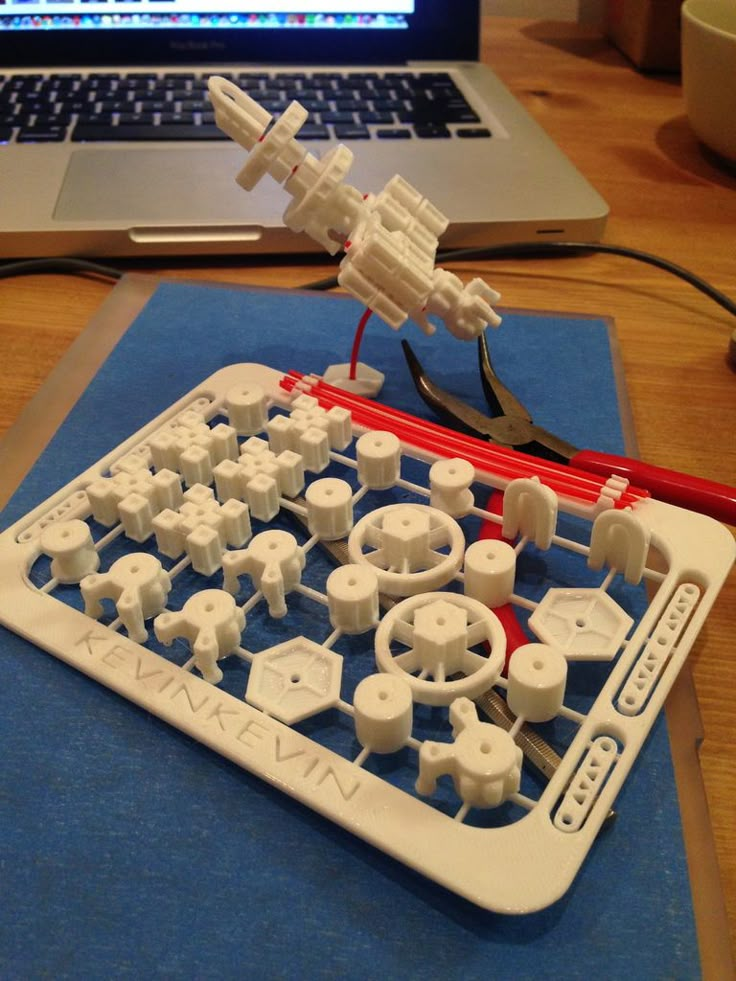

3D print model kit

3d Print Kit - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

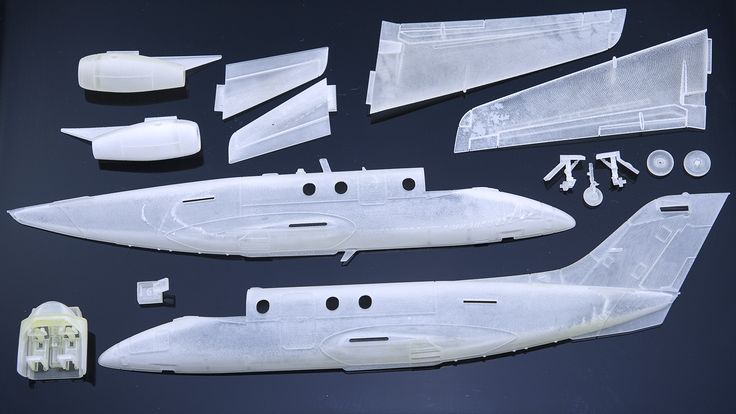

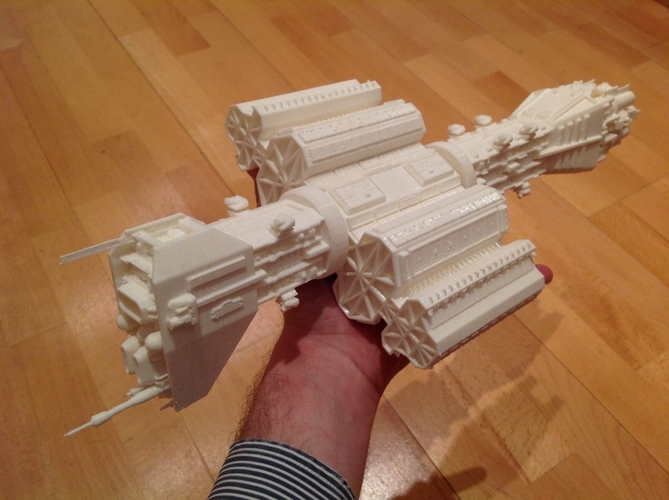

Weekly Roundup: Ten More 3D Printable Nerdy Model Kits - 3DPrint.

