3D printer background

When Was 3D Printing Invented? The History of 3D Printing -

May 15, 2020

When you first heard the words “3D printing” did you imagine a super futuristic technology, like in the movies but, when was it really invented?

While the term 3D printing may sound like something you’d expect to hear in a science fiction novel, the history of 3D printing, also known as additive manufacturing, is longer than you might think.

Keep reading to learn about the history of 3D printing, and our BCN3D predictions on where we see this technology going in the future.

The History of 3D Printing in 3 PhasesThe 1980s: When Was 3D Printing Invented?The first documented iterations of 3D printing can be traced back to the early 1980s in Japan. In 1981, Hideo Kodama was trying to find a way to develop a rapid prototyping system. He came up with a layer-by-layer approach for manufacturing, using a photosensitive resin that was polymerized by UV light.

Although Kodama was unable to file the patent requirement of this technology, he is most often credited as being the first inventor of this manufacturing system, which is an early version of the modern SLA machine.

Across the world a few years later, a trio of French researchers was also seeking to create a rapid prototyping machine. Instead of resin, they sought to create a system that cured liquid monomers into solids by using a laser.

Similar to Kodama, they were unable to file a patent for this technology, but they are still credited with coming up with the system.

That same year, Charles Hull, filed the first patent for Stereolithography (SLA). An American furniture builder who was frustrated with not being able to easily create small custom parts, Hull developed a system for creating 3D models by curing photosensitive resin layer by layer.

In 1986 he submitted his patent application for the technology, and in 1988 he went on to found the 3D Systems Corporation. The first commercial SLA 3D printer, the SLA-1, was released by his company in 1988.

The first commercial SLA 3D printer, the SLA-1, was released by his company in 1988.

But SLA wasn’t the only additive manufacturing process being explored during this time.

In 1988, Carl Deckard at the University of Texas filed the patent for Selective Laser Sintering (SLS) technology. This system fused powders, instead of liquid, using a laser.

