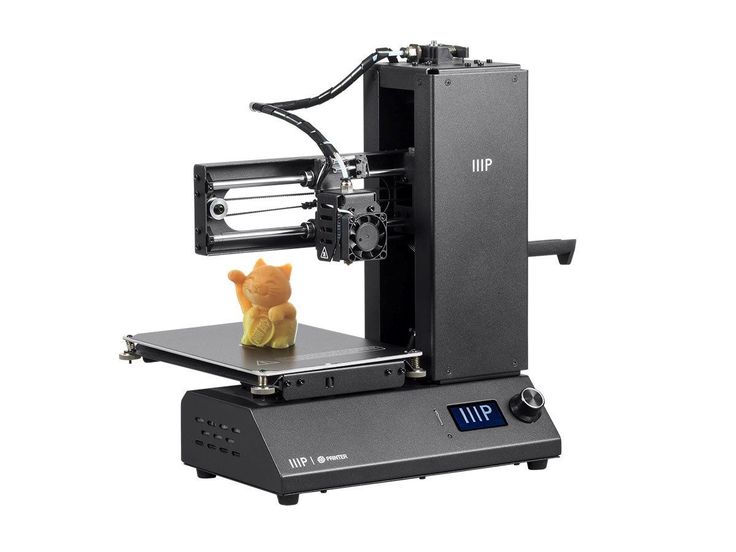

Monoprice maker architect 3d printer

Monoprice Maker Architect 3D Printer Review [2022]: Good Budget Pick?

- About

- Latest Posts

Total 3D Printing Team

3D Printing Experts at Total 3D Printing

We're the Total 3D Printing team and we love to help others learn more about 3D printing. Whether this is your first time checking out 3D printers or you've got multiple 3D printers and want to add more, we're here to help show you the ropes and to give you the information you need to succeed.

Latest posts by Total 3D Printing Team (see all)

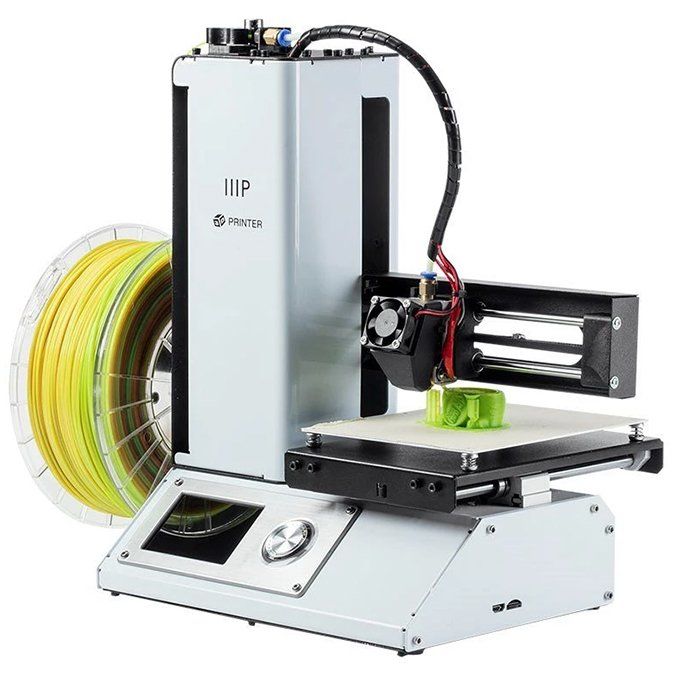

Monoprice has made a name for themselves in the 3D printing world by finding their own niche within the industry. They often reproduce open-source systems and sell them for a fraction of the cost of the real 3D printer. With the low price though, you often still get top-notch quality, at least for some of their models.

Monoprice Maker Architect is a “workhorse” for a fraction of the cost. We put workhorse in quotes as this model has been the middle of a lot of controversies. Some users report amazing reviews of an awesome machine for dirt cheap, while others report a machine that barely stands on its own. It had all the promise of being a break-through.

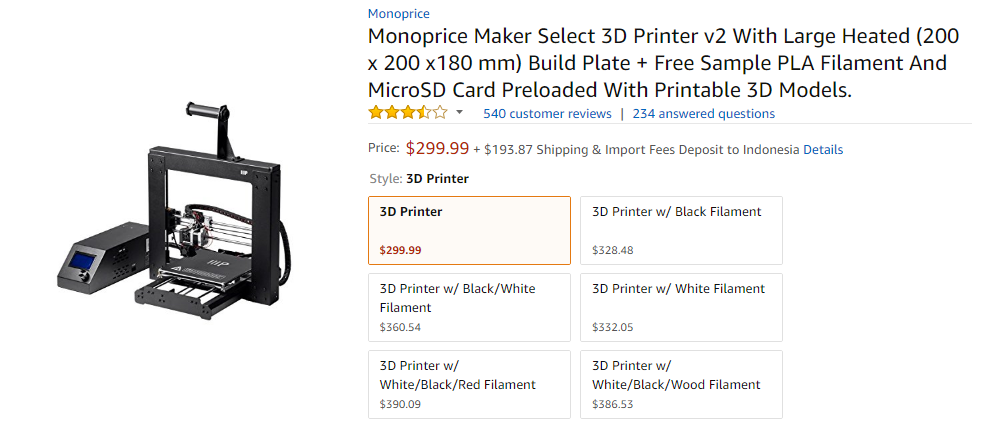

Unfortunately, cutting costs in this situation did not work out. One of the biggest sales of the Maker architect is it is modeled after the Flash Forge Pro and MakerBot Replicator, which each run well over $1,500. You could find the Maker Architect for about $300.

Of course, this is a budget 3D printer, so it does have its limitations. It does not have a heated bed, nor is there an auto-leveling feature. You can upgrade it, but Monoprice no longer supports this machine, so you are on your own with this. But, if you can get past the limitations, this is a decent 3D printer for very few dollars.

