3D printing assets

2022's Top 10 Sites For Free 3D Printing STL Files

by 3devo on Mar 17, 2022 11:34:00 AM

Have you decided to take the jump and buy a 3D printer? Or maybe you’ve been considering, and are looking for more details as to how it can benefit you?

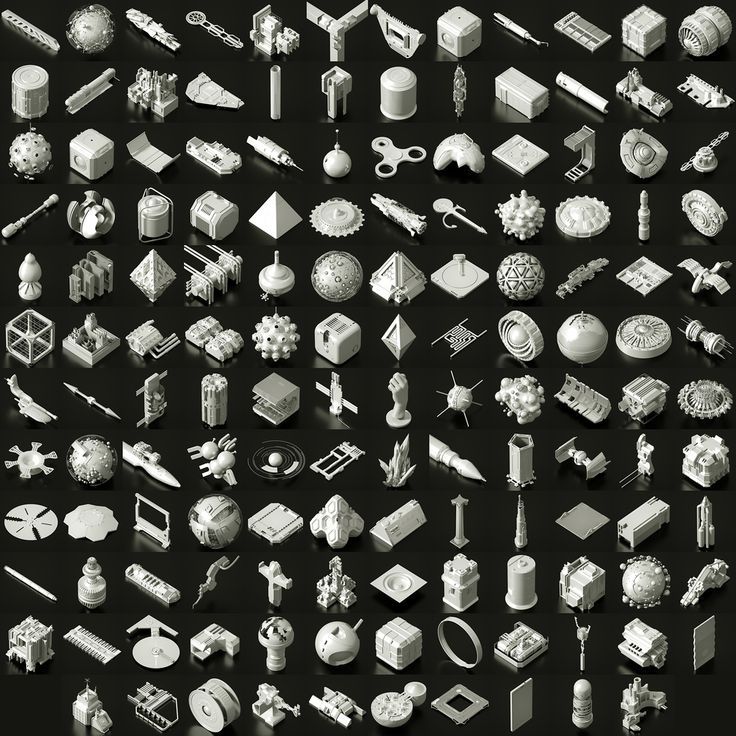

Well, there comes a time where you have all the knowledge and resources for your 3D-printing activities, but no time when it comes to designing or redesigning your STL models. Luckily, you can download free STL files from a variety of great sites. Most are free while others offer their work for a price. Some even have the option to order the model to be printed and then get it sent straight to you!

The best part about these STL file downloads would be the sheer variety available as 3D-printing has gone mainstream. Below is a list featuring some great sites that we use to find free STL models. Enjoy!

Our Top 10 Free STL File Sites

10.Set up in 2012 to build up a community-based 3D model online repository, this French-based site has grown to offer both free and paid downloads. It was among the first to offer models created with any of the major 3D creation tools, further supporting VR and AR on compatible hardware. This site is easy to navigate using the search feature and to better navigate through the sheer volume of STL files available, they have been grouped into convenient categories. Be warned that you may end up spending more time at this Sketchfab site than you may have planned to as there are just too many choices offered.

9. GrabCAD

GrabCAD is not your typical place to just download free STL files for 3D printing. It has many CAD models, many of which are also available in STL format. You can download 3D models in other formats and also try to convert them into STL files for 3D printing, but you may experience trouble with more complex ones. The Resource area is great, giving you access to tutorials, case studies, and even helpful e-books. It also features the useful GrabCAD Workbench tool. It’s a very popular site with many interesting models and resources available so do check the website out soon.

The Resource area is great, giving you access to tutorials, case studies, and even helpful e-books. It also features the useful GrabCAD Workbench tool. It’s a very popular site with many interesting models and resources available so do check the website out soon.

8. SketchUp’s 3D Warehouse

Once owned by Google, SketchUP 3D Warehouse is the go-to place for all your 3D model needs. Laying claim to being one of the largest 3D model online depositories, with over 4 million free downloads available, this site is easy to navigate using the search feature. To better navigate through the sheer volume of STL files available, they have been grouped into convenient categories. The site has also just released a handy feature that gives users the option to have the SketchUp models they upload automatically converted to STL. Be warned that you may end up spending more time at SketchUp’s site than you may have planned to as there are just too many choices offered.

7. Thingiverse

Operated by the popular Makerbot, one of the leaders in 3D printers, Thingiverse provides access to a huge variety of 3D models as well as a knowledgeable community. You can find many 3D models that you can download for free in STL format, and new models are added daily. The only drawback, though, is not all the models are available as STL files format, therefore not fully optimized for 3D printing (some editing may be needed). This doesn’t happen often, though, and the site is definitely worth a visit.

6. My Mini Factory

Don’t be put off by this pages clean UI and high prices on the homepage. The site is managed by iMakr, so you don’t have to worry about the lack of quality models that the site has to offer. All the objects are curated, meaning that “every object uploaded on MyMiniFactory has been test-printed on desktop 3D printers. ” Simply type “free” in the search box and you’ll get instant access to some rather impressive designs. Still going strong since its 2013 launch, MyMiniFactory aims to be the YouTube of 3D files.

” Simply type “free” in the search box and you’ll get instant access to some rather impressive designs. Still going strong since its 2013 launch, MyMiniFactory aims to be the YouTube of 3D files.

5. 3DFindIT.com

3DfindIT.com is the next dimension visual search engine that crawls billions of 3D CAD & BIM models from hundreds of manufacturer catalogs for architecture, mechanical and electrical engineering. The platform allows users to search for digital engineering data provided by manufacturers worldwide. 3DfindIT.com reduces search times and increases efficiency in engineering and construction with intuitive search functions:

- Parametric Text Search

- 3D Shape Search

- 2D Sketch Search

- 2D Photo Search

- Color Search

- Feature/Topology Search

- Search by Category

The download and use of this CAD data is free of charge. Many catalogs offer 150+ different neutraland native formats such as Autodesk Revit, Autodesk Inventor, SOLIDWORKS, and more!

Many catalogs offer 150+ different neutraland native formats such as Autodesk Revit, Autodesk Inventor, SOLIDWORKS, and more!

4. Free3D

Being one of the smaller repositories, Free3D by TurboSquid has both free and paid models. It offers models created by various 3D software but the downloads aren’t in STL format and need to be converted before usage. Multiple language options make for easier navigation and searches. As one of the newer community-focused sites, while also aiming to grow into a marketplace, Free3D has some great potential.