I’ve said it before and I’ll say it again, a 3D printer is a nerd’s best friend. You know that dream toy that you want more than you want oxygen but isn’t popular enough for anyone to manufacture? Well, with a desktop 3D printer you can just make all of the obscure, barely known nerdy things that you want and never have to wait for something to be sold in stores. Granted, you’ll have to wait for someone to design a 3D printable model, but trust me, there is a 3D printed version of just about everything out there. And if there isn’t, give it time, there will be.

Last time I made a list of 3D printable model kits I found so many amazing options that paring it down to ten was virtually impossible. I managed of course, but I had so many leftover model kits that I really wanted to share with you that I had to make a second list. Believe it or not, I had found so many cool model kits that even cutting down the leftovers from my last list was really hard.

So here are Ten More 3D Printable Nerdy Model Kits:

DALEK FROM DOCTOR WHO

Openable Detailed Dalek by Ellindsey

Found on: Thingiverse

Cost: Free

The Doctor’s nemesis isn’t a single person, it’s the very concept of the Dalek. A being whose entire purpose in life is to destroy life is literally the antithesis of what the Doctor is, and it is no wonder that he hates them so much. This fantastic kit is a wonderful recreation of the modern Dalek, and the model really opens up to reveal the Dalek’s true face.

A being whose entire purpose in life is to destroy life is literally the antithesis of what the Doctor is, and it is no wonder that he hates them so much. This fantastic kit is a wonderful recreation of the modern Dalek, and the model really opens up to reveal the Dalek’s true face.

The designer has also posted extremely detailed assembly instructions, so despite being a complicated model, it should be relatively simple for just about anyone to make. All of the parts are individual STL files, so you should be able to actually print them in different color filaments pretty easily and avoid painting altogether.

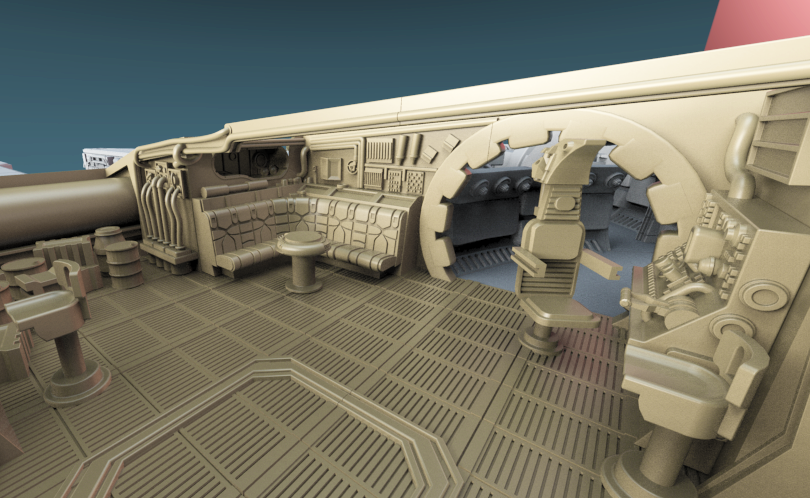

DOOF WAGON FROM MAD MAX: FURY ROAD

MAD MAX FURY ROAD DOOF WARRIOR WAGON by Evavooo

Found on: MyMiniFactory

Cost: Free

It is going to be years before we see another major Hollywood blockbuster that is as original and iconic as last year’s epic Mad Max: Fury Road. You’re just not going to get a character like the Doof Warrior, fearlessly playing a flame throwing guitar on his giant speaker truck, very often.

The assembly guide from MyMiniFactory.

This great model kit for the Doof Wagon is a pretty simple print, but the parts are large enough that you’ll need a decent-sized 3D printer to make them. This will take a bit of painting, but the model really isn’t very complicated.

WALL-E

WALL-E by Leon Alexander Single

Found on: MyMiniFactory

Cost: Free

The lovable title character from Pixar’s WALL-E, the last robot on Earth, is immortalized in this great 3D printable kit. The design is almost completely movie-accurate, and was made to snap together. The parts will need to be glued, but the kit is pretty self-explanatory and should be a relatively easy build.

You can either try to print the parts in colors that match the character from the movie, or give it a more realistic paint job. The creator of this kit did a great job painting his and it will make an excellent guide if you try to paint your own.

CLASSIC 1960’S BATMOBILE

The Classic Batmobile by larry009

Found on: Thingiverse

Cost: Free

BIF! POW! ZONK! Those are the sounds that your 3D printer will be making when you print this cool, retro Batmobile that is based off of the design from the classic, and cheesy, Batman TV series from the 1960’s. The finished model has a ton of great details, including a screen accurate interior and bat symbols for the doors.

The finished model has a ton of great details, including a screen accurate interior and bat symbols for the doors.

The designer included both 3D printing and assembly instructions, and it looks like he made the parts really easy to print. A few of the parts may need a raft, but other than that this is a pretty straightforward kit. You will need a transparent filament for the windows, of course, but everything else can be printed in a single material and then painted.

