3D printing associations

The National Additive Manufacturing Association

Advocacy

Key Legislative Issues

Key Legislative Issues

Key Legislative Issues

The NAMA has one mission - advocacy to protect the industry. We fight on issues like tax, trade, IP protection, R&D tax credit, accelerated depreciation, support for DOD expenditures and funding for manufacturing hubs. Join today and help prioritize the issues we address.

Events

Key Legislative Issues

Key Legislative Issues

Contact us for your personal invitation to our next quarterly economic and legislative update. We offer an in-person one hour lunch in Washington, DC, or 30 minute webinar.

Economic Facts

Key Legislative Issues

Membership Categories

According to Wohlers Associates, AM is a $7.3 billion revenue industry which grew 21% in 2017. Join NAMA to learn how AM is creating jobs and new opportunities for manufacturing in the U.S.

Membership Categories

Membership Categories

Membership Categories

NAMA is partnering with corporations, processes producers, the supply chain, trade associations, educational institutions and individuals who want to protect and grow AM.

Latest News

Membership Categories

Latest News

AM and 3D printing is in the news! Find recent and relevant articles here. Members receive regular updates.

Articles

Why Join?

Membership Categories

Latest News

As an industry disruptor, proactive leadership is required. We need a united effort to be the most effective. Now is time to build relationships with Congress.

Now is time to build relationships with Congress.

About Us

Advocacy

Directing the united voice of the industry in Congress and in federal agencies for protecting and advancing Additive Manufacturing.

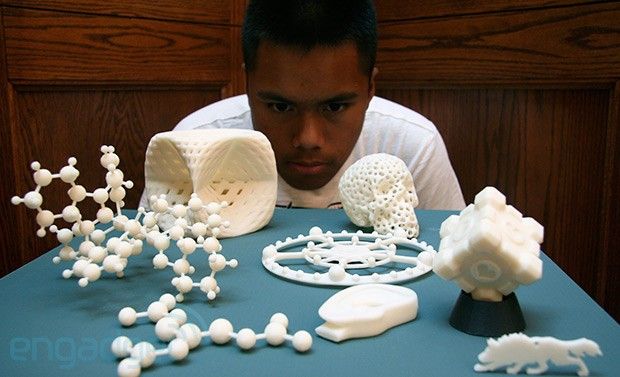

Image

Working to improve and protect the image of AM as the solution to many complex manufacturing challenges and to communicate the many advantages the industry is bringing to manufacturing in America. Educating elected officials at all levels about the economic impact and jobs which AM is creating in communities across America.

Presence

Promoting legislative knowledge and protecting our community from governmental action through collaboration and consensus within the growing industry. Building the advocates who can deliver local stories to elected officials. If you need a speaker about the legislative or political climate, NAMA is your resource.

Building the advocates who can deliver local stories to elected officials. If you need a speaker about the legislative or political climate, NAMA is your resource.

Association of 3D Printing

Posted on November 23, 2020 by Rich Benvin

Data Gumbo’s Blockchain to be Used to Secure 3D Printing of Parts

Yesterday industrial blockchain firm Data Gumbo announced a contract with Norway-based deep tech company Fieldmade. The Norwegian company delivers 3D designs so that its defense and energy clients can manufacture parts onsite. The project aims to leverage Data Gumbo’s blockchain network, GumboNet, to verify the origin of Fieldmade’s 3D product designs and materials. Houston-based Data Gumbo is backed by energy firms Saudi Aramco and Equinor.

With 3D printing, or additive manufacturing, the importance of using the correct design or quality of metallic components for parts cannot be overstated.

Fieldmade CEO, Christian Dunn Norberg, hopes Data Gumbo’s network will increase the trust in all stages of their equipment supply market place. He also mentions GumboNet offers Fieldmade additional security to protect intellectual property and other sensitive information, ensuring transactional certainty.

He also mentions GumboNet offers Fieldmade additional security to protect intellectual property and other sensitive information, ensuring transactional certainty.

