3D printer wanted

4,000+ 3d Printing jobs in United States (198 new)

Skip to main content

-

Past 24 hours (198)

Past Week (834)

Past Month (2,480)

Any Time (4,076)

-

Concorde Education (4)

Prototek - Rapid Prototyping & Low-Volume Production (3)

Milestone Technologies, Inc. (3)

InProduction (2)

Advanced Energy Engineering & Design (2)

-

$40,000+ (591)

$60,000+ (559)

$80,000+ (504)

$100,000+ (438)

$120,000+ (387)

-

New York, NY (52)

Miami, FL (13)

Chattanooga, TN (7)

Mesa, AZ (7)

Springfield, MO (5)

-

Full-time (3,351)

Part-time (144)

Contract (145)

Temporary (71)

Volunteer (4)

-

Internship (558)

Entry level (1,578)

Associate (145)

Mid-Senior level (1,184)

Director (102)

-

On-site (3,524)

Hybrid (434)

Remote (106)

Get notified about new 3d Printing jobs in United States.

Sign in to create job alert

You've viewed all jobs for this search

9 Great 3D Printing Jobs

- 3D printing is a technology that creates a three-dimensional object using a computer-aided design (CAD).

- The 3D printing industry is rapidly growing thanks to its ability to create a wide range of versatile products in a fast, cost-effective way.

- For job seekers, the 3D printing industry offers some cool jobs on the cutting edge of the technology.

- This article is for professionals and entrepreneurs who want to work in the 3D printing industry.

President Barack Obama once said 3D printing has the “potential to revolutionize the way we make almost everything.” For that reason, the 3D printing industry was valued at $13.78 billion in 2020. And market research projections suggest it will continue its meteoric growth through 2028 – when it is expected to reach an estimated $59.65 billion.

As the 3D printing industry booms, what does it mean for job seekers? Here are 9 opportunities that will be created or get a boost from 3D printing.

What is 3D printing?

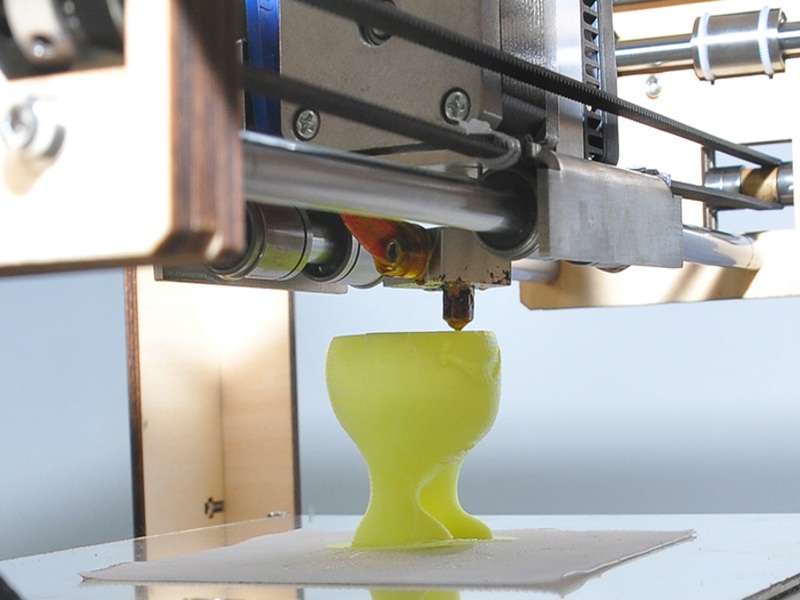

Rather than using ink and paper, a 3D printer uses materials like plastic, metal or ceramic to create a 3D model. By using computer-aided design (CAD) files as digital instructions to create an object, a 3D printer repeatedly covers a work surface with layers of material in precisely the right spots to create a structure from scratch.

By using computer-aided design (CAD) files as digital instructions to create an object, a 3D printer repeatedly covers a work surface with layers of material in precisely the right spots to create a structure from scratch.

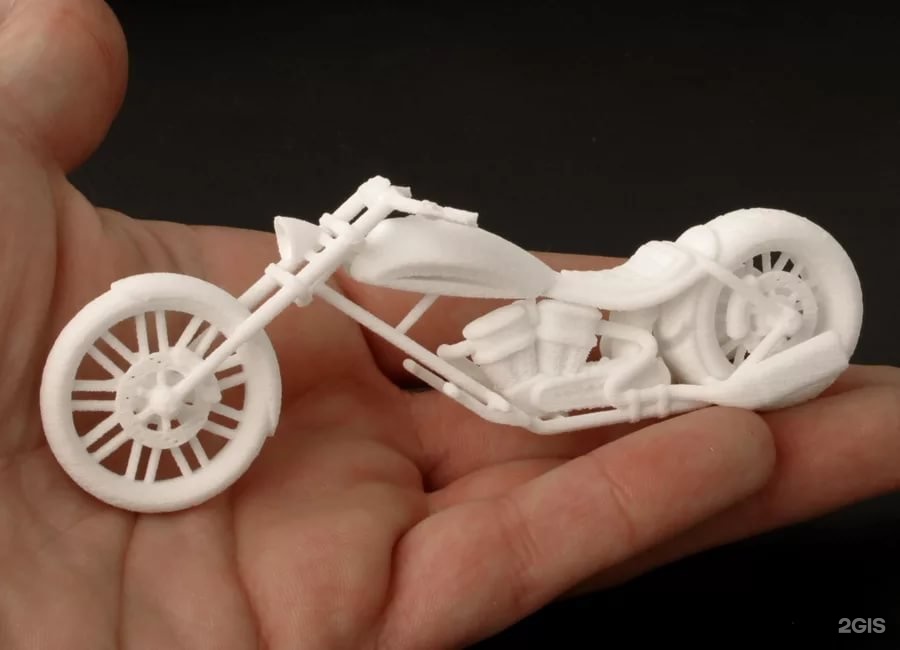

While 3D printing can be used for large-scale structures, 3D printing is most useful in creating smaller, customized parts or prototype components for various uses – including automotive engineering or the medical industry. With the versatility of 3D printing, it’s a field that’s filled with opportunities. Let’s take a look at some of the areas 3D printing is being used today.

