZacatecasŚląskieŁódzkieŚwiętokrzyskieDolnośląskieKujawsko-pomorskieLubelskieLubuskieMałopolskieMazowieckieOpolskiePodkarpackiePodlaskiePomorskieWarmińsko-mazurskieWielkopolskieZachodniopomorskieAdygeya, RespublikaAltay, RespublikaAltayskiy krayAmurskaya oblast'Arkhangel'skaya oblast'Astrakhanskaya oblast'Bashkortostan, RespublikaBelgorodskaya oblast'Bryanskaya oblast'Buryatiya, RespublikaChechenskaya RespublikaChelyabinskaya oblast'Chukotskiy avtonomnyy okrugChuvashskaya RespublikaDagestan, RespublikaIngushetiya, RespublikaIrkutskaya oblast'Ivanovskaya oblast'Kabardino-Balkarskaya RespublikaKaliningradskaya oblast'Kalmykiya, RespublikaKaluzhskaya oblast'Kamchatskiy krayKarachayevo-Cherkesskaya RespublikaKareliya, RespublikaKemerovskaya oblast'Khabarovskiy krayKhakasiya, RespublikaKhanty-Mansiyskiy avtonomnyy okrug-YugraKirovskaya oblast'Komi, RespublikaKostromskaya oblast'Krasnodarskiy krayKrasnoyarskiy krayKurganskaya oblast'Kurskaya oblast'Leningradskaya oblast'Lipetskaya oblast'Magadanskaya oblast'Mariy El, RespublikaMordoviya, RespublikaMoskovskaya oblast'MoskvaMurmanskaya oblast'Nenetskiy avtonomnyy okrugNizhegorodskaya oblast'Novgorodskaya oblast'Novosibirskaya oblast'Omskaya oblast'Orenburgskaya oblast'Orlovskaya oblast'Penzenskaya oblast'Permskiy krayPrimorskiy krayPskovskaya oblast'Rostovskaya oblast'Ryazanskaya oblast'Sakha, RespublikaSakhalinskaya oblast'Samarskaya oblast'Sankt-PeterburgSaratovskaya oblast'Severnaya Osetiya-Alaniya, RespublikaSmolenskaya oblast'Stavropol'skiy kraySverdlovskaya oblast'Tambovskaya oblast'Tatarstan, RespublikaTomskaya oblast'Tul'skaya oblast'Tverskaya oblast'Tyumenskaya oblast'Tyva, RespublikaUdmurtskaya RespublikaUl'yanovskaya oblast'Vladimirskaya oblast'Volgogradskaya oblast'Vologodskaya oblast'Voronezhskaya oblast'Yamalo-Nenetskiy avtonomnyy okrugYaroslavskaya oblast'Yevreyskaya avtonomnaya oblast'Zabaykal'skiy krayCentral SingaporeNorth EastNorth WestSouth EastSouth WestA CoruñaÁlava / ArabaAlbaceteAlicante / AlacantAlmeríaAsturiasÁvilaBadajozBalearsBarcelonaBurgosCáceresCádizCantabriaCastellón / CastellóCiudad RealCórdobaCuencaGironaGranadaGuadalajaraGuipúzcoa / GipuzkoaHuelvaHuescaJaénLa RiojaLas PalmasLeónLleidaLugoMadridMálagaMurciaNavarra / NafarroaOurensePalenciaPontevedraSalamancaSanta Cruz de TenerifeSegoviaSevillaSoriaTarragonaTeruelToledoValencia / ValènciaValladolidVizcaya / BizkaiaZamoraZaragozaAargauAppenzell AusserrhodenAppenzell InnerrhodenBasel-LandschaftBasel-StadtBernFribourgGenèveGlarusGraubündenJuraLuzernNeuchâtelNidwaldenObwaldenSankt GallenSchaffhausenSchwyzSolothurnThurgauTicinoUriValaisVaudZugZürichChanghua CountyChiayi CityChiayi CountyHsinchu CityHsinchu CountyHualien CountyKaohsiung CityKaohsiung CountyKeelung CityMiaoli CountyNantou CountyPenghu CountyPingtung CountyTaichung CityTaichung CountyTainan CityTainan CountyTaipei CityTaipei CountyTaitung CountyTaoyuan CountyYilan CountyYunlin CountyŞırnakŞanlıurfaİstanbulİzmirAğrıAd?yamanAdanaAfyonkarahisarAksarayAmasyaAnkaraAntalyaArdahanArtvinAydınBalıkesirBartınBatmanBayburtBilecikBingölBitlisBoluBurdurBursaÇanakkaleÇankırıÇorumDenizliDiyarbakırDüzceEdirneElazığErzincanErzurumEskişehirGaziantepGiresunGümüşhaneHakkâriHatayIğdırIspartaKırşehirKırıkkaleKırklareliKahramanmaraşKarabükKaramanKarsKastamonuKayseriKilisKocaeliKonyaKütahyaMalatyaManisaMardinMersinMuşMuğlaNevşehirNiğdeOrduOsmaniyeRizeSakaryaSamsunSiirtSinopSivasTekirdağTokatTrabzonTunceliUşakVanYalovaYozgatZonguldakCrimeaCherkasyChernihivChernivtsiDnipropetrovskDonetskIvano-FrankivskKharkivKhersonKhmelnytskyiKirovohradKyivLuhanskLvivMykolaivOdesaPoltavaRivneSumyTernopilVinnytsiaVolynZakarpattiaZaporzhzhiaZhytomyrAberdeen CityAberdeenshireAngusAntrimArgyll and ButeArmaghAvonBanffshireBedfordshireBerkshireBlaenau GwentBordersBridgendBristolBuckinghamshireCaerphillyCambridgeshireCardiffCarmarthenshireCeredigionChannel IslandsCheshireClackmannanshireClevelandConwyCornwallCumbriaDenbighshireDerbyshireDevonDorsetDownDumfries and GallowayDurhamEast AyrshireEast DunbartonshireEast LothianEast RenfrewshireEast Riding of YorkshireEast SussexEdinburghEssexFalkirkFermanaghFifeFlintshireGlasgowGloucestershireGreater ManchesterGwyneddHampshireHerefordshireHertfordshireHighlandHumbersideInverclydeIsle of AngleseyIsle of ManIsle of WightIsles of ScillyKentLancashireLeicestershireLincolnshireLondonLondonderryMerseysideMerthyr TydfilMiddlesexMidlothianMonmouthshireMorayNeath Port TalbotNewportNorfolkNorth AyrshireNorth East LincolnshireNorth LanarkshireNorth YorkshireNorthamptonshireNorthumberlandNottinghamshireOrkneyOuter HebridesOxfordshirePembrokeshirePerthshire and KinrossPowysRenfrewshireRhondda, Cynon, TaffRoxburghshireRutlandShetlandShropshireSomersetSouth AyrshireSouth LanarkshireSouth YorkshireStaffordshireStirlingSuffolkSurreySwanseaTorfaenTyne and WearTyroneVale of GlamorganWarwickshireWest DunbartonshireWest LothianWest MidlandsWest SussexWest YorkshireWiltshireWorcestershireWrexhamAlabamaAlaskaAmerican SamoaArizonaArkansasCaliforniaColoradoConnecticutDelawareDistrict of ColumbiaFederated MicronesiaFloridaGeorgiaGuamHawaiiIdahoIllinoisIndianaIowaKansasKentuckyLouisianaMaineMarshall IslandsMarylandMassachusettsMichiganMinnesotaMississippiMissouriMontanaNebraskaNevadaNew HampshireNew JerseyNew MexicoNew YorkNorth CarolinaNorth DakotaNorthern Mariana IslandsOhioOklahomaOregonPalauPennsylvaniaPuerto RicoRhode IslandSouth CarolinaSouth DakotaTennesseeTexasUnited States Minor Outlying IslandsUS Virgin IslandsUtahVermontVirginiaWashingtonWest VirginiaWisconsinWyoming

Industry - None -Academic & ResearchAerospace & DefenseDentalHealthcareManufacturing & PrototypingTransportation & Motorsports

Sub-Industry - Select -Medical Device ManufacturersMedical Contract ManufacturersHospital or Medical ClinicMedical SchoolsOther HealthcareDental ClinicsDental Equipment ManufacturersDental LabsDental SchoolsOther DentalMilitary AviationCommercial AviationDefenseSpace & UAVOther Aerospace & DefenseAutomotiveTruck, Bus & RailMotorsportsAftermarket & ServiceRecreation & MarineOther Transportation3D Printing Service BureausFoundriesElectronics & ConnectorsSemiconductorTurbomachineryJewelryConsumer & Durable GoodsOther Manufacturing

Address

Postal Code

Job Level -- Select Job Level --C-LevelPresident or VPDirectorManagerProfessional StaffConsultant or ContractorIntern or StudentHobbyist

Job Function -- Select Job Function --Engineering - SoftwareEngineering - HardwareManufacturingFinanceITLegalMarketingPurchasingSalesService Technician - HardwareService Technician - SoftwareOther

Level of Interest -- Select Your Level of Interest --Beginning ResearchEvaluating Solutions and CompetitorsInterested in Buying in 1-3 MonthsInterested in Buying in 3-6 MonthsInterested in Buying in 6-12 MonthsI would like to speak with a Solutions SpecialistI have a Support Issue or Question

Area of Interest - Select -Printers• Professional Printer (ColorJet, MultiJet)• Production Printer (SLA, SLS, Metal/DMP)• Figure 4• Titan Additive• OtherSoftwareHaptics• HapticsHealthcare• Virtual Surgical Planning• Anatomical Modeling• Kumovis Additive

3D Printer - Select -MJP• ProJet 2500• ProJet 2500 Plus• ProJet 2500W• ProJet 2500 IC• ProJet 3600• ProJet 5600CJP• ProJet 260 Plus• Projet 360• ProJet 460 Plus• ProJet 660Pro• ProJet 860ProDMP• DMP Flex 100• ProX 200• DMP Flex 200• DMP Flex 350• DMP Factory 350• DMP Factory 500• ProX 100• ProX 300SLS• SLS 6100• SLS 380• sPro 140• sPro 230SLA• SLA 750• ProJet 6000• ProJet 7000• ProX 800• ProX 950Figure 4• Figure 4 Standalone• Figure 4 Modular• Figure 4 Production• Figure 4 JewelryNextDent• NextDent 5100Kumovis• Kumovis R1Atlas• Atlas H• Atlas HSMaterialsBioprinter

Software product - Select -3D Connect Manage3D Connect Service3D Modeling Services3D Sprint3D Sprint Pro for SLA3DXpertGeomagic Control XGeomagic Design XGeomagic for SOLIDWORKSGeomagic FreeformGeomagic SculptGeomagic TouchGeomagic Touch XGeomagic WrapOpenHapticsPhantom Premium

Area of Interest - Select -Medical Device Design and ManufacturingMedical SimulatorsAnatomical ModelsD2P SoftwareDental Manufacturing and Design Services

I consent to receive 3D Systems CommunicationsWould you like to receive special offers, product updates, and event news from 3D Systems? By clicking "Yes", you agree to receive follow-up communications from 3D Systems or our partners. You can also choose to opt out of communications at any time. Please click here to view our Privacy Policy or click here to manage your Preferences.

