3D print pros

What are the Advantages and Disadvantages of 3D Printing?

3D printing, also known as additive manufacturing, is becoming popular with manufacturers. The demand is growing due to some of the revolutionary benefits that it can provide. Like almost all technologies it has its own drawbacks that need considering.

This page aims to help with the selection process. We will cover each of the advantages and disadvantages of 3D printing.

This production process offers a range of advantages compared to traditional manufacturing methods. These advantages include those related to design, time and cost, amongst others.

1. Flexible Design

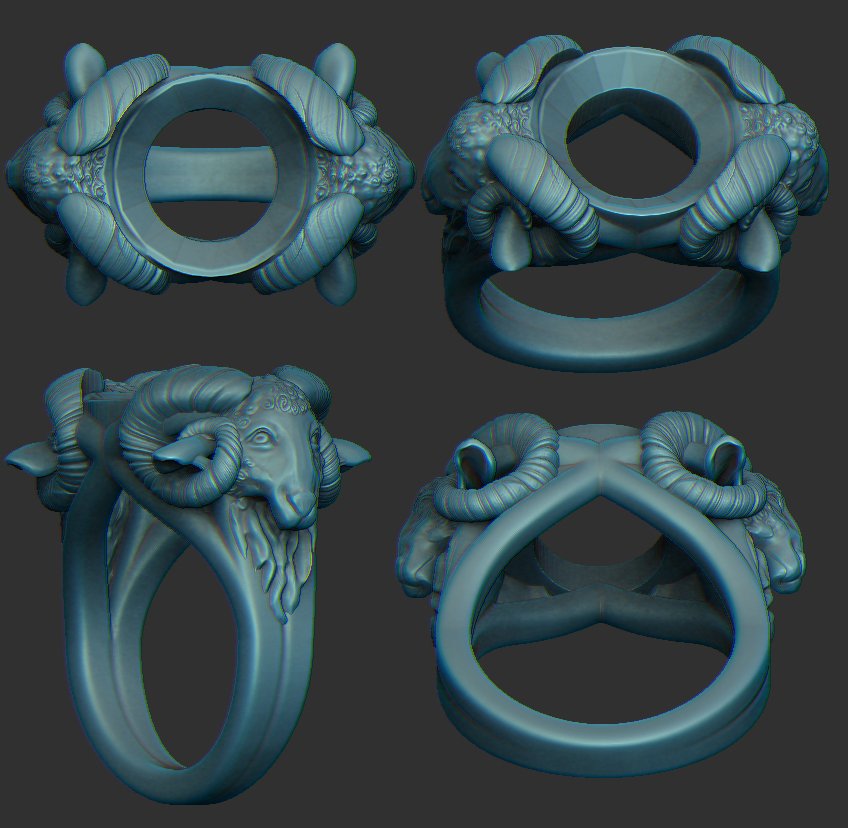

3D printing allows for the design and print of more complex designs than traditional manufacturing processes. More traditional processes have design restrictions which no longer apply with the use of 3D printing.

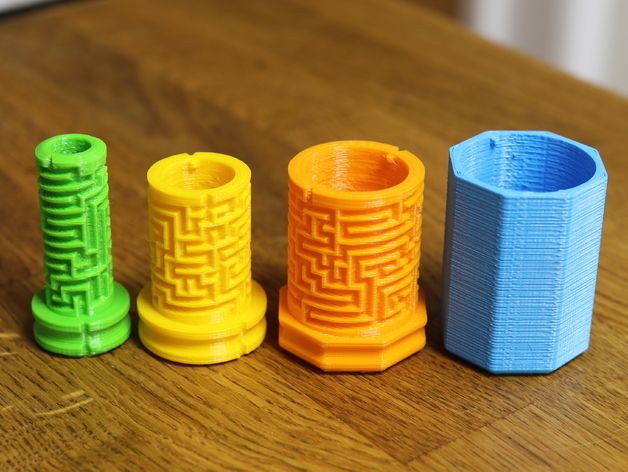

2. Rapid Prototyping

3D printing can manufacture parts within hours, which speeds up the prototyping process. This allows for each stage to complete faster. When compared to machining prototypes, 3D printing is inexpensive and quicker at creating parts as the part can be finished in hours, allowing for each design modification to be completed at a much more efficient rate.

3. Print on Demand

Print on demand is another advantage as it doesn’t need a lot of space to stock inventory, unlike traditional manufacturing processes. This saves space and costs as there is no need to print in bulk unless required.

The 3D design files are all stored in a virtual library as they are printed using a 3D model as either a CAD or STL file, this means they can be located and printed when needed. Edits to designs can be made at very low costs by editing individual files without wastage of out of date inventory and investing in tools.

4. Strong and Lightweight Parts

The main 3D printing material used is plastic, although some metals can also be used for 3D printing. However, plastics offer advantages as they are lighter than their metal equivalents. This is particularly important in industries such as automotive and aerospace where light-weighting is an issue and can deliver greater fuel efficiency.

However, plastics offer advantages as they are lighter than their metal equivalents. This is particularly important in industries such as automotive and aerospace where light-weighting is an issue and can deliver greater fuel efficiency.

Also, parts can be created from tailored materials to provide specific properties such as heat resistance, higher strength or water repellency.

5. Fast Design and Production

Depending on a part’s design and complexity, 3D printing can print objects within hours, which is much faster than moulded or machined parts. It is not only the manufacture of the part that can offer time savings through 3D printing but also the design process can be very quick by creating STL or CAD files ready to be printed.

6. Minimising Waste

The production of parts only requires the materials needed for the part itself, with little or no wastage as compared to alternative methods which are cut from large chunks of non-recyclable materials. Not only does the process save on resources but it also reduces the cost of the materials being used.

7. Cost Effective

As a single step manufacturing process, 3D printing saves time and therefore costs associated with using different machines for manufacture. 3D printers can also be set up and left to get on with the job, meaning that there is no need for operators to be present the entire time. As mentioned above, this manufacturing process can also reduce costs on materials as it only uses the amount of material required for the part itself, with little or no wastage. While 3D printing equipment can be expensive to buy, you can even avoid this cost by outsourcing your project to a 3D printing service company.

8. Ease of Access

3D printers are becoming more and more accessible with more local service providers offering outsourcing services for manufacturing work. This saves time and doesn’t require expensive transport costs compared to more traditional manufacturing processes produced abroad in countries such as China.

9. Environmentally Friendly

As this technology reduces the amount of material wastage used this process is inherently environmentally friendly. However, the environmental benefits are extended when you consider factors such as improved fuel efficiency from using lightweight 3D printed parts.

However, the environmental benefits are extended when you consider factors such as improved fuel efficiency from using lightweight 3D printed parts.

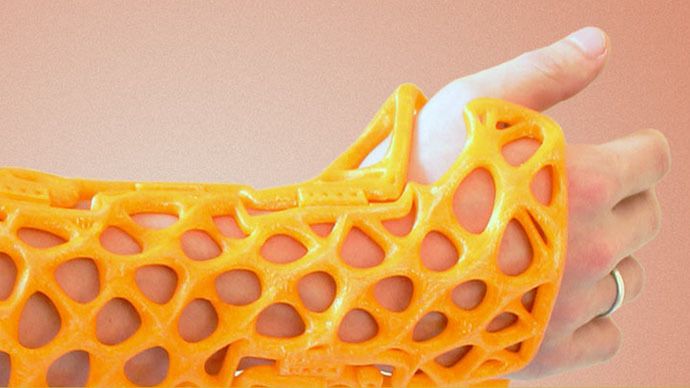

10. Advanced Healthcare

3D printing is being used in the medical sector to help save lives by printing organs for the human body such as livers, kidneys and hearts. Further advances and uses are being developed in the healthcare sector providing some of the biggest advances from using the technology.

