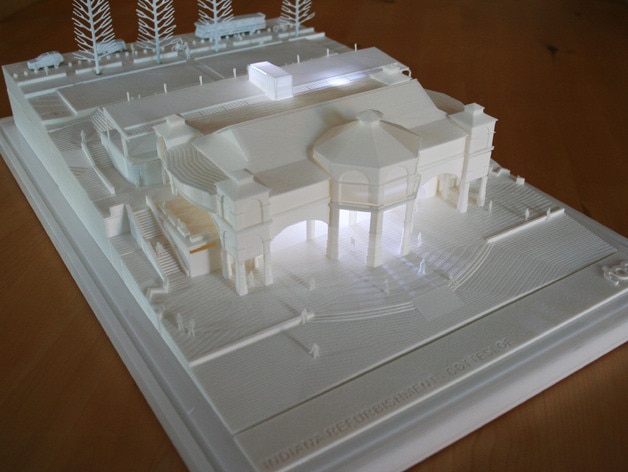

3D printing building in india

L&T Construction completes India’s first 3D printed two-storey building in 106 hours

0Shares

Following the 3D printing of a one-storey house back in November of 2019, India’s largest construction company, Larsen & Toubro Construction (L&T), has now completed the country’s first 3D printed two-storey building.

With a modest floor space of 65m², the building was fabricated using a large-format concrete 3D printer supplied by OEM COBOD, and is made up of a locally sourced 3D printable concrete mix developed by L&T’s own in-house team. Located at the company’s Kanchipuram facility near the city of Chennai, the building even has integrated reinforcement bars, and is fully compliant with all of India’s building codes.

M. V. Satish, Director & Senior Executive Vice President of Buildings at L&T, states, “3D concrete printing is one of the technology disruptors with the potential to radically redefine construction methodologies and I am extremely happy that by demonstrating our growing expertise in 3D printing, we are well positioned to push the boundaries of automated robotic construction. ”

Printing with real concrete

The fact that L&T printed the building using its own real concrete mix is a major milestone in and of itself. According to COBOD, the vast majority of 3D printed buildings to date have been constructed using ready mix mortars, which are relatively easy to print with.

Unfortunately, ready mix mortars have a maximum particle size of 4mm, meaning they tend to be weaker than traditional concrete due to a lack of coarse additives, all while being significantly more expensive to produce. Furthermore, mortars generally do not adhere to the building codes of most countries, limiting the material’s scalability.

Impressively, L&T’s building also featured vertical reinforcement bars and horizontal welded mesh distributors, and was printed in a grand total of 106 hours.

Henrik Lund-Nielsen, Founder and General Manager of COBOD, adds, “L&T Construction’s project marks a huge step forward for our industry, on a global scale. Not only is the project showing that more and more conventional construction companies are adapting 3D printing, but the 3D printing of a real concrete made by L&T themselves is significant, as this helps to drive down the cost even further. It is really impressive how L&T developed the 3D printable concrete and applied integral horizontal and vertical reinforcement in the building.”

Not only is the project showing that more and more conventional construction companies are adapting 3D printing, but the 3D printing of a real concrete made by L&T themselves is significant, as this helps to drive down the cost even further. It is really impressive how L&T developed the 3D printable concrete and applied integral horizontal and vertical reinforcement in the building.”

The push for 60 million houses

The project could not come at a better time, as India is currently striving to build 60 million houses as part of the ‘Housing for All by 2022’ program. L&T has stated that it expects the recent 3D printed building to pave the way for further work, providing real housing for the country’s citizens. The company strongly believes that additive manufacturing will result in higher throughput construction, all while improving the build quality of new residential properties throughout the region.

The benefits of COBOD’s concrete 3D printing technology are not limited to India either, as construction company PERI Group recently announced the commencement of its own project to 3D print a three-floor commercial apartment building on-site in Wallenhausen, Germany. The news came just a few months after the company revealed it was 3D printing the first ‘market ready’ building in Germany, in the town of Beckum.

Elsewhere, in the Flanders region of Belgium, building company Kamp C also 3D printed an entire two-floor, 90m² house using a COBOD system. Beyond just being a one-off test run, the model home is intended to showcase the advantages 3D printing can bring to the construction sector. Through experimentation with the printer, the Kamp C engineers managed to diminish heat loss and significantly reduce condensation.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows India’s first 3D printed two-storey building. Photo via COBOD.