POWER LOADER FROM ALIENS

Power Loader & Power Loader 2 by Aaronh25241

Found on: Pinshape

Cost: Free

One of the greatest action/sci fi movies of all time is Aliens, the James Cameron-directed sequel to Alien. It is hard to pick the best action scene from the movie, since there were so many amazing ones, but the penultimate showdown between the queen alien and Ripley is probably near the top of that list. It takes place in a spaceship’s cargo bay, where Ripley faces off against the xenomorph while wearing a power loader exo-suit.

We’ve featured this design before, and it’s definitely worth another look now. This kit is a highly detailed recreation of that power loader suit, even down to the seat belts and the various tubes and wires that drive the suit’s hydraulics. This kit has a ton of parts, so many that the creator had to upload them to two different pages. But that makes it really easy to 3D print everything in different colored filaments so you won’t need to do any painting.

TYRANNOSAURUS REX SKELETON

T-Rex Skeleton by MakerBot

Found on: Thingiverse

Cost: Free

MakerBot has put tons of great 3D printable models up on Thingiverse, but this anatomically correct T-Rex skeleton is probably the best thing they’ve ever shared. It’s a fantastically detailed model that shows off every bone in the legendary dinosaur’s body. It takes more than 24 hours to print all 79 of the snap-together parts, and thankfully MakerBot was kind enough to include illustrated assembly instructions. This is perfect as an educational tool, to use as a science project or just to have a cool 3D printed model on your shelf.

This is perfect as an educational tool, to use as a science project or just to have a cool 3D printed model on your shelf.

Here is a time-lapse video of the T-Rex skeleton being assembled:

BLUTH COMPANY STAIR CAR FROM ARRESTED DEVELOPMENT

Arrested Development Stair Car by jwilcott

Found on: Thingiverse

Cost: Free

I won’t be bold enough to suggest that Arrested Development is the funniest TV series ever made, but I will say that it’s probably one of the funniest TV series ever made. If you’re familiar with the show then you will need no introduction to the Bluth Company stair car. When the Bluth family became temporarily embarrassed former millionaires they lost everything, including the family’s private jet. They got to keep the stair car though; in fact, it was the only car that they had left.

Banana for scale.

This hilarious model is really easy to assemble, and includes working wheels. You’re probably going to need to paint the finished product, but the model has raised most of the areas that will need to be painted so it shouldn’t give you any trouble at all. If your printer supports it then you can even change filament colors mid-print so you won’t even need to do any painting.

If your printer supports it then you can even change filament colors mid-print so you won’t even need to do any painting.

TRON LIGHTCYCLE

Lightcycle Model Kit by cbabbage

Found on: Thingiverse

Cost: Free

This Tron Lightcycle has a TON of little parts, but don’t let that discourage you; the kit is actually really well-designed and easy to put together. The parts were all designed so they can be printed in different colored filaments, making it easy to make without needing to do any painting. You can even print some of the parts in glow in the dark filament to really make it stand out.

The designer has included a super detailed printable illustrated assembly guide, so building it should be a piece of cake. The model kit also includes a 3D printable stand for the lightcycle.

BENDER BENDING RODRIGUEZ, SR.

Bender articulated by Simonarri

Found on: Thingiverse

Cost: Free

The robot known as Bender, or his full name Bender Bending Rodriguez, Sr. , designated Bending Unit 22, is the foul-mouthed, alcohol-loving sidekick of Futurama’s erstwhile hero Fry. He’s not especially fond of humans, or aliens, or even other robots, but he seems to like Fry enough to not kill him. I know many a nerd is going to want their own articulated Bender sitting on their shelf.

, designated Bending Unit 22, is the foul-mouthed, alcohol-loving sidekick of Futurama’s erstwhile hero Fry. He’s not especially fond of humans, or aliens, or even other robots, but he seems to like Fry enough to not kill him. I know many a nerd is going to want their own articulated Bender sitting on their shelf.

This great kit will take a bit of work to assemble, and it will need a lot of post processing to get everything to work properly, but man is it worth it. The kit includes a bunch of props, including a cigar, bottle of beer, top hat, head jar and even an optional beard.

PLANET EXPRESS ROCKET FROM FUTURAMA

Planet Express Ship [Futurama] by ChaosCoreTech

Found on: Thingiverse

Cost: Free

I couldn’t include a Bender figure without including a 3D printable Planet Express ship to go along with him. This versatile kit can be sized up and turned into an exact replica of the ship, left normal size and painted or remixed as part of a diorama. The designer didn’t leave any details out, including the logo on the tail fin, the port holes and even the side hatch.

The designer didn’t leave any details out, including the logo on the tail fin, the port holes and even the side hatch.