Like with almost any other process there are also drawbacks of 3D printing technology which should be considered before opting to use this process.

1. Limited Materials

While 3D Printing can create items in a selection of plastics and metals the available selection of raw materials is not exhaustive. This is due to the fact that not all metals or plastics can be temperature controlled enough to allow 3D printing. In addition, many of these printable materials cannot be recycled and very few are food safe.

2. Restricted Build Size

3D printers currently have small print chambers which restrict the size of parts that can be printed. Anything bigger will need to be printed in separate parts and joined together after production. This can increase costs and time for larger parts due to the printer needing to print more parts before manual labour is used to join the parts together.

3. Post Processing

Although large parts require post-processing, as mentioned above, most 3D printed parts need some form of cleaning up to remove support material from the build and to smooth the surface to achieve the required finish. Post processing methods used include waterjetting, sanding, a chemical soak and rinse, air or heat drying, assembly and others. The amount of post processing required depends on factors including the size of the part being produced, the intended application and the type of 3D printing technology used for production. So, while 3D printing allows for the fast production of parts, the speed of manufacture can be slowed by post processing.

4. Large Volumes

3D printing is a static cost unlike more conventional techniques like injection moulding, where large volumes may be more cost effective to produce. While the initial investment for 3D printing may be lower than other manufacturing methods, once scaled up to produce large volumes for mass production, the cost per unit does not reduce as it would with injection moulding.

5. Part Structure

With 3D printing (also known as Additive Manufacturing) parts are produced layer-by-layer. Although these layers adhere together it also means that they can delaminate under certain stresses or orientations. This problem is more significant when producing items using fused deposition modelling (FDM), while polyjet and multijet parts also tend to be more brittle. In certain cases it may be better to use injection moulding as it creates homogenous parts that will not separate and break.

6. Reduction in Manufacturing Jobs

Another of the disadvantages of 3D technology is the potential reduction in human labour, since most of the production is automated and done by printers. However, many third world countries rely on low skill jobs to keep their economies running, and this technology could put these manufacturing jobs at risk by cutting out the need for production abroad.

However, many third world countries rely on low skill jobs to keep their economies running, and this technology could put these manufacturing jobs at risk by cutting out the need for production abroad.

7. Design Inaccuracies

Another potential problem with 3D printing is directly related to the type of machine or process used, with some printers having lower tolerances, meaning that final parts may differ from the original design. This can be fixed in post processing, but it must be considered that this will further increase the time and cost of production.

8. Copyright Issues

As 3D printing is becoming more popular and accessible there is a greater possibility for people to create fake and counterfeit products and it will almost be impossible to tell the difference. This has evident issues around copyright as well as for quality control.

Get Further Advice On 3D Printing

Need help with determining whether 3D printing is the right process for you?

Contact our team of world-leading experts with over 20 years of experience in the additive manufacturing field.

Our technology experts help to ensure our customers apply the correct technology process depending on each individual or company requirements:

Related Frequently Asked Questions (FAQs)

Complete Guide to the Pros and Cons of 3D Printing

3D printing is an additive manufacturing technology that is used to incrementally build up a part one layer at a time either in plastic or metal. It offers a wide range of advantages, which has allowed for its rapid adoption across every manufacturing industry. However, despite its many pros, some cons need to be considered when deciding whether or not the technology will be beneficial for a specific application. This article will describe all the key 3D printing pros and cons in detail.

What is 3D Printing?

