3D printer palette

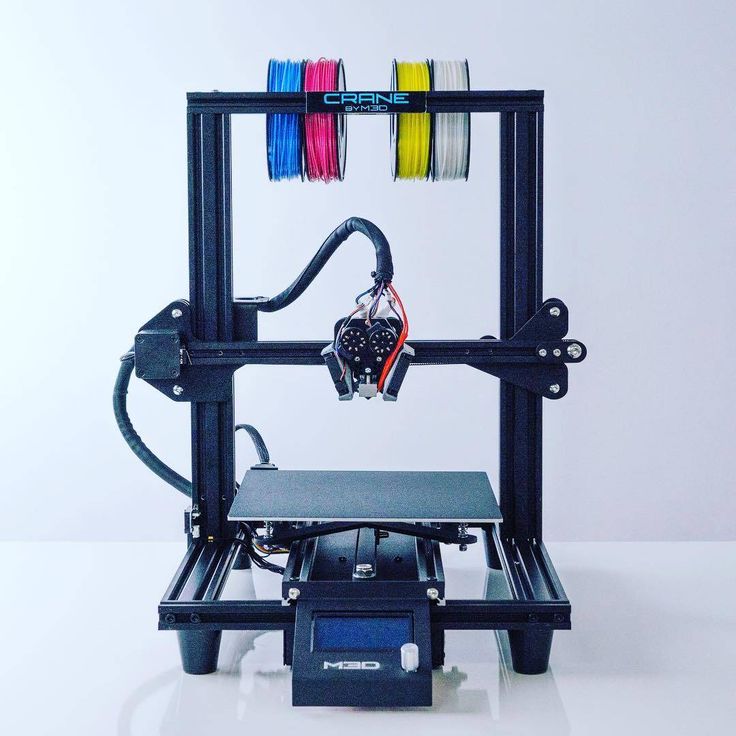

Palette 3 Pro – Mosaic Manufacturing

Multiple colours, infinite potential

Communicate your ideas with realistic, multi-colour prints. Palette 3 Pro enables you to achieve prints with up to 8 different colours.

Multi‑Material 3D Printing

Achieve high-quality, functional prints with flexible or rigid materials, or simplify prints with challenging overhangs using breakaway or soluble support.

3rd Generation Splice Core Pro

Engineered to strategically splice filaments, our Splice Core Pro allows your Palette 3 Pro to reach up to 10% faster splicing and cooling speeds.

Automate your filament

If a spool runs out, Palette will automatically splice to another spool and keep your print going. With 8 spools available your prints will always continue to run.

A modern 3D printing experience

To create a more seamless experience, Palette 3 Pro comes with built-in WiFi connectivity to connect your Palette, your printer and your computer.

Customize, Store and Slice

Experience a simple, powerful software suite. With our easy-to-use Canvas software you can slice, paint, stamp, and manage all your prints in the cloud.

Reliable, Plug and Play Material

While Palette 3 will work with most 1.75mm 3rd party filaments, Mosaic's tight tolerance PLA ensures the most reliable printing experience for your Palette 3 and printer.

Palette 3 Pro

With an industry leading 8 material inputs, Palette 3 Pro gives you the most flexibility when it comes to creating multi-material 3D prints

To ensure you always have the best experience, Palette 3 Pro comes with an extended 2-year warranty, Ethernet port and extra spare parts.

Experience the fastest splicing yet with 3rd Generation Splice Core Pro Technology, 10% faster than Palette 3 and 30% faster than Palette 2.

Product Comparison

Palette 3 vs Palette 3 Pro

Palette 3

Palette 3 Pro

Compatibility

Open 1.75mm filament,

.gcode/.x3g (and more)

Ultimaker and Lulzbot machines

Explore Palette Technology

Palette 3

Introducing Palette 3 and Palette 3 Pro

Learn the ins and outs of Palette 3 and Palette 3 Pro, as well as the biggest development changes when compared to previous generations of Palette.

Learn moreExplore Palette Technology

Element

Introducing Element and Element HT

Learn more about Mosaic's multi-material 3D printer line, with Palette X technology embedded inside.

