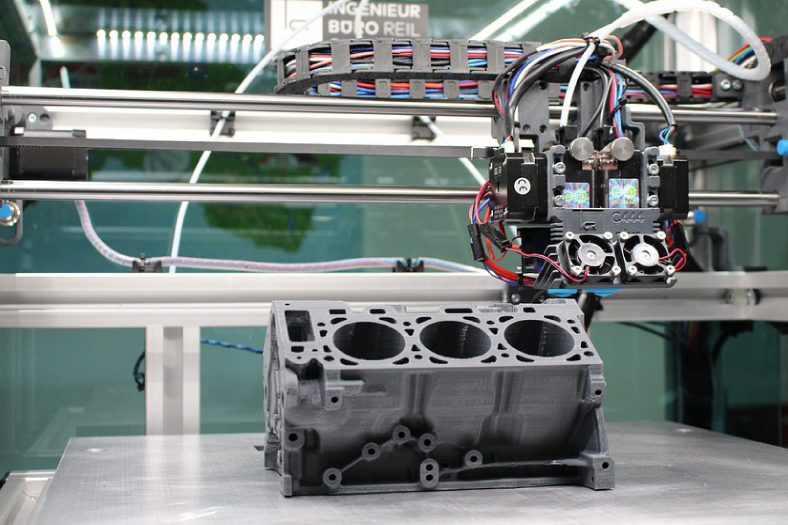

Acetone vapor 3d printer

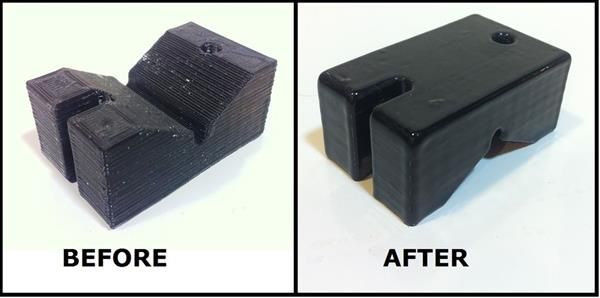

Acetone vapor baths & other ways to remove layer lines

As a low-cost 3D printing material, ABS is one of the most popular filaments among FDM 3D printer users, beginners and experts alike. Although it has its disadvantages — such as a strong smell when printing and a dependence on heated print beds — it creates durable parts that are resistant to fairly high temperatures.

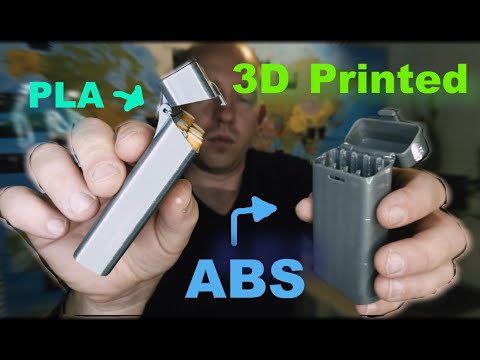

For many casual 3D printing users, the decision often comes down to PLA, PETG, or ABS filament. PLA has a low melting point and environmental credentials, while PETG is highly impact-resistant. But ABS has one unique advantage over its low-cost competitors: it can be easily dissolved with acetone, which means printed objects can be post-processed to give them an exceptionally smooth surface. While other thermoplastics can be dissolved with other solvents, no combination is quite as effective as acetone on ABS.

That being said, smoothing 3D printed parts made of ABS requires a certain level of skill. Acetone is highly flammable and an irritant to the skin and eyes, so it must be handled with extreme caution. Fortunately, this guide explains exactly how you can safely carry out ABS acetone smoothing, as well as part smoothing via other post-processing methods like sanding and polishing.

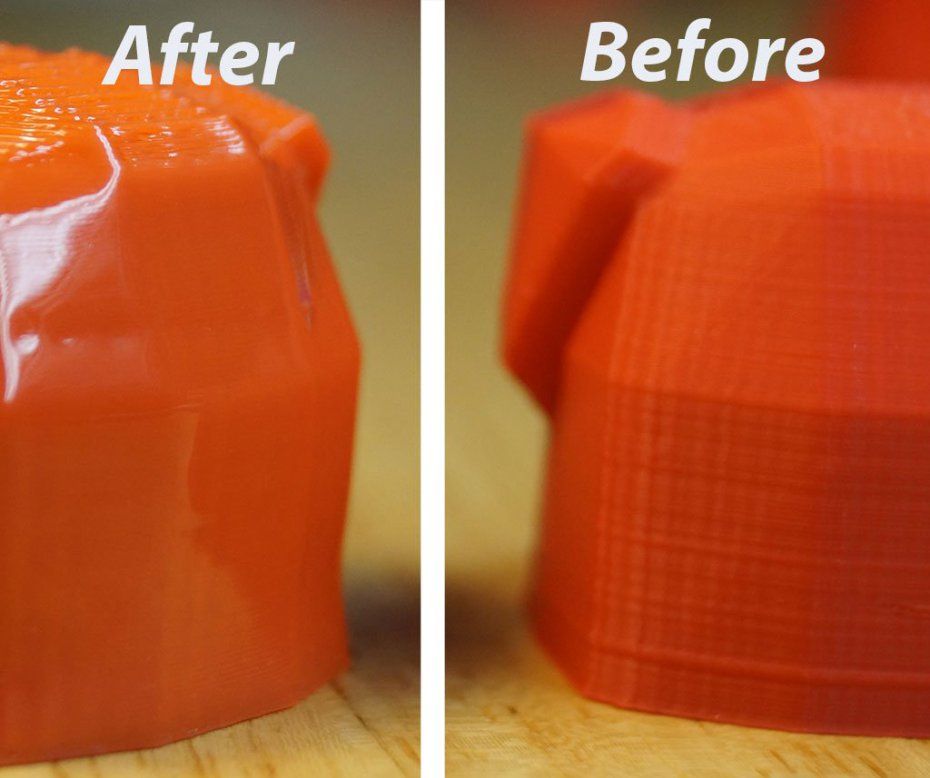

One of the major disadvantages of FDM 3D printing is that it produces visible layer lines — ridges on the surface of a part — as a result of moving from one layer to the next along the Z axis. Layer lines are especially pronounced when using a greater layer height (lower Z-axis resolution) and when printing curved parts.