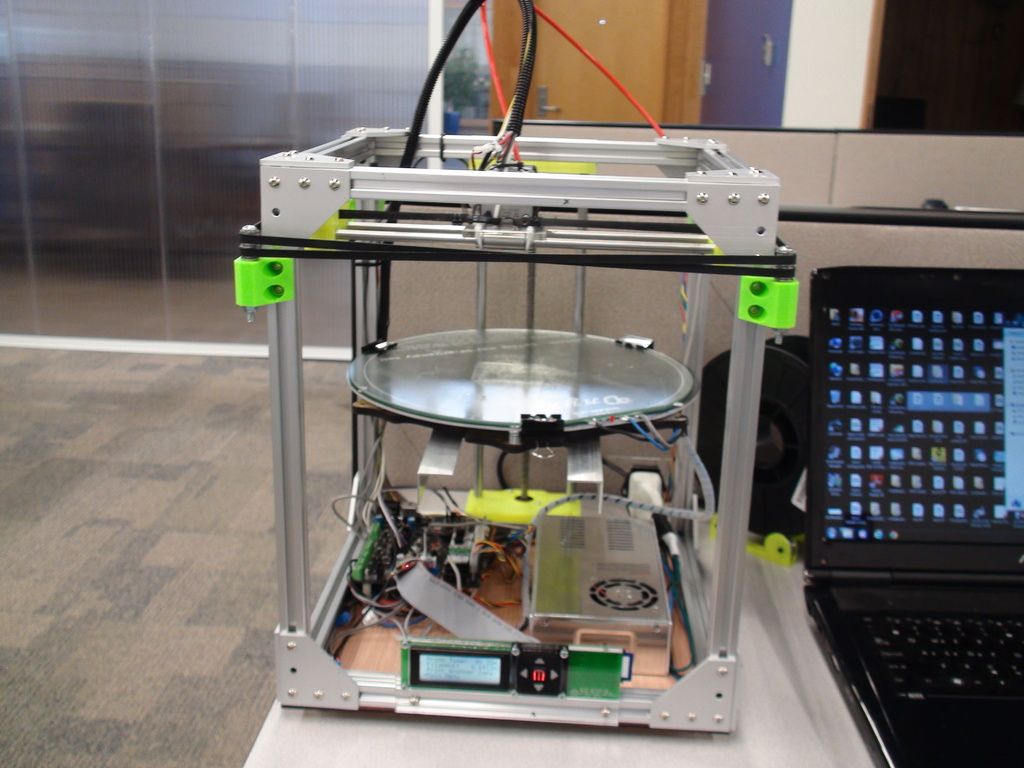

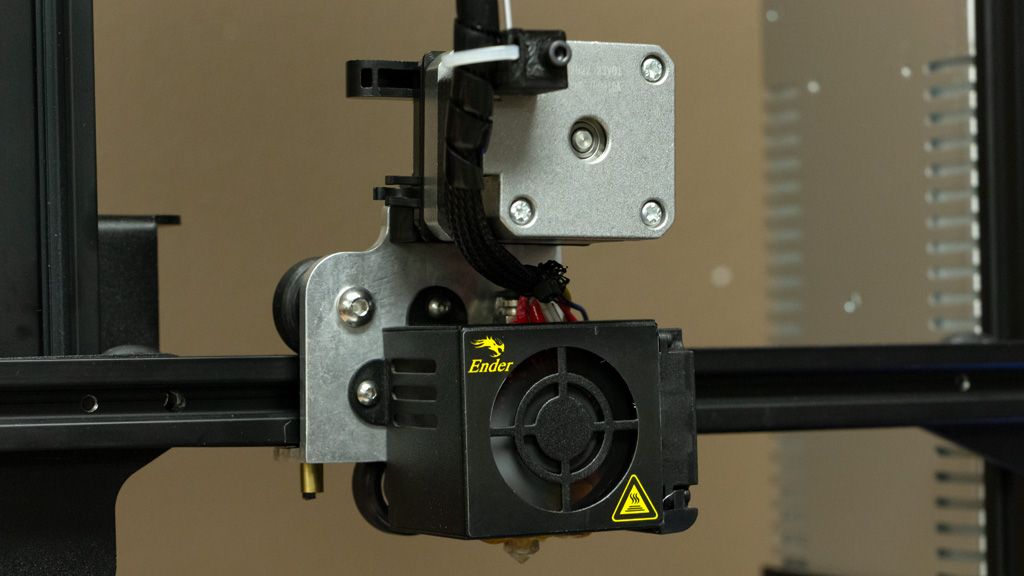

3D printing is an additive manufacturing technology used to produce parts out of a wide range of plastics and metals. There are many different technologies available, from FDM (Fused Deposition Modeling) which extrudes plastic one layer at a time, to DMLS (Direct Metal Laser Sintering) which uses a laser to fuse metal powder one layer at a time into a final part. For more information, see our guide on 3D printing.

For more information, see our guide on 3D printing.

What Are the Pros of 3D Printing?

3D printing pros are:

1. Print on Demand

3D printing requires a very limited setup to begin printing. The setup process and the 3D printing machine are the same regardless of the type of part being printed. All that is required is to convert the 3D model of the part, usually handled with either OEM or third-party software. After the conversion is complete, the file is loaded into the printer through a USB-A connector, wirelessly, or an SD card. The material is then added to the printer, typically either as a liquid photopolymer, a filament, or a powder. Thereafter the print process will continue without any human intervention. When the part is complete some post-processing, like the removal of support structures, may be required. On-demand cloud services simply require a 3D model and will 3D print and ship your item without the need to invest in a 3D printer.

2. Reasonably Priced

The 3D printing process is reasonably priced when compared to other manufacturing technologies like injection molding. This is especially true at low-to-medium production volumes and high part complexity. This is because 3D printers are priced from $200, with used 3D printers being even cheaper. Materials can also cost as little as $15 per kg – for ABS for example. Although, 3D printing materials are generally more expensive than the comparable baseline raw material cost. This is due to the requirement to prepare the raw material for the specific printing process, i.e. filament spools for FDM and fine powder for SLS. Despite this additional raw material cost, 3D printing makes use of less material due to not being completely dense.

This is especially true at low-to-medium production volumes and high part complexity. This is because 3D printers are priced from $200, with used 3D printers being even cheaper. Materials can also cost as little as $15 per kg – for ABS for example. Although, 3D printing materials are generally more expensive than the comparable baseline raw material cost. This is due to the requirement to prepare the raw material for the specific printing process, i.e. filament spools for FDM and fine powder for SLS. Despite this additional raw material cost, 3D printing makes use of less material due to not being completely dense.

3. Eco-Friendly

3D printing can be considered eco-friendly due to the use of recyclable materials like metals and thermoplastics. Parts can also be printed exactly where they are needed instead of being shipped from a centralized heavy-manufacturing plant. This eliminates the significant energy costs associated with transport. The additive nature of 3D printing also results in less wastage.

4. Quick Prototyping

The low cost and print-on-demand features of 3D printing make it ideally suited to developing prototypes. A 3D printed part can be produced in less than a day. This allows for rapid iteration of new concepts without the up-front tooling cost typical of other common technologies like injection molding.

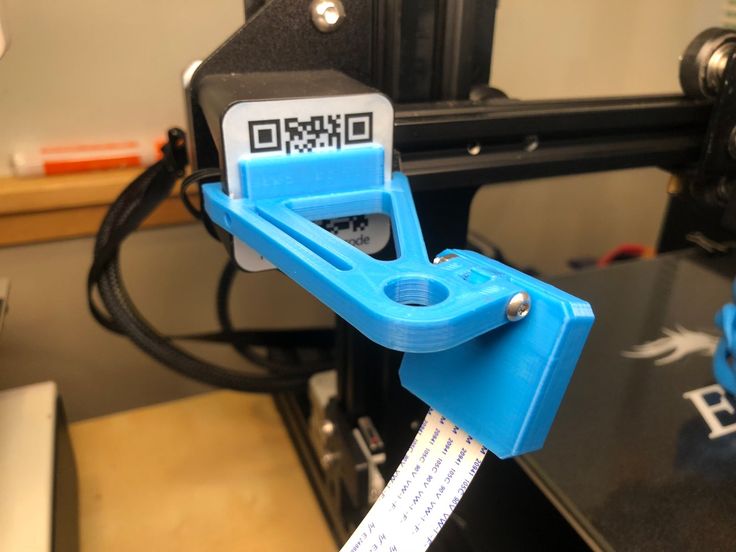

5. Accessibility

3D printing has gained widespread adoption over the past decade. This can be traced back to some key patents held by Stratasys expiring in 2009. The open-source nature of 3D printing since then has allowed for the development of low-cost consumer 3D printing machines. The increased user base allowed for the creation of a large body of easy-to-access online knowledge on best practices, fault finding, and general optimization techniques for 3D printing. This has allowed for unprecedented accessibility that is very rare in other technology spaces.

6. Advanced Medical Care

The adoption of 3D printing in the medical industry has allowed a significant increase in personalized medical care through the development of custom, patient-matched implants, prostheses, and bioprinting of organs. Many biocompatible materials have also been developed for use in the medical industry.

Many biocompatible materials have also been developed for use in the medical industry.

7. Design Flexibility

3D printing has fewer design constraints when compared to other technologies. For example, complex internal voids are not possible with CNC machining and injection molding without having to resort to multi-component assemblies. This adds cost and complexity. With 3D printing, complex parts can be printed just as easily as simple ones. While 3D printing still has a range of DFM (Design for Manufacturing) guidelines, these are, however, not as restrictive as other manufacturing technologies.

8. Waste Reduction

3D printing produces very little waste. This waste is typically in the form of support structures that are removed after printing, in the case of SLS-printed parts. These support structures are optimized to be as lightweight as possible. Subtractive manufacturing techniques require the removal of large volumes of material which produces significant waste. Additive technologies like 3D printing are designed to selectively add material only where needed. This then offsets the minimal waste produced by support structures.

Additive technologies like 3D printing are designed to selectively add material only where needed. This then offsets the minimal waste produced by support structures.

9. Strong and Lightweight Components

3D printing only adds material exactly where needed. For example, internal volumes can be made to have mesh structures that are dense where stress concentrations are high and less dense in areas where they are low. Techniques like topological optimization and generative design also produce parts whose geometry is optimized for a specific load case and remove material wherever it won’t have a structural benefit. These techniques often produce parts with highly complex, organic-style geometries which makes them impossible to manufacture with other technologies.

10. Rapid Design and Manufacturing

Understanding how to design for 3D printing requires familiarity with its DFM requirements. It is less stringent than other fabrication technologies. This makes it easier for engineers to design parts, as they don’t need to consider the wide range of limitations present in other manufacturing technologies. In terms of manufacturing, 3D printing is often quicker, especially for complex parts. Complex parts may need multiple setups on a CNC machine and may also need to be manufactured on multiple machines, whereas 3D printing can complete the entire part in one setup.