3D printing jobs

1. 3D design

3D printing relies heavily on designers who can take a product idea and bring it to life. Thanks to its growth, 3D printing will create jobs for 3D designers at 3D printing firms, in companies as part of creative teams and as freelancers.

3D printers are being used in many design disciplines – such as product design, medical device design, architectural visualization and entertainment design, said Erol Gunduz, a professor at New York University’s School of Continuing and Professional Studies (NYU-SCPS), which offers programs in 3D printing, design and modeling.

To be competitive, job seekers should gain hands-on experience in 3D technologies and stay current on how companies are using 3D printing. For instance, recent graduate student designers and researchers who are familiar with 3D printing methods have the benefit of knowing how to use the technology within their design process, Gunduz explains.

“This gives them a significant advantage when looking for career opportunities within creative fields,” Gunduz said.

3D printers can create replacement parts for the human body, among the many things that 3D printers make.

2. 3D CAD modeling

3D printing would not be possible without CAD experts who have the skills to convert product designs into digital blueprints that the printers need. Along with product designers, there will be a demand for 3D CAD modelers.

“I see a lot more demand for CAD and 3D modeling jobs on the horizon because of 3D printing,” said Alex English, owner of ProtoParadigm. ProtoParadigm is a 3D printing business that also performs research and development on 3D printing hardware and new printing materials.

Although 3D CAD professionals are also needed to construct models for mass 3D printing, they are especially important for custom products.

“Bespoke manufacturing and custom prototyping both rely on the user’s ability to conceptualize the object they want and accurately create its digital representation,” English said.

Consequently, 3D CAD modeling jobs will require printing-specific modeling skills, such as feature size, geometrical constraints and knowledge of materials, English added.

3. Research and development

3D printing is all the buzz – and not just in the gadget world. Just as the 3D printing industry will require more product designers and CAD modelers, jobs will open up for forward-thinking research and development professionals who understand the intersection of tech and consumer products.

“While 3D visualization technologies have been used in the past within various fields, such as engineering and scientific agendas, many artistic and consumer product industries – such as fashion design and jewelry design – are beginning to take advantage of 3D printing systems,” Gunduz said.

Companies will need people who can find the best way to utilize 3D printing for consumer products at the lowest cost possible.

“The ability to visualize a line of fashion accessories or jewelry designs before committing to working with expensive materials affords an advantage for companies to reduce costs in development cycles,” Gunduz said.

Is your business experimenting with 3D printing research and development? Consider these tax credits that are available to companies performing cutting-edge research.

4. Biological and scientific modeling

3D printing is not limited to consumer products; it creates many products that promote medical advancement and save lives. It can also create drone and defense equipment, and possibly even space food.

Accordingly, the 3D printing industry will need more engineers, designers and modelers who have a biomedical or scientific background to further innovate and produce highly advanced 3D-printed products.

“While all manner of designers will be able to print the things they design, there will be a high end to the market – particularly in medical, aerospace, military, and other high-precision or mission-critical applications – for those that better understand the printing technologies and how to design for their strengths and limitations,” English said.

5. Architecture and construction modeling

3D printing will disrupt various industries, particularly those that rely heavily on blueprinting or prototyping. For the construction industry, this paradigm shift will boost the need for 3D modelers that may replace current 2D construction planning solutions.

“In the architecture, engineering and construction industries, 3D printing will redefine the production of construction documents,” said Lira Luis, chief collaboration architect at Atelier Lira Luis LLC, a Chicago-based architecture and design firm.

Instead of 2D CAD modeling on paper, 3D printing can produce true-to-life models to better represent what structures will look like.

“As the 3D printing process becomes more streamlined, it could potentially eliminate the need for construction documents and move directly to printing full-scale mock-ups prior to construction of structures,” Luis said.

6. Education

What good are these jobs if no one has the qualifications to fill them? To help fill the skills gap, schools are developing – and some have already launched – 3D printing programs at all grade levels. This will open up jobs for educators who can teach the technical and business aspects of 3D printing.

This will open up jobs for educators who can teach the technical and business aspects of 3D printing.

“From an educational perspective, many K-12 schools are looking to 3D printing as a point of exposure for students within the arts as well as scientific areas of study,” Gunduz said. Colleges and universities are also launching 3D printing courses and certificate programs, such as NYU-SCPS’ certificate in 3D printing rapid prototyping.

Teachers will need to have a background in the 3D printing industry. They will also need specific skill sets to teach specialized courses and stay current on the latest trends.

“For educators, having an understanding of 3D modeling and 3D printing techniques will be invaluable, as the culture of fab labs is starting to gain support as an important aspect of education,” Gunduz said. “Teachers with 3D modeling and fabrication experience have a range of opportunities open to them within educational programs looking to incorporate this new technology. ”

”

7. Legal professionals

3D printing is not confined to the tech world. As a creative field, the industry is wide open to legal issues, prompting a need for more lawyers and legal professionals who specialize in intellectual property (IP) rights.