Table of Contents

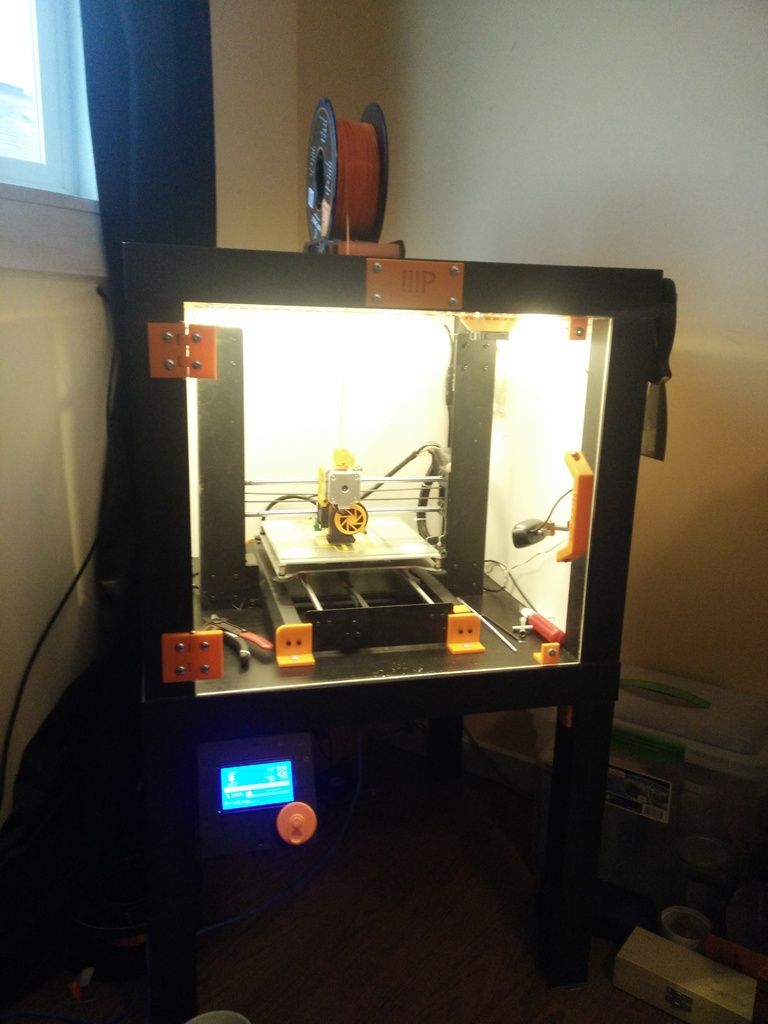

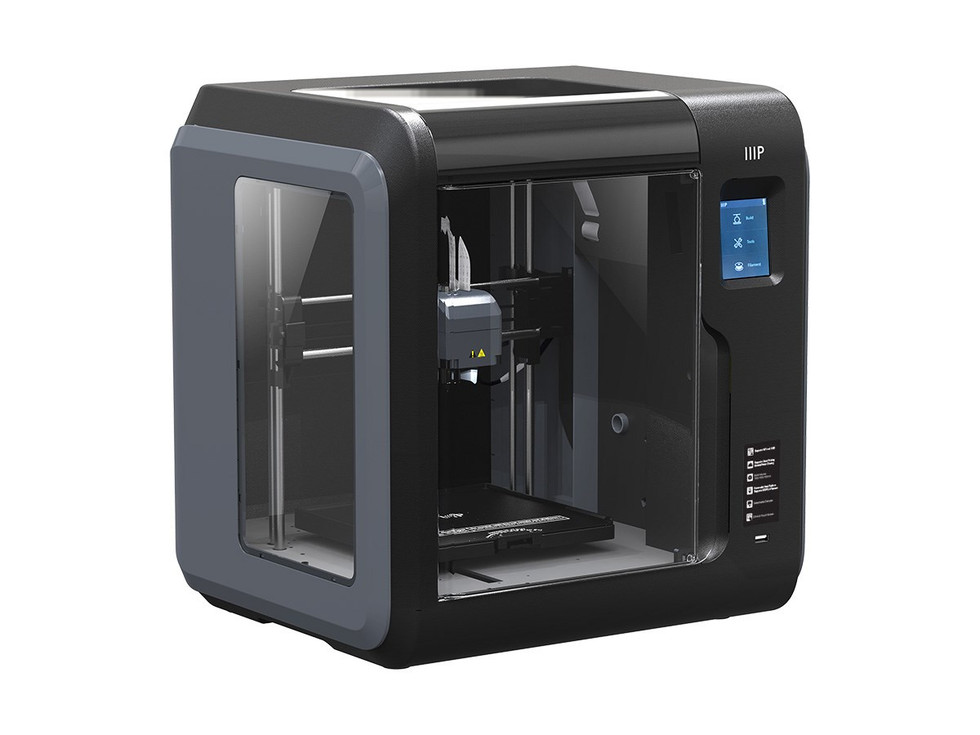

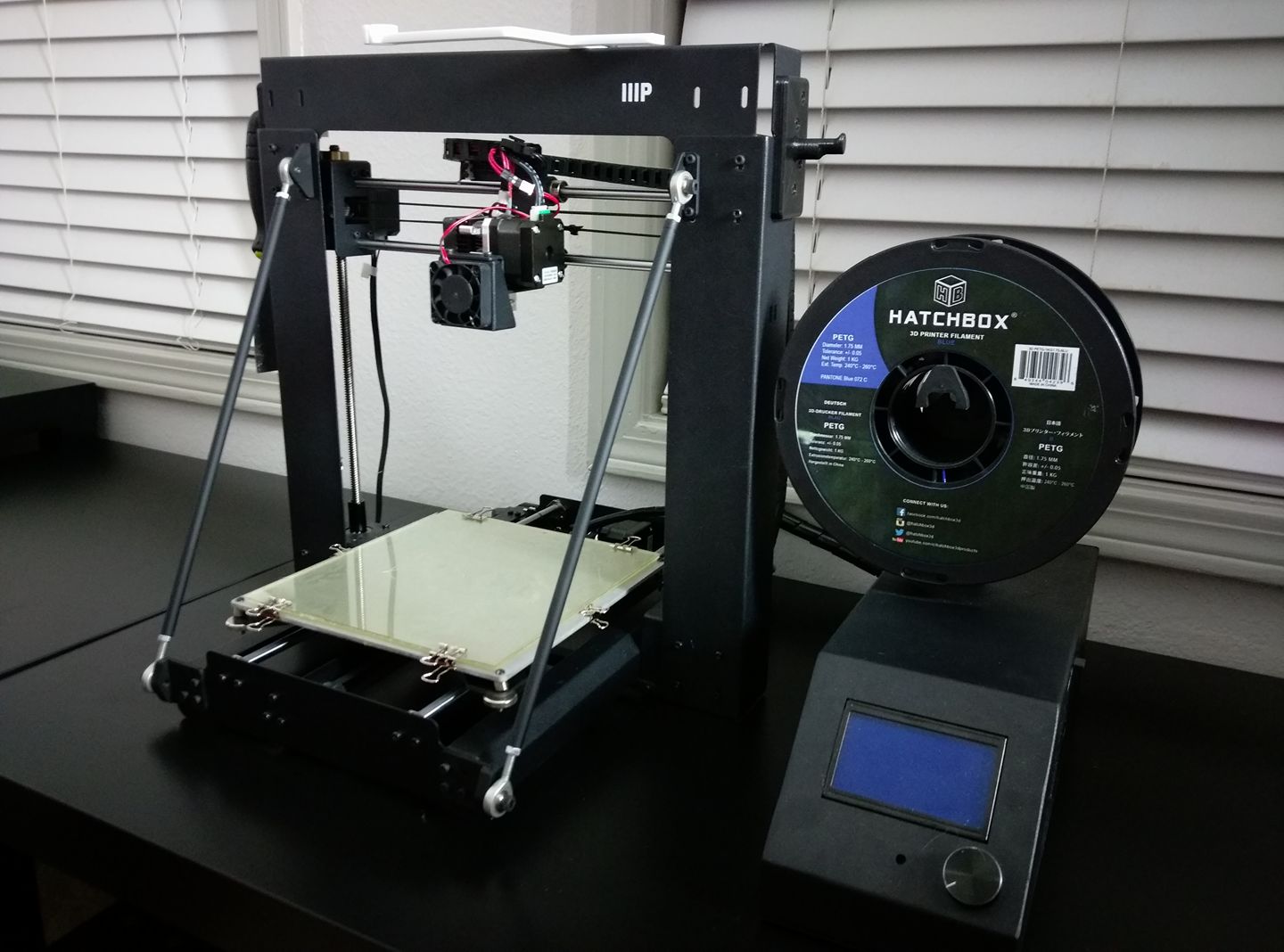

Core Features of the Monoprice Maker Architect:- Wooden Frame: Put the Monoprice Maker Architect right next to the MakerBot Replicator, and you will have a hard time saying which is which.

The Maker Architect uses an extremely similar wooden mostly enclosed design. The top of the machine is open where the wiring and cable run. Other than that, the walls are clear plastic windows framed by thin wood walls. I do really like the design, even if it is borrowed from another printer.

The Maker Architect uses an extremely similar wooden mostly enclosed design. The top of the machine is open where the wiring and cable run. Other than that, the walls are clear plastic windows framed by thin wood walls. I do really like the design, even if it is borrowed from another printer. - FlashForge Mighty Board: As I previously mentioned, Monoprice is known for using open source 3D printers as the basis for their models. They took it as far as installing the FlashForge Mighty Board in the Maker Architect. This is the main