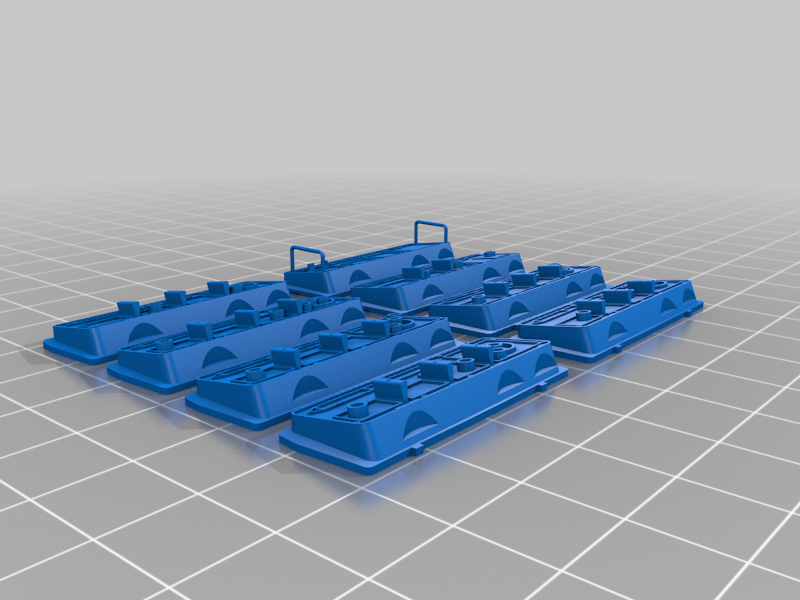

3D printed fuel tank

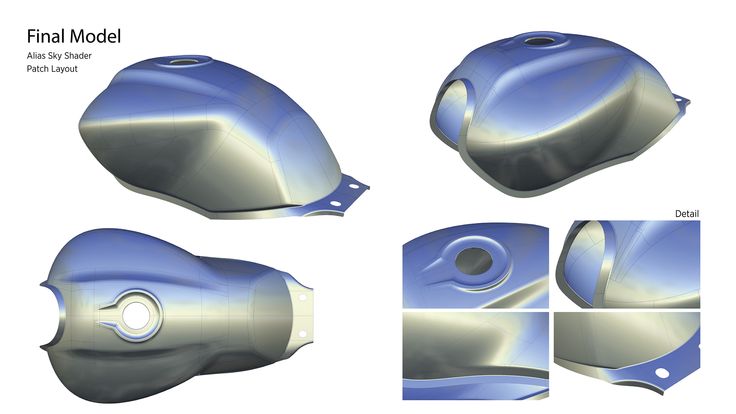

Minibike features ground-breaking 3D-printed fuel tank

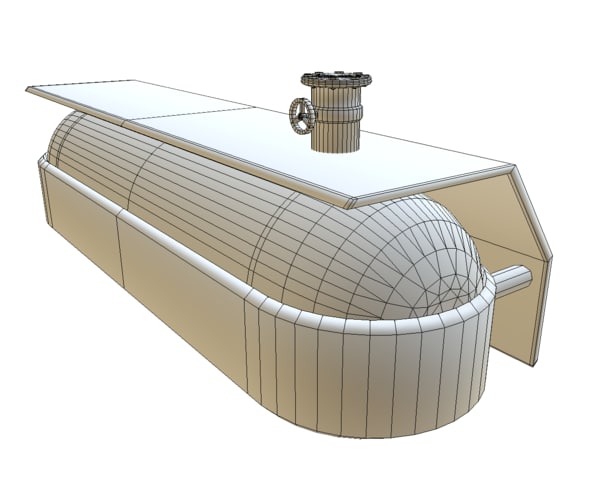

VIBA designed and engineered the Jane minibike, inspired by the Honda Monkey, using numerous 3D-printed aluminum parts, including a fuel tank with a innovative internal honeycomb design. Photos courtesy of VIBA

To Yann Bakonyi, the Honda Monkey minibike is a global icon.

“Everybody knows the Monkey,” said Bakonyi, co-founder and lead designer of VIBA, a 5-year-old France-based motorcycle manufacturer with headquarters on the outskirts of Bourges and a design studio on the Bay of Biscay shores in La Rochelle.

Honda Motorcycle’s iconic Z series debuted in the early 1960s at an amusement park in Tokyo, Japan, and quickly made its way west through Europe and over to the U.S., evolving through numerous model updates, building a cult following, and inspiring emulators throughout the decades.

For that reason, Bakonyi wanted to put his own spin on the famed Monkey. And this past autumn he and his VIBA team finalized their minibike version using 3D printing technology.

“It's dedicated to people who like the original Monkey,” said Bakonyi, who studied at Strate School of Design in Paris and IAAD in Italy, “but are looking for something new – different than something else you can see on the streets.”

They branded the minibike as “Jane,” named after famous actresses such as Jane Fonda and Jane Birkin, who were at the height of their popularity in the 1960s and 1970s, the era in which the Monkey minibike was becoming famous in its own right. Establishing Jane as a limited-series release featuring a 125cc engine, VIBA will produce only 23 of the minibikes (two have already been complete), which officially hit the market on Jan. 10.