Purchase

Palette 3 Pro

Simple multi-material 3D printing

Palette 3 Pro

$799.00 USD

Multi-material 3D printing at its best – Mosaic Manufacturing

Enabling multi-material 3D printing has been Mosaic’s mission since our early days in 2014. Since then, we’ve sold tens of thousands of Palette units to customers in over 70 countries. Introducing the latest generation of Palette:

Palette 3 + Palette 3 Pro

Design ApproachTwo of the most important aspects that Palette 3 improves on are user experience, and reliability.

Additionally, Palette 3 Pro allows for the printing of up to 8 materials on a single extruder 3D printer. This is double the 4 inputs on every other Palette to date, and more available materials than any other approach on the market.

Simple Multi-Material 3D Printing

Palette 3’s new user interface, and approach to connectivity means that you’re able to get an incredibly simple experience. One of the biggest changes when compared to Palette 2 is the integrated Canvas Hub S. This means that you’re able to connect Palette 3 (Pro) to your printer, and access easier loading, connected calibration, and a simpler printing workflow.

Alongside this, Mosaic has developed our own version of printer control and communication in Canvas, which allows you to send files directly to your Palette 3, with no USB drives or SD cards. Through this interface, you’re able to heat up your printer, start prints, and monitor your print job.

Including Canvas Hub S functionality meant the Mosaic team had more flexibility to add in additional workflows, tutorials, and walkthroughs on Palette itself. This means Palette is better able to guide you through setup and printing.

These three aspects combine to ensure your Palette printing experience will be straightforward and simpler than ever before.

Increased ReliabilityWith product feedback on thousands of Palette 2 units, the Mosaic team was able to isolate the most common failure modes and design Palette 3 to ensure these were no longer present for users.

There were two main wear points that were focused on - splice tubes and limit switches.

Re-Engineered Splicing

Each Palette Splice Core consists of a few main components, one of the important ones being the PTFE tube. This PTFE tube is where the filament is actually spliced, and re-formed to a tight tolerance in order to allow the spliced filament to feed into your 3D printer. These tubes are made through an incredibly precise manufacturing process. Based on our team’s data collection and endurance testing, we found that the typical Palette 2 splice tube would wear out between 5,000 and 10,000 splices.

This PTFE tube is where the filament is actually spliced, and re-formed to a tight tolerance in order to allow the spliced filament to feed into your 3D printer. These tubes are made through an incredibly precise manufacturing process. Based on our team’s data collection and endurance testing, we found that the typical Palette 2 splice tube would wear out between 5,000 and 10,000 splices.

This wear is very dependent on the quality of the filament used, which leads to the range seen above. Increasing the average time for a splice tube to wear is one of the primary reasons we launched Mosaic PLA last year. With tolerances of +/- .02mm, Mosaic PLA guarantees a higher average life of your PTFE tube, especially when compared to +/- .05mm filaments.

Palette 3 was designed to splice in a different way, and due to the Palette Engineering teams’ ability to modify hardware and splicing algorithms - Palette 3 splice tubes average life now ranges from 10,000 splices, up to 25,000 splices.

What that means for you is that you’ll experience a more reliable printing experience.

Filament Sensor Re-Design

One of the requirements of Palette is that it understands where filament is in the system at any given time. In order to accomplish this, Palette has a number of ‘filament sensors’ inside in order to understand if filament is present in that area of Palette (or not present).

The filament sensors on Palette 2 used an off the shelf mechanical switch that was directly in contact with the filament. Sometimes the filament would apply excessive load to the switches requiring them to be replaced leading to a less than optimal user experience.

When working through the initial designs of Palette 3, the Palette engineering team knew that these switches needed to be redesigned and optimized for longer term operation. The team took an entirely new approach to switch design, and the results came in illustrating a new lifetime of over 2,000,000 splices. The new switch features a hardened steel, bi-directiional spring loaded switch tab that activates an optical sensor when the filament displaces the tab. The filament no longer engages with the switch allowing for drastic performance and durability improvements. These switches were run for millions of cycles without fail, and have gone from one of the weaker links in the Palette system to one of the strongest.

The new switch features a hardened steel, bi-directiional spring loaded switch tab that activates an optical sensor when the filament displaces the tab. The filament no longer engages with the switch allowing for drastic performance and durability improvements. These switches were run for millions of cycles without fail, and have gone from one of the weaker links in the Palette system to one of the strongest.