Smoothing your ABS parts is a way to eliminate the appearance of visible layer lines and change the surface texture of the part from matte to glossy. The process is generally carried out for cosmetic reasons, but it can also have functional benefits: smooth, frictionless parts may be required for mechanical reasons or to facilitate the assembly of multiple components.

You should smooth your ABS prints if you want to maximize the aesthetic quality. However, you should exercise caution when smoothing if the part needs to meet strict dimensional tolerances; this is because smoothing takes away a small amount of surface material and consequently alters the dimensions of the part.

Recommended reading: ABS print temperature considerations: Nozzle, bed, enclosure

If you’re looking to eliminate the appearance of layer lines on your ABS parts, your best bet is to invest in some acetone. This section explains how acetone smoothing works and examines four common methods of applying the solvent to printed parts.

Acetone is a solvent found in nail polish remover

How does smoothing with acetone work?

Acrylonitrile butadiene styrene (ABS) is a thermoplastic polymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. As with all polymers, ABS is resistant to certain substances and vulnerable to others.

As with all polymers, ABS is resistant to certain substances and vulnerable to others.

When it comes to smoothing, the most relevant fact about the chemical makeup of ABS is its solubility in esters, chloroform, ethylene dichloride, and various ketones, of which acetone is one. Substances like chloroform and ethylene dichloride are toxic and require extensive safety precautions, but acetone is milder and much easier to handle in non-controlled environments. It is an active ingredient in nail polish remover, for instance.

So, chemically speaking, why does acetone dissolve ABS? The short answer is that because ABS is soluble in ketones, the presence of acetone causes the ABS (the solute) to dissolve into the acetone (the solvent), forming a sort of soup or slurry (the solution) on the surface of the plastic.

This means that when you apply a small amount of acetone to a 3D printed ABS part, the surface of the part will dissolve. When this is done in a controlled manner, it is possible to dissolve just enough ABS to eliminate imperfections like layer lines, leaving behind a smoother (and fractionally smaller) version of the part. Some researchers have even suggested that acetone smoothing can improve the strength of ABS parts by increasing interlayer adhesion.[1]

Some researchers have even suggested that acetone smoothing can improve the strength of ABS parts by increasing interlayer adhesion.[1]

So what is the best way to smooth ABS with acetone? There are different methods for applying acetone to ABS parts in a controlled manner, and we will explore four of them here, noting which ones we recommend and which we don’t.

Safety measures

Acetone is a highly flammable substance that can irritate the skin and eyes, so it must be handled with extreme care. The following safety precautions should be followed with all acetone application methods:

Always store acetone in a cool, well-ventilated area away from direct light, fire, and any other potential ignition sources

Only open your acetone container in a well-ventilated area, wearing a protective mask to avoid inhalation of fumes

It is recommended to wear eye protection and non-nitrile gloves to prevent potential eye and skin irritation

Method 1: Brush application

The simplest way to achieve a fairly smooth finish on ABS parts is to apply liquid acetone to a 3D printed part with a brush. Deposit a small amount of liquid acetone into a shallow container, then dip the brush into it and apply a very thin coating over the surface of the part.

Deposit a small amount of liquid acetone into a shallow container, then dip the brush into it and apply a very thin coating over the surface of the part.

This method is not highly recommended as it uses a large amount of acetone and produces uneven results: the surface may appear streaked or unevenly smoothed. By applying acetone with a brush, it is also easy to apply too much of the solvent, potentially causing permanent deformation to the part or fully dissolving thin walls.

Method 2: Acetone bath

Another way to achieve a smooth surface finish on ABS parts is to create an acetone bath. This method involves fully submerging the part in a polypropylene (PP) container of liquid acetone for a short period of time, allowing the entire surface of the ABS part to come into contact with the solvent.

This method is not recommended as it requires a very large amount of acetone and can excessively dissolve the ABS part or cause it to warp and twist. Furthermore, removing the part from the acetone requires one of two difficult procedures: either removing the part from the bath (and therefore touching it, potentially causing surface deformations) or draining the liquid into a container underneath (requiring a more complex, multi-container setup).

Furthermore, removing the part from the acetone requires one of two difficult procedures: either removing the part from the bath (and therefore touching it, potentially causing surface deformations) or draining the liquid into a container underneath (requiring a more complex, multi-container setup).

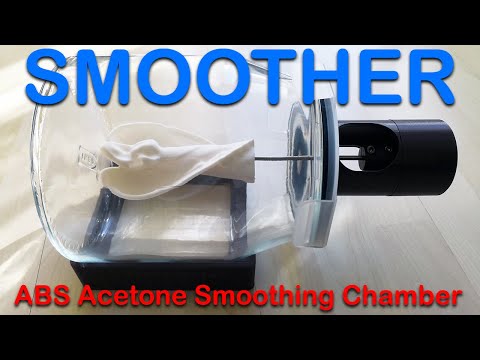

Method 3: Acetone vapor smoothing

A much more effective means of ABS smoothing is the creation of an acetone steam bath or vapor bath. This method does not involve the direct application of liquid acetone to the ABS part, but instead allows acetone fumes to slowly penetrate the surface of the part. This can be achieved by keeping the part and the acetone within a container.

This is the most highly recommended method, both for its safety and effectiveness, and we will explain how to do it with step-by-step instructions.

Create a smoothing box

The vapor smoothing method requires a partially enclosed container to keep the acetone fumes close to the printed part and prevent them from escaping into the room (though the container should not be airtight).

For small ABS parts, you could use a glass container such as a glass jar. For larger parts, or to smooth several parts at once, it is better to use a transparent polypropylene (PP) storage container; these are cheap, available in various sizes, and will not dissolve upon contact with the acetone.

A PP container can function as a smoothing box for vapor smoothing

Place a raised platform in the box

Your ABS parts should not touch the bottom of the smoothing box. You will therefore need a small raised platform on which to place your ABS parts. This platform should not be made from a material that is soluble in acetone, or it will dissolve. Metal works best, and a regular plate coated in aluminum foil is one option.

