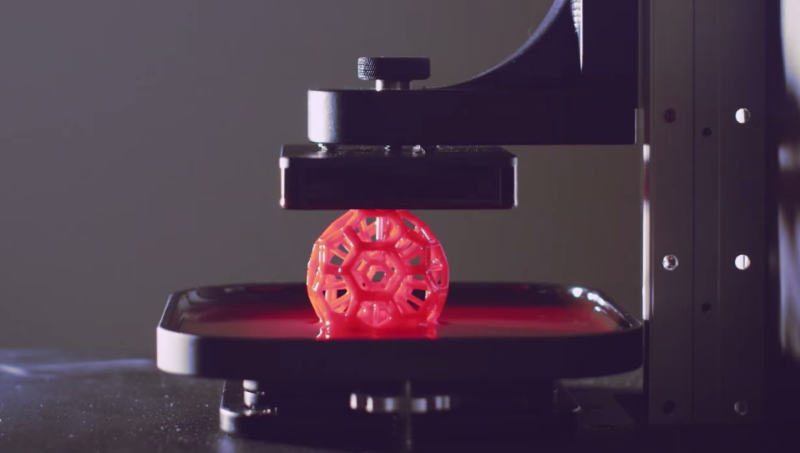

Liquid interface 3d printing

All About Continuous Liquid Interface Production

Image credit: Carbon Finally Unveils First Commercial CLIP™ 3D Printer - 3D Printing Industry

3D printers demand much attention in the additive manufacturing sphere – and for good reason. These machines print components from computer 3D models and eliminate many of the downsides of subtractive manufacturing methods. 3D printers are more efficient with materials, power, and operator costs, and are quickly becoming the go-to production tool for many applications for these reasons. This article will explore cutting-edge technology in 3D printing, continuous liquid interface production, also known as CLIP™ and/or digital light synthesis (DLS) printing. Through an investigation of what CLIP™ is, how it works, and its benefits and limitations, this article will provide a basic overview of this technology and will show how it surpasses the standard approaches to 3D printing.

To see an overview of the different types of additive manufacturing processes available, read our article on the types of 3D printing technologies.

What is Continuous Liquid Interface Production (CLIP™)?

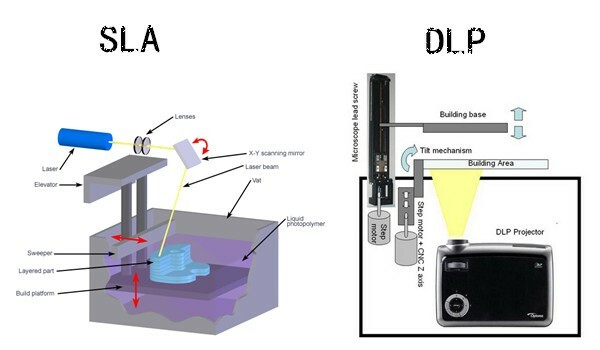

Continuous liquid interface production (CLIP™) is a proprietary 3D printing method patented in 2014 by Carbon3D (formerly EiPi Systems). It is a 3D printing technology that falls under the general process of vat polymerization and shares many similarities with the older stereolithography (SLA) and digital light processing (DLP) printing methods. We recommend looking over our articles all about SLA and all about DLP 3D printing, as these two methods directly inspired CLIP™ and serve as the basis of its functionality. CLIP™ is also referred to as digital light synthesis (DLS), though both names refer to the same novel approach to 3D printing. For brevity, this article will primarily use the acronym CLIP™, but also uses CLIP™/DLS when referring to printer devices.