Pushing the boundaries of 3D printing

CamDrive Design and 8 Material 3D Printing

One of the biggest challenges Mosaic’s engineering team faced was how to scale the number of materials Palette could print, without scaling the size and cost of the product accordingly. The Palette Engineering team came up with a cam system that would still allow for 4 inputs on Palette 3 while also enabling up to 8 inputs for Palette 3 Pro.

Building on the backbones of Mosaic’s patent pending sliding selection drive system from a 2014 application, this new rotary CAM system embodies the key benefits of 2 motors to drive any number of filament. Unlike other simpler rotary feeder systems on the market, Palette 3’s CAM is a first of it’s kind workhorse with unrivaled drive strength and consistency between all inputs.

Unlike other simpler rotary feeder systems on the market, Palette 3’s CAM is a first of it’s kind workhorse with unrivaled drive strength and consistency between all inputs.

Cam system works with one motor ‘selecting’ which material is to be driven via rotating a cylinder with a number of idler bearings. Depending on the position of the cam, a certain input’s idler bearing will be opposite the drive gear. This idler bearing pushes the filament into the gear, and the filament is driven when the gear rotates. The other 3 (or 7) materials are not pressed up against the gear so these materials do not move forward when the drive gear rotates.

Cam systems have an incredible amount of nuance to them and must be designed, tested and manufactured in a specific way in order to operate reliably. The cam system in Palette 3 has gone through torture testing of over 100,000 material changes.

Designed with a combination of metal and solid polymer components, the system is strong and rigid enough to last through the most rigorous printing processes.

Constrained Buffer System

The Palette engineering team re-imagined the buffer system inside Palette 3 in order to allow for higher print speeds, and a more constrained material path. This updated buffer system has the material staying inside of a PTFEtube, constraining the material through the buffer.

Unlike Palette 2, The lower limit buffer switch has been moved out to allow for additional movement once this switch has been triggered. In the past, if this switch was triggered it meant that there was no buffer remaining, and if the printer was pulling filament, this could lead to skips in extrusion and small gaps in your part.

With the lower limit switch moved out, there is an additional buffer below this switch, which means Palette 3 will have more time to move filament out into the buffer and continue feeding material to your printer. We also added a buffer maximum switch to further optimize buffer performance.

The constrained buffer system allows for easier automated loading and system clearing.

Additional Cooling Systems

Airflow and cooling is an understated aspect of the Palette system that most operators don’t think about. Cooling splices, and ventilating the electronics systems are incredibly important to reliable operation over longer periods of time.

With the help of some new thermal imaging equipment, we were able to collect data over tens of thousands of splices and use this data to ensure efficient cooling and airflow when Palette 3 is being run over extended periods of time.

3D Printing, Evolved.Palette 3 and Palette 3 Pro are the simplest, most reliable way to achieve multi-material 3D printing on your 3D printer. This generation of Palette is the culmination of 7 years of expertise in multi-material 3D printing, all created to allow you to get the most flexibility out of your machine.

Palette 3 and Palette 3 Pro will begin arriving as early as July 2021, check out the Palette 3 and Palette 3 Pro product page here.

"3D palette" will bring order to the desktop of the owner of a 3D pen / Sudo Null IT News Now such pens are already available not only for geeks and professional designers, but also at the workplaces of engineers, IT specialists, in circles where children or teenagers are taught to do something with their own hands. Each owner of a 3D pen works with rolls of plastic, which, after receiving and unpacking, look something like this:

Everything is pretty nice. The problem arises after the owner of the pen unwinds the twisted plastic and begins to work.

Already after half an hour of work, tangled coils of plastic are scattered on the desktop, the remnants of the coils with which they work most often. If there is something else on the table, for example, paper, pencils and other accessories, the situation is aggravated - everything is confused with everything.

Sometimes the spools fall off the table, "hide" under the paper. All this creative mess, in general, is familiar to many, but it does not add to the efficiency of work. If the reels for the handle are a little more voluminous, the plastic from them often winds up on its own, turning into a “beard” familiar to all fishermen.

Not to say that this is a huge problem, but putting things in order takes a lot of time. In addition, if you work with several colors at the same time, you have to constantly shift the coils from place to place, unravel problem areas. Naturally, work efficiency drops.

There are people who know how to keep track of all this, their work desk is ascetic and orderly in any situation. But such people are few and far between. Everyone else can use the ready-made solution for all owners of a 3D pen. The solution is called 3D palette.

A single photo is enough to understand what it is: a set of rolls of plastic of different colors for a 3D pen in a single package, which also serves as a distributor.