GumboNet will support Fieldmade’s 3D printing services across its aerospace defense and energy sectors, recording data ranging from intellectual property to delivery information. Data Gumbo also claims to be able to automate and implement smart contracts with ‘unprecedented speed, accuracy, visibility, and transparency.’…

READ MORE

3D Printing and other Decentralized Technologies

DECENTRALISATION. Technologies such as 3D printing and Blockchain represent a major trend with growing importance. This is the trend towards technology being used in a distributed, collaborative way, rather than being centrally controlled.

In 2015, this trend was still in its infancy, but could be seen through the ongoing evolution of the Internet through the “Internet of Things” to the “Internet of Industry”. Another name for the Internet of Industry, common in Germany, is “Industry 4.0”.

Another name for the Internet of Industry, common in Germany, is “Industry 4.0”.

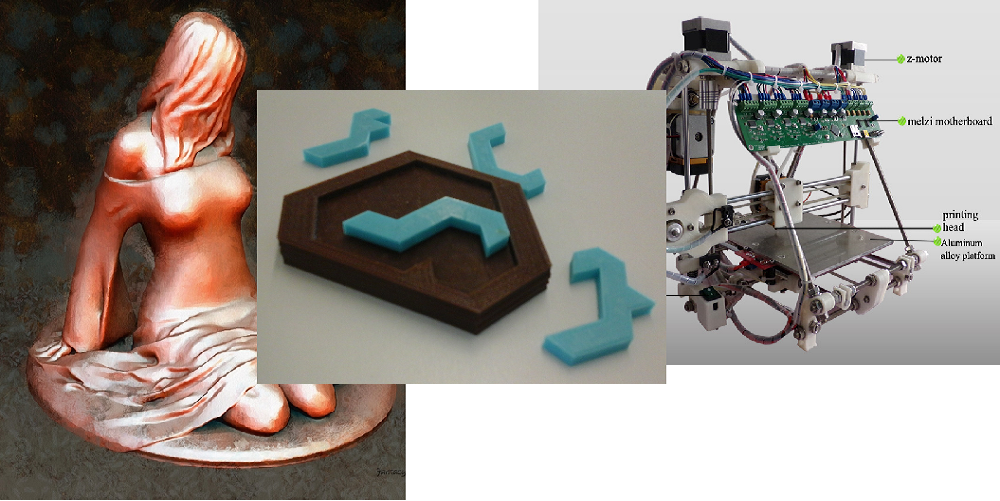

In this vision, people will be able to study designs, modify them, download them onto nearby 3D printers, and thereby create new goods. This will happen with minimal legal and contractual overhead, due to Blockchain.

These printers won’t necessarily be in people’s homes but will be accessible in the local neighbourhood. For example, in late 2013 the French La Poste launched an experimental trial of a new 3D printing service at a number of post offices in Boulogne-Billancourt and Paris. Items expected to be 3D printed as part of this trial include jewellery, cardholders, and smartphone cases, along with any other item whose design is contained on files brought by users to the post office.