You can also choose to opt out of communications at any time. Please click here to view our Privacy Policy or click here to manage your Preferences.

Area of Interest - None -Appearance ModelsCast UrethaneCJPCNCCNC MetalCNC PlasticDie CastingDigitalization/ScanningDMPEngineering ProjectsFDMInjection MoldingInjection ToolingInvestment CastingInvestment Casting PatternJigs and FixturesMetal CastingMJPMJP-ElastomersQuick Cast PatternsRIMSheet MetalSLASLSToolingVacuum castingVacuum forming

Custom Area of Interest

PPP

PST

Software

Healthcare

ODM

Area of interest Required

This site is protected by reCAPTCHA. The Google Privacy Policy and Terms of Service apply.

You Might Also Be Interested In

sPro 140

High repeatability and throughput of sls production parts

sPro 230

Large capacity SLS printer for high throughput of tough and durable thermoplastic parts

Commercial & Professional 3D Printer Buyer's Guide 2022 (Under $10,000)

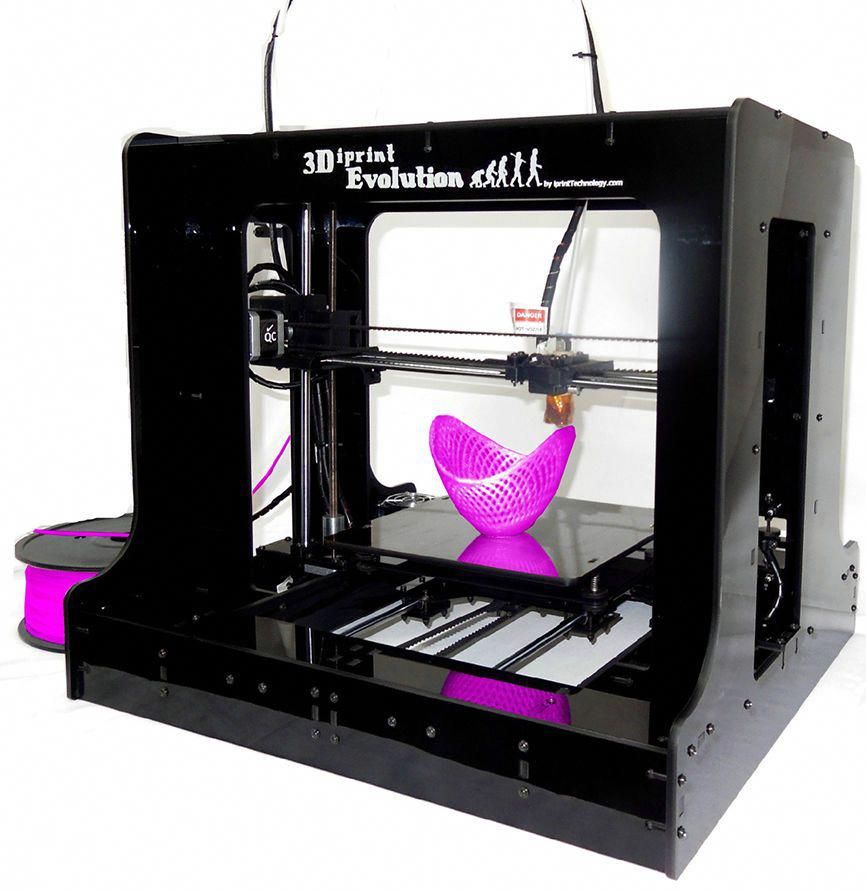

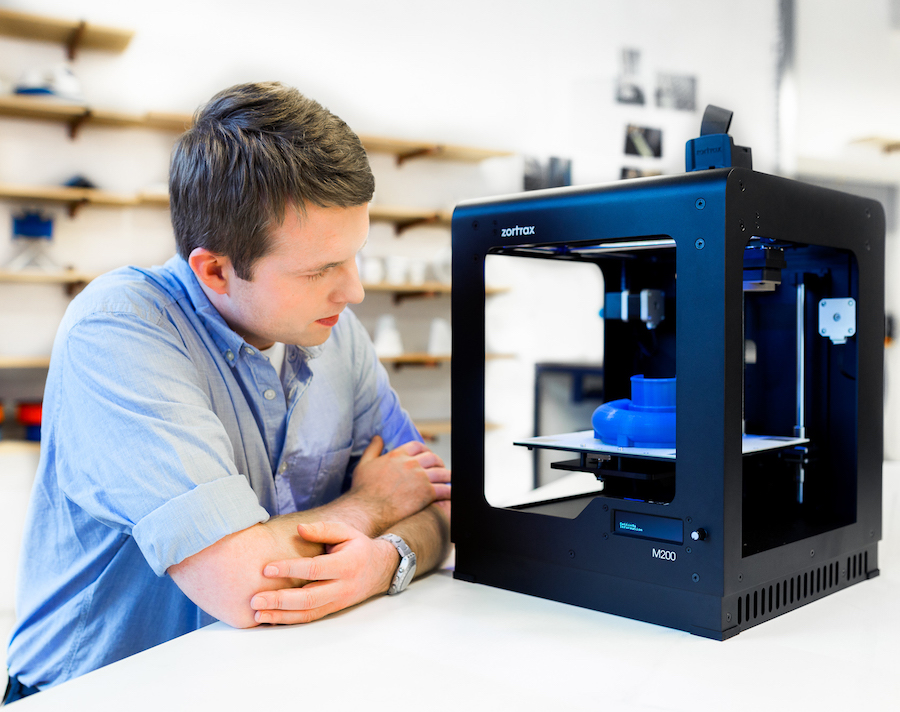

Commercial 3D printers are changing how small businesses manufacture, how designers create and iterate, and how schools, healthcare professionals and engineers work.

These professional 3D printers, more expensive than standard desktop 3D printers but less than $10,000+ industrial 3D printers, allow small businesses to be more effective than ever in prototyping and improving their products.

This article focuses on highlighting the best commercial 3D printers, also known as prosumer 3D printers, production 3D printers, commercial grade 3D printers, or high end 3D printers, that are capable of producing professional-grade parts at decent scale, but cost less than $10,000. We therefore categorize commercial 3D printer price as up to $10,000, with no low end price provided it meets professional and small business 3D printer requirements.

What to expect in a commercial 3D printer?

Commercial grade 3D printers can take many forms: some need an FDM 3D printer that can 3D print PEEK or Ultem filaments, create extremely precise prototypes, or create multi-colored architectural models.

On the other hand, you may need a professional resin 3D printer to create ultra smooth resin prototypes for dental, aesthetic prototypes for items like sunglasses, and much more.

You may also be looking for a professional SLS 3D printer — though they often cost more than $10,000 — for high quality PA12 prototypes, functional parts, and various useful parts for engineers and designers.

Generally however, you should expect the following from a professional 3D printer:

- Commercial grade 3D printing performance: such as powerful heated chambers in FDM 3D printers for tougher material printing and systems for consistent and accurate printing.

- Wide material compatibility: with heated beds and extruders that can reach high temperatures for printing tougher filaments like Nylon, PC, PP, and perhaps even Ultem or PEEK.

- Fast printing and workflow: the best 3D printers for small businesses not only print quickly (at least twice the speed of desktop printers), but the entire workflow — from CAD software, to slicing, to printing, and then to iterating again — needs to be efficient for overall rapid prototyping.

- Very accurate: where resin 3D printers and SLS printers have advantages are in accuracy and surface finish.

Resin printers can reach precisions that FDM printers cannot, so for precise and intricate models, such as characters for films or games, or wax molds for casting into precious metal jewelry, they’re ideal commercial 3D printers. SLS 3D printers require less post processing as they do not print with supports, making them ideal production 3D printers for ready-to-go prototypes made from Nylon.

Resin printers can reach precisions that FDM printers cannot, so for precise and intricate models, such as characters for films or games, or wax molds for casting into precious metal jewelry, they’re ideal commercial 3D printers. SLS 3D printers require less post processing as they do not print with supports, making them ideal production 3D printers for ready-to-go prototypes made from Nylon. - Large printing area: commercial 3D printers should have large enough build areas to support either large prototypes, or the printing of multiple small parts simultaneously, as a scalable production 3D printing system. 3D printers for commercial uses we recommend are typically larger for effective batch production 3D printing.

Our commercial 3D printer comparison sorts low to high price, making recommendations on the best 3D printer for business, for production, and many other 3D printers for different commercial uses.