Tags COBOD Henrik Lund-Nielsen Larsen & Toubro M. V. Satish

Kubi Sertoglu

Kubi Sertoglu holds a degree in Mechanical Engineering, combining an affinity for writing with a technical background to deliver the latest news and reviews in additive manufacturing.

Popular Construction 3D Printing Companies In India

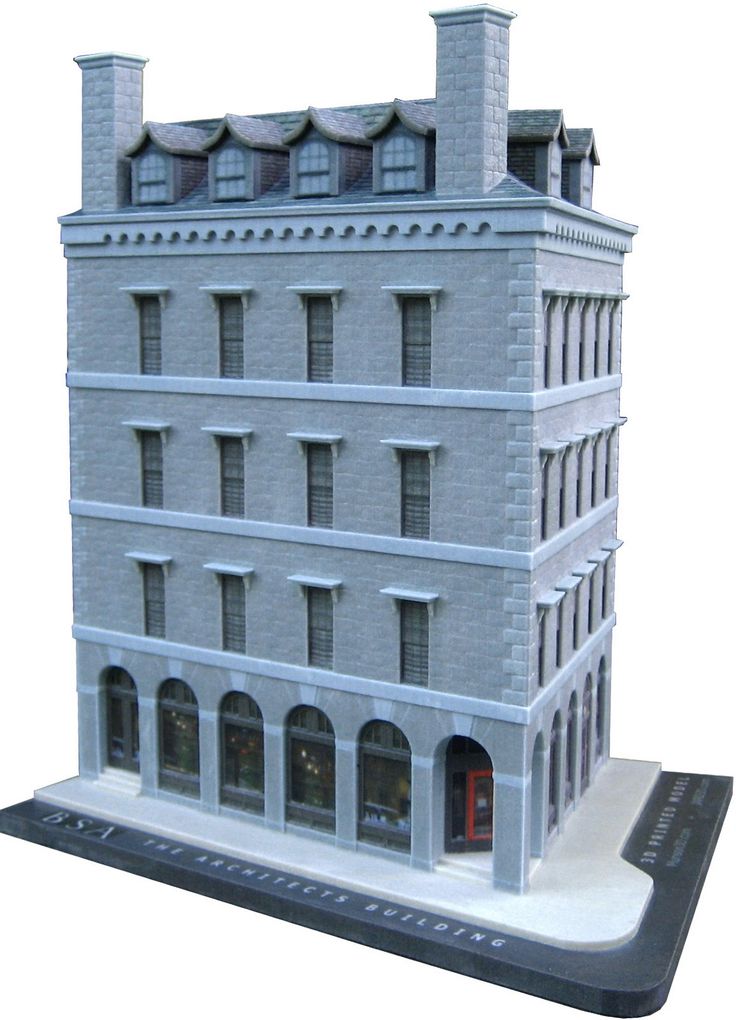

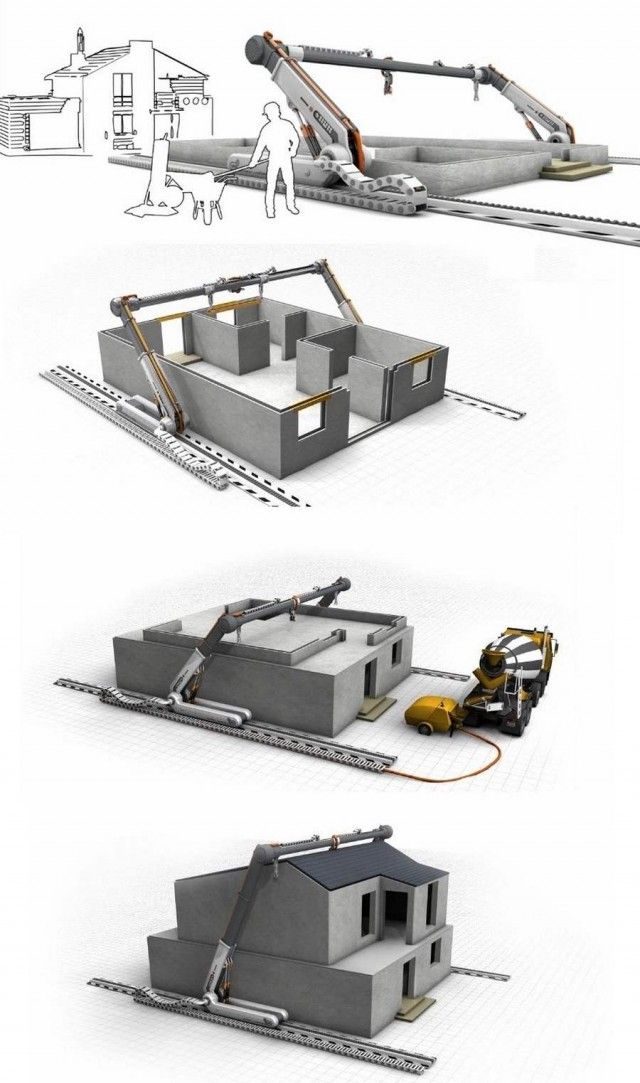

Above: Construction 3D Printing Ecosystem in India/Source: Manufactur3D3D printing is a novel method of constructing structures. It enables users to build objects from the ground up using a digital file. Lately, 3D printing in construction is gaining wide popularity and we are witnessing a rise in the number of construction 3d printing companies in India.

If you’re looking for a resource to know about India’s entire construction 3D printing ecosystem, look no further!

Contents

- 1 Top Construction 3D Printing Companies in India

- 1.

1 3D Printer Manufacturers

1 3D Printer Manufacturers- 1.1.1 Tvasta

- 1.1.2 DELTASYS E FORMING

- 1.1.3 Simpliforge Creations

- 1.2 Top Construction 3D Printing Materials Manufacturers

- 1.2.1 MYK Laticrete

- 1.2.2 Sika

- 1.3 Legacy Companies exploring Construction 3D Printing in India

- 1.3.1 L&T Construction

- 1.3.2 Godrej Construction

- 1.3.3 India Cements

- 1.4 Construction 3D Printing Service Providers in India

- 1.4.1 Hamilton Labs

- 1.4.2 Ekaksha Robotic Abstracts Limited

- 1.

- 2 Conclusion

Top Construction 3D Printing Companies in India

3D Printer Manufacturers

