3D printing building

Architects: Here’s the Problem With 3D-Printed Buildings

The Oak Ridge National Laboratory, the same place that developed the atomic bomb, recently produced a little white structure with a vehicle attached that it says demonstrates the future of construction. Both the structure and vehicle are 3D-printed, produced via enlarged versions of the same tabletop machines that have become popular with “makers” around the world. Building-scale printers work the same way as their smaller cousins, depositing thin layers of material over previous layers, until the form is finished.

AMIE, Oak Ridge, Tenn.; photo courtesy SOM

The idea that buildings could be printed with the click of a button has excited everyone from quirky inventors building a village in Italy to the CEO of Alphabet, one of the world’s largest companies. Designers have produced an assortment of eye-catching printed structures, taking advantage of the technique’s flexibility to create exotic forms out of plastic, concrete, metal or even salt. The pictures look nice, and 3D printing naturally has a futuristic aura out of “The Jetsons” or “Star Trek.” Evangelists claim it is the answer to the world’s housing and ecological crises, as printers will conjure cheap housing with almost no waste.

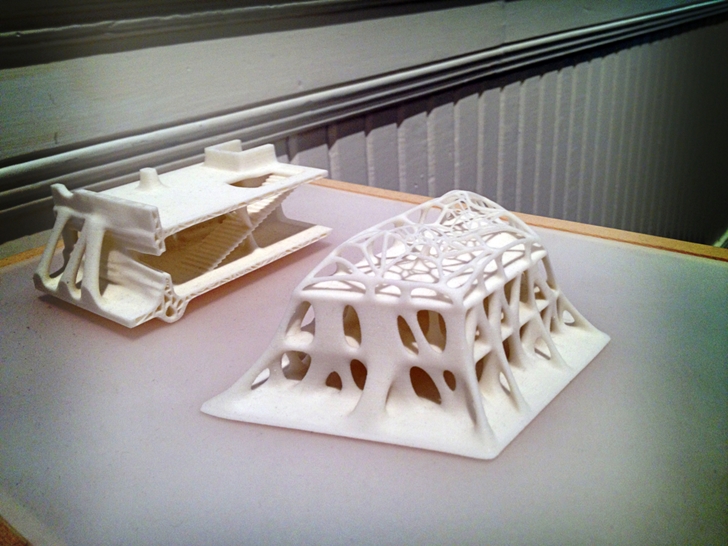

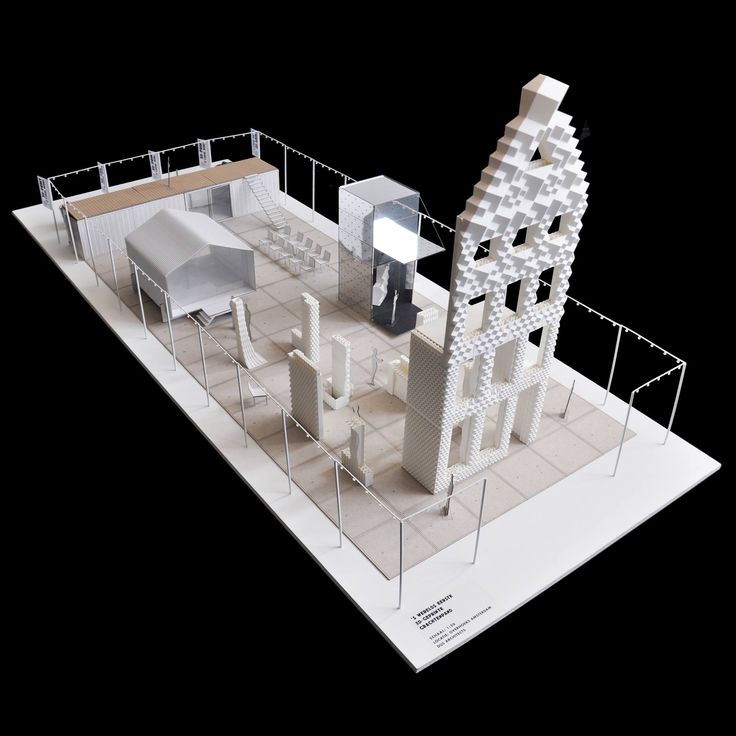

The problem is this: No one has been able to successfully take the leap from printing a fancy art pavilion to printing a functional building, and it’s still not clear if the technology is going to save the world or be another decorative footnote of architectural history.

Saltygloo by Emerging Objects, Berkeley, Calif.; photo courtesy Emerging Objects

3D printing has been around since the 1980s. Technologists developed the process, known more officially as additive manufacturing, as an alternative to other industrial manufacturing techniques, like extrusion and casting, and it has proven to be an effective, efficient way to make especially complex mechanical parts like wind turbines.

But conventional buildings are not made by extrusion or casting or any other single manufacturing process; they are accretions of dozens of different techniques from cast-and-pour concrete to spot-welded steel extrusions to laminated glass. How could one process replace the dozens of others that we currently use? Yes, that is part of 3D printing’s promise — that it’s versatile enough to do the work of multiple machines — but current printed buildings are either minimally functional, if gorgeous, pavilions or houses that are basically dumb printed boxes with traditional bric-a-brac tacked on.

How could one process replace the dozens of others that we currently use? Yes, that is part of 3D printing’s promise — that it’s versatile enough to do the work of multiple machines — but current printed buildings are either minimally functional, if gorgeous, pavilions or houses that are basically dumb printed boxes with traditional bric-a-brac tacked on.

The promise of printed buildings has yet to manifest, but if it does, it’s likely to come from one of these three sources:

Villa by WinSun, China; photo courtesy 3DPrint.com

WinSun

For whatever reason, the only printed buildings that look remotely habitable have been built by Chinese companies. But just because they look habitable doesn’t mean that they are. No one lives in these houses, and when you get close enough, they don’t really look like the kind of place you’d want to live, unless you have a thing for creepy-cave chic. WinSun claims to have printed 10 homes in a day and to have contracts with Saudi Arabia and Egypt to build thousands of these buildings.

There’s more than a little reason to be skeptical, though: WinSun refuses to allow observers to see their printing device, and none of the buildings seem to be occupied. It’s also not clear how much is 3D-printed; photos show printed walls but not much else. If its claims are true, WinSun’s techniques could replace cinder block–based construction common around the world, but without more transparency, it’s hard to see them as more than a publicity stunt.

Office of the Future by Gensler, Dubai, United Arab Emirates; photo courtesy of Inhabitat

Dubai

Dubai wants to become the global center of 3D printing. Why is unclear; perhaps because it’s all about the future! Or something … The United Arab Emirates has a history of grand, futuristic, failed architectural experiments (see: Masdar), but it also has a lot of money and political will to spend on developing a viable industrial niche in the post-petroleum world. So, who knows? Maybe they will print 25 percent of their buildings by 2030 like they claim. Stranger things have happened — like a sleepy desert backwater port suddenly transforming into one of the world’s most affluent nations — and Dubai has recruited Gensler and WinSun, that Chinese world leader in 3D printing.

Stranger things have happened — like a sleepy desert backwater port suddenly transforming into one of the world’s most affluent nations — and Dubai has recruited Gensler and WinSun, that Chinese world leader in 3D printing.

Together they have built the world’s first printed office building, and it seems pretty nice. Maybe this thing will work. But in a nation of skyscrapers, it’s hard to see how a technology that produces modestly sized pods is going to keep up with demand. Even if the pods are somehow stacked together, they are likely to run into the same problems that traditionally built modular high-rises have run into. Again, there is a lot of hype without much to back it up other than a few model structures.