The effect when using the 3D palette is immediately noticeable - no lumps of plastic on the table (except, perhaps, already used to create models). All coils are stored compactly, placed vertically. And you no longer need to look for a coil of the desired color - all the plastic, of all the colors of the rainbow, is in its place. It is not required to extract the entire array at the beginning of work - you need to get the thread of the desired color and insert it into the pen.

Working with a rainbow

In principle, the absence of disorder on the table when working with a “3D palette” is not even the main advantage. The main thing here is the ability to create multi-color figures without constantly changing coils. Inside the box there are small skeins of plastic of different colors, which allows you to realize your idea with virtually no loss of time, no matter how multi-colored it may be.

To work with a certain color, you just need to take the appropriate plastic thread and insert it into the pen:

When another color is needed, remove the previous color and select the desired thread. Everything is simple. The skein will end sooner or later, then you need to replace the plastic, for which you just need to open the lid and insert the skein into the appropriate compartment of the cassette. By passing the plastic thread through the output hole, you can close the cover and forget about the plastic until the next replacement.

Everything is simple. The skein will end sooner or later, then you need to replace the plastic, for which you just need to open the lid and insert the skein into the appropriate compartment of the cassette. By passing the plastic thread through the output hole, you can close the cover and forget about the plastic until the next replacement.

What else?

Another important advantage of "Palette" is the price. The "3D Palette" costs the same as a regular coil of ABS plastic. If a person works with plastic of various colors, then the plastic in the "Palette" will last him for a long time. Now imagine how much money would have to be spent on acquiring plastic spools of different colors. If the skein of plastic in the box is over, you can immediately insert a new one.

As for the price, let's not be unfounded. The price of "3D Palette" is (at the time of writing) 1 490 p.

The price of an ABS plastic coil (weighing 750 grams) is 1300 rubles.

3D palette, for the user's convenience, supplied with ABS spools in the following colors:

• White

• Gray

• Pink

• Violet

• Red

• Orange

• Bronze

• Brown

• Green

• Blue

• Metallic blue

• Black

3D palette specifications:

- Weight 300 g

- Optional Diameter: 1.75 mm

- Dimensions Roll length: 10 m

- Color Number of colors: 12

Can you see the results of working with Palette?

Here are examples of some of the work of designers who used the "3D palette" (by the way, everyone who has tried the system agrees with our slogan for it - "Easy to work. Easy to store!":

And one more thing:

One more picture, and that's enough:

Where can I buy a 3D palette?

You can buy this tool both online and offline stores of the Dajet company.

We offer a 10% discount to all Geektimes readers using code GEEKT-PALITRA .

Design competition

We at Dajet love to hold all sorts of contests, and now you have the opportunity to take part in an open-ended contest of 3D pen owners' designs. You can exhibit your work here and get ratings from grateful viewers. And here, once a week, a drawing of a plastic reel or a 3D palette is held (at the choice of the contestant).

Invitation to test gadgets

Dajet invites authors interested to test our devices and write an objective review to cooperate. The device after the publication of the review remains with you. Read more about the offer here.