Above: DELTASYS E FORMING concrete 3D printer built for IIT Bombay/Image Source: DELTASYS E FORMINGAs of today, there are at least three construction 3D printer manufacturers in India. There are multiple kinds of 3D printers, namely, gantry-style, D-shape and Robotic-arm style. In India you will find the Gantry-style and Robotic Arm style being developed and sold commercially.

In India you will find the Gantry-style and Robotic Arm style being developed and sold commercially.

Below are the three Startups developing Construction 3D Printers in India.

TvastaTvasta, an IIT-Madras alumni startup, is the most popular construction 3d printing companies in India. It is a 3D printer manufacturer that has completed numerous projects for well-known clients. Despite the fact that the majority of these projects were for capability testing, they are quite remarkable.

Some of its most popular projects have been the 3D printed house on the campus of IIT Madras, 3D printed houses for the Indian Army, and the recently completed 3D printed Bus Shelter developed in collaboration with Godrej Construction.

DELTASYS E FORMINGDELTASYS E FORMING, founded in 2018, is an emerging 3D printer manufacturer based in Belgaum, Karnataka. The company produces a wide range of 3D printers such as FDM, DLP, and Pellet-extrusion printers, as well as building and selling Construction 3D printers.

This rapidly growing company has already sold more than six concrete 3D printers in India, with multiple orders still pending fulfilment. IIIT Bombay, IIT Guwahati and IISc Bengaluru are among the notable customers of their concrete 3D printers.