Lunar Habitation by Foster + Partners; image courtesy of Foster + Partners

NASA and ESA

NASA and the European Space Agency have some of the most ambitious plans of all: printing on the moon! And Mars! NASA is currently in the second round of an architectural competition to design a Martian colony, building on the first round where the winner proposed a dome printed out of Martian ice. The ESA is also betting on printing its lunar colony, working with Foster + Partners to design a structure that could be built out of regolith or moon rock.

The ESA is also betting on printing its lunar colony, working with Foster + Partners to design a structure that could be built out of regolith or moon rock.

The advantages here are clear: Rather than having to transport construction materials from Earth, printed buildings could use local materials as their substrate. All that would have to be transported would be the printing apparatus, which is a big saver when you consider how much of a headache it is to move stuff between planets. NASA has already started printing in space, making a little wrench with a printer on the International Space Station carried up by a SpaceX rocket, but seeing as their bigger plans are built around a literal moon shot, it’s hard to know where they will go.

Printing may open up new and unforeseen solutions, but it may also be just another manufacturing process that is incredibly efficient in some ways but not necessarily “revolutionary.” Thermoplastic extrusion may be a good analogue here: It’s incredibly helpful to make necessities of the modern age, like PVC pipe and steel I-beams, but you would never hear people getting excited about making an “extruded building. ” It should sound just as silly to get excited about the idea of a printed building. Additive manufacturing is a great tool, but it alone isn’t going to change architecture.

” It should sound just as silly to get excited about the idea of a printed building. Additive manufacturing is a great tool, but it alone isn’t going to change architecture.

Read more articles by Jack

Province of Bolzano - South Tyrol, Trentino-Alto Adige/South Tyrol, Italy

“If you take a very complicated microcosm of the whole world and collapse it into one little ball, I think you can find it here in this city.”

6 of the World’s Most Impressive 3D Printed Buildings

Photo: Kamp C & Jasmien Smets

Over the last few years, 3D printing, also known as additive manufacturing, has been gaining popularity in construction and architecture. As the technology matured, it’s position changed from a curiosity to a viable tool of the building trade, with companies producing and selling 3D-printed structures around the world.

In construction technology, additive manufacturing is still considered an emerging technology. Still, it’s already shown great promise for its ability to slash budgets and shorten building times. Some printers are even capable of creating an entire structure from scratch in less than a day and at a fraction of the cost of conventional construction methods.

Still, it’s already shown great promise for its ability to slash budgets and shorten building times. Some printers are even capable of creating an entire structure from scratch in less than a day and at a fraction of the cost of conventional construction methods.

3D printing is also considered a very real potential solution to humanitarian issues like the global housing crisis. In parts of the world where a roof over your head is far from a guarantee, the ability to quickly and inexpensively produce a livable structure has enormous potential, like this entire 50-home 3D-printed community in Mexico.

The following six 3D-printed structures showcase what can be accomplished with this technology and might offer a glimpse of the global housing landscape in the years ahead.

WinSun’s 3D-Printed Apartment Block, Jiangsu Province, ChinaPhoto: WinSunChinese company WinSun Decoration Design Engineering Co. is no stranger to testing the limits of 3D printing. Having already built 10 3D-printed houses in under 24 hours, it quickly gained the distinction of building the world’s tallest 3D-printed structure, a 5-story apartment block it completed back in 2015.

Having already built 10 3D-printed houses in under 24 hours, it quickly gained the distinction of building the world’s tallest 3D-printed structure, a 5-story apartment block it completed back in 2015.

According to ArchDaily, the apartment building was made using a 20-feet tall, 33-feet wide, and 132-feet long 3D printer. Ir brought the structure to life layer by layer using a mixture of glass fiber, steel, cement, hardening agents, and recycled construction waste. The individual building sections were then pieced together, much like any other modular construction project. At the same time, WinSun built an 1,100 square-meter mansion, fully decorated inside and out. ArchDaily writes that a Taiwanese real estate company ordered 10 of the prototype mansions. Each will cost about $160,000 to build.

At the time, Ma Rongquan, China Construction No. 8 Engineering Bureau’s chief engineer, said in a news conference that he hoped the projects would pave the way towards more unified standards around 3D-printed construction.

“These two houses are in full compliance with the relevant national standards. It is safe, reliable, and features a good integration of architecture and decoration. But as there is no specific national standard for 3D printing architecture, we need to revise and improve such a standard for the future,” he said.

Municipal Building, Dubai, United Arab EmiratesPhoto: Apis CorNot to be outdone, Dubai opened the world’s largest 3D printed building in early 2020, a 6,900 square-foot administrative building for the Dubai Municipality. Dubai has long been known to aim for the impossible when it comes to construction. After all, it’s already the home of Burj Khalifa, the world’s tallest building, which towers over the desert landscape at over half a mile high.

For the municipal building project, Dubai collaborated with Boston-based Apis Cor, the company known for building a 3D printed house in Russia in under 24 hours, according to SingularityHub. The building’s structure is much like a conventional building, made of precast concrete and reinforced with rebar and concrete. Contractors were brought in to add touches like windows and a roof after the structure came together.

Contractors were brought in to add touches like windows and a roof after the structure came together.

Dubai has grand plans for 3D printing technology. It’s aiming to create as much as one-quarter of all new buildings using the method by 2030. SingularityHub writes that it’s part of the government’s plan to reduce building costs and save time on construction projects.

Two-Story Detached House, Beckum, North Rhine-Westphalia, GermanyPhoto: Mense-KorteBuilder PERI GmbH and designer MENSE-KORTE ingenieure+architekten collaborated on the first-ever 3D printed house in Germany, a two-story building with approximately 860 square feet of livable space per floor, according to ArchDaily.

The project uses a special 3D printer called BOD2, pioneered by Danish manufacturer COBOD. The machine allows the addition of pipes and other internal building components, even while the printing is underway. It can print up to 10 square-feet of double-skin wall in just 5 minutes, ArchDaily writes, and only needs to be calibrated once before getting to work on each section.

“The concrete printing process affords us, designers, a high degree of freedom when we are designing buildings. With conventional construction methods, this would only be possible at a great financial cost. With our printed residential building in Beckum, we are demonstrating the potential of the construction printing process,” said Waldemar Korte, partner MENSE-KORTE ingenieure+architekten.