Prusa i3 MK3S+ — low cost commercial 3D printer for small businesses on a budget

- Price: $999 fully assembled — Available on Prusa Store here / $749 as a kit — Available on Prusa Store here

- Build volume: 250 x 210 x 210 mm

With a price of under $1,000 you’d expect the Prusa i3 MK3S to be limited to standard consumer uses like printing fun models from Thingiverse, or fun basic 3D printing projects. However, it excels far beyond this, functioning as one of the best 3D printers for small businesses if you’re on a tight budget.

However, it excels far beyond this, functioning as one of the best 3D printers for small businesses if you’re on a tight budget.

It can’t compete with higher end 3D printers in some areas, like size of build area, but it’s a fantastic commercial 3D printer for standard size prototypes in materials like PETG, ASA, Nylon, PC, PP, HIPS, and carbon fiber filaments.

Prusa 3D printers are known for their reliability and with an above 200mm/s travel speed, it’s fairly quick for the price. These factors, combined with precise 50-micron minimum layer heights, make it a great overall commercial 3D printer for professional and precise prototype production.

For those looking for a larger 3D printer, a 3D printer for materials like PEEK, or more precise resin 3D printers, keep reading.

Ultimaker S3 — accurate commercial 3D printer for high quality prototypes

- Price: $4,080 — Available on Dynamism here / Available on Matterhackers here

- Build volume: 230 x 190 x 200 mm

The Ultimaker S3 follows the incredibly popular Ultimaker 3, and is an effective production 3D printer for small businesses and engineers capable of fantastic 20-micron resolutions. It can extrude composite filaments from either of its extruders, and can easily print soluble filaments with the dual extruder for easier post processing.

It can extrude composite filaments from either of its extruders, and can easily print soluble filaments with the dual extruder for easier post processing.

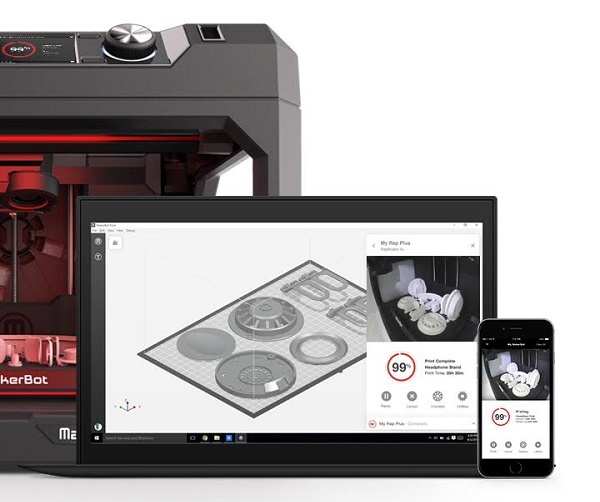

Ultimaker created and develop Cura, the world’s most loved 3D slicer, but also offer more professional 3D printer software as part of their Enterprise packages for commercial 3D printing needs. These premium 3D printer options include the ability to open CAD files in Cura, unlimited storage of your parts in their digital parts library, as well as integrating 3D modeling software like SolidWorks and Autodesk Inventor into your workflow with their plugins. All these make for an efficient commercial 3D printing workflow for quick and effective iterating and part production.

The touchscreen is easy to navigate, and WiFi connectivity makes it quick to access and print your files remotely in their digital library.

As a professional 3D printer, Ultimaker serve not just 3D printers for small businesses, but also huge clients like Volkswagen. The German multinational used Ultimaker 3D printers to produce over 1,000 parts, remarking on the productivity and ergonomics of Ultimaker’s printers.

The German multinational used Ultimaker 3D printers to produce over 1,000 parts, remarking on the productivity and ergonomics of Ultimaker’s printers.

The only factor affecting the Ultimaker S3’s usefulness as a full professional grade 3D printer is the build volume size, which could be larger. However, Ultimaker also offer the S5 for larger print needs, so read on for more information on this.

Ultimaker S5 — all-round excellent production 3D printer

- Price: $6,355 — Available on Dynamism here / Available on Matterhackers here

- Build volume: 330 x 240 x 300 mm

The Ultimaker S5 is the big brother of the already very powerful S3, and a commercial grade 3D printer for high quality engineering parts and accurate prototypes.

The main difference between the S3 and S5 is the larger print volume, a major improvement for those looking for a 3D printer for their small business capable of large prototype printing. It still features the same workflow options, dual extrusion, 20-micron layer heights, and trademark reliability and and precision.

However, you can also turn the S5 into a scalable production 3D printer with the Ultimaker’s S5 Pro Bundle for another few thousand dollars. This bundle adds both a spool holder and top filter. The material handler can hold up to six filament spools, and can automatically change them in and out for different uses as well as protecting filaments from moisture that would deteriorate print quality and protect them from dust, with the environment control filtering out fumes.

- The Ultimaker S5 Pro Bundle costs around $9,550 — Available on Dynamism here / Available on Matterhackers here

The Pro Bundle turns the S5 into the complete commericial 3D printer, able to print continuously, accurately, large parts — everything except super high grade material printing like PEEK and Ultem.

The Ultimaker S5, alongside the S5 Pro Bundle with material holder and environment control add-ons.Formlabs Form 3 — precise professional 3D printer for accurate resin parts

- Price: $3,499 — Available on Dynamism here

- Build volume: 145 x 145 x 185 mm

The Form 3 is sold as a professional quality 3D printer at desktop prices, building on the Form 2’s stellar reputation with incredible resolutions and able to create parts you can barely see the individual layer lines on.

Featuring their LFS (low force stereolithography) tech, layer spot clarity, as well as consistency, surface quality and better translucent material printing are some of the improvements made to the Form 3.

For production engineers looking for a workhorse production 3D printer that can go non-stop, the Form 3 is more than capable, with data on ongoing print performance constantly relayed and alerts if print performance changes so you can make alterations.

You can print in standard resins, or castable wax for jewelry casting, as well as specialized biocompatible commercial grade 3D printing resins for dental uses — which you should instead get the Form 3B for.

Their PreForm software makes preparing your prints easy, and if you’re looking to scale up to a 3D printing factory with multiple printers Formlabs have specialized consulting teams to help, and offer software for managing multiple 3D printers simultaneously.

Raise3D Pro2 Plus — large production 3D printer for small businesses

- Price: $5,999 — Available on Dynamism here / Available on Matterhackers here

- Build volume: 305 x 305 x 605 mm

A true workhorse production 3D printer, the Raise3D Pro2 Plus can work 24/7 without much issue. Able to reach 300°C extruder temperatures, printing with filaments ranging from HIPS, ASA, PP, PVA, flexible filaments like TPU and TPE, Nylon, glass, carbon fiber, metal and wood filled filaments is no problem.

Able to reach 300°C extruder temperatures, printing with filaments ranging from HIPS, ASA, PP, PVA, flexible filaments like TPU and TPE, Nylon, glass, carbon fiber, metal and wood filled filaments is no problem.

As well as the huge build volume and wide material compatibility, the Raise3D Pro2 Plus also offers great precision, with up to 0.01 mm layer heights and 5-micron repeatability. You can change the nozzle out to a smaller or larger one depending on whether your project favors speed or precision.

The large 7-inch touchscreen simplifies your workflow and makes it easy to switch settings or choose your model to print — made easier by Raise3D’s visual model selection previewer. And, if during printing you run into any problems with the power or any other error, the printer can resume from whenever it was stopped without issue.

Marking itself as one of the best 3D printer for business uses, it has some of the largest print areas, as well as an aerospace grade build plate offering excellent adhesion, durability, and preventing warping that can affect or ruin prints — as well as making prints easy to remove. It’s all fully enclosed, so you can effectively maintain and control the chamber temperature to minimize warping and prevent fumes from spreading.

It’s all fully enclosed, so you can effectively maintain and control the chamber temperature to minimize warping and prevent fumes from spreading.

If you want the workhorse benefits of the Raise3D Pro2 Plus, but don’t need the extra Z-axis height building, you can save a couple thousand dollars by going with their standard Pro2 model instead, with a 300mm maximum print height instead of the Pro2 Plus’ 605mm.

Intamsys Funmat HT Enhanced — professional 3D printer for PEEK & Ultem printing

- Price: $7,500 — Available on Matterhackers here

- Build volume: 260 x 260 x 260 mm

For those looking for a specialized PEEK and Ultem 3D printer, the Intamsys Funmat HT Enhanced is the best professional 3D printer for PEEK that’s in most small business’s budget. Costing $6,000 rather than the $20,000+ commonly seen among commercial 3D printers for PEEK, the Intamsys Funmat HT is a great entry-level production 3D printer.

With 90°C constant chamber temperatures, a 160°C heated build plate, and 450°C maximum extruder temperatures from its all-metal hot end, printing PEEK, PEKK, PPSU and Ultem are no problem. However, if you want to use it for printing PEEK as well as more standard plastics you can also do that, with interchangeable nozzles for different printing plastics like PLA and ABS, PC, Nylon, ASA, and more.

However, if you want to use it for printing PEEK as well as more standard plastics you can also do that, with interchangeable nozzles for different printing plastics like PLA and ABS, PC, Nylon, ASA, and more.

Therefore, the Intamsys Funmat HT is a great entry-level production 3D printer for high performance polymer printing. It can automatically level itself with its four advanced drivers offering great precision, and the industrial build platform quality and design features PEI film and glass ceramic materials for great durability and minimal deformation during printing — as well as being safe to use with biocompatible materials like PEEK that may be used to print medical or dental parts.

With PEEK’s extensive use in medical parts, electrical engineering, aerospace, dental, Ultem’s industrial uses, and PPSU’s medical applications, the Intamsys Funmat HT capitalizes on 3D printing’s fastest growing material segment, but at a low price. Intamsys sell their own Ultem and PEEK filaments, and overall, the Funmat HT Enhanced is one of the best 3D printers for small businesses looking to print high performance plastics to either create parts for other companies, or iterate in-house. The Intamsys Funmat HT Enhanced is an ideal professional 3D printer for PEEK without breaking the bank.

The Intamsys Funmat HT Enhanced is an ideal professional 3D printer for PEEK without breaking the bank.