Here is a video detailing how the model was designed, printed and then painted:

And another Ten 3D Printable Things column comes to a close! Thanks so much for reading and making this column so much fun to put together. My 11th favorite thing in the world is to see what 3D printing projects all of you are working on, so please make my day and share with me! You can either email me, or you can find me on Twitter @SJGrunewald. Happy 3D Printing!

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printable models • aliens • Arrested Development • batman • batmobile • Bender • Bluth Company stair car • dalek • doctor who • Doof Wagon • Futurama • Lightcycle • Mad Max Fury Road • makerbot • myminifactory • nerdy model kits • pinshape • Planet Express • Ripley • t-rex skeleton • Ten 3D Printable Things • Ten3dpthings • thingiverse • Tron

Please enable JavaScript to view the comments powered by Disqus.

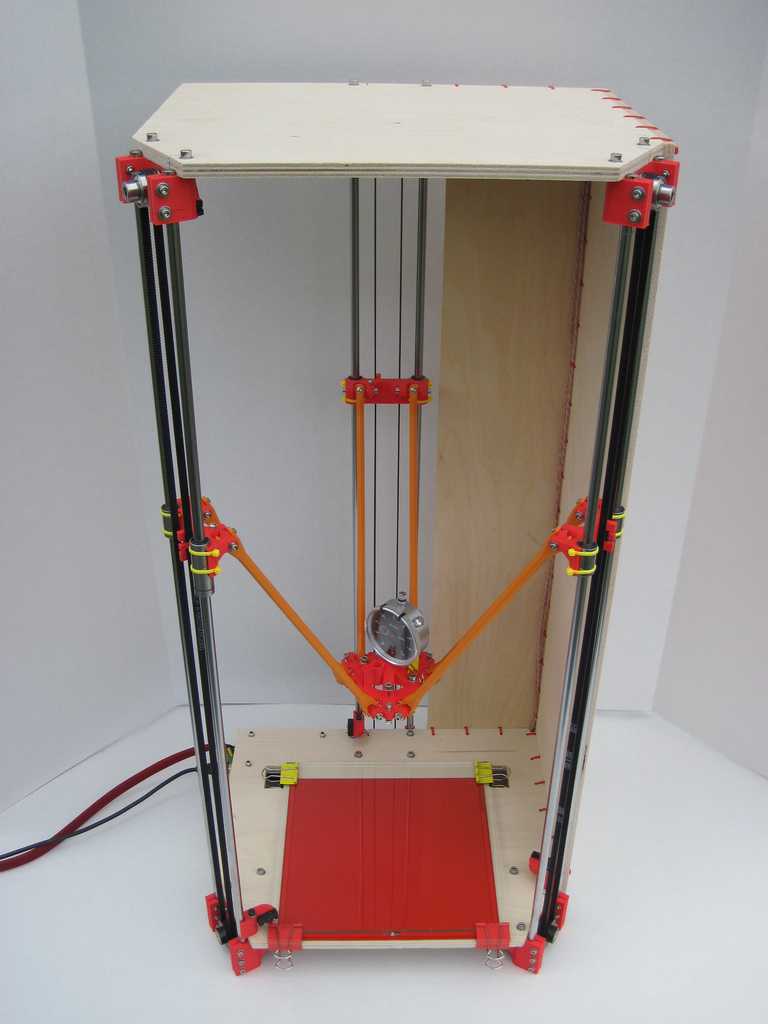

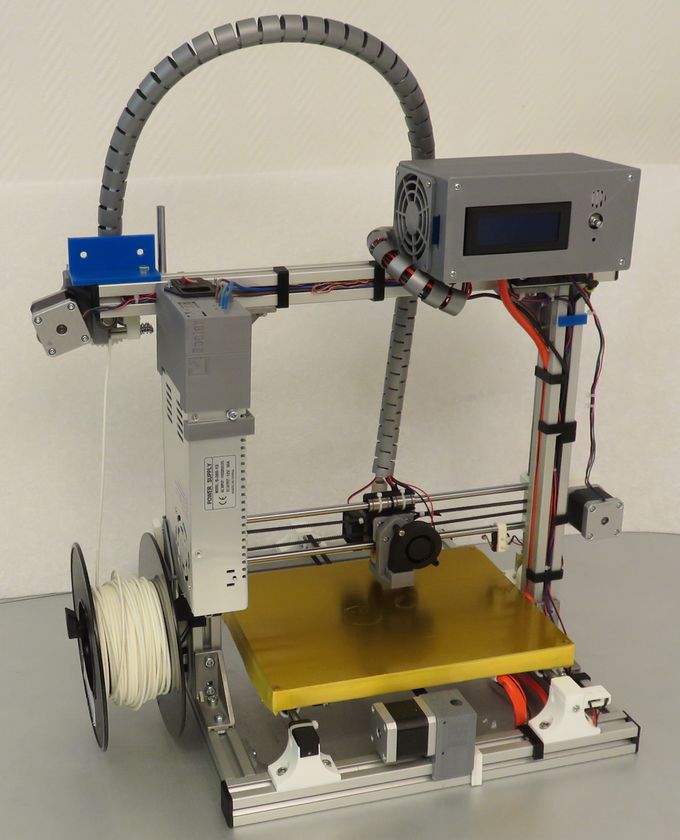

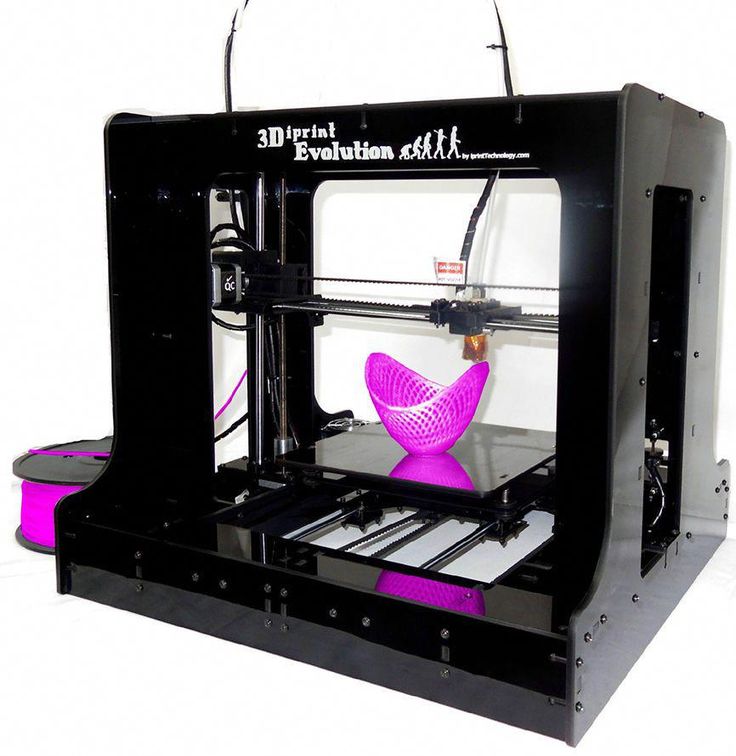

3D printer assembly kit vs self-assembly, which is cheaper? / 3D printers, machines and accessories / iXBT Live

3D printing and 3D printers have long been in use, from year to year the price of the printers themselves, components and consumables is falling lower and lower. Reading numerous forums where owners of eminent branded printers costing from 50,000 to 250,000 rubles complain about the same problems as with cheap self-assembly ones, I thought. If there is no difference, why pay more? I have already tested 2 ready-made sets of 3D printers from China in practice and I was very pleased with the quality. One interesting point remains, what comes out cheaper? Assemble yourself from components or buy one of the sets?

The photo shows my printer from the previous review - JG Aurora, dressed in a steel frame. In principle, I just replaced the frame and that's it, but the printer began to look much better. He didn’t get much better at typing, before that everything was in order, but it prompted me to certain thoughts. Why is it necessary to take sets with a brand, as if Chinese or European, and overpay them, albeit a little in the case of China, but still. And if you take components without a frame, and buy the frame already here in Russia? Wouldn't it come out cheaper?