In terms of manufacturing, 3D printing is often quicker, especially for complex parts. Complex parts may need multiple setups on a CNC machine and may also need to be manufactured on multiple machines, whereas 3D printing can complete the entire part in one setup.

What Are the Cons of 3D Printing?

The cons of 3D printing are:

1. Post-Processing

Most 3D printed parts require some form of post-processing. Typically post-processing may include support removal, UV-light curing, sintering in a furnace, polishing, and even machining for high-tolerance features like bearing housings.

2. Copyright Concerns

Due to the ease and low cost with which 3D printed objects can be manufactured, it becomes easy to duplicate designs without the original creator's consent. There are millions of freely available designs on the internet that can be easily downloaded and copied without crediting or compensating the original owner of the intellectual property or them ever being aware of it. 3D scanning has also become more accessible, which means that real-world objects can be scanned and then duplicated.

3D scanning has also become more accessible, which means that real-world objects can be scanned and then duplicated.

3. Large Quantities

3D printing has always been a low-to-medium-volume production process. This is mainly due to the layer-by-layer method in which 3D printed objects are manufactured. This problem is further amplified if high-quality parts are desired which require thinner layers to be placed at a time. Some printing technologies, like HP multijet, can utilize the entire volume to print multiple parts. But even so, the cycle time is significantly slower than other more mature manufacturing technologies.

4. Materials are Limited

3D printing is continually adding new materials. However, these are still limited when compared to more mature manufacturing technologies. While it is possible to print parts in many popular plastics and metals, it is not possible to make use of the thousands of alloys and compounds that have been developed. This is simply because these alloys and compounds have not been converted into a form that is compatible with 3D printing.

5. Part Structure

Some 3D printing technologies like FDM and SLS produce parts whose properties are anisotropic. This means that the parts’ performance varies depending on the direction of load applied. Typically, the parts will be weakest on the Z-axis, which is defined as the axis that points up from the 3D printer print bed.

6. Build-Size Restrictions

3D printers have a wide range of build sizes. However, the printers commonly used for production, have build volumes smaller than large-scale manufacturing technologies like: laser cutting, horizontal mills, and metal casting. As such, 3D printing is generally used for small-scale manufacture of complex components. It must be noted that there are exceptions to this rule, as some specialized 3D printers have very large build volumes.

7. Job Cuts in Manufacturing

3D printing is a highly automated technology. The only interaction from a human is: part setup, removal, and post-processing, which can all be typically handled by one person. In fact, one person can easily operate multiple machines. A 3D printer can also produce a part that would typically require multiple machines and, by extension, multiple machine operators. This means that some jobs can be made redundant in cases where 3D printing is applicable. However, this is not a situation unique to 3D printing and is taking place all across the manufacturing sector.

In fact, one person can easily operate multiple machines. A 3D printer can also produce a part that would typically require multiple machines and, by extension, multiple machine operators. This means that some jobs can be made redundant in cases where 3D printing is applicable. However, this is not a situation unique to 3D printing and is taking place all across the manufacturing sector.

8. Inaccuracies in Design

3D printed objects are not known for their accuracy and dimensional stability. Parts may warp during printing. Even the most accurate 3D printers cannot match the accuracy achievable with top-tier CNC machines. CNC machines can repeatedly produce parts with an accuracy of 0.025 mm compared to 0.4 mm with DMLS 3D printing machines.

What Should I Know Before Purchasing a 3D Printer?

When purchasing a 3D printer it is important to understand the intended application. For example, if the goal is to produce visual prototypes, then an FDM printer may be better suited. However, if the need is to produce aerospace-grade parts for high-stress applications then technologies like DMLS would be better.

However, if the need is to produce aerospace-grade parts for high-stress applications then technologies like DMLS would be better.

What Applications Does 3D Printing Have Today?

3D printing applications are varied. It has infiltrated every major industry and has applications in the automotive, aerospace, medical, biotech, and even the food industry. In some cases, 3D printing is used to produce hip joints and in other cases adopts an auxiliary role to add value to existing manufacturing technologies like jigs for CNC machining.

What Applications Will 3D Printing Have in the Future?

3D printing technology will continue to mature. Many of the cons present today may be gone in the next decade. 3D printing is on track to becoming a more mainstream manufacturing technology with a wide range of applications. One of the more exciting advances is the production of patient-specific organs for rejection-free transplants. Another is the production of parts with fluid channels, multiple materials, and various other auxiliary components printed into the part in one go. An example would be the leg of the next generation of the Boston Dynamics Atlas robot.

An example would be the leg of the next generation of the Boston Dynamics Atlas robot.

Is 3D Printing Advantageous?

Yes, 3D printing is advantageous and has found uses in many applications. In cases where it cannot be used to directly manufacture a part, 3D printing finds uses in improving the efficiency of machine and assembly operators.

Summary

This article presented the pros and cons of 3D printing, explained what they are, and discussed how each plays a part in 3D printing in manufacturing. To learn more about 3D printing, contact a Xometry representative.

Xometry provides a wide range of manufacturing capabilities, including 3D printing and other value-added services for all of your prototyping and production needs. Visit our website to learn more or to request a free, no-obligation quote.

Disclaimer

The content appearing on this webpage is for informational purposes only. Xometry makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.

Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by third-party suppliers or manufacturers through Xometry’s network. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.

Team Xometry

This article was written by various Xometry contributors. Xometry is a leading resource on manufacturing with CNC machining, sheet metal fabrication, 3D printing, injection molding, urethane casting, and more.

10 Benefits of a 3D Printer: Save Time and Money

More recently, 3D printing has been viewed as something completely new. The technology was underdeveloped, the hardware was too expensive for widespread use. But only a few years have passed, and the situation has changed radically. Not only did more and more 3D printers begin to appear in stores, but also some enthusiasts began to assemble this equipment themselves.

1. Economy

Although large-scale projects with thousands of 3D printed parts are not cheap, they are still much more profitable than other technologies. Many manufacturers use 3D printing for small runs or for prototyping. Plastic can also be used for injection molding, but casting small batches can require expensive equipment. But even in this case, manufacturers can produce cast 3D parts several times cheaper than using aluminum.