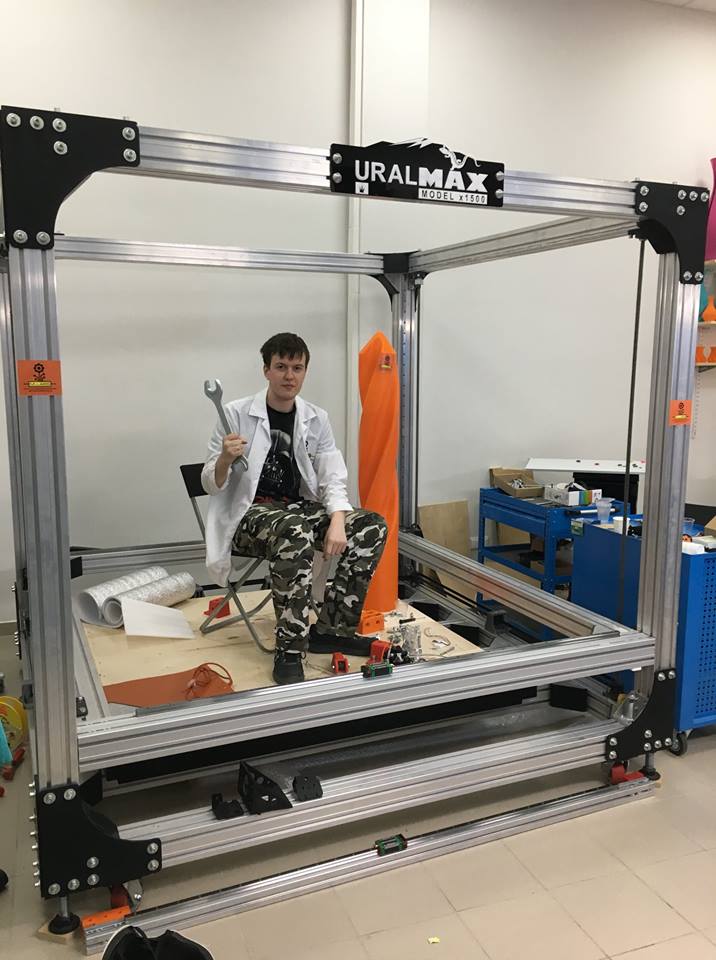

Simpliforge CreationsSimpliforge Creations is another 3D printing startup that started as a service provider but has since expanded into the development of construction 3D printers. Simpliforge Creations is based in Hyderabad, India’s upcoming 3D printing hub, is developing a robotic arm 3D printer.

Their current 3D printer, claimed to be the largest robotic concrete 3D printer in India, can create structures up to 7m in size. Apsuja Infratech (Charvitha Meadows) and the company have collaborated to create a new-age gated community project in Telangana.

Top Construction 3D Printing Materials Manufacturers

Above: Construction 3D Printing/Image Source: Sika GroupConcrete 3D printers use a type of cement that differs from traditional concrete..jpg) To maintain control over the whole process and ensure ideal performance, companies usually develop their own materials, but not always. Sometimes they rely on material experts who can collaborate and develop a material that satisfies the printing hardware and suits the regional atmosphere where the material will be used. The material mostly is a complex mixture of Portland cement, fillers, plasticisers, additives, etc.

To maintain control over the whole process and ensure ideal performance, companies usually develop their own materials, but not always. Sometimes they rely on material experts who can collaborate and develop a material that satisfies the printing hardware and suits the regional atmosphere where the material will be used. The material mostly is a complex mixture of Portland cement, fillers, plasticisers, additives, etc.

There aren’t many companies offering concrete 3D printing materials manufacturers in India but we list down the top two companies specialising in these materials.

MYK LaticreteMYK Laticrete, a collaboration between LATICRETE International in the United States and the MYK Group in India, creates 3D Mortar (concrete material for 3D printing). It has an advanced R&D centre that evaluates tile and stone installation materials against multiple industry standards in order to provide customers with technical solutions. This is the first of its kind in the building materials industry, developing products to meet the needs of the global market.

MYK Laticrete has already developed a 3D printing-specific material and is available in India.

SikaSika AG is a Swiss company that works in the construction industry. Sika has been researching 3D construction printing (3DCP) technology for quite some time. Along the way, it has obtained 7 patents on printing processes, developed novel materials, and additives for 3D printing. The patents demonstrate its expertise and scope of operations, which include not only materials but also the technology and process to ensure a successful outcome.

Its scope spans the entire 3D printing ecosystem, including the development of unique 3D mortar formulations, concrete technology and mixture design, on-demand coloration technology, the development of precise printheads, CAD and technical design support, automation, and much more.

Sika AG also has a subsidiary in India, Sika India.

Legacy Companies exploring Construction 3D Printing in India

Above: L&T Construction portfolio/Source: L&T ConstructionIn addition to Startups, several legacy companies are investigating construction 3D printing in India. These Indian companies are partnering with Startups to experiment with 3D printers and materials to test the technology’s capabilities. The goal is to assess the potential and develop a business case for the future.

These Indian companies are partnering with Startups to experiment with 3D printers and materials to test the technology’s capabilities. The goal is to assess the potential and develop a business case for the future.

We take look at a few of these legacy construction firms that are interested in 3D printing.

L&T ConstructionL&T Construction is one of the largest construction companies in India and the construction arm of the Larsen & Toubro conglomerate. It has collaborated with COBOD International, a Danish innovator and manufacturer of 3D construction printers and bought their 3D printer – a first in India. L&T used COBOD’s BOD2 printer to construct a two-story building in Tamil Nadu as part of the collaboration. For the material, L&T created a special concrete mix for 3D printing out of locally available regular construction materials.

