3D printing a house in 20 hours

3D Printer Can Build You A House In 20 Hours: Welcome To The Future

Luke Hopewell

Published 11 years ago: August 9, 2012 at 3:00 pm -

We’ve seen 3D printers used for everything from iPhone cases to makeshift weapons, but if you think bigger, what can these new printers really be used for? Could you really make your own house with a 3D printer in less than 20 hours? Turns out you can, and the technology is now set to be used by NASA for a future Moon colony.

The man behind this ambitious housing project is Professor Behrock Khoshnevis, and he’s disgusted that in the 21st century, the world is still ridden with poverty-stricken slums characterised by make-shift corrugated iron shacks. He wanted to find a way to improve the basic concept of house construction so that it was accessible to everyone, because with better shelter comes a more civilised society.

To build a house right now, you’re looking at a slow, labour-intensive, dangerous process that’s almost always over-budget. Professor Khoshnevis said that housing construction is one of the only industries that still does things manually, unlike the motoring or technology industries for example that use automated production methods to complete routine construction tasks.

So how do you fix a slow, expensive housing concept that has been set in stone for the last few centuries so that everyone around the world can get access to it? That’s easy, Professor Khoshnevis says. You use 3D printing.

Khoshnevis is heavily involved in computer-aided design (CAD), robotics and rapid prototyping with the University of Southern California, and he’s using that experience to scale up 3D printing so that it can be used in housing construction.

“I name this process Contour Crafting, which is essentially a way of streamlining the process by benefiting from the experience we have gained in the domain of [automated and technology-assisted] manufacturing,” he told TEDxOjai attendees earlier this year.

Khoshnevis wants to build entire neighbourhoods with Contour Crafting, and he claims it can be done at a fraction of the cost in a smaller block of time.

As far as expenses go, the materials for the 3D printed house are projected to cost 25 per cent less than traditional houses and labour costs can be cut in half. In terms of timing from start to finish, Khoshnevis said that “we anticipate that an average house, like 2500 square foot house, can be built in about 20 hours from a custom design”.

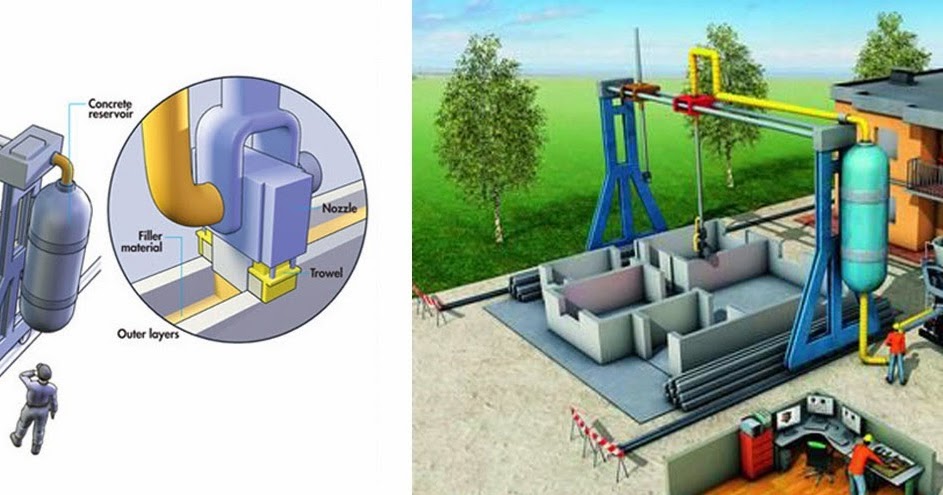

Here’s how it works. A CAD design is sent to a large-scale 3D printer that is mounted to a block of land. The printer lays out the concrete-like foundation of the home through a nozzle that can move anywhere on the property. Like any 3D print-out, the house is made layer-by-layer and reinforced with various materials — like electrical, plumbing and communication infrastructure — as the build progresses.

The concrete used is a mixture of concrete and fibre polymers, meaning that it is more than three times stronger than traditional concrete used in today’s houses. The concrete that goes into your house right now can withstand roughly 3000 pounds per square inch of pressure, while the new printed concrete can withstand around 10,000 pounds per square inch.