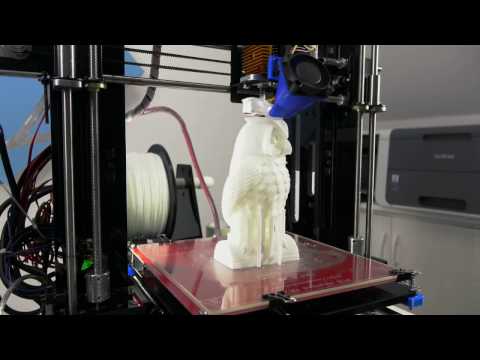

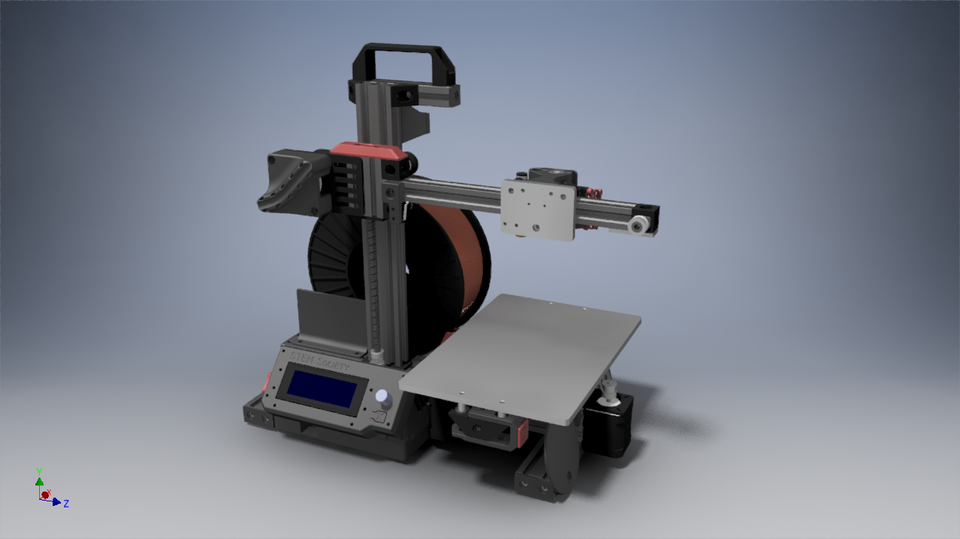

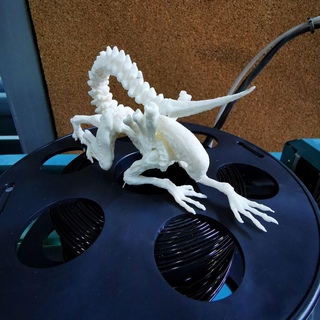

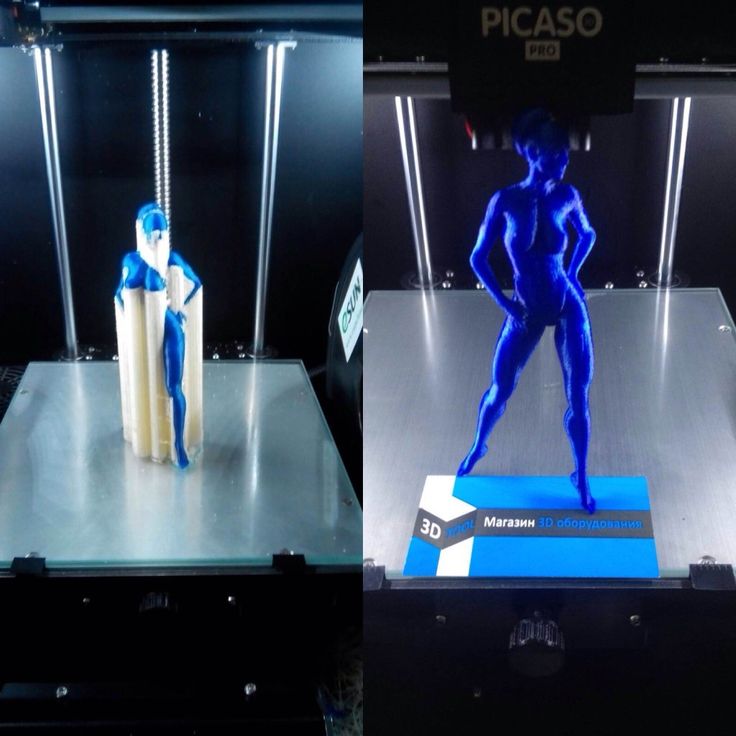

Prototype parts printed on Prusa i3 Bizon 3D printer, layer height 0.1mm, PLA material

2. Faster production cycle

Compared to traditional production methods, the entire process can take weeks or days, and most products are printed in hours. Some manufacturers have even begun to make parts to order, which has also allowed them to optimize their warehouse capacity and resource management scheme, making them more flexible. With this new approach, the manufacturer does not need to store every single part or component, they can simply be printed as needed and immediately put into action.