Some other articles you may be interested in:

- The best 3D printers for small business

- Best PEEK 3D printers

- Best industrial 3D printers

- Best 3D printers under $2,000

- Best 3D printers under $5,000

- Best metal 3D printers

What types of 3D printers are there? 3D printing technologies

This article does not pretend to be scientific, but rather a small introduction to 3D printing "for dummies".

What exactly do we mean by the concept of 3D printing?

In the early 1980s, new methods for the production of parts began to develop, based not on the removal of material, as in traditional machining technologies, but on the layer-by-layer production of a product according to a three-dimensional model obtained in CAD by adding materials in the form of plastic, ceramic, metal powders. and their bundles by thermal, diffusion or adhesive methods. And what does this mean in practice? That it became possible to create physical objects in a completely new way.

And what does this mean in practice? That it became possible to create physical objects in a completely new way.

The first to patent this technology back in 1984 was Chuck Hull, who also created 3D Systems in 1986, which is still one of the industry leaders. The first commercial 3D printer, the 3D Systems SLA-1, was introduced in 1987.

Thus, we smoothly approach the story of the first and perhaps the most promising 3D printing technology today, namely photopolymer resin printing. Initially, this technology was called SLA, but over time, this name has become not entirely correct.

Photopolymer printing

The essence of photopolymer 3D printing is that a liquid photopolymer resin solidifies under the influence of light and forms a 3D model. Initially, a laser acted as a light source, and the technology was called SLA or stereolithography.

Despite the apparent simplicity, 3D Systems has spent more than 10 years to bring to market the first full-fledged commercial product. This required a shift in other technological products, such as solid-state lasers, which use a solid-state substance as an active medium.

This required a shift in other technological products, such as solid-state lasers, which use a solid-state substance as an active medium.

Without going deep into the technological wilds, we can say that about 25 years of gradual development of this technology passed until 2013-2014, when SLA 3D printers cost hundreds of thousands of dollars and were available only to large companies, where they were also used very limitedly due to the high cost as equipment and materials.

Created in 2011, a startup called FormLabs reimagined Chuck Hull's ideas and developed the first desktop SLA 3D printer, which began selling for up to $3,000. Thus, it made it possible for a wide range of users to get involved in 3D printing. Over the years, FormLabs has delivered tens of thousands of its printers to market, avoided being taken over by larger players, and became the first 3D printing unicorn to be worth over $1 billion. This story was one of two turning points in the breakthrough made by 3D printing technology in recent years. But other companies also did not stand still and very soon realized that a laser as a light source for illuminating a photopolymer resin is not the only solution, and they proposed another way to form a model, which was called DLP (Digital Light Processing) .

But other companies also did not stand still and very soon realized that a laser as a light source for illuminating a photopolymer resin is not the only solution, and they proposed another way to form a model, which was called DLP (Digital Light Processing) .

Without going into technical details, it is important to note that the advantage of this technology lies in higher productivity due to the illumination of the entire layer at once, in contrast to the laser, which must physically illuminate the entire model, so it must be constantly moved. With a simple example, it is very easy to explain what this means. Suppose you need to print a ring, this task on printers of both technologies will take about the same time, but if you need to print 10 rings at once, DLP technology will take advantage. That is, with a DLP printer, you will print 10 rings in the same time as one, while an SLA printer will spend a certain time drawing each of the rings, although this will make it possible to achieve better quality.

A few numbers...

The Form2 SLA printer takes 11 hours and 22 minutes to print 55 models.

As a result, 12.4 minutes for one ring .

And the Uniz Slash Plus 3D printer, which is based on DLP technology, will spend only 3 hours 51 minutes printing 6 rings, it turns out one ring in 3.8 minutes .

DLP technology gained some popularity and began to compete with traditional SLA, but did not become a breakthrough, when suddenly a new revolution happened - LCD 3D printers appeared on the scene.

The principle of formation is even simpler, a powerful LED lamp, enhanced by a lens system, shines on an LCD matrix, which projects the desired image onto a polymer bath, where a 3D model is formed.

The creation of this technology in 2016 made it possible to reduce the price of a 3D printer by 10 times compared to the FormLabs Form 2 printer that was the hit of that time, the price for budget LCD 3D printers started from $300. This drastic cost reduction has greatly expanded the customer base and has given home users and small print studios the opportunity to try this technology for their needs.

This drastic cost reduction has greatly expanded the customer base and has given home users and small print studios the opportunity to try this technology for their needs.

What is its advantage over others, besides the price itself?

LCD, as well as DLP printers, illuminate the layer immediately, this gives them an advantage in performance, although at first users were faced with not very high quality of the models themselves. But with the advent of 3D printers with a 2K LCD matrix in 2019, and then a little later 4K, this problem was solved, and LCD printers today are superior both in speed and in the minimum layer thickness of their older brothers.

Vivid examples of 2K resolution printers are models - Elegoo Mars, Anycubic Photon S, Wanhao GR1, Phrozen Shuffle Lite, Phrozen Shuffle 2019, Phrozen Shuffle XL 2019, Phrozen Sonic, 4K - Phrozen Shuffle 4K, Phrozen Transform.

The introduction of 8K sensors in the near future, as well as the use of special monochrome sensors that increase print speed, will make this technology dominant in the 3D printer market.

PHOTOPOLYMER 3D PRINTING TECHNOLOGIES:

I hope I was able to convey to you the essence of the differences between these technologies, but now, in fact, I want to tell you why SLA / DLP / LCD 3D printing is most often chosen. Here it is immediately worth dividing printers into industrial and desktop.

industrial 3D printers are mainly used for large-scale prototyping, as well as small-scale production and mold making. With a sufficiently high productivity and good quality of the final products, this equipment is used in the automotive industry, aerospace industry, and also for printing massive objects, such as this mammoth bone, printed by Materialize in cooperation with the Belgian Royal Institute of Natural Sciences in Brussels.

Desktop SLA/DLP/LCD printers are widely used, primarily in such areas as dentistry, jewelry, ship and aircraft modeling, as well as the manufacture of unique gifts and souvenirs. You can read more about this in our articles on these topics.

You can read more about this in our articles on these topics.

The use of a 3D printer in dentistry

3D printing in prototyping

The use of a 3D printer in jewelry

3D printing in small-scale production

High detail and high-quality finish makes this 3D printing technology an excellent tool for solving numerous problems that previously had to be solved in much more time-consuming and expensive ways in the areas of activity that I mentioned above.

Photopolymer printing on a 3D printer in dentistry.

Photopolymer 3D printing in jewelry. On the right is a 3D printed master model of the bracelet.

Photopolymer printing for prototyping

3D Resin Printing Souvenirs

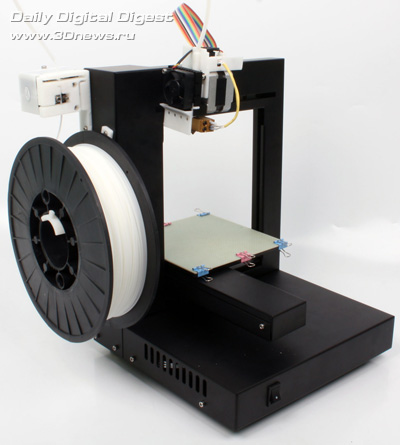

FDM 3D Printing Development Path

The second father of 3D printing can be safely called S. Scott Crump, who at 19In 1988, he patented FDM (Fused Deposition Modeling) technology, and in 1989, together with his wife, he created Stratasys, which is still one of the main companies in the industry.

Scott Crump, who at 19In 1988, he patented FDM (Fused Deposition Modeling) technology, and in 1989, together with his wife, he created Stratasys, which is still one of the main companies in the industry.

The abbreviation FFF (Fused Filament Fabrication) is also often used for this technology, but this should not mislead you. The essence of the technologies is the same, but the names are different in order to avoid patent disputes.