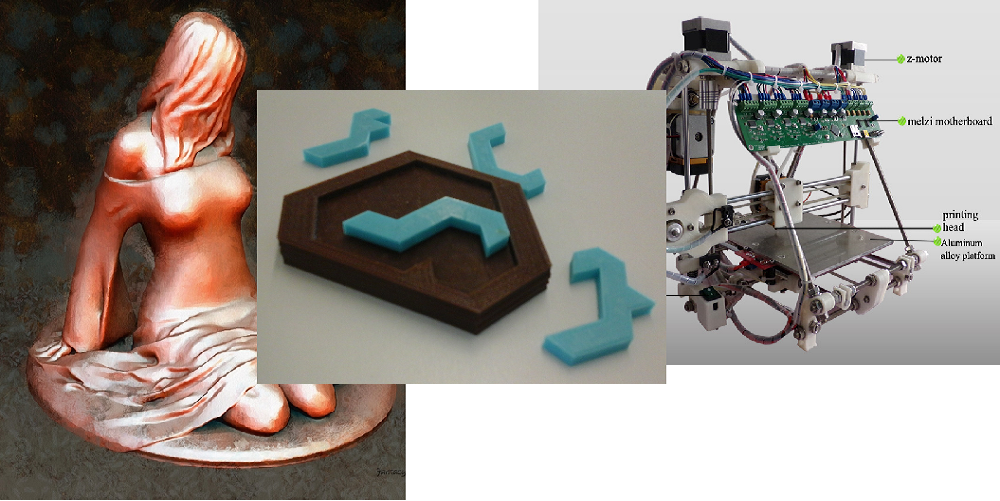

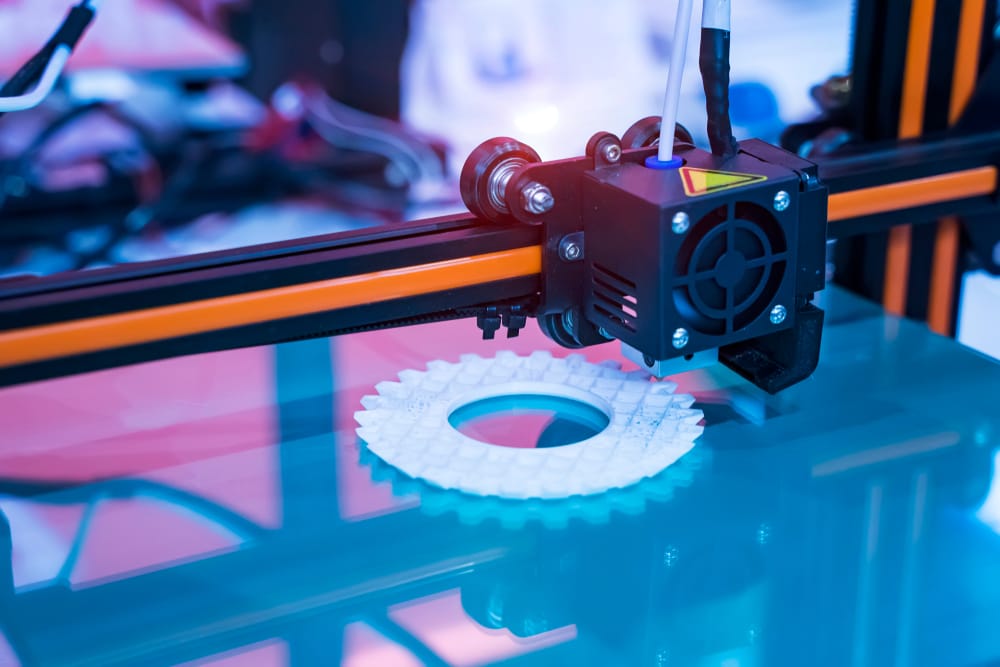

SLS fabrication machines in the Fundació CIM warehouseFused Deposition Modeling (FDM) was also patented around the same time by Scott Crump. FDM, also called Fused Filament Fabrication, differs from SLS and SLA in that rather than using light, the filament is directly extruded from a heated nozzle. FFF technology has gone on to become the most common form of 3D printing we see today.

These three technologies are not the only types of 3D printing methods that exist. But, they are the three that serve as the building blocks that would lay the groundwork for the technology to grow and for the industry to be disrupted.

In the 90s, many companies and startups began popping up and experimenting with the different additive manufacturing technologies. In 2006, the first commercially available SLS printer was released, changing the game in terms of creating on-demand manufacturing of industrial parts.

CAD tools also became more available at this time, allowing people to develop 3D models on their computers. This is one of the most important tools in the early stages of creating a 3D print.

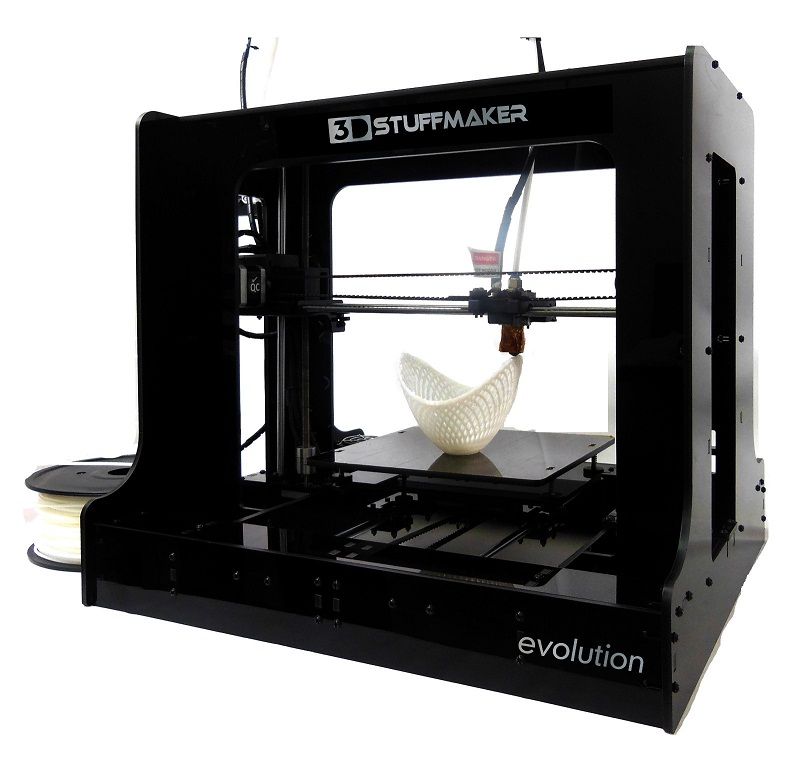

During this time, the machines were very different from those that we use now. They were difficult to use, expensive, and many of the final prints required a lot of post-processing. But innovations were happening every day and discoveries, methods, and practices were being refined and invented.

Then, in 2005, Open Source changed the game for 3D printing, giving people more access to this technology. Dr. Adrian Bowyer created the RepRap Project, which was an open-source initiative to create a 3D printer that could build another 3D printer, along with other 3D printed objects.