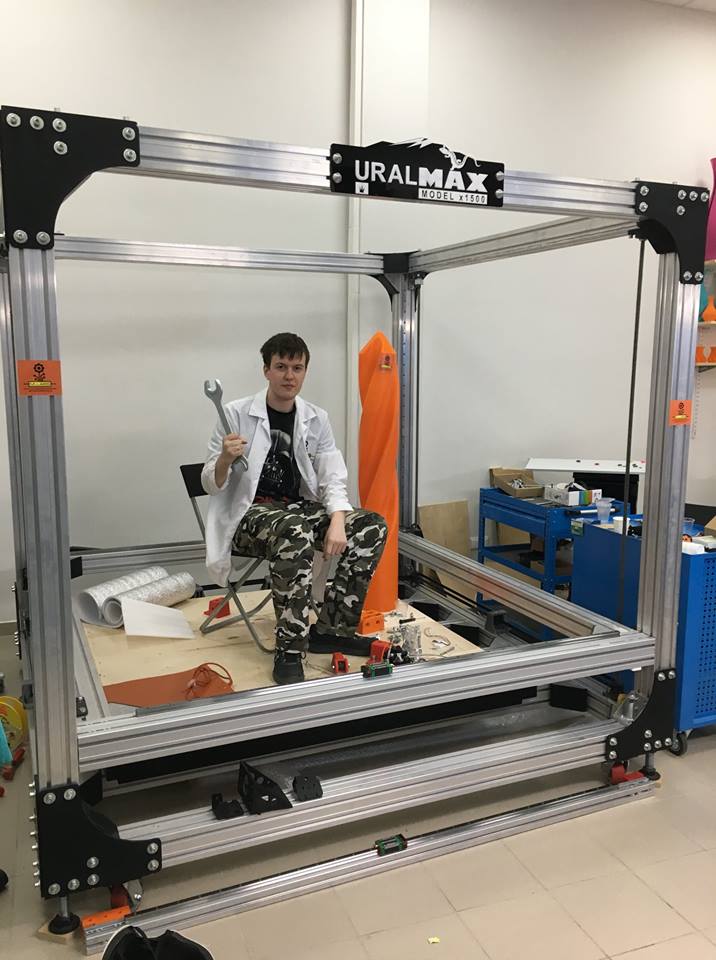

As a comparison for the present status of 3D printing, we’re about the status of the IT industry in the 1970s. The field has its share of enthusiasts and pioneers, along with serious researchers doing serious research. However the field still lacks successful business models, powerful corporations focused on the subject, and full stable infrastructure. These changes lie ahead, building on what the Internet already provides…

However the field still lacks successful business models, powerful corporations focused on the subject, and full stable infrastructure. These changes lie ahead, building on what the Internet already provides…

READ MORE

Blockchain: What’s In It For The Manufacturing Industry?

Blockchain holds much promise for the manufacturing industry says Nitesh Bansal, Senior Vice President and Head of Manufacturing Practice – Americas and Europe, Infosys. In this video, he elaborate on how the technology can help industries like aviation, defense and others…

Tagged with: 3d printing and blockchain, additive manufacturing, blockchain, crypto, decentralized technology

