3D print your own drone

Best 3D printed drone projects

Is a 3D printed drone as efficient as a traditional drone?

Drones and 3D printing are a perfect match! The benefits of drones are more and more attracting for numerous sectors, as it allows to go to areas which are inaccessible for humans. The problem is that a traditional drone can be very expensive if you want a high-quality device. Moreover, it may occur that the quadcopter that you chose isn’t totally adapted to your project and doesn’t have all the features you need. Or on the contrary, the drone can have too many features and you will not use all of them.

The 3D printing industry allows to create your own drone, it’s the perfect way to get a drone customized to fit your needs. It’s is cheaper and the product development process is faster with the additive manufacturing technology. It is possible to create really lightweight drones, little or bigger ones, and even faster ones. 3D printing appears to be a smart choice to develop a drone project.

And if you’re not planning to use 3D printing to manufacture your drone, at least, it is possible to use 3D printing for your prototyping phase.

Now, let’s see in our top the best projects developed with 3D printed drones!

Top 15 of the best 3D printed drone projects

1 – The 3D printed drone project of the Marine Corp

Drones are already well-used in the military sector since they allow the troops to get real-time images of dangerous areas and situations. But the major problem with a drone is its cost. If the drone is broken, it is quite expensive to replace. And even if there’s just a broken part, the budget to fix it can be really high.

source: https://www.popsci.com/marine-corps-3d-printed-drones

As they were beginning to be unwilling to use it, they looked for another solution. With a more affordable drone, they would be more confident to use it. And here came the solution: 3D printing. To 3D print a drone is way cheaper and fast to assemble. By using additive manufacturing, the entire system that they are planning to use only costs 615$ while an individual Raven drone costs 30 000 $.

By using additive manufacturing, the entire system that they are planning to use only costs 615$ while an individual Raven drone costs 30 000 $.

This 3D printed drone project is the proof that additive manufacturing can be useful in various sector: even the Marine Corp wants to 3D print their drone. It is also the proof that these kind of drones are reliable.

2 – 3D printed drone to save lives during disaster relief

This 3D printed quadcopter drone as designed by Yuki Ogasawara and Ryo Kumeda. The idea of the project emerged after the earthquake that touched Japan in 2011.

During this disaster, nearly 16 000 people were killed and 2 500 missing. The goal of this 3D printed drone is to fly in dangerous zones to find survivors, after a catastrophe, such as an earthquake. These drones could enable emergency services to see images in real time and be more efficient by saving time in the research.

Source: https://3dprint.com/181435/generative-design-x-vein-drone/

3D printing allowed them to create a model that they could customize and adapt to their project. It has the perfect size and weight for these kinds of conditions, it has an extended flight time, and a reinforced frame. The drone is also capable of carrying thermographic and infrared-imaging equipment, which can be particularly useful to locate people needing help.

It has the perfect size and weight for these kinds of conditions, it has an extended flight time, and a reinforced frame. The drone is also capable of carrying thermographic and infrared-imaging equipment, which can be particularly useful to locate people needing help.

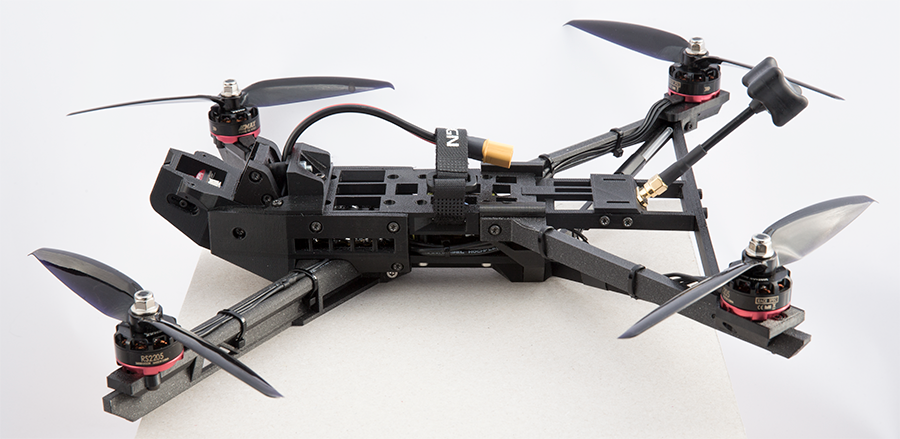

3 – UVify and their 3D printed racing drones using autonomous technology

UVify is an american tech company, working on racing drones, robotics, and artificial intelligence systems. Their will is to develop their drones with FPV (First Person View) in the e-sport world. This 3D printed drone is called Draco. Some of the drones created by UVify are raced by professionals in different competitions.

