3D printing carlsbad

3D Printing Service Carlsbad, CA | Instant Quotes Online

Our 3D printing capabilities

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

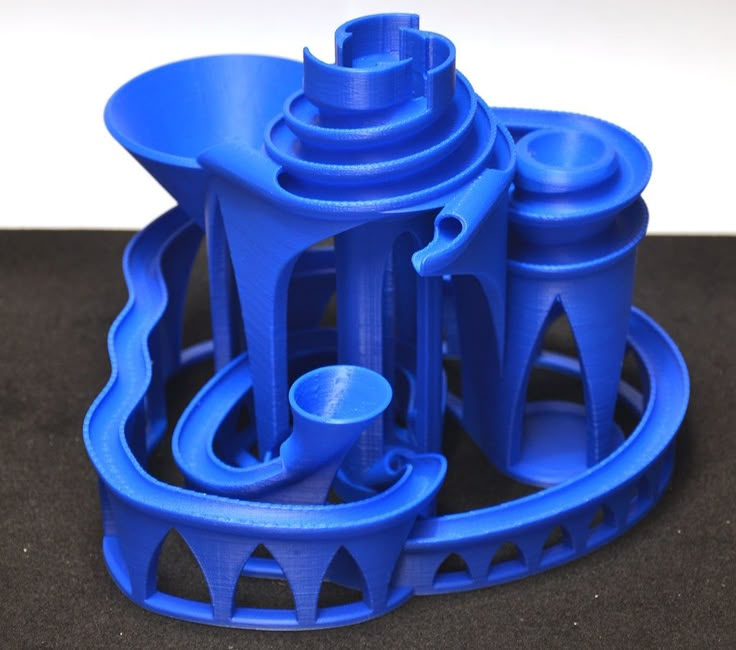

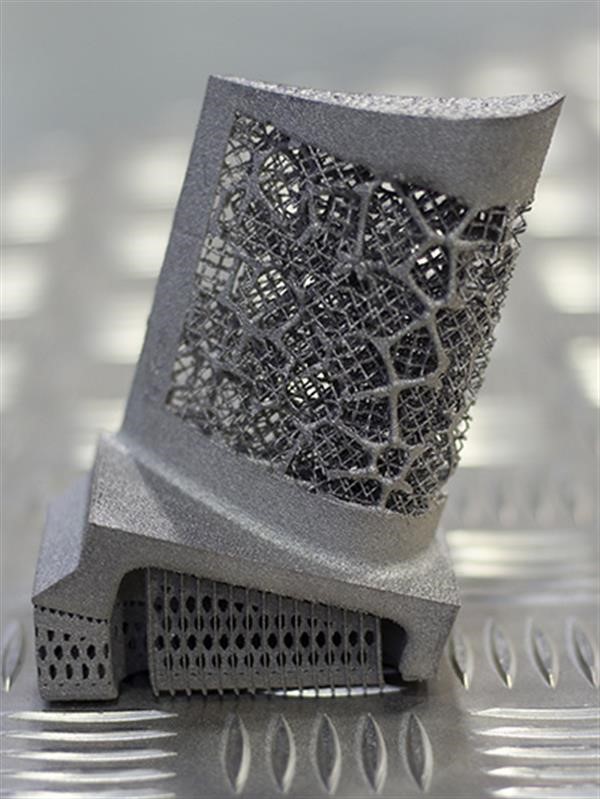

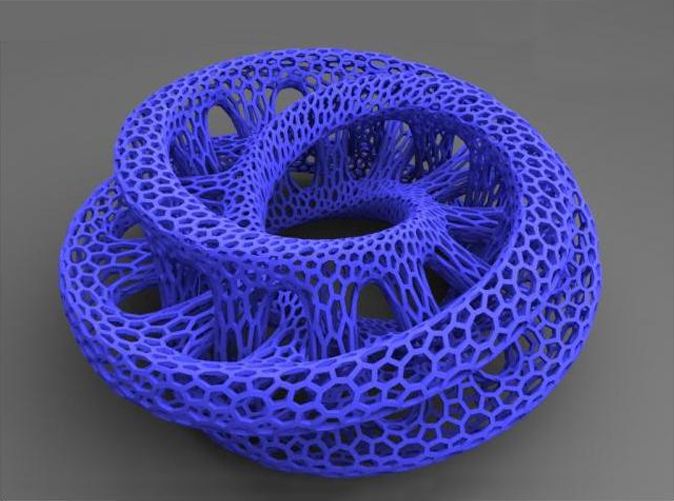

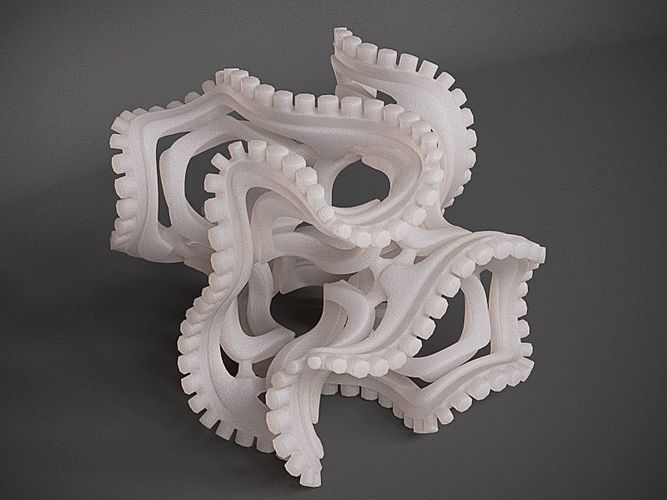

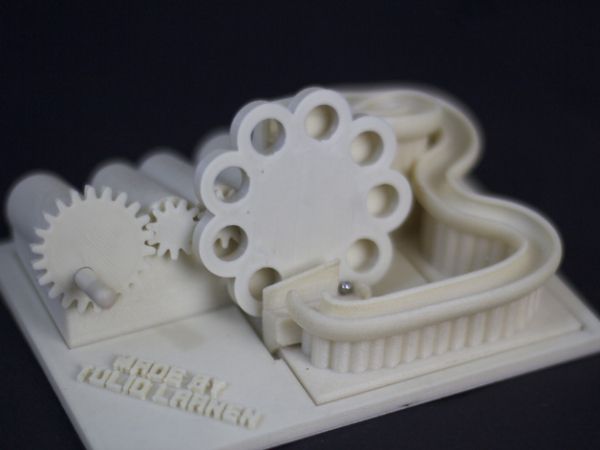

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc.

.

. -

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.9/5

Over 273 customers are satisfied with our 3D printing service.

“Same day print and real time feed back. Excellent job”

“5 star service. Fast response, great print quality, and quick turn around. Thank you. ”

“Parts look great and were delivered early.”

“Hubs is great.. I'm planning on making many more purchase orders!”

“First time having an item 3D printed. Truly amazed with the quality of the items I received!”

“very good prints, great communications and very fast prints”

“Couldn't ask for better service or product. Great communication. Worked with me in selecting a suitable material. Fast turnaround. ”

“Great service. Fast turn around and shipping.”

“Great looking parts done in a timely manner.”

“excellent parts fast turn around and very good pricing.”

“Can't believe how quick this was!! A+ Thank you!”

“Great service and quality. Would use again.”

“Excellent service and hugy knowledgeable. ”

“The print quality was precise and turnaround time was fast!”

“Great parts, fast shipping. Great quality ”

Great quality ”

“Awesome job! Pieces turned out great, nice work :D”

“great 3D printing service meets the expectations.”

“Great print that came with great customer service.”

“Excellent service. Very fast and high-quality results.”

“Better than expected quality. Great service.”

“Great communication. Fast printing and delivery. Great quality. Thank you !”

“Amazing quality, and delivered in just a few days!”