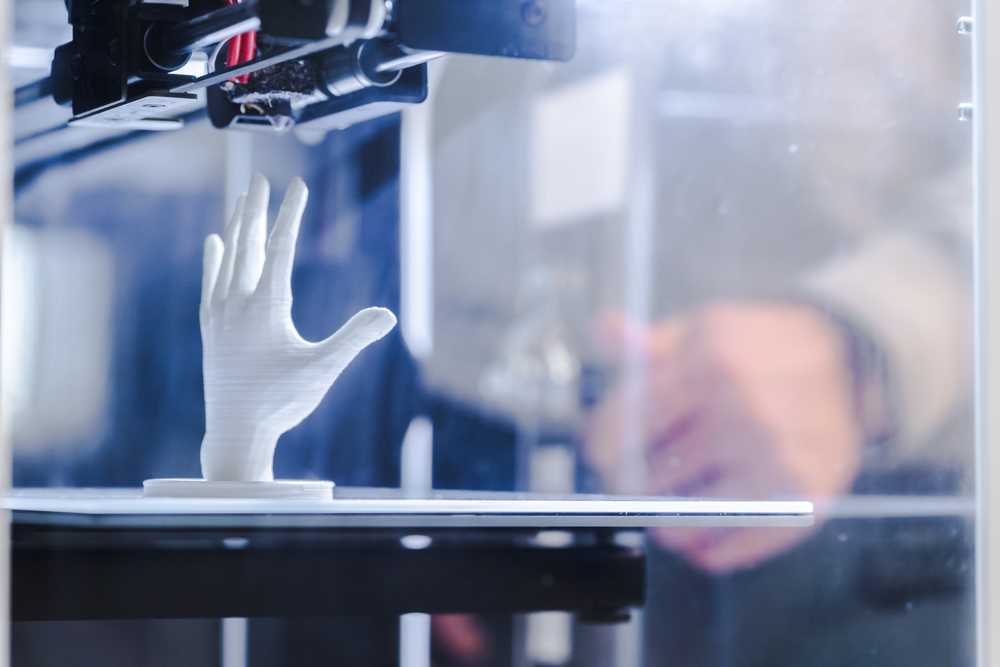

In 2008, the first prosthetic leg was printed, propelling 3D printing into the spotlight and introducing the term to millions across the globe.

Then, in 2009, the FDM patents filed in the 80s fell into the public domain, altering the history of 3D printing and opening the door for innovation. Because the technology was now more available to new companies and competition, the prices of 3D printers began to decrease and 3D printing became more and more accessible.

3D Printing NowIn the 2010s, the prices of 3D printers started to decline, making them available to the general public. Along with the lowering prices, the quality and ease of printing also increased.

The materials that printers use have also evolved. Now there are a variety of plastics and filaments that are widely available. Materials like Carbon Fiber and Glass Fiber can also be 3D printed. Some creatives are even experimenting with printing materials like chocolate or pasta!

Some creatives are even experimenting with printing materials like chocolate or pasta!

In 2019, the world’s largest functional 3D printed building was completed. 3D printing is now consistently used in developing hearing aids and other healthcare applications, and many industries and sectors have adopted the technology into their everyday workflow.

It’s safe to say that the history of 3D printing is still being written.

Innovations and ideas are created every day. We’re very excited to see what’s next!

From the 80s to Today

3D Learning Hub

See all categories

Contents:

- Introduction

- The 1980s: Birth of the main 3D Printing Techniques

- The 1990s: Emergence of the Main 3D Printers Manufacturers & CAD tools

- The 2000s: 3D Printing Gains Media Visibility

- The 2010s: Years of Visibility, Innovation and Hopes for 3D Printing

- What about now, and what about the future?

Introduction

3D printing is not as new as you may think! Actually, FDM (Fused Deposition Modeling) technology became quite popular and impressive for the general public around 2009 because of its media coverage. At some point, a lot of people actually thought that FDM was the only additive manufacturing technology. But FDM is not even the first 3D printing technology developed, and 3D printing actually started in the 1980s.

At some point, a lot of people actually thought that FDM was the only additive manufacturing technology. But FDM is not even the first 3D printing technology developed, and 3D printing actually started in the 1980s.

Here is a quick 3D printing timeline from the 1980s to today. The history of 3D printing is fascinating. The first machines, the great expectations, and the many 3D printing applications that are now flourishing. Let’s take a look back at the 3D printing history.

The 1980s: Birth of the main 3D Printing Techniques

The concept of 3D printing has been imagined back in the 1970’s, but the first experiments are dated from 1981. The first 3D printing attempts are granted to Dr Kodama for his development of a rapid prototyping technique. He was the first to describe a layer by layer approach for manufacturing, creating an ancestor for SLA (or Stereolithography): a photosensitive resin was polymerized by an UV light. Unfortunately, he did not file the patent requirement before the deadline.

A few years later, a French team of engineers, Alain Le Méhauté, Olivier de Witte and Jean-Claude André, was interested by the stereolithography but abandoned due to a lack of business perspective. This 3D printing attempt was also using a stereolithography process.

If you want more information about these first experiences, check out our interview of Jean-Claude André. At the same time, Charles Hull was also interested in the technology and submitted a first patent for stereolithography (SLA) in 1986. He founded the 3D Systems Corporation and in 1988, released the SLA-1, their first commercial product.

If SLA was the first 3D printing technology developed, what about SLS (Selective Laser Sintering) and FDM (Fused Deposition Modeling) back then?

In 1988, at the University of Texas, Carl Deckard brought a patent for the SLS technology, another 3D printing technique in which powder grains are fused together locally by a laser.

In the meantime, Scott Crump, a co-founder of Stratasys Inc. filed a patent for Fused Deposition Modelling (FDM). In less than ten years, the three main technologies of 3D printing were patented and 3D printing was born!

filed a patent for Fused Deposition Modelling (FDM). In less than ten years, the three main technologies of 3D printing were patented and 3D printing was born!