Godrej ConstructionGodrej Construction has been investigating 3D printing for some time, and it recently collaborated with Tvasta to build a concrete 3D printed bus shelter at its Mumbai plant. Godrej Construction and Tvasta together created a sustainable concrete mix for the bus shelter that included 30% recycled concrete aggregates (RCA) sourced from concrete waste debris and recycled at the Godrej Recycled Concrete Plant in Vikhroli, Mumbai.

Godrej Construction and Tvasta together created a sustainable concrete mix for the bus shelter that included 30% recycled concrete aggregates (RCA) sourced from concrete waste debris and recycled at the Godrej Recycled Concrete Plant in Vikhroli, Mumbai.

The pilot project assisted the company in better understanding the technology, which it is now optimising in order to develop a commercially viable technology.

It’s still too early to comment on how Godrej intends to leverage the technology but once a business case is established, it scale-up the use of the 3DCP technology.

India CementsTvasta and India Cements, a Chennai-based cement manufacturing company, signed a memorandum of understanding (MoU) for a technology partnership earlier this year. The partners will work together on dedicated research and development activities as well as the development of raw material formulations for 3D printing applications. They will also collaborate closely on key projects to develop and deliver affordable housing solutions. Both companies plan to use technology to create sustainable building solutions such as 3D printed houses or structures.

Both companies plan to use technology to create sustainable building solutions such as 3D printed houses or structures.

Construction 3D Printing Service Providers in India

Above: Service providers help in building a clients construction projects/Source: COBODReal estate developers are constantly on the lookout for new building techniques that will not only save them money and time, but will also be an attractive selling proposition. And 3D printing fits seamlessly into the narrative. It is not only sustainable and one-of-a-kind, but also quite strong for ground-level structures like toilets, single room homes, bus shelters, etc.

As a result, these real estate companies can always collaborate with construction 3D printing service providers to build their designs to generate curiosity and buzz around their new residential or commercial project.

Unlike other technologies which are much more developed and comparatively easier to operate for service providers, the construction 3D printing technology is big and messy and thus a service provider ecosystem is nearly absent.

As a result, all technology manufacturers, including Tvasta, DELTASYS E FORMING, and Simpliforge Creations, offer such services. Besides these manufacturers, India has two more construction 3D printing service providers.

Hamilton LabsHamilton Labs, the Singapore-based complete construction 3D printing solutions provider, was among the first to enter the Indian market. It primarily serves as a service provider but has also developed its own gantry-style 3D printer. In 2017, a 3D printed toilet project was carried out in collaboration with NUS, NAMIC and Hamilton Labs to accelerate the production of toilet units in India under the ‘Swachh Bharat Mission’.

Hamilton Labs has formed a number of partnerships with key stakeholders. Laticrete, Saint-Gobain, G-Cast, Ekaksha Robotic Abstracts Limited (more on them below), and others are among their partners.

Ekaksha Robotic Abstracts LimitedEkaksha Robotic Abstracts is a public company based in Mumbai that provides complete 3D Construction Printing services. It is a new company, but they have partnered with Hamilton Labs.

It is a new company, but they have partnered with Hamilton Labs.

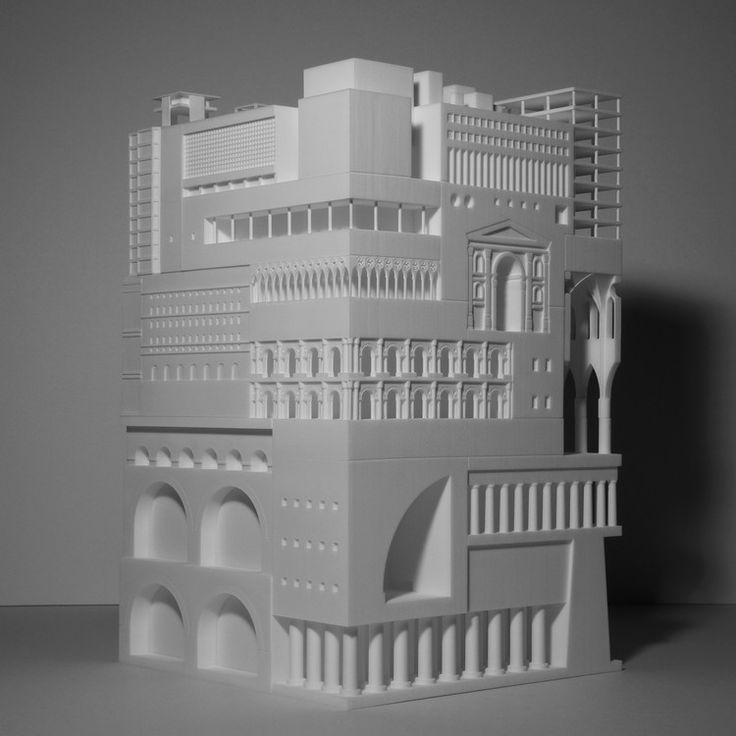

They provide three services: pre-construction planning, architectural models, and construction management.