He didn’t get much better at typing, before that everything was in order, but it prompted me to certain thoughts. Why is it necessary to take sets with a brand, as if Chinese or European, and overpay them, albeit a little in the case of China, but still. And if you take components without a frame, and buy the frame already here in Russia? Wouldn't it come out cheaper?

I started looking for the cheapest 3D printer kit on a well-known site and found a suitable one for 8,700 rubles. about. The price already includes delivery.

Let's take a closer look at this set.

The basis of any 3D printer is the brain. The brains here are standard - Arduina Mega 2560 and the shield for it - Ramps 1.4.

In principle, this is a standard and most printers are assembled on this scheme. More expensive boards, such as MKS Gen or Base, are also based on the same Arduin.

The main thing here is to look at the Ramps for the presence of unsoldered places or, on the contrary, extra influxes, because of this, most often people have problems.

Next. I see in this set there is a four-line LCD2004 screen with a card reader. This is a very convenient addition, I have not used a 3D printer + computer for a year now. I throw a G-code for printing on a memory card and the printer prints offline.

The red scarf is an adapter for Ramps with leads for this screen, it is included in the kit, as well as wires for the screen.

Drivers, wires, limit switches. It's all there. Drivers are ordinary - DRV8825, limit switches on boards, wires without braid. Cheap and cheerful, but effective. Radiators were also put to the drivers. The motors here are also standard for most 3D printers, these are NEMA17 stepper motors.

Also in the set there is a heating element for the table - MK2A board on a textolite basis. For me, this is a more successful heater than the MK3 version, which is integrated on an aluminum plate. The fact is that I print on glass and I don’t need an additional layer between the glass and the heater. MK2 will heat up faster.