They are according a big importance to the drone design and the rapidity of the drones. They have to be efficient. Uvify wants to create an out of the box drone, specially made for the professional drone racing market.

“We used and are still using 3D Printing in our activity: we’re creating at least a new iteration every week thanks to 3D printing prototypes. ” said Robert Cheek in one of our previous blogposts.

” said Robert Cheek in one of our previous blogposts.

They are using the 3D printing technology both for prototyping and production. It allows them to get their drone with a fast lead time and get a high-quality final product.

4 – Earth observation with a 3D printed drone thanks to Svarmi

Svarmi is an Icelandic company, specialized in drones as a service, for remote sensing or earth observation. Their clients are architects, engineers, researchers, and any people wanting aerial images.

As their product development is based on their clients’ expectations, 3D printing allows them to be free and customize their drone as much as their customers need it. As this company explained to us: “Other traditional manufacturing methods are too slow and costly for our purposes since we need to be able to have something ready within a week or two. After integrating the new sensors to our drones we test them out with our customers and redefine the requirements if needed to suit the task and sometimes redo the process again by refining the design or selection of sensors. ”

”

These 3D printed quadcopters are the challenging and innovative project of two mechanical engineers. They created 3D printed drones thanks to our online 3D printing service, they state that 3D printing allowed them to save 40% time on their product development process.

5 – CargoCopter 3D printed drones: the future of delivery

Delivery services are more and more requested. Recently, we’ve heard a lot in the past few years about delivery services that could be using drones in the future. This is now a reality, and it’s the goal of the CargoCopter, a fully 3D printed drone. This drone is able to transport a charge of 5 kg and reach the speed of 150 km/h. It is an efficient drone which aims to deliver goods on a long distance.

3D printing is allowing these KU Leuven researchers to do some rapid prototyping, so they can adjust the design of the drone through the years to finally create this CargoCopter. This drone project may be the future traditional way to deliver goods!

This drone project may be the future traditional way to deliver goods!

6 – Jarriquez and their 3D printed drone

As for the military or rescuing sector, using a drone is firstly a way to go where humans can’t go. It is also the goal of the 3D printed drone developed by Jarriquez

This 3D printed drone is actually able to find its way with minimal human intervention. This unmanned aerial vehicle can generate a high quality 3D map, and can go in dangerous zones. Why did they chose 3D printing to develop their project? Because it was easy to get an object from a CAD model in a few days only, and with a reasonable price.

Jarriquez Drone with its 3D mount for the LIDAR sensor

“Our solution integrated a LIDAR sensor that could have been used for many different devices. Attaching it to the body of the drone in the proper way was essential for the feature to work. 3D printing gave us the possibility to do it in a record time and at a very reasonable price” added Mathieu Agostinucci, from the Jarriquez team in our previous interview.

3D printing gave us the possibility to do it in a record time and at a very reasonable price” added Mathieu Agostinucci, from the Jarriquez team in our previous interview.

7 – A 3D printed drone for rescuing missions

This drone is the result of the work of a swiss-based doctoral assistant Przemyslaw Mariusz Kornatowski. This 3D printed drone is called PackDrone.

This quadcopter can be deployed in rescue missions. It is made to deliver water, food or any first aid equipment to people trapped after a catastrophe.

source: https://www.redbull.com/gb-en/packdrone-folding-drone

A lot of parts of this drone were created thanks to additive manufacturing. It has a particular design: it actually is a folding drone, created especially to be safe and easy to put in a backpack by the teams in charge of rescuing missions.

8 – Blue Robotics and their underwater 3D printed drones

The company Blue Robotics created underwater drones. This crazy project started with a crazy idea: they decided to send a GPS-guided solar-powered robotic boat from Los Angeles to Hawaii.

“The industry of Marine Robotics has stifled innovation by keeping the mechanics and technology expensive. With 3D printing people are able to prototype and final manufacture parts inexpensively and quickly. That’s why we chose Sculpteo!” – said Rusty Jehangir, the founder of Blue Robotics

Using additive manufacturing is also a way to get small batches for the parts of the final product, which isn’t possible with traditional manufacturing. This drone is quite a challenging project, as the final result has to be resistant, light, and ready for a special journey!

9- Local Motor and their 3D printed drone connected to its… 3D printed car.

This project is quite ambitious but it is above all managed to see the limits of three different technologies : autonomous cars, drones and 3D printing.

source: https://www.cnet.com/roadshow/news/local-motors-3d-printed-car-now-has-a-drone-because-autonomy/

It is an impressive challenge, driven by Local Motor. The autonomous car is able to drive by itself thanks to a dedicated software. In the meantime, the driver of the car is able to pilot the rc drone to look around with the specific view of the drone. It enables the driver to see eventual traffic jams, or just see the landscape, and explore new areas.