“[Fonda and Birkin] were bringing freshness, desire, and smiles to these years,” Bakonyi explained. “We wanted the same feeling for our Jane.”

Minibike parts by way of additive manufacturing

But VIBA wanted that freshness to come with the enhanced value of modern technologies and an innovative design process by way of additive manufacturing (AM) – and some German ingenuity.

After visiting the 3D Print 2018 Congress & Exhibition in Lyon last June, VIBA worked out a partnership with Lübeck, Germany-based SLM Solutions, a provider of metal-based AM technology, and 3D printing service provider Rolf Lenk Werkzeug- und Maschinenbau GmbH of Ahrensburg, Germany.

The decision to go the 3D printing route instead of the milling processes common in motorcycle manufacturing was a no-brainer for VIBA. “For us, doing some limited production run, it's a great production method, because we can build all the parts we want with a good cost,” said Bakonyi.

The fuel tank was created using a selective laser melting (SLM) process, which uses a high-power-density laser to melt and fuse metallic powders together into a 3D part.

At Rolf Lenk’s production center north of Hamburg, SLM offered VIBA three different 3D printers to use for a range of operational needs: the SLM®280, SLM 500, and SLM 800.

“For a limited series of a revamped product, the goal was to limit the amount of tooling setups or molds needed, which would be costly and add time to development,” said Ralf Frohwerk, head of business development, at SLM Solutions. “Lightweighting the bike was a design goal, and metal 3D printing was the logical solution.”

Besides the obvious benefits of an efficient process to produce complex and lightweight parts, Bakonyi craved something different than what VIBA used for its more traditional motorcycle product lines, Qora and Lara. He also wanted to avoid leaving 3D-printed parts at the prototype stage.

“At tradeshows we see a lot of [3D-printed] parts, but they are usually just for showcase and are not functional,” Bakonyi said. “So, this project was to show that 3D printing can be integrated in an industrial process to work perfectly.”

Together, VIBA, SLM Solutions, and Rolf Lenk designed and engineered various 3D-printed aluminum (AlSi10Mg) parts that were fully functional for Jane.

Printed on the SLM 280 machine were the gauge bracket (print time 2 hours, 50 minutes), which also combines the upper handlebar riser, and levers (2 hours, 40 minutes), which are hollow so that wiring can pass through to power LED turn signals. Printed on the SLM 500 machine were the front luggage rack (18 hours) and the front mudguard/headlight support (14 hours), which has a design inspired by the Voronoi diagram used in mathematic equations.

The levers and mudguard specifically would have been impossible to manufacture using traditional milling techniques.

“We are designers and are curious,” Bakonyi said with a laugh. “It makes you rethink how you design your parts and how to integrate engineering. For us, we like the challenge.”

3D-printed honeycomb fuel tank

But by far the project’s biggest challenge was engineering the minibike’s ground-breaking 3D-printed aluminum fuel tank, which VIBA believes to be the first of its kind.

While most minibikes are usually already fuel-efficient, the design of Jane’s fuel tank takes that capability to a whole different level with an internal honeycomb structure.

The honeycomb design throughout the tank’s interior provides a baffle structure to help decrease fuel sloshing around in the tank during braking, acceleration, and turning, resulting in more stability for the minibike during a ride.

“It is the most innovative part because it's the display of 3D printing added value,” Bakonyi said of the 1-mm-thick tank, which was printed on an SLM 800 machine over a 27-hour and 22-minute time frame. “You’ll find that almost everything possible has to do with this technology.”

The fuel tank was created using a selective laser melting (SLM) process, also known as direct metal laser sintering (DMLS) or laser powder bed fusion (LPBF), which uses a high-power-density laser to melt and fuse metallic powders together into a 3D part. And Jane’s fuel tank displays several benefits from the SLM process.

The main technical benefit, however, is the incorporation of functional optimization, said Frohwerk. The honeycomb design throughout the tank’s interior provides a baffle structure to help decrease fuel sloshing around in the tank during braking, acceleration, and turning, resulting in more stability for the minibike during a ride.

The honeycomb design throughout the tank’s interior provides a baffle structure to help decrease fuel sloshing around in the tank during braking, acceleration, and turning, resulting in more stability for the minibike during a ride.

A reduction in the number of parts of the fuel tank was showcased because it was built as one piece, which eliminates welding seams. And tank features such as the push-up fuel cap were fused in along with aesthetic customization through the texturing of the exterior side panels.

“It really shows what’s capable with this technology,” said Frohwerk. “Designers can integrate functional features while creating new, custom designs.”

With its pioneering fuel tank design using AM, VIBA may have very well added a new chapter to the minibike narrative.

“We decided to reinvent the Honda Monkey because, every time we are building a project at VIBA, we care about telling a story,” said Bakonyi. “We wanted to revive childhood memories of riders.”

The mud guard and headlight support rack were designed into one 3D-printed aluminum part.