control board for 3D printers. So you were essentially getting a FlashForge 3D printer brain inside of a MakerBot Replicator frame. Find one online where they sell for under $300, that’s a steal.

Here are the key specs of the Monoprice Maker Architect 3D printer:

| Build Area | 8.9″ x 5.7″ x 5.9″ |

| Filament Types | PLA |

| Extruders | 1 |

| Nozzle Diameter | 0. 4 mm 4 mm |

| Open/Closed System | Open |

| Warranty | None |

| Price | Discontinued |

Some of the “nice to have things” on the Monoprice Maker Architect:

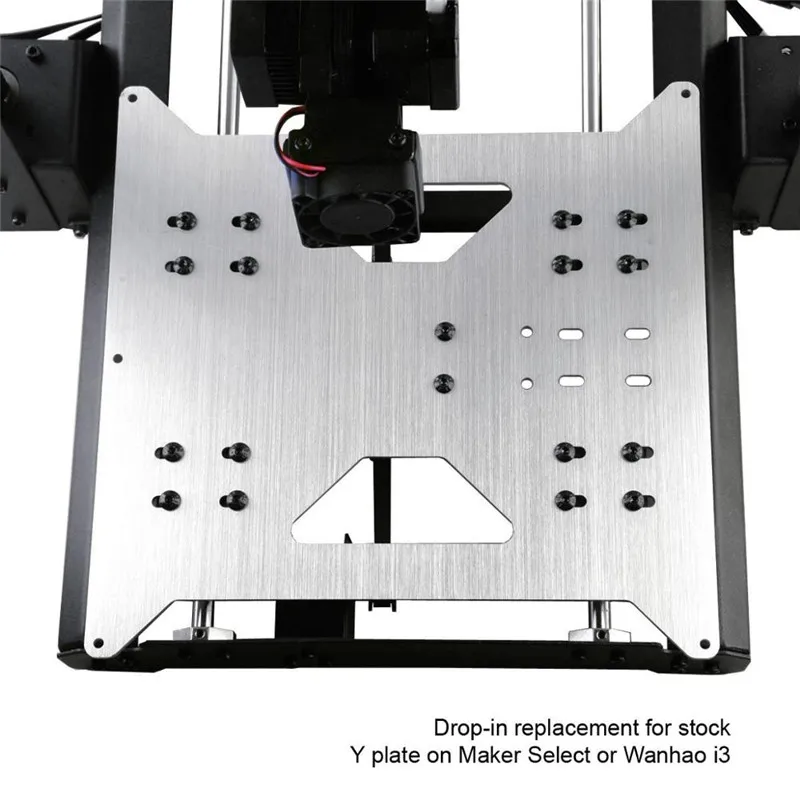

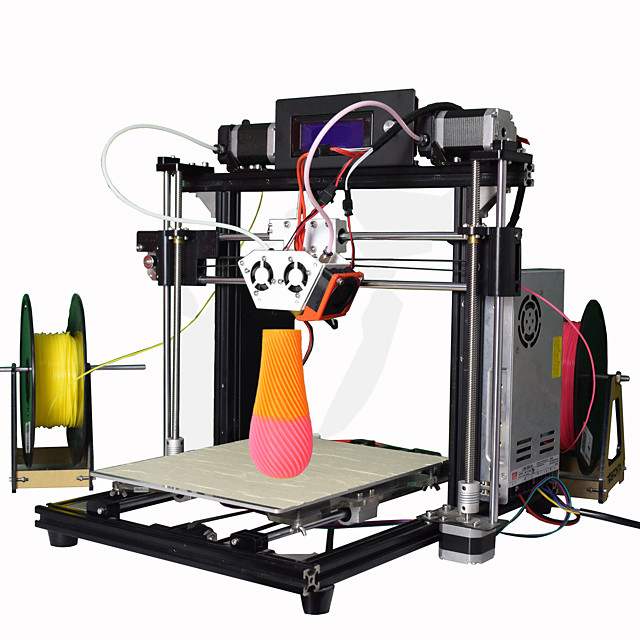

- Upgradable (somewhat): depending on who you talk to you will get different results when it comes to successfully upgrading the Maker Architect 3D printer. Some users have reported not being able to upgrade their machines at all. While others have upgraded it without any issues, however, if you can upgrade, they are awesome. You can get yourself a heated build plate to be print with more filaments. Also, you can set up the Maker Architect with dual extruders. Multiple filaments, colors, prints, and quicker printing is always a good thing.