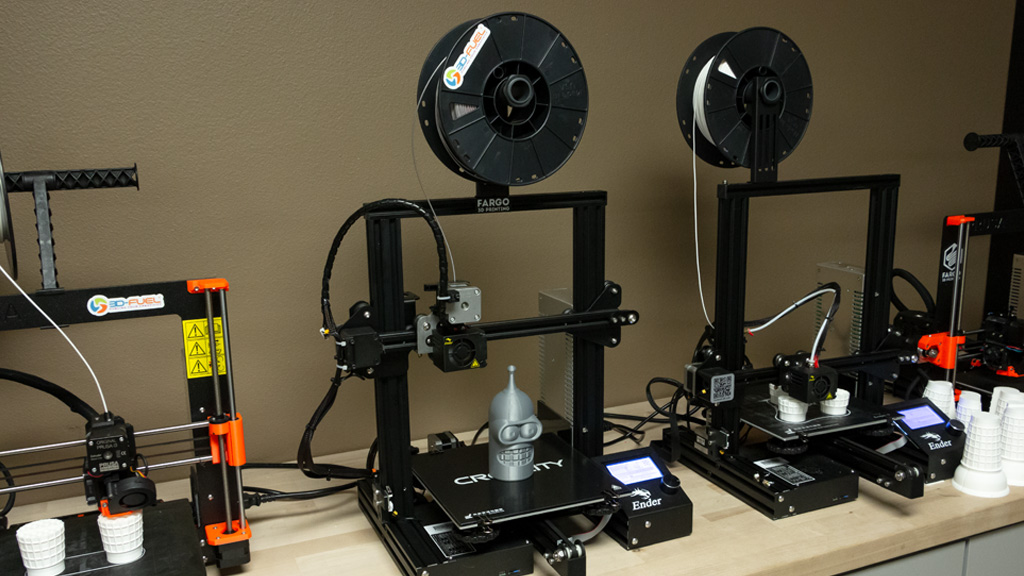

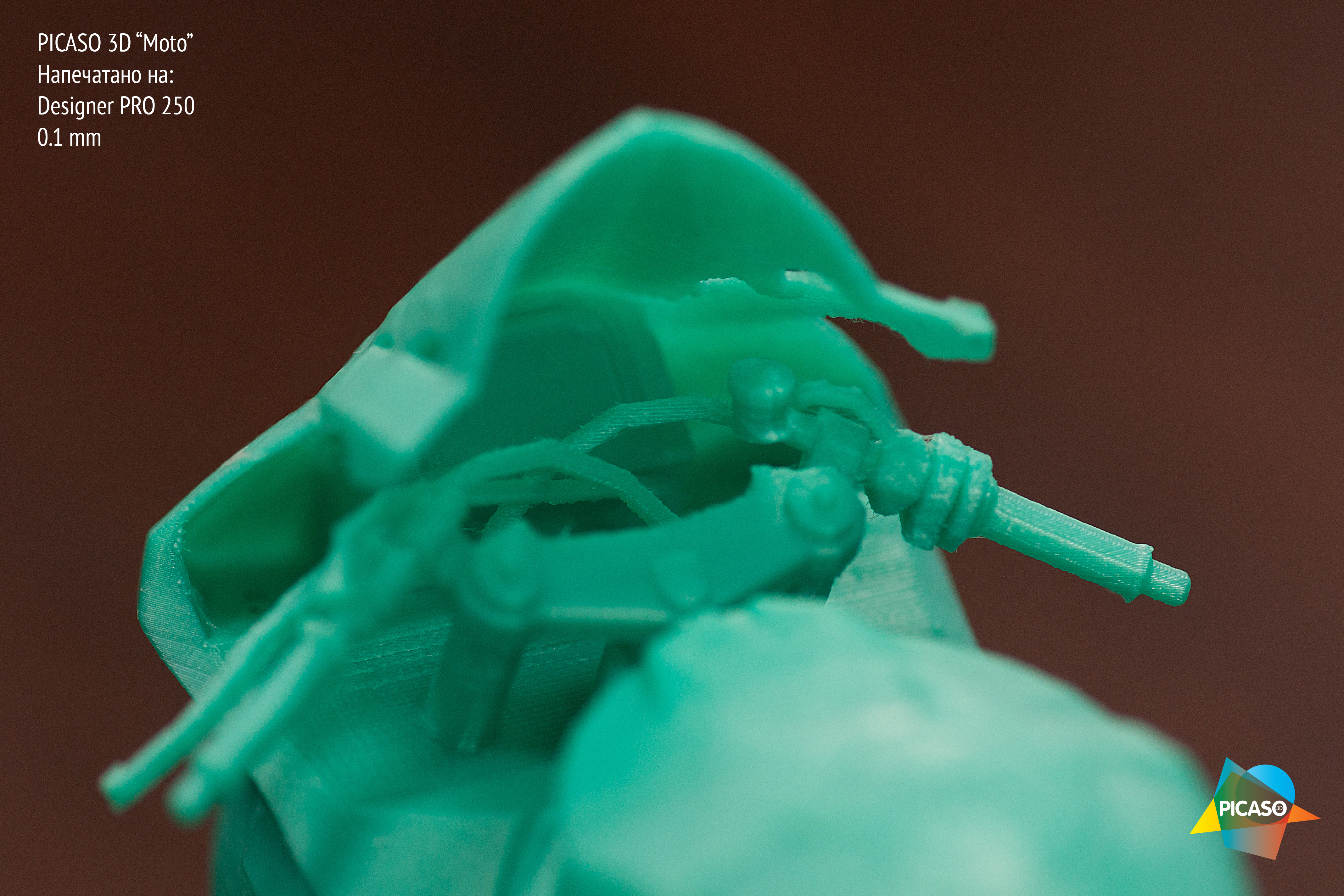

Miniature parts printed by Wanhao Duplicator 7 photopolymer 3D printer, layer height 0.5mm, photopolymer resin material

It not only affects the reputation of the company in its industry, insufficient technical control can lead to injury to employees and customers. Since 3D printing uses a completely different production method than most machine tool operations, the process has significantly fewer weaknesses and flaws overall.

Model printed on Picaso Designer X PRO 3D printer, 0.2 mm layer, ABS materials, HIPS

4. Less waste

The press is gaining more and more support in the form of supporters of the "green" movement. Because 3D printing produces significantly less waste than traditional processing, the technology is more environmentally friendly while reducing costs. 3D printing has even made its way into the textile industry, allowing clothing and prototypes to be printed.

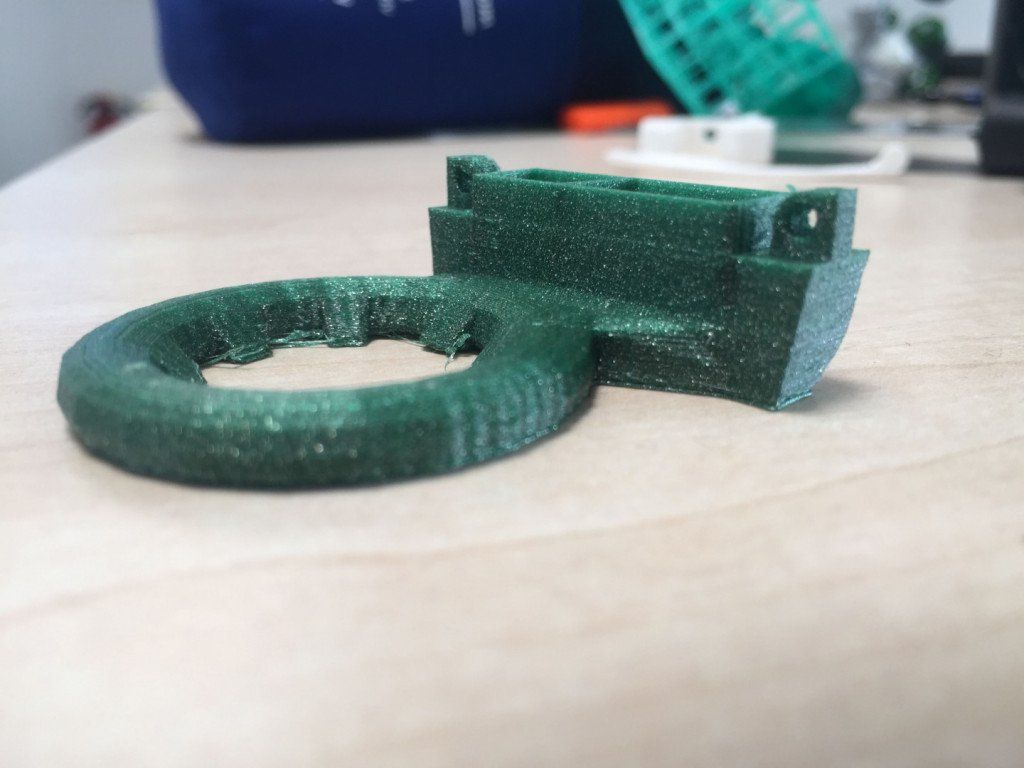

Hercules Strong 3D printed yacht steering parts. Details printed in 15 hours with a 0.5 mm nozzle and a layer height of 0.3 mm at a speed of 60 mm/s.

Details printed in 15 hours with a 0.5 mm nozzle and a layer height of 0.3 mm at a speed of 60 mm/s.

5. Greater customization

3D printed products are also highly customizable. Parts can be printed not only with light plastic, some next-generation models may also have a metal coating. As a result, objects are not only aesthetic, but also functional. In addition, they can acquire thermal and chemical resistance. The existing metallization method can also be used for plastic.

Functional parts printed on Hercules. Material ABS, nozzle diameter 0.5 mm, layer height 150 µm, filling 100%. The model consists of 3 parts: the body and 2 halves of the latch, after printing and processing, the parts were glued together with acetone.

6. Customer Accessibility

If some craftsmen set up small mechanical workshops, for example, in garages, then most of us cannot afford such a luxury. 3D printing allows you to bring a significant part of the manufacturing process directly into the home, made possible by the availability of user-grade 3D technology. While it turns out to be quite expensive for one-off projects, the price of 3D printers and consumables is dropping rapidly.

3D printing allows you to bring a significant part of the manufacturing process directly into the home, made possible by the availability of user-grade 3D technology. While it turns out to be quite expensive for one-off projects, the price of 3D printers and consumables is dropping rapidly.

Technical wing caps in REC RUBBER or REC FLEX. The models are printed on a Prusa i3 Steel 3D printer.

7. High complexity

In most cases, when it comes to complex parts and elements, the manufacturing process imposes certain limitations. Techniques used in casting and finishing objects may not be subtle enough for sophisticated design details. 3D manufacturing processes make it possible to realize almost any design solution, regardless of its complexity, and in a reasonable time. This not only eliminates the extra assembly steps required by traditional methods, but also provides more freedom to create future-proof designs.