MK2 will heat up faster.

And the crown of this set is the E3D version 5 clone print head. The head comes assembled with a heating element and a thermistor. The only thing missing is a pushing mechanism for plastic - an extruder. And since there are 5 motors here, it means that only a small part of the extruder is needed. Under this element, a Bowden-type extruder is required, which means the plastic will be fed through a PTFE tube to a heated nozzle. I don’t see a PTFE tube in the picture, although the seller writes that it is included, perhaps he means a small Teflon tube inside the thermal barrier.

Now what is missing in the set.

Well, the main missing piece is the frame. I bought 2 types of steel frames from Nioz and Soberistanok. The Nioz is easier to assemble and doesn't require any printed parts, but there are no bolts included. The assembler puts bolts in the kit, but the frame itself uses a few printed elements, without a printer, which are not so easy to get. Both frames are cut in Chelyabinsk and at a price of about 3000-3500 rubles. without painting and weight 3-5 kg. delivered by a transport company. For delivery from Chelyabinsk to Moscow, I paid a little less than 600 rubles for the frame.

Both frames are cut in Chelyabinsk and at a price of about 3000-3500 rubles. without painting and weight 3-5 kg. delivered by a transport company. For delivery from Chelyabinsk to Moscow, I paid a little less than 600 rubles for the frame.

The cost of the frame 3800 + delivery is 4400 rubles.

In addition to the frame, shafts, bearings, trapezoidal or conventional screws and belt spools must be added.

Shafts, like the frame, are better to take from us in Russia, they come out cheaper than on Aliexpress. For example, a set of shafts for a given frame from the same Nioz will be 1380r.

Trapezoidal screws with a nut on Ali are almost 2 times cheaper and come out at about 800r per pair.

Only a Bowden extruder and a pair of belted spools need to be added.

The extruder is also better to take on Ali: Bowden Extruder - 600 rubles.

There is already a motor mount to the frame and a good hardened steel gear with fine teeth is used.

GT-2 belt can be taken from the same seller: GT-2 belt — 200 rubles, especially since it already has 2 spools.

Bearings - 400 rubles for 12 pieces, which is quite enough.

And you also need to add a power supply, this is about 1400r.

Total comes out to about 17900r.

All that remains is to upload the Marlin firmware to the board via the Arduino IDE and adjust the parameters for your printer. It is convenient to substitute the necessary parameters into the firmware using a calculator, for example this one: http://prusaprinters.org/calculator/

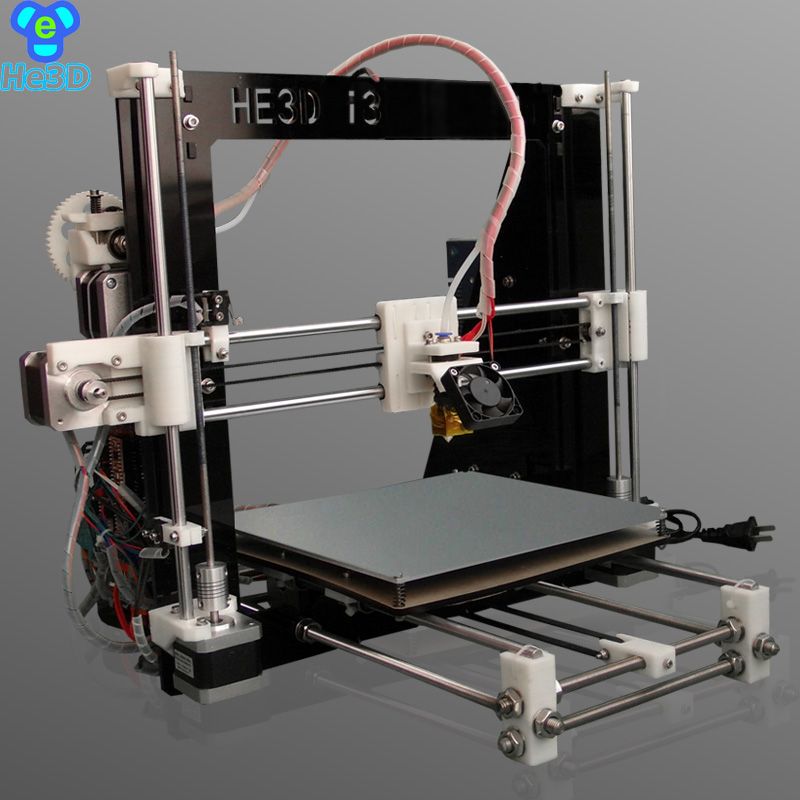

Now consider the assembly kit, for example the cheapest one - Annet A6.

According to the link, the manufacturer is listed as Infitary, but this is definitely a clone of the rather popular Annet A6, possibly with some modifications.