- Price: Monoprice’s claim to fame is using open-source designs and finding ways to cut costs, which trickles down to the consumer. They have created some amazing, high-performing 3D printers for a fraction of the cost of the original.

The Maker Architect is no different. You can save yourself about $1,000 by going with Monoprice. If you just need a cheap addition to your collection or need to get into the game without breaking the bank, the Monoprice Maker Architect 3D Printer is a great option for that. Check out the latest prices on Amazon.

The Maker Architect is no different. You can save yourself about $1,000 by going with Monoprice. If you just need a cheap addition to your collection or need to get into the game without breaking the bank, the Monoprice Maker Architect 3D Printer is a great option for that. Check out the latest prices on Amazon.

Some of “not so nice to have things” with the Monoprice Maker Architect:

- Unheated build plate: This means limited choices with a filament. It is mostly suited for printing with PLA, but there are a few other filaments you can use as well.

- Limited connectivity: You can use either a USB connection or print files stored on an SD card, but there is no WiFi capability. Well, this isn’t terrible, it does take away some functionality and you will need to have a computer nearby if that is how you plan to transfer models to the printer.

- Discontinued: Unfortunately, the Monoprice website no longer provides support for this 3D printer, so buyer beware.

You can still find it on Amazon and a few other sites, but you will have to dig through websites and forums for any troubleshooting help. If you enjoy a tough problem and are good at finding solutions, then this shouldn’t be an issue for you.

You can still find it on Amazon and a few other sites, but you will have to dig through websites and forums for any troubleshooting help. If you enjoy a tough problem and are good at finding solutions, then this shouldn’t be an issue for you.

When Monoprice supported the Maker Architect, it was a great 3D printer. It is a duplicate of one of the best workhorse 3D printers we have ever seen. It was very similar to its popular open-source, still manufactured, models it is based off. With many similar parts and components, the Monoprice machine ran almost identical to its counterparts. As well Monoprice is known for making high quality, budget-friendly 3D printers. But there is a reason the company decided to stop supporting the Maker Architect.

There have been too many issues surrounding this 3D printer to advise anyone to pursue it. From miss-marketing of an upgradeable machine to failing parts, it is not worth the headaches. There are a lot of other duplicates that perform just as well and even better than the Maker Architect, and their respective companies still support them. Don’t let this one scare you from Monoprice. They are still a great and reliable 3D printer company and offer many other great machines.

There are a lot of other duplicates that perform just as well and even better than the Maker Architect, and their respective companies still support them. Don’t let this one scare you from Monoprice. They are still a great and reliable 3D printer company and offer many other great machines.

Further Read

- Monoprice Maker Select Plus Review

- Maker Farm Prusa i3 Review

- The Ultimate Simplify 3D Review: What Will You Think?

- The Full Bibo 2 Touch x Laser 3D Printer Review: A Good Budget Option?

- MP Select Mini V2 3D Printer Review You’ll Love

Monoprice Maker Architect 3D Printer

300.00Print Speed

7.0/10Build Area

6.0/10Precision

7.0/10Value

5. 0/10

0/10Ease of Use

9.0/10Pros

- Price

Cons

- Unheated build plate

- Limited connectivity

- Discontinued

- Failing Parts

Page not found - Total 3D Printing

We didn't find the posts for that URL.

Latest Posts

In our Intamsys FunMat HT review, we’re going to go over why this particular 3D printer is a solid choice for small businesses on a tight budget.

While there are many affordable 3D printers out there that are mainly aimed at hobbyists and for personal use, the cost of a 3D printer to print engineering-grade objects can often be very high.

One of the main reasons for this is that industrial 3D printers need to reach much higher temperatures than those that are used at home, and they generally need to be in operation much longer and more frequently as well.

The Intamsys FunMat HT is made in Shanghai, China, and for a small business, it offers a powerful 3D printer that doesn’t have the same high cost as some other models. Does that mean that it is as good as the 3D printers that have a higher price tag?

Let’s find out.

Read More about Intamsys FunMat HT Review: Will This Work for You?

Our BCN3D Epsilon review is going to show you the ins and outs of the different features this 3D printer has and how it performs. It is a newcomer onto the market as it was only released at the start of 2020.

Made by the Barcelona based, BCN3D, this 3D printer has been designed as a midway point between home and desktop 3D printers and those that can print on an industrial scale. The price range reflects this but you can find out more about how much 3D printers generally cost here.

Let’s start by looking at the key specifications of the Epsilon 3D printer.

Key specifications of BCN3D Epsilon

The BCN3D Epsilon is a pretty large printer that is designed to be a step up from home desktop 3D printers but not at the same size and power of those that are used for industrial 3D printing.

Here is a list of the specifications.

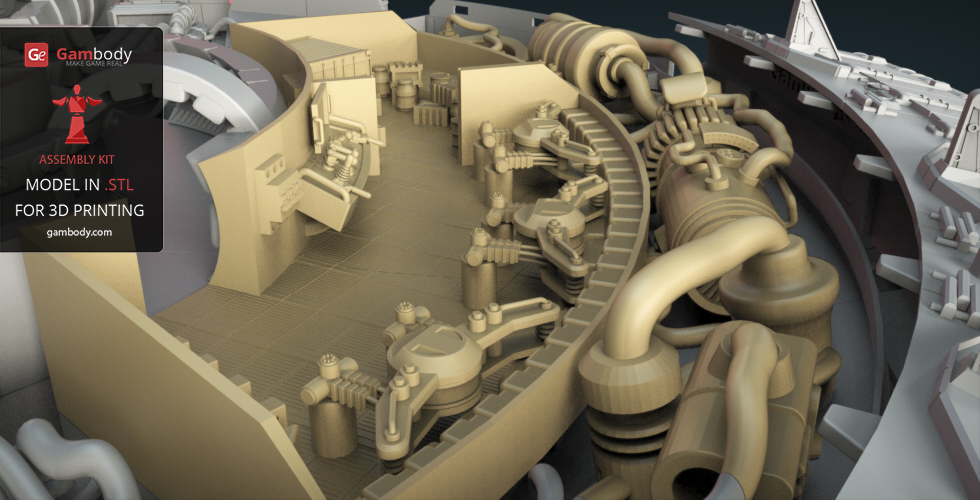

3D printer for architect and designer, pros and cons, examples of use

3D technologies are becoming good helpers in various fields. In architecture and design, 3D printers are successfully used mainly to create architectural models.