Soak tissue paper in acetone

Instead of pouring liquid acetone directly into the smoothing box, you need only soak some tissue or paper towels in the solvent before adding the paper to the edges of the smoothing box, either by pressing them firmly against the walls of the container or attaching them with magnets (one inside and one outside the box).

Leave at least a small window of uncovered wall surface so you can see the part while it is being smoothed.

Close up the smoothing box

The vapor smoothing will only work if the smoothing box is closed off, as this prevents the acetone fumes from escaping. If you are using a jar or a storage container with a snap-on lid, lay the lid gently on top of the container without sealing it, and make a few small holes in the lid.

It is critical that the smoothing box is not fully sealed, as this can cause a dangerous amount of pressure buildup.

Let the vapor smoothing take place

The ideal amount of vapor smoothing could take between 10 minutes and an hour. We therefore recommend observing the process through the transparent smoothing box, at least until you have an idea of how long you will need for future prints.

Once the desired smoothness has been attained, you can remove the lid from the box and safely dispose of the acetone-soaked paper. Leave the parts untouched for as long as possible, as their surface will still be soft from the acetone.

Leave the parts untouched for as long as possible, as their surface will still be soft from the acetone.

Add heat and air circulation (optional)

Once you are comfortable with the basic vapor smoothing process, you can improve its efficacy in two ways: by placing the smoothing box on a warm (not hot) surface or by putting a small fan within the box. However, be careful with electronics, as an errant spark could ignite the acetone and cause a fire.

Method 4: Automated acetone vapor smoothing

A much safer and more consistent method of vapor smoothing can be carried out when using a dedicated post-processing machine such as the Zortrax Apoller. Such machines distribute the solvent fumes evenly while maintaining constant air circulation and gentle heat, resulting in the best possible surface finish and meeting strict safety requirements.

Unfortunately, these machines are much more expensive than the DIY method outlined above. Also note that the popular Polymaker Polysher device will not work with ABS and acetone, as it is only compatible with the company’s proprietary smoothable filaments and solvents.

Also note that the popular Polymaker Polysher device will not work with ABS and acetone, as it is only compatible with the company’s proprietary smoothable filaments and solvents.

Advantages | Disadvantages | |

Brushing | Requires minimal equipment | Uneven application Uses more acetone than necessary Easy to damage printed parts |

Bath | Even application | Uses more acetone than necessary |

Vapor smoothing | Even application | Hard to maintain even smoothing with larger parts |

Auto vapor smoothing | Most even application | Expensive |

Sanding

The most common method for smoothing 3D printed parts, sanding, does not require the use of chemicals. Sandpaper is applied manually to the part, and its rough surface removes a small amount of material from the part surface.

Sandpaper is applied manually to the part, and its rough surface removes a small amount of material from the part surface.

When sanding ABS parts, start with coarse sandpaper (80-grit, for example), then gradually move to finer grit (120 and 240). Finally, use a very fine-grit sandpaper (1000) with water to make the parts as smooth as possible. Try to apply even coverage right across the surface of the part. Note that while powered sanders can rapidly speed up the sanding process, the heat generated by these machines can adversely affect printed parts. If you have time, we recommend manually sanding ABS parts.

Sanding is safe and easy to do, but it can be difficult to reach deep crevices in the part and to apply an even amount of pressure over the entire surface.

Sandpaper is a safe and simple alternative to acetone smoothing

Polishing

If you don’t want to deal with a strong solvent like acetone, it is possible to create a high-shine finish for your ABS parts by applying a liquid polish (Brasso, for example) with a piece of cloth. This should be done after sanding, when the surface of the parts is already fairly smooth.

This should be done after sanding, when the surface of the parts is already fairly smooth.

Apply the polish-soaked cloth firmly, making circular motions over the surface of the part until it is fully glossy.

Methods to avoid

Some smoothing methods that work for other thermoplastic filaments won’t work with ABS. For example, isopropyl alcohol (IPA) works just like acetone when printing PVB, but won’t cut through the surface of your ABS parts. Another common smoothing agent is d-lemonene, but this only works for HIPS 3D printed parts. We would also advise against using very strong chemicals like chloroform as a solvent, since acetone is less toxic and just as effective.[2]

Recommended reading: Smoothing PLA 3D prints with sandpaper, solvents, and more

After support removal, smoothing is possibly the most important post-processing technique for FDM 3D printed parts. Smoothing removes unsightly layer lines, giving printed parts the appearance of high-quality injection moldings, and the process can be carried out on a small budget.

Of all common 3D printing materials, ABS is perhaps the best suited to smoothing. Its solubility in acetone provides printer users with an easy route to smooth and glossy parts, making it a highly suitable filament for cosmetic parts such as display prototypes, models, and figurines. In fact, smoothed ABS parts more closely resemble molded or stereolithography parts than as-printed FDM parts.

However, as we have mentioned, acetone smoothing should be carried out with caution. Although less dangerous than other smoothing agents like chloroform, acetone poses risks to human safety, the most significant of which are its flammability and its potential to irritate the skin and eyes. Newcomers to the acetone smoothing process should familiarize themselves with the necessary precautions, investing in a mask and gloves and only carrying out the process in a well-ventilated area.

If these safety precautions are followed, printer users will find acetone smoothing to be a highly effective means of improving the visual quality of their ABS parts.

[1] Gao H, Kaweesa DV, Moore J, Meisel NA. Investigating the impact of acetone vapor smoothing on the strength and elongation of printed ABS parts. Jom. 2017 Mar;69(3):580-5.

[2] Joshi DR, Adhikari N. An overview on common organic solvents and their toxicity. J. Pharm. Res. Int. 2019 Jun;28(3):1-8.