“Amazing quality for the best affordable Price. Communication was great and professionalism was perfect. Parts arrived sooner than expected. ”

“Model was perfect, good packing...overrall great experience! :) ”

“Great communication! Sent many extra samples that were very useful.”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near Carlsbad, CA

Poway, CA Santee, CA Escondido, CA

El Cajon, CA San Diego, CA San Marcos, CA

La Mesa, CA Encinitas, CA Vista, CA

Carlsbad, CA

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

GKN Powder Metallurgy Acquires FORECAST 3D, Expands Additive Manufacturing Capabilities to Include Plastics

US-based plastic parts provider adds 25 years of experience in polymers to GKN’s advanced additive manufacturing production capabilities and market leadership ambitions in this high growth market

Highlights- GKN Powder Metallurgy, global producer of metal powder and parts, acquires leading plastic 3D printing company FORECAST 3D

- Companies join to deliver industrial 3D printing capabilities to more industries across a larger global footprint

- Acquisition builds off rapid success of HP Metal Jet technology, links businesses that successfully leverage HP 3D printing solutions in metal and plastic

London, UK – October 22, 2019 – GKN Powder Metallurgy, the world’s largest producer of metal powder and parts, has acquired FORECAST 3D, a leading US specialist in plastic additive manufacturing offering a full range of services from concept to series production. The acquisition furthers GKN Powder Metallurgy’s ambition to achieve global market leadership in industrializing additive manufacturing. The combination creates a geographic and market expansion for GKN Powder Metallurgy’s conventional and additive manufacturing customers.

The acquisition furthers GKN Powder Metallurgy’s ambition to achieve global market leadership in industrializing additive manufacturing. The combination creates a geographic and market expansion for GKN Powder Metallurgy’s conventional and additive manufacturing customers.

FORECAST 3D, headquartered in Carlsbad, California and founded in 1994, serves a diversified target audience in the North American west coast. Prior to the acquisition, GKN Powder Metallurgy’s primary market focus was in North America’s midwestern region, as well as Europe and China. By combining both businesses, GKN Powder Metallurgy now serves all markets with a full range of 3D printing production technology and an expanded global footprint.

The US-based plastic parts provider adds 25 years of experience in polymers to GKN's advanced additive manufacturing production capabilities and market leadership in this high growth market.“FORECAST 3D is a perfect fit,” said Peter Oberparleiter, CEO, GKN Powder Metallurgy. “They are everywhere we aren’t – geographies, markets, technologies and base materials. Combining our individual capabilities will present unparalleled advantages to our customer bases and enable us to cross-promote additive manufacturing in metal and plastic over more diversified markets. It is an important step on our journey to become No. 1 in this high growth market.”

“They are everywhere we aren’t – geographies, markets, technologies and base materials. Combining our individual capabilities will present unparalleled advantages to our customer bases and enable us to cross-promote additive manufacturing in metal and plastic over more diversified markets. It is an important step on our journey to become No. 1 in this high growth market.”

FORECAST 3D leads the plastic 3D printing industry, with a fleet of industrial-grade HP Jet Fusion 3D printers. FORECAST 3D and HP Multi Jet Fusion technology both deliver industry-leading advantages in quality, speed and economics, complementing GKN Powder Metallurgy’s advancements in metal 3D printing for mass production.

“At FORECAST 3D, our roots run deep in the world of nimble, low volume polymer additive manufacturing. As we continue to branch out and focus on high volume additive production, what better partner to pair with than GKN; a company that produces over 13 million parts per day?” said Corey Weber, CEO and co-founder, FORECAST 3D. “GKN’s resources, production experience and footprint will be the perfect fuel for this new FORECAST 3D engine as we prime it for the new world of local, on-demand manufacturing.”

“GKN’s resources, production experience and footprint will be the perfect fuel for this new FORECAST 3D engine as we prime it for the new world of local, on-demand manufacturing.”

Both GKN and FORECAST 3D have been pioneers in using HP’s metals and plastics platforms. As foundational partners in the HP Digital Manufacturing Network, this acquisition brings together two experienced parts producers to further accelerate the mass production of high-quality final parts for customers around the world.

“There is enormous opportunity for growth in 3D printing and it is exciting to see GKN and FORECAST 3D come together to push the boundaries in both metals and plastics mass production,” said Christoph Schell, President, HP 3D Printing and Digital Manufacturing. “Customers worldwide now have the confidence of two of the premiere producers of 3D-printed parts at the ready to help accelerate digital manufacturing transformation and deliver innovative, high-quality applications. ”

”

About GKN Powder Metallurgy

GKN Powder Metallurgy is a full metal shapes solutions provider, shaping powder metal into high performance and high precision components. It provides leading powder metal expertise and process experience to transform ideas into production. The company consists of GKN Hoeganaes, GKN Sinter Metals, and GKN Additive to provide powder materials, conventional components, and Additive Manufacturing production. It combines three focused businesses under one brand. Together it employs over 7,400 problem solvers over 30 locations, setting its global engineering network at the highest standard.