“As 3D printing technologies advance and become more widely accessible, it will be easier for infringers to create, market, and sell products that infringe patents, copyrights, and valuable brands,” said Julie Matthews, partner at Edwards Wildman – an Am Law 100 firm with offices in the U.S., the U.K. and Asia. “As 3D printing technologies advance, new business models will emerge in which consumer products and their component parts can be copied, modified, juxtaposed with others and produced almost anywhere.”

As a result, there will be an increased need for IP enforcement actions and lawsuits, as well as expanded services to monitor for infringements, Matthews explained.

Growth areas include IP ownership, scope of rights, licensing, fair use and international rights.

8. Startup companies

Thinking of starting a new business? 3D printing offers opportunities for innovation – not only in creating products, but also for entrepreneurship. 3D printing spans across various technical and design roles, many of which make great business ideas to support companies’ 3D printing needs.

“As 3D printing technologies advance and become readily accessible to home users, undoubtedly, this will lead to new business opportunities for individuals and companies offering onsite and remote 3D printing services, new product and industrial designers, and computer-aided design specialists,” Matthews said.

With 3D printing costing between $1,999 and $3,500, anyone with 3D printing knowledge can start their business.

Consider a 3D-printing-as-a-service franchise for your new business venture.

9. Administrative roles

3D printing companies don’t run on engineers and technicians alone. As the industry grows, new and established 3D printing companies will need employees to keep their business running smoothly. This includes operations and administrative staff, analysts, finance and sales professionals, and retail employees.

This includes operations and administrative staff, analysts, finance and sales professionals, and retail employees.

“The businesses that will spring up with new business models centered on 3D printing will also have a need for more common jobs that other businesses need, like marketing, clerical, shipping, etc.,” English said.

These jobs will open up in all types of 3D printing companies, including vendors, manufacturers and retail stores.

Business News Daily editorial staff contributed to the writing and reporting in this article. Source interviews were conducted for a previous version of this article.

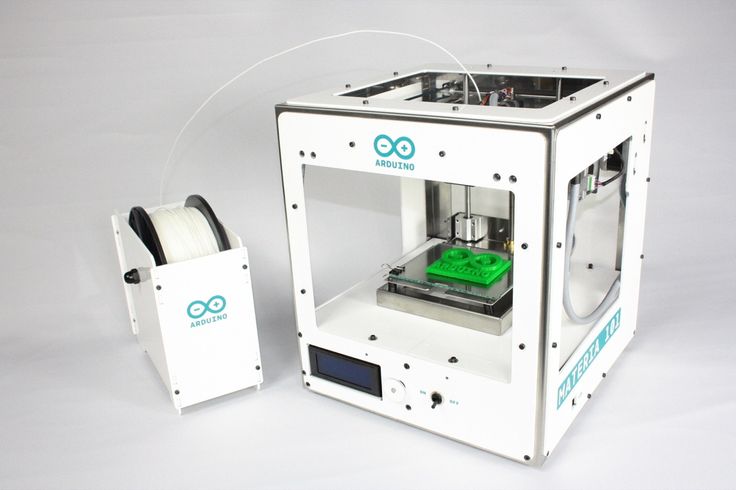

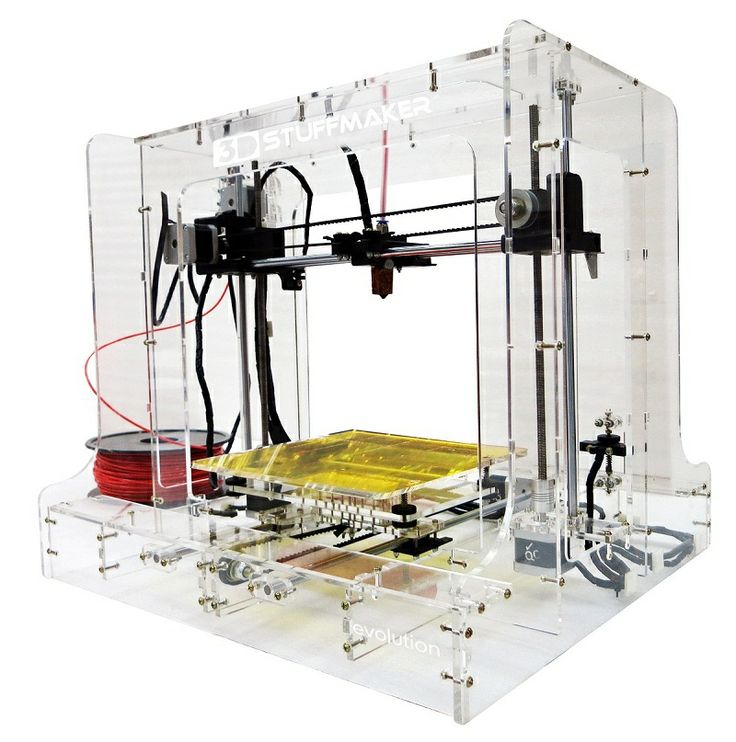

What is a 3D printer and why is it needed? / Amperka

Additive technologies have been going to the masses for a long time: institutes and research centers have been closely involved in them since the 80s, and now the moment has come when you can touch high-tech and master 3D printing right at home. You don’t even have to break the bank to do this: the prices of 3D printers have caught up with average smartphones. We understand how it works and what opportunities open up for makers and DIY enthusiasts!

We understand how it works and what opportunities open up for makers and DIY enthusiasts!