The autonomous car is able to drive by itself thanks to a dedicated software. In the meantime, the driver of the car is able to pilot the rc drone to look around with the specific view of the drone. It enables the driver to see eventual traffic jams, or just see the landscape, and explore new areas.

10 – 3D printed drone, created only using 3D printing and laser cutting technology

Most of the time, 3D printed drone projects are using additive manufacturing to create prototypes, and some parts of the finished product.

Here, the project was to create a traditional quadrotor drone, using exclusively 3D printing and laser cutting. They 3D printed the arms, the motor mounts, and every parts of the drone. It was a success, showing that it is possible to create anything with 3D printers. This drone is extremely light and it is the proof that everything is 3D printable, thanks to all of our 3D printing materials and technologies. Moreover, this project shows the capacity and accuracy of the laser cutting technology.

11 – A 3D printed drone to capture professional images with Hexadrone

Hexadrone is a company based in France, building drones and offering their service to film for TV shows, advertisements or movies. As they are creating high quality filming, they need a stable drone.

As there is actually a weight limitation for drones, Hexadrone needed to use a light material. And that is where 3D printing shows to be a helpful solution. They used our plastic material, and the SLS technology enables them to get resistant and complex parts, perfectly fitting their needs.

“Thanks to 3D printing, parts are really quickly available, which means we can test them within a few days, and make changes reactively” said Alexandre Labesse, CEO at Hexadrone.

12 – 3D robotics and My Mini Factory create 3D printed drones

3D robotics and My Mini Factory collaborated on the development of drones and the model Iris+ is one of them. You can then download all the technical STL files with great 3D details, and you can then 3D print at home using your 3D printer, or a 3D printing service such as Sculpteo.

13 – The Dark Matter, by Clogworks

The Dark Matter is a drone developed by Clogworks, based on a modularity concept.

This drone is not fully 3D printed, but is manufactured using CNC Machining, Carbon fibre and 3D printing. The goal of this Dark Matter project, was to create a drone with a bigger flexibility and a great ease of maintenance. The performances of the drone are quite impressive, all about precision.

14 – The smallest drone, by UPenn

The 3D printed mini drone made by UPenn, Piccolissimo just has one motor and two rigid bodies. Researchers at the University of Pennsylvania’s School of Engineering and Applied Science developed the smallest flying vehicle. In order to make a really light device, this tiny drone has been 3D printed with really light plastic.

15 – Skeleton x14 quadcopter

The Skeleton x14 quadcopter can be printed by any desktop 3D printers, as its STL files are available online. The design of this drone is quite interesting as it is based on an intricate design mesh. It is totally possible to customize it once you have the 3D files of the drone!

It is totally possible to customize it once you have the 3D files of the drone!

DIY: build your own drone!

You have an idea for a drone project ? Keep in mind that your ideas are 3D printable, and that we can totally help you with this, thanks to the 3D printers of our online 3D printing service. Here, at Sculpteo, an intern created a 3D printed drone from scratch and we are sure that you could do it as well.

As we just saw, it is possible to create a drone using 3D printing and laser cutting you don’t need traditional manufacturing, just 3D printers. First, you will have to use a 3D printing software. If you don’t know which software to use check out our blogpost to choose the perfect free 3D modeling software, adapted to your level of expertise. Some of them are pretty easy to use.

Once your drone is 3D designed, you can choose the 3D printing materials to print your parts. Then, you have to complete your order, and you’ll receive your 3D printed models in a few days. Obviously, you’ll have to assemble the different parts. If you are a little bit crafty and determined, ready to deal with electronic components, motor mounting and camera mounting, you can achieve a great 3D printed drone project.

Obviously, you’ll have to assemble the different parts. If you are a little bit crafty and determined, ready to deal with electronic components, motor mounting and camera mounting, you can achieve a great 3D printed drone project.

You want to give it a try ? Upload your 3D model now and 3D print your own unmanned aerial vehicle!

If you want more informations to 3D print your drone, don’t hesitate to contact us.

The Top 6 Frames to 3D Print for Your DIY Drone

On your way to building a DIY drone? Here are some of the best drone frames you can 3D print for free.

3D Printable Drone Frames

Making a sturdy and standard frame is a key part of the process of building your own DIY drone. Of course, you could also buy a frame, but that doesn't match the DIY spirit. Especially if you've already got access to a 3D printer.

One advantage of 3D printing your drone's frame is that you can do it again. This means that if you ever get in a flying accident and damage the frame, you won't have to go looking for spare parts as you can simply print them.

So if you plan on 3D printing a frame for your drone, there are plenty of models available for download and print online, and here are some of the best ones.