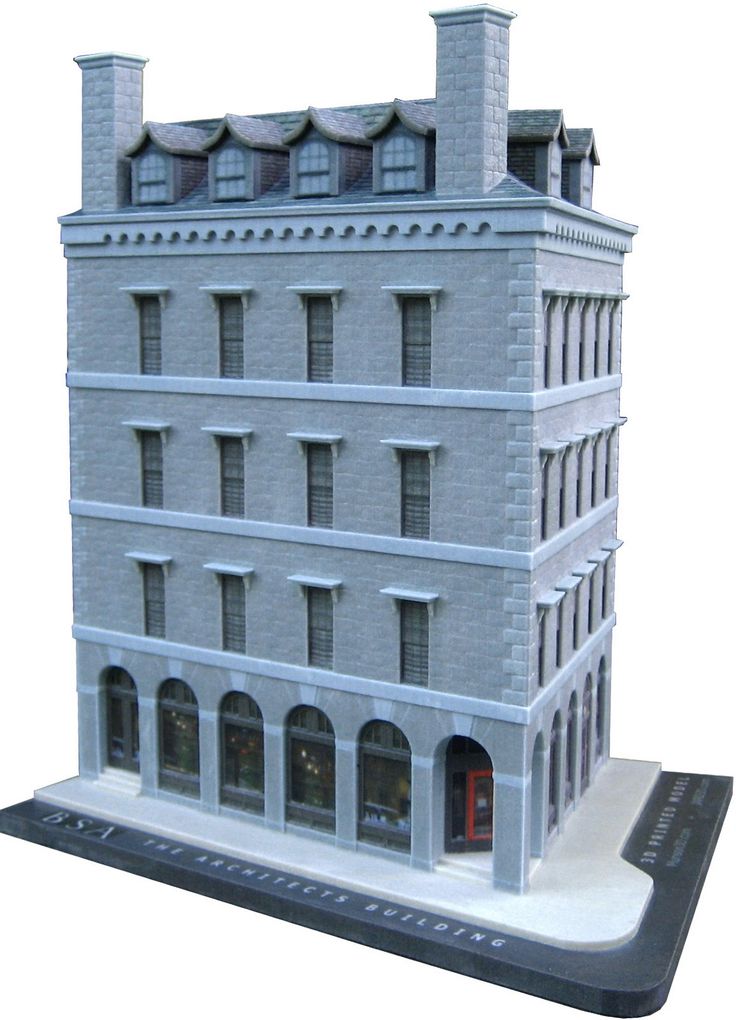

3D-Printed Office Building, Dubai, United Arab EmiratesPhoto: Gulf NewsBefore Dubai became the home of the world’s largest 3D printed building, it had already been known for the world’s first 3D-printed office building. According to Architect Magazine, the 2,600 square-foot office complex houses the Dubai Future Foundation (DFF) headquarters. Each building is made of individual concrete components, which were printed in Shanghai and shipped to Dubai for placement. To complete the job, Dubai enlisted the help of WinSun’s enormous 3D printer, measuring 120-feet long, 40-feet wide, and 20-feet high.

According to Architect Magazine, the firm said the combination of 3D printing and modular assembly reduced labor costs by 50%–80% and construction waste by 30%–60%. The building, which first opened for business in the summer of 2016, was designed by Gensler for the United Arab Emirates National Committee.

“This paves the way for a future where 3D printing can help resolve pressing environmental and urbanization issues, and it allows us to deliver highly customized spaces for our clients in a much shorter time frame,” Gensler principal Richard Hammond told Architect Magazine in a statement.

3D-Printed House Prototype, Antwerp, BelgiumPhoto: Kamp C & Jasmien SmetsThis past summer, Kamp C erected a 3D-printed two-story house in Belgium, according to New Atlas. The house is just shy of 1,000 square feet and was made using the same COBOD BOD2 printing technology as the detached house in Germany. The printer measures 32 by 32 feet and extrudes a cement-like mixture in individual layers until the structure is complete. After it was done, human contractors added windows and other essential elements.

After it was done, human contractors added windows and other essential elements.

This project took around three weeks to complete, but Kamp C told New Atlas it would reduce the building time to under two days. The building includes an entrance hall, two conference rooms, and a kitchen and is outfitted with modern amenities, including heated floors, solar panels, and a heat pump.

Project manager Marijke Aerts told New Atlas that 3D printing technology for the project saved approximately 60% on time, budget, and materials.

14Trees’ Affordable, Sustainable Buildings, Malawi, AfricaPhoto: 14TreesAffordable housing isn’t a given in many places. 14Trees, a joint venture between CDC Group and cement producer LafargeHolcim, is looking to improve residents’ quality of life by increasing the availability of affordable homes and school buildings around Africa.

Starting in Malawi, 14Trees has begun producing its sustainable and affordable structures, once again using COBOD’s BOD2 3D printer, according to 3D Printing Media Network. The printer’s enormous size requires two human operators, so COBOD sent experts to Malawi to ensure local workers’ proper training.

The printer’s enormous size requires two human operators, so COBOD sent experts to Malawi to ensure local workers’ proper training.

“We are very encouraged by the fact that 14Trees now has brought our technology to beneficial use in Africa, and we are impressed by the speed they manage to achieve for the printing of the walls of the first buildings, COBOD Founder and General Manager Henrik Lund-Nielsen told 3D Printing Media Network.

“The shortage of affordable housing and schools in Africa is overwhelming, and we do believe that our technology can play a vital role in solving this, not at least by increasing the speed of execution.”

3D printers in construction: prospects for application

At first glance, 3D printing structures seem to be some kind of shell of a half-finished building. But upon closer examination, you will not find even a brick. Layers of material seem to build up one on top of the other - this is how a complex structure is created. It's a futuristic world of 3D printing where robotic arms automatically layer and compress layers of concrete or plastic or any other material into a foundation and build a structure.

This method of construction is quite niche today - only a few prototypes of 3D houses and offices have been printed in the world. However, this technology represents an exciting and potentially powerful solution to building change.

What is 3D printing in construction, what is the potential, and will we be working on 3D printed projects in the near future?

- What is 3d printing in construction?

- 3D printers in construction: how is it done?

- 5 examples of innovation

- How can 3d printed projects help construction companies?

- 3D printing distribution

- 3D printing in civil engineering

- Wiki House technology - an open source project for 3D printing: what is behind the concept

- Reverse side of the coin

- How can 3D printing be integrated into construction

- About PlanRadar

3D printing in construction - what kind of technology?