To resume:

1980: First patent by japanese Dr Kodama Rapid prototyping

1984: Stereolithography by French engineers then abandoned

1986: Stereolithography taken up by Charles Hull

1988: First SLA-1 machine

1988: First SLS machine by DTM Inc then buy by 3D system

The SLA 1The 1990s: Emergence of the Main 3D Printers Manufacturers & CAD tools

Now that the basics were established, the evolution of additive manufacturing is pretty fast. The main 3D printers manufacturers are emerging, new technologies are perfected, and 3D modeling tools start to be developed as well, bringing additive manufacturing to the next level.

In Europe, EOS GmbH was founded and created the first EOS “Stereos” system for industrial prototyping and production applications of 3D printing. Its industrial quality is today recognized worldwide in SLS technology (Selective Laser Sintering technology) for plastics and metals.

Its industrial quality is today recognized worldwide in SLS technology (Selective Laser Sintering technology) for plastics and metals.

In 1992, the Fused Deposition Modeling patent was issued to Stratasys, which developed many 3D printers for both professionals and individuals. From 1993 to 1999, the main actors of the 3D printing sector emerged with various techniques:

ZCorp and binder jetting: Based on MIT’s inkjet printing technology, they created the Z402, which produced models using starch- and plaster‐based powder materials and a water‐based liquid binder

Arcam MCP technology and Selective Laser Melting.

At the same time, we can see that more and more new CAD tools, allowing to create 3D models, are becoming available and developed, with, for example, the creation of Sanders Prototype (now known as Solidscape), one of the first actors to develop specific tools for additive manufacturing.

Charles Hull was awarded the European Inventor Award in the Non-European countries category, by the European Patent Office Price in 2014.

To resume:

1990: First EOS Stereos system

1992: FDM patent to Stratasys

1993: Solidscape was founded

1995: Z Corporation obtained an exclusive license from the MIT

1999: Engineered organs bring new advances to medicine

Charles Hull was awarded the European Inventor Award in the Non-European countries category, by the European Patent Office Price in 2014.The 2000s: 3D Printing Gains Media Visibility