The concrete that goes into your house right now can withstand roughly 3000 pounds per square inch of pressure, while the new printed concrete can withstand around 10,000 pounds per square inch.

The best thing about the construction process, Khoshnevis added, is that it can print out any house design you like. Curved walls? No problem. Water feature in your front yard? Can do. Custom tile design and a few feature walls? Simple, thanks to the addition of laser jet printer nozzles attached to the printing array.

As if that’s not impressive enough, Professor Khoshnevis’ concept is currently being supported by NASA so that the space agency can one day be used to build a colony on the Moon. You read it right, the Moon.

This is the future I want to live in. One where I can print out my own house in less than a day, for half the cost, using the same technology NASA is using on the moon. I want to go to there. [TEDxOjai via Reddit]

More From Gizmodo Australia

About the Author

3D-Printed Homes Could Help Solve Affordable Housing Crisis

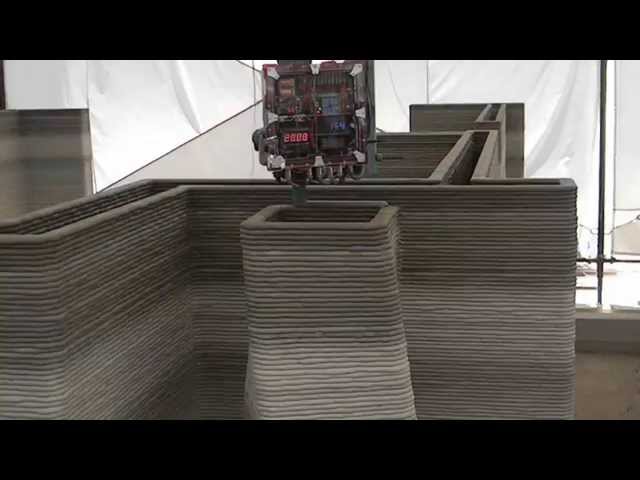

Watching a giant robotic arm methodically deposit layers of concrete may not sound like a transfixing experience. But on TikTok, videos of this exact process—otherwise known as 3D printing—are racking up tens of millions of views and helping people envision a world in which affordable 3D-printed houses are the new norm.

But on TikTok, videos of this exact process—otherwise known as 3D printing—are racking up tens of millions of views and helping people envision a world in which affordable 3D-printed houses are the new norm.

Known as @thelayerlord on TikTok, Aiman Hussein has gained nearly 50,000 followers since joining the social platform last year to showcase the work of Alquist 3D, where he’s the director of printing. His TikToks revolve around the process of 3D printing houses, with his most-watched videos showing how Alquist’s printers systematically layer row after row of concrete to build up a home’s exterior walls in a computer-generated pattern.