3. PinshapeWhile this is technically a marketplace, Pinshape is a thriving community which make available quirkier models that range from Star Wars-inspired miniatures to jewelry. The free models are displayed along with clearly-marked paid pieces, so you can easily distinguish them or you can simply spend hours browsing and admiring the creativity which went into all these pieces.

This United States government agency for biomedical and public health research offers scientifically accurate or medically applicable models for download. The STL file collections include face shields and low-cost prosthetics, plus models of various human organs for education and research purposes. Especially interesting are the DNA molecules and virus models, so you can get a closer look at these microscopic objects.

1. NASAWhile this site may have the least number of 3D models available, it more than makes up in quality as STL files made available for free lets you fabricate landmark objects in the history of space exploration – like the Apollo 11 landing site, the Curiosity Rover or the Hubble Space Telescope. What makes this site really cool is that you also get to download models of spacesuits and rockets which had been deployed by America’s National Aeronautics and Space Administration.

Endless Possibilities with STL Files

We really appreciate that there are sites like these where you don’t have to spend large amounts of money to try out your much-loved hobby. Even though not all of these STL files are designed for 3D printers, some editing can make them suitable for your printer.

If you are unsure on the correct method of doing this conversion, we recommend you first do some research on some 3D-printing blogs before you start. It will save you a lot of time as well as money in the end.

Buy Professional 3D Printing Models

Our website uses cookies to collect statistical visitor data and track interaction with direct marketing communication / improve our website and improve your browsing experience. Please see our Cookie Notice for more information about cookies, data they collect, who may access them, and your rights. Learn more

Explore 3D Printing Model

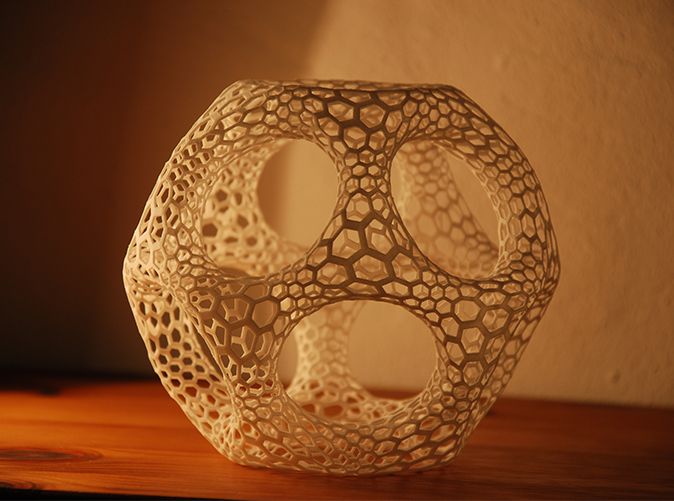

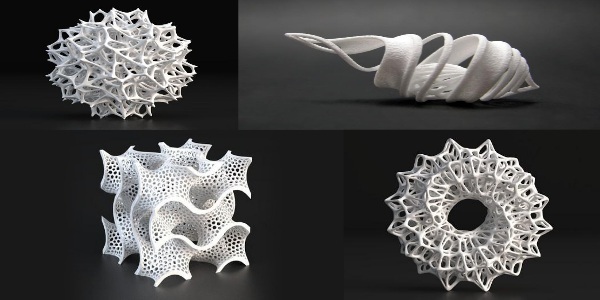

CategoriesProfessional 3D models ready to be printed at home with desktop FDM or industrial SLS 3D printers, available in many industry formats including OBJ, STL, WRL. If you are 3D printing hobbyist, maker, educator or business prototyping by 3D-printing, our home decorations, trendy gadget accessories, eye-catching fashion pieces, unique jewelry, mechanical parts, and variety of miniatures will surely give you an inspiration boost.

If you are 3D printing hobbyist, maker, educator or business prototyping by 3D-printing, our home decorations, trendy gadget accessories, eye-catching fashion pieces, unique jewelry, mechanical parts, and variety of miniatures will surely give you an inspiration boost.

This is where the artistic 3D prints go. Looking for fancy sculpture design recreating classical works and statues of historic personalities, or inspiring figurines, maybe even 3D-printable logos? That is the category.

Fashion 3D Printing ModelsBeautiful and stylish things that you can wear are found in this category. See if you can find any use for fancy space age footwear, novelty glasses and cosplay accessories found here.

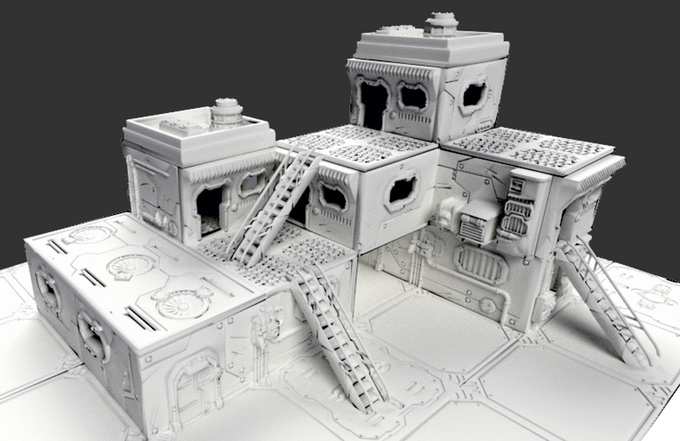

Gadgets 3D Printing ModelsAll iPhone, iPad (and other smart devices) cases can be found in gadget category. From simple 3D add-ons to complex parts and “hacks” for your items, this is the category for the creatives, and lovers of technology.