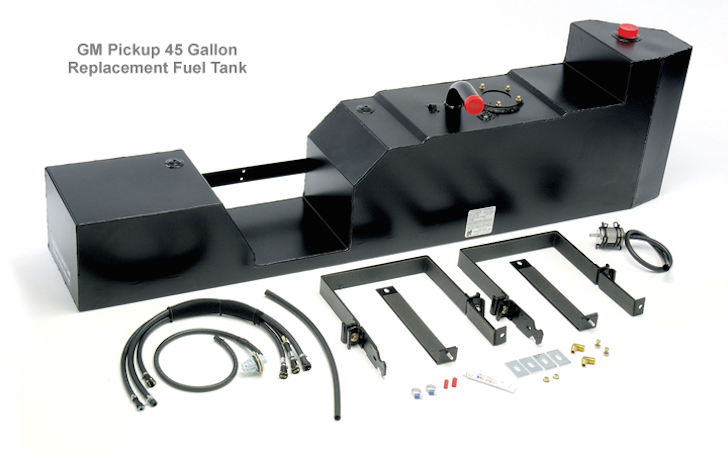

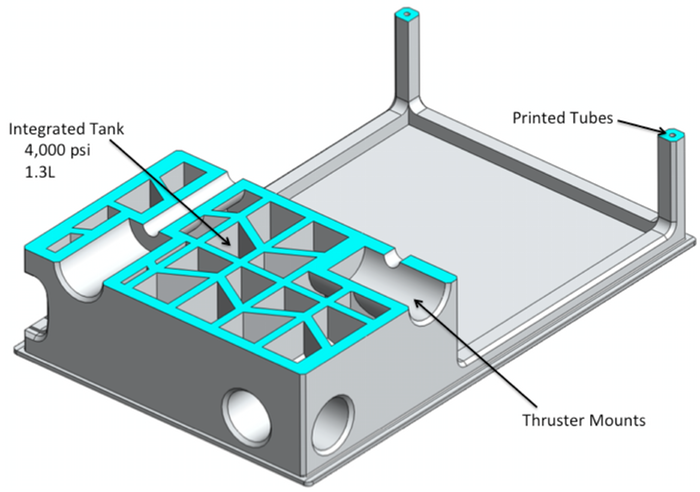

3D Printed Fuel Tank | Lockheed Martin Case Study | Stratasys Direct

Lockheed Martin 3D Prints Fuel Tank Simulation with Help from Stratasys Direct Manufacturing

True innovators in aerospace know that fast development times and constant performance improvement are not the only essential qualities of a leader—it takes thorough testing processes, and the ability to control costs and reduce risk. One company accelerating innovation in aerospace is Lockheed Martin’s Space Systems Company (SSC). The division designs, develops, tests, manufactures and operates a full spectrum of advanced-technology systems for national security, civil and commercial customers."We chose Stratasys Direct Manufacturing because they have the machines and finishing capabilities to build tanks of this size."

Validation of design

In early 2012, Lockheed Martin SSC began looking at ways to improve and add value to their satellite design. The goal was to design a satellite that would make more efficient use of space and increase the satellite’s payload. It would require testing many assembly configurations and producing several simulators and prototypes to validate design changes. One change that needed to be validated was in the satellite’s fuel tanks.

The goal was to design a satellite that would make more efficient use of space and increase the satellite’s payload. It would require testing many assembly configurations and producing several simulators and prototypes to validate design changes. One change that needed to be validated was in the satellite’s fuel tanks.

Before building the actual fuel tanks for final use, Lockheed would need to test form, fit and function and assembly with tank simulators. Producing test parts with traditional manufacturing methods would not be realistic given the deadline and costs. Machining the larger tank at 6.75’x3.8’x3.8’ and the second tank at 3.8’x3.8’x3.8’ would take over 6 months and around $250,000. The recent advancements in large-scale 3D printing motivated Lockheed to apply Stratasys’ Fused Deposition Modeling (FDM) to the tank simulators.

Lockheed Martin is no stranger to 3D printing technology. In fact, they are considered a 3D printing leader for aerospace applications and own several additive manufacturing machines. But this particular application, part size, post processing requirements and project deadline posed a challenge for their in-house capacity. The parts would have to be built in many pieces and bonded together, requiring an army of machines and a team of FDM finishing experts. That’s when they turned to Stratasys Direct Manufacturing's aerospace team.

But this particular application, part size, post processing requirements and project deadline posed a challenge for their in-house capacity. The parts would have to be built in many pieces and bonded together, requiring an army of machines and a team of FDM finishing experts. That’s when they turned to Stratasys Direct Manufacturing's aerospace team.

Constructing the tanks

Lockheed Martin has partnered with Stratasys Direct Manufacturing over the last several years to manufacture parts and often comes to Stratasys Direct Manufacturing when size, material or machine capacity limit their in-house additive manufacturing systems. Lockheed knew Stratasys Direct Manufacturing would deliver high quality parts on time and offered the engineering thermoplastic and finishing processes required for the form, fit and function tests.

“We chose Stratasys Direct Manufacturing because they have the machines and finishing capabilities to build tanks of this size,” said Andrew Bushell, senior manufacturing engineer at Lockheed Martin SSC. “We also decided to go with Stratasys Direct Manufacturing for their speed and engineering support we had received on past projects.”

“We also decided to go with Stratasys Direct Manufacturing for their speed and engineering support we had received on past projects.”