Posted in Blockchain, Business, Crypto, Manufacturing

Posted on November 16, 2020 by Bill Decker

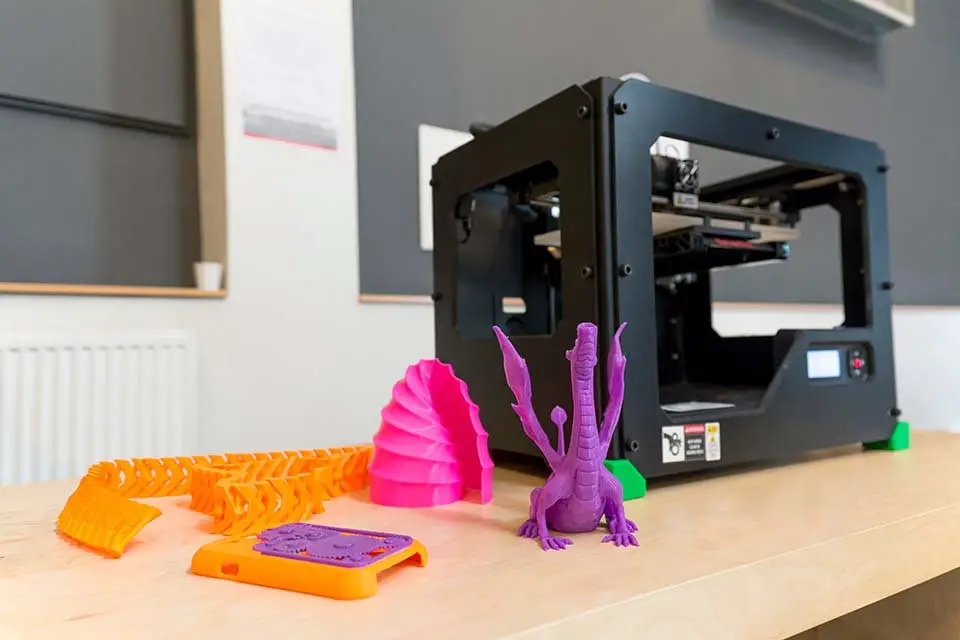

In a recent survey conducted by Jabil, we discovered that in just over a year, the number of companies utilizing 3D printing as well as the variety of applications rocketed dramatically; the percentage of companies using additive to manufacture production parts rose from 27 percent to 52, bridge production increased from 23 percent to 39, and repair went from 14 percent to 38. Although the 3D printing industry is currently worth around $9.3 billion, a report by Smithers Pira predicts that the additive manufacturing industry will be worth $55.8 billion by 2027

Although the 3D printing industry is currently worth around $9.3 billion, a report by Smithers Pira predicts that the additive manufacturing industry will be worth $55.8 billion by 2027

What does this mean for 3D Printing enthusiasts? Growth!

Tagged with: 3d printing advances, 3d printing association, 3d printing trends

Posted in Education, Industry Statistics, Industry Stats

Posted on October 27, 2020 by Bill Decker

Nowadays, it is possible to 3D print a wide variety of objects from the comfort of your home: owning a home desktop printer allows virtually anyone to manufacture a toothbrush or a toy for example. However, oftentimes, the tricky part is to add electronics to your 3D printed pieces. Researchers from MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) have developed a unique 3D design environment: called MorphSensor, it enables users to digitally model not only the physical form of an object, but also its electronic function.

Embedding electronics such as sensors, chips, and tags typically means that you need to design them separately, making it difficult to create items where the added functions are integrated with the form. Can that change with the invention of MorphSensor? Lead author on a paper about the project, MIT PhD student Junyi Zhu, says: “MorphSensor fits into my long-term vision of something called ‘rapid function prototyping’, with the objective to create interactive objects where the functions are directly integrated with the form and fabricated in one go, even for non-expert users. This offers the promise that, when prototyping, the object form could follow its designated function, and the function could adapt to its physical form.”

Tagged with: 3d printing association, 3d printing MIT, 3d printing news

Posted in Education

Posted on October 12, 2020 by Bill Decker

Well, its easy to see that the less humans we need, the less there is a chance of passing Covid 19 to each other! 3D Printing can help mitigate the risk and the contact.

The global uncertainty created by the COVID-19 pandemic has plunged the world into a crisis that is still unfolding. Logistical challenges owing too disruptions in manufacturing and transportation, together with pushbacks against globalization and free trade, have constrained supply chains, resulting in critical shortages of essential goods. . Crisis-response efforts are in motion to alleviate shortages of much-needed medical supplies.

There is a need for factories to manufacture, on demand, materials and devices for a range of essential services, in particular for healthcare. In this context, a resilient advanced manufacturing network enabled by a distribution of 3D Printing factories has great potential.

The digital versatility and quick prototyping of 3D printing empowers a swift mobilization of the technology and hence a rapid response to emergencies. Even during severe disruptions in supply chains, critical parts can be manufactured on-demand by any decentralized 3D-printing facility in the world by leveraging designs shared online. Moreover, the additive nature of 3D printing enables product customization and complex designs. The broad spectrum of 3D-printing applications in the fight against COVID-19 includes personal protective equipment (PPE), medical, medical technologies, personal accessories, visualization aids and emergency dwellings…not to mention the advances in Bioprinting

Moreover, the additive nature of 3D printing enables product customization and complex designs. The broad spectrum of 3D-printing applications in the fight against COVID-19 includes personal protective equipment (PPE), medical, medical technologies, personal accessories, visualization aids and emergency dwellings…not to mention the advances in Bioprinting

Tagged with: 3d printing advances, 3d printing news, covid 19

Posted in Health, Industry Statistics, Manufacturing

Posted on September 25, 2020 by Bill Decker

Over the last few decades hair transplantation surgery has rapidly evolved, becoming more sophisticated and successful, however the process has still fundamentally relied on hair follicles being redistributed from one part of the body to another. Growing human hair follicles in laboratory conditions has proved challenging for researchers, ultimately limiting the efficacy of hair restoration surgery, especially in patients without hair already present that can be grafted.