Improve your 3D prints with chemical smoothing

FFF 3D printers like the Original Prusa i3 MK3S enable you to print fascinating models with a very good level of accuracy. Yet sometimes it’s not enough. There are things that require a perfectly smooth and shiny surface – either for aesthetic or functional reasons. With SLA 3D printers, it’s no difficult job. But what about FFF 3D prints? Layer lines are usually quite prominent. Smoothing them out can be accomplished only by proper postprocessing. You might have heard of it, or tried it on your own already – like smoothing ASA/ABS 3D prints with acetone vapors. We still receive a lot of questions about how to make various materials smooth, though. So let us walk you through our instructions on how to make your model perfectly smooth and glossy.

So let us walk you through our instructions on how to make your model perfectly smooth and glossy.

First, we need to remind you that in all cases of chemical smoothing we’ll work with flammable organic dissolvents and/or their fumes. Please follow the recommended safety precautions to protect yourselves and the people around you. Remember that you work with these chemicals at your own risk. Do everything necessary to avoid direct contact with and inhalation of chemicals. Always work in well-ventilated areas, as far as possible from flammable objects and use protective equipment such as gloves and face protection (protective shield or protective glasses). Acetone vapors tend to be very prominent and may cause respiratory issues.

Acetone vapors tend to be very prominent and may cause respiratory issues.

When chemical smoothing is mentioned, many users will probably remember ABS or ASA filaments as materials that can be smoothed easily. This is why we will pay attention mostly to these materials. However, these types of filament are not the only ones which can be smoothed to a certain level. Every material has its own dissolvent (you can find it in chemistry tables) that will smoothen the material sooner or later. However, not every process is recommended, because many dissolvents are usually hazardous materials that are unavailable to a vast majority of people (e.g. chloroform, dichloromethane, etc.). Moreover, dissolving some filaments takes way too long, which makes them impractical for this type of postprocessing. Let’s evaluate several basic combinations of filaments and dissolvents that are often recommended among makers and see what are their advantages and disadvantages.

By far, the most suitable materials for smoothing are ABS and ASA in combination with acetone. You should be able to buy acetone at your local drugstore or hardware store and use it in your home workroom. Prusament ASA, in particular, can be smoothed out easily. And using the right method, you’ll get a nice smooth and shiny surface in no time. We will pay more attention to ABS and ASA in the following chapters.

PVBAnother very popular material is PVB (PolyVinyl Butyral), because it’s also easy to use (like PLA), it’s not prone to warping and it can be smoothed with isopropyl alcohol (IPA). However, if you use IPA vapors for smoothing (as you would with ABS/acetone), the process might take up to several hours. To speed it up, IPA should be applied directly onto the surface of your 3D prints. It’s better to disperse it just like the Polymaker Polysher and Zortrax Apoller do it.

HIPS

HIPS, aka high-impact polystyrene is generally used as a support material for ABS and ASA prints. It can be dissolved with d-lemonene. The best way is to wash the model for 10-20s in lemonene and let it dry (it might take several hours or even days). Curiously, the model will always smell like orange peels as a result of being washed in d-lemonene. We’ve tested that some HIPS can also be smoothed with acetone (the best way is to use acetone fumes).

It can be dissolved with d-lemonene. The best way is to wash the model for 10-20s in lemonene and let it dry (it might take several hours or even days). Curiously, the model will always smell like orange peels as a result of being washed in d-lemonene. We’ve tested that some HIPS can also be smoothed with acetone (the best way is to use acetone fumes).

HIPS smoothed with acetone (left) and D-lemonene (right)

PLASmoothing PLA is a little bit more challenging. Various internet discussions offer many tips and tricks on how to do it. And apparently, there is quite a lot of people who did it successfully with some of the following methods. The most frequent piece of advice is to use chloroform. However, it is a dangerous chemical that can be obtained only with special permission that most people won’t get. Even we were unable to get our hands on this chemical, so at this point, we can’t confirm whether it works or not.

Another option is to use NaOH (Sodium hydroxide aka lye). We can’t recommend this method either, especially if you intend to do it at home. It’s a dangerous substance and usually, instead of smoothing your print, it will most likely disintegrate the object into small fragments. There is a small chance of getting a better result with various concentrations but we cannot confirm that. More testing in laboratory conditions would be required.

The third piece of advice is using acetone. Our tests confirmed that all colors of Prusament PLA can be glued together perfectly with acetone – it works as a superglue. However, our attempts at dissolving PLA with acetone can be hardly called successful. We printed samples of almost every Prusament PLA and exposed them to acetone vapors. After several hours of exposition, they got a little bit softer, but not even close to being smooth. Then, we’ve tried to apply acetone onto the model’s surface directly using a brush, again with no noteworthy result. Finally, we’ve submerged the models in an acetone bath, which caused partial bleaching of several filaments and total destruction of all models. A short bath won’t cause any particular damage, but after a few hours (or even days), the model will crack not only between layers but also in other directions (it’s caused probably by an effect called “solvent crazing”). It’s interesting that the layers remained visible in every case, no matter what happened to the rest of the mode.

Finally, we’ve submerged the models in an acetone bath, which caused partial bleaching of several filaments and total destruction of all models. A short bath won’t cause any particular damage, but after a few hours (or even days), the model will crack not only between layers but also in other directions (it’s caused probably by an effect called “solvent crazing”). It’s interesting that the layers remained visible in every case, no matter what happened to the rest of the mode.

PLA treefrog bathed in acetone for 3 hours and 48 hours

PETGYou can smooth out PETG, too. The best way is to use dichloromethane. The main advantage of PETG smoothing is the fact that the chemical can be applied with a brush easily – it does not leave marks on the surface and the prints won’t twist afterward (like ABS or ASA). But there’s a catch: dichloromethane is a dangerous dissolvent just as chloroform and can be bought only with special permission. These chemicals should be used only by experienced users with proper protection.

These chemicals should be used only by experienced users with proper protection.

Most of the dissolvents can be applied in several ways but we’ve tried them and confirmed that one solution stands above the rest: the best way to make your print smooth is to expose it to dissolvent fumes. Applying the dissolvent with a brush will most likely consume a lot of the chosen chemical and the surface will never be perfectly smooth and shiny. Plus you risk leaving white marks on the surface. The model could also start to twist and warp. Sinking a 3D print directly into, for example, an acetone bath is also not a good idea. It introduces various issues with the handling of the object – you will most likely touch it while removing it from the bath and damage the softened surface. Plus, the dissolvent can leak inside your model and cause even more damage. Not only that, but it’s usually difficult to estimate the correct submersion time, so in the end, you will more likely spoil the bath with dissolved plastic. ABS/ASA-based objects treated this way tend to twist a lot.