Building on the success of the original MHQ, the Hovership MHQ2 is a complete and functioning frame model designed for brushless rotors. This frame is designed to accommodate the rotors in an H shape, and the arms are foldable so that you can tuck them inside the body when you're not using the drone.

The MHQ2's design has room for plenty of auxiliary modules and sensors, though if you're planning on building your drone with Arduino, you're better off using a smaller board like the Arduino Nano.

The MHQ2 is easy and straightforward to print and doesn't have any tricky parts. It's best if you print the arms with an infill above 75% so that they don't snap in your first flying accident. You're going to need a handful of M3 bolts and nuts to put the frame together.

Related: What Is Arduino? What Can You Do With It? Explained

This Micro H-Quadcopter frame is designed for tiny brushed 8. 5mm motors and is small enough to fit in the palm of your hand. The arms are attached in an H shape, and the frame houses a rubber band mount for a small 1S LiPo battery. It's also got a mount for attaching a tiny camera with double-sided tape.

5mm motors and is small enough to fit in the palm of your hand. The arms are attached in an H shape, and the frame houses a rubber band mount for a small 1S LiPo battery. It's also got a mount for attaching a tiny camera with double-sided tape.

The flight controller compartment is 30x37mm, so there isn't much room for extra modules, but you can easily fit a flight controller or a tiny Arduino board in there.

The Micro H-Quadcopter's frame model is easy to print and it's also a quick print as it's pretty small. Keep the infill above 60% to get a sturdy frame. You can put the frame parts together with M3 bolts, no glue required.

The Crossfire 2 might be the best true X-shape DIY frame out there. Sturdy and yet lightweight, and with a spacious three-story compartment to fit nearly every module you want, it’s a great choice for beginners and veterans alike.

This frame is large enough to house a 4S LiPo battery, a large flight controller (or Arduino Uno), and tons of modules. The electronic speed controllers are mounted on the arms and tightened with plastic clamps.

The electronic speed controllers are mounted on the arms and tightened with plastic clamps.

The entire frame weighs around 400 grams, which means the print will take quite some time, but it's a full package as it comes with numerous plates and even a GoPro cover. The Crossfire 2 has been standardized to work with M3 hardware and the designer MikeyB has included an extensive guide on how to print the frame and build a drone on it.

Related: The Best Cheap Drones With Cameras

Though most DIY drones show off their wirework, the PL1Q Vampire offers a different approach. The only visible parts in a drone with this frame are the motors and the propellers, and everything else is hidden inside the frame, or under the vampire's cloak if you will.

The model is designed to work with brushless motors, the arms are long enough to use 8" propellers, and the flight controller compartment is big enough for an Arduino Uno.

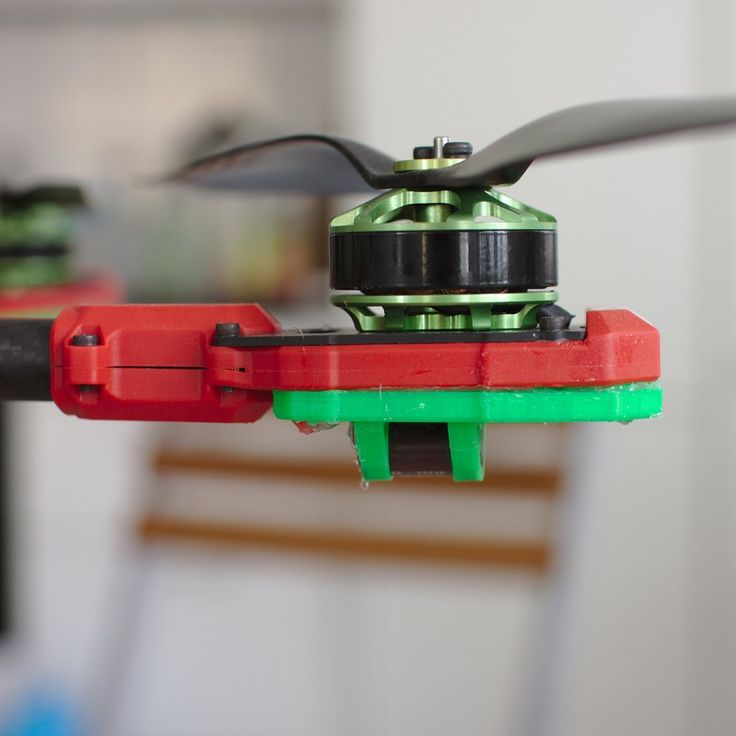

The PL1Q Vampire is harder to print than the other models in this list, and some parts will require supports to print properly. Use 100% infill on the motor mounts and 40% for the rest. Print the landing gear in 100% if you plan on making rough landings.