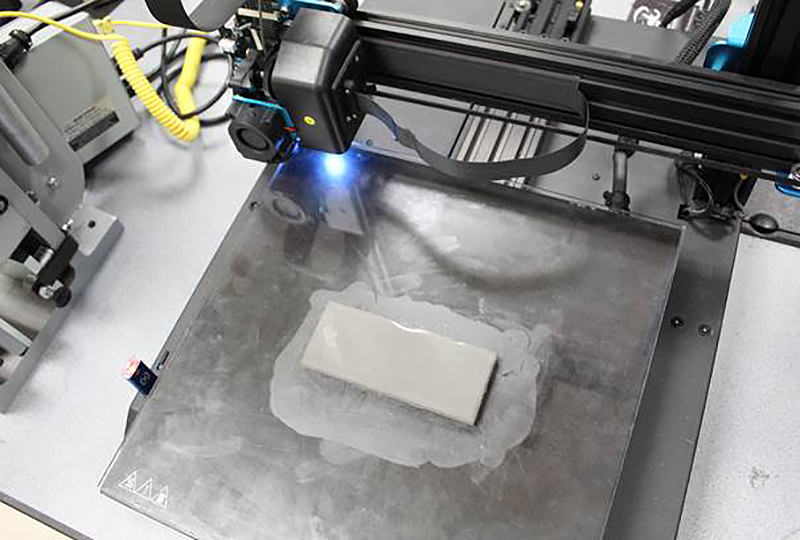

When the Stratasys Direct Manufacturing's aerospace team received design files from Lockheed’s engineers, they were stunned with the size of the tanks. “These are the largest parts we’ve ever built using FDM,” said Joel Smith, the strategic account manager for aerospace and defense at Stratasys Direct Manufacturing. The project required many preliminary meetings between Lockheed and the Stratasys Direct Manufacturing team as it was the first time building a design of this magnitude. “We completed an extensive design review to determine the best orientation and slice height to ensure we could accurately build and bond the sections together in post processing and meet Lockheed’s dimensional requirements,” said Smith. Stratasys Direct Manufacturing landed on building the larger tank in 10 sections and the smaller tank in 6 sections in polycarbonate (PC) on the Fortus 900mcs.

Stratasys Direct Manufacturing and Lockheed had to adapt and make adjustments to the plan along the way to meet tolerances. “We decided to alter the orientation of the exterior clocking rings that go around the tanks and increase their wall thicknesses to support inserts,” said Trevor Stolhanske, aerospace and defense project engineer at Stratasys Direct Manufacturing. Each section of the tanks took 150 hours to build, but even so, Stratasys Direct Manufacturing was able to build multiple sections at once, maximizing lead times and controlling costs. After all of the sections were complete, the support material was washed away and the sections were sent to finishing services for bonding.

Because of their round shape and weight, the only way Stratasys Direct Manufacturing could successfully bond the tanks was to build customized fixtures to hold the sections while fusing pieces together. After several hours of welding each section together, Stratasys Direct Manufacturing sanded the tank seams and surfaces. After finishing, the tanks and rings were sent to Hutchinson Manufacturing, Inc. to be machined to the design’s critical dimensions. When Stratasys Direct Manufacturing received the tanks from Hutchinson, they added brass inserts to the rings and assembled the tanks per Lockheed’s specifications.

After finishing, the tanks and rings were sent to Hutchinson Manufacturing, Inc. to be machined to the design’s critical dimensions. When Stratasys Direct Manufacturing received the tanks from Hutchinson, they added brass inserts to the rings and assembled the tanks per Lockheed’s specifications.

Final assembly

“These tanks were built in a fraction of the time it would have taken with traditional manufacturing methods. Even with the machining process and design changes made along the way, we were able to deliver these parts ahead of schedule” said Smith.

The tanks went through a number of quality assurance and accuracy measurements and were approved for the first concept assembly. Lockheed Martin’s Space Systems Company performed form, fit and function testing as well as process development, in order to validate the proposed design changes.

Next, Lockheed will take what they learned from the first phase and use the information to optimize the design and assembly to print the second iteration of tanks.

Learn more about Lockheed Martin’s Space Systems Company (SSC) at: lockheedmartin.com/us/ssc.html

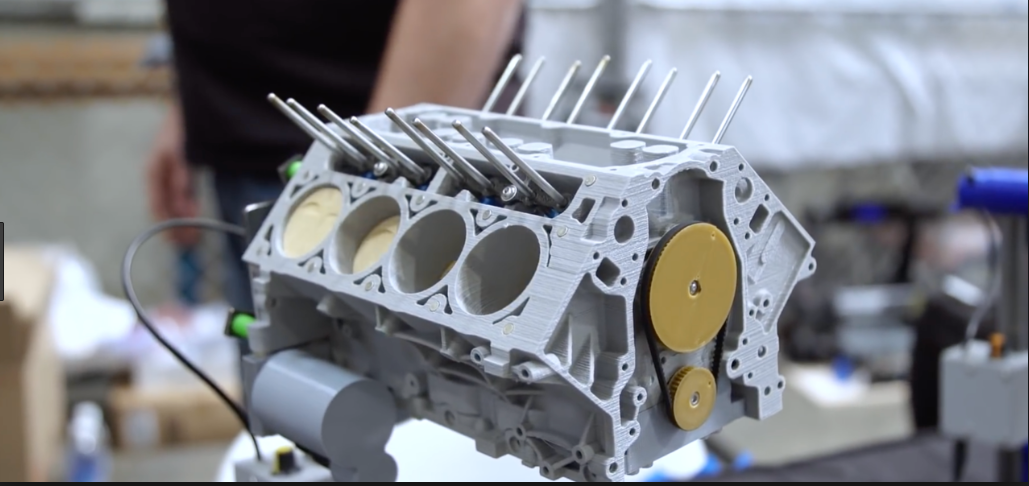

Does the world need 3d printed rockets?