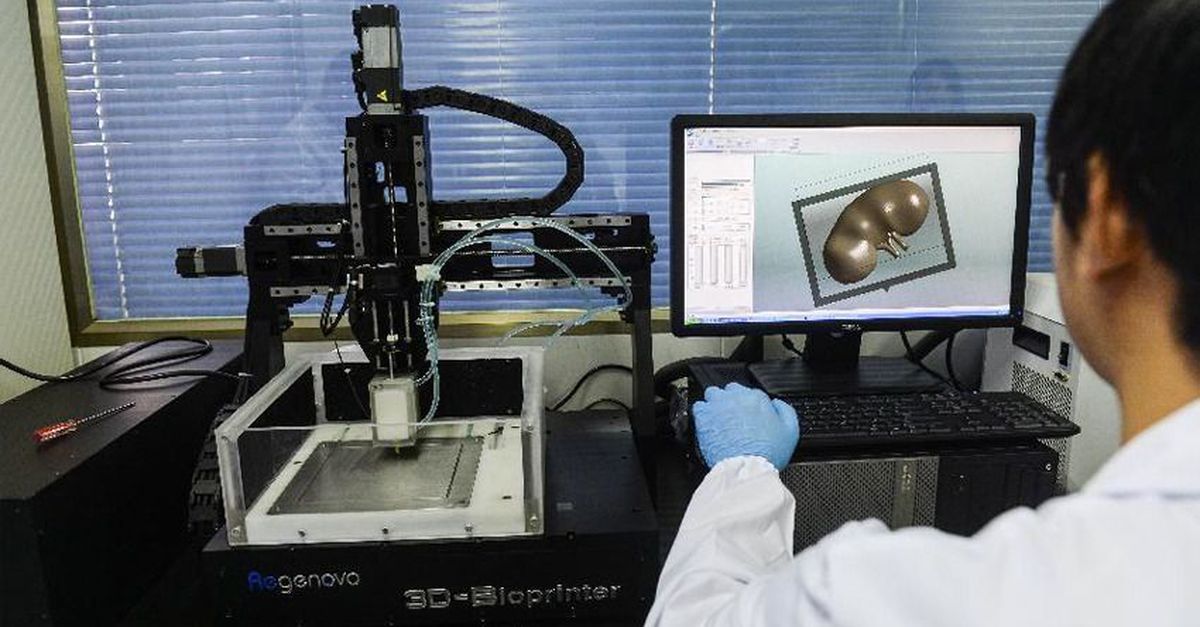

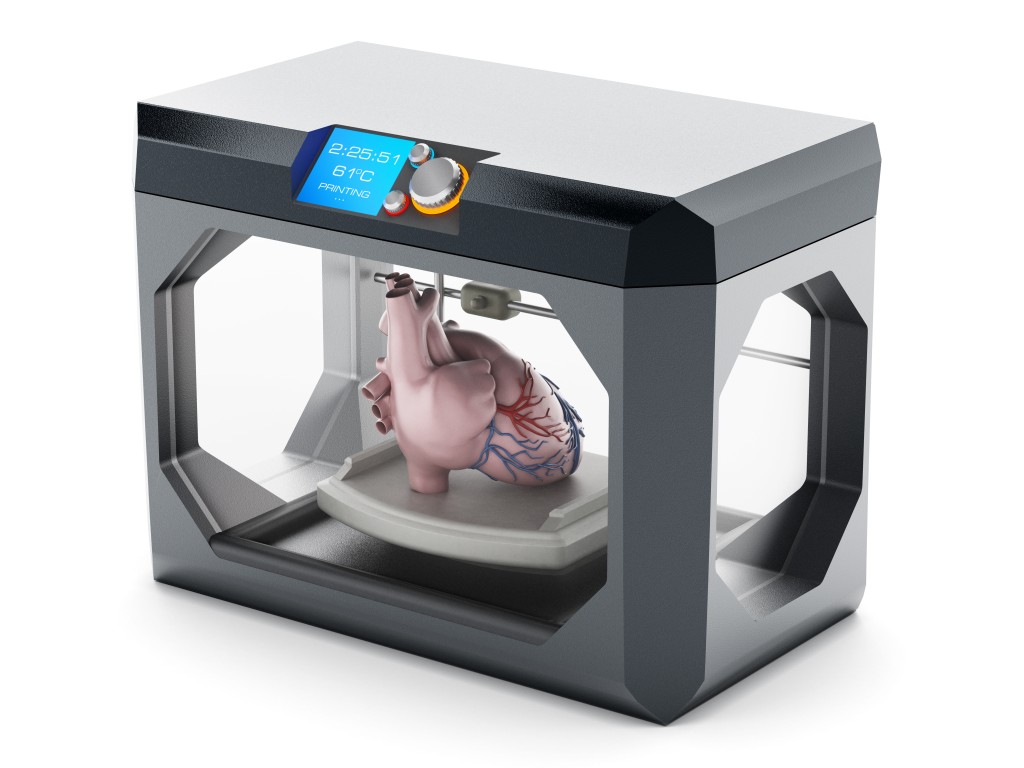

In 2000, the millennium saw the first 3D printed kidney, but we would have to wait 13 more years to see it transplanted into a patient. 3D printed kidneys are now working perfectly and researchers are experimenting on accelerated growth to transplant organs very rapidly.

2004 was the year of the initiating of the RepRap Project which consists of a self-replicating 3D printer. Yes, it is possible to 3D print a 3D printer. This open-source project led to the spreading of the FDM 3D desktop 3D printers, and of the popularity of the technology in the makers community.

In 2005, ZCorp launched the Spectrum Z510, the very first high-definition color 3D printer.

In 2008, 3D printing reached an even greater media presence thanks to another medical application: the first 3D printed prosthetic limb.

This amazing medical 3D printing project incorporated all parts of a biological limb, was printed ‘as is’, without the need for any later assembly. Nowadays, combined with 3D scanning, 3D printed medical prosthesis and orthosis are more and more cheaper and faster to get for the patient. Moreover, these prostheses are more and more optimized and adapted to the morphology of the patient. Additive manufacturing is bringing new opportunities regarding mass-customization.

http://www.ufunk.net/en/tech/exo-prosthetic-leg/2009 was the year in which the FDM patents fell into the public domain, opening the way to a wide wave of innovation in FDM 3D printers, a drop of the desktop 3D printers price, and consequently, since the technology was more accessible, an increased visibility.

2009 was also the year Sculpteo’s online 3D printing service was created, one of the pioneers of the now flourishing online 3D printing services, another step toward 3D printing accessibility!

To resume:

2000: a 3D printed working kidney is created

2000: MCP Technologies (an established vacuum casting OEM) introduced the SLM technology

2005: Z Corp. launched Spectrum Z510. It was the first high-definition color 3D Printer on the market.

2006: An open source project is initiated (Reprap)

2008: The first 3D printed prosthetic leg

2009: FDM patents in the public domain

2009: Sculpteo is created

The 2010s: Years of Visibility, Innovation and Hopes for 3D Printing

The recent years have been very important for 3D Printing. With the FDM patent expiration, the first years of the decade have become the years of 3D printing. Additive manufacturing is then becoming a real and affordable prototyping and production technique for businesses, opening new possibilities

In 2013, President Barack Obama mentioned 3D printing as a major issue for the future in his State of the Union speech, which made “3D printing” an absolute buzzword.

It is now very present in the general public’s mind, and in policy makers’ decisions. The technology is forever progressing, just as are the uses of this technology. More and more small and big companies take advantage of the low prototyping price that 3D printing offers, and have fully integrated it in their iteration, innovation and production processes.