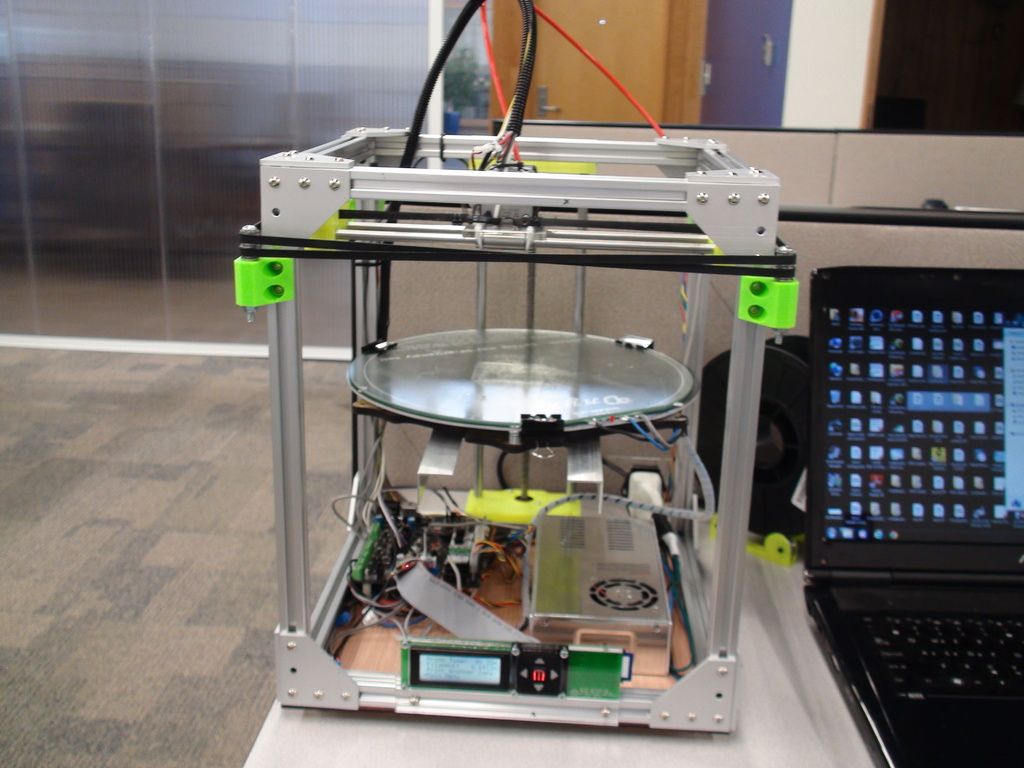

Just like smaller-scale 3D printers, Alquist’s machines have a dispenser that pumps out layers of material—in this case, concrete—on top of each other, to construct a physical object. They follow a predetermined layout to form the design provided by a digital file. The process can be used to create anything from jewelry to furniture to the walls of a house.![]()

Hussein says he started out taking his videos to document the company’s work, but realized that something about them resonated with people on TikTok. “It’s an oddly satisfying process that we do here,” he says.

Viewers often leave jokey comments like “forbidden soft serve” and “I can’t even get toothpaste to come out that smooth” on Hussein’s posts, the most popular of which have been watched nearly 20 million times. However, others have questions. “I mean it’s handy but how long does it take to build a house,” one user commented on an August post that garnered over 16 million views. (Answer: an average of 20-30 hours).

But despite the growing potential of the 3D-printed homebuilding industry, challenges still exist that could hamper its mainstream expansion. For one thing, demand is very high but availability is extremely limited.

What is the current state of the 3D-printed home industry?Since it was founded in 2020, Alquist has completed two 3D-printed house builds, one in Williamsburg, Va. , and one in Richmond, Va. The idea of 3D-printed houses has also been gaining popularity in recent years. A survey published by Realtor.com in August 2021 found that 66% of consumers would consider living in a 3D-printed home. That number was even higher among younger generations, with 75% of millennials saying they’d be open to 3D-printed living accommodations. Around a third of respondents also said they believe that 3D printing is the future of homebuilding and will eventually come to replace more traditional methods.

, and one in Richmond, Va. The idea of 3D-printed houses has also been gaining popularity in recent years. A survey published by Realtor.com in August 2021 found that 66% of consumers would consider living in a 3D-printed home. That number was even higher among younger generations, with 75% of millennials saying they’d be open to 3D-printed living accommodations. Around a third of respondents also said they believe that 3D printing is the future of homebuilding and will eventually come to replace more traditional methods.

Zachary Mannheimer, founder and CEO of Alquist, says that one of the biggest benefits of 3D printing is that it produces houses that are affordable, energy-efficient, and customizable.

Alquist is seeing cost savings of 15% for 3D-printed homes compared to traditional stick-built homes—i.e., homes that are built on site using a wooden frame. The company’s goal is to increase cost savings to 30% by 2023, Mannheimer says.

In December, a Virginia family moved into the first 3D-printed Habitat for Humanity home in the U. S, built by the company. The concrete exterior of the 1,200-square-foot home was constructed in just 22 hours—around two-three weeks quicker than the standard construction schedule—and resulted in a three-bedroom, two-bathroom house.

S, built by the company. The concrete exterior of the 1,200-square-foot home was constructed in just 22 hours—around two-three weeks quicker than the standard construction schedule—and resulted in a three-bedroom, two-bathroom house.

“There’s nothing different about one of our homes versus any other home except that the exterior walls are made out of concrete instead of wood. These homes are built nearly identically otherwise,” Mannheimer says. “Our process just involves extruding concrete from a giant robot, which gives you savings in time and labor and material.”

Through Habitat for Humanity’s homebuyer program, the family living in Alquist’s first owner-occupied 3D-printed home is responsible for monthly mortgage payments that are no more than 30% of its income, including real estate taxes and homeowner’s insurance.