In architecture and design, 3D printers are successfully used mainly to create architectural models.

Illuminated layout

Architectural layouts can be divided into several types:

Layouts can be used for a variety of purposes:

-

Visualization for buyers or to coordinate the project with the client. Many customers find it much more difficult to perceive a digital layout of a building or interior. 3D printing allows you to quickly and inexpensively produce, for example, a miniature apartment model with a furniture model. The client himself will be able to visually see a variety of interior options and choose the one he likes the most.

-

Project presentation. A presentation with a beautiful layout looks much more colorful and effective, for example, a building or an entire microdistrict. But making an architectural model in the classical way is a long and painstaking, often manual, work.

What if you need multiple layouts? A 3D printer can significantly speed up and reduce the cost of production of a layout.

What if you need multiple layouts? A 3D printer can significantly speed up and reduce the cost of production of a layout.

The cost of the layout depends on several factors - this is the complexity of manufacturing and artistic value. The use of a 3D printer allows you to speed up and significantly simplify the production of complex and simple layouts. For example, making a layout of modern buildings with non-linear geometry becomes a real headache for layout designers. 3D printing allows you to quickly and accurately reproduce an exact copy of any building, regardless of its geometry.

Non-linear building layout

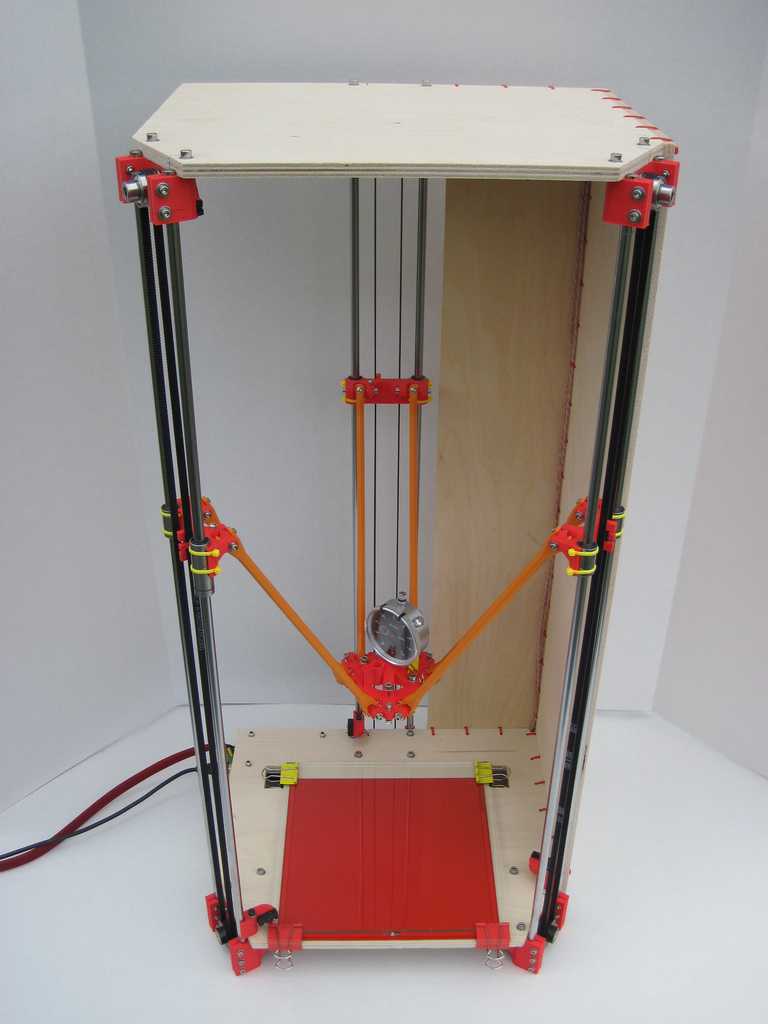

FDM printers for architecture and design

FDM is a technology for layer-by-layer deposition of plastic to obtain a physical model. As a consumable material, a plastic thread is used - a filament.

FDM printers are very popular due to their large working area, printing speed and inexpensive consumables.

The choice of printer model depends on what needs to be produced. Some devices are poorly designed to work with some engineering plastics.

Pros and cons

pros

Models of 3D printers appeared with an “infinite” printable area along one of the axes. These printers use a conveyor belt instead of a printtable. Such printers are suitable for mass production.

For the manufacture of simple layouts, you can give preference to models with a single extruder. But if a 3D printer is required to solve a variety of tasks, then models with two extruders and a closed chamber should be preferred. Such devices are universal and can print on almost any material.

Minuses

Application and printing examples

Model of the city of Astana. Production took 1 month.

Building kit

Prefabricated house model

San Francisco layout

Furniture and interior elements made on a 3D printer

Layout of the floor of the building for arranging furniture

Printer Rating

CreatBot D600 Pro

CreatBot D600 Pro

Features:

Print technology: FDM/FFF

Workspace size: 600x600x600

Number of extruders: 2

Max. extruder temperature: 420 degrees

extruder temperature: 420 degrees

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, PEEK, Decorative plastics, others

CreatBot D600 Pro is a professional device that has many options that will be useful not only for a beginner, but also for an experienced user. Two extruders with a high heating temperature and a closed chamber allow you to print on all available types of plastics. And automatic table calibration using the BL-Touch sensor eliminates the need to level the table plane.