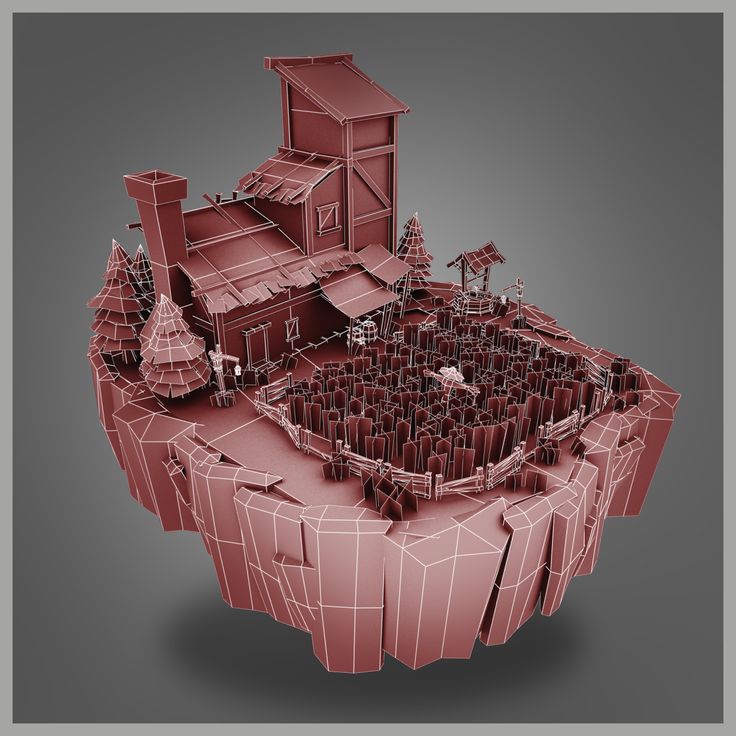

Games and toys is the category covering printable 3D alien or monster miniatures, tiny tanks, funky chess pieces, movie character helmets, hobby paraphernalia and accessories. This is the to-go category for all things geeky.

Hobby & DIY 3D Printing ModelsIf you are our next great inventor and want to build your DIY project or get some spare parts for your drone, this is the place to be. Additionally, it features a lot things for people who want to make their own figurines or plastic gun replicas.

House 3D Printing ModelsAll sorts of knick-knacks can be found here. Lamps, artistic bowls, and all kinds of holders whether you cannot find a right spot for your phone, keep order of toothpicks, pile of pens or jewelry on your desk.

Jewelry 3D Printing ModelsJewelry is where you go to get bracelets and pendants or rings with diamonds. While 3D printers aren’t good enough to make diamonds - yet - you can still print out a metallic ring as a base for your IT geek proposal ring.

While 3D printers aren’t good enough to make diamonds - yet - you can still print out a metallic ring as a base for your IT geek proposal ring.

3D printable characters, famous people, landmarks, animals, Male, female, monsters, aliens - it’s all here. Whether you’re printing utility vehicles to put on your table or creating miniatures for your tabletop games, it’s your category.

Browse all models

The Masters Movement, IP Litigation and Law Reform

October 2019

Author: ), Brisbane, Australia

3D printing is an industry based on the principle of additive manufacturing (as opposed to the subtractive manufacturing principle that underlies the traditional manufacturing industry). 3D printing is also associated with the Craftsmen Movement, a social movement whose main idea is to develop designs for various products and share them.

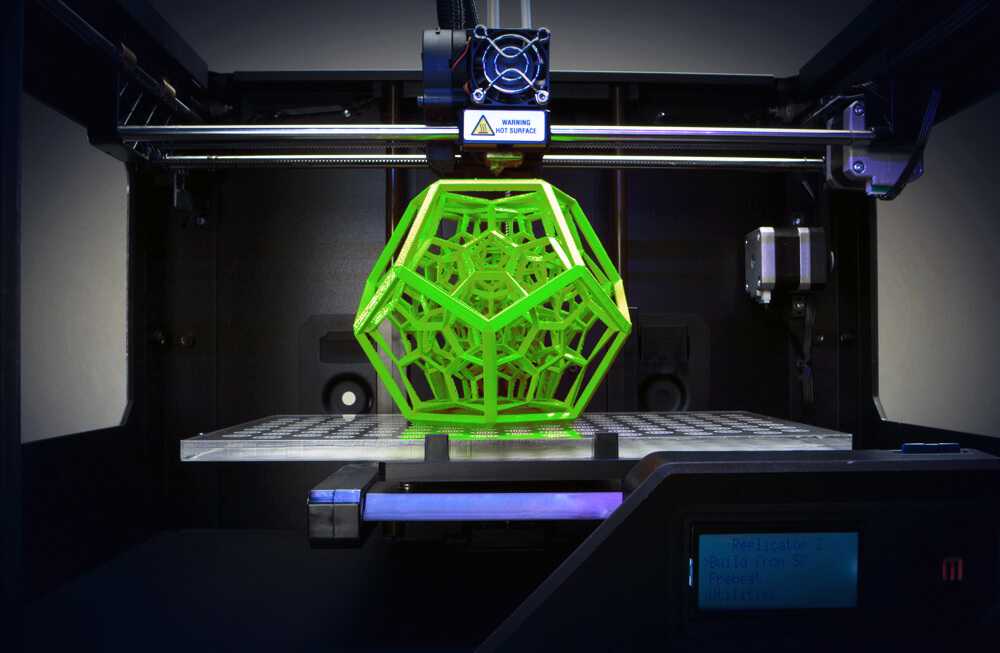

Currently, the development of 3D printing is in a transitional phase. While the consumer “3D printing revolution” has failed, other varieties and categories of 3D printing have seen growth. (Photo courtesy of Queensland University of Technology)

While the consumer “3D printing revolution” has failed, other varieties and categories of 3D printing have seen growth. (Photo courtesy of Queensland University of Technology) 3D printing is currently in transition. The consumer "3D printing revolution", which aimed to have a 3D printer in every home, has failed. MakerBot, a pioneer in 3D printing, is having trouble with its changing approach to intellectual property (IP) issues, disrupting its ties to the open source software community, and the user audience turned away from it. As former MakerBot CEO Bre Pettis said in an interview, "The open source community has kicked us out of their paradise." As a result, MakerBot was acquired by Stratasys, a leader in the 3D printing industry, which restructured and repurposed it.

Some other key players also went bankrupt. In particular, TechShop, a membership-funded and open-to-all network of studio-workshops for home craftsmen, went bankrupt. Maker Media, which publishes Make magazine and hosts craft festivals in the United States, has gone under external control. Make magazine founder Dale Doherty is trying to revitalize his project with a new structure he created called Make Community LLC.

Make magazine founder Dale Doherty is trying to revitalize his project with a new structure he created called Make Community LLC.

Industrial 3D printing continues to grow

Although personal 3D printing has not developed as expected, there has been growth in a number of other forms and categories of 3D printing. Along with robotics and big data, 3D printing has become one of the promising technologies in the manufacturing industry. Companies specializing in information technology and design are working to improve the way 3D printing is used. Significant investments, especially from transport companies, have been attracted by the technology of 3D printing of metal products. In addition, there have been large-scale experiments related to the application of 3D printing in the healthcare sector, including 3D printing in dentistry, 3D printing in medicine, and bioprinting.