Everything for 3D printing ❯

Why you need a 3D printer

The printer is very useful for do-it-yourself engineers. You no longer have to look for a universal case for the project, and then drill additional holes in it. 30 minutes of design, a few hours of printing - and you already have a case that is perfect for your device. Assembly of 5 shields does not fit anywhere? Forget about such problems.

The printer is sure to help you repair gizmos around the house. Everyone has had a situation in life when a thing had to be thrown away, although only one plastic part was broken in it. With the help of 3D printing, you can easily replace rare plastic parts in appliances that are difficult to find separately.

Until you learn how to model plastic parts yourself, you can simply download them on the Internet. There are many sites with millions of ready-made free models that are freely exchanged by users. We devoted a separate article to the search for models.

We devoted a separate article to the search for models.

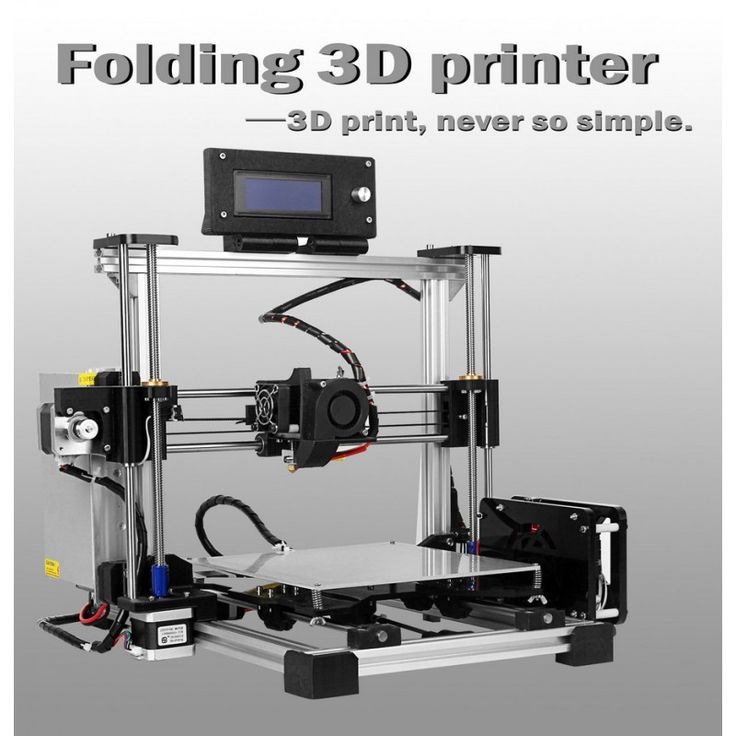

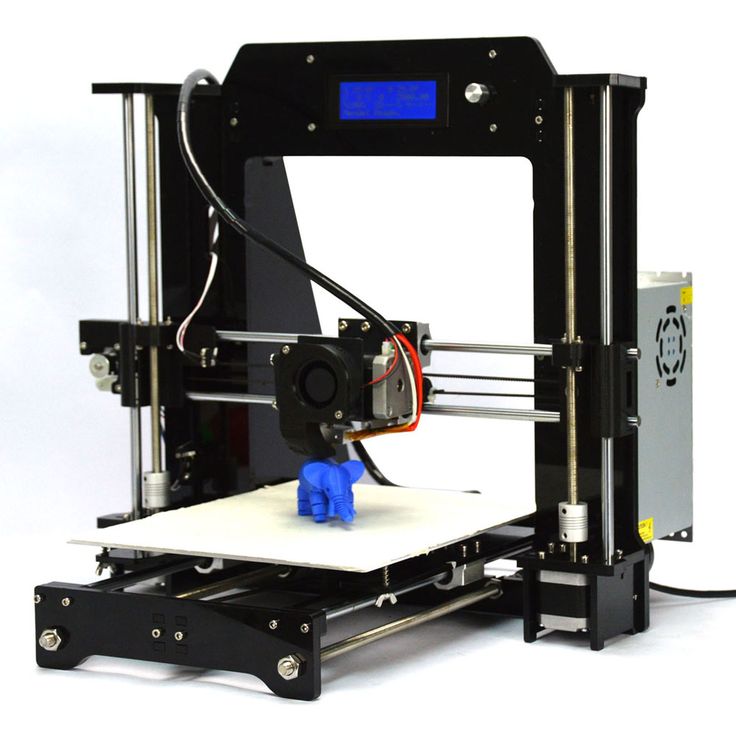

Types of 3D printers

There are several main types of 3D printers that differ fundamentally in terms of how they work.