ABS/ASA-based objects treated this way tend to twist a lot.

At this point, we have decided that we need to use dissolvent vapors to smooth out our prints. To do this, we’ll need to build a proper box to succeed. It should have several basic parameters:

First, let’s decide which chemicals we plan to use and choose a suitable material for the box. You shouldn’t use a box made of ABS for acetone smoothing or PETG box for dichloromethane smoothing, because they would quickly dissolve. Since ASA/acetone is the most used combination, we chose a transparent PP (polypropylene) storage box available at IKEA. It’s good to have several boxes of different sizes for various models to save acetone and make the process a little bit faster.

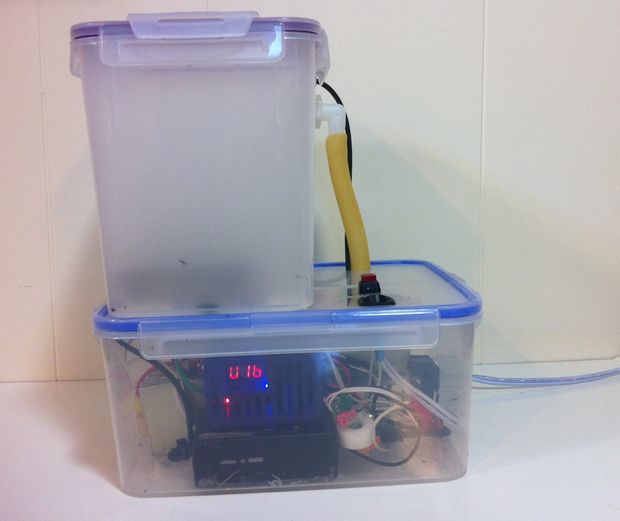

Examples of smoothing boxes: An elevated platform (old and damaged spring sheet works fine) is necessary Electronics are optional and should be used by experienced users only!

The most common and the safest process is placing napkins or pieces of toilet paper soaked with acetone under and around the model. This works well for tiny models. However, with larger models, this becomes much more challenging, because the smoothing effect may not be consistent across the entire surface – e.g. the lower part may be smoother than the top part. Of course, there are some methods that can make this work even with larger models. First, the most recommended and the safest method is getting a professional smoothing station, such as Polymaker Polysher or Zortrax apoller. These machines work at low temperatures, disperse the dissolvent equally and create a nice glossy look. The downside of smoothing stations is their high price.

This works well for tiny models. However, with larger models, this becomes much more challenging, because the smoothing effect may not be consistent across the entire surface – e.g. the lower part may be smoother than the top part. Of course, there are some methods that can make this work even with larger models. First, the most recommended and the safest method is getting a professional smoothing station, such as Polymaker Polysher or Zortrax apoller. These machines work at low temperatures, disperse the dissolvent equally and create a nice glossy look. The downside of smoothing stations is their high price.

There is one more (and cheap) method how to make every model smooth evenly – and that is warming the acetone. But be aware that this method is dangerous and we cannot stress this more – if you decide to heat acetone, you are doing it at your own risk. Do it as far as possible from anything flamable, wear protective equipment (face shield, gloves etc. ) and always check the box (stay in a distance and always watch it). Working in a safe environment is absolutely essential – we can’t stress that enough. If you are not sure about it, use the cold method or buy a professional smoothing station. Better safe than sorry!

) and always check the box (stay in a distance and always watch it). Working in a safe environment is absolutely essential – we can’t stress that enough. If you are not sure about it, use the cold method or buy a professional smoothing station. Better safe than sorry!

Now, if you aren’t discouraged by our safety warnings, let’s see the list of recommended hardware. As we said, we’re going to heat up the acetone bath. Its fumes will increase in volume and if there would be a source of ignition in the sealed box, it could cause an explosion. Please, keep in mind that the box must not be perfectly sealed to prevent pressure build-up inside. We recommend using a light plastic plate with no locks (just lying on top of the box) and making a couple of tiny holes in the lid to help acetone fumes escape. Under no circumstances a box with rubber isolation and any type of locks should be used!

Place a metal plate inside the box and make sure it’s at least a few centimeters (1-2 inches) above the bottom. This will serve as a baseplate for smoothened models. The platform must be raised to prevent direct contact of models with acetone. We found an old printer steel sheet to be the best smoothing pad. We can work with it easily, without touching the models.

This will serve as a baseplate for smoothened models. The platform must be raised to prevent direct contact of models with acetone. We found an old printer steel sheet to be the best smoothing pad. We can work with it easily, without touching the models.

Another thing your box might need is a fan. It is an optional part, but it will truly improve the effectivity due to improved air circulation. Without a fan, your models might get too soft at the bottom, but visible layers on the top might remain. The ventilator should be placed at the underside of the lid, so the airflow is directed right onto the models. Again, safety first: The fan should be working perfectly if you decide to put it inside of the box. Damaged electronics can cause spark and ignite the fumes. If you are unsure about the quality of the fan, do not use it!

The second optional part is a heated pad. Heating will saturate the air inside with acetone fumes better and accelerate the whole process. If you don’t feel like constructing a heated pad, you can also place the box onto a warm (not hot!) surface (a sun-heated pavement, printer heatbed, etc.). However, enthusiasts can build their own integrated heating. Before you try to add a heated element, remember that the heating must be placed outside of the box! It is not a good idea to insert a heater inside the acetone bath!

If you don’t feel like constructing a heated pad, you can also place the box onto a warm (not hot!) surface (a sun-heated pavement, printer heatbed, etc.). However, enthusiasts can build their own integrated heating. Before you try to add a heated element, remember that the heating must be placed outside of the box! It is not a good idea to insert a heater inside the acetone bath!