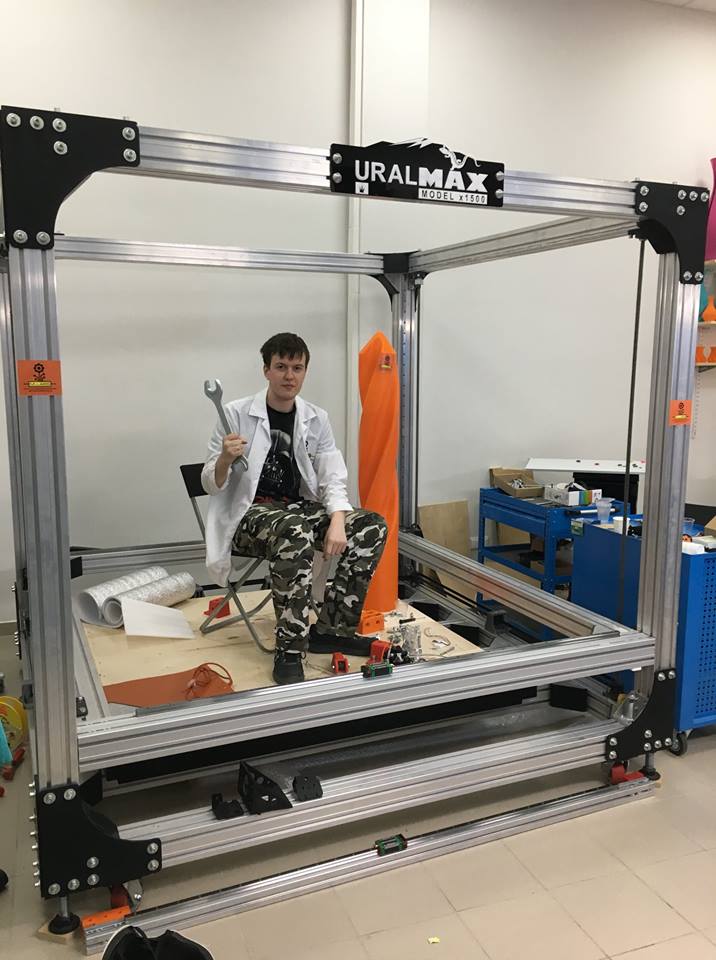

In 2010, Urbee was the first 3D printed car. Its body was fully 3D printed using a very large 3D printer. Now, the 3D printed car is progressively becoming a reality, and additive manufacturing is taking more and more space in the automotive sector. Indeed, from the integration of 3D printing technology for the tooling process, to 3D printed car parts, additive manufacturing appears to be quite helpful on many levels, helping to go through brand new challenges.

credit: EDAG3D printing technology keeps on evolving, and progressing. New 3D printers are being issued regularly, they are more efficient, they print faster, and they give access to new 3D printing materials. Technologies like CLIP (DLS) are being developed by Carbon, making the printing process even faster and more accurate than ever.

Technologies like CLIP (DLS) are being developed by Carbon, making the printing process even faster and more accurate than ever.

If you check the offers of our online 3D printing service, you will find a wide-range of materials from strong and accurate 3D printed resins such as Rigid Polyurethane, to 3D printed flexible plastic, and heat resistant 3D printed metals: everything is now printable, making it easy for companies to find materials adapted to their needs and products.

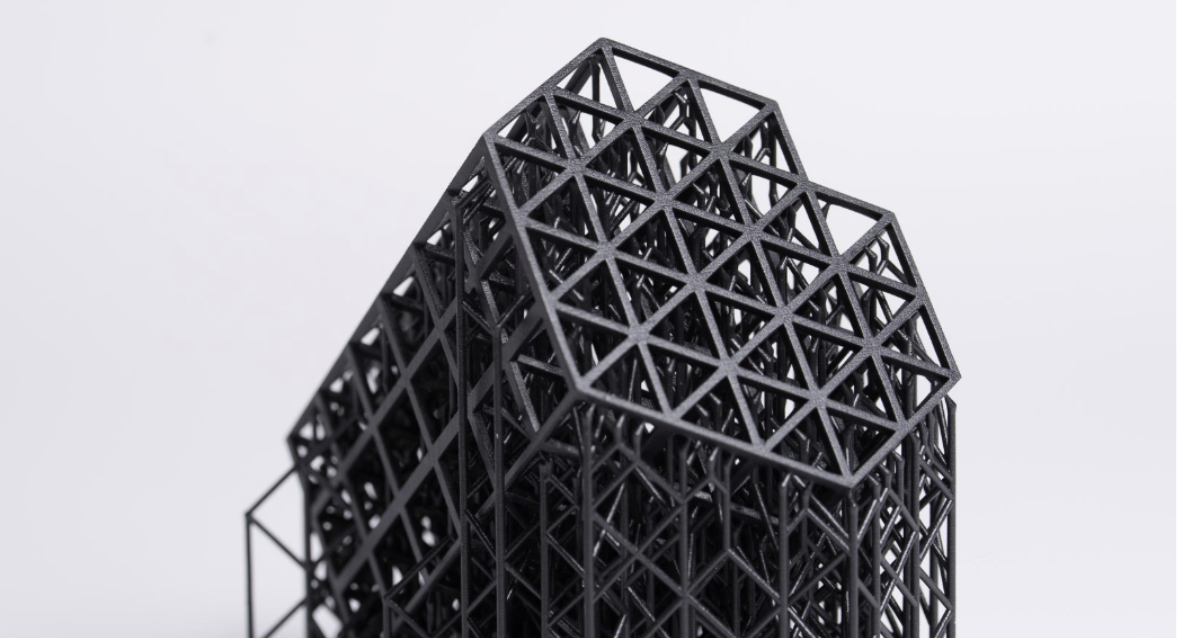

New 3D printing materials are being explored every day, from Daniel Kelly’s lab who’s 3D printing bone to the French startup XtreeE, who’s 3D printing concrete to revolutionize the construction industry! Indeed, regarding architecture application, 3D printing concrete is now a real thing, and families are starting to move into 3D printed houses. The first family to move into a 3D printed house actually did in 2018. The house is 1022 square feet, is perfectly habitable and took two days to print.