More from TIME

“Working with Habitat for Humanity was a fantastic experience. They were very like-minded and driven to drop costs down on all their structures,” Hussein says. “It really showed how we can fulfill that mission statement of getting people into homes they can afford.”

“It really showed how we can fulfill that mission statement of getting people into homes they can afford.”

Mannheimer says that since the news of the Habitat home broke, Alquist has seen a big increase in requests, showing just how much demand there is for more affordable housing. “Since the home was completed and the first story about it came out, we’ve been averaging anywhere between 25-50 requests for 3D-printed homes per hour,” he says. “So it has confirmed all our beliefs about why this is so important. The need is huge.”

Following the success of its first two 3D-printed homes, Alquist is working on a new project related to affordable housing, to be announced at the end of April.

A 3D printed home, complete

Courtesy Alquist 3D

Alquist’s machines pump out layers of concrete on top of each other to construct a physical object

Courtesy Alquist 3D

What challenges are 3D printing construction companies facing?With the White House estimating that the U. S. has a shortage of as many as 4 million affordable housing units, the problem goes beyond anything that a viral TikTok could solve on its own. The biggest challenge currently facing the 3D-printed housing industry is scale, says Mannheimer: “At the moment, there’s less than 10 companies using this technology in America. To really make a dent in the affordable housing crisis, we’d need more like 50.”

S. has a shortage of as many as 4 million affordable housing units, the problem goes beyond anything that a viral TikTok could solve on its own. The biggest challenge currently facing the 3D-printed housing industry is scale, says Mannheimer: “At the moment, there’s less than 10 companies using this technology in America. To really make a dent in the affordable housing crisis, we’d need more like 50.”

But some experts say there are other fundamental issues holding 3D printing back from revolutionizing housing. Ryan Smith, director of the School of Design and Construction and a professor of architecture at Washington State University, says that while 3D printing has long-term potential to transform the construction industry, America’s penchant for building houses with light wood framing is a major challenge for wider implementation of tech that relies on concrete.

Since labor and supply chains in the U.S. are set up to handle wood, Smith says that trying to upend the current system would create considerable logistical obstacles for the installation and repair of plumbing, electricity, HVAC and other systems. “If you change the means and methods of construction from a lightweight frame to concrete-based housing, you would have to develop a whole workforce around that to be able to manage it,” he says.

“If you change the means and methods of construction from a lightweight frame to concrete-based housing, you would have to develop a whole workforce around that to be able to manage it,” he says.

Rather than trying to replace existing wall construction methods with 3D printing, Smith says companies should produce components of a house in a factory setting before assembling them at a homebuilding site. “You can embed mechanical, electrical, and plumbing much more easily in a factory than you can at the job,” he says.

Some other housing companies already do this.

How TikTok is fueling the 3D printing hypeAll of those hurdles mean that, for now, affordable 3D-printed homes aren’t going mainstream anytime soon. But building interest is the first step, Mannheimer says. “The videos are getting views because they’re so satisfying to watch,” he says.

For members of younger generations facing a difficult path to home ownership, it’s a compelling fantasy.

“It starts to unlock your imagination for what else is possible, ” he says. “We can excite a whole new generation about building things with computers and machines instead of shovels.”

“We can excite a whole new generation about building things with computers and machines instead of shovels.”

Write to Megan McCluskey at [email protected].

17 real buildings printed on a 3D printer - The Future on vc.ru

3D printing technologies are developing extremely fast and are used in various areas of human life.

45,824 views

Recently, much attention has been paid to the printing of buildings, and printed houses are increasingly appearing in recent years in different countries of the world - in the USA, Saudi Arabia, Mexico, France, Russia, the United Arab Emirates and others. I have prepared a list of existing 3D printed buildings for 2020.

What is a 3D printer for construction.

Today's 3D construction printers differ in designs and wall construction methods. The most common printers are portal construction, two- and four-support construction, based on a manipulator arm or a circular design. The equipment allows you to create small architectural forms and elements of structures for their subsequent assembly on site, or allow you to print the entire building on the construction site. The height and dimensions of the printed building depend on the specifications of the printer being used.

The equipment allows you to create small architectural forms and elements of structures for their subsequent assembly on site, or allow you to print the entire building on the construction site. The height and dimensions of the printed building depend on the specifications of the printer being used.