Use 100% infill on the motor mounts and 40% for the rest. Print the landing gear in 100% if you plan on making rough landings.

Yet another Micro-Quad, albeit this time with foldable arms. This Foldable Brushed Micro-Quad isn't as micro as you would expect, but it still fits in the palm of your hand if you tuck its arms inside. This frame is built in a stretched X shape which gives you more stability at high speeds.

You can build this quadcopter with 8.5mm brushed motors and a 1S LiPo. You'll be skipping the speed controllers since this model works with brushed motors. The frame is a bit too heavy for doing acrobatics, but since it's got a nice camera mount it's perfect for FPV flying.

The print process for this foldable Micro-Quad is simple, as the parts are small and you don't need any rafts or supports. You can put the frame together with M2 and M3 bolts and nuts.

Related: Essential Drone Photography Apps and Guides for Beginners

The idea behind Nanolongrange was to make a long-range lightweight drone that's designed around a single lithium battery and it does a great job at that, as the entire drone, with a camera, weighs under 45 grams. Having built the drone around a single lithium battery gives the frame a unique structure shape, which is neither an X and nor an H.

Having built the drone around a single lithium battery gives the frame a unique structure shape, which is neither an X and nor an H.

This frame is designed for brushless motors. However, it cannot accommodate external electronic speed controls, so you should use an AIO flight control. This makes building this drone with Arduino harder, compared to other frames.

The print is a single file that you can print at above 40% infill with PLA or ABS filaments. This design uses lithium-ion batteries instead of the go-to LiPo batteries that most brushless drones use.

Related: Unique Ways That Drones Are Being Used Today

Print Your Own Drone Frame

Now that you've got a good array of frames to pick from and print, you can further customize the frames by changing the size, the material, the color, and more to build a truly unique drone. Be it an X or H shape, with brushed motors or brushless motors, you can build just about any sort of drone if you've got the right frame.

If you've recently gotten yourself into drones and want to start learning more, then you should start with the first step and first learn how drones fly.

3D Printer Drone and Quadcopter Models

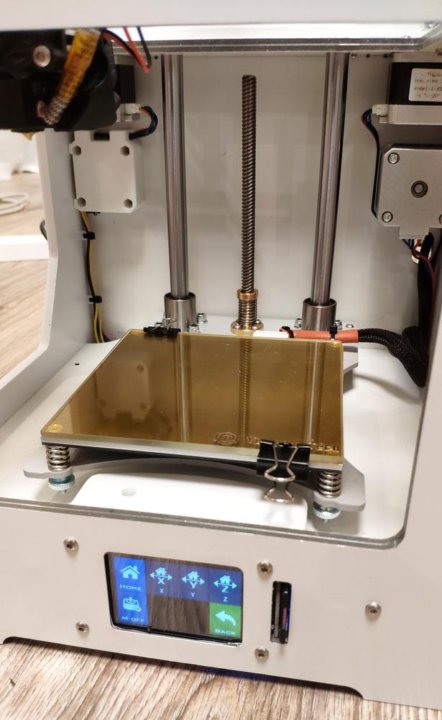

This article is an introduction to 3D Printing your own quadcopter drone. You will get acquainted with some basic principles of drone building, and we will describe some points step by step. The task will be relatively simple, since the description will be detailed.

What we need to get started

In addition to the 3D printer, we will need some non-printable parts such as a motor, batteries or accumulators, some electronics, sensors, a remote control and a knack to put it all together.

Why print a drone?

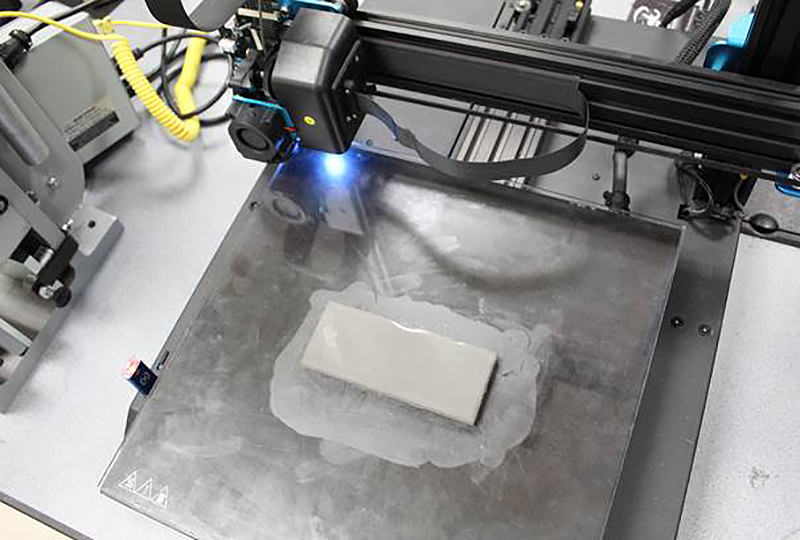

Actually, we will be printing the frame and body structure. Sometimes propellers can be printed. Why is it important? Because drones fall and break. Especially if you are a beginner pilot. This picture shows everything clearly:

If we 3D print parts, we will have an almost infinite supply of spare parts, which will make it easier to survive pilot training and regular plane crashes. Apart from the fact that the quadcopter will be easier to repair, a homemade drone will allow you to get a better feel for its inner workings and mechanics.