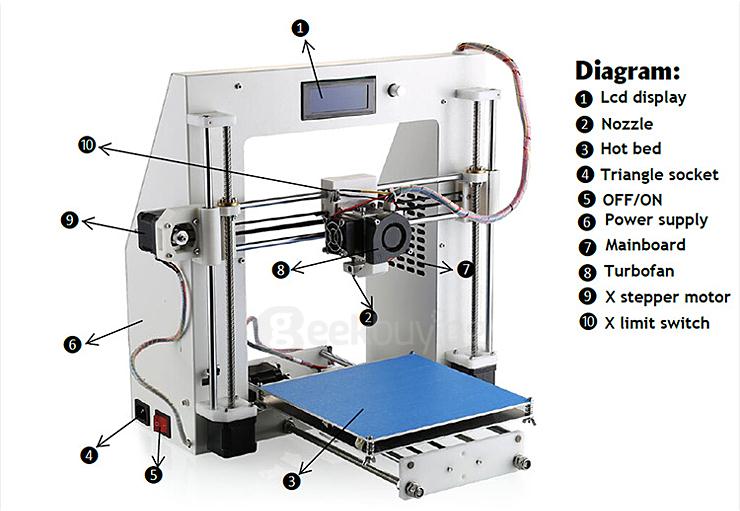

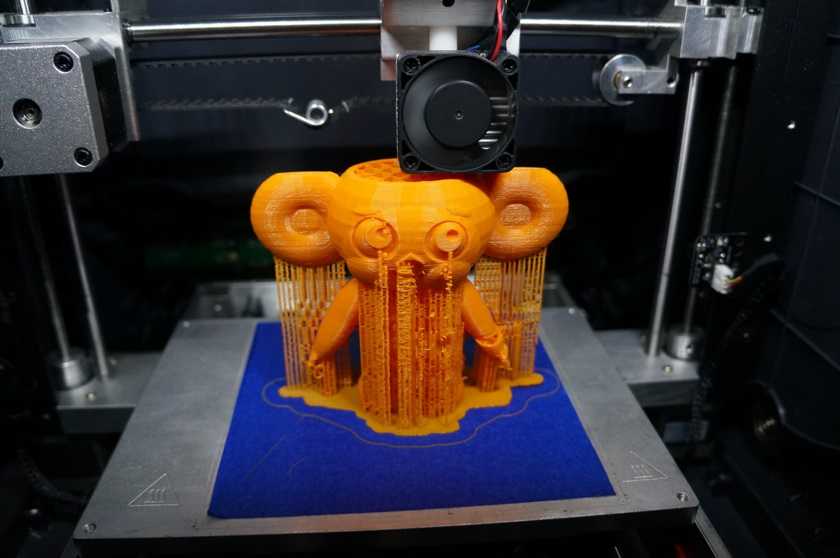

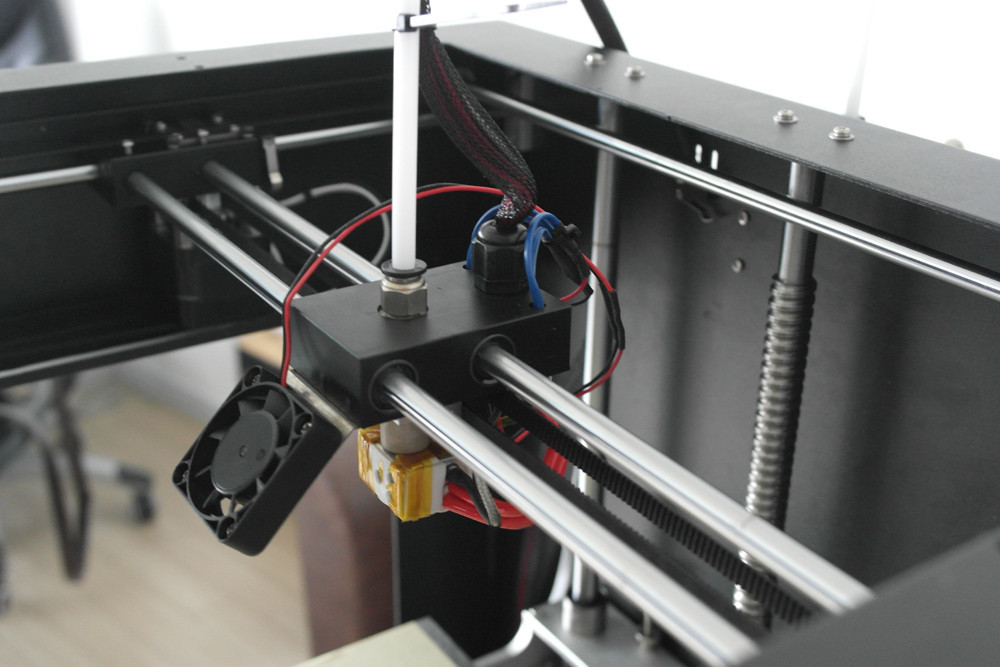

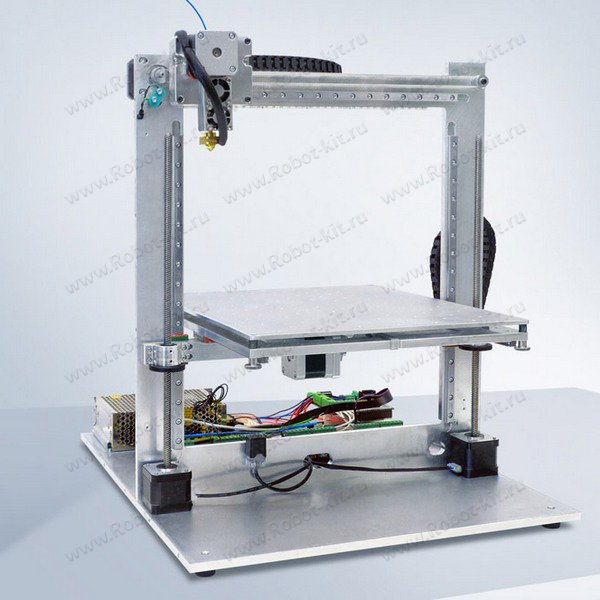

So, what, in fact, was invented. The essence of the idea was that a plastic thread is fed into an extruder, where it melts at a high temperature and forms a model in layers through a small nozzle.

Based on this invention, Stratasys began to produce industrial 3D printers, which were mainly used as well as the first SLA machines in the automotive industry, aerospace industry, and with the advent of various durable plastics such as polycarbonate (PC), polyetheretherketone (PEEK), polyetherimide (PEI, Ultem), polyphenylsulfone (PPSF/PPSU), and for functional prototyping. This technology did not become widespread until more than 20 years later, the RepRap (Replicating Rapid Prototyper) project, a self-replicating mechanism for rapid prototyping, appeared.

This technology did not become widespread until more than 20 years later, the RepRap (Replicating Rapid Prototyper) project, a self-replicating mechanism for rapid prototyping, appeared.