How the printing process works.

The extruder extrudes a fast-hardening concrete mixture with various additives. Each subsequent layer is applied on top of the previous one, due to which a vertical structure is formed. The concrete layers below are thus compacted, thereby increasing their ability to withstand the next layers, and hence the entire weight of the structure. To strengthen the structure, it is reinforced, which can be both vertical and horizontal. The laying of the horizontal armored belt is carried out between the layers, the vertical reinforcement is installed after the composition has hardened, and then it is poured with concrete.

Advantages of 3D printing over other construction methods.

3D printer fabrication opens up great opportunities for construction and related industries. Practical application has revealed the following advantages of additive manufacturing:

- It removes the limits from the imagination of designers and architects who design buildings, as it provides opportunities that are not available with the construction methods we are used to.

- High speed of construction of buildings and structures.

- Complete process automation.

- Low power equipment.

- Significant savings compared to conventional construction methods by reducing labor and energy costs and accelerating construction time.

- The formation of waste building materials is completely eliminated.

- Minimization of human intervention in the construction process not only allows building in places inaccessible to people, but also eliminates the human factor in ordinary territories and reduces the likelihood of error.

1. June 2014. China. China's Shanghai WinSun Decoration Design Engineering Co has unveiled 3D printed houses at an industrial park in China's Jiangsu province. A total of ten houses were created, each of which cost a little more than three thousand pounds sterling. Over the next ten months, the technology improved and the company produced several different types of buildings for the exhibition, the tallest of which has five floors.

2. August 2014. USA. Andrey Rudenko's company Totalkustom printed the lock. The printing took a total of 2 months. The machine's printing speed was 50 cm in 8 hours. The main part of the castle, measuring 3m x 5m and 3.5m high, was printed as a single unit, and the towers were then printed separately.

3. July 2015. China. Chinese company Zhuoda assembled a two-story house in record time. The modular home, made up of six 3D printed modules, was assembled on site in less than 3 hours. Of course actually about 90% of the work was carried out in the company's workshops, and on the site they were only assembled into a single building.

Of course actually about 90% of the work was carried out in the company's workshops, and on the site they were only assembled into a single building.

4. September 2015. Philippines. Andrey Rudenko's Totalkustom company built apartments on the territory of a hotel in the Philippines, 10.5 mx 12.5 m in size and 3 meters high. The building was built using local materials - sand and volcanic ash.

5. May 2016. UAE. Chinese company Shanghai WinSun Decoration Design Engineering Co printed prefabricated structures for the subsequent assembly of an office building in Dubai. The area of a one-story building is about 250 square meters. m.

6. March 2017. Russia. Apis Cor introduced the first 37 sq. m.. The printed house has an interesting shape, but as the participants themselves say: this is just to show the flexibility of printing technology, the shape of the buildings can also be the usual square. Compared to other construction 3D printers, this printer is very compact (4×1. 6×1.5 m), weighs 2 tons, and can be easily transported to the construction site.

6×1.5 m), weighs 2 tons, and can be easily transported to the construction site.

7. October 2017. Russia. In Yaroslavl, the company Spetsavia presented the first residential building in Europe and the CIS, built using construction 3D printing technology. Construction of the house began in 2015. The box of the building was printed by a portal printer piece by piece and then assembled on the foundation in one month in December 2015. In the summer of 2017, the roof was completed and the bulk of the interior finishing work was carried out.

8. March 2018. France. Yhnova presented a five-room one-story house with an area of 95 square meters. For its construction, the engineers used a large manipulator, at the end of which an extruder for polyurethane foam is fixed. While working, he applied the foam in accordance with the 3D model of the building loaded into it. After applying the foam, the builders periodically filled the erected part with concrete, and also inserted the frames of doors and windows.

9. March 2018. USA. American Company Icon built a prototype home in Texas to prove the technology's performance. The area of the building was 32 sq.m., printing was performed by a portal type 3D printer moving along rails installed on the site.

10. July 2018. Spain. Be More 3D printed a 24 m2 concrete building. For the construction, a two-support 3D printer was used, the width of which is 7 meters and the height is 5 meters.