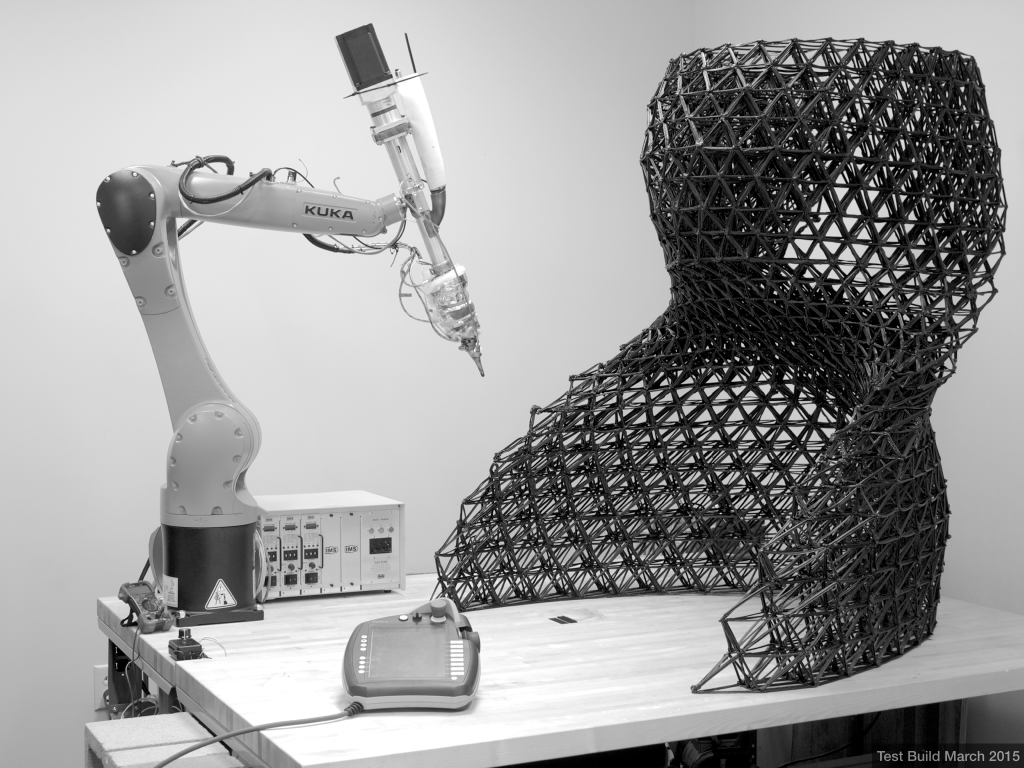

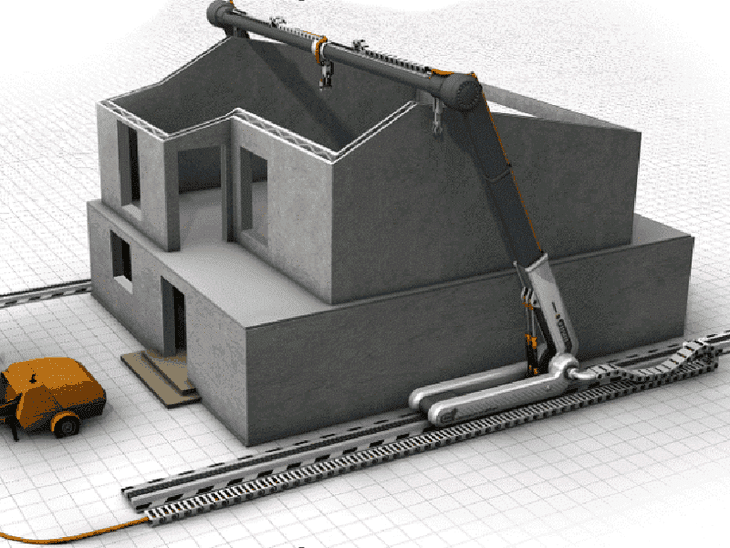

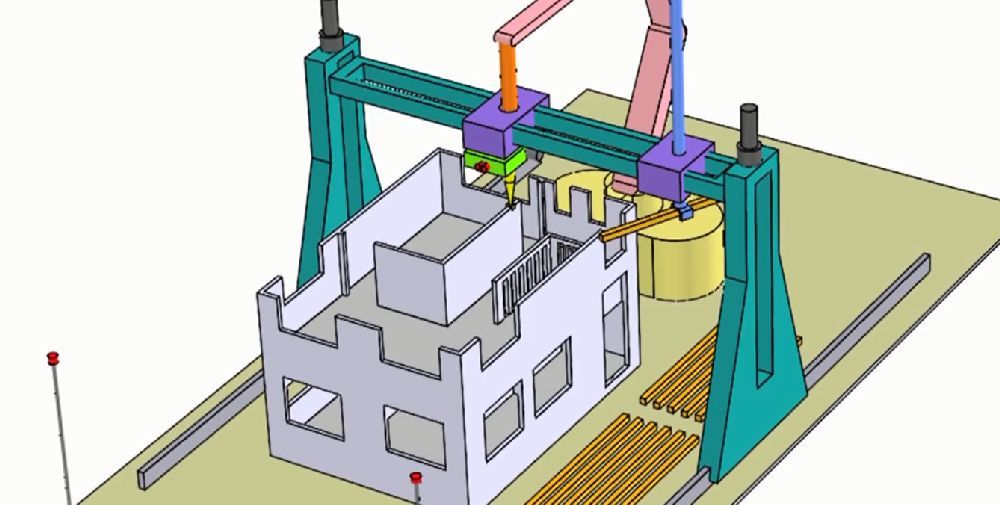

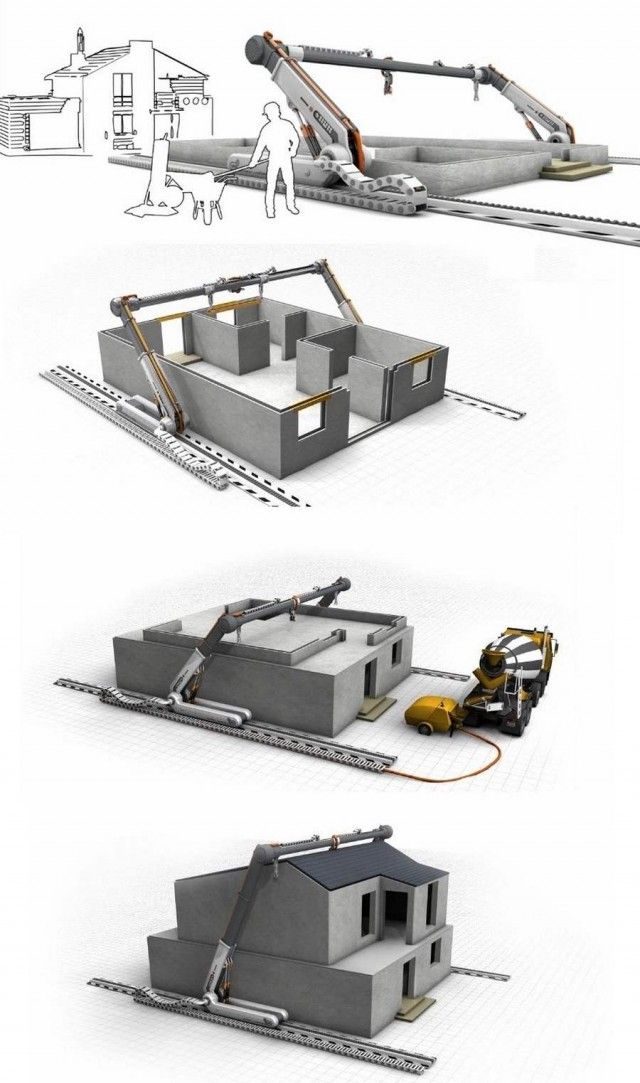

3D printing for construction uses both a 3D printer that has a robotic “crane-arm” that builds structures right on the construction site, and the creation of certain elements by printers at the factory, which are already assembled into a structure on site.

The concept of 3D printing is not new: it first appeared in the 80s. But it's only in the last decade that this technology has been improved enough (and the cost significantly reduced) to become a real mainstream.