As technology improves and develops, there have been several cases of lawsuits being filed in the courts, as well as certain political developments regarding the regulation of the 3D printing industry. Our recently published book 3D Printing and Beyond explores some of the major developments in IC and 3D printing. In particular, it analyzes the issues of 3D printing in relation to areas such as copyright law, trademark law, patent law, and trade secrets (as well as some of the broader issues related to the regulation of 3D printing). In addition, the book highlights the use of open licensing mechanisms in the field of 3D printing.

Our recently published book 3D Printing and Beyond explores some of the major developments in IC and 3D printing. In particular, it analyzes the issues of 3D printing in relation to areas such as copyright law, trademark law, patent law, and trade secrets (as well as some of the broader issues related to the regulation of 3D printing). In addition, the book highlights the use of open licensing mechanisms in the field of 3D printing.

3D printing and copyright law

A few years ago, there was a panic that the widespread use of 3D printing would lead to a wave of large-scale infringements of authors' rights, similar to the situation that arose with the advent of the Napster file-sharing network . Although such fears have not yet materialized, there have been various conflicts related to copyright and 3D printing. For example, Augustana College (United States) objected to 3D scanning of Michelangelo's statues, even though they were not subject to copyright protection and were clearly in the public domain. The American cable television network HBO has blocked the sale of an iPhone stand in the form of an "iron throne" from the TV series "Game of Thrones", made according to the drawings of designer Fernando Sosa using 3D printing. United States singer-songwriter Katy Perry has demanded a ban on the sale of a 3D-printed "shark on the left" figure by the same designer (nevertheless, this product subsequently reappeared in the Shapeways 3D Printing Systems catalog). The heirs of the French-American artist Marcel Duchamp opposed the production of a 3D-printed set of chess pieces based on the works of this artist.

The American cable television network HBO has blocked the sale of an iPhone stand in the form of an "iron throne" from the TV series "Game of Thrones", made according to the drawings of designer Fernando Sosa using 3D printing. United States singer-songwriter Katy Perry has demanded a ban on the sale of a 3D-printed "shark on the left" figure by the same designer (nevertheless, this product subsequently reappeared in the Shapeways 3D Printing Systems catalog). The heirs of the French-American artist Marcel Duchamp opposed the production of a 3D-printed set of chess pieces based on the works of this artist.

3D printing was also subject to the on-demand removal of content under the Digital Millennium Copyright Act (USA). Shapeways and a number of other 3D printing firms have raised concerns about the implications of this regime for online platforms and 3D printing intermediaries.

In addition, discussions took place on issues related to the use of technical protection measures in the context of copyright law and 3D printing. For example, the US Copyright Office has confirmed a limited technical protection exception for 3D printing stocks.

3D printing and design law

Developments in 3D printing have also raised the issue of product repair rights.

Efforts have been made across the European Union to recognize the right to repair in order to support consumer rights and develop a circular economy. In this regard, one of the important factors in achieving changes in the behavior of companies and consumers has become the European Greening Directive (Directive 2009/125/EC).

In July 2019, the United States Federal Trade Commission held a Hearing on "Can't be Repaired: A Workshop on Product Repair Restrictions." Significant differences remain between IP owners and right-to-repair advocates in the United States. Presidential candidate Elizabeth Warren has called for legislation to secure the right to repair for the benefit of farmers in the agricultural regions of the United States.

Significant and first-of-its-kind litigation in Australia regarding right to repair under Design Law ( GM Global Technology Operations LLC v S . . - S - Auto Parts Pty Ltd [2019] FCA 97). The Australian Treasury is considering policy options regarding the practice of sharing vehicle repair information.

Australian Capital Territory (ACT) Consumer Affairs Minister Shane Rettenbury called for recognition of the right to repair from the rostrum of the Consumer Affairs Forum, which includes ministers from both Australia and New Zealand. Federal Minister Michael Succar asked the Australian Productivity Commission to look into the matter.

Calls for right-to-repair laws, both at the provincial and federal levels, are also being heard in Canada. As Laura Tribe, Executive Director of Open Media, noted in this regard, “We are committed to ensuring that people have the opportunity to be the real owners of the products they own. ”

”

3D printing and trademark law

3D printing also brings uncertainty to trademark law and related legal regimes, including product substitution, identity rights, commercial use of characters, and trade dress. The legal conflict surrounding Katy Perry's trademark application for the "shark on the left" image provides some insight into some of the issues that arise in this regard.

Regarding bioprinting, Advanced Solutions Life Sciences sued Biobots Inc. Due to the alleged violation of its trademark rights ( Advanced Solutions Life Sciences , LLC V BIOBIOTS Inc 15 May 201111111111111. Advanced Solutions Life Sciences owns and uses the registered trademark Bioassemblybot for 3D bioprinting and tissue growth.

3D Printing and Patent Law

According to the 2015 WIPO Global Intellectual Property Report, Revolutionary Innovation and Economic Growth, 3D printing patent applications are on the rise. Some industrial 3D printing companies, including 3D Systems and Stratasys, have managed to build large 3D printing patent portfolios. Large industrial companies, including GE and Siemens, have also accumulated significant patent assets in 3D printing and additive manufacturing. Information technology companies, including Hewlett Packard and Autodesk, also play an important role in the 3D printing industry.

Some industrial 3D printing companies, including 3D Systems and Stratasys, have managed to build large 3D printing patent portfolios. Large industrial companies, including GE and Siemens, have also accumulated significant patent assets in 3D printing and additive manufacturing. Information technology companies, including Hewlett Packard and Autodesk, also play an important role in the 3D printing industry.

With the growing commercial importance of 3D printing in the manufacturing industry, there have been a significant number of litigations related to 3D printing of metal products. In July 2018, as part of the “Desktop Metal Inc.” v. Markforged, Inc. and Matiu Parangi (2018 Case No. 1:18-CV-10524), a federal jury found that Markforged Inc. did not infringe two patents owned by rival Desktop Metal Inc. (See Desktop Metal Inc. v. Markforged, Inc. and Matiu Parangi (2018) 2018 WL 4007724 (Massachusetts District Court, jury verdict). In this regard, the CEO of Markforged Inc. .” Greg Mark stated, “We are pleased with the jury's verdict that we have not infringed patents and that Metal X technology, which is the latest addition to the Markforged 3D printing platform, is based on our own Markforged's proprietary designs. " For its part, a spokesman for Desktop Metal noted that it was "satisfied that the jury recognized the validity of all claims in both Desktop Metal patents, which were discussed in a lawsuit against the company "Markforged"

" For its part, a spokesman for Desktop Metal noted that it was "satisfied that the jury recognized the validity of all claims in both Desktop Metal patents, which were discussed in a lawsuit against the company "Markforged"

In 2018 (after the above verdict) Desktop Metal Inc. and Markforged Inc. entered into a confidential financial agreement that settled all other litigation between them. However, in 2019 Markforged Inc. filed another lawsuit against Desktop Metal Inc. due to the fact that, according to her, the latter violated that part of the agreement, which concerned non-disclosure of negative information.