We are repeating ourselves, but a reminder doesn’t hurt: be careful with flammable organic dissolvents used in the smoothing process! Do not leave the box unattended when the process is running! We are using a smoothing box with a Noctua fan and a heatbed from the MK3S regularly for many months and we experienced no issues. However, we still recommend to exercise appropriate caution!

Amount of acetone, time and temperature

It’s time to test the smoothing box! It might take some time before you find the perfect balance of exposure time, temperature, and amount of acetone. For our setup, the best temperature of heatbed is approx. 80°C, with approximately 5 mm of acetone at the bottom and 20 minutes of exposure. However, keep in mind that you need to check your print regularly: If you expose it for too long, it can deform irreversibly.

For our setup, the best temperature of heatbed is approx. 80°C, with approximately 5 mm of acetone at the bottom and 20 minutes of exposure. However, keep in mind that you need to check your print regularly: If you expose it for too long, it can deform irreversibly.

The model can stay quite soft for several hours after smoothing. Remember that before removing it from the box. You can easily damage the softened surface merely by touching it. It might feel solid if you touch it gently, but don’t be mistaken. It’s better to leave the model on the pad and remove it from the box with it. Take the pad with your models and place it into a dry clean box and leave the models to recover for at least several hours (or even a whole day). This way, you will ensure that no fingerprints are visible on the surface and no dust particles are caught on it.

Don’t be surprised if you find out that the model smells like acetone a few days after. It takes some time for the chemical to evaporate completely.

Not every model is suitable for acetone smoothing. Tiny and complex structures are usually not good since they usually lose their details and/or start to deform. This also applies to large and flat models: for example, this medkit will sooner or later deform after being smoothed in acetone vapors. Plus, ASA and ABS tend to warp during the printing process if you don’t have your printer inside an enclosure.

Tip: If you don’t have any enclosure, set the skirt in PrusaSlicer (Print settings/skirt and brim) to the highest possible number of layers (9999). This will help to create a microclimate and reduce warping a lot. The layer height is also a huge factor. The lower your layer height is, the better the smoothing process gets. Try to experiment with variable layer height to achieve the best results.

It’s good to use an enclosure for ASA prints to reduce warping.

Thin parts tend to twist after smoothing and can become unusable.

Functional (mechanical) parts are not suitable for acetone smoothing. The process can change their dimensions and shapes (especially sharp edges) and it will not improve their mechanical properties – it’s only aesthetical.

A little bit of testing

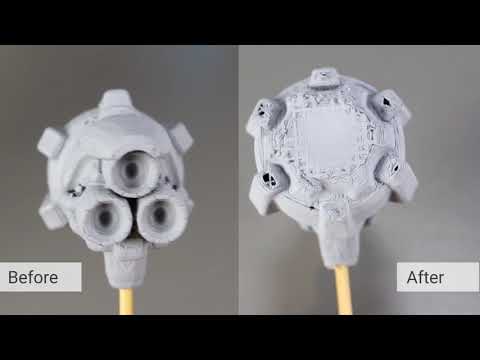

We thought that you might be interested in the comparison of various ABS and ASA filaments. We printed two sample objects (3Dbenchy and a sheep) with 10 different filaments and smoothed them out with acetone vapors. And the results differ – a lot.

Here’s our list of tested brands and materials: Fiberology ABS, Filament PM ASA, ABS, ABS-T, Gembird ABS, Hatchbox ABS, Nebula ABS 702, Prusament ASA, Spectrum ASA 275

The easiest (fastest) to smooth was our Prusament ASA Prusa Orange. For this filament, 15-20 minutes of exposure was more than enough and the result was a nice glossy surface. Most of the other filaments could be smoothed after a little longer time (20-40 minutes) with a few exceptions: ABS-T by Filament PM (green) and Spectrum ABS 275 (blue) had clearly visible layers even after one hour of exposure. With a longer time these models started to deform, but the layers remained visible. Similarly, the layers were visible on grey ASA by Filament PM (fourth from the right). However, what was interesting, was the fact that the perceived layer visibility was caused only by the pigment – the surface was in fact as clear as a mirror.

Most of the other filaments could be smoothed after a little longer time (20-40 minutes) with a few exceptions: ABS-T by Filament PM (green) and Spectrum ABS 275 (blue) had clearly visible layers even after one hour of exposure. With a longer time these models started to deform, but the layers remained visible. Similarly, the layers were visible on grey ASA by Filament PM (fourth from the right). However, what was interesting, was the fact that the perceived layer visibility was caused only by the pigment – the surface was in fact as clear as a mirror.

Finally, we tested a few physical properties of our Prusament ASA Orange. We were interested in the difference between untreated and smoothed objects. We printed 60 test objects for the Charpy pendulum test, 30 sample objects for traction test, and 15 objects for layer adhesion test. Two-thirds of all models were treated with acetone for 30 minutes. The smoothened models were split into two batches, one was dried for one day and second for five days. Then we tested it the same way we did it in our annealing article.

Then we tested it the same way we did it in our annealing article.

The results showed us that smoothened models have slightly better tenacity than the untreated ones, plus they have more than twice better layer adhesion. On the other hand when testing tensile strength, the force at which material tears were a little bit lower for smoothened parts.

As you can see, acetone smoothing is not rocket science. With several simple gadgets, you can make it work even in your garage or workshop without any difficulties. So go ahead and give your models the professional look they deserve 🙂 Just don’t forget about safety! Always use protective equipment, work in well-ventilated spaces, and don’t leave the smoothing box unattended. We’re really curious to see your creations, so don’t forget to share the photos and your own tips and tricks on smoothing. And as always – Happy printing!

Post-processing of PLA and ABS prints with acetone and dichloromethane

06/03/2015

Reviews

Interesting

Comments: 0

In an ideal world, 3D prints always turn out the way we intended them to. But every owner of a 3D printer knows that this does not happen and often you have to remove imperceptible supports from the resulting object and make the surface look smoother. We have a few tricks to help with this fight against props and excess material when post-processing 3D prints from PLA and ABS plastics. nine0003

But every owner of a 3D printer knows that this does not happen and often you have to remove imperceptible supports from the resulting object and make the surface look smoother. We have a few tricks to help with this fight against props and excess material when post-processing 3D prints from PLA and ABS plastics. nine0003

Objects treated with acetone vapor.