In September 2018 GKN Powder Metallurgy announced a breakthrough partnership with HP and Volkswagen to bring Metal 3D printing to mass production:

https://www.gknpm.com/en/news-and-media/news-releases/2018/gkn-powder-metallurgy-partners-with-hp-and-and-volkswagen-to-bring-metal-3d-printing-to-mass-production/

About FORECAST 3D

FORECAST 3D was founded in 1994 by brothers Corey and Donovan Weber, in a small garage with a single machine. Today, with over 45 industrial 3D printers in-house and three facilities, FORECAST 3D services companies of all sizes across all industries. Offering a diverse range of additive manufacturing technologies - with HP's Multi Jet Fusion, FDM (Fused Deposition Modeling), DMLS (Direct Metal Laser Sintering), SLA (Stereolithography), PolyJet, as well as Urethane Casting and CNC Machining services - FORECAST 3D emphasizes their focus on the customer and the quality of parts delivered.

Today, with over 45 industrial 3D printers in-house and three facilities, FORECAST 3D services companies of all sizes across all industries. Offering a diverse range of additive manufacturing technologies - with HP's Multi Jet Fusion, FDM (Fused Deposition Modeling), DMLS (Direct Metal Laser Sintering), SLA (Stereolithography), PolyJet, as well as Urethane Casting and CNC Machining services - FORECAST 3D emphasizes their focus on the customer and the quality of parts delivered.

10 Amazing Future Technologies That Already Exist / The Best of the Internet

In the near future, we will get acquainted with several more revolutionary technologies that will radically change our lives.

Implementation of "smart environments" allows transforming even micro-apartments into luxury suites

Life in such housing is simply fabulous. After all, when you get out of bed in the morning, invisible sensors can smoothly lower the bed to the floor. A small sink and mirror will automatically slide out of a special compartment in the wall as soon as you approach them. Also, using the digital inputs (such as a phone or tablet), the gestures and speech needed to communicate with your smart home, you can turn one room from a bedroom into an office, kitchen or living room.

A small sink and mirror will automatically slide out of a special compartment in the wall as soon as you approach them. Also, using the digital inputs (such as a phone or tablet), the gestures and speech needed to communicate with your smart home, you can turn one room from a bedroom into an office, kitchen or living room.

Exosuits increase the capabilities of the human body and help people with disabilities

The military has already tested some of these developments during training. Their main purpose is to reduce fatigue when walking, running long distances or lifting and carrying heavy objects. In addition, some exosuits help people with physical disabilities regain their former mobility and independence. Just imagine that today a person in a wheelchair can get bionic legs - this is truly a brave new world.

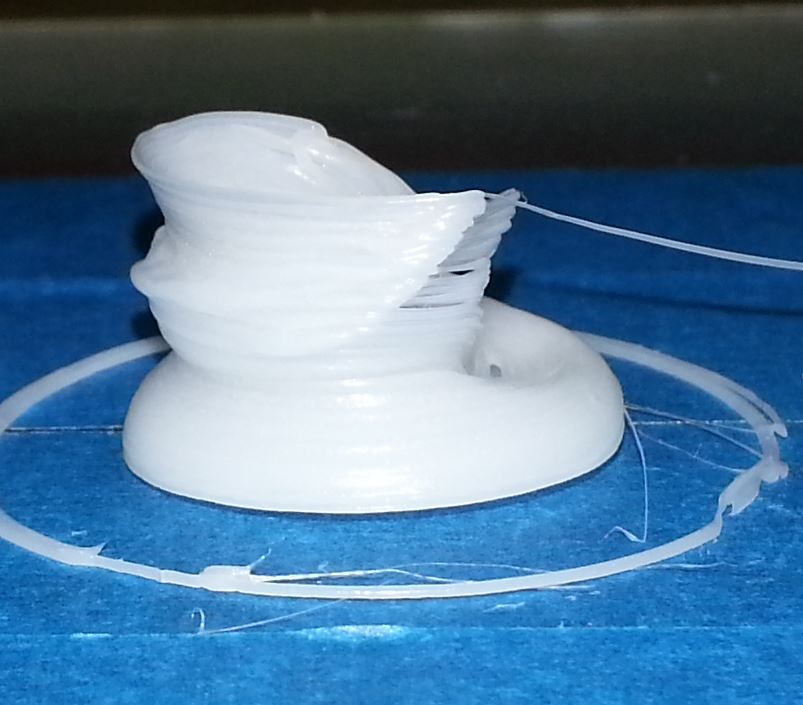

3D printing will do all the hard and boring work for us, including replacing shopping and home delivery, which will soon be a thing of the past