Apart from the fact that the quadcopter will be easier to repair, a homemade drone will allow you to get a better feel for its inner workings and mechanics.

And one more important point: 3D printing allows you to quickly develop parts according to your own project. Let's say you have purchased a new camera and want to install it on your quadcopter. Then you just open up your favorite 3D modeling program and end up printing out the part and testing it. Make changes, print again, etc.

What is a quadcopter drone?

A quadcopter is a multi-rotor helicopter that rises and moves with four main rotors and does not have a tail rotor. This is the most common type of amateur radio-controlled drones.

Small in size and highly maneuverable, these quadcopter drones can fly both indoors and outdoors. In addition, at this size, quadcopter drones are cheaper than conventional helicopters and more reliable due to their simple design.

Here is a detailed overview of the details of a commercially available high-end quadcopter drone used for aerial photography.

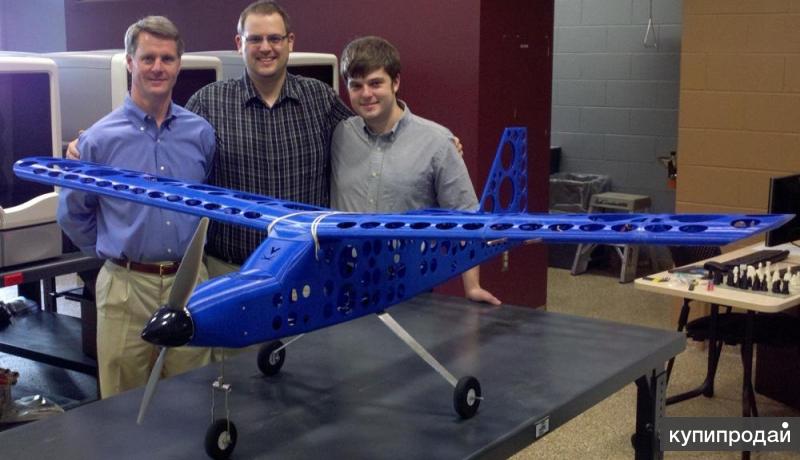

Almost all parts that are not motor or electronics can be 3D printed. The printed version of the drone looks a little different.

3D printed Crossfire quadcopter. Link to the project: http://www.thingiverse.com/thing:32281

In addition to the visual and aesthetic differences, the printed version has the advantage of being easy to update and modular. In the next video, Dennis Baldwin talks in detail about his quadcopter.

How to Print a Quadcopter Drone

If you want to build your own drone, we offer several entry points to the project. Here is a detailed guide to 3D printed quadcopter:

http://www.instructables.com/id/3D-Printed-Quadcopter-with-Arduino/?ALLSTEPS

Titch Micro Drone

https://www.myminifactory.com/object/ 38967

Brushed Y6 Micro Quad

https://www. myminifactory.com/object/brushed-y6-micro-quad-31348

myminifactory.com/object/brushed-y6-micro-quad-31348

Millennium Falcon Drone Shell

https://www.myminifactory.com/object/millennium-falcon-drone-shell-10144

Micro 105 FPV Quadcopter

https://www.myminifactory.com/object/micro-105-fpv-quadcopter-21362

Micro 105 FPV Quadcopter

https ://www.myminifactory.com/object/3drobotics-iris-19615

Hexacopter drone

https://www.myminifactory.com/object/hexacopter-drone-19600

And this is the instructions for building an H-shaped drone:

http://www.instructables.com/id/Make-an-H-Quadcopter-with-3D-printing/?ALLSTEPS

Printed remote control

If you want to 3D print

insectoid ornithopter on a 3D printer

9002 Detailed Guide to the Insectoid Ornithopter:http://www.instructables.com/id/3D-Printed-Ornithopter-Micro-UAV-Drone/

Regulations

Please be aware that there are a number of laws governing the flying of amateur drones and drones, they are different everywhere and it is important to get acquainted with them. Safety is also important! High-flying objects with propellers rotating at high speed in the hands of inexperienced pilots can cause considerable damage to people and property.