This new breakthrough brings together a couple of recent innovations. First, the researchers created a unique plastic mold using 3D printers. The moulds are designed to resemble a natural micro-environment stimulating hair follicle growth through tiny extensions just half a millimeter wide.

“Previous fabrication techniques have been unable to create such thin projections, so this work was greatly facilitated by innovations in 3D printing technology,” explains first author on the study, Erbil Abaci.

Tagged with: 3d printed hair, 3d printing association, 3d printing news

Posted in fun, Health

Posted on September 11, 2020 by Bill Decker

The FDA continues to take creative and flexible approaches to address access to critical medical products in response to COVID-19. Researchers at academic institutions, non-traditional manufacturers, communities of makers, and individuals are banding together to support and fill local and national needs. The FDA is actively engaged across this spectrum and developing ways to assist and support people who are looking to help their communities in these ways. Our goal is to help expand the availability of certain products in ways that are consistent with FDA’s public-health mission.

Our goal is to help expand the availability of certain products in ways that are consistent with FDA’s public-health mission.

For example, the FDA is working in partnership with the NIH, VA, and America Makes to support non-traditional manufacturing approaches, such as 3D printing, to address devices shortages including personal protective equipment (PPE). Through this partnership, 3D-printable designs for COVID response are given a clinical assessment by the VA and the NIH posts them on the 3D Print Exchange. FDA has, among other things, provided information on labeling and testing for face shields and face masks.

This page provides an update on how this partnership has contributed to the number of medical devices—including PPE—and parts available to support the COVID-19 response since it was launched in March 2020. For example, 31 community-submitted designs passed the testing performed by VA clinics and were given clinically reviewed status in the first three months. In addition, this effort has so far matched more than 500,000 3D-printed face shields and more than 348,000 3D-printed face masks with health care providers and others in need. FDA has issued a temporary policy for face masks and respirators during the COVID-19 public-health emergency.

FDA has issued a temporary policy for face masks and respirators during the COVID-19 public-health emergency.

Tagged with: 3d printing trade association, covid 19, FDA

Posted in Education, Health

Posted on August 17, 2020 by Bill Decker

The FDA continues to take creative and flexible approaches to address access to critical medical products in response to COVID-19. Researchers at academic institutions, non-traditional manufacturers, communities of makers, and individuals are banding together to support and fill local and national needs. The FDA is actively engaged across this spectrum and developing ways to assist and support people who are looking to help their communities in these ways. Our goal is to help expand the availability of certain products in ways that are consistent with FDA’s public-health mission.

For example, the FDA is working in partnership with the NIH, VA, and America Makes to support non-traditional manufacturing approaches, such as 3D printing, to address devices shortages including personal protective equipment (PPE). Through this partnership, 3D-printable designs for COVID response are given a clinical assessment by the VA and the NIH posts them on the 3D Print Exchange. FDA has, among other things, provided information on labeling and testing for face shields and face masks.

Through this partnership, 3D-printable designs for COVID response are given a clinical assessment by the VA and the NIH posts them on the 3D Print Exchange. FDA has, among other things, provided information on labeling and testing for face shields and face masks.

This page provides an update on how this partnership has contributed to the number of medical devices—including PPE—and parts available to support the COVID-19 response since it was launched in March 2020. For example, 31 community-submitted designs passed the testing performed by VA clinics and were given clinically reviewed status in the first three months. In addition, this effort has so far matched more than 500,000 3D-printed face shields and more than 348,000 3D-printed face masks with health care providers and others in need. FDA has issued a temporary policy for face masks and respirators during the COVID-19 public-health emergency.

Tagged with: 3d printing association, 3d printing news, 3d printing trade

Posted in Announcements, Bioprinting, Health

Posted on July 30, 2020 by Bill Decker

KFC has been experimenting with food innovation process for a while now, including the introduction of plantchicken nuggets last year. But a new effort in Russia might just be the Louisville-based company’s most ambitious project yet.