Technically, 3D printing is already actively used, but still remains out of reach for many. Chances are you've never used a 3D printer yourself. But soon this will change. Within the next few years, you will be able to print anything yourself (mostly plastic or rubber) from the comfort of your home. As you can see, we have become one step closer to achieving our "cherished" goal - the complete exclusion of direct interaction between people.

Chances are you've never used a 3D printer yourself. But soon this will change. Within the next few years, you will be able to print anything yourself (mostly plastic or rubber) from the comfort of your home. As you can see, we have become one step closer to achieving our "cherished" goal - the complete exclusion of direct interaction between people.

Invisibility cloaks will help you easily and easily avoid uncomfortable social interactions

Yes, as everyone knows, an "invisibility cloak" makes things invisible to radar, but the scientific principles of a true invisibility cloak are basically the same. The scientists behind the device say the same technique that allows us to redirect radio waves can be used to redirect the waves that allow us to see people and things around us. Get ready for a future where you can just hide when you see someone in the crowd and don't want to talk to them.

Nanotechnology will allow many small things to perform really significant functions

Nanotechnology is sort of a generic term for very small circuits, wires and chips that power tons of equipment. Whether we like it or not, many of the most promising applications for nanotechnology involve incorporating them into the human body. Research shows that "nanotechnology" can help diagnose cancer at its earliest stages, develop electrically conductive inks, and even deliver drugs or gene therapy inside our cells.

Whether we like it or not, many of the most promising applications for nanotechnology involve incorporating them into the human body. Research shows that "nanotechnology" can help diagnose cancer at its earliest stages, develop electrically conductive inks, and even deliver drugs or gene therapy inside our cells.

Major desalination projects will help turn ocean water into clean drinking water

The process of using "hot solar cells" to distill clean water from salty sea water can already be observed today in Cyprus, as well as in Egypt and Australia. The photo above shows the Poseidon Water desalination plant located in Carlsbad, California, which is projected to be online later this year. However, Californians need not worry, as long as they can safely continue to use process water to wash cars and water plants.

Digital graffiti will help resolve the conflict between public art lovers and private property

Using a combination of digital art, photography and geotagging will soon turn any wall into digital graffiti. Some applications of this technology make it possible to use special software to "paint" on the walls. Other apps let you mark walls with "hidden" images that can only be viewed through a smartphone or tablet.

Some applications of this technology make it possible to use special software to "paint" on the walls. Other apps let you mark walls with "hidden" images that can only be viewed through a smartphone or tablet.

Smart clothing will soon combine wearable technology and high fashion

Since circuits and chips can be both tiny and microscopic, in the future, wearable devices will not look like standard gadgets at all. What if your socks could automatically record your heart rate and calculate the number of calories you've burned? What if your glasses could track your eye movements and tell you when you need to turn off your TV or computer? What if your clothes "learned" to change colors so you could wear the same skirt to work and to parties? It won't be long before we answer these questions.

Geoengineering will prevent the formation of hurricanes and tornadoes, and possibly even cool the Earth

Scientists have been trying to change the weather since 1960, when they first started throwing silver iodide at hurricanes to help stop them. They are striving for this even now, and therefore modern geoengineers are trying to cope with everything from preventing adverse weather conditions to intensifying rainfall in areas suffering from drought, and even trying to eliminate the effects of global warming.

They are striving for this even now, and therefore modern geoengineers are trying to cope with everything from preventing adverse weather conditions to intensifying rainfall in areas suffering from drought, and even trying to eliminate the effects of global warming.