How to fly the quadcopter drone?

Youtube is full of instructional videos about this, they can be your starting point. Once you get the hang of it, you can do fun things like cockpit drone racing.

From the screw!

everything you need to know before you start

Contents

- 1 Introduction

- 2 Fundamentals of 3D Printing Drone Parts

- 2.

1 Benefits of

1 Benefits of - 2.2 Best Materials 23 003

- The main advantage of 3D printed parts is that they can be completely customized. In addition, they are generally inexpensive (assuming you already have a printer and filament (3D printing filament)), and the design can be quickly iterated from initial to final version.

- The printed parts are available in various materials and colors. This approach allows the use of a material with better mechanical properties for specific elements. For example, your GoPro mount might be blue TPU with nylon prop guards. Camera holders are best printed with TPU (Thermoplastic Polyurethane; TPU) as this material absorbs vibration from the frame and holds the GoPro tightly in place, while the durable nylon can absorb shock and protect both the propellers and the object/obstacle itself.

Other durable materials such as reinforced nylon can even be used to create gliders, awnings and camera hangers.

Other durable materials such as reinforced nylon can even be used to create gliders, awnings and camera hangers. - Another advantage of using printed parts is their relatively low density. With 3D printing, parameters such as the number of perimeters and infill percentage can be adjusted to significantly reduce weight, with the former more predetermined in the final result.

- While the parts being made are fully customizable and lightweight, they can be quickly iterated. For example, when designing a canupi, the first draft of the blank can be printed from an inexpensive material such as PLA, and after the fitting process, all required changes can be easily made into the next iteration. Once the model is considered complete, it can be printed in more expensive material such as carbon fiber, nylon, or even, if budget allows, PEEK carbon fiber.

- In addition, if you have a printer and filament, the problem of a broken part is not relevant, since you can start creating a new one right away. Even though many retailers offer fast shipping, it's always best to print the part yourself.

- Thingiverse is a great free resource for finding mounts for public cameras (GoPro, Insta 360, etc.) and frames (TBS Source One, ImpulseRC, Iflight, etc.).

- GrabCAD is another popular free resource that tends to offer more engineering models, however there are still models related to quadcopters on the list. Please note that you will need an account to upload models (remarkably for Thingiverse this is not necessary).

If you download models from any repositories (including the websites listed above), be sure to check the license under which they are located so that they do not infringe copyright when selling. - If you happen to have a specific frame or chamber, remember that the manufacturer of those components often has design data available for download and printing.

In this case, this approach will be most useful, because the likelihood that the part will match yours may be higher than if you use the data of a third-party website.

In this case, this approach will be most useful, because the likelihood that the part will match yours may be higher than if you use the data of a third-party website. - If you can't find what you need anywhere, you can design your own parts in CAD software or have someone else design them for you.

Fundamentals of 3D Printing Drone Parts

Hero 8 Printed 5" Mini Quad Mount (Source: Rob Davey via All3DP)

are vehicles capable of operating autonomously. In other words, a drone is not necessarily an aircraft; they can also include cars, boats and even hovercraft. However, the term is used to refer specifically to an aircraft that has three or more rotors to provide lift and thrust. They are also commonly referred to as multicopters, tricopters, quadcopters, and so on.

In general, UAVs are mechanically very simple and consist of a frame, flight controller, el. motors, propellers, speed controllers and possibly first person view (FPV) equipment.

3D printing has long been a great drone hobby. This technology allows the user to easily produce many different parts on their own. This can be anything from protective bumpers and action camera mounts to accessories that add functionality to the quad.

In this article, we'll talk about what to consider when 3D printing drone parts, the most relevant parts to print, and where to find models and resources. We'll then wrap things up with a few projects to get you started. But first, let's figure out why you even need to print parts on a 3D printer. Read on to find out more!

Benefits

Smartphone holder (Source: Digit Design and Prints via Facebook)

This photo shows the manufacturing sequence of the canupi for an FPV drone (Source: Rob Davey via All3DP)

Considerations

Do you need all these components? (Source: Rob Davey via All3DP)

While 3D printing opens up a whole new world of possibilities in terms of additional features, the most important thing to keep in mind is the weight of your aircraft. Not everything that can be printed and installed is useful! It should be understood that every gram of a drone affects the flight time and flight characteristics, especially for rotorcraft. In other words, on a UAV whose primary purpose is long flight, the presence of components such as a GoPro mount, a head tracker, and a reset mechanism is not necessary.

You may also notice that large companies such as DJI who sell UAVs and similar aircraft usually offer the necessary mounts and accessories; they are all printed, but their number is as limited as possible, because they simply add weight.