Conclusion

With this comprehensive article, you should have a good understanding of the construction 3D printing ecosystem in India. Though small, the ecosystem is expanding and gaining popularity in India. It is currently difficult to estimate the size of this market in India because most companies are working on pilot projects, research institutions are experimenting and developing materials, and legacy companies are investigating the feasibility and future potential.

The sector is expected to see significant investments over the next five to ten years, followed by growth in adoption over the next decade or so. It will be interesting to see if the Government of India approves the use of this technology for its social welfare and infrastructure development schemes.

The global construction 3D printing market is also growing rapidly and you can check out the top construction 3D printing in the world to know more about them.

(In case you want to connect with any of these companies, mail us at [email protected])

About Manufactur3D: Manufactur3D is an online magazine on 3D Printing. Visit our Indian Scenario page for more updates on 3D Printing News from India. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter.

Read an article about the first 3D printed houses?

3D printing has been used in construction for several years now. In this article, you will learn about the first real houses printed on 3D printers.

3D printing of houses is still quite new to the layman. While construction 3D printing technologies have been developed for many years, only a few "real" projects have already seen the light of day. We are still far from technology taking over conventional construction methods. But with each new project, she is getting closer to becoming mainstream.

But with each new project, she is getting closer to becoming mainstream.

There are many benefits to 3D printing. For example, the cost of a 3D printed house can be much lower. And it will take much less time to build.

In order to draw a line under what has already been achieved in this area and show some interesting projects, we have devoted an article to the "first" and the best. These projects will always remain milestones in the 3D construction printing industry as they set the stage for future advances in the field.

First 3D printed house in Germany

Germany is a country often associated with cutting edge engineering, so let's start our list with Germany's first ever 3D printed house.

The house itself is located in Beckum, a city that is partly located in North Rhine-Westphalia, next to Holland and Belgium. This is the first 3D printed house to be fully certified to official building codes. This project will give way to many other 3D printed construction projects in Germany as well as the rest of Europe.

The project is the result of a collaboration between German construction company Peri and Danish construction 3D printing firm COBOD. Peri is a large corporation that operates not only in Germany, but throughout the EU. Its portfolio includes many products, including scaffolding and formwork solutions that every construction site needs.

Peri followed the construction 3D printing segment for years before acquiring a stake in COBOD in 2018. Now they are pushing the technology together and further. The construction of the house in Beckum began two years after the acquisition of the share.

For 3D printing at home, a BOD2 modular 3D printer from COBOD was used. The printing itself took just over 100 hours.

• Built: (started) September 17, 2020

• Commissioned: summer 2021

• Where: Beckum, North Rhine-Westphalia, Germany

• By: Peri, COBOD

First occupied 3D printed home in the US

Several homes have been printed in the US, but this home is the first officially occupied home, according to CNN. Its creators: the construction company Alquist and the humanitarian organization Habitat for Humanity Peninsula.

Its creators: the construction company Alquist and the humanitarian organization Habitat for Humanity Peninsula.

From a distance, you might think that this is an ordinary house. However, when approaching it, the layered structure of the concrete walls becomes noticeable. After all, 3D printing creates an object in layers.

Surprisingly, the 111.5 square meter concrete structure of the house (was printed in about 12 hours, significantly faster than traditional construction methods would allow.

The house was reportedly purchased by April Springfield, who lives there with her son and dog She bought the house through Habitat for Humanity's housing program, and given that the nonprofit's goal is to help solve the global housing crisis, it makes sense to use 3D printing to create affordable homes that will make many people's dreams of home ownership come true.0005

• Built: 2021

• Commissioned: December 22, 2021

• Where: Williamsburg, Virginia, USA

• By: Alquist 3D, Habitat for Humanity Peninsula, Greater Williamsburg

The first five-story 3D printed house

This project, made by the Chinese company WinSun, is a real record holder. It is a 3D printed five-story residential building with a height of 10 meters - the tallest 3D printed building so far.