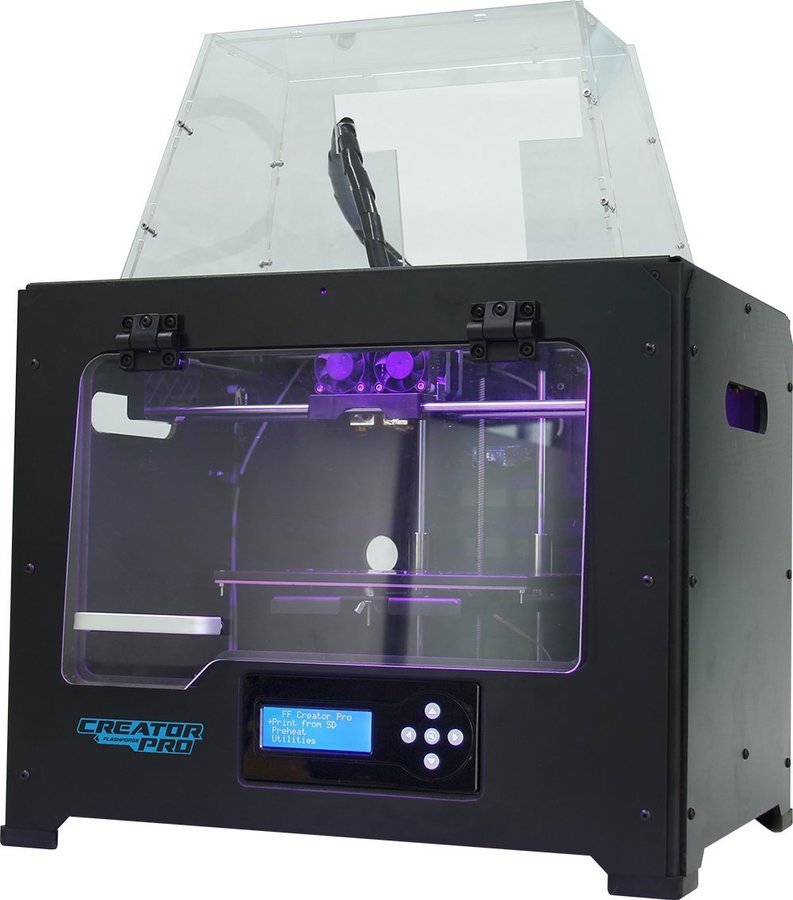

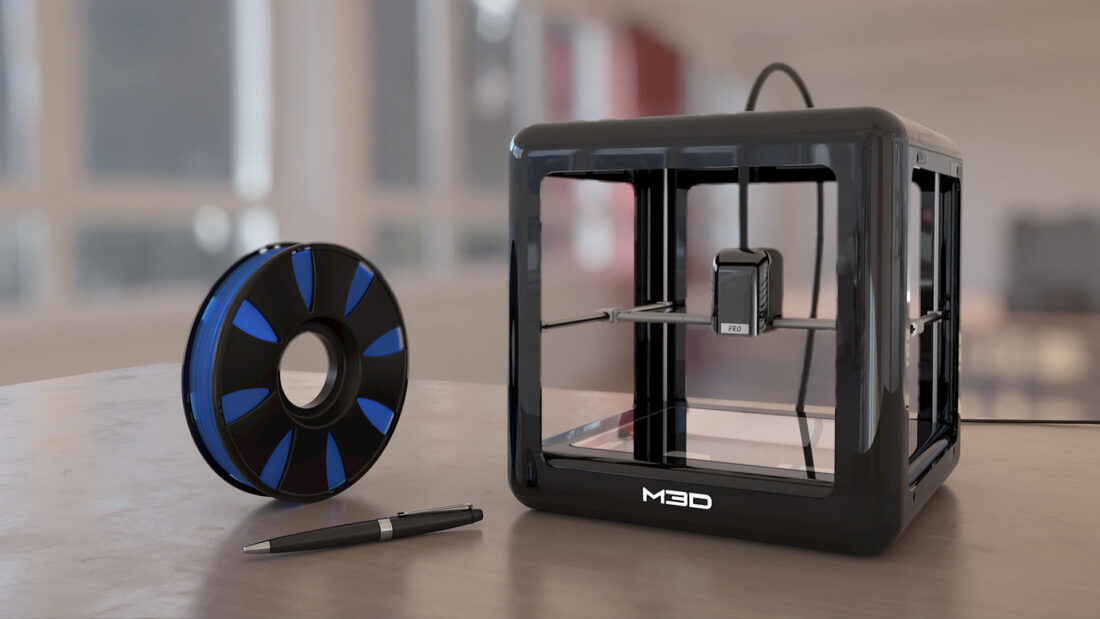

3D printers are not much different from conventional inkjet office printers. The software tells the printer about the dimensions of the final product. And then the printer starts to output the material to the platform according to the plan. 3D printers often use liquid metals, plastics, cement, and variations of various materials that, when cooled and dried, form a structure.

In a 3D construction printer, the CAD or BIM programs tell the device what to print, and the machine begins layering the material according to the design plan.

3D printers in construction: how do they work?

3D printing concept - The printer extrudes a defined liquid mixture in layers, level by level, creating a design based on a 3D model. The prepared mix of concrete, filler, plasticizer and other components is loaded into the hopper of the device and fed to the print head. The mixture is applied to the surface of the site or to the previous printed layers. This is how most 3D printers work. Among them, there are three types of devices for 3D printing:

The mixture is applied to the surface of the site or to the previous printed layers. This is how most 3D printers work. Among them, there are three types of devices for 3D printing:

Robotic printer

Read also: New technologies in construction 2021

5 innovative examples of 3D printing

To date, only a few 3D printing projects have been implemented in the construction industry. Here are five of the most impressive and promising projects:

Dubai City Hall Office Building, UAE

1. Dubai City Hall Office Building, UAE

3D printed building. The office block built in the UAE is 9,5 meter high building with an area of 640 m2.

An Apis Cor 3D printer moved around an open-air construction site with a crane and erected different parts of the structure.

2. Office of the Future, UAE

Office of the Future, UAE

Another impressive 3D printed building in the UAE, the Office of the Future is a unique, fairly large structure that currently houses a temporary headquarters organization Dubai Future Foundation.

For this building, the elements were not created on site and were printed in 17 days, while the building itself was assembled in 48 hours.

3. WinSun 3D Printer Homes, China

WinSun 3D Printer Homes, China

WinSun 3D Printing Company of China has also applied factory-built 3D printers to build residential buildings. The company has created several house projects, including a small multi-storey building. All construction details can be printed quickly and cheaply and then quickly assembled on the construction site.

The company calculated that it would cost as little as $161,000 to build and print their five-story building.

4. 3D printed license plate at Lewis Grand Hotel, Philippines

3D printed license plate at Lewis Grand Hotel, Philippines

When planning a trip to the Philippines, consider staying at the Lewis Grand Hotel in Angeles City , Pampanga, where visitors will be greeted with the world's first 3D printed hotel suite. The hotel room was designed by Lewis Jakich, hotel owner and materials engineer, in collaboration with 3D printing specialist Anthony Rudenko. They created a massive 3D printer that prints sand and concrete based on volcanic ash. The room was printed in 100 hours.

The hotel room was designed by Lewis Jakich, hotel owner and materials engineer, in collaboration with 3D printing specialist Anthony Rudenko. They created a massive 3D printer that prints sand and concrete based on volcanic ash. The room was printed in 100 hours.

5. Two-story mansion in Beckum, Germany

Two-story mansion in Beckum, Germany

The first 3D-printed residential building with an area of about 80 square meters - the brainchild of the German construction company PERI GmbH and the architectural design bureau MENSE-KORTE ingenieure + architecture. A BOD2 3D printer was used to print one square meter of double wall cladding in 5 minutes. The building is a structure with three-layer hollow walls filled with insulating mass. Installation of hollow pipes and connections during printing was carried out manually.

3D printing in construction seems really impressive, but what are the real benefits of such technology?

How can 3D printed designs be useful for construction companies?

Proponents of 3D printing houses and commercial offices point to several advantages of this construction method:

- Zero waste construction

In the UK, almost a third of the waste comes from the construction industry. According to the Transparency Market Research Group, the construction industry worldwide will produce 2.2 billion tons of construction waste by 2025. And although most of the waste is related to the demolition of buildings, the construction sites themselves produce a lot of waste.

According to the Transparency Market Research Group, the construction industry worldwide will produce 2.2 billion tons of construction waste by 2025. And although most of the waste is related to the demolition of buildings, the construction sites themselves produce a lot of waste.