But a new effort in Russia might just be the Louisville-based company’s most ambitious project yet.

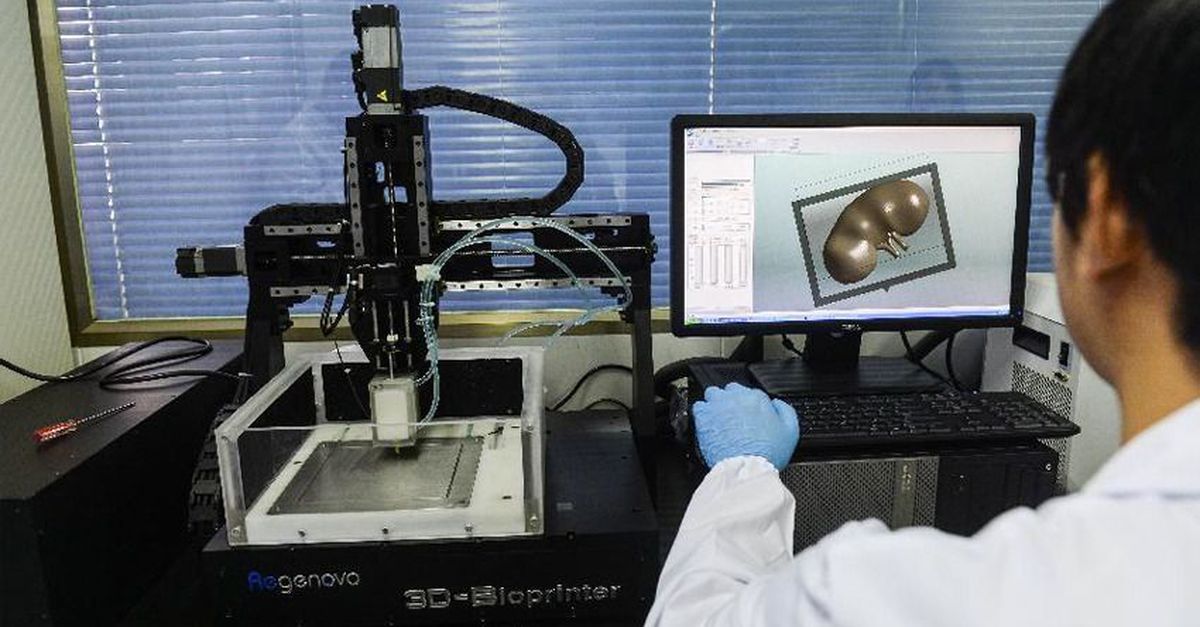

KFC is launching the development of innovative 3D bioprinting technology to create chicken meat in partnership with 3D Bioprinting Solutions research labs based in Moscow, Russia. Mmm 3D Printed Chicken.

The project aims to create the world’s first laboratory-produced chicken nuggets, using chicken cells and plant material. According to a release on KFC’s website, the idea of crafting the “meat of the future” arose among partners in response to the growing popularity of a healthy lifestyle and nutrition, the annual increase in demand for alternatives to traditional meat and the need to develop more environmentally friendly methods of food production. Can we get these 3D Printed to look like someone we know?

“At KFC, we are closely monitoring all of the latest trends and innovations and doing our best to keep up with the times by introducing advanced technologies to our restaurant networks,” said said Raisa Polyakova, general manager of KFC Russia & CIS, in the release. “Crafted meat products are the next step in the development of our ‘restaurant of the future’ concept. Our experiment in testing 3D bioprinting technology to create chicken products can also help address several looming global problems. We are glad to contribute to its development and are working to make it available to thousands of people in Russia and, if possible, around the world.

“Crafted meat products are the next step in the development of our ‘restaurant of the future’ concept. Our experiment in testing 3D bioprinting technology to create chicken products can also help address several looming global problems. We are glad to contribute to its development and are working to make it available to thousands of people in Russia and, if possible, around the world.