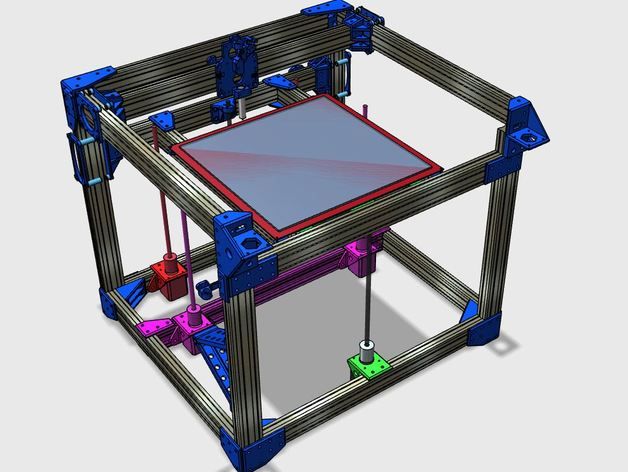

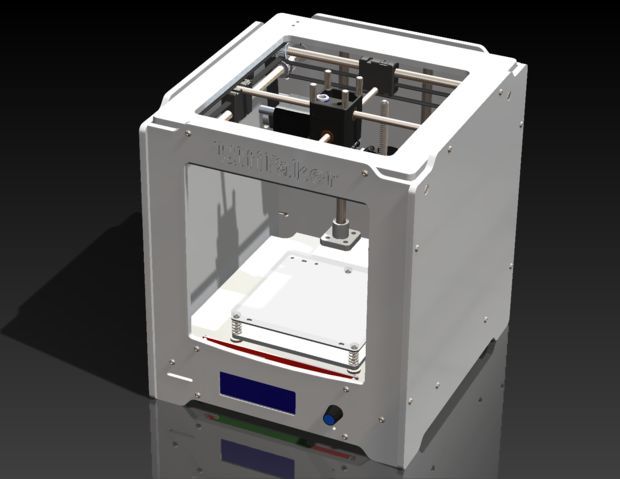

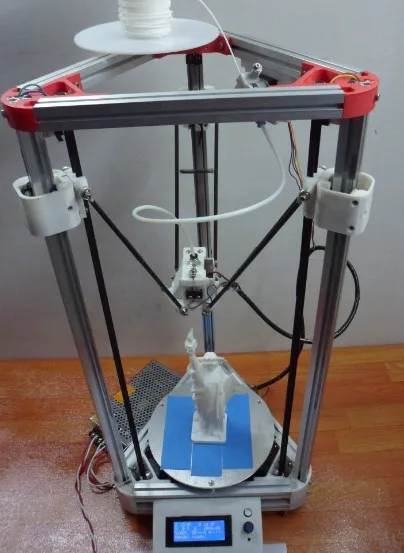

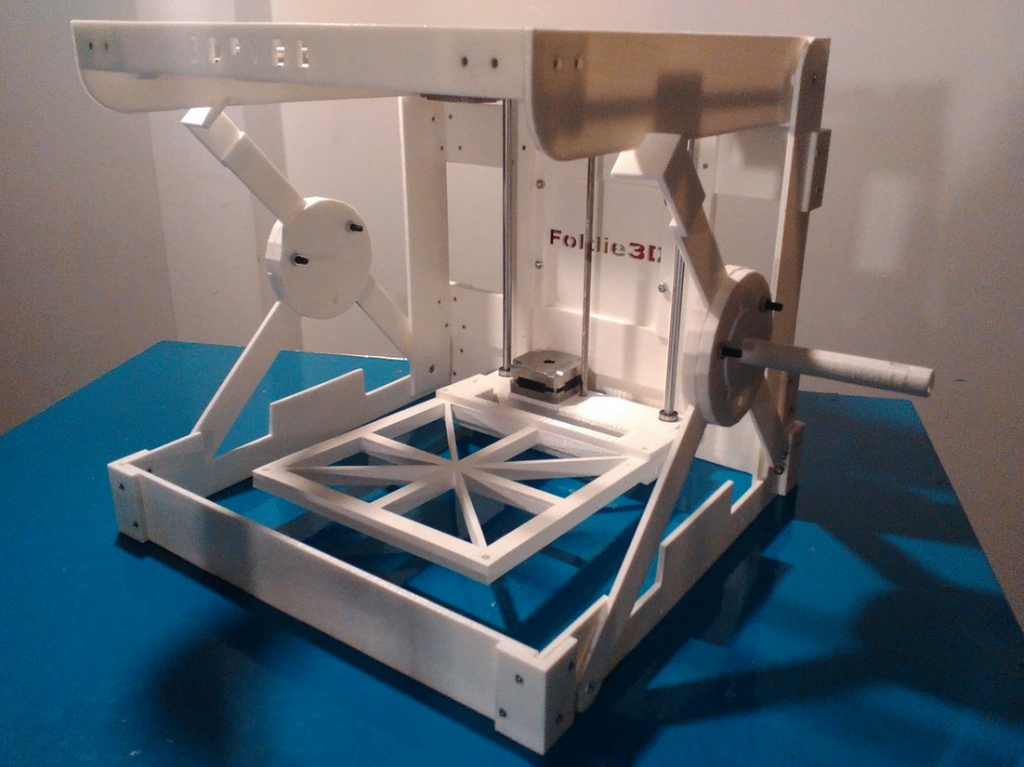

FDM (Fused Deposition Modeling)