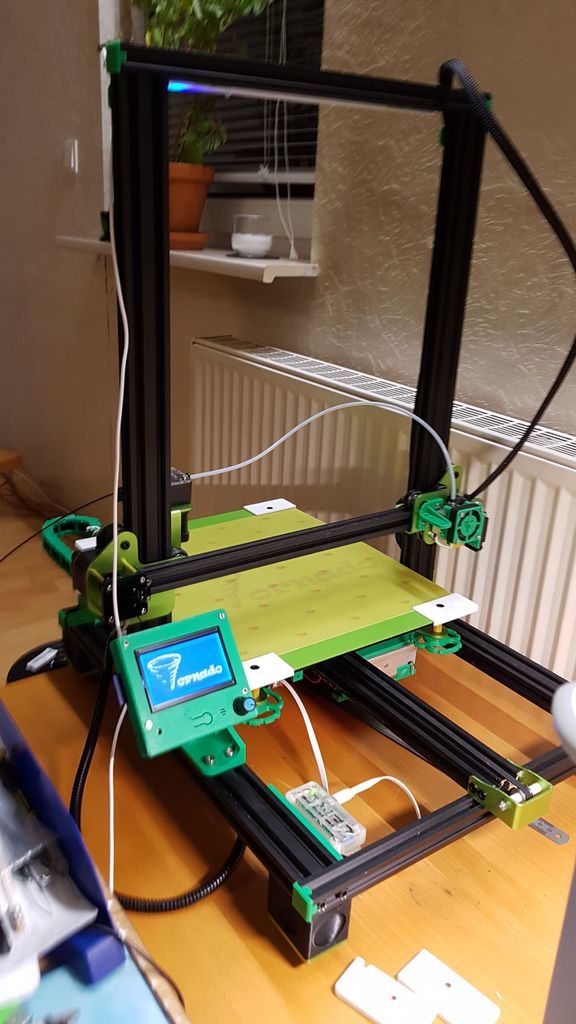

3D printing

3D printing

3D printing

https://masterkit.ru/shop/3d

0

25190

3D printers 3D pens 3D milling machines Electronics Mechanics Accessories Plastic