The spotlessly clean floors recently seen in Relativity Spaces promotional photos are now scuffed and covered in typical machine shop debris. Inside the firm's warehouse on the outskirts of Los Angeles, three robotic arms loom grandiosely over a container filled with spools of metal wire. A jagged hole is visible in the lid of the container, as if someone had unsuccessfully punched it. The hole is covered with adhesive tape to cover the sharp edges of the hole. This is a machine that has been pushed to its limits, in the service of a proud purpose. Led by its founders Tim Ellis and Jordan Noone, Relativity is trying to create 95% of their Terran 1 rocket using 3d printing.

You read it right: the plan is to get a rocket ready for take-off from raw materials in two months. If that sounds too cheeky, it's because it is. Very bold. 3D printing is gaining momentum in the spaceflight industry – everyone from SpaceX, to Blue Origin, from lesser-known newcomers to the old guard in rocket science, are trying to use the technology. And someone has gone so far as to completely print their own engines. But even the engineers at the forefront of 3D printing in rocket science don't know what to do with Ellis and Noon's newfound firm. And many of them think that these guys are just crazy.

Very bold. 3D printing is gaining momentum in the spaceflight industry – everyone from SpaceX, to Blue Origin, from lesser-known newcomers to the old guard in rocket science, are trying to use the technology. And someone has gone so far as to completely print their own engines. But even the engineers at the forefront of 3D printing in rocket science don't know what to do with Ellis and Noon's newfound firm. And many of them think that these guys are just crazy.

Traditionally, the aerospace industry is not characterized by rapid changes, and for good reason: a rocket is a controlled explosion that poses serious risks to the huge funds spent on it, and sometimes to people's lives. Relativity is aiming to win over the naysayers and the skeptics by scheduling a test launch in 2020. The problem is, they haven't even printed the entire rocket yet.

In principle, a rocket consists of four main parts: payload, control system, propulsion system and structure. The payload is what the rocket carries. The control system consists of sensors that keep it on target, while the propulsion system contains the fuel and engine that makes the missile move. The structure of the rocket is the rest of the frame, the cone and the stabilizers of the rocket - that is, what is usually made using high-precision CNC milling machines and hand welding.

The control system consists of sensors that keep it on target, while the propulsion system contains the fuel and engine that makes the missile move. The structure of the rocket is the rest of the frame, the cone and the stabilizers of the rocket - that is, what is usually made using high-precision CNC milling machines and hand welding.

It follows from the above that behind every successful rocket launch there is a huge amount of work and an extensive network of suppliers working together to assemble each rocket. By simplifying the supply chain, Relativity hopes to significantly reduce production time.

But this goal of 3D printing a body and fuel tank over 30 meters raises an additional challenge: printers must be built that can handle the task. “Starting a rocket company is a very difficult task, starting a 3D printer company is an equally difficult task, and doing both at the same time borders on insanity,” says Ellis, who serves as president of Relativity. "But while it's the most difficult part of the job, it's also the secret sauce that will make Relativity a world-changing company. "

"

If the Terran I is going to go into space, its over 3 meters high fuel tank should work perfectly. “We won't launch a rocket until we develop these metal 3D printing technologies,” Ellis admits. “And this task requires something quite an existential kick in the ass to figure out how to do it, since this is the only way we intend to actually achieve our goal.”

Stargate kids

The company's only 3D printer, the 6m tall Stargate, has been in the company's service since it stepped out of the shadows in 2017. But now it's almost out of action. There are four new, unused models in a nearby building. Each of them is covered with long black doors that run from the ceiling of the warehouse to the floor, and betray their newness with a sharp smell of plastic. On one of them hangs a small toy basketball hoop - as if until now it has more often played the role of a basketball backboard, and not a 3D printer for rockets.

A huge graphic covering the entire wall gives a glimpse of the company's vision for the future: the entire warehouse is filled entirely with Stargate printers, small printers and robotic arms. Paradise for an engineer, but a nightmare for a mechanic. These are the slogans “robots are taking away our jobs” in the form of drawings on the wall.

Paradise for an engineer, but a nightmare for a mechanic. These are the slogans “robots are taking away our jobs” in the form of drawings on the wall.

Giant machines seem to smirk at the thought of decades of building rockets. During the Apollo program, engineers faced enormous challenges trying to achieve the perfect weld for the Saturn rockets. Even experienced welders were forced to receive special training in order to make long, precise welds. Now, all welding is done by a robot.

The Stargate 3d printer and its descendants use a variant of a technology called direct material delivery. Traditional production methods are to cut the finished product from a block of material. Instead, when 3D printing, an object is formed layer by layer, which allows you to create lightweight objects with complex internal structures that cannot be made in any other way. The most common form of 3D printing is called FDM (molten material modeling) - material (often plastic) is melted and extruded from a nozzle into the exact position of the object being created. Combine this with welding and you have direct material delivery technology.