3D printing and trade secrets

In addition, the first litigation regarding 3D printing and trade secret legislation took place. In 2016, Florida-based 3D printing startup Magic Leap filed a lawsuit in federal court for the Northern District of California against two of its former employees for misappropriation of trade secret information within the meaning of Trade Secret Protection Act (“ Magic Leap Inc . " v Bradski et al (2017) case no. 5:16-cvb-02852). In early 2017, a judge granted the defendants' request to stay the case, stating that Magic Leap had failed to provide "a reasonable degree of specificity" to the disclosure of alleged trade secrets. Subsequently, the judge allowed Magic Leap to amend the text of its submission. In August 2017, the parties entered into a “confidential agreement” in connection with this issue. In 2019Mafic Leap sued the founder of Nreal for breach of contract, fraud, and unfair competition (Magic Leap Inc. v. Xu, 19-cv-03445, U.S. District Court for the Northern District of California (San Francisco)).

" v Bradski et al (2017) case no. 5:16-cvb-02852). In early 2017, a judge granted the defendants' request to stay the case, stating that Magic Leap had failed to provide "a reasonable degree of specificity" to the disclosure of alleged trade secrets. Subsequently, the judge allowed Magic Leap to amend the text of its submission. In August 2017, the parties entered into a “confidential agreement” in connection with this issue. In 2019Mafic Leap sued the founder of Nreal for breach of contract, fraud, and unfair competition (Magic Leap Inc. v. Xu, 19-cv-03445, U.S. District Court for the Northern District of California (San Francisco)).

3D printing and open licensing

In addition to proprietary IP protections, 3D printing has a widespread practice of open licensing. Companies with a free distribution philosophy include Prusa Research (Czech Republic), Shapeways (Netherlands-US) and Ultimaker (Netherlands). Members of the Craft Movement used open licensing mechanisms to share and distribute 3D printing files. As noted in The State of the Commons 2017, the Thingiverse platform was one of the most popular platforms using Creative Commons licenses.

Companies with a free distribution philosophy include Prusa Research (Czech Republic), Shapeways (Netherlands-US) and Ultimaker (Netherlands). Members of the Craft Movement used open licensing mechanisms to share and distribute 3D printing files. As noted in The State of the Commons 2017, the Thingiverse platform was one of the most popular platforms using Creative Commons licenses.

Other issues arising from the development of 3D printing

In addition to IP issues, the development of 3D printing also raises a number of other legal, ethical and regulatory issues. In healthcare, regulators have faced challenges with personalized medicine. The United States Food and Drug Administration and the Australian Health Products Administration held consultations on the development of a balanced set of regulations for medical 3D printing and bioprinting. The European Parliament has adopted a resolution calling for a comprehensive approach to the regulation of 3D printing.

Litigation regarding 3D printing of firearms is also ongoing in the United States. Several state attorneys general have sued the current administration to obstruct an agreement between the federal government and Defense Distributed. Several criminal cases have been filed in Australia, the United Kingdom, the United States and Japan in connection with attempts to 3D print firearms. Legislators are debating the feasibility of criminalizing crimes related to possession of digital blueprints for 3D printed firearms.

Several state attorneys general have sued the current administration to obstruct an agreement between the federal government and Defense Distributed. Several criminal cases have been filed in Australia, the United Kingdom, the United States and Japan in connection with attempts to 3D print firearms. Legislators are debating the feasibility of criminalizing crimes related to possession of digital blueprints for 3D printed firearms.

Footnotes

* Dr. Matthew Rimmer is Head of the KTU Research Program on Intellectual Property Law and Innovation and is involved in the KTU Research Center for Electronic Media, the KTU Australian Health Law Research Center and the KTU Research Program in International Law and global governance. In addition, he is a Senior Research Fellow at the Australian IP and 3D Printing Research Council Innovation Project. Dr. Rimmer is the author of numerous publications on copyright and information technology, patent law and biotechnology, access to medicines, anonymous packaging of tobacco products, IP and climate change, and IP of indigenous peoples. His current research interests include IP, Creative Industries and 3D Printing; IP and Public Health; and IP and Trade, including the Trans-Pacific Partnership, the Transatlantic Trade and Investment Partnership and the Agreement on Trade in Services. His work is held in the SSRN Abstracts and Bepress Selected Works archives and funded by the Australian Research Council.

His current research interests include IP, Creative Industries and 3D Printing; IP and Public Health; and IP and Trade, including the Trans-Pacific Partnership, the Transatlantic Trade and Investment Partnership and the Agreement on Trade in Services. His work is held in the SSRN Abstracts and Bepress Selected Works archives and funded by the Australian Research Council.

Related Links

- Read more about 3D printing and IP Litigation

3D printers in construction: prospects for application

At first glance, 3D printing structures seem to be some kind of shell of a half-finished building. But upon closer examination, you will not find even a brick. Layers of material seem to build up one on top of the other - this is how a complex structure is created. It's a futuristic world of 3D printing where robotic arms automatically layer and compress layers of concrete or plastic or any other material into a foundation and build a structure.

This method of construction is quite niche today - only a few prototypes of 3D houses and offices have been printed in the world. However, this technology represents an exciting and potentially powerful solution to building change.

However, this technology represents an exciting and potentially powerful solution to building change.

What is 3D printing in construction, what is the potential, and will we be working on 3D printed projects in the near future?

- What is 3d printing in construction?

- 3D printers in construction: how is it done?

- 5 examples of innovation

- How can 3d printed projects help construction companies?

- 3D printing distribution

- 3D printing in civil engineering

- Wiki House technology - an open source project for 3D printing: what is behind the concept

- Reverse side of medal

- How 3D printing can be integrated into construction

- About PlanRadar

3D printing in construction - what kind of technology?