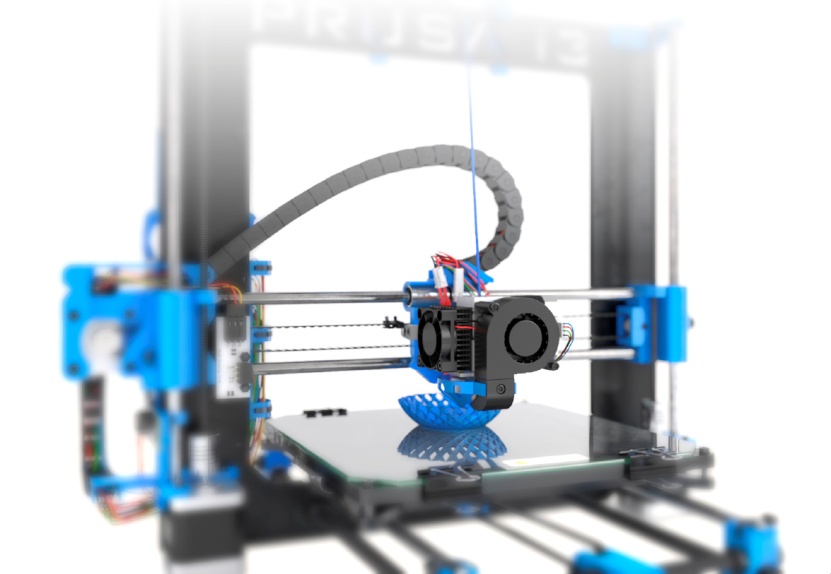

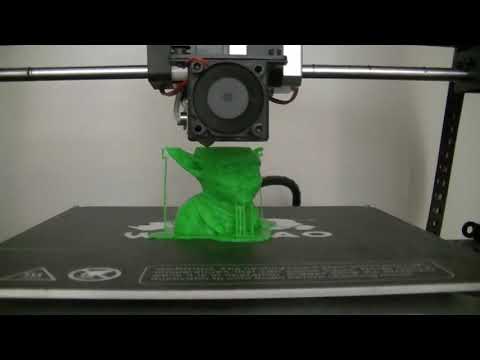

FDM printers are the most common type. They work due to a movable print head with a heating element. Plastic is fed into it in the form of a rod, which melts and is squeezed out in liquid form onto the printing table. At the same time, the plastic is blown by a fan and instantly freezes, and the head begins to squeeze out a new layer over the frozen one.

SLA technology (Stereolithography Apparatus)

SLA printers work on the basis of stereolithography: instead of plastic, a special photopolymer resin is used, which cures under the influence of ultraviolet rays. For printing, the resin is filled into a tray, below which there is a display with ultraviolet pixels. A drawing of the lower layer of the model is displayed on it for several seconds. In this case, the resin above the display solidifies in the form of a displayed pattern and then sticks to a special movable table from above. After that, the table with the first layer rises, and the next layer polymerizes in the resin.

In this case, the resin above the display solidifies in the form of a displayed pattern and then sticks to a special movable table from above. After that, the table with the first layer rises, and the next layer polymerizes in the resin.

SLS (Selective Laser Sintering) Technology

SLS printers use selective laser sintering technology, which uses a special plastic powder. During the printing process, a thin layer of powder is poured, and the printer processes it with a laser so that the layer hardens according to the model. Then the next layer of powder is poured and fused with the previous one - and so on in a circle. At the end, it remains only to clean the finished part from the remnants of the powder, which can then be reused.

Technology comparison

Each type of 3D printer has its advantages and disadvantages.

- SLS printers are large and require expensive raw materials. They are often used in high-tech industries for piece parts.

- SLA printers are much more widespread. The UV display improves accuracy, but working with toxic photopolymer resin at home is difficult.

- FDM printers are the most popular among hobbyists. A plastic rod is much cheaper than a special powder or photopolymer resin. However, to print complex geometry on such a printer, you will have to take care of auxiliary support. And the print speed is on average lower than on other technologies. But FDM printers are the easiest and safest to maintain.

How to prepare a print

The process from the conception of an idea to the production of a finished plastic part is simple - a schoolboy can handle it. We've broken it down in a 3D printing guide using the Flying Bear Ghost 5 printer as an example, but here we'll show you the general principle.

Initial model

First you need to create or download a 3D model of the future part. As a rule, sources are stored in the STL format, which describes the polygonal structure of the model as a set of triangles. But it will not be possible to immediately send such a file to the printer: for successful printing, you first need to break a detailed 3D model into layers that the printer can handle.

But it will not be possible to immediately send such a file to the printer: for successful printing, you first need to break a detailed 3D model into layers that the printer can handle.

Slicing

The program for cutting models (slicer) will require you to enter the model of your printer and set the print settings: layer thickness, percentage of internal filling of the part, auxiliary supports and the like. Based on this data, the slicer will automatically prepare a special code for the printer - G-Code, which describes how to move the print head, to what temperature it should be heated, and at what speed to extrude plastic in order to get the desired model layer by layer. Then it remains to load this code into a 3D printer and be patient until the end of printing.

The whole process of model preparation is clearly illustrated by the program and provided with intuitive tips for novice users. In general, slicing is not as scary as it is painted!

Finishing

After the model is ready, it can be further processed with sandpaper or a chemical solution. This will smooth out the unevenness between the layers, and the part will look just like the factory. There are a lot of life hacks on the Internet that will help minimize the flaws of the model and give it an improved look.

This will smooth out the unevenness between the layers, and the part will look just like the factory. There are a lot of life hacks on the Internet that will help minimize the flaws of the model and give it an improved look.

Printing consumables

The properties of the printed item largely depend on the raw material. As we said before, FDM 3D printers use plastic filament as a consumable, and you have a lot of room to experiment with different types of plastic.

- PLA is highly extrudable and allows complex shapes to be printed at relatively low head operating temperatures of 190°C. The biodegradability of PLA plays into the hands of the environment, but at the same time, things from it are not very durable.

- PETG plastic is stronger than PLA, but also well suited for printers with temperatures around 200 °C. Varieties of PET plastic are well known to you from bags and plastic soda bottles.

- ABS plastic is more durable than other types.

However, your printer will need an elevated extrusion temperature of around 250°C and a heated bed up to 120°C to print quality ABS plastic, so not every model aims to support it.

However, your printer will need an elevated extrusion temperature of around 250°C and a heated bed up to 120°C to print quality ABS plastic, so not every model aims to support it. - HIPS plastic is close in temperature properties to ABS, but has low caking with it and is easily removed with an organic solvent. Because of this, HIPS plastic is often used for printing composite models and supports for ABS models.

- Wood plastic is produced with the addition of wood dust. Finished models from it imitate wood not only in their appearance, but also in smell.