Combine this with welding and you have direct material delivery technology.

Welding is based on a continuous flow of metal wire on one side and heat on the other. The Stargate printer does this automatically by feeding the wire from the extruder to the end of a tall robotic arm. The metal is heated using an electrical plasma (and sometimes a laser) and then laid out under computer control. The combination of electronic control, thermal cameras and sensors installed near the material supply site allows you to control the printing process of the created object. “Our vision for 3D printing is software-controlled manufacturing automation for the aerospace industry,” says Ellis. “It stretches in the direction of a long-term vision of 3D printed rockets on Mars. These are exactly the tools that we will need for real construction on other planets.

The way Ellis talks about his company is reminiscent of Elon Musk's exaltation over SpaceX and Tesla, with the only difference being that Ellis says he fills in a part of the Mars exploration picture that Musk hasn't mentioned yet. “The idea is to have two products. One is a rocket. The second is a factory,” he says. “Over time, we will see that the factory can get smaller and smaller until it becomes something that we can send with a big rocket.” In other words, you make a machine that makes other machines. And then send it to Mars. Everything is very simple.

“The idea is to have two products. One is a rocket. The second is a factory,” he says. “Over time, we will see that the factory can get smaller and smaller until it becomes something that we can send with a big rocket.” In other words, you make a machine that makes other machines. And then send it to Mars. Everything is very simple.

Relativity last month took a small step towards that vision by announcing that it signed a nine-year lease with NASA for a 2-hectare facility in Mississippi that will house its first stand-alone rocket factory.

But other companies that are actively using 3D printing (so-called additive manufacturing) are not entirely sure what the future looks like. Rocket Lab, one of a small number of small companies that launch commercial satellites, uses additive manufacturing to create engines, valves, nozzles and a range of other complex components. Its president, Peter Beck, says: "There is no way we could, without resorting to 3D printing technology, produce engines of the size and performance that we produce today. " But to make the entire rocket entirely? “It doesn’t make sense to 3D print an avionics unit, or a tank, or something like that, because there are much more efficient processes for such work,” says Beck. “I don’t want to spoil Tim’s holiday, I sincerely wish him good luck, but from an engineering point of view, this approach does not make any sense for us.”

" But to make the entire rocket entirely? “It doesn’t make sense to 3D print an avionics unit, or a tank, or something like that, because there are much more efficient processes for such work,” says Beck. “I don’t want to spoil Tim’s holiday, I sincerely wish him good luck, but from an engineering point of view, this approach does not make any sense for us.”

Ultimately, it is customers who need proof of the wisdom of Relativity's approach. Like most rocket companies, before its first launch, Relativity offers its customers only test data and an assembled team of specialists. “Ultimately, we have to use faith and take decisive action,” says Ellis. - Well, yes, the confidence is great enough. And definitely, this process will lead us to the goal.”

Naturally, some customers will want to take this drastic step. Relativity has already announced three customers that have booked launches in 2021 and 2022: Canadian telecommunications company Telesat, Washington-based Spaceflight (which launches navigation satellites as part of larger launches), and Thailand-based mu Space. Noon says that once Relativity shows that it can deliver successful launches in 2020, it plans to increase its annual launch rate from 12 to 24.

Noon says that once Relativity shows that it can deliver successful launches in 2020, it plans to increase its annual launch rate from 12 to 24.

Aggressive plans of this sort are based on the history of the company. Three years ago, shortly after Ellis and Noone left their first post-college jobs at Blue Origin and SpaceX, respectively, they emailed investor Mark Cuban for seed funding for the new company. The subject of the message was: "Space is attractive: 3d printing of the entire rocket." Cuban, who did most of his business by email, responded five minutes later saying he was willing to invest $500,000. Which he did two months later. According to Cuban, it wasn't the element of additive manufacturing that attracted him. “The idea itself was unique. I would like it to be offered by me,” he says. “The guys were qualified, they were local (Ellis himself is from Texas, where Cuban lives).

Since its inception, Relativity has "never taken its foot off the gas pedal." Last year, its staff grew from 14 to 80. Today, the company's team includes Tim Buzza, an early SpaceX employee and former vice president of rocket launches at SpaceX and Virgin Orbit. Also on the team is David Giger, who spent 12 years at SpaceX as senior director of engineering for the Dragon capsule.

Today, the company's team includes Tim Buzza, an early SpaceX employee and former vice president of rocket launches at SpaceX and Virgin Orbit. Also on the team is David Giger, who spent 12 years at SpaceX as senior director of engineering for the Dragon capsule.

People are still involved with the Stargate printers - at least for now

Ellis, who is in charge of recruiting and raising capital, seems to have no problem winning over people at all levels. He is a member of the White House's National Space Council User Advisory Group, which helps keep contracts and funds flowing into his company. Relativity has completed another $35 million fundraising round. She signed a contract with NASA to test her engines at the Stennis Space Center in Mississippi (the very center where her autonomous factory is supposed to move), and received permission to launch at one of the most prestigious launch sites in the world: Cape Canaveral in Florida.