Quantum computing will be... well, we're not exactly sure when, but it's going to be crazy technology

Quantum computing can really be called crazy, because the central unit of the latter is a qubit, which literally ignores all existing laws of physics due to its ability to represent two different things at the same time. Also (and we swear it's true) the moment you try to figure out how it works, it stops working altogether. But one thing we know for sure: a quantum computer is much faster and more powerful than anything that exists today. Much more powerful than we can imagine. 9

10 Amazing Futuristic Technologies That Already Exist

environments allows you to transform even micro-apartments into luxury suites

Living in such housing is simply fabulous. Imagine: you get out of bed in the morning, pull on your pants, fasten your heart rate monitors-watches on your wrist, and invisible sensors at this time smoothly lower the bed to the floor, giving way to the most modern sports simulator. A small sink and a mirror automatically slide out of a special compartment in the wall as soon as you approach them. Also, using the digital inputs (such as a phone or tablet), the gestures and speech needed to communicate with your smart home, you can turn one room from a bedroom into an office, kitchen or living room.

Imagine: you get out of bed in the morning, pull on your pants, fasten your heart rate monitors-watches on your wrist, and invisible sensors at this time smoothly lower the bed to the floor, giving way to the most modern sports simulator. A small sink and a mirror automatically slide out of a special compartment in the wall as soon as you approach them. Also, using the digital inputs (such as a phone or tablet), the gestures and speech needed to communicate with your smart home, you can turn one room from a bedroom into an office, kitchen or living room.

Exosuits increase the capabilities of the human body and help people with disabilities

The military has already tested some of these developments during training. Their main purpose is to reduce fatigue when walking, running long distances or lifting and carrying heavy objects. In addition, some exosuits help people with physical disabilities regain their former mobility and independence. Just imagine that today a person in a wheelchair can get bionic legs - this is truly a brave new world.

Just imagine that today a person in a wheelchair can get bionic legs - this is truly a brave new world.

3D printing will do all the hard and tedious work for us, including replacing shopping and home delivery, which will soon be a thing of the past

remains out of reach for many. Chances are you've never used a 3D printer yourself. But soon this will change. Within the next few years, you will be able to print anything yourself (mostly plastic or rubber) from the comfort of your home. As you can see, we have become one step closer to achieving our "cherished" goal - the complete exclusion of direct interaction between people.

Invisibility cloaks make it easy to avoid uncomfortable social interactions

Yes, as everyone knows, an invisibility cloak makes things invisible to radar, but the scientific principles of a true invisibility cloak are basically the same the most. The scientists behind the device say the same technique that allows us to redirect radio waves can be used to redirect the waves that allow us to see people and things around us. Get ready for a future where you can just hide when you see someone in the crowd and don't want to talk to them.

Get ready for a future where you can just hide when you see someone in the crowd and don't want to talk to them.

Nanotechnology will enable a lot of little things to do really big things

Nanotechnology is sort of a general term for the very small circuits, wires and chips that power tons of equipment. Whether we like it or not, many of the most promising applications for nanotechnology involve incorporating them into the human body. Research shows that "nanotechnology" can help diagnose cancer at its earliest stages, develop electrically conductive inks, and even deliver drugs or gene therapy inside our cells.

Major desalination projects will help turn ocean water into clean drinking water

The process of using “hot solar cells” to distill clean water from salty sea water can already be observed today in Cyprus, as well as in Egypt and Australia. The photo above shows the Poseidon Water desalination plant located in Carlsbad, California, which is projected to be online later this year. However, Californians need not worry, as long as they can safely continue to use process water to wash cars and water plants.

However, Californians need not worry, as long as they can safely continue to use process water to wash cars and water plants.

Digital graffiti will help resolve the conflict between public art lovers and private property

Using a combination of digital art, photography and geotagging will soon turn any wall into digital graffiti. Some applications of this technology make it possible to use special software to "paint" on the walls. Other apps let you mark walls with "hidden" images that can only be viewed through a smartphone or tablet.

Smart clothing will soon combine wearable technology and high fashion

Since circuits and chips can be both tiny and microscopic, wearable devices in the future will not look like standard gadgets at all. What if your socks could automatically record your heart rate and calculate the number of calories you've burned? What if your glasses could track your eye movements and tell you when you need to turn off your TV or computer? What if your clothes "learned" to change colors so you could wear the same skirt to work and to parties? It won't be long before we answer these questions.