Conversely, 3D printing can reduce waste to almost zero. A 3D printer uses a well-defined amount of material that is required to print a design - no more, no less. This can be a big savings.

- Reduced energy consumption

3D printing in construction encourages the use of locally available materials and natural ingredients. This practice can reduce energy costs in transportation, construction and manufacturing, as most local materials require less energy to process or install. If traditional materials with toxic chemical impurities are replaced with natural ones, then the toxicity of the entire construction can be reduced. In addition, local materials are often better suited to local climates and can reduce a building's heating or cooling load, which also reduces construction costs.

- Save time and money

As with AI in construction, a 3D printer can run 24 hours a day, 7 days a week. This means construction projects have the potential to be completed much faster and a number of low-skilled labor costs can be avoided. What's more, 3D printing eliminates the need for temporary structures, such as formwork and scaffolding, that are commonly used in traditional construction. Studies of 3D printed concrete structures have shown a significant reduction in formwork requirements, reducing costs by 35-60%.

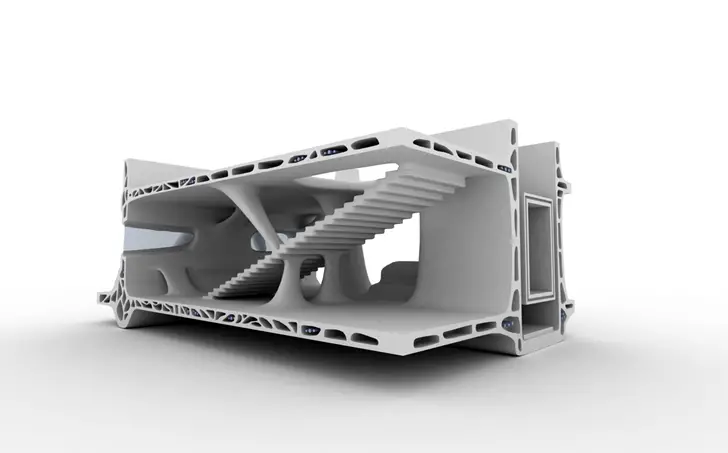

- Can realize unusual design shapes

One of the most attractive characteristics of 3D printers is their ability to create complex and unusual design designs, including a single, unique one. Since the job of a 3D printer is to layer the material, they can be programmed into absolutely any unusual shape that would be much more difficult to create with traditional techniques.

- Minimize human error and improve safety

The published injury statistics at the workplace by the American agency BLS in 2020 indicates that construction is one of the most traumatic areas and a high incidence of diseases. Every day, about 5333 workers die on the construction site. And with the advent of 3D printing, the number of work injuries and fatalities will obviously decrease, as it makes construction more programmable and automated. Robotic construction requires standardized, accurate and complete digital building information, making this technology more accurate and efficient, with minimal rework due to human error or any information inconsistencies. The usual problems with materials and components that need to be stored somewhere, protected from damage are leveled out, problems with installation and work in progress due to damage also disappear - 3D elements are created as they are built, they do not need to be moved and stored.

- Exploring new markets

The use of a 3D printer also allows construction companies to enter new market sectors that were previously inaccessible to them. And for start-up companies, having a 3D printer will be a competitive advantage. What's more, 3D printing is a brilliant way to elevate or improve the reputation of a construction company's brand among those who believe that concrete production has an impact on the planet's environment.

Distribution of structural 3D printing

3D printing for structural reinforcement, small scale components and structural steel could revolutionize design, construction and space exploration. In addition, the European Space Agency (ESA) believes that using 3D printed metals to create high-quality complex shapes can significantly reduce their cost, and they will become very common.

ESA has developed a project with the European Commission to improve the printing of metal components that can be used in space. In total, 28 European partners have united for the joint project AMAZE (Additive Manufacturing Aiming Towards Zero - layer-by-layer 3D printing for zero waste from production and efficient production of high-tech metal products).

In total, 28 European partners have united for the joint project AMAZE (Additive Manufacturing Aiming Towards Zero - layer-by-layer 3D printing for zero waste from production and efficient production of high-tech metal products).

Almost everything can be designed on a computer, so AMAZE plans to install a 3D printer on board the spacecraft, and as soon as an astronaut needs any part, a tool, he can simply print it.

Structural 3D printing

Civil engineering 3D printing

Civil engineering 3D printing has been gaining popularity over the past decade, as has the aerospace and biomedical industries. This revolutionary manufacturing technique is based on its unique ability to create any geometric shape without any formal restrictions, minimizing waste but increasing productivity and results. The construction industry's push towards automation has recently reached important milestones, including the creation of the first structures using robotic "arms" and 3D printing technology.

The use of 3D printing in the creation of structural elements from polymer materials, concrete and metals is becoming more common.

These civil engineering technicians can create freeform and innovative architectural designs using CAD-integrated software.

However, despite considerable research in the aerospace and bioengineering industries to evaluate and analyze this mechanism, there is still a lack of understanding of its use, the impact of 3D printed materials in civil structures, both in terms of material properties and structural response.

Imperial College London

Read also: Best Building Apps in 2021

WIKI HOUSE - 3D printing in construction: what is the concept behind

Wiki House is an innovative project created by a small group of architects in London in 2011 . It offers an open source digital house design system that allows users to create, upload and share designs and print their own houses.

The kit does not require any special knowledge and training and can be created in 1 day. Elements are digitally cut from ordinary sheet material, like plywood, using a CNC machine. And it's much faster, less costly, and doesn't require the involvement of experts, as in conventional traditional construction.

Elements are digitally cut from ordinary sheet material, like plywood, using a CNC machine. And it's much faster, less costly, and doesn't require the involvement of experts, as in conventional traditional construction.

A standard two bedroom house can be built for less than £50,000 and additional components such as cladding, insulation, windows and more can be added to the main frame of the structure. The first house that was built on the basis of the open source Wiki House technology was a two-story building. The 3D printed house was presented at the London Design Festival in 2014.

The Wiki House movement was spearheaded by Alastair Parvin, whose TED presentation "Architecture for People, Built by People" talked about the promise of 3D printing in construction. The creator of this project believes that Wiki House can help solve the housing problem, especially in emergency situations such as earthquakes (there is already evidence that 3D-printed houses can withstand shocks up to magnitude 8).

In the future, this could become a real alternative to low-cost houses, while allowing the customer to control the design of the project.

3D building built using Wiki House

Will 3D printing be the sustainable future of building?

3D printing has the potential to revolutionize the supply chain and structure through a new method of design and manufacturing. According to the study, 3D printing can help the construction industry become more economical, more efficient and greener.

Saxon University of Applied Sciences scientists Ivo Kotman and Neils Faber claim that 3D printing technology will be a "game changer". They explored the possibilities of 3D printing concrete, and their conclusions are:

- 3D printing shortens the supply chain and the entire design process. 3D printing right on the job site eliminates time-consuming steps in the design process. The architects, engineers, contractors, clients, and executives who normally have to be actively involved in a project are no longer needed in 3D printing.

Since all tasks can be combined in one figure of the architect, who uses the modeling method and reproduces the exact holistic designs.

Since all tasks can be combined in one figure of the architect, who uses the modeling method and reproduces the exact holistic designs. - Pipe fitting and electrical wiring become easier and more efficient. Heating systems, insulation, plumbing and electricity all require the laborious on-site installation of conventional construction. However, in 3D printing, some of these features can be incorporated into the 3D printing process. Cavity wall printing is less resource intensive, improves insulation, and allows the use of 3D-printed hot or cold water channels. Moreover, the need for on-site installation is eliminated, which directly affects the reduction of waste.