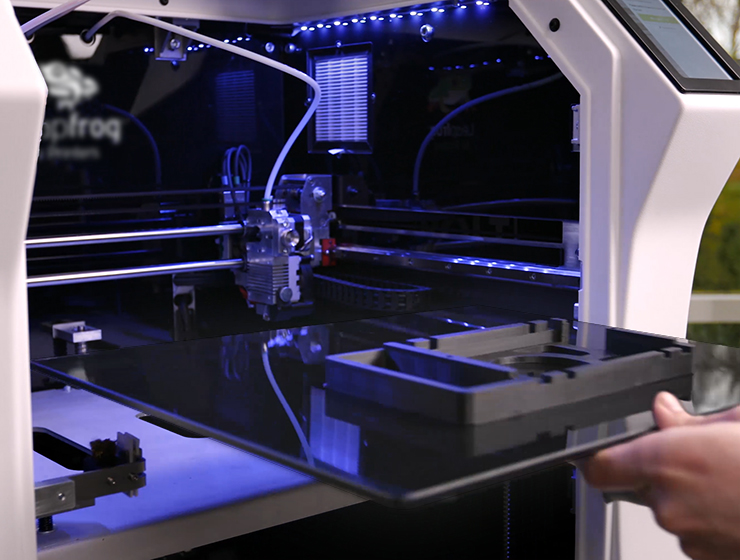

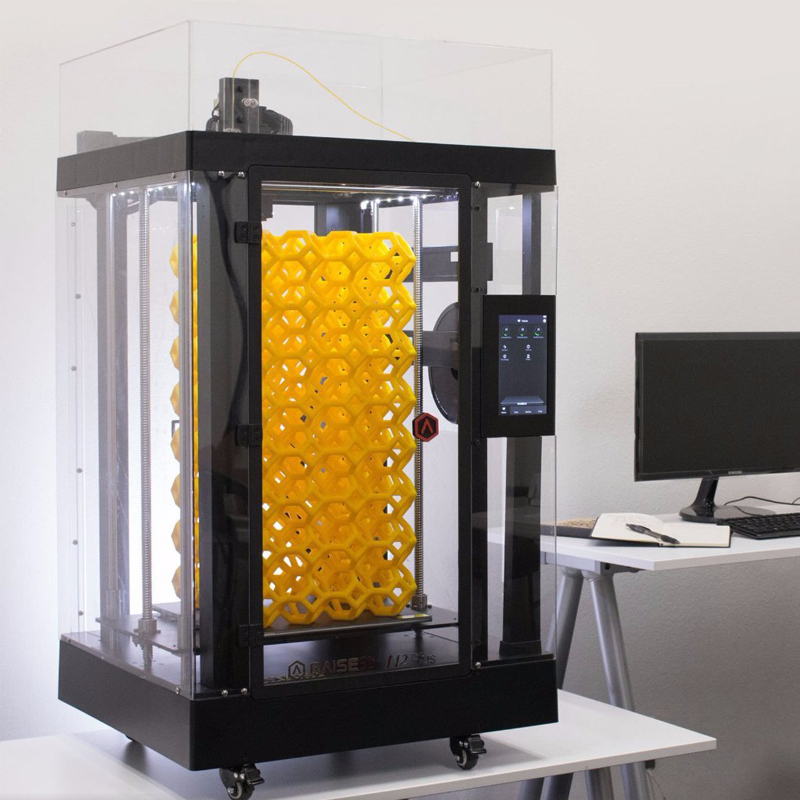

Zenit 3D Printing Big Details From Engine 3D Printer

8.

Less risk

Less risk While there are inherent risks associated with these new technologies, in terms of day-to-day business, 3D printing risks are significantly lower than with traditional manufacturing methods. Not only is 3D printing much cheaper when it comes to testing a new design or product, the printed prototypes themselves can stir up investor and customer interest and get them to decide whether to proceed with mass production of a product, whether it is worth the time and effort required.

Wanhao Duplicator i3 3D Printer Miniature Printing

9. Variety of materials

The materials used in today's 3D printers are much more diverse than most raw materials in traditional production methods. 3D printing also provides the ability to mix different substances, a luxury that is not always available with conventional methods. Although many 3D printer manufacturers offer their own, very limited set of sources, 3D printers can work not only with original materials, allowing you to simulate ceramics, metal, glass and more.

Wanhao D6 3D Printer PEGT, ABS-PC, PLA, SBS

The manufacturer not only needs to clearly understand what the customer wants, the manufacturer must also be able to explain what he himself can. Drawings, diagrams, diagrams are all good, of course, but there is nothing better than a real prototype that you can hold, look at and study. The fact that the materials are inexpensive, coupled with the short prototyping time on today's 3D printers, helps a lot during the prototyping phase, keeping all stakeholders connected.

THE PAST, PRESENT AND FUTURE OF 3D PRINTING

Despite a relatively slow start, the concept of 3D printing is finally gaining momentum and popularity among manufacturers and customers. We already see a lot of benefits of 3D printing, including shorter production cycles, more complex designs and improved quality, and the peak of the popularity and functionality of this technology is yet to come.

3D printer advantages and disadvantages

If you ask any owner of a 3D printer what the main advantage of his device is, he will start talking about high quality printing and the ability to make any prototypes. When asked about the shortcomings, the answer is usually about some shortcomings in the design of the printer: someone is not satisfied with an insufficiently rigid frame, some complain about too slow printing rates. In the article, we understand what advantages most 3D printers have and find out what disadvantages their owners have to face.

When asked about the shortcomings, the answer is usually about some shortcomings in the design of the printer: someone is not satisfied with an insufficiently rigid frame, some complain about too slow printing rates. In the article, we understand what advantages most 3D printers have and find out what disadvantages their owners have to face.

Despite a relatively slow start, additive technologies are finally gaining momentum. Now 3D printers have gained well-deserved popularity both in the user environment and in the field of production. We have already appreciated the many benefits of 3D printing, including the ability to print complex models, but the peak of popularity and functionality of 3D technologies is yet to come. We talk about the main advantages and disadvantages of 3D printers.

Benefits of 3D printers

Let's start with the benefits: 3D printing allows you to quickly and relatively inexpensively produce the desired prototypes with high accuracy, independently adjusting the printer settings and choosing the optimal parameters. Let's dwell on each plus of 3D printers in more detail.

Let's dwell on each plus of 3D printers in more detail.

Value - speed of production

3D printers can significantly reduce the time spent on each project. Unlike traditional manufacturing methods, when using additive technologies, the entire printing process will take from several weeks or days, and the bulk of the models can be printed in a matter of hours. Some manufacturers have decided to optimize their inventory by starting to make parts to order. This approach allows you to take mass production to a new level: now you do not need to store a lot of parts in stock, because you can simply print them as needed, immediately sending them to sale.

Advantage - cost of production

Large-scale projects with a large number of 3D printed parts are not cheap, but additive manufacturing still remains more profitable than traditional technologies. Many manufacturers use 3D printing for short runs or prototyping. For example, it is much more profitable for jewelers to print wax prototypes of jewelry than to cast them from metal. The plastic used in 3D printing is relatively inexpensive, and even the simplest printer can help save money.

The plastic used in 3D printing is relatively inexpensive, and even the simplest printer can help save money.