Let's compare it with the set above. There are already trapezoidal screws and even with aluminum dampers. A more expensive Direct-type extruder is installed and already with blowing, which has a positive effect when printing with PLA or HIPS plastics.

The heating table is more expensive - MK3, although MK2 is more attractive for me. The control board is not a sandwich from Mega + Ramps, but something more impressive, there is no name of the board in the description, but everything looks in order, it resembles something from the MKS line.

There is also a screen 2004 with a card reader and additionally there is a stand for a reel with plastic.

The price for such a set of 3D printer is about 14200r.

That is, it turns out a difference of about 4000 rubles. Which just matches the steel frame. And printers with a steel frame are already being sold for 25,000 rubles, for example, in the same Chelyabinsk.

In principle, I suspected that taking a 3D printer kit from the Chinese is about the same as assembling it yourself in parts, only in the kit everything is already set up and fits together, and in a self-assembly printer you will also have to figure out what to connect and tinker with firmware.

Another option to get an inexpensive 3D printer remains - buying on Avito, etc. through ads, but here you need to monitor message boards more often in search of good offers, and even then, you can end up with a problem copy.

News

Publications

A DVR is one of the most important assistants of a modern motorist, it will help confirm your case and sort out a controversial situation on the road, provide protection from auto-fraud....

all civil and modern transport aircraft have only one keel in the tail, and in most cases the military has two. Many people think that two...

What to try in Kyrgyzstan? First, drinks. We drink kvass in the summer, and kvass, maksym, chalap and aralash in Bishkek. Sold on tap in glasses and plastic bottles. Aunts sit under umbrellas...

USAMS T50 Charger (US-CC163) - an upgrade from the previous USAMS T44. Both models are made with gallium nitride (GaN) transistors and have a maximum power of 100W per. ..

..

weather stations rather got stronger: This is curious because ...

Double-decker vehicles were used and are now used not only in the UK, but also in some cities in Europe, Asia and Australia. In addition, at one time the citizens of the USSR also had ...

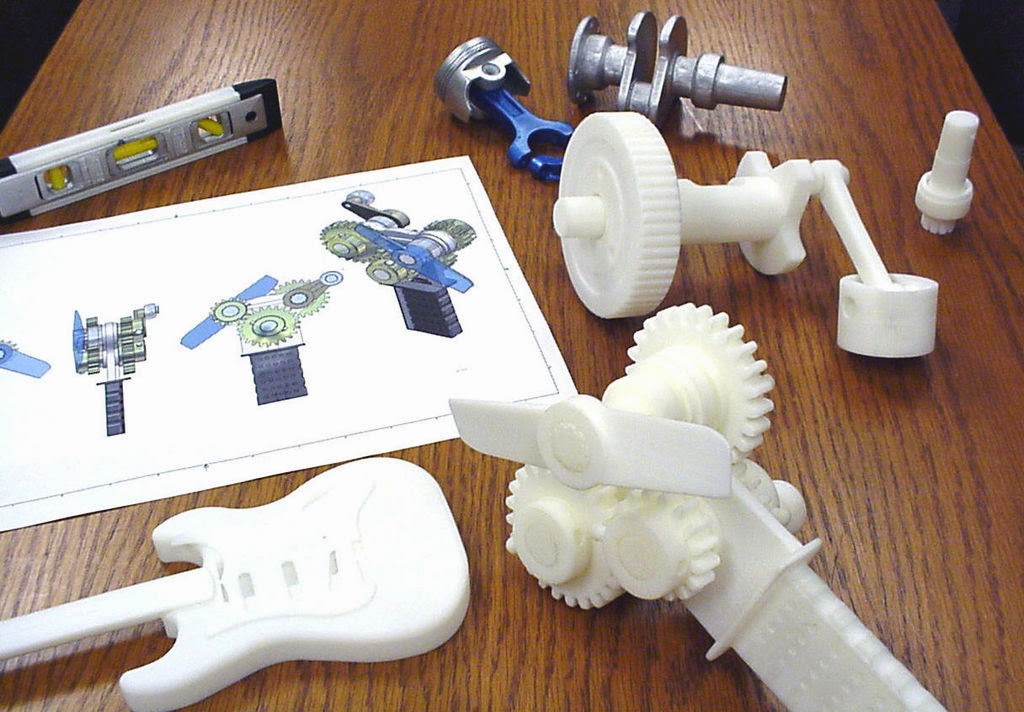

how to work from scratch for beginners and dummies, what it looks like

Three-dimensional printing has become increasingly introduced into our daily lives. Thanks to new technologies, it has become possible to easily print from a small detail to a large building. The range of products is also pleasing - today you can find a lineup that includes both affordable devices and more expensive ones. But how to work with a 3D printer? This is a completely normal question that any beginner will have, it is for this reason that we will try to answer it as simply and accessible as possible.