It is a 3D printed five-story residential building with a height of 10 meters - the tallest 3D printed building so far.

The house is located in Suzhou Industrial Park in Jiangsu province in eastern China. It stands next to a mansion that was also built by WinSun using a concrete 3D printer.

Looking at the WinSun designs, you can't help but notice that they don't look like they've been 3D printed. Usually 3D printed structures are gray in color, the layer lines are clearly visible. But WinSun adds color and makes walls smoother. Nowhere is it stated how the company achieves the smoothness of the walls, but we assume that the workers smooth them by hand. WinSun projects are not like the ones we're used to.

• Built: Winter 2014

• Commissioned: Not specified

• Where: Suzhou, Jiangsu, China

• By: WinSun

First 3D printed biodegradable house

Can you guess that there is rice in the walls of this house?

Most 3D printed buildings are made from concrete mix. But this project is different from the rest. With the aim of creating housing solutions with little to no environmental impact, Italian company WASP 3D printed Gay's house using soil and agricultural waste.

But this project is different from the rest. With the aim of creating housing solutions with little to no environmental impact, Italian company WASP 3D printed Gay's house using soil and agricultural waste.

WASP developed the sustainable blend in collaboration with Ricehouse, a company that specializes in using natural and agricultural materials such as clay and rice in construction.

The house is named Gaia in honor of the ancient Greek goddess of the earth. In fact, 25% of the mixture contains local soil, 10% hydraulic lime, 25% rice husks and 40% crushed rice straw (a by-product of rice production at harvest).

An innovative solution not only in terms of material, but also in the design of the walls themselves. The specific corrugated structure was used to provide ventilation on warm days as well as insulation on cold periods, virtually eliminating the need for air conditioning.

Gay's house is small - about 20 square meters. The wall printing took only 10 days, while the estimated materials cost is just under $1,000.

• Built: not specified

• Commissioned: October 7, 2018

• Where: Massa Lombarda, Ravenna, Italy

• By: WASP, Ricehouse

AirBnB's first 3D printed house

The perfect weekend getaway.

You can find many different types of accommodation on AirBnB, but what about a 3D printed home?

The so-called Fibonacci house is the first 3D printed house to be offered for booking through AirBnB. Considering that it is located in rural British Columbia, it will be a wonderful place to stay.

Although the Fibonacci house looks small, it has a lot to offer vacationers. About 35 square meters is enough to accommodate up to four people.

The concrete walls of the house were designed and printed by Dutch 3D printing firm Twente. 20 concrete parts were produced offsite in just 11 days. The material was produced by Laticrete. The parts were later transported and assembled at their current location.

• Built: 2020

• Commissioned: Not specified

• Where: Kootenays, British Columbia, Canada

• By: Twente Additive Manufacturing

First 3D printed houseboat

Prvok is not only the first 3D printed house in the Czech Republic, but the world's first floating 3D printed house on a pontoon.

The project was implemented by the start-up company Scoolpt. The concrete structure of the houseboat took only 22 hours to print.

About 43 square meters of living space divided into bathroom, bedroom and living room with kitchen. Weight isn't usually discussed in the context of houses, but given that this one is on water, it's interesting to note that Prvok weighs 43 tons.

The house is equipped with a built-in recirculating shower and tanks for drinking and municipal water and has a service life of at least 100 years.

• Built: June 2020

• Commissioned: August 18, 2020

• Where: Prague, Czech Republic

• By: Scoolpt

Europe's first 3D printed residential house

Not every 3D printed house has visible line layers.

More often than not, 3D printed houses are demos made to show what the technology can do. For most of them there is no information about the actual residents. But in 2017, the couple did move to live in a 3D printed house located in Nantes, France. Thus, the house of "Yanov" became the first of its kind, which was inhabited in Europe.

Thus, the house of "Yanov" became the first of its kind, which was inhabited in Europe.

The house is a project of the University and the Laboratory of Digital Sciences of Nantes. An interesting aspect of the project is the special technique used in its construction by BatiPrint3D. Instead of 3D printing a concrete structure, the robotic arm created wall shells using polyurethane, a material used for insulation. Later, these membranes were filled with concrete.

It took a total of 54 hours to print. It took a little over 4 months to complete the construction. Mainly due to the fact that the rest of the components were created using conventional means. House area - 95 square meters.

• Built: 2017

• Commissioned: March 2018

• Where: Nantes, France

• By: University of Nantes, Nantes Digital Science Lab

India's first 3D printed house

This building was built in a couple of days.