Product quality

Modern 3D printers demonstrate high product quality. In our opinion, the quality depends on the following characteristics of the device:

- Photopolymer printing. This technology allows you to get the highest possible quality of the finished product.

- FDM technology. Despite the fact that FDM printers are in demand, they simply cannot create detail above 100 microns.

- Metal body. When choosing FDM printers, you should give preference to models whose body is made of metal. Such printers demonstrate the best quality of products at high print speeds.

- Regardless of which printer model is chosen, the finished product printed at low speed and quality materials is almost the same as that produced on high speed equipment.

Thus, it is possible to achieve decent print quality on inexpensive printers using high-quality filament at low speeds.

Copy Accuracy

3D Printing Accuracy is the minimum layer height allowed. Modern devices can produce high quality down to 20 microns, but in order to actually obtain prototypes of such accuracy, the user will need to meet certain conditions.

First of all, the accuracy of the finished copies depends on the 3D printer itself - on its technical characteristics, layout, etc. You should not rely only on the layer height value that is indicated in the device description.

The accuracy of prototypes depends on many factors. For example, printers made in a closed case are able to produce much better model accuracy than their counterparts in an open case, due to the uniform temperature regime inside the printer.

In addition, it is required to correctly set all print settings, monitor the calibration of the table, the operating conditions of the device, and the temperature regime. High-quality plastic plays an important role in the accuracy of the copies made.

Production flexibility

The introduction of 3D printing in various areas of production is due to the fact that the technology makes it possible to create geometric shapes of almost any size and unlimited complexity.

Printers print with a wide variety of materials, making the production process as flexible as possible. For example, on the same device, you can create both waxes for jewelers and dentures for dentists. Such versatility cannot be achieved using standard production equipment. 3D printers open up new horizons and prospects for the development of their own business and additive technologies for engineers, designers and device owners.

Availability

The availability of 3D printing makes it possible to experiment using printers both at home and at work. Even the most inexpensive 3D printer can be used in architecture, construction, small-scale production, medicine, education, jewelry, printing, souvenirs, and advertising. A standard spool of filament will last for a long time, and almost everyone can afford to buy a 3D printer. One of the most budget models costs about $100.

A standard spool of filament will last for a long time, and almost everyone can afford to buy a 3D printer. One of the most budget models costs about $100.

Any technique has its downsides, and 3D printers are no exception. Therefore, today additive technology has a certain number of significant drawbacks.

Minus - the small size of the camera

Perhaps the most significant drawback of printers are the small size of the print area. Look at any 3D printer, evaluate its dimensions - that's it, everything is limited to them. The device can only print the model that will fit on its platform. If you need to create a larger prototype, you will have to resort to various tricks: for example, you can print the model in parts, and then assemble them in some way. Despite the fact that there is already a prototype of a 3D printer with an unlimited size of the working platform, it is not yet possible to talk about the mass introduction of such a technology.

Minus - inaccuracies of the part

It is impossible to completely get rid of thermal contraction or shrinkage of the finished model. This is a physical process - you can only compensate for it. The layers floated, the vertical is not observed, the layers do not lie exactly on top of each other. The protrusions on the top layer of the part can be either open or closed. Essentially, this is due to the sagging of the plastic, which does not have time to cool when printed in the air without supports.

This is a physical process - you can only compensate for it. The layers floated, the vertical is not observed, the layers do not lie exactly on top of each other. The protrusions on the top layer of the part can be either open or closed. Essentially, this is due to the sagging of the plastic, which does not have time to cool when printed in the air without supports.

Disadvantage - post-processing

Most finished products printed on a 3D printer require post-processing and cleaning. The process helps to achieve the best look and smoothness of the model. Finished models are processed in various ways. Users grind parts, chemically process them, cut supports, dry products. The need for post-treatment depends on many factors. For example, the scope of work varies depending on the size of the model, the material, the type of technology chosen in the manufacture of the prototype. Thus, given that 3D printing allows fast production of parts, the speed of production can be reduced through subsequent post-processing.

Strength properties of models

As a rule, the production of a three-dimensional model using additive technologies occurs by layer-by-layer application of a filament. Despite the fact that the layers are well glued together, this is not a guarantee of the perfect solidity of the finished product, and it can delaminate under certain loads. This problem is especially common when using FDM printers. Experienced users advise using injection molding to improve the strength properties of parts. Using this method, the structure of the finished part is more uniform and less brittle.

3D printers are not user-friendly

Manufacturers claim that 3D printers are easy to use. Some companies produce devices specifically for beginners. However, even for the initial assembly and preparation of the printer for operation, the user will need certain skills. Calibrating the desktop on your own, setting up the slicer program, and setting the desired print settings is not as easy as the manufacturers assure. Some models are delivered already assembled - we advise you to choose them as your first printer.

Some models are delivered already assembled - we advise you to choose them as your first printer.

Harmful emissions

The size of the device and the amount of thermoplastic produced by the printer significantly affect the amount of harmful aerosol emissions into the atmosphere. The chemicals settle in our lungs and also contribute to the increase in the size of the ozone hole. A team of researchers led by Professor Brent Stevens conducted their own experiment, which tested five models of 3D printers. As a result, scientists were able to calculate the concentration of nanometer particles that are formed during the 3D printing process.

The results of the experiment did not please either printer manufacturers or device owners and users. The fact is that 3D printers using polylactic acid (PLA) in printing have demonstrated extremely high levels of ultrafine particles - from 20 billion per minute. Acrylonitrile butadiene styrene (ABS)-powered gadgets emit up to 200 billion particles per minute into the atmosphere.

Scientists have stated that harmful emissions in such quantities are similar to emissions into the atmosphere from burning tobacco or scented candles, burning natural gas. In addition, when using a laser printer using powder as a printing material, no less harmful emissions are produced.

Slow

3D printers are actually very slow. Some manufacturers claim high print speeds, but this figure is relative. Especially when it comes to making a lot of prototypes. Many users who own budget printers leave them running all night to have a small finished model by morning. Depending on the dimensions and quality of the printed product, the process may be delayed. On average, the process of creating a model can take from several hours to several days. The duration is directly proportional to the size of the object: the larger the future prototype, the more time it will take to print.

Environmental pollution

Waste plastic by-products of additive printing have long been of interest to conservationists. Production waste ends up in landfills, creating a negative additional burden on the environment. Scientists believe that the ABS plastic used in most 3D printers is quite toxic. This type of filament has a long period of decomposition in the soil. However, ABS is the most common type of material used in additive printing. PLA is a greener alternative to ABS. This material is more biodegradable and less toxic. The problem of environmental pollution can be solved with the spread of household plastic convertors into 3D printing filament.

Production waste ends up in landfills, creating a negative additional burden on the environment. Scientists believe that the ABS plastic used in most 3D printers is quite toxic. This type of filament has a long period of decomposition in the soil. However, ABS is the most common type of material used in additive printing. PLA is a greener alternative to ABS. This material is more biodegradable and less toxic. The problem of environmental pollution can be solved with the spread of household plastic convertors into 3D printing filament.

Three-dimensional printers open up a wide range of possibilities for their owners. The list of advantages of such devices is endless, but we have chosen only the main ones. In our opinion, one of the main advantages of 3D printers is their affordability. Finished models are of sufficient quality even on budget models. The main thing is that the user sets the correct settings and fills the printer with good material.

But 3D printers also have their drawbacks.