What is a 3D printer and how does it work?

The 3D device consists of the printer itself and a computer that controls all processes. The principle of operation of such a design is to create 3D models by superimposing layers of liquid material. There are a large number of printer models - from large industrial ones to compact ones, but they all have the same principle of operation and component parts:

The principle of operation of such a design is to create 3D models by superimposing layers of liquid material. There are a large number of printer models - from large industrial ones to compact ones, but they all have the same principle of operation and component parts:

- Extruder - the print head through which the thread passes. The head heats the thread to a semi-liquid state and evenly supplies the material to the working surface.

- Work surface - a printing platform on which a 3D model is formed.

- Motors - mechanisms responsible for the accuracy of movement and speed of printing.

- Sensors are electronic devices that limit moving parts to specified coordinates.

- The frame is the structure that connects all parts of the printer.

The principle of operation of a 3D printer: features

Work with the aim of building a three-dimensional model begins with a sketch, which is created in a special program. After that, the software independently generates a plan for the movement of the print head and a print sequence. The 3D model is reproduced by strongly heating the plastic and distributing it evenly.

The 3D model is reproduced by strongly heating the plastic and distributing it evenly.

3D printers are used in many areas. Let's list some of them:

- Architecture - creation of models of buildings.

- Medicine - dental prosthetics, making models of organs for study.

- Construction - production of houses using 3D printing technology.

- Education - a visual aid for learning 3D printing.

- Automotive - creation of tuning parts, prototype layouts and other products.

This is a small list of industries where 3D printing is actively used. Today, almost every entrepreneur and just an enthusiastic person can afford a printer.

The following printers are distinguished by design features:

- RepRap - self-reproducing printers that can create their own copies.

- DIY-kit - the device comes disassembled with instructions, the assembly of which will take a sufficient amount of time.

- Ready-Made - models are delivered assembled and ready to use.

- Commercial and industrial - devices capable of printing metal, concrete, polymers and other materials.

How to use a 3D printer: tips for beginners, where to start

Mastering the technique of 3D printing is not difficult if you follow the recommendations and tips. Especially for those who plan to learn the basics of 3D modeling, an up-to-date list of questions and detailed answers to them has been prepared.

Printer Installation

To begin, you will need to carefully unpack the box and remove any stops. The next step is to install the printer on the surface using the building level. This will allow you to place the device as evenly as possible, which will provide better printing.

Note. Some 3D printers come with a level for installation.

Next, you will need to connect the printer to your computer and install the necessary drivers. The software disc comes with the 3D device.

The software disc comes with the 3D device.

Preparing for work

To get started, you need to calibrate the working surface - without this, printing quality products is impossible. This process is carried out automatically or manually. The attached instructions have detailed information on how to perform manual calibration.

Extruder patency test

The next important step is setting up the extruder. First of all, you will need to check its nozzle. If the printer has already been used, the nozzle should be cleaned of solidified particles that will interfere with the throughput of the material. Refueling the 3D printer The thread is fed into the extruder directly from the spool. But there is one caveat - for this you must first warm it up. To thread the thread, you will have to make a small effort in order to loosen the presser mechanism.

Working with models

Models can be created in various 3D modeling programs. The process of manufacturing three-dimensional parts is creative, requiring careful preparation. The better and more detailed the model is drawn, the better the 3D layout will be at the output.

The better and more detailed the model is drawn, the better the 3D layout will be at the output.

Start printing

After creating the model in the program and preparing the printer for work, you need to send the file for printing and wait for the result. The print speed varies depending on the printer model and specifications, as well as the media used.

Processing of the finished product

3D products obtained by printing on a printer usually do not please the user with an ideal appearance: the parts have an uneven surface. But this is typical for models of 3D printers on FDM, SLA and DLP devices, which are distinguished by higher print quality. Owners of FDM printers should not despair - a simple processing of products will give products an attractive appearance and make the surface smooth.

Several effective methods for the subsequent processing of 3D printed parts:

- Mechanical - carried out by sanding the surface with sandpaper or a special polishing sponge.

- Chemical - surface treatment with aggressive solvents such as acetone and dichloroethane.

- Mixed - In this case, the above two processing methods are used.

What are the possible mistakes and how to avoid them?

3D printing technology can be mastered even by a beginner, but despite this, the production of the first products causes excitement for the user. Simple operation, detailed instructions and recommendations on the Internet will allow everyone to deal with almost any printer model. But there are a few useful life hacks, the knowledge of which will help you avoid typical beginner mistakes:

- Calibrate and test the 3D printer before starting work.

- Be sure to use the correct file extension for quality printing.

- Do not remove the finished product from the printer immediately after processing, as this may damage the part and cause defects.

- If you encounter errors during the 3D printing process, try restarting the device - this usually helps.

Learn more