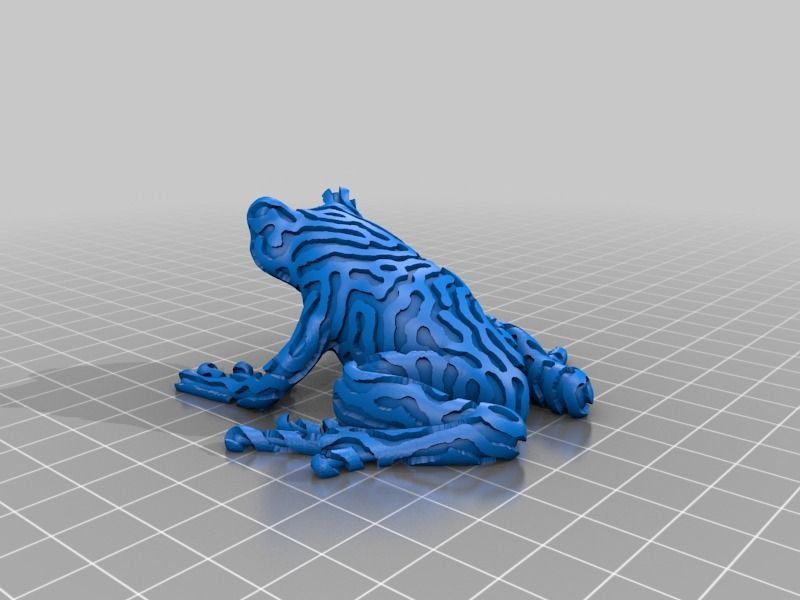

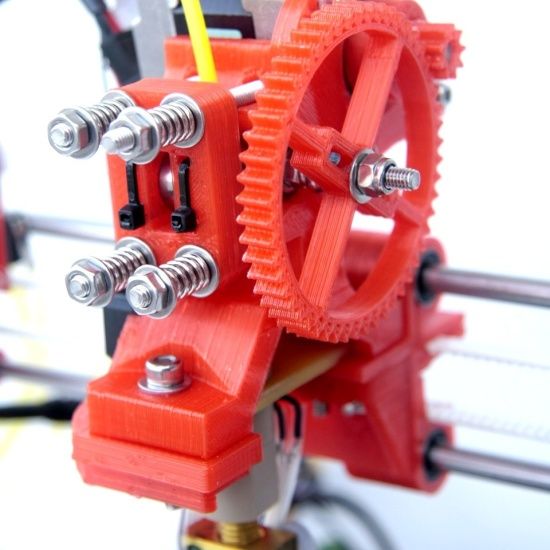

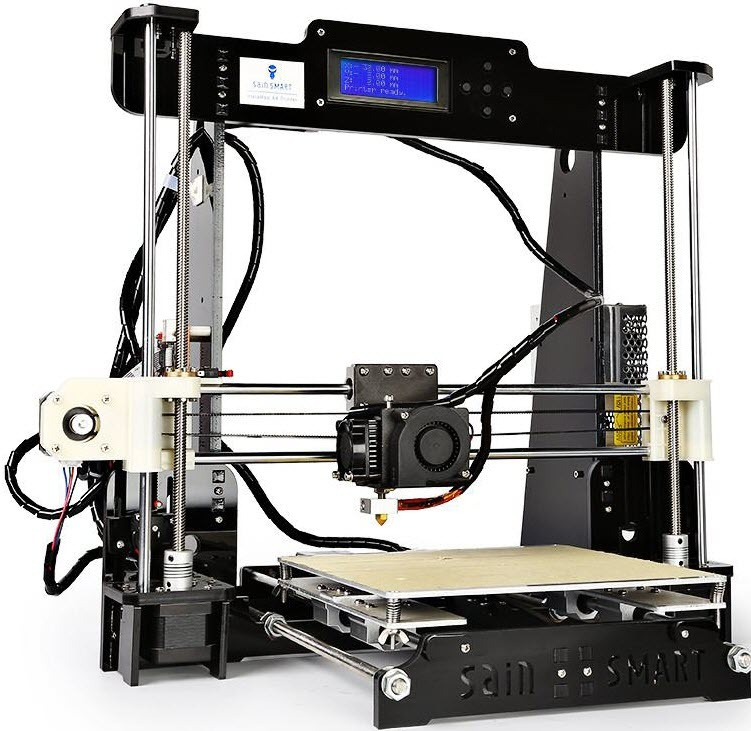

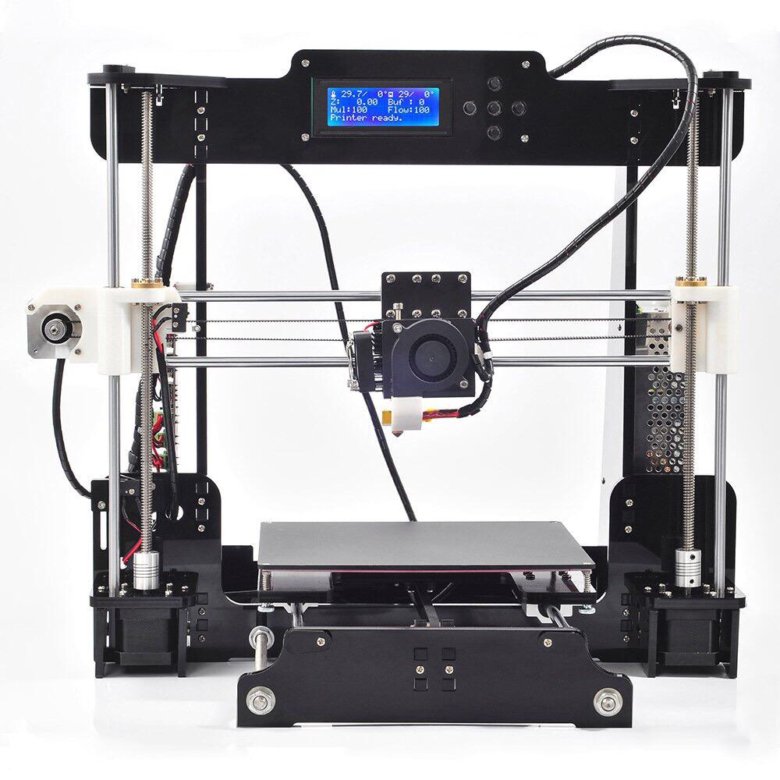

The original idea was to create a 3D printer that another 3D printer could print, in this photo all the plastic parts of the "child" are printed on the "parent". In fact, something completely different happened - a group of enthusiasts were able to create a budget 3D printer for home or office use. The idea was quickly picked up by three geeks from New York, who created the MakerBot company and began commercial production of desktop FDM 3D printers. This was the second turning point in the modern history of 3D printing.

The cost of printers was about $1000, and this price became quite acceptable for many enthusiasts, technologists, engineers and students who are passionate about the idea of 3D printing.

In 2013, MakerBot was taken over by Stratasys for a record $400 million. The result of all this was that the world received a very interesting technology for creating physical objects. A huge advantage of FDM technology is its cheapness and a large selection of printing materials, which began to appear in large quantities after the start of the spread of 3D printing. FDM printers primarily spread among home users, who began numerous experiments with printing at home, you can read more about this in the article 3D printing as a hobby.

The result of all this was that the world received a very interesting technology for creating physical objects. A huge advantage of FDM technology is its cheapness and a large selection of printing materials, which began to appear in large quantities after the start of the spread of 3D printing. FDM printers primarily spread among home users, who began numerous experiments with printing at home, you can read more about this in the article 3D printing as a hobby.

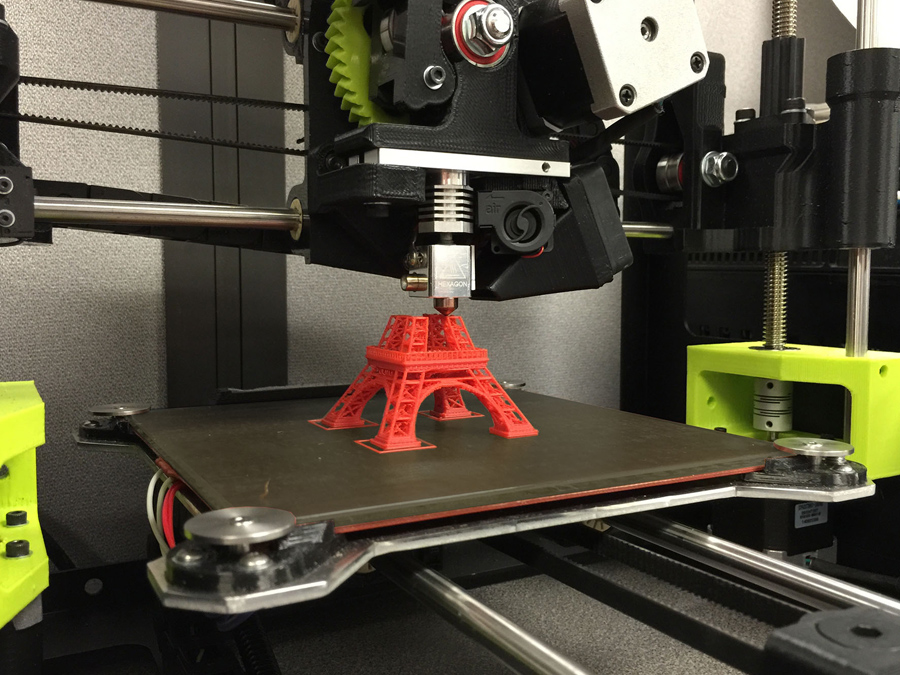

In addition, FDM printing has found its main professional application - prototyping. With the introduction of 3D printing into this process, it will never be the same again. Prototyping has become significantly cheaper and faster, and this made it possible to try many more ideas from engineers to create the highest quality and thoughtful products, more about this can also be found in the article 3D printing in prototyping. There are also active efforts to introduce FDM 3D printing into small-scale production, and this story took an unexpected turn during the COVID-19 epidemic. when doctors urgently needed to produce parts for ventilators, as well as mask holders for doctors who are forced to wear them all day.

when doctors urgently needed to produce parts for ventilators, as well as mask holders for doctors who are forced to wear them all day.

FDM 3D printing was able to fully demonstrate its main advantages compared to classical production, namely the speed of modeling a new model and launching it into series in the shortest possible time, less than one day.

Another major advantage of FDM printing is the wide choice of materials, ranging from biodegradable PLA plastic to materials such as PEEK, which can be sterilized at high temperature and pressure.

In the near future, we expect the widespread introduction of so-called "3D printing farms", which will be able to implement the concept of "flexible production", the essence of which is that such a farm can produce any available product, and not specialize in the manufacture of any specific products. , as happens in a classic production. Today it can be spare parts for old models of railway cars, and tomorrow it can be medical mask holders or souvenir cups for competition winners or plastic end caps for furniture.

In the meantime, let's continue our story about the different types of 3D printing that arose in parallel with the development of the two mainstream technologies that I have already talked about. Many engineers and entrepreneurs in different countries and companies have realized that it is possible to start using the principles of 3D printing using other materials and ways of forming models, and this is what they came up with.

Other 3D printing

SLM (Selective Laser Melting) - selective laser melting, also known as DMLM and LPBF. The principle of 3D printing here is that, under the influence of a powerful laser, metal powder melts and forms a 3D model. This allows you to create models of complex shapes and high strength, most of all this technology has been used in aerospace and medicine. A rocket is not a mass product, and some elements are much more convenient and more profitable to print on a 3D printer than to mill or cast.

Pictured above is the world's largest printed rocket engine. It was printed on the SLM 800 printer by SLM Solutions for the British aerospace company Orbex. The engine is manufactured as an all-metal nickel alloy product. SLM 3DSLM 3D printing has reduced time by 90% and costs by 50% compared to CNC machines.

It was printed on the SLM 800 printer by SLM Solutions for the British aerospace company Orbex. The engine is manufactured as an all-metal nickel alloy product. SLM 3DSLM 3D printing has reduced time by 90% and costs by 50% compared to CNC machines.

In medicine, metal 3D printing has begun to be used to create individual titanium implants made directly for a particular patient, which significantly increases the chances of recovery.

EBM (Electron Beam Melting) - electron beam melting. This is a technology similar to SLS/DMLS, only here the object is formed by melting a metal powder with an electron beam in a vacuum.

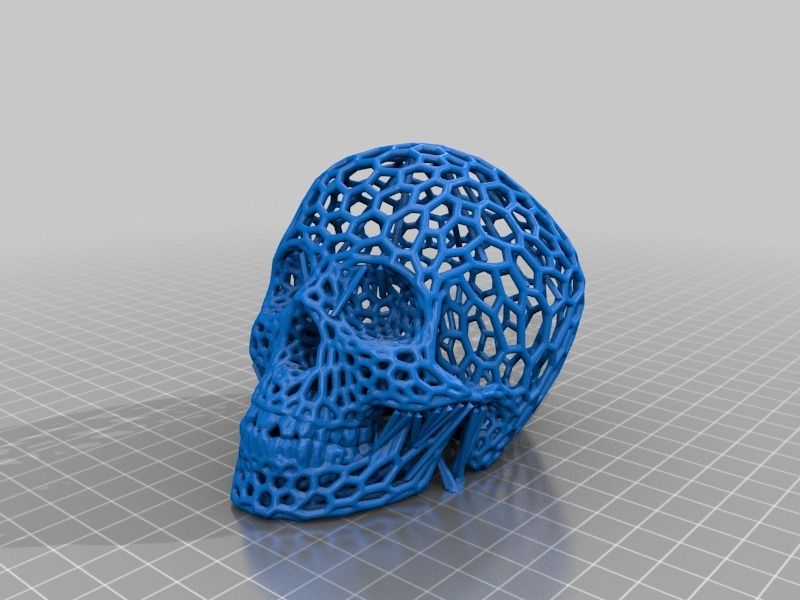

SLS (Selective Laser Sintering) is selective laser sintering, another very interesting technology. The model formation process here is the same as in SLM, but instead of metal powder, polyamide or nylon powder is used. This makes it possible to form very strong, wear-resistant products of complex shapes, which, first of all, can be used as functional prototypes of future metal or durable plastic products.

SLS Printed Engine Manifold

SLS printed furniture

MJF (Multi Jet Fusion) is an original technology developed by HP that essentially repeats the principle of SLS, but does not use a laser. This gives the printer a certain performance advantage over laser technology, as it bakes the layer immediately, just as it does with LCD 3D printers, which we wrote about in detail earlier in this article. Being one of the world's technology giants, HP quickly broke into the small 3D printing market and quickly took a large share in the industrial equipment segment, unfortunately, as of 2020, HP has not started shipping its 3D printers to the Russian market.

Surgical instrument and cylinder block printed on MJF printer

PolyJet is a technology similar to conventional inkjet printing. Liquid polymer is fired through many tiny nozzles onto the surface of the printing platform, after which they are cured using ultraviolet radiation. Using this technology, you can create high-quality full-color layouts and prototypes with the highest level of detail and finish quality comparable to industrial serial samples. Unfortunately, the high cost of equipment and materials does not allow a wider implementation of this technology.