11. September 2018. Denmark. 3D Printhuset printed a 50 square meter office in Nordhavn. The 3D printer used for printing is of the portal type and has a size of 8 x 8 x 6 meters. Print speed 2.5 meters / min. Each layer is 50-70 mm. The print material is concrete made largely from recycled tiles and sand.

12. October 2018. Italy. Company Crane Wasp using a three-bearing construction 3D printer erected a building in ten days. The house uses passive solar heating technology and natural ventilation. The composition for printing was created on the basis of waste from rice cultivation (it was 25% local soil (clay and sand), 40% straw, another 25% - from rice husks and 10% - from hydraulic lime).

The composition for printing was created on the basis of waste from rice cultivation (it was 25% local soil (clay and sand), 40% straw, another 25% - from rice husks and 10% - from hydraulic lime).

November 13, 2018. Italy. Arup in collaboration with the architectural bureau CLS Architetti erected a building in 1 week with an area of 100 sq.m. The building was printed in segments with subsequent assembly at the construction site.

November 14, 2018. Saudi Arabia. The Dutch company CyBe Construction has completed the construction of a building with an area of 80 sq.m. It took about a week to 3D print the necessary elements, and a little more than a day to assemble. The walls are made up of 27 printed blocks, and the parapets needed another 21 blocks to make.

15. August 2019. USA. S-Squared 3D Printers (SQ3D) showed a prototype residential building that can be built from floor to roof in just twelve hours. The house has an area of 46 m2. During the printing process, a 3D printer of a two-support design was used.

The house has an area of 46 m2. During the printing process, a 3D printer of a two-support design was used.

16. October 2019. UAE. Apis Cor has announced the completion of the world's largest 3D printed building. Located in Dubai, the 650 sq. meters has a building height of 95 meters and entered the Guinness Book of Records as the largest building printed directly on the construction site.

17. December 2019. Mexico. American company Icon erected two residential buildings for the non-profit organization New Story, in southeastern Mexico. The imprinted buildings have a flat roof, curved walls and an area of 46.5 square meters

As can be seen from the impressive list of completed projects, progress in the field of construction 3D printing clearly does not stand still, new techniques are constantly being introduced, various materials are being created, including from recycled raw materials, and high-tech equipment is being developed. In a short period of time, the technology has attracted the interest of a large number of enterprises that are engaged in the development of equipment, special building mixtures, libraries of structural solutions for designing buildings for 3D printing, as well as the preparation of a legislative, regulatory and regulatory framework.

In a short period of time, the technology has attracted the interest of a large number of enterprises that are engaged in the development of equipment, special building mixtures, libraries of structural solutions for designing buildings for 3D printing, as well as the preparation of a legislative, regulatory and regulatory framework.

I am sure that in the future the entire construction process will be able to become fully automated, without human intervention, not only when printing foundations and walls, but also when printing ceilings and roofs, automatically install utilities, doors and windows. Also, perhaps in the future we will not be limited to printing houses of 2-3 floors, but will be able to move on to multi-storey construction. All this is no longer something impossible and has ceased to sound like fantastic dreams of a high-tech future. It is only necessary to give time for the natural evolution of 3D construction technology.

From bunkhouses to palaces: ten 3D-printed buildings

iPhone-priced garbage houses and palaces printed in a few days. We tell how 3D printing has transformed the construction industry and what modern printers are capable of

We tell how 3D printing has transformed the construction industry and what modern printers are capable of

Refuge from the elements in Amsterdam - 8 sq. m

In 2015, the Dutch bureau Dus Architects built a tiny house of 8 square meters. m. It is located in the industrial area of Amsterdam, and anyone can rent it. Despite the small area, the shelter has a veranda and a sofa that converts into a double bed. The bathroom, also created on a 3D printer, is taken outside. The shelter was built from bioplastic based on linseed oil. To make a stable house without heavy frames, the engineers designed the walls in the form of a honeycomb.

Photo: DUS Architects

Urban Retreat is part of a temporary functional housing project. The Dutch authorities hope that 3D printing will help provide housing for victims of natural disasters in the future.

Garbage and Clay Houses - 30 and 60 sqm

Italian company WASP printed a tiny 30 sqm house m, the cost of which was only about $ 1,000. The building received the symbolic name Gaia - in honor of Gaia, the ancient Greek goddess of the Earth, since only natural materials were used in the construction.