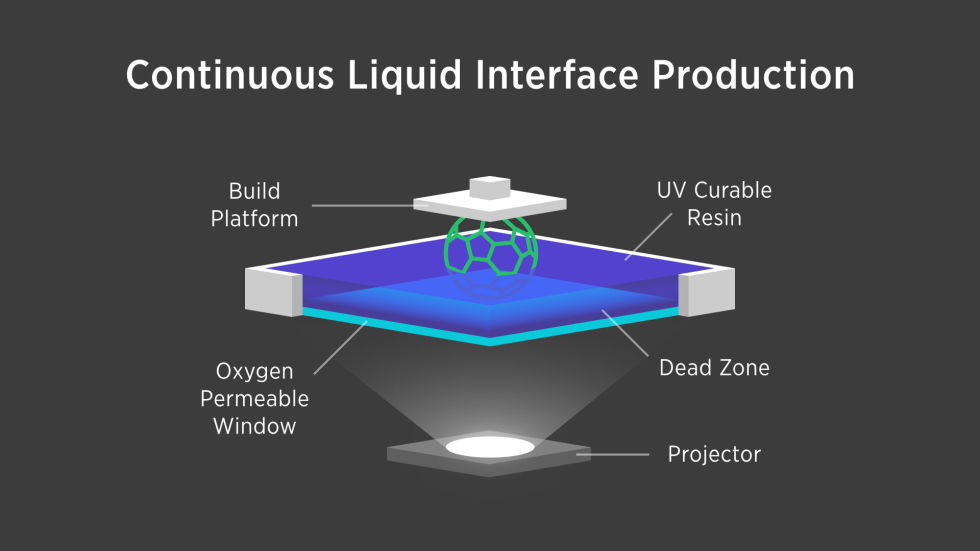

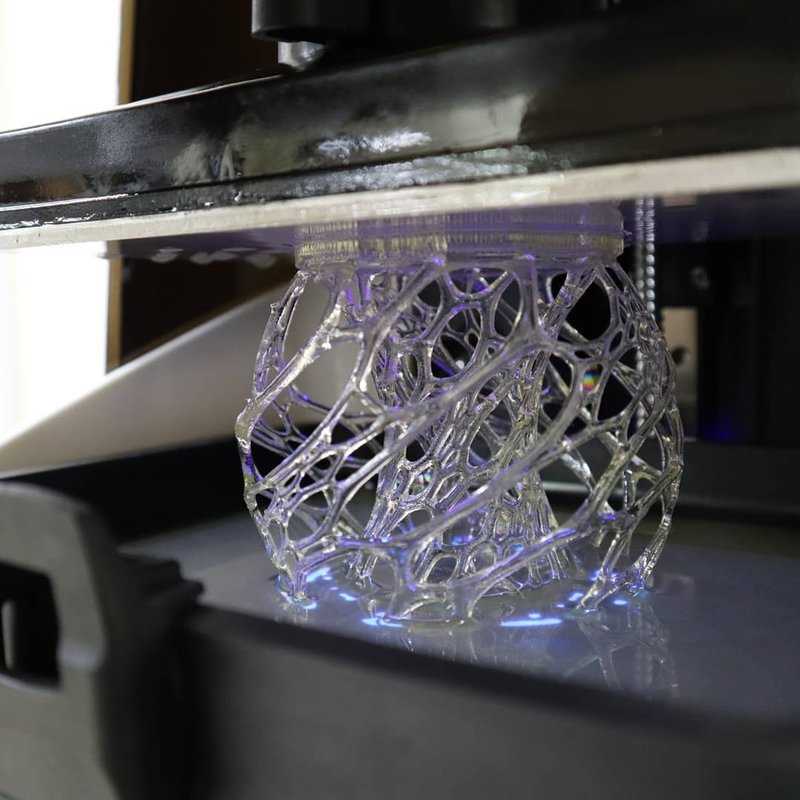

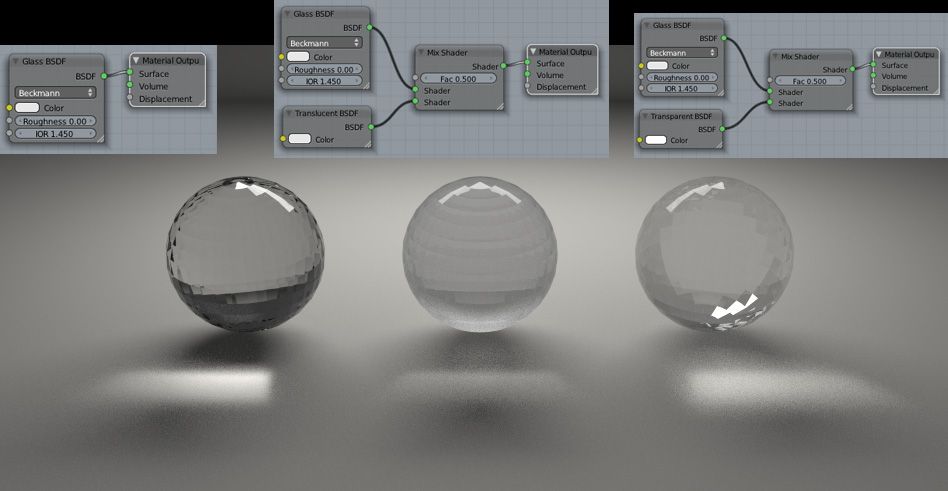

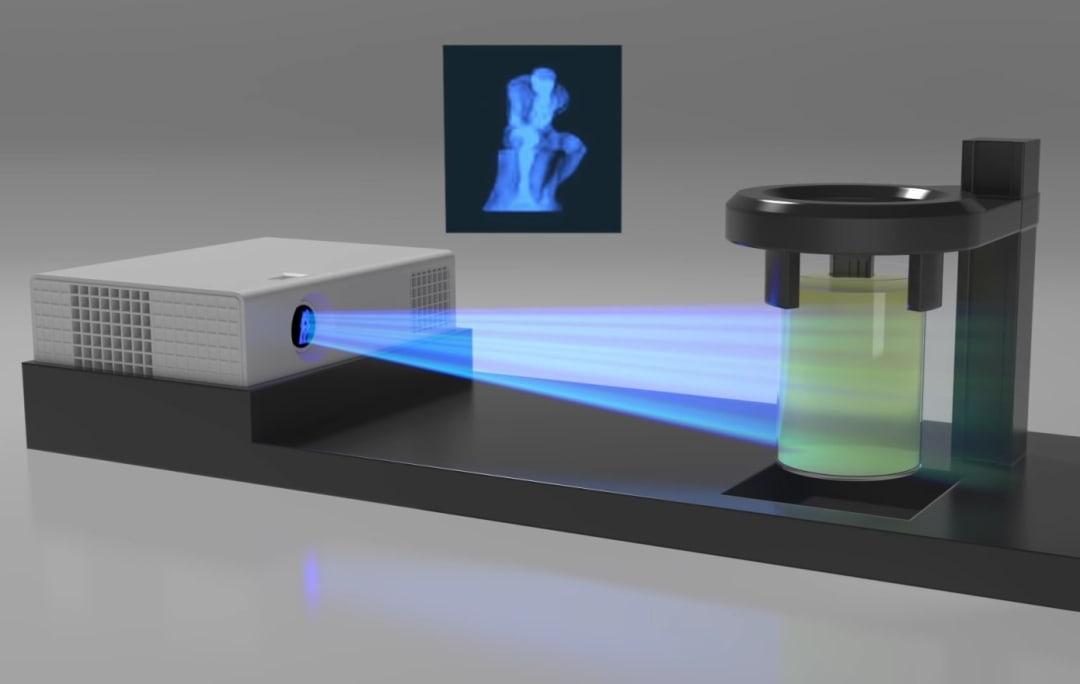

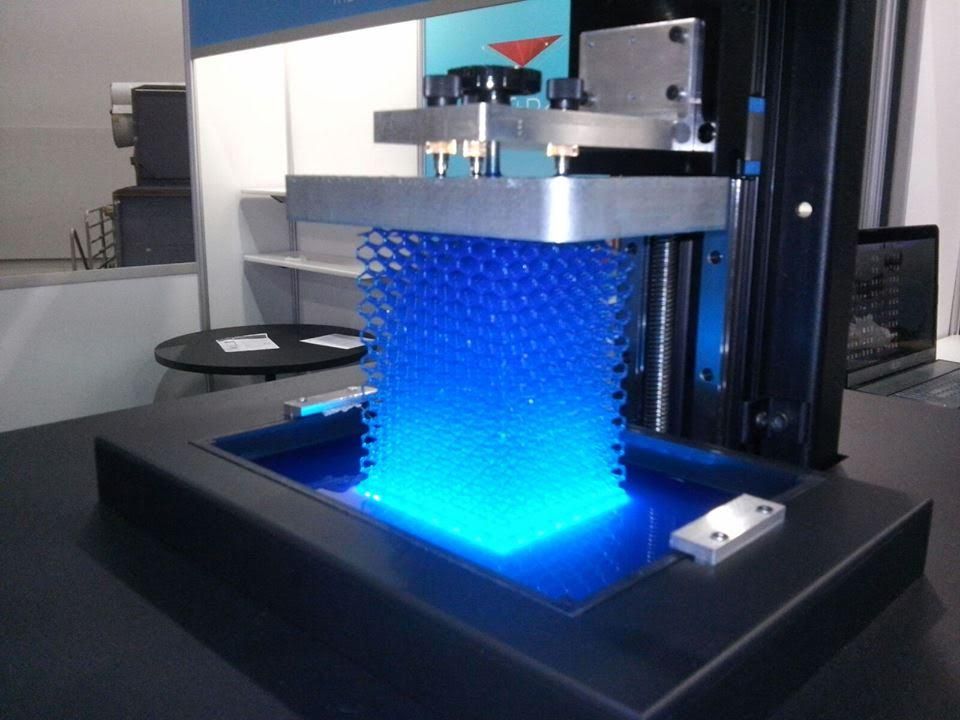

In CLIP™, liquid photopolymer resin is selectively exposed to a UV light source and is solidified into parts. Despite initial appearances, CLIP™ is unique from SLA and DLP as it is a truly continuous process that “grows” parts, removing the discrete steps of previous printing methods. CLIP™’s innovation lies in its oxygen-permeable membrane that creates a dead zone underneath the part (known as a persistent liquid interface), allowing for continuous curing as the part is drawn out of the resin. Instead of using a layer-by-layer approach, CLIP™ uses a digital projector and various microcontrollers to project an ever-changing picture of a 3D model, streamlining the print into a layer-less design (see Figure 1 below).