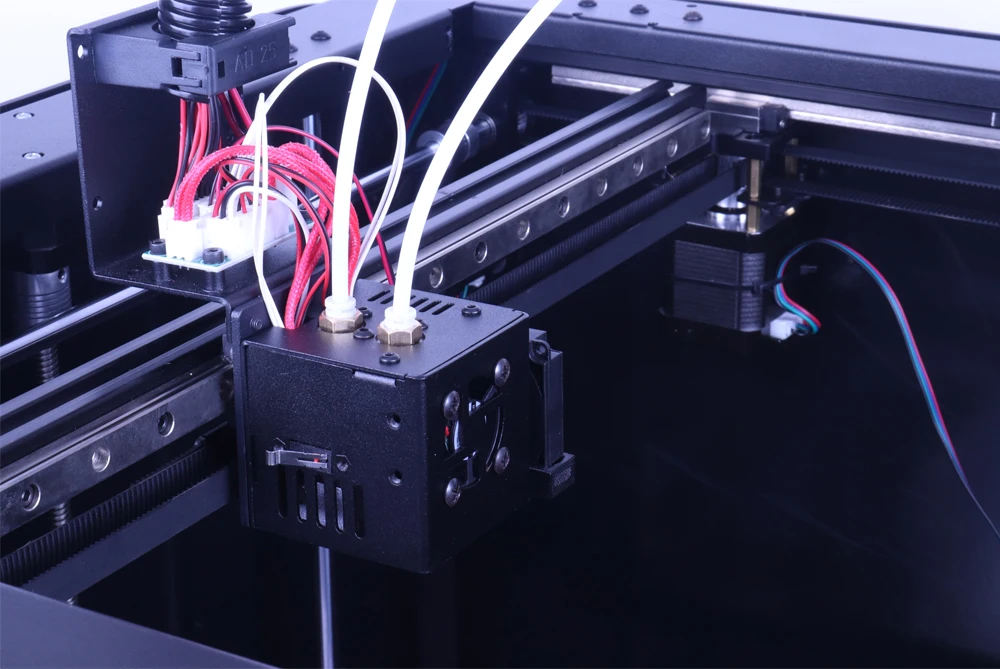

3D printing for construction uses both a 3D printer, which has a robotic "crane-arm" that builds structures right on the construction site, and the creation of certain elements by printers at the factory, which are already assembled into a structure on site.

The concept of 3D printing is not new: it first appeared in the 80s. But it's only in the last decade that this technology has been improved enough (and the cost significantly reduced) to become a real mainstream.

3D printers are not much different from conventional inkjet office printers. The software tells the printer about the dimensions of the final product. And then the printer starts to output the material to the platform according to the plan. 3D printers often use liquid metals, plastics, cement, and variations of various materials that, when cooled and dried, form a structure.

In a 3D construction printer, the CAD or BIM programs tell the device what to print, and the machine begins layering the material according to the design plan.

3D printers in construction: how do they work?

3D printing concept - The printer extrudes a defined liquid mixture in layers, layer by layer, creating a design based on a 3D model. The prepared mix of concrete, filler, plasticizer and other components is loaded into the hopper of the device and fed to the print head. The mixture is applied to the surface of the site or to the previous printed layers. This is how most 3D printers work. Among them, there are three types of devices for 3D printing:

The mixture is applied to the surface of the site or to the previous printed layers. This is how most 3D printers work. Among them, there are three types of devices for 3D printing:

Robotic printer

Read also: New technologies in construction 2021

5 innovative examples of 3D printing

To date, only a few 3D printing projects have been implemented in the construction industry. Here are five of the most impressive and promising projects:

Dubai City Hall Office Building, UAE

1. Dubai City Hall Office Building, UAE

3D printed building. The office block built in the UAE is 9,5 meter high building with an area of 640 m2.

An Apis Cor 3D printer moved around an open-air construction site with a crane and erected different parts of the structure.

2. Office of the Future, UAE

Office of the Future, UAE

Another impressive 3D printed building in the UAE, the Office of the Future is a unique, fairly large structure that currently houses a temporary headquarters organization Dubai Future Foundation.

For this building, the elements were not created on site and were printed in 17 days, while the building itself was assembled in 48 hours.

3. WinSun 3D Printer Homes, China

WinSun 3D Printer Homes, China

WinSun 3D Printing Company of China has also applied factory-built 3D printers to build residential buildings. The company has created several house projects, including a small multi-storey building. All construction details can be printed quickly and cheaply and then quickly assembled on the construction site.

The company calculated that it would cost as little as $161,000 to build and print their five-story building.

4. 3D printed license plate at Lewis Grand Hotel, Philippines

3D printed license plate at Lewis Grand Hotel, Philippines

When planning a trip to the Philippines, consider staying at the Lewis Grand Hotel in Angeles City , Pampanga, where visitors will be greeted with the world's first 3D printed hotel suite. The hotel room was designed by Lewis Jakich, hotel owner and materials engineer, in collaboration with 3D printing specialist Anthony Rudenko. They created a massive 3D printer that prints sand and concrete based on volcanic ash. The room was printed in 100 hours.

The hotel room was designed by Lewis Jakich, hotel owner and materials engineer, in collaboration with 3D printing specialist Anthony Rudenko. They created a massive 3D printer that prints sand and concrete based on volcanic ash. The room was printed in 100 hours.

5. Two-story mansion in Beckum, Germany

Two-story mansion in Beckum, Germany

The first 3D-printed residential building with an area of about 80 square meters - the brainchild of the German construction company PERI GmbH and the architectural design bureau MENSE-KORTE ingenieure + architecture. A BOD2 3D printer was used to print one square meter of double wall cladding in 5 minutes. The building is a structure with three-layer hollow walls filled with insulating mass. Installation of hollow pipes and connections during printing was carried out manually.

3D printing in construction seems really impressive, but what are the real benefits of such technology?

How can 3D printed designs help construction companies?

Proponents of 3D printing houses and commercial offices point to several advantages of this construction method:

- Zero waste construction

In the UK, almost a third of the waste comes from the construction industry. According to the Transparency Market Research Group, the construction industry worldwide will produce 2.2 billion tons of construction waste by 2025. And although most of the waste is related to the demolition of buildings, the construction sites themselves produce a lot of waste.

According to the Transparency Market Research Group, the construction industry worldwide will produce 2.2 billion tons of construction waste by 2025. And although most of the waste is related to the demolition of buildings, the construction sites themselves produce a lot of waste.

Conversely, 3D printing can reduce waste to almost zero. A 3D printer uses a well-defined amount of material that is required to print a design - no more, no less. This can be a big savings.