Liquid polymer is fired through many tiny nozzles onto the surface of the printing platform, after which they are cured using ultraviolet radiation. Using this technology, you can create high-quality full-color layouts and prototypes with the highest level of detail and finish quality comparable to industrial serial samples. Unfortunately, the high cost of equipment and materials does not allow a wider implementation of this technology.

MJM (Multi Jet Modeling) is a multi-jet modeling technology similar to PolyJet, but wax can also be used as a material. The technology was developed by 3D Systems, therefore, for reasons of patent protection, it has a different name. Wax printing is widely used in the jewelry business for making individual models to order and creating master models. There are also specialized printers from SolidScape that print with a two-component wax for subsequent melting of the support material in hot water.

CJP (Color Jet Printing) is a technology, the essence of which is layer-by-layer gluing and coloring of powder based on gypsum or plastic. With this technology, you can create full-color products, and this is most often used for printing architectural models and figures of people. The cost of printing in this case is lower than with PolyJet technology, which gives more opportunities for its wider use.

With this technology, you can create full-color products, and this is most often used for printing architectural models and figures of people. The cost of printing in this case is lower than with PolyJet technology, which gives more opportunities for its wider use.

LOM (Laminated object manufacturing) - a technology similar to CJP, but here the building materials are paper, each sheet of which is glued to the previous one, painted with an inkjet printer and perforated. This gives a full color 3D model and is also well suited for architectural and decorative models.

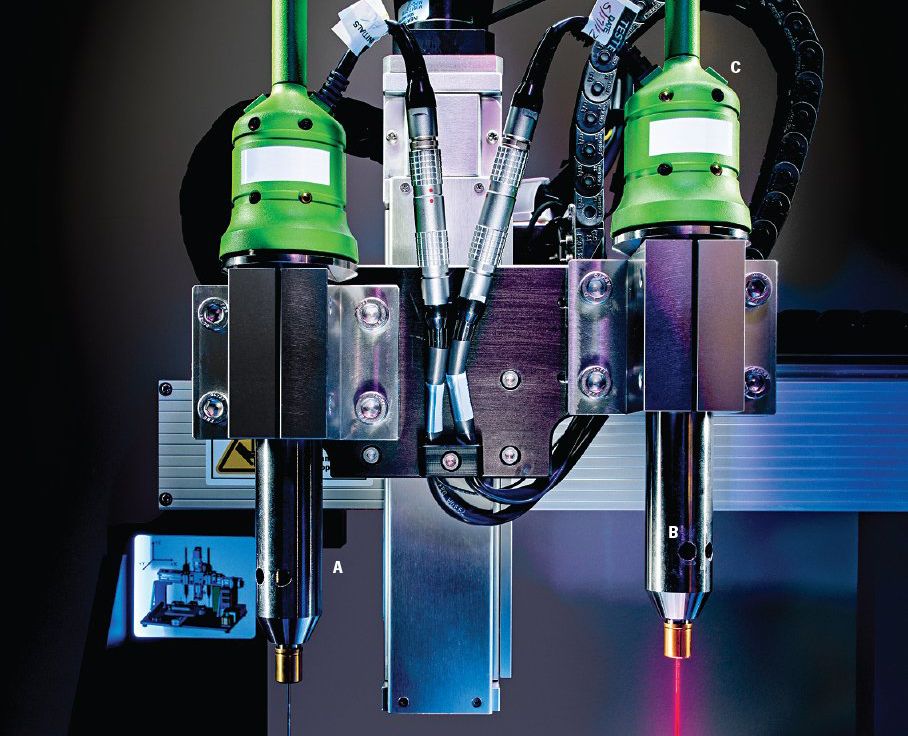

Another technology with great prospects is the combined technology of metal 3D printing, which combines 3 stages of creating a model: printing on an FDM printer with a special composite thread, where metal and polymer are mixed in certain proportions, melting the polymer and baking the metal model. Based on this technology, the American companies DeskTop Metal and MarkForged have already created their commercial models of 3D printers and started selling them both in America and Europe, but so far the technology is very crude and does not guarantee good quality of finished products. But its huge advantage is the significantly lower price of both printers and finished products. These systems have not yet been delivered to Russia, so we are waiting for the opportunity to independently evaluate their quality and effectiveness. In the next few years, this technology may become the most popular of all possible 3D printing methods.

But its huge advantage is the significantly lower price of both printers and finished products. These systems have not yet been delivered to Russia, so we are waiting for the opportunity to independently evaluate their quality and effectiveness. In the next few years, this technology may become the most popular of all possible 3D printing methods.

Studio System+ by Desktop Metal

How it works:

3D printing with ceramics is also a promising direction in various industries. There are a number of companies that produce equipment that prints ceramic models. Various manufacturers use the already mentioned DLP and SLA for this, as a slightly adapted multi-jet simulation technology Ceramic binder jetting (CBJ) . This seal is used in dentistry, jewelry, as well as to create high-quality prototypes with the necessary functional properties. Also, on the basis of FDM printers, printers are being created that print with clay to create ceramic products in a new way. For example, the Italian company WASP has been offering such systems for several years based on its delta printers that print with plastic filament.

For example, the Italian company WASP has been offering such systems for several years based on its delta printers that print with plastic filament.

Construction 3D printers essentially also use the same construction principle as in FDM printers, only liquid concrete is applied instead of a molten filament. This makes it possible to build the walls of a 100 square meter house in about 3 days, which is significantly faster than standard construction methods and, in addition, it makes it possible to create objects of complex shapes. Of course, this direction is promising, but today it has not been widely used, although in China construction 3D printers were used to quickly build autonomous blocks for self-isolation of patients with mild coronavirus, who did not get a place in hospitals, but they were at home dangerous. An interesting fact is that the most promising housing project on Mars is also recognized as a 3D printing method.

House printed by an Irkutsk company in Dubai in 3 days

Coronavirus boxes in China. 15 rooms were made in 1 day.

15 rooms were made in 1 day.

Food 3D printing is another way to use FDM technology, only here the material is edible raw materials. Chocolate printers are the most widely used. The tempered chocolate enters the extruder and forms a 3D model in layers through the nozzle. Because chocolate, unlike plastic, is a very delicate material, so it is not so easy to print with it, although it makes it possible to quickly create customized culinary masterpieces or desserts of unusual shapes. In addition to chocolate, it is possible to print using puree, dough or jam. This technology is still at an early stage of development, and perhaps in the near future we will see more advanced equipment that can be used more widely. One of the representatives of 3D printers for printing chocolate is Choc Creator.

And last but not least, the kind of 3D printing that has very high hopes for the future is 3D bioprinting . At its core, this is a layer-by-layer printing, where living cells act as a material. This is a relatively new type of 3D printing, the first experiments were carried out in 2000 by bioengineer Thomas Boland, who modified conventional desktop printers to print DNA fragments. For 20 years, this industry has stepped far forward, and now, in addition to prototypes of human organs, implants, vascular tubes, heart valves, auricles, cartilage, bone tissue and skin for subsequent transplantation are successfully printed. This type of printing has been successfully used to create "simulators" for doctors, on which they can rehearse operations or for students for live practice. And, of course, one of the main purposes of bioprinting is to print functioning internal organs for transplantation from the patient's biomaterial. So far, this direction is at the stage of development and testing and is not fully used to treat patients, but a large number of successful experiments have already been carried out. Like the heart seal by Israeli scientists in 2019year, while very tiny in size, but the main thing is that it is able to perform its functions.

This is a relatively new type of 3D printing, the first experiments were carried out in 2000 by bioengineer Thomas Boland, who modified conventional desktop printers to print DNA fragments. For 20 years, this industry has stepped far forward, and now, in addition to prototypes of human organs, implants, vascular tubes, heart valves, auricles, cartilage, bone tissue and skin for subsequent transplantation are successfully printed. This type of printing has been successfully used to create "simulators" for doctors, on which they can rehearse operations or for students for live practice. And, of course, one of the main purposes of bioprinting is to print functioning internal organs for transplantation from the patient's biomaterial. So far, this direction is at the stage of development and testing and is not fully used to treat patients, but a large number of successful experiments have already been carried out. Like the heart seal by Israeli scientists in 2019year, while very tiny in size, but the main thing is that it is able to perform its functions. Also, bioprinting has great prospects in the experimental testing of medicines produced by pharmaceutical companies.

Also, bioprinting has great prospects in the experimental testing of medicines produced by pharmaceutical companies.

Of course, I did not manage to cover all 3D printing technologies in this article, but even if you are not a technical expert, you can get a first idea of 3D printing, its various technologies and methods of application. If you are interested in the use of 3D printing in your work or hobby, please contact the specialists of our company and we will always be happy to advise you further.

Alexander Kornweitz

3D Printing Market Expert

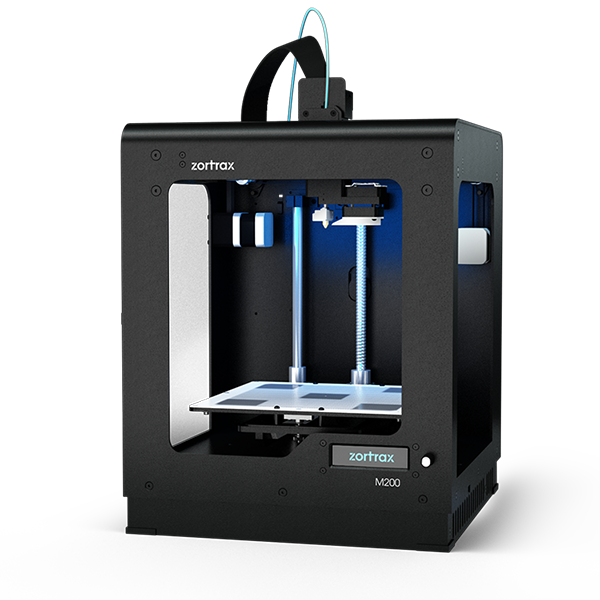

Top 10 3D Printers Available to Buy in 2020

3D printing is relatively new. Therefore, special attention is riveted to it, both experienced and novice users of office equipment. In this article, we will present a list of the top ten 3D printers available for purchase in 2020. Here you will find devices that meet high quality standards, are simple and easy to use, and are also capable of producing large volumes of products. After reviewing the information provided, you can easily choose a 3D printer that suits your requirements.