Raise3D E2

Raise3D E2

Features:

Print technology: FDM/FFF

Working area size: 330 * 240 * 240 mm - when printing with the 1st extruder

295x240x240 mm - when printing with 2 extruders

Number of extruders: 2

Max. extruder temperature: 300 degrees

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, Decorative plastics, others

Raise3D E2 is a small device with unusual kinematics. Raise3D E2 has two independent extruders that allow the printer to work in several modes:

Raise3D E2 has two independent extruders that allow the printer to work in several modes:

In addition, Raise3D E2 is equipped with a convenient touch screen, automatic table calibration, an assistant for calibrating the height of extruders relative to each other and other nice features that do not affect the final print, but make working with the printer easier and more comfortable.

Raise3D Pro2 and Pro2 Plus

Raise3D Pro2 left and Pro2 Plus right

Features:

Print technology: FDM/FFF

Stage size: Raise3D Pro2

305x305x300 mm - when printing with the 1st extruder;

280x305x300 mm - when printing with 2 extruders

Raise3D Pro2 Plus 305x305x605 mm - when printing with the 1st extruder;

280x305x605 mm - when printing with 2 extruders

Number of extruders: 2

Max. extruder temperature: 300 degrees

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, Decorative plastics, others

As you can see from the specifications, the only difference between Raise3D Pro2 and Pro2 Plus is the size of the workspace in height. Pro2 Plus has twice as much.

Pro2 Plus has twice as much.

The Raise3D Pro2 series has proven itself in various fields. These are reliable workhorses with a set of all the necessary options for high-quality printing, and the presence of two extruders allows you to make models of any complexity.

PICASO 3D Designer XL Pro

PICASO 3D Designer XL Pro

Characteristics:

Print technology: FDM/FFF

Working area size: 360 x 360 x 610 mm

Number of extruders: 2

Max. extruder temperature: 410 degrees

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, PEEK, PC, Decorative plastics, others

PICASO 3D Designer XL Pro is a Russian-made professional printer with an enlarged working area. Designer XL Pro is equipped with automatic table calibration, plastic feed control sensor and other nice features.

Photopolymer printing in architecture and design

The principle of operation of a photopolymer printer is based on the illumination of a special resin using directional UV radiation. Photopolymer printers can work on one of three technologies:

Photopolymer printers can work on one of three technologies:

Photopolymer printers allow you to get a product with an ideal surface. It is not for nothing that LCD, DLP and SLA devices are actively used in the jewelry and dental industries, where accuracy and the ideal surface of the finished model are important.

Currently, LCD technology has gained particular popularity due to its availability and inexpensive printers.

Pluses and minuses

pros

Minuses

-

After printing, it is necessary to rinse and dry the product in a UV chamber. After printing, it is necessary to wash off excess polymer from the surface of the finished print. For this, isopropyl alcohol is usually used, although resins have now appeared that can be washed with plain water. In order for the photopolymer to gain the declared strength, it must be additionally illuminated under an ultraviolet lamp or in a special box.

Application and printing examples

Miniature model of building

Model of the Cathedral of the Intercession of the Most Holy Theotokos on the Moat (St. Basil's Cathedral)

Basil's Cathedral)

City map

Miniature “extras” for layout

Printer rating

Prismlab RP400

Prismlab RP400

Features:

Print Technology: DLP/LCD/SLA

Material: Photopolymer resin

Construction area size: 384x216x384 mm

XY positioning accuracy: 100/67/50 microns

Z-axis positioning accuracy: 100/50 microns

Prismlab RP400 is a professional photopolymer machine with a large printable area. Humidity and temperature sensors in the build chamber allow Prismlab to adjust print settings for the best print quality, while open source software allows the use of third-party photopolymer resins.

Peopoly Phenom XXL

Peopoly Phenom XXL

Characteristics:

Print Technology: DLP/LCD/SLA

LCD display resolution: 3840x2160 (23. 8", 16:9, UHD 4K)

8", 16:9, UHD 4K)

Material: Photopolymer resin

Construction area size: 527x296x550 mm

XY positioning accuracy: 137 µm

The Peopoly Phenom XXL is a large format photopolymer printer with a huge printable area. The improved monochrome LCD matrix allows you to quickly and accurately produce large models or small batches of small products.

Phrozen Sonic MEGA 8K

Phrozen Sonic MEGA 8K

Features:

Print Technology: DLP/LCD/SLA

LCD resolution: 15" 8K Mono LCD

Material: Photopolymer resin

Build area size: 330 x 185 x 400 mm

XY Positioning Accuracy: 43 µm

Sonic Mega 8K is the first LCD printer with a matrix resolution of 8k, but the accuracy of printing depends on the resolution of the matrix. Sonic Mega 8K allows you to produce large models with amazing clarity, without “blurring” or smoothing small elements.

Construction printers

Construction printers are just groping for their niche for application, and the technology itself is still far from ideal. But the projects already implemented allow us to imagine a possible future where it will be possible to print entire houses.

But the projects already implemented allow us to imagine a possible future where it will be possible to print entire houses.

Application and printing examples

Bridge in Shanghai.

In Shanghai, using a construction 3D printer, a whole bridge was printed and installed over a pond in the Baoshan area. The new bridge is 26.3 meters long and 3.6 meters wide.

Shanghai Bridge

Before making a concrete, full-size model, a reduced copy of the bridge 1: 4 was printed for testing the strength and safety of the structure. 3D printing took 450 hours. A load and deformation monitoring system was installed in the finished bridge. This allows you to explore the properties of printed concrete elements in real time.

Up close, you can see the concrete layers that appeared due to the peculiarities of printing

Bridge in Amsterdam

In Amsterdam, a printed steel bridge was installed. It connects the embankments of the Oudesijds Achterburgwal canal. The length of the finished bridge is 12.2 m, the width is 6.3 m, and the weight is 6000 kg.

It connects the embankments of the Oudesijds Achterburgwal canal. The length of the finished bridge is 12.2 m, the width is 6.3 m, and the weight is 6000 kg.

Bridge in Amsterdam

Sensors were installed in the bridge to track the deformation of the structure and count the number of people passing through it. For the manufacture of a modern "crossing" 4 robots for 6 months layer-by-layer made a construction of stainless wire.

Bridge manufacturing process

Printed house in Germany

In Germany, builders built an entire house using a 3D construction printer. The house is designed for 5 families, the total area is 380 sq.m.

Almost finished house

In the model of the house, cavities are initially laid for all communications, which the builders will later install. Thus, while the printer is building walls, the workers are solving other tasks.

The structure of the walls is hollow, after hardening it is filled with a special insulating material.