To resume:

2010: Urbee is the first 3D printed prototype car presented

2011: Cornell University began to build 3D food printer.

2012: The first prosthetic jaw is printed and implanted

2013: “3D printing” in Obama’s State of the Union speech

2015: Carbon 3D issues their revolutionary ultra-fast CLIP 3D printing machine

2016: Daniel Kelly’s lab announces being able to 3D print bone

2018: The first family moves into a 3D printed house

The 2020s: the arriving of more advanced Additive Manufacturing materials

Additive manufacturing is now offering the possibility to create parts for demanding sectors using advanced materials such as extremely resistant and rigid materials, or professional flexible plastics: we call them high performance materials. It is also a way to implement more sustainable manufacturing using bio-based materials, with a series of Nylon PA11 materials. BASF and Sculpteo are combining their strengths to offer you these high-performance materials and help you go even further in your projects.

Some of these impressive materials are offering thermal resistance, chemical resistance, or even heat resistance for the most demanding applications.

You can try out some interesting materials such as Ultrasint® PA11 ESD and its electrostatic discharging properties, Ultrasint® PA11 CF reinforced with carbon fibers for more rigidity, Ultrasint® PA11 & MJF PA11 bio-based powders with great resistant properties, Ultrasint® PA6 FR a flame-resistant material, Ultrasint® PA6 MF mineral filled for more resistance, Ultrasint® TPU88A & TPU01 for resistance and flexibility

What about the future?

We can see today that 3D printing is revolutionizing big sectors such as automotive, architecture or medical. But where can this technology still improve?

3D Bioprinting is becoming a big subject for the medical field. Indeed, applications of 3D bioprinting could be numerous. You can easily see the diverse advantages of this technology. It could create human tissue for burn victims. It is also a way to create human organs, in order to perform organ transplants. We can see today that there is not enough donors and bioprinting could be an excellent, fast, and life saving solution. The 3D bioprinting technology could allow to create various tissue structures, such as kidney tissue, skin tissue.

The 3D bioprinting technology could allow to create various tissue structures, such as kidney tissue, skin tissue.

3D printing for architecture is also improving, but could really become bigger in the upcoming years. Projects faster to build, cheaper, and that avoid material waste: the benefits of this technology for the construction sector are numerous.

3D printing hasn’t reached its limits and many projects and amazing stories are waiting to be written. We already imagine this future in our article on the innovations to come in 3D printing and the top 10 materials 3D printing materials of the future that already exist!

Are you ready to write the future of 3D printing history, and improve your manufacturing process? Start your 3D printing project now. upload your 3D file here and choose among our 3D printing materials catalog to make the most of our 3D printing service.

Voir aussi:

- Return to Top

Get the latest 3D printing news delivered right to your inbox

Subscribe to our weekly newsletter to hear about the latest 3D printing technologies, applications, materials, and software.

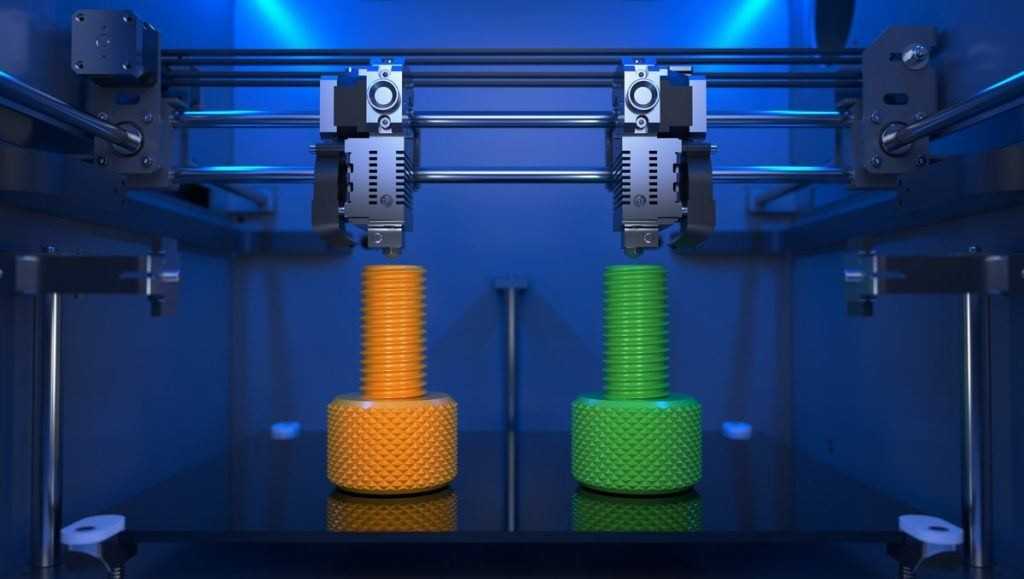

Printing a 3D box with a 3D printer. Blue background . Stock Photo ©3dmentat 88914716