The very first thing to consider when working with print supports is your slicer software. When you set it up for a specific printout, you should pay attention to the preferred direction of the props and try to avoid such a direction of as . Your goal is to minimize the number of props and therefore the work that will be required when post-processing PLA and ABS printouts.

How you handle 3D prints depends on the material they are made from, so the next steps depend on the material you choose. When planning 3D printing, it is very important to consider the characteristics of the material, because the methods of working with different materials are different, the processing time and tools depend on the material (PLA, ABS or something else). nine0003

nine0003

-

Safety measures

It is important to note that while both polishing chemicals can be used at home, they are relatively toxic. Therefore, care must be taken when handling these substances. We are talking about the fact that the room should be well ventilated , and on your hands - gloves . Moreover, gloves should not be made of latex (nitrile or neoprene are well suited.

It is also important to note that it is not expected that objects made of PLA and ABS post-processed by this method can later come into contact with food and can be taken in hands and mouths by small children: such objects, even very small ones, dangerous to swallow.

ABS Post-Treatment

The easiest and most effective way to smooth ABS plastic is to use acetone vapor.

You will need:

- Paper napkins

- Acetone

- Foil

- Sealed container

To smooth the printout:

- Remove as much excess material from the printout as possible.

- Line all four sides of a plastic container with paper towels.

- In a well-ventilated area, drop a small amount of acetone into the bottom of a container, covering the bottom with foil. nine0021 Place your 3D print in a container and let it sit there for a few hours until it is smooth enough.

- Remove the printout and allow it to stand in air for a few minutes to allow any residual acetone to evaporate.

- The printout is now polished and ready!

PLA post-processing

For objects made of PLA - instead of acetone in the case of ABS - polishing with Dichloromethane (methylene chloride, DCM) is a good option. This solvent dissolves both ABS and PLA 9 equally well.0003

You will need:

- Non-latex gloves

- Lint-free and undyed cloth

- Dichloromethane (DCM)

To polish the printout

- Remove as much excess material from the printout as possible.

- Put on gloves (not made of latex), take a cloth.

- In a well-ventilated area, dip a cloth in DXM and polish the object with it as if you were polishing shoes - in a circular motion is fine. nine0024

- Allow polished object to dry (in a well ventilated area) to allow excess DXM to evaporate.

- The printout is now polished and ready!

06/03/2015

© 3DPT - Techno 3D - 3dpt.ru

Processing of 3D printed models

One of the problems that all fans of FDM 3D printing, without exception, encounter is the ribbing of external surfaces. Since the technology itself is based on the sequential application of layers of plastic, this effect cannot be avoided. You can, of course, make it less noticeable by increasing the vertical resolution of the printer (i.e. applying thinner layers), but you won’t be able to completely get rid of the ribbing. nine0003

nine0003

PLA 3D model before and after torch treatment. The internal structure is visible under the sagging outer layer

Almost from the very first days of the RepRap project, the search began for methods of processing finished models in order to smooth surfaces. Emphasis was placed on two features of thermoplastics: the ability to melt when exposed to high temperatures and soften on contact with the appropriate chemicals.

As a rule, heat treatment does not give good results - it is quite difficult to control the heating of the surface, and this leads to plastic boiling, sagging or simply emitting toxic fumes. However, this method can be tried on solid PLA models. nine0003

Chemical treatment is more promising, but it also comes with its own set of challenges. In addition to technological problems, the problem of reagents is relevant - different plastics react with different solvents. If acetone perfectly dissolves ABS plastic, then it has almost no effect on PLA plastic. With limonene, everything is exactly the opposite.

With limonene, everything is exactly the opposite.

The main chemical smoothing techniques still revolve around ABS plastic due to its high popularity and low cost of suitable solvents. nine0003

A typical ABS solvent is acetone. Its good dissolving power allows it to be used as an adhesive for component parts of ABS models, although a homemade mixture is usually used for this, produced by dissolving ABS chips in acetone. The same glue (only a thicker consistency) is often used to repair delaminations or cracks.

Along with increased aesthetics, an important factor in the development of smoothing methods is increased strength. The monolithic outer shell reinforces the models, preventing delamination and ensuring their tightness. nine0003

Hand shaping

Makeraser is a combination tool designed to also work on the outer surface of models models. However, processing with a brush is a laborious task, and even requiring a certain skill. After all, already softened plastic is easy to deform with the brush itself, that is, the hairs will leave a mark on the plastic, which may not even out before the acetone evaporates. It is possible to equalize pronounced irregularities with this method, but it is quite difficult to achieve a smooth surface. nine0003

After all, already softened plastic is easy to deform with the brush itself, that is, the hairs will leave a mark on the plastic, which may not even out before the acetone evaporates. It is possible to equalize pronounced irregularities with this method, but it is quite difficult to achieve a smooth surface. nine0003

The advantage of this treatment is the selective application of acetone, which avoids smoothing sharp corners. After all, a pyramid was built for Cheops, not a cone, right?

An attempt to create a special tool for manual processing was a device called Makeraser. Basically, it's a simple felt-tip pen with a reservoir filled with acetone or acetone glue and a built-in scraper to remove models from the platform. From a practical point of view, this tool is best suited for gluing parts of a model or applying ABS/Acetone glue to the build bed just before printing to combat underlayer curl. nine0003