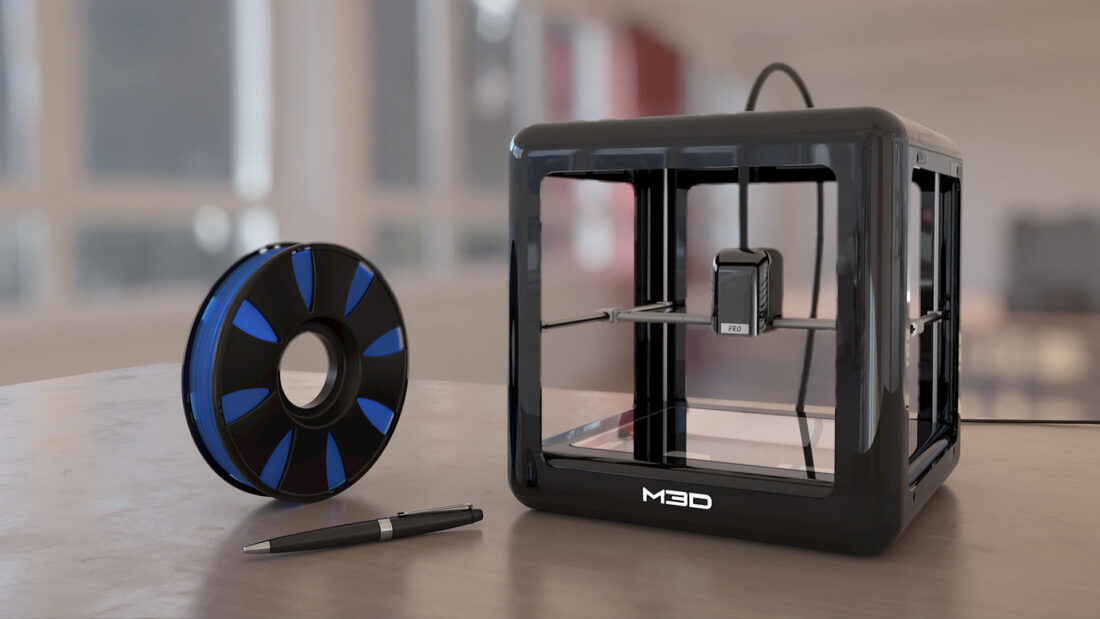

3D MC7 Prime mini

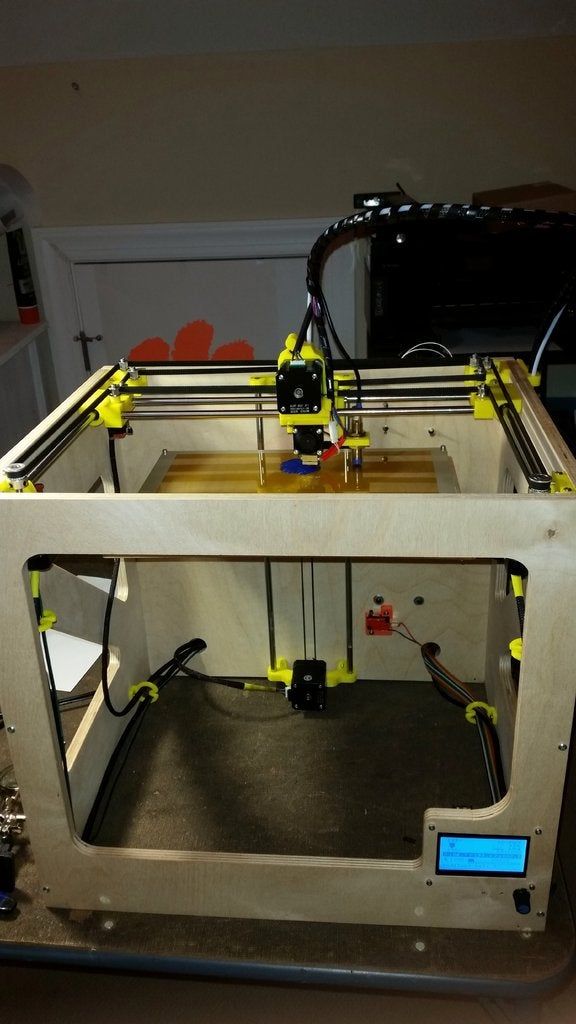

3D printer-constructor, 3D START v2.

0

0 Printer Constructor 3D START v2.0 is designed for DIY 3D printer assembly. The easiest to assemble, compact, fast, portable and very attractive 3D printer from Master Kit. Power supply included!

13 990

MP1511

3D printer control module

MP1511 is a replication of Arduino Mega and RAMPS. Thus, MP1511 is compatible with the Arduino environment and supports 3D printer control programs designed for the Arduino Mega 2560.0003

Discount

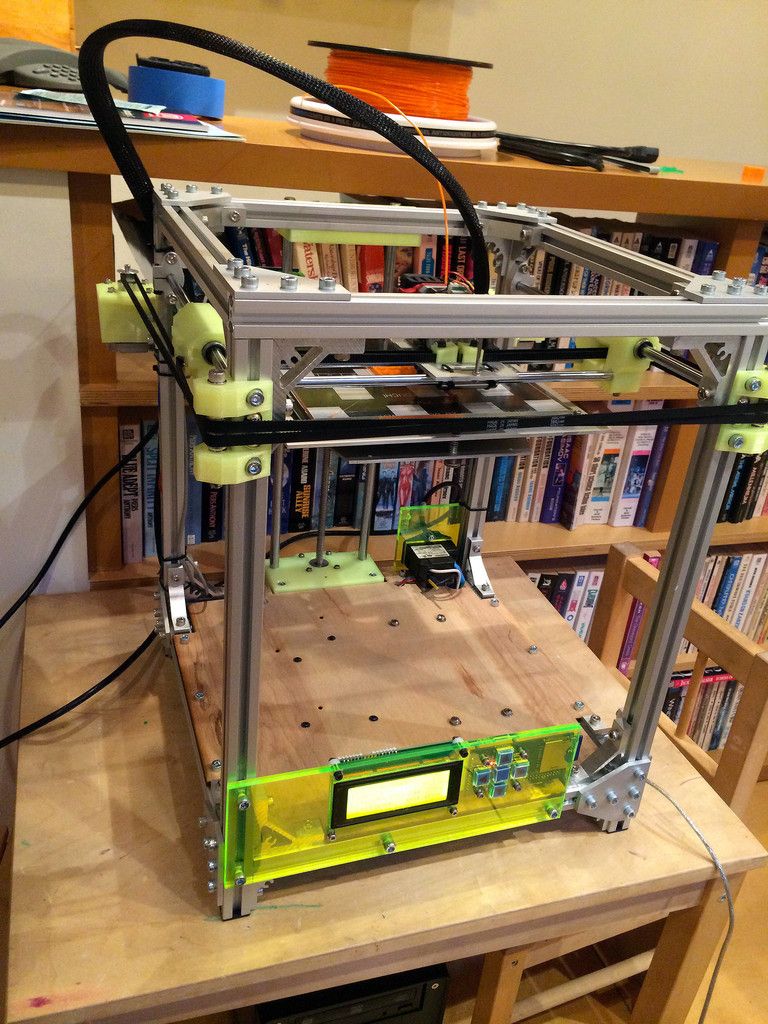

SH RAMPS

REPRAP 3D printer platform. Extension for Arduino MEGA 2560

1 420

SH RAMPS V1.4 is designed to assemble all the electronics needed for RepRap in one small package. SH RAMPS has great potential for expansion. The board has connectors for stepper motor drivers, an extruder, and a heated panel. SH RAMPS is installed on the Arduino MEGA controller, which makes it easy to configure the printer, change electronics, upgrade and expand.