The company's latest achievement, announced in January, was the launch queue for Terran 1 from the famous Launch Complex 16, which launched the Titan rockets, the Apollo program, and the Gemini program. As a result of these notable moves, Relativity's name began to appear in conversations about companies such as SpaceX, Blue Origin, and United Launch Alliance, which used to be the only companies to get the right to launch from Cape Canaveral.

As a result of these notable moves, Relativity's name began to appear in conversations about companies such as SpaceX, Blue Origin, and United Launch Alliance, which used to be the only companies to get the right to launch from Cape Canaveral.

Building a rocket with a 3D printer means making test pieces, cutting them into pieces, and doing more testing. Did we mention testing?

The Rise of 3D Printing

Relativity is far from alone in its hopes that 3D printing will propel it into the ranks of the elite of spaceflight. Newcomers such as Virgin Orbit, Firefly, and Electron are also keen to prove that they, like Rocket Lab, have what it takes to launch small satellites into space. Even established companies like Aerojet Rocketdyne are trying to demonstrate that 3D printing is as good, if not more reliable, than traditional manufacturing methods.

But no company has come as far or as fast as Relativity. Aerojet builds engines under government contracts, and human-flight rockets like NASA's Space Launch System, which must have added compatibility and reliability. The company says that more than 60% of its research and development work in the field of 3D printing is just compiling a database of chemical and structural properties of various materials. “Others may ignore such works. And it is their right to take a position that accepts possible risks,” says Aerojet senior program manager for advanced programs, Jeff Haynes (Jeff Haynes).

The company says that more than 60% of its research and development work in the field of 3D printing is just compiling a database of chemical and structural properties of various materials. “Others may ignore such works. And it is their right to take a position that accepts possible risks,” says Aerojet senior program manager for advanced programs, Jeff Haynes (Jeff Haynes).

In contrast, at Relativity, “if we put a fully printed engine on a test rig, successfully launch it, and then take it off, then that would be a success for us,” Noon says. “You could make hundreds of spec sheets telling you how to make it and how to make it, but we go our own way. I don't want to deal with specs instead of trying something and demonstrating that it works."

This "going fast, contrary to tradition" approach causes insomnia for most rocket designers. Relativity's rival Virgin Orbit uses 3D printed parts in its first rocket, LauncherOne, but it doesn't want to abandon the technology. “The production of the LauncherOne rocket engine today uses very reliable methods that have been tested by NASA since 1950s and 1960s because the top priority for a first rocket launch is reliability,” says Virgin Orbit's head of modern operations, Kevin Zagorski.

Other companies are also pursuing additive manufacturing, from Jeff Bezos' Blue Origin - where Ellis, during his internship, had a hand in buying the company's first metal-printing 3D printer - to a small new company, Launcher, that claims to produced the world's largest 3D printed rocket engine. Major players in the field such as SpaceX, NASA, Rocket Lab, United Launch Alliance, and ArianeGroup have also entered the 3D printing ring.

The reasons most of these organizations are turning to this technology are twofold: you get the ability to build something with less detail, and you get the ability to change designs faster. Early on, Rocket Lab's Beck saw that additive manufacturing was getting a bad rap because it was used inefficiently. “Someone takes a subtractive manufacturing component and tries to 3D print it. It turns out to be more expensive and takes more time,” he says. – But, as with any new technology, everything is connected with new processes. The 3D printed parts are great where you face very high complexity and assemble a lot of parts into one. ”

”

For its part, Relativity claims that the Terran 1 rocket will have a hundred times fewer parts than a standard rocket. Its engine, the Aeon 1, is made up of only three parts joined together.

It's hard to say what proportion of the advertising hype is here. It is very tempting to announce that you have done something for the first time, especially for a small, new company. For example, Relativity claims to have built the largest metal-printing 3D printer — as do Sciaky and Titomic, two non-aerospace industrial hardware companies. “Everyone wants to try and stand out, trying to get ahead,” says Beck. “If someone wants to talk about 3D printing, that’s fine, but sometimes it’s funny.”

Even if 3D printing an entire rocket isn't practical, "I'm really sure it's going to be useful anyway," says Dan Erwin, head of aerospace engineering at the University of Southern California. Irwin ran the university's rocket lab when Ellis and Noon were students, but didn't work with them after that. "I intuitively feel that this is one of the 'If you can do it, it will go' kind of stuff," he says. Whether or not Relativity can launch its rocket next year is forcing a slow-moving industry to take notice of a possibly superior technology already in use outside of aerospace. The end result of these efforts may just be a new generation of 3D printers. But maybe there will be a rocket to fly to Mars, which everyone promises us. “Life is too short to just wait for the future to come,” says Ellis. “We have to create it ourselves.”

"I intuitively feel that this is one of the 'If you can do it, it will go' kind of stuff," he says. Whether or not Relativity can launch its rocket next year is forcing a slow-moving industry to take notice of a possibly superior technology already in use outside of aerospace. The end result of these efforts may just be a new generation of 3D printers. But maybe there will be a rocket to fly to Mars, which everyone promises us. “Life is too short to just wait for the future to come,” says Ellis. “We have to create it ourselves.”

Source

molten material modeling), Rocket Lab

Key benefits of 3D printing for industrial products

Manufacturers are increasingly turning to 3D printing to stay flexible, responsive to changing market needs and innovative.