After all the work, the apartments in the house will be rented out, and one, the manufacturer, will be used as an exposition to demonstrate the possibilities of construction 3D printing.

Totals

Architecture and design are already firmly established digitally, making it possible to more visually demonstrate models of future buildings and interiors. It is already difficult to meet an architect who draws his masterpieces only on paper.

Three-dimensional technologies make the visualization process simpler and more visual. Already today, 3D technologies make it possible to partially abandon painstaking manual labor in the manufacture of models, and perhaps in the future, with the help of construction 3D printers, it will be possible to build beautiful architectural structures much faster and easier.

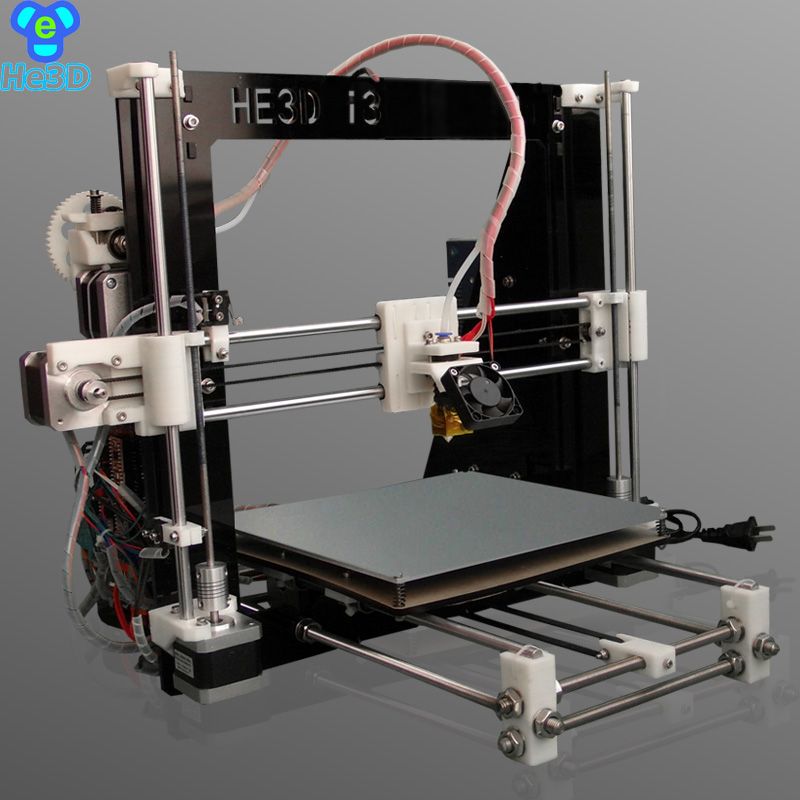

Overview of the budget 3D printer Monoprice Select Mini

3DPrintStory Reviews Overview of the budget 3D printer Monoprice Select Mini

Prices for desktop 3D printers continue to fall. There were times when a $600 3D printer was a delight and a desire to order it as soon as possible, but technology does not stand still, and developers and manufacturers are looking for new options to lower the price even lower. This review is dedicated to one of the budget 3D printers costing about $200 - Monoprice Select Mini.

There were times when a $600 3D printer was a delight and a desire to order it as soon as possible, but technology does not stand still, and developers and manufacturers are looking for new options to lower the price even lower. This review is dedicated to one of the budget 3D printers costing about $200 - Monoprice Select Mini.

It is worth noting that this inexpensive model breaks established traditions and did not start with Kickstarter, unlike others like M3D Micro, Tiko, OLO / ONO and Trinus, which attracted the attention of consumers and investors thanks to crowdfunding platforms (by the way, this is really an effective development strategy for small startups, but there is often a mismatch between expectations and the final product).

Monoprice is different. This is an American company that did not particularly bother with the development and production of its own 3D printer, but simply imported the Malyan M200 from China, hung its logo on it and put an attractive price of $199. What if you got a defective 3D printer? No problem, send it back and they will replace it for you.

What if you got a defective 3D printer? No problem, send it back and they will replace it for you.

A reasonable question arises: can such a cheap 3D printer compete with Ultimakers or Printrbots? And is it even worth comparing? We will try to answer these and other questions in the review below.

Features Monoprice Select Mini

- Available;

- Robust design;

- Easy to use;

- Predictable 3D printing at low speed;

- Works with any slicing software and standard 3D printing materials;

- Amenable to improvements and upgrades;

- I think we already mentioned the price?

Disadvantages Monoprice Select Mini

- Difficult to calibrate;

- Prints poorly at high speeds;

- Print table not protected;

- Faulty power supply;

- WiFi module not active;

- Unstable nozzle temperature;

- Strange oddities...

Short Verdict

The Monoprice Select Mini is a great 3D printer for the price. There is a heated table, easy to operate if you do not use high speeds, stable 3D printing quality.

There is a heated table, easy to operate if you do not use high speeds, stable 3D printing quality.

Naturally, there are disadvantages. During operation, the temperature of the nozzle may change, and at high speeds, 3D printing errors occur. The calibration process takes a lot of time and the first time you have to tinker. Well, the most interesting thing is that the power supply burned out after 12 hours. But the latter, incorrect, can be attributed to an accidental marriage.

Despite all the shortcomings, the Monoprice Select Mini is a wonderful little 3D printer with many great features. In general, it performs in accordance with the information in the technical specifications, and the quality of the 3D printing even exceeded our expectations.

If you are not afraid to take it apart / put it back together, then you can do a few upgrades. The first thing to do is to replace the hotend and update the firmware to activate the WiFi module ( be careful! These upgrade options have not been tested as part of this review and may damage your 3D printer! ). You can install the glass on the print table. Even with these upgrades, the price will still remain acceptable.

You can install the glass on the print table. Even with these upgrades, the price will still remain acceptable.

Would you recommend the Monoprice Select Mini as your first 3D printer? Yes, definitely.

Specifications and features Monoprice Select Mini

Monoprice Select Mini workspace 120 x 120 x 120 mm. The maximum resolution of 3D printing is 100 microns. Heated table. The 3D printing speed is 55 mm/s.

You can upload your 3D model via micro SD card or USB. The manual states that compatible slicing programs are Cura, Repetier-Host, ReplicatorG, and Simplify3D. This means that the Monoprice Select Mini recognizes the standard G-code, and this 3D printer is not tied to any particular software. Cura was used during testing for this review.