India's first ever 3D printed house was completed back in 2020. The project was carried out by construction startup Tvasta, founded by graduates from the Indian Institute of Technology Madras. In fact, the institute's Chennai campus was chosen as the location of the building.

The project was carried out by construction startup Tvasta, founded by graduates from the Indian Institute of Technology Madras. In fact, the institute's Chennai campus was chosen as the location of the building.

The significance of this project lies in its possible impact on the solution of the housing crisis worldwide and in India in particular. The ability to build such a house within a few days and at a low cost cannot be underestimated.

House 55.7 sq.m. with a spacious layout, one bedroom, combined kitchen and living room.

The concrete structure of the house was 3D printed off site and the parts were later transported and assembled on campus. The foundation, meanwhile, was built using the conventional method of pouring concrete into the ground.

• Built: 2020

• Commissioned: Not specified

• Where: Chennai, India

• By: Tvasta Construction

Africa's first 3D printed house

Back in 2019, in the Moroccan city of Ben Guerir, Spanish firm Be More 3D created Africa's first 3D printed house. The project originated during the team's participation in the Solar Decathlon in Africa. This is an international competition during which teams design and build solar-powered houses.

The project originated during the team's participation in the Solar Decathlon in Africa. This is an international competition during which teams design and build solar-powered houses.

Be More 3D printed house 32 sq.m. in about 12 hours, took first place and received the title of the most innovative startup.

Be More 3D didn't stop building in Africa and later created the first 3D printed house in Spain and developed its own concrete 3D printer in partnership with several corporations from the automation and materials industries.

• Built: 2019

• Commissioned: Not specified

• Where: Ben Guerir, Morocco

• By: Be More 3D

First 3D printed home for sale in the US

Last on our list is the first 3D printed home for sale in the US.

This house was printed in the same place by SQ4D, a company specializing in the development of robotic building systems. The building was printed with SQ4D's Arcs concrete extrusion system and has a 50-year warranty on the printed structure.

Living area of 130.7 sq.m. with three bedrooms and two bathrooms. There is also a garage for 2 cars.

The house was listed for sale in January 2021 for $299,999. Considering the size of the house and the fact that it is priced 50% below the cost of comparable newly built houses in the same area, the deal is pretty good.

• Built: 2020

• Commissioned: 2021

• Where: Riverhead, New York, USA

• By whom: SQ4D

Translation source: https://m.all3dp.com/2/first-3d-printed-house/

On our website you can choose and order a construction 3D printer for both building construction and small building forms. To do this, go to the catalog of construction 3D printers. "Tsvetnoy Mir" is a reliable supplier of 3D printers with many years of experience, supplying directly from manufacturers and guaranteeing their quality.

Indian scientists plan to build houses in three days using building 3D printing

Miscellaneous

Construction 3D printing continues to expand its reach and has reached India.

Employees of the Indian Institute of Technology in Madras, together with TVasta, developed a program to introduce 3D printing technology to the construction industry and printed the first building.

Employees of the Indian Institute of Technology in Madras, together with TVasta, developed a program to introduce 3D printing technology to the construction industry and printed the first building. A team of educators from the Indian Institute of Technology Madras is working with tech start-up Tvasta to explore rapid building technology. It is expected that the additive method will allow you to create a box of a one-story house in just three days. A functional prototype is already ready, which has become the first step towards achieving the global goal - to solve the housing problem of the whole country.

Researchers have been studying the application of additive technologies in construction since 2016. Researchers are interested in finding ways to quickly erect a building, in particular, exploring the possibilities of 3D printing in the construction of walls and formwork. As part of the scientific work of the work, the Indian Institute of Technology cooperates with government agencies that are interested in the development of modern technologies. Scientists consider the availability of raw materials, speed of production, automation of labor and savings on the transportation of materials to be the key advantages of the technology.

Scientists consider the availability of raw materials, speed of production, automation of labor and savings on the transportation of materials to be the key advantages of the technology.

“3D concrete printing is perfect for modern architecture. The right combination of binder additives allows the concrete mixture to achieve the desired physical properties: easy extrusion and fast setting,” explains Professor Manu Santanam.

The Government of India is recognizing the need for innovation in construction as the housing shortage becomes more pronounced. According to officials, 3D printing technologies help speed up construction and significantly save resources.

The first 3D printed houses are expected to appear in India later this year.

Follow author

Follow

Don't want

2

Article comments

More interesting articles

Roketa

Loading

11/19/2022

2150

46

Follow author

Follow

Don't want

Hello!

I registered on this site in order to share.