Plastic spools are everywhere - you can easily choose the right consumables and combine different properties and colors of parts when printing.

In conclusion

Home 3D printing is easier than you think. With a 3D printer at hand, you can create any plastic parts you can think of: cases, mock-ups, figurines, and more. Do not forget that you have at your disposal a huge library of models that are shared on the Internet. Broken vacuum cleaner nozzle or window opening limiter? No problem! Having your own 3D printer, you just need to take the finished model from the Internet, run it through the slicer program in a couple of clicks and send it to print.

Broken vacuum cleaner nozzle or window opening limiter? No problem! Having your own 3D printer, you just need to take the finished model from the Internet, run it through the slicer program in a couple of clicks and send it to print.

Useful Links

- Where to Download Free 3D Models of

- Flying Bear Ghost 5 3D Printing Manual

- Creality Ender-3 V2 3D Printing Manual

How does a 3D printer work and what is it for - Code magazine

Over the past couple of years, there has been a lot of news about someone printing something on a 3D printer:

- hearing aid,

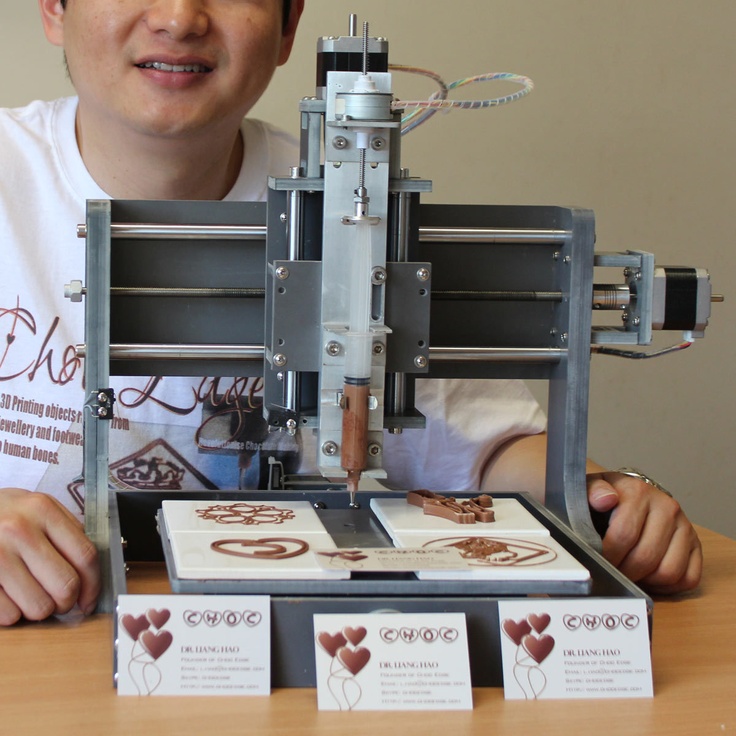

- milk products,

- residential building,

- robotic fingers,

- brain implants,

- 1mm statue of David,

- prefabricated electronic devices.

Let's see how this technology works, what its limitations are and whether it has a future.

Why you need a 3D printer

3D printers print 3D things from plastic or other materials. They can be used at home or in production. For example, here is what you can print on a 3D printer:

They can be used at home or in production. For example, here is what you can print on a 3D printer:

How it works

Usually a 3D printer uses special plastic to print. It comes in the form of powder, liquid resin or plastic wire in coils. It is from this material that the printed part will consist.

Further, roughly speaking, the process looks like this:

- this plastic is either applied using a moving nozzle;

- or "baked" with a laser;

- or the excess is cut out from the array of finished material using a movable cutter (but this is more like turning and is often not attributed to 3D printing).

Material takes the shape you want, layer by layer. When all layers are passed, the detail turns out.

Fast 3D Printing with Moving Nozzle:

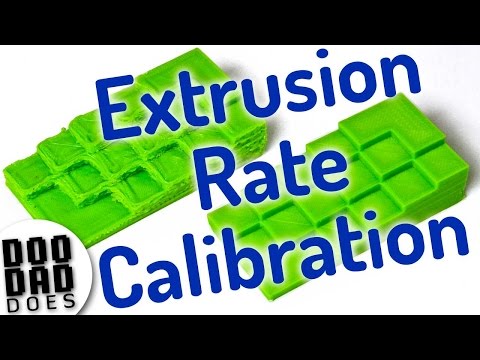

Due to the fact that the printer needs to constantly heat the plastic, 3D printers do not print very quickly: a part the size of a phone can take 15-20 minutes. The speed also depends on the thickness of the layer: the thicker the layer, the faster the print. But with a large layer thickness, the part may turn out to be sloppy: layers will be visible:

The speed also depends on the thickness of the layer: the thicker the layer, the faster the print. But with a large layer thickness, the part may turn out to be sloppy: layers will be visible:

Printing Technologies

3D printing is very much needed in industry and industrial design, so there is a whole zoo of printing technologies, each with its own advantages and disadvantages.

Stereolithography . Instead of plastic, a special resin is used here, which hardens in the light. The detail is also formed in layers, but the layers themselves are almost invisible - the resin fills the relief and the detail seems to be a single whole even from a very close distance.

Polymer synthesis (SLS) . This type of printing uses powder, which is then baked with a laser beam. Since the laser beam can be focused anywhere with the desired accuracy, very complex models with high detail can be obtained in this way of printing:

Polyjet. The peculiarity of this technology is that it can print objects simultaneously from different materials. This allows you to create almost any thing of the most complex shape, which immediately have the desired properties. On such a printer, you can even print sneakers that you can wear:

The peculiarity of this technology is that it can print objects simultaneously from different materials. This allows you to create almost any thing of the most complex shape, which immediately have the desired properties. On such a printer, you can even print sneakers that you can wear:

What can be printed

Anything can be printed on a 3D printer, as long as you have the right media, a finished model, and a large enough printer.