Printing a 3D box with a 3D printer. Blue background . Stock Photo ©3dmentat 88914716Sign In to See December Specials

Images

VideosEditorialMusic & Sounds

Tools

Business

Our Prices

All Images

LoginRegister

0019 by registering an account

Already have an account? Log in

I accept the terms of the User Agreement Receive news and special offers

Process of a 3D object from an electronic 3D printer .

— Photo by 3dmentat

Similar licensed images:

Show moreShow more

Same series:

Process of a 3D object made in an electronic 3D printer and packaging. 688 _ 001a Aquarius (the Water-Bearer), a sign of zodiacal astrology with a warm color of the luminous surface .3D object process from electronic 3D printer and packaging .Pile of hundreds of Chinese yuan banknotesPregnancy test in action. Question mark in result window .Growth business graph with financial profit Libra (libra), astrology horoscope zodiac sign with warm color glowing surface .Barrels with hazardous biological waste thrown under water .Stacks of chinese yuanClose up big red button during an emergency. Red emergency light flashes in the background .Image of shooting under water toredo .Suitcase with labels of world famous travel destinations at the airport New type of Trip Switch Fuse box. All switches are in the "ON" position. Electricity, electricity, fuses .

688 _ 001a Aquarius (the Water-Bearer), a sign of zodiacal astrology with a warm color of the luminous surface .3D object process from electronic 3D printer and packaging .Pile of hundreds of Chinese yuan banknotesPregnancy test in action. Question mark in result window .Growth business graph with financial profit Libra (libra), astrology horoscope zodiac sign with warm color glowing surface .Barrels with hazardous biological waste thrown under water .Stacks of chinese yuanClose up big red button during an emergency. Red emergency light flashes in the background .Image of shooting under water toredo .Suitcase with labels of world famous travel destinations at the airport New type of Trip Switch Fuse box. All switches are in the "ON" position. Electricity, electricity, fuses . View More

Similar Stock Video:

Simple Animation of 3D Printing .Printing a plant box with a 3D printer. Blue background .Simple animation of printing on a 3D printer .Simple animation of printing on a 3D printer . Simple animation of printing on a 3D printer .Simple animation of printing on a 3D printer .Old rusty bicycle carcass in a freshly plowed field on a cloudy day, time is running out 4K A simple 3D printer print animation .Startup process shows animation. Web technologies online application service internet business animated concept flat 3d isometric. Spaceship rocket taking off laptop keyboard 4k video .The luggage basket rotates on a white background. The solar swing swings, but no one is on it. 4K Abandoned empty swings swinging in the wind at the outdoor playground - in the park on an autumn sunny day, Close up of a swing in autumn Outdoor swings in motion without anyone on them. 4KEmpty hanging swing in the open yard, sad childhood memories, creepy horror

Simple animation of printing on a 3D printer .Simple animation of printing on a 3D printer .Old rusty bicycle carcass in a freshly plowed field on a cloudy day, time is running out 4K A simple 3D printer print animation .Startup process shows animation. Web technologies online application service internet business animated concept flat 3d isometric. Spaceship rocket taking off laptop keyboard 4k video .The luggage basket rotates on a white background. The solar swing swings, but no one is on it. 4K Abandoned empty swings swinging in the wind at the outdoor playground - in the park on an autumn sunny day, Close up of a swing in autumn Outdoor swings in motion without anyone on them. 4KEmpty hanging swing in the open yard, sad childhood memories, creepy horror Show more

Usage information

You can use this royalty-free photo "Printing a 3D box with a 3D printer. Blue background ." for personal and commercial purposes under the Standard or Extended License. The Standard License covers a variety of uses, including advertising, UI design, product packaging, and allows printing up to 500,000 copies. The Extended License covers all use cases as the Standard, with the right to unlimited printing, as well as the use of downloaded stock images for merchandise, resale and free distribution.0003

The Extended License covers all use cases as the Standard, with the right to unlimited printing, as well as the use of downloaded stock images for merchandise, resale and free distribution.0003

You are using an outdated browser. For a faster, safer browsing experience, upgrade for free today.

3D printer background vector image ©Palau83 91722444

3D printer background vector image ©Palau83 91722444Sign In to See December Specials

Images

VideosEditorialMusic & Sounds

Tools

For business

Our prices

All images of

Sign in

I accept the terms of the User AgreementGet news and special offers

Vector background of flat 3d printer icons

— Vector by Palau83

0034

View More

Similar Stock Videos:

View More

Usage Information

You may use this royalty-free 3D Printer Background vector image for personal and commercial purposes under a Standard or Extended License.