New perspectives for the industrial parts and products industry.

The manufactured goods sector includes the manufacture of machine parts, tools and equipment used in the manufacture of other goods. With manufacturing costs rising and the digitization of manufacturing, industrial OEMs must constantly evolve to maintain agility and reduce costs.

With manufacturing costs rising and the digitization of manufacturing, industrial OEMs must constantly evolve to maintain agility and reduce costs.

Key Benefits of 3D Printing for Industrial Goods

Design complexity

As we have seen in other industries, rapid prototyping is a key use case for 3D printing in the industrial goods sector. Design changes that could take months using traditional manufacturing methods can be implemented much faster, often in less than a week, using 3D printing.

Faster lead times

According to Sculpteo's 2018 State of the Industry Report, 52% of those working in the industrial goods sector prefer 3D printing the most because of its ability to reduce lead times. Since 3D printing does not require tooling, manufacturers can reduce the time it takes to produce parts by bypassing the time-consuming and expensive tooling step.

Design complexity

3D printing is a cost-effective technology for manufacturing complex geometries. Structures that would otherwise be impossible to manufacture in a conventional way can now be created using 3D printing.

Structures that would otherwise be impossible to manufacture in a conventional way can now be created using 3D printing.

Manufacture on demand

Since 3D printing can produce physical parts from digital files in hours, companies can use the new model of production on demand.

Industrial Applications:

Functional Parts Creation

Polymertal in Israel replaced aluminum drone fuel tank production with BigRep ONE printed fuel tanks using an additional metallized coating. This allowed them not only to reduce weight compared to an aluminum fuel tank, but also to reduce the use of other structural elements, because now the tank is printed as one single piece and there are fewer structural elements.

One-piece seamless tank printed on the BigRep ONE printer proved to be as strong as aluminum, lighter and more fuel resistant. It is installed in a drone. This technology has found its place in many other applications. The company has patented many new similar developments using 3D printing.

The company has patented many new similar developments using 3D printing.

01| BigRep ONE Printed Fuel Tanks

Tooling

The ability to 3D print manufacturing ancillary equipment such as fixtures, gauges and fixtures opens up new perspectives for manufacturers of industrial products.

"3D printing has revolutionized the production of rigid tooling such as molds"In addition to fixtures and fixtures, 3D printing has revolutionized the production of rigid tooling such as injection molds. Traditionally, molds are made on CNC machines and can go through multiple iterations that take weeks, if not months, before the final design is achieved. This results in a process that is time consuming and very costly with a significant amount of material waste.

Metal 3D printing technologies such as DMLS or SLM can now be used instead, enabling tooling companies to not only reduce material waste but also improve mold functionality. This can be achieved by integrating more complex cooling channel shapes into the design, greatly improving the cooling performance of the mold.

HBD and FARSOON are Chinese market leaders in selling their SLM machines to the mold market. Due to the fact that China occupies a leading position in the world in the creation of plastic products - the World Factory, this market segment is very developed. For example, according to studies 90% of molds for complex plastic cases and products in Russia are ordered in China. Most complex thin wall designs require rapid cooling of the molds to avoid buckling of the mold material. To do this, use special inserts printed on 3D printers with internal cooling channels.

02| 3D printed special inserts with internal cooling channels

Until recently, the use of stereolithography (SLA) as a way to validate designs and certify products was difficult because molds were made from different materials. This difference in material often resulted in different test scores and made the certification process difficult. With the introduction of composite materials, engineers can use high-precision SLA technology to quickly create molds that are capable of producing real molded parts.

Molds in less than 3-5 days is the main goal of rapid prototyping using SLA technology. Engineers can test the product at the design stage. Plastic molds give the designer the ability to quickly and cost-effectively produce hundreds (and in some cases thousands) of products.

Below is an example of making a mold using SLA on a UnionTech 3D printer.

03| Example of making a mold using SLA on a UnionTech 9 3D printer0003

When time is of the essence, SLA technology can be used for high quality end product tooling. 3D printing is being used by customers to produce real-world texting products and develop new designs, greatly speeding up the product development cycle and ultimately reducing the time to market for new products.

Spare parts manufacturing, repair

3D printing on demand allows manufacturers to produce spare parts quickly and cost effectively. This approach is useful, for example, when obsolete equipment that may be obsolete or difficult to obtain needs to be replaced. 3D printing on-demand replacement parts can also help reduce inventory by bypassing the costly storage of low-demand parts.

3D printing on-demand replacement parts can also help reduce inventory by bypassing the costly storage of low-demand parts.

Deutsche Bahn has an alternative to having, storing and maintaining huge warehouses for spare parts. BigRep was asked to develop a new material that complies with company and EU standards in order to ensure the production of spare parts on demand.

Deutsche Bahn is now printing more than 2,000 parts for its rolling stock on BigRep printers, which has significantly reduced the stock of spare parts for rolling stock, as well as 3D printing spare parts for old trains and wagons, spare parts for which have been out of production for a long time. In collaboration with BigRep, special materials have been developed to meet the special requirements of Deutsche Bahn.

04| Deutsche Bahn parts for its rolling stock on BigRep printers

3D printed parts reduce costs and lead times from a week to several hours, as well as increase work efficiency.