- The best logistics. 3D printing eliminates 3 logistics and shipping issues. Firstly, a lot of materials and elements often deteriorate upon delivery, and if everything is printed on site, then damage is minimized

Secondly, in order to withstand transportation, the parts must be with increased technical characteristics, which by default increases the cost of them, and therefore the entire project. 3D printing right on the construction site will help to avoid such additional costs.

3D printing right on the construction site will help to avoid such additional costs.

- Creation of individual house designs available to the general market. Usually, building a house with the involvement of an architect is an expensive pleasure for most consumers. But with concrete 3D printing, you don't have to worry about the chosen shape, it won't cost more. In fact, this means that in the future, more people will be able to buy houses of their own design, according to their individual needs

Reverse side of the coin

While 3D printing is definitely attractive, it's still important to look at it impartially, removing some of the promotional stimulus. Skeptics note several disadvantages of this technology.

- Research and development costs

Most construction companies operate with relatively low profitability. To start using 3D printing everywhere, significant investments will be required.

- Will consumers see this as a marketing ploy?

3D printed houses, offices, shops and other infrastructure are often impressive. But do most people really want to live or work in one? For most people, brick houses are much more familiar and attractive. Other technologies such as prefabricated houses also seemed like an attractive technology of the future for some time, but have not been widely adopted, despite the fact that in many cases they were cheaper than traditional ones.

- Difficulty integrating with other components

3D printers can create unique and interesting designs. However, if you need a building that will use different materials or different elements that will not be suitable for 3D printing, then it will be a challenge to include a 3D printer for the building process.![]()

- Skilled labor shortage

With the current problem of a shortage of skilled labor in the construction sector as a whole, 3D printing will require an even larger set of specialized knowledge and skills, which will have to be selected from an already small niche of candidates. So finding specialists to work in 3D printing for construction may be another difficult task in the future.

- Construction quality control

Weather conditions can slow down the traditional building process, but things are even worse for 3D printing. The environmental factor for commercial construction may reduce the demand for 3D printing. What's more, quality control can be a much more serious task, requiring constant monitoring of the process by real people at the construction site.

- No standards and regulations

Despite the regular mention of 3D printing in the media, it still has not had a significant impact on the construction sector. There is an obvious liability issue when using these printers, even more so than human liability when doing some construction work. And quite a few other ambiguities regarding this technology. So until norms and standards are established, as well as rules in this area, 3D printing is unlikely to become mainstream in the construction industry.

There is an obvious liability issue when using these printers, even more so than human liability when doing some construction work. And quite a few other ambiguities regarding this technology. So until norms and standards are established, as well as rules in this area, 3D printing is unlikely to become mainstream in the construction industry.

Read also: New technologies in construction 2021

How can 3D printing be integrated with construction?

At the moment there is strong evidence that 3D printing is worthy of attention and can be applied in the construction segment, and most likely that this technology will be used more in the coming years. True, it is not known how widely these devices will be used on the construction site, or whether they will remain only a tool for the manufacture of block elements for prefabricated structures. But for certain projects, it is reasonable to assume that 3D printers and this technology in construction will be a must-have tool in the arsenal of builders.

ABOUT PLANRADAR

PlanRadar was founded in 2013 and provides an innovative mobile software solution for construction and real estate. Our app is available on all iOS, Android and Windows devices and has already helped over 13,000 customers digitize their workflow in over 55 countries. Find out more about the app here.

Construction 3D printing is waiting for a breakthrough / Sudo Null IT News

3D printing technology originated in the 80s of the 20th century, but construction 3D printing appeared much later. The first construction projects using this technology appeared only in 2014. We are talking, first of all, about the so-called small architectural forms (benches, flower beds, fences). They never even dreamed about building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed.

Construction is the world's number one market. And, if many technological innovations are being introduced in the field of high-rise construction, then little has changed in the field of low-rise construction over the past decades. The last 30 years have seen the availability of the Internet, mobile phones, mobile internet, robotics taken to a new level, etc., but when you get to a house construction site, you are unlikely to find many technological innovations. Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more.

This Internet meme shows what happened to the cost of building materials in just a year. And the process is still going on. At the same time, there is a serious rise in the cost of labor, and there is an acute shortage of it. All this leads to a sharp rise in the cost of building houses. No matter how strange it may sound, statistics show that the growth of automation does not occur when everything is fine, but precisely in crisis situations, during increased competition, reduced demand and the need to urgently look for new technologies to increase production efficiency. So it happened this time, and after some stagnation, construction 3D printing received a new impetus for development.

All this leads to a sharp rise in the cost of building houses. No matter how strange it may sound, statistics show that the growth of automation does not occur when everything is fine, but precisely in crisis situations, during increased competition, reduced demand and the need to urgently look for new technologies to increase production efficiency. So it happened this time, and after some stagnation, construction 3D printing received a new impetus for development.

Preparing to write an article, I turned to the founder of Arkon - Boris Kozlov y. Arkon was established in 2020 and is engaged in the production of construction 3D printers, both a workshop type for creating prefabs (prefabricated houses) and a portal one capable of printing a two-story house. I asked Boris the key, in my opinion, question:

- Construction 3D printing appeared in 2014, but no mass introduction of this technology followed in 7-8 years. Why do you think this happened, and why is there a surge of new projects right now?

- It seems to me that the reason is the snowball effect.

The technology had to mature, grow from a hypothesis to a pilot implementation, and finally to commercialization and scaling (what is happening now). In addition, it should be borne in mind that construction is one of the most conservative industries, where, unlike even aviation and the automotive industry, there is still an extremely low introduction of digital solutions and automation in the field of the production process itself - the construction itself. The issue of regulation and certification also plays an important role - this process is long and creates an additional lag.

In 2014-2016 the first samples of building 3D printers and prototypes of printed buildings appeared. The concepts of various form factors of construction 3D printers and types of printing materials were tested.

In 2017-2018 in the world, the first notable investments were made in a number of construction 3D printing start-ups. Further, by 2020, these investments "rolled" in the form of reaching a certain level of technology maturity - the first commercial products (3D printers and houses) appeared.

Finally, in 2020-2022 it became clear that the hypotheses of the effectiveness of construction 3D printing were justified (cheaper, faster, more environmentally friendly), and large investments began in the industry. A striking example is the investment of GE (the French division of General Electric) in the Danish COBOD or the achievement of a capitalization of $ 2 billion by the American company ICON.

In 2022-2023 over 1,000 buildings will be printed worldwide already, scaling from single buildings/pilot projects to entire villages and major infrastructure/reinforced concrete implementations. In addition, in a number of countries, by now, a regulatory framework has been created or is being actively created for the introduction of additive technologies in the construction industry.

Thus, I believe that the specified time period is a fairly natural cycle of technology development, which is likely to experience exponential growth in the next decade.

According to ResearchAndMarket report, the global construction 3D printing market is valued at USD 354.3 million in 2022 and is projected to reach USD 11068.1 million by 2027, an increase of 99.04%.

Various market processes affect the prices and behavior of participants in the global 3D construction printing market. They create price signals that are the result of changes in the demand and supply curves for a product or service. They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals.