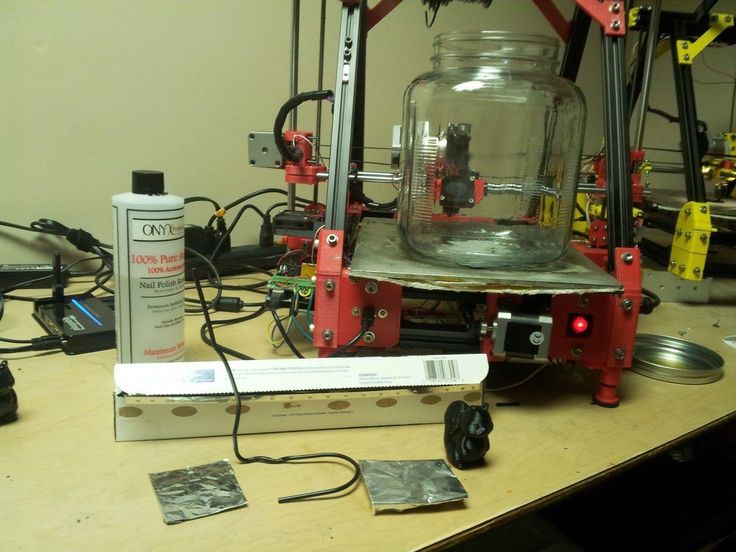

Acetone dip

Failed surface leveling by dip

A more promising and simpler method is acetone dip. Exposure of the ABS model in undiluted acetone for about 10 seconds is sufficient to dissolve the outer layer of the model. The specific exposure time may vary depending on the quality of the original model and the concentration of acetone. Since the sale of pure acetone is regulated, a technical solvent can be used. nine0003

Exposure of the ABS model in undiluted acetone for about 10 seconds is sufficient to dissolve the outer layer of the model. The specific exposure time may vary depending on the quality of the original model and the concentration of acetone. Since the sale of pure acetone is regulated, a technical solvent can be used. nine0003

After exposure, the model must be exposed to air until the acetone has evaporated. The process may take about half an hour.

Although this method is quite fast, it is difficult to control the process. With excessive exposure, the model will simply begin to dissolve, quickly losing small features. In addition, contamination of acetone with plastic of the same color can lead to streaks on subsequent models dipped in the same solution. A more controlled process is acetone vapor treatment. nine0003

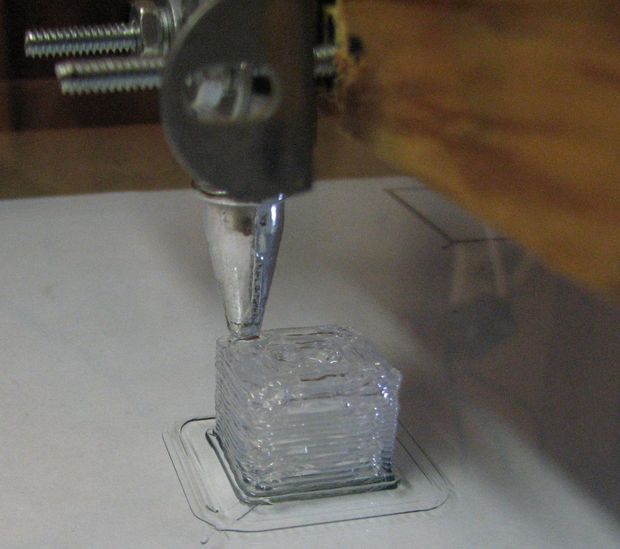

Probably the most efficient way to get glossy ABS models. This method requires placing the model in a container with a small amount of acetone at the bottom. The model itself should not come into contact with acetone, so the model should be placed on a platform or hung above the surface of the solvent. When installing on a platform, the material properties of the stand should be taken into account. Wood is not suitable for this task due to its porosity: the bottom surface of the model will stick to the wood, and it will be quite difficult to separate it. The best option is to use a metal stand. nine0003

The model itself should not come into contact with acetone, so the model should be placed on a platform or hung above the surface of the solvent. When installing on a platform, the material properties of the stand should be taken into account. Wood is not suitable for this task due to its porosity: the bottom surface of the model will stick to the wood, and it will be quite difficult to separate it. The best option is to use a metal stand. nine0003

It is advisable not to use wood as a platform

After placing the model, the container must be heated to increase the temperature of the acetone. Acetone also evaporates at room temperature, but too slowly. Please note that boiling acetone is not recommended, as this will cause condensation to accumulate on the model, which in turn can cause streaks. Thus, for best results, do not exceed the temperature threshold of 56°C. nine0003

A safe, homemade steamer that uses boiling water in an outer pot to heat the acetone in an inner pot.

Holding time varies greatly with the temperature of the acetone. So, when boiling, only a few seconds can suffice, while experiments at room temperature required up to 40 minutes of exposure. Fortunately, using a transparent container, you can determine the readiness of the model "by eye".

As with dipping, the completed model must be aired out before the outer surface hardens, avoiding unnecessary physical contact. nine0003

Both when immersing models in acetone and when working with steam, the wall thickness of the models must be taken into account. The shell must be thick enough to withstand the inevitable loss of the outer layer. In addition, especially subtle features may simply dissolve, and sharp corners will be smoothed out.

Safety Instructions

Results of Successful Treatment of an ABS Model with Acetone Vapors

Acetone is not considered to be highly toxic, but care must be taken nonetheless. Inhalation of vapors can lead to pulmonary edema and pneumonia. A sign of poisoning is a feeling of intoxication, accompanied by dizziness. In addition, acetone causes irritation of the mucous membranes. When working with acetone, do not neglect personal protective equipment - goggles and gloves. nine0003

Inhalation of vapors can lead to pulmonary edema and pneumonia. A sign of poisoning is a feeling of intoxication, accompanied by dizziness. In addition, acetone causes irritation of the mucous membranes. When working with acetone, do not neglect personal protective equipment - goggles and gloves. nine0003

Particular attention should be paid to the flammability of acetone. Air mixtures with an acetone concentration of up to 13% by volume are explosive - when processing with acetone vapors, it is strongly recommended to work in a well-ventilated room and, if possible, use an exhaust hood. Do not use an open fire to heat acetone: since solvent vapors are heavier than air, they will displace air from the vessel, and once outside, they will cool and come into direct contact with the fire with all the ensuing consequences. It is also not recommended to tightly close the vessel, especially with strong heating, in order to avoid destruction under pressure. nine0003

Commercial options

Stratasys Finishing Touch Smoothing Station

In addition to the Makeraser described above, there are also commercially produced units for steaming both acetone and other solvents - dichloromethane, butanone, etc.