Monoprice Select Mini doesn't limit you in the media you use. You can print with any standard 1.75 filament using PLA or ABS thermoplastics. In our case, PLA plastic from ColorFabb was used.

These two points - the freedom to choose software and filament - are very important in this price range, because manufacturers such as M3D Micro and XYZprinting, which are Monoprice's main competitors in this niche, tend to use proprietary software and their own materials for 3D printing .

Unpacking and installation of Monoprice Select Mini

Installation of Monoprice Select Mini is quite simple. You can start typing within 20 minutes.

Inside the box you will find a 3D printer, a power supply, an imbus wrench for calibrating the table, a plastic spatula for scraping off the rest of the material from the table after printing, a 256 mb micro SD card and a micro USB cable.

One piece of paper contains a basic instruction and a link to a website where you can download the full version.

You will also find a rectangular steel sheet, the purpose of which is not at all clear at first. It turns out that this is a coil holder that is attached to the side of the main unit.

It is important to note that the Monoprice Select Mini kit does not include media test samples. So stock up on filament with a diameter of 1.75 mm.

You can use the wheel to adjust. The menu is well structured and easy to understand. You can start the calibration process, preheat the extruder and feed the filament.

Calibration can be somewhat difficult. In theory, it should be carried out even before shipment, in production, and you should have a piece of paper between the nozzle and the printing table. If it doesn’t work, then hex keys will come in handy here. It will be necessary to try and tighten the screws at the corners of the table so that the sheet still passes.

At this stage, the first important shortcoming of this model becomes clear. The printing table is made of aluminum and does not have a special protective film or coating on it. So stock up on blue 3D printing tape or install glass right away. Otherwise, the table will wear out very quickly and you will have to change it.

Well, one more bug that got out in our particular case. The power supply burned out after 12 hours of use. Foaming it was not difficult, but it was very unpleasant. You can probably throw it off for marriage, but in any case, be prepared for a similar turn of events.

Construction and build quality of the Monoprice Select Mini

Very pleased with the build quality of the Monoprice Select Mini. The construction is strong, reliable, with a steel sheet metal case that hides all the electronics. So don't worry about shipping damage.

The construction is strong, reliable, with a steel sheet metal case that hides all the electronics. So don't worry about shipping damage.

This 3D printer uses deposition modeling technology. The classical Cartesian coordinate system is used. The design is similar to Printrbot Simple. One cooler is used to cool the nozzle. It is likely that problems may arise during 3D printing with unusual materials.

The extruder has a diameter of 0.4 mm and can be heated up to 230°C. We have not been able to test how easy it is to change, but in the long run this is an important factor as the nozzle will still need to be changed over time.

Monoprice Select Mini Print Quality

Pre-loaded models will already be on the micro SD card. They are supposed to be optimized for 3D printing on the Monoprice Select Mini. So before uploading our own models, we printed test ones.

The cat was printed first. The resolution was 200 microns. Everything went well until the last layers. The upper part of the paw and ears could not be printed even once. There were 3 attempts in total.

The upper part of the paw and ears could not be printed even once. There were 3 attempts in total.

G-code analysis in Simlify3D shows that the table accelerates up to 55 mm/s during the printing of the last layers. That is why the error was repeated. Quite a strange decision of the company - to provide a test model, which a priori will be printed with errors...

The second model that we printed is a test elephant. The resolution was also 200 microns and 10% infill. There were no problems! The result is excellent and you can see it in the photo below.

Next we moved on to our own models. We used Cura for slicing. This article reveals the excellent Cura settings for 3D printing on the Monoprice Select Mini and we used them.

We printed a classic 3DBenchy and Graphica model: a MEGA Ghost with 200 micron resolution and 10% infill, a V29 whistle with 200 micron resolution and 100% infill, and another 3DBenchy model with 100 micron resolution and 10% infill.

The simple 200 micron models worked well. There are no special problems with small protrusions and holes, although there are sagging. The layers are laid evenly along the X and Y coordinate axes.

The V29 whistle sounds as loud as intended, which means that the partitions were printed correctly. The Graphica Mega Ghost with its long tongue also printed correctly. The hinge glided smoothly. The

3DBenchy at 100 microns worked well too. When you look at the photo, don't forget that this is a $19 3D printer.9.

We have noticed that most errors in 3D printing occur when the spool of filament clings or there is not enough adhesive coating on the printing table. This cannot be attributed to the shortcomings of the Monoprice Select Mini itself, since this is a global problem for all FFF printers.

During operation, the print table may block access to the control wheel. This point is implemented in the design is not very ergonomic.

Another disadvantage is that the nozzle temperature has an error in the region of 5°C. For example, when the 3D printing temperature is set to 215°C, it jumps between 213°C and 217°C on the control panel.

For example, when the 3D printing temperature is set to 215°C, it jumps between 213°C and 217°C on the control panel.

This does not particularly affect printing with PLA plastics, but may have a negative effect during 3D printing with materials that are more sensitive to temperature changes.

Finally, we printed a Low Poly Moai bust. We scaled the model by 50% and printed with 100 micron settings and 30% infill. It turned out well on the whole, the only small marriage is the influx of material on the chin. By the way, we observed the same effect when printing 3DBenchy with resolution settings of 100 microns.

Life hacks and upgrades Monoprice Select Mini

A few words about upgrading the Monoprice Select Mini 3D printer. There are no official upgrades! But here are a few options that you can try to implement on your own.

In our opinion, it is necessary to deal with the temperature of the extruder, make it more stable. For example, you can implement a PID temperature controller.

The evolution of hardware is catching up to the needs of large build volume printing, starting with the physical …

The evolution of hardware is catching up to the needs of large build volume printing, starting with the physical … It’s a professional system at an affordable price, making it accessible for anyone who needs a machine for a group of people.

It’s a professional system at an affordable price, making it accessible for anyone who needs a machine for a group of people. They are willing to spend a lot of money to come up with bigger, better, more elaborate, and more intricate costumes at every cosplay event. Money.com reports that some enthusiasts spend more than $1,000 on one costume alone. What’s more, around three out of four cosplayers buy anywhere from one to four costumes a year.

They are willing to spend a lot of money to come up with bigger, better, more elaborate, and more intricate costumes at every cosplay event. Money.com reports that some enthusiasts spend more than $1,000 on one costume alone. What’s more, around three out of four cosplayers buy anywhere from one to four costumes a year.