- Reduced energy consumption

3D printing in construction encourages the use of locally available materials and natural ingredients. This practice can reduce energy costs in transportation, construction and manufacturing, as most local materials require less energy to process or install. If traditional materials with toxic chemical impurities are replaced with natural ones, then the toxicity of the entire construction can be reduced. In addition, local materials are often better suited to local climates and can reduce a building's heating or cooling load, which also reduces construction costs.

- Save time and money

As with AI in construction, a 3D printer can run 24 hours a day, 7 days a week. This means construction projects have the potential to be completed much faster and a number of low-skilled labor costs can be avoided. What's more, 3D printing eliminates the need for temporary structures, such as formwork and scaffolding, that are commonly used in traditional construction. Studies of 3D printed concrete structures have shown a significant reduction in formwork requirements, reducing costs by 35-60%.

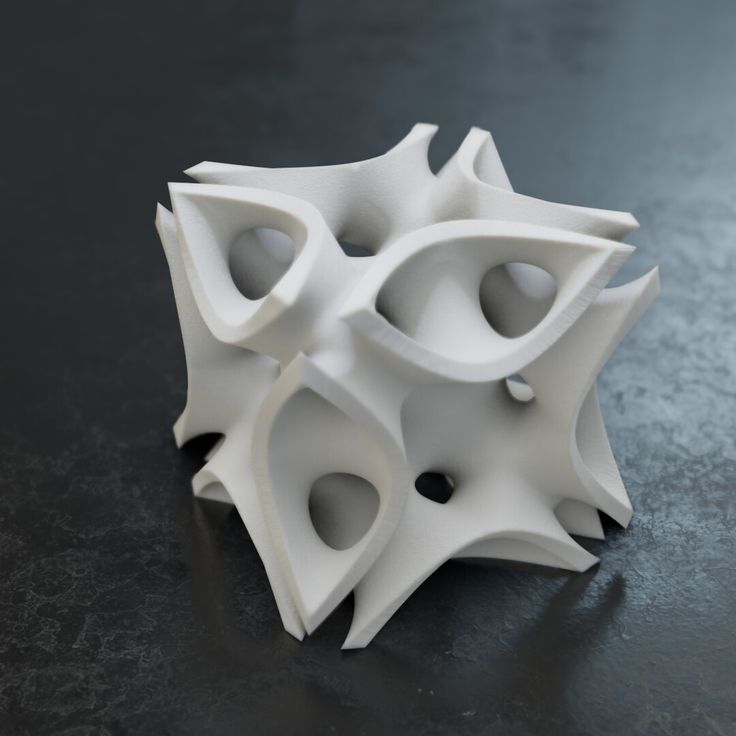

- Can realize unusual design shapes

One of the most attractive characteristics of 3D printers is their ability to create complex and unusual design designs, including the only one that is unique. Since the job of a 3D printer is to layer the material, they can be programmed into absolutely any unusual shape that would be much more difficult to create with traditional techniques.

- Minimize human error and improve safety

The published injury statistics at the workplace by the American agency BLS in 2020 indicates that construction is one of the most traumatic areas and a high incidence of diseases. Every day, about 5333 workers die on the construction site. And with the advent of 3D printing, the number of work injuries and fatalities will obviously decrease, as it makes construction more programmable and automated. Robotic construction requires standardized, accurate and complete digital building information, making this technology more accurate and efficient, with minimal rework due to human error or any information inconsistencies. The usual problems with materials and components that need to be stored somewhere, protected from damage are leveled out, problems with installation and work in progress due to damage also disappear - 3D elements are created as they are built, they do not need to be moved and stored.

- Exploring new markets

The use of a 3D printer also allows construction companies to enter new market sectors that were previously inaccessible to them. And for start-up companies, having a 3D printer will be a competitive advantage. What's more, 3D printing is a brilliant way to elevate or improve the reputation of a construction company's brand among those who believe that concrete production has an impact on the planet's environment.

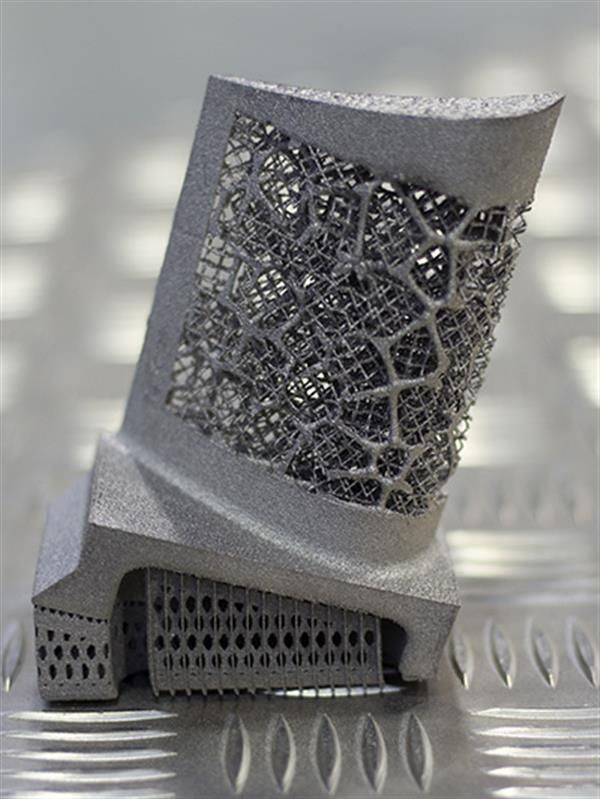

Distribution of structural 3D printing

3D printing for structural reinforcement, small scale components and structural steel could revolutionize design, construction and space exploration. In addition, the European Space Agency (ESA) believes that using 3D printed metals to create high-quality complex shapes can significantly reduce their cost, and they will become very common.

ESA has developed a project with the European Commission to improve the printing of metal components that can be used in space. In total, 28 European partners have united for the joint project AMAZE (Additive Manufacturing Aiming Towards Zero - layer-by-layer 3D printing for zero waste from production and efficient production of high-tech metal products).

In total, 28 European partners have united for the joint project AMAZE (Additive Manufacturing Aiming Towards Zero - layer-by-layer 3D printing for zero waste from production and efficient production of high-tech metal products).

Almost everything can be designed on a computer, so AMAZE plans to install a 3D printer on board the spacecraft, and as soon as an astronaut needs any part, a tool, he can simply print it.