In addition, in many countries, including the Russian Federation, the rules require registration of models weighing more than 250 grams. Accordingly, the demand for quadcopters weighing below this limit is much higher.

Best materials

Beam guard, GoPro mount and antenna mount all printed in TPU (Source: Digit Design and prints via Facebook)

Most commonly used material for quads (particularly for mini niches) ) is TPU. This is because it is highly flexible and can deform on impact, absorbing energy and protecting important UAV components. Due to its flexibility, it can also absorb vibration, reducing visible artifacts in recorded video. Fortunately, this has become less of an issue with the introduction of in-camera stabilization. Another suitable material is nylon. It is stiffer than TPU, but still has some flexibility.

Material Applicability

The main parts printed on TPU are bumpers, camera mounts, antenna mounts and propeller guards.

Nylon can also be used to protect props, but is less common because it is harder to print.

Nylon can also be used to protect props, but is less common because it is harder to print. While TPU and nylon are versatile, they are not suitable for all parts. Where more rigidity and strength are required, such as in the manufacture of gliders, carbon-fiber-reinforced nylon (CFRPA6) is recommended. This approach will provide the benefits of standard nylon, coupled with the rigidity of carbon fiber. It's also easier to print on than regular nylon because it warps less and sticks better to the 3D printer's build plate.

One way to protect the underside of the boat's frame, as well as the motor mounting bolts, is to add 3D-printed "stands or landing pads". They are especially useful when flying over concrete surfaces. The ideal material for this is CFRPA6. You can also print them in TPU, but the abrasion resistance won't be as good.

Variety of Parts

5" Racing Quadcopter with Turtle or Turtle Mode Tandem Fin (Source: Rob Davey via All3DP)

Fins

If racing drones are your hobby, you should try using a fin.

This component is especially relevant in tandem with the mode known as "turtle or turtle". When the drone is flipped upside down, thanks to the fin, the two motors free from contact with the surface will be able to rotate freely, which will subsequently allow you to quickly flip the quad and continue the race. They are most often printed in TPU and sometimes in nylon.

This component is especially relevant in tandem with the mode known as "turtle or turtle". When the drone is flipped upside down, thanks to the fin, the two motors free from contact with the surface will be able to rotate freely, which will subsequently allow you to quickly flip the quad and continue the race. They are most often printed in TPU and sometimes in nylon. Antenna Mount

FPV transmitter antenna holder printed in TPU (Source: rapnit via Thingiverse)

If you are flying in FPV mode, VTX antennas are vital. Thus, there are many mounting options for such components. If the device is intended for flights over long distances, then enclosing the active part of the antenna in a TPU is not a good idea, as this will adversely affect the video signal. For them, TPU is the preferred choice because it is very elastic and can deform without breaking for a long time.

It is also possible to enable head tracking in FPV mode, when the FPV camera is mounted in a motorized drive, allowing it to move in two or three dimensions according to your FPV goggles.

Thus, the camera copies the movements of your head, contributing to greater immersion. For this, inflexible materials such as PETG, ABS, ASA or even PC should be used. Rigidity is needed to eliminate play in the components.

Thus, the camera copies the movements of your head, contributing to greater immersion. For this, inflexible materials such as PETG, ABS, ASA or even PC should be used. Rigidity is needed to eliminate play in the components. Functional components

The 2-axis gimbal (to stabilize the camera) was printed in PLA (Source: turbi via Thingiverse).

If FPV flying or racing isn't your thing, you can always print the parts to expand the functionality. Maybe it's a camera stabilizer for aerial photography or video shooting, or a mechanism for grabbing and dropping objects? For a gimbal, the moving parts must be printed on a non-flexible material to eliminate play.

When installing the stabilizer on the drone, there must be a flexible part between it and the gimbal to isolate it from vibration.Guard

This stick guard was designed by Fusion 360 (Source: Motorpixiegimbals via Thingiverse)

Finally, another good print option is parts to protect items such as the control sticks of a remote control.

They can be either flexible or non-flexible, depending on your preference.

They can be either flexible or non-flexible, depending on your preference. Model sources

GrabCAD search results for "Drones" (Source: GrabCAD)

Resources

This site has an active user base and many helpful discussions (Source: DIYDrones)

While many of the individual components can be downloaded from the sites listed above, there are also additional resources such as forums. The main forums for drone manufacturers are DIYDrones and RCGroups. A complete list of printable gliders on RCgroups can be found in one helpful thread, or similar listings can be found on DIYDrones. In addition, there is a subreddit for drones that discusses 3D printing topics, as well as a subreddit for do-it-yourself drones.

Projects to get you started

Canupi model with custom molded GoPro holder (Source: basdelfos via Thingiverse).

Learn more

- 2.