Read the full article here

Tagged with: 3d chicken, 3d printed chicken, 3d printing news

Posted in Bioprinting, fun, Makers

Posted on July 27, 2020 by Bill Decker

The FDA continues to take creative and flexible approaches to address access to critical medical products in response to COVID-19. Researchers at academic institutions, non-traditional manufacturers, communities of makers, and individuals are banding together to support and fill local and national needs. The FDA is actively engaged across this spectrum and developing ways to assist and support people who are looking to help their communities in these ways. Our goal is to help expand the availability of certain products in ways that are consistent with FDA’s public-health mission.

Our goal is to help expand the availability of certain products in ways that are consistent with FDA’s public-health mission.

For example, the FDA is working in partnership with the NIH, VA, and America Makes to support non-traditional manufacturing approaches, such as 3D printing, to address devices shortages including personal protective equipment (PPE). Through this partnership, 3D-printable designs for COVID response are given a clinical assessment by the VA and the NIH posts them on the 3D Print Exchange. FDA has, among other things, provided information on labeling and testing for face shields and face masks.

This page provides an update on how this partnership has contributed to the number of medical devices—including PPE—and parts available to support the COVID-19 response since it was launched in March 2020.

Read the full article here

Tagged with: 3d printing association, 3d printing mask, FDA

Posted in Announcements, Health

Posted on July 7, 2020 by Rich Benvin

Interview: Relativity CEO Tim Ellis on 3D Printing Rocket Ships

We sat down with co-founder Tim Ellis to talk about the 3D printing process, and the new space industry…

3D Print Materials Copyright Law Battle

Micheal Weinberg writes of an interesting legal battle taking place over use of third party 3D print materials.

New York-based Weinberg often writes on the legal issues facing the 3D print industry, of which there are many. The revolutionary technology, combined with the modern world of networking, social media and cloud-based systems has exposed quite a number of puzzling situations where the law is far behind…

READ MORE

Tagged with: 3d print industry, 3d print materials, copyright, rocket ships, space

Posted in Legal, Space

3D Printing Videos

Medical 3D Printing Association

-

Latest technology

Association of

3D Printers in medicine Join -

The future is near

Join the Association -

Innovative Medicine

Join Association

Members of the Association

3D technology

Biotechnology

04. 10.2022

10.2022

VII All-Russian Scientific and Practical Conference "3D Technologies in Medicine"

Administrator 256 0

On February 17, 2023, the VII All-Russian Scientific and Practical Conference "3D Technologies in Medicine" will be held

Read further18.02.2022

I Congress of Traumatologists and Orthopedists of the Volga Federal District (May 19-20, 2022)

Administrator 497 0

Acceptance of applications for participation with reports in the section Biotechnology and new materials in traumatology and orthopedics has begun

Read further01/31/2022

III Conference "Additive technologies for medicine: world and Russian experience"

Administrator 646 0

Results of the III conference "Additive technologies for medicine: world and Russian experience"

Read further 25. 07.2021

07.2021

Evaluation of the effectiveness of the use of individual layouts for preoperative planning

Administrator 853 0

Dear colleagues!!! We invite you to take part in survey

Read further05/28/2021

TOMSK 3D DESIGN TEAM PRINTING BONES ON A PRINTER

Administrator 1130 0

IN THE DEPARTMENT OF GENERAL ONCOLOGY OF THE TOMSK NIMC WORKING A GROUP OF 3D-DESIGN OF IMPLANTS

Read further05/28/2021

Results of clinical testing of hybrid knee endoprostheses

Administrator 1116 0

GITO-INNOVATION LLC conducted clinical testing of personalized precision hybrid endoprostheses

Read further 11. 03.2021

03.2021

Russia will host the Eurasian Orthopedic Forum for the third time

Administrator 1581 0

Eurasian Orthopedic Forum

will be held in Russia for the third time Read further11.01.2021

MIMIX BIOTHERAPEUTICS RELEASES CYMATIX ACOUSTIC 3D BIOPRINTER

Administrator 1457 0

BASED ON PATENTED SOUND INDUCED MORPHOGENESIS (SIM)