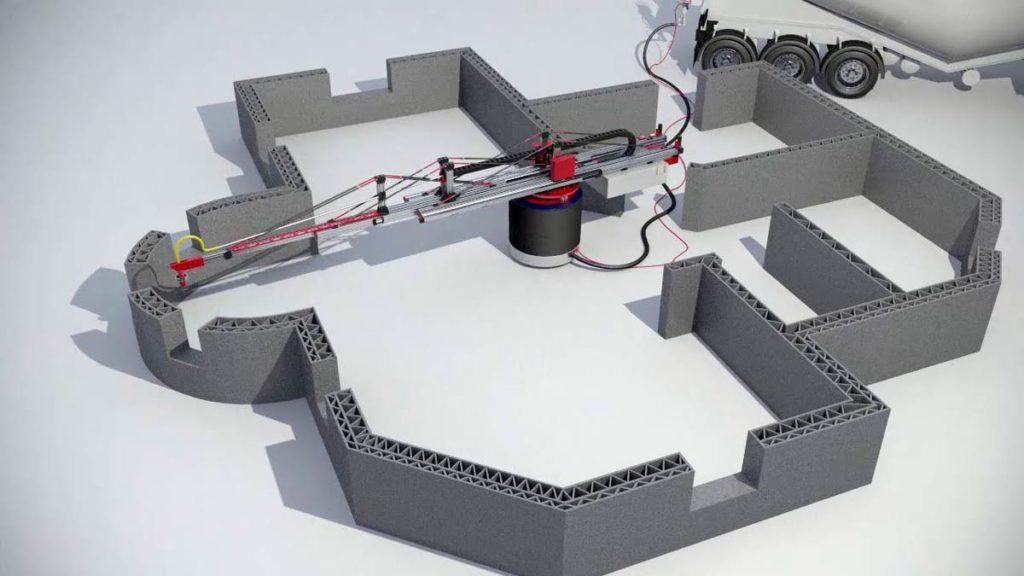

Now let's take a quick look at what is the construction 3D printer. Without delving too deeply into the technology, we can say that construction 3D printers are very similar to classic FDM/FFF printers that print with plastic, but instead of plastic, the material here is a cement mixture, which is fed directly into the nozzle and forms an object by layer-by-layer overlay. Printers are also portal, on the basis of a flying boom, with a robotic arm.

Printers are also portal, on the basis of a flying boom, with a robotic arm.

Pictured left is a construction printer based on a boom. The figure on the right is a gantry construction 3D printer

In the figure above, a construction 3D printer in the form of a robot arm installed on a mobile platform.

Everything changed completely when, in the summer of 2021, the American company ICON, which was trying to introduce 3D printing into the construction of various auxiliary facilities, signed a contract with one of the largest American developers, Lennar, to build a village of 100 houses in Texas and immediately became a unicorn , having received 200 million dollars of investments from several investment funds.

Pictured is a 3D printed house in Austin, Texas. A 3D printed house in Austin, Texas. At the same time, the Danish company COBOD, created by the world's largest construction formwork company PERRI, began selling its gantry 3D construction printers and participating in construction projects around the world. In the photo below, a modern two-story house built in Germany and a school building in Malawi, built in record time with a minimal budget.

In the photo below, a modern two-story house built in Germany and a school building in Malawi, built in record time with a minimal budget.

Few things unite developed, developing and poor countries, everywhere their problems and tasks, but Affordable housing shortage is a global agenda . If in poor countries there is an acute problem with the increase in the number of homeless people due to a lack of housing, as such, then in developing countries it is necessary to dramatically accelerate the number of new housing being built to meet the needs of a growing population. In developed countries, the problem is primarily in the cost of housing, which has risen in price to such an extent that it has become practically inaccessible to young people. And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse.

At the same time, the trend towards “green agenda ”, CO2 reduction, building with more environmentally friendly materials, etc. is developing. But, unfortunately, so far the construction industry is the absolute leader in CO2 emissions, as well as in the amount of garbage that each construction site leaves behind. This is not to say that construction 3D printing solves all these problems, but at least it is moving in the right direction. Let's look at this with a few illustrative examples.

is developing. But, unfortunately, so far the construction industry is the absolute leader in CO2 emissions, as well as in the amount of garbage that each construction site leaves behind. This is not to say that construction 3D printing solves all these problems, but at least it is moving in the right direction. Let's look at this with a few illustrative examples.

Today, when we talk about 3D printing of houses, we are talking about printing walls. Everything else (foundation, windows, doors, ceilings and roof) is done in the traditional way. 3D printed walls are erected as fixed formwork, which significantly saves the amount of cement used , and this, in turn, reduces the cost of construction and reduces the environmental impact of cement production. In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly.

At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly.

Eco-concrete with the addition of polymers is now being actively developed , the production of which reduces CO2 emissions from 30% to 100%. The Apis Cor company mentioned at the beginning of the article, which built a house in the suburbs in 2015, is now based in hot Florida, plans to start using this material in its projects.

Another startup from Russia, Mighty Buildings, headquartered in California, initially relied on a polymer with the addition of mineral chips. And while the company doesn't build entire homes, it only makes wall panels, it has won numerous design awards, as well as a $400 million valuation in several investment rounds.

As a result, with a rough calculation, we can say that the total savings on the construction of walls can reach 30%, and the total cost of the house can be reduced by 10%. This is true for houses designed for conventional construction. And if you initially design with 3D printing, you can improve this ratio by optimizing the laying of communications, the ability to immediately print interior walls, bookmark niches for bathrooms, fireplaces, built-in wardrobes and kitchens, as was done in the house built by COBOD in Germany.

"There are spots on the sun." Despite all the advantages of construction 3D printing, has several significant disadvantages of . The main one is layering, which cannot be avoided at the current level of technology development.

The photo above shows the layering of the 3D printed walls.

This task can be worked in several directions:

-

Ribbed walls can be plastered, painted and played with as a design element.

That's how ICON does it in the US, for example their latest project House Zero is done that way and has won a number of design awards.

That's how ICON does it in the US, for example their latest project House Zero is done that way and has won a number of design awards.

-

Use special "shutters" on the print head that allow smooth layers, as COBOD and other manufacturers do. The photo below shows that this does not ensure the complete absence of layering.

-

Fully sand the surface to get the usual smooth wall for plastering, painting, wallpapering or other finishing. It is possible, but it will require huge labor costs, which can reduce the overall efficiency of using 3D printing.

Pictured above is a 3D printed wall sanded smooth.

The second problem is the required temperature. Ideally, printing should take place at temperatures between +5C° and +30C°. Humidity is also important. Using additives, you can push these boundaries, but not indefinitely. At strong sub-zero temperatures, printing will be possible in the field only if the construction site is covered with a dome and the required temperature is reached inside with the help of heat guns. In conditions of intense heat, it is preferable to print at night. Another solution could be to print the wall panels in the shop and assemble them on site. Of course, each of these decisions will have a negative impact on the economic efficiency of the project.

In conditions of intense heat, it is preferable to print at night. Another solution could be to print the wall panels in the shop and assemble them on site. Of course, each of these decisions will have a negative impact on the economic efficiency of the project.

Building 3D printing can be useful not only for the construction of houses . With its help, you can solve many other problems, and there its disadvantages will not matter. For example, the American concern GE uses COBOD printers to build towers for wind turbines in the shop. Ribbed surface and temperature restrictions in this case do not play any role. Construction takes place in the shop, after which the object is transported to the installation site.

3D printed wind tower. 3D printed wind tower. Construction 3D printing, or, as it is also called, additive construction, has just appeared, and I want to believe in its bright future. There are many prerequisites for this, but a lot still needs to be done for success.

Learn more