Prototypes. Often, before starting production, a company needs to understand how comfortable a thing will turn out to be in use. In order not to launch a line for the sake of one product, it is printed on a 3D printer and they look at what needs to be changed or finalized. On such prototypes, you can notice, for example, that the buttons turned out to be too small and it would be inconvenient to press them, or that the buttons turned out to be very far from the fingers and you will need to reach them specially.

Parts and parts. Sometimes it is difficult or almost impossible to find a spare part for a tool: the manufacturer does not produce them or the model has been out of production for a long time. In this case, you can find a three-dimensional model of the desired part on the Internet or draw it yourself in the editor, so that you can then send it to print.

Medicine. 3D printing is actively used in medicine to create new joints, tissues and treat patients. The difference from traditional printing is that instead of plastic, they print with special “living” solutions that interact with each other and behave like real organs and tissues. Thanks to this technology, it is now easy to print a joint that a surgeon can put on a person instead of a damaged one.

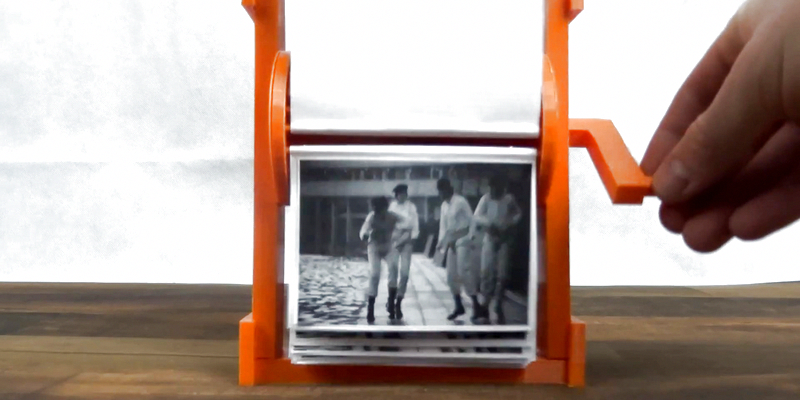

Hobbies and modeling. It is easy to print various miniatures, collectible figures and models on a 3D printer.

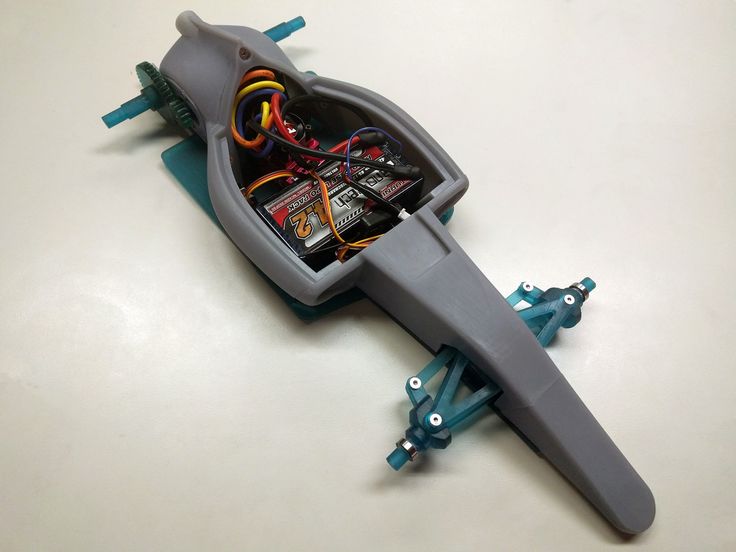

Manufacture of other robots. 3D printers do not yet know how to produce servos and microprocessors, but they already know how to print bodies and frames of robots.

3D printers do not yet know how to produce servos and microprocessors, but they already know how to print bodies and frames of robots.

Houses and buildings. We take hefty rails with motors and controllers. We install a movable nozzle, on which you can supply a building mixture (concrete or polymers). You can print the walls of buildings. Unlike traditional brick, panel and block construction technologies, the shape of the walls and the building as a whole can be any. The foundation, floors and roof are not yet printed, but this is for now.

Imagine: we send fifty 3D printers on a mobile basis to Mars. For a year, each of them prints another 100 printers. Then all these 5,000 printers disperse around Mars and begin to build the first colony. While they are building, we order furniture from Ikea, arrange delivery, and just in time for delivery, our robots will finish printing everything. Apple trees on Mars are unlikely to bloom, but five-story buildings can.

While they are building, we order furniture from Ikea, arrange delivery, and just in time for delivery, our robots will finish printing everything. Apple trees on Mars are unlikely to bloom, but five-story buildings can.

Criticisms and issues

❌ Slow and no guarantees: printing is quite slow, not accurate enough. A huge problem in amateur printers is marriage. For example, a part can peel off the substrate right during printing, and hell will happen. Or the motors will decalibrate, and the nozzle will begin to miss the right places.

❌ Low efficiency: To print a 10 x 10 cm part, you need a printer that is at least 50 x 50 cm, which will cost several hundred dollars.

❌ Not the strongest materials: 3D printing has so far been limited to plastics and resins. There are separate printing technologies based on metal powder, but if you need a steel part, you don’t need a 3D printer, but a normal turner and machine tool. But not every detail can be made on the machine.