The building received the symbolic name Gaia - in honor of Gaia, the ancient Greek goddess of the Earth, since only natural materials were used in the construction.

Engineers believe the cost-effective technology can be used to build temporary shelters for victims of natural disasters or refugees. The house became part of the Shambhala Village project, the first settlement in the world where all buildings will be printed.

Photo: WASP

Another WASP project is the futuristic Tecla house created in 2021 with Mario Cucinella Architects. Residential building with an area of 60 sq. m printed in 200 hours.

Photo: dezeen

The company's printer can use both concrete and a biodegradable mixture of clay, straw, rice husks and hydraulic lime as "ink". Construction takes place in two stages: first, the concrete frame of the wall is printed, and then the printer fills its inner layer with clay. The main advantage of the technology that WASP uses is the absence of construction debris.

Printed house in the suburbs - 37 sq. m

An unusual house in Stupino near Moscow is one of the first projects of Apis Cor, a Boston startup with Russian roots. The construction of the building was completed in the winter of 2017. House of 37 sq. m was built in 20 hours, and its cost was ₽590 thousand. The material sets only at temperatures above 5°C, so the construction site was covered with a tent. At the same time, the finished building can withstand temperatures down to minus 35°C. For construction, an industrial printer weighing 2.5 tons was used, which allows you to design up to 100 square meters. m of housing per day.

Unlike most competitors, Apis Cor prints its buildings on site rather than assembling them from prefabricated blocks. The house in Stupino became an advertisement for startup technology: Apis Cor founder Nikita Chen-yun-tai intended to sell printers, not houses. The idea of the Russian startup was successful - even Time wrote about an innovative house in the Moscow region.

Homes for the homeless - 38 and 45 sq. m

Icon is an American robotics startup that 3D prints large objects. For example, together with NASA, they designed a prototype rocket landing pad, and are now planning a project for a printed lunar space station, Olympus. But the company is also engaged in more mundane buildings.

Together with design firm Logan Architecture, Icon printed six houses for the poor in 2020. Each area is 38 sq. m. For construction, a Vulcan II 3D printer and special concrete were used. All buildings have an equipped kitchen, living room, bedroom and bathroom. The 3D quarter was built on the territory of an already existing community for the former homeless, where more than two hundred people now live.

Photo: Shane Reiner-Roth / The Architect's Newspaper

In Mexico, Icon is partnering with New Story, a foundation that raises donations to build safe, affordable housing for the poor. In 2019th project organizers said they plan to print 50 houses, each of which will have two bedrooms, a bathroom, a kitchen and a living room. The area of Mexican houses is 45 square meters. m.

The area of Mexican houses is 45 square meters. m.

Photo: Icon

Because 3D-printed houses are built many times faster and cheaper than usual, they can be a lifesaver for the homeless.

"Lotus House" - 60 sq.m. m. It was designed by students of the University of Washington as part of the Solar Decathlon China 2018 competition. The task of the participants was to create an environmentally friendly building that would run on alternative energy sources. The student team went further and decided that even the construction process itself should be waste-free and carbon-neutral.

The building itself is only partly 3D printed. On it, engineers made molds for casting concrete walls. The advantage of this approach is that the printed designs can be used at least a hundred times. In conventional construction, wooden molds are used, which wear out after only two castings.

The building itself was made in the shape of a lotus - the designers said that they wanted to emphasize the beauty and delicacy of Chinese culture in the design.

Photo: Liam Otten / Archinect

Germany's first two-storey printed house - 80 sq. m

A two-story villa printed in North Rhine-Westphalia is an example of the use of 3D printing in the construction of luxury housing with custom design. The living area of the building was 80 sq. The 3D villa is a joint project of MENSE-KORTE ingenieure+architekten and developer PERI GmbH.

Photo: Mense-Korte

The villa was built using a unique BOD2 3D printer that can print pipes. This feature gives designers a free hand: complex engineering solutions on BOD2 can be completed faster and cheaper than with standard construction. ArchDaily writes that an innovative printer used in the construction of a German villa can print 1 sq. m wall in just five minutes.

Curve Appeal Ecosystem House - 240 sq. m

Another example of conceptual 3D printing is the 240 sq. m Curve Appeal Ecosystem Home. The building belongs to WATG Urban Architecture Studio. The printing of the building was completed in 2020.