After reviewing the information provided, you can easily choose a 3D printer that suits your requirements.

In the list you will find the following 3D printer models:

- Original PRUSA i3 MK3s

- CEL-UK RoboxPro

- Ultimaker S3

- FormLabs Form 3

- Original PRUSA SL1

- TRILAB DeltiQ 2

- Raise3D E2

- CEL-UK RoboxDual

- LulzBot Mini 2

- Snapmaker 2.0 A350

Immediately, we note that all printers are diverse and suitable for use in various fields of activity. Therefore, we did not list them in any particular order. Purchasing any printer from the list is a smart financial investment. | Size: 550x400x500 mm | Weight: 7 kg

Advantages:

- excellent working speed;

- high quality printing.

Disadvantages:

- lack of protective walls.

Description: Josef Pruscha is a leader in 3D printing. Their products are famous for their high reliability and long service life. The flagship model is the Original PRUSA i3 MK3s. It is characterized by high speed, low noise and excellent print quality. The most innovative developments are used in the production of the device: Bondtech extruder, P.I.N.D.A. 2, E3D V6 nozzle and thread sensor. The main feature of the printer is that it can be used for a variety of purposes. It is worth noting that the device is supplied both assembled and as a kit for assembly.

3D printer for business

Model:

Cel -uk RoboxPro

9000

Material: thread 1.75 mm | Working area: 210x300x400 mm | Layer thickness: 50-500 µm | Size: 513x508x605 mm | Weight: 26 kg

Advantages:

- interchangeable print heads;

- network connection option.

Disadvantages:

- oversized.

Description: CEL-UK is a leader in 3D printing innovation. Their Robox series printers are the most functional in the FDM class. The flagship model CEL-UK RoboxPro is a direct proof of the above words. The device has a huge set of functions, including: auto-filament, automatic layer alignment, Wi-Fi and the ability to print over a network. In addition, the closed design and interchangeable print heads make it the best choice for businesses.

3D printer for educational institutions

Model:

Ultimaker S3

Material: thread 2.85 mm | Working area: 230x190x200 mm | Layer thickness: 20-600 µm | Size: 394x489x637 mm | Weight: 14. 4 kg

4 kg

Advantages:

- easy to connect to the network;

- high quality printing.

Disadvantages:

- high price.

Description: Ultimaker has been attracting attention ever since 3D printing began to take off. Although representatives of the company have only recently begun to use modern open source software. The new Ultimaker S3 is valued for its fast speed, robust design and excellent print quality. The main features include replaceable cartridges, a touch-screen display and a Cura-branded slicer. Ease of use makes the device indispensable for educational institutions. | Weight: 17.5 kg

Pros:

- high print quality;

- large selection of materials.

Flaws:

- prints need to be reworked (cleaned and trimmed).

Description: FormLabs manufacture SLA 3D printers. These devices use a special liquid resin as the main material for printing. Form 3 is the most compact device in the series. But because of the precise laser that guarantees the highest quality prints, this printer is most suitable for the production of product prototypes, jewelry and various castings. The device is considered the most original 3D printer available on the market.

3D printer MSLA

Model:

Original Prusa SL1

9000

Material: resin 405 nm | Working area: 120x68x150 mm | Layer thickness: 25-100 µm | Size: 400x237x225 mm | Weight: 10.6 kg

Pros:

- high print quality;

- large selection of materials.

Flaws:

- prints need to be reworked (cleaned and trimmed).

Description: With the Original PRUSA SL1, Josef Pruša's company was able to conquer the SLA 3D printer market (previously they worked only in the field of FDM technologies). True, the device was classified under the MSLA subcategory, due to the fact that it uses an LCD matrix and an ultraviolet LED backlight for resin processing, instead of standard high-precision lasers. Despite the fact that the printer consists of cheap components, the print quality meets the highest standards. | Size: 410x500x810 mm | Weight: 10 kg

Advantages:

- advanced technology;

- versatility and versatility of use.

Disadvantages:

- difficult to master the printer.

Description: In this 3D printer, the print head is mounted on 3 articulated supports. This is what distinguishes it from conventional 3D printers. This approach allows you to reduce the space occupied by the device, as well as the amount of additional equipment used. At the same time, TRILAB DeltiQ 2 is characterized by a large working area and a wide range of features. The device has an E3D hotend extruder and a Wi-Fi Duet 2 panel. In addition, the printer can be connected and controlled from a smartphone.

This is what distinguishes it from conventional 3D printers. This approach allows you to reduce the space occupied by the device, as well as the amount of additional equipment used. At the same time, TRILAB DeltiQ 2 is characterized by a large working area and a wide range of features. The device has an E3D hotend extruder and a Wi-Fi Duet 2 panel. In addition, the printer can be connected and controlled from a smartphone.

3D printer for work

Model:

RAISE3D E2

Characteristics: 0 NECK Material: thread 1.75 mm | Working area: 330x240x240 mm | Layer thickness: 20-250 µm | Size: 9039Ø 607x596x465 mm | Weight: 40 kg Features: Disadvantages: Description: The Raise3D E2 is a printer capable of producing high quality FFF prints. Great for home, education, medical and business. The printer is equipped with two independent extruders. Has a strong and reliable design. In addition, the 3D printer is easy to operate and maintain. Such an apparatus will be able to meet the needs of any consumer involved in modeling, design or design. High quality of the press is provided with automatic calibration of a platform. 9Size:

Advantages:

- robust construction;

- easy to operate.

Disadvantages:

- use only branded consumables.

Description: The printer went on sale in 2016 but is still the best in its segment. Equipped with a dual extruder, smart spools, autoloader, self-levelling and flexible platform, the CEL-UK RoboxDual allows you to quickly prepare the material, as well as fully control the printing process. The device is adapted to work in any conditions. Therefore, it is great for both home and industrial use.

Equipped with a dual extruder, smart spools, autoloader, self-levelling and flexible platform, the CEL-UK RoboxDual allows you to quickly prepare the material, as well as fully control the printing process. The device is adapted to work in any conditions. Therefore, it is great for both home and industrial use.

3D printer for newcomers

Model :

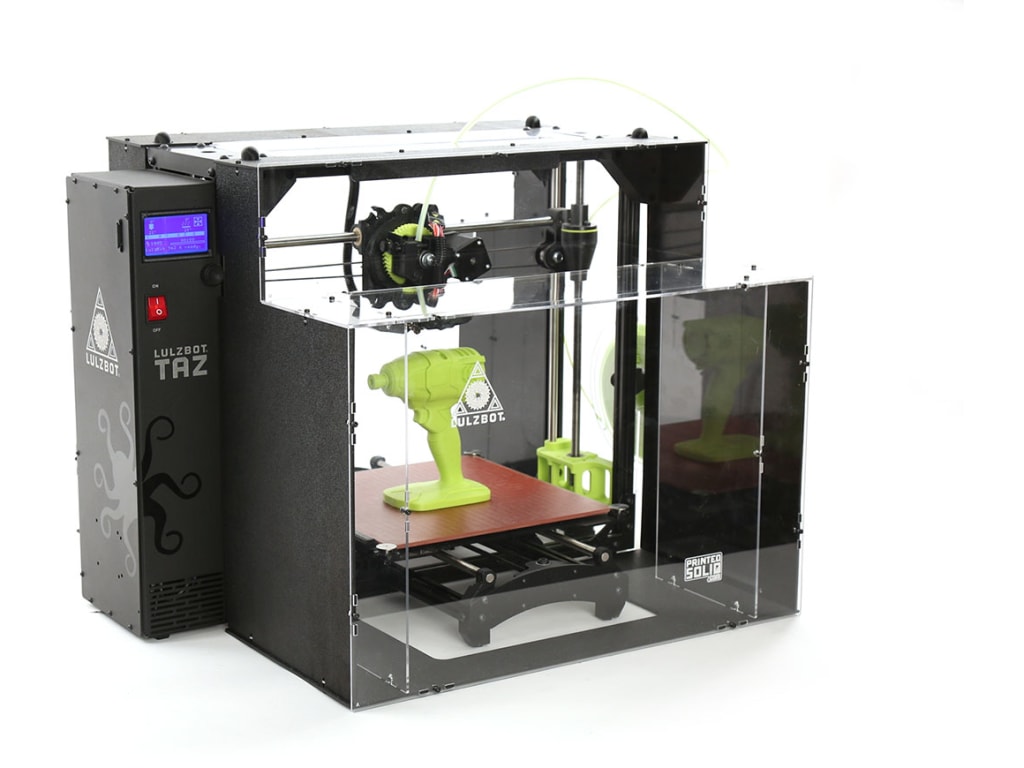

Lulzbot Mini 2

9000

Features:

- Open source software;

- ease of operation.

Disadvantages:

- lack of protective walls.

Description: If you are just learning the basics of 3D printing, then start with the LulzBot Mini 2 printer. Another important advantage of the device is its moderate overall dimensions. The compact design and light weight allow this printer to be placed on a typical desktop. | Size: 645x480x580 mm | Weight: 9.8 kg

Advantages:

- multifunctional;

- structural strength.

Disadvantages:

- delay between mode changes.

Description: The Snapmaker 2.0 A350 is a multifunctional device with second generation replaceable modules. The product is capable of performing the functions of a 3D printer, laser engraver and CNC router. Updated filament sensors and an auto-leveling flexible bed ensure high-quality prints. It should be noted that the device is the largest in the series (only three models).