Read further 11. 01.2021

01.2021

3D-PRINTING HYBRID BIO-INK TO HELP CARTILAGE REGENERATION

Administrator 1519 0

RESEARCHERS CREATED NEW

HYBRID BIO-INK Read further11/21/2020

VIDEO RECORDING OF THE VI ALL-RUSSIAN SCIENTIFIC AND PRACTICAL ONLINE CONFERENCE "3D TECHNOLOGIES IN MEDICINE"

Administrator 1529 0

VIDEO RECORDING OF THE VI ALL-RUSSIAN SCIENTIFIC AND PRACTICAL ONLINE CONFERENCE "3D TECHNOLOGIES IN MEDICINE"

Read moreSite search

Registration Forgot your password?

Sitemap

- Home

- About the Association

- News

- 3D printing

- Biotechnology

- Services

- Forum

- Members of the Association

Contacts

603155 Russia, Nizhny Novgorod,

Verkhne-Volzhskaya embankment, 18

8 (831) 436 0160

as3dmed@yandex. ru

ru

Stay up to date with the latest developments. Subscribe to our VKontakte group.

© Copyright 2017. All rights reserved. Privacy Policy.

cMedical 3D Printing Association

Materials

Presentations

Kovalenko A.N. - Treatment of pelvic defects using 3D - HH 04/08/2016 💾 Rukin Ya.A. - Application of 3D printing technologies for planning complex cases of primary and revision hip arthroplasty 💾 Karyakin N.N. - 3D printing in medicine Boyarintsev I.A. - Additive technologies in reconstructive neurosurgery 💾 Gazimiev M.A. - 3D technologies in creating a model of a kidney for preoperative and intraoperative navigation. Our first experience. . 💾 Gorbatov R.O. - Additive 3D printing technologies in traumatology and orthopedics 💾 Esekhina E.S.- The use of thermoformed orthoses "Zdravprint" in treatment of subcutaneous ruptures of the extensor tendons fingers brush 💾 Korotkova NL - 3D technologies in reconstructive maxillofacial surgery. 💾 Kudan E.V. - Tissue spheroids as the basis of technology bioprinting of three-dimensional organ constructs. Printing a mouse thyroid gland construct as a special case of technology application. 💾 Maryakhin A.D. - Additive technologies in reconstructive neurosurgery: from preoperative planning to the creation of individual implants 💾 Novikov A.E. - Development of a new technique for the reconstruction of the maxillofacial region using implants from bioactive ceramics and 3D technologies 💾 Salimi K.G. - Application of 3D printing in the technology of manufacturing personalized bone implants from porous ceramics 💾 Stolyarov I.I. - External fixation device for the hand and forearm based on components obtained by 3D printing 💾 Sharkeev Yu.P. - Gorbatov R.O., Niftullaev R.M., Novikov A.E. 💾

💾 Kudan E.V. - Tissue spheroids as the basis of technology bioprinting of three-dimensional organ constructs. Printing a mouse thyroid gland construct as a special case of technology application. 💾 Maryakhin A.D. - Additive technologies in reconstructive neurosurgery: from preoperative planning to the creation of individual implants 💾 Novikov A.E. - Development of a new technique for the reconstruction of the maxillofacial region using implants from bioactive ceramics and 3D technologies 💾 Salimi K.G. - Application of 3D printing in the technology of manufacturing personalized bone implants from porous ceramics 💾 Stolyarov I.I. - External fixation device for the hand and forearm based on components obtained by 3D printing 💾 Sharkeev Yu.P. - Gorbatov R.O., Niftullaev R.M., Novikov A.E. 💾 Library

Articles

Gorbatov R.O., Niftullaev R.M., Novikov A.E. - PRECISION PERSONALIZED IMPLANTS TO REPLACE BONE DEFECTS IN THE TREATMENT OF PATIENTS WITH OSTEOONCOLOGY 💾 Yu.