MP1512

Power module for 3D printer

The MP1512 module is designed to control the heating of extruders and the 3D printer bed.

3D Smart Controller

External control board for a 3D printer. Encoder, SD card and LCD display 20x4

3D Smart Controller contains SD card reader, encoder and 4 line 20 characters LCD display. You can easily connect it to your RAMPS or Mastertronics control boards with the included adapter.

3DY0001

3D pen (Printing Pen 3DYAYA)

This is almost a real 3D printer, only much simpler, which even a child can handle. The plastic of this printer hardens almost instantly, which allows you to draw without support, on weight. The printer is made in the form factor of a pen, so the owner of this wonderful invention can draw three-dimensional objects without using a computer and software.

FB0021B

3D pen "3Dali Plus" Blue

A device for flat and three-dimensional "drawing" with plastic, is a more functional version of a 3D pen, the main features of which are the presence of an LCD display and the ability to adjust the heating temperature with an accuracy of 1 °C. This function allows the use of plastics with different melting points - PLA or ABS.

FB0021Y

3D pen "3Dali Plus" Yellow

A device for flat and three-dimensional "drawing" with plastic, is a more functional version of a 3D pen, the main features of which are the presence of an LCD display and the ability to adjust the heating temperature with an accuracy of 1 °C. This function allows the use of plastics with different melting points - PLA or ABS.

RU0076PLA

Modular set of plastic 3D palette (PLA)

3D palette consists of 10 spools of plastic in different colors, securely separated from each other to avoid tangling. When finished painting, you simply close the lid and remove the palette from the table.

When finished painting, you simply close the lid and remove the palette from the table.

What's more, the palette itself is a handy storage case for your 3D pen. Just put your pen in the palette and everything you need to paint will fit in a compact box that can be quickly and conveniently removed from the table.

1.75mm/0.5mm E3D brass nozzle

Nozzle with a hole of 0.5 mm. for extruder E3D V6

1.75mm/0.5mm E3D brass nozzle for extruder E3D V6 Full Kit

SC6UU

Linear bearing D 6mm

Linear bearing for 3D printers.

Shaft - 6 mm.

Length - 25 mm

Discount Kit

FB0021B + RU0076PLA

3D pen "3Dali Plus" Blue + plastic set PLA 3D palette

1 980

Since the invention of the 3D pen for drawing in three dimensions, the flight of fancy has become truly limitless!

Particularly fascinated by 3D drawing for children. Having received a 3D pen in their hands, they often do not tear themselves away from it for hours, creating the most bizarre shapes right in the air.

Having received a 3D pen in their hands, they often do not tear themselves away from it for hours, creating the most bizarre shapes right in the air.

This activity develops the child's spatial thinking, imagination and fine motor skills. And the resulting figures can be shown to friends or given to relatives and friends, receiving their portion of praise, which is so important for children.

1.75mm/0.2mm E3D brass nozzle

Nozzle with an opening of 0.2 mm. for extruder E3D V6

1.75mm/0.2mm E3D brass nozzle for extruder E3D V6 Full Kit

MK-8 All-metal Remote Extruder

Filament feed mechanism for 3D printers

All metal 3D printer filament feeder.

Thread 1.75 mm

Stepper motor not included!!!

1.75mm/0.3mm E3D brass nozzle

Nozzle with a hole of 0.3 mm.

for extruder E3D V6

for extruder E3D V6 1.75mm/0.3mm E3D brass nozzle for extruder E3D V6 Full Kit

1.75mm/0.4mm E3D brass nozzle

Nozzle with a hole of 0.4 mm. for extruder E3D V6

1.75mm/0.4mm E3D brass nozzle for extruder E3D V6 Full Kit

FB0021P

3D pen "3Dali Plus" Purple

A device for flat and three-dimensional "drawing" with plastic, is a more functional version of a 3D pen, the main features of which are the presence of an LCD display and the ability to adjust the heating temperature with an accuracy of 1 °C. This function allows the use of plastics with different melting points - PLA or ABS.

Discount Kit

FB0021Y + RU0076PLA

3D pen "3Dali Plus" Yellow + plastic set PLA 3D palette

1 980

Since the invention of the 3D pen for drawing in three dimensions, the flight of fancy has become truly limitless!

Particularly fascinated by 3D drawing for children.