Structural 3D printing

Civil engineering 3D printing

Civil engineering 3D printing has been gaining popularity over the past decade, as has the aerospace and biomedical industries. This revolutionary manufacturing technique is based on its unique ability to create any geometric shape without any formal restrictions, minimizing waste but increasing productivity and results. The construction industry's push towards automation has recently reached important milestones, including the creation of the first structures using robotic "arms" and 3D printing technology.

The use of 3D printing in the creation of structural elements from polymer materials, concrete and metals is becoming more common.

These civil engineering technicians can create freeform and innovative architectural designs using CAD-integrated software.

However, despite considerable research in the aerospace and bioengineering industries to evaluate and analyze this mechanism, there is still a lack of understanding of its use, the impact of 3D printed materials in civil structures, both in terms of material properties and structural response.

Imperial College London

Read also: Best Building Apps in 2021

WIKI HOUSE - 3D printing in construction: what is the concept behind

Wiki House is an innovative project created by a small group of architects in London in 2011 . It offers an open source digital house design system that allows users to create, upload and share designs and print their own houses.

The kit does not require any special knowledge and training and can be created in 1 day. Elements are digitally cut from ordinary sheet material, like plywood, using a CNC machine. And it's much faster, less costly, and doesn't require the involvement of experts, as in conventional traditional construction.

Elements are digitally cut from ordinary sheet material, like plywood, using a CNC machine. And it's much faster, less costly, and doesn't require the involvement of experts, as in conventional traditional construction.

A standard two bedroom house can be built for less than £50,000 and additional components such as cladding, insulation, windows and more can be added to the main frame of the structure. The first house that was built on the basis of the open source Wiki House technology was a two-story building. The 3D printed house was presented at the London Design Festival in 2014.

The Wiki House movement was spearheaded by Alastair Parvin, whose TED presentation "Architecture for People, Built by People" talked about the promise of 3D printing in construction. The creator of this project believes that Wiki House can help solve the housing problem, especially in emergency situations such as earthquakes (there is already evidence that 3D-printed houses can withstand shocks up to magnitude 8).

In the future, this could become a real alternative to low-cost houses, while allowing the customer to control the design of the project.

3D building built using Wiki House

Will 3D printing be the sustainable future of building?

3D printing has the potential to revolutionize the supply chain and structure through a new method of design and manufacturing. According to the study, 3D printing can help the construction industry become more economical, more efficient and greener.

Saxon University of Applied Sciences scientists Ivo Kotman and Neils Faber claim that 3D printing technology will be a "game changer". They explored the possibilities of 3D printing concrete, and their conclusions are:

- 3D printing shortens the supply chain and the overall design process. 3D printing right on the job site eliminates time-consuming steps in the design process. The architects, engineers, contractors, clients, and executives who normally have to be actively involved in a project are no longer needed in 3D printing.

Since all tasks can be combined in one figure of the architect, who uses the modeling method and reproduces the exact holistic designs.

Since all tasks can be combined in one figure of the architect, who uses the modeling method and reproduces the exact holistic designs. - Pipe fitting and electrical wiring become easier and more efficient. Heating systems, insulation, plumbing and electricity all require the laborious on-site installation of conventional construction. However, in 3D printing, some of these features can be incorporated into the 3D printing process. Cavity wall printing is less resource intensive, improves insulation, and allows the use of 3D-printed hot or cold water channels. Moreover, the need for on-site installation is eliminated, which directly affects the reduction of waste.

- The best logistics. 3D printing eliminates 3 logistics and shipping issues. Firstly, many materials and elements often deteriorate upon delivery, and if everything is printed on site, then damage is minimized

Secondly, in order to withstand transportation, the parts must be with increased technical characteristics, which by default increases the cost of them, and therefore the entire project. 3D printing right on the construction site will help to avoid such additional costs.

3D printing right on the construction site will help to avoid such additional costs.

- Creation of individual house designs available to the general market. Usually, building a house with the involvement of an architect is an expensive pleasure for most consumers. But with concrete 3D printing, you don't have to worry about the chosen shape, it won't cost more. In fact, this means that in the future, more people will be able to buy houses of their own design, according to their individual needs

Reverse side of the coin

While 3D printing is definitely attractive, it's still important to look at it impartially, removing some of the promotional stimulus. Skeptics note several disadvantages of this technology.

- Research and development costs

Most construction companies operate with relatively low profitability. To start using 3D printing everywhere, significant investments will be required.

- Will consumers see this as a marketing ploy?

3D printed houses, offices, shops and other infrastructure are often impressive. But do most people really want to live or work in one? For most people, brick houses are much more familiar and attractive. Other technologies such as prefabricated houses also seemed like an attractive technology of the future for some time, but have not been widely adopted, despite the fact that in many cases they were cheaper than traditional ones.

- Difficulty integrating with other components

3D printers can create unique and interesting designs. However, if you need a building that will use different materials or different elements that will not be suitable for 3D printing, then it will be a challenge to include a 3D printer for the building process.

- Lack of skilled labor

With the current problem of a shortage of skilled labor in the construction sector in general, 3D printing will require an even larger set of specialized knowledge and skills, which will have to be selected from an already small niche of candidates. So finding specialists to work in 3D printing for construction may be another difficult task in the future.

- Construction quality control

Weather conditions can slow down the traditional building process, but things are even worse for 3D printing. The environmental factor for commercial construction may reduce the demand for 3D printing. What's more, quality control can be a much more serious task, requiring constant monitoring of the process by real people at the construction site.

- No standards and regulations

Despite the regular mention of 3D printing in the media, it still has not had a significant impact on the construction sector. There is an obvious liability issue when using these printers, even more so than human liability when doing some construction work. And quite a few other ambiguities regarding this technology. So until norms and standards are established, as well as rules in this area, 3D printing is unlikely to become mainstream in the construction industry.

There is an obvious liability issue when using these printers, even more so than human liability when doing some construction work. And quite a few other ambiguities regarding this technology. So until norms and standards are established, as well as rules in this area, 3D printing is unlikely to become mainstream in the construction industry.

Read also: New technologies in construction 2021

How can 3D printing be integrated with construction?

At the moment there is strong evidence that 3D printing is worthy of attention and can be applied in the construction segment, and it is likely that this technology will be used more in the coming years. True, it is not known how widely these devices will be used on the construction site, or whether they will remain only a tool for the manufacture of block elements for prefabricated structures. But for certain projects, it is reasonable to assume that 3D printers and this technology in construction will be a must-have tool in the arsenal of builders.