CLIP™’s innovation lies in its oxygen-permeable membrane that creates a dead zone underneath the part (known as a persistent liquid interface), allowing for continuous curing as the part is drawn out of the resin. Instead of using a layer-by-layer approach, CLIP™ uses a digital projector and various microcontrollers to project an ever-changing picture of a 3D model, streamlining the print into a layer-less design (see Figure 1 below).

Image credit: DLS 3D Printing Technology | Carbon (carbon3d.com)

Figure 1: Layering effect from SLA/DLP printers (left) vs. virtually continuous surface from CLIP™ printers (right).

How does CLIP™ work?

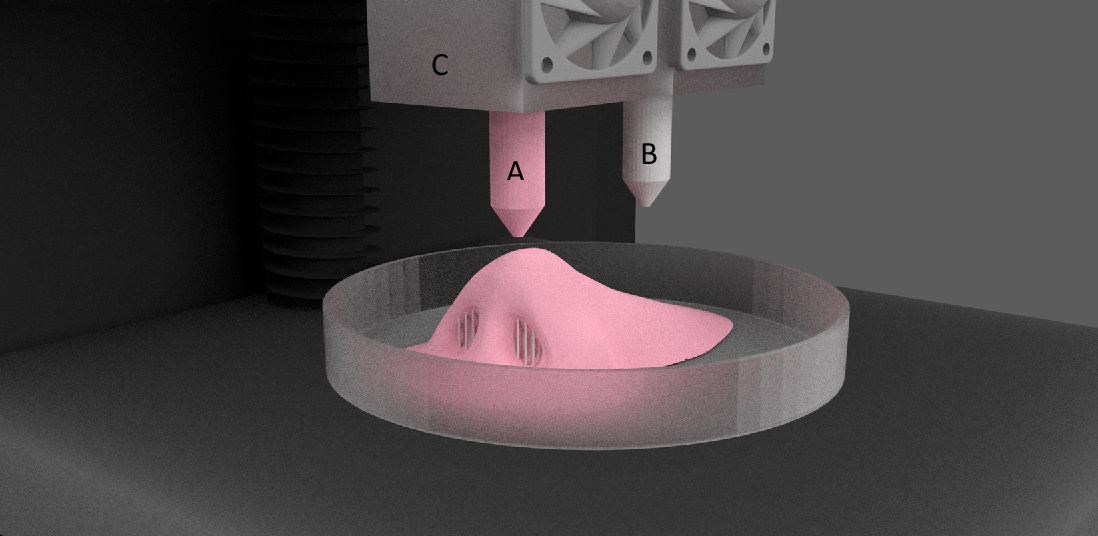

Image credit: https://www.irjet.net/

Figure 2: Diagram of the functional components of a CLIP™ printer. Note this is a simplified diagram that may not fully represent real-world models.

This section will explore the workings of a CLIP™ printer to explain its differences over other vat polymerization technologies. Figure 2 shows the important components of CLIP™/DLS printers and their general arrangement, and we will use Figure 2 to briefly explain the functionality of each part, starting from the bottom up.

Figure 2 shows the important components of CLIP™/DLS printers and their general arrangement, and we will use Figure 2 to briefly explain the functionality of each part, starting from the bottom up.

Light Engine/Projector

The projector, also known as the light engine, provides a curing light source for the print and is situated underneath the resin vat. The light engine projects a sequence of UV images through the vat and onto the build platform. Note that these images are not the discrete layers found in SLA/DLP light sources, but a changing sequence of cross-sectional images, leading to a layer-less print.

These light engines are like those found in DLP designs; they have a set resolution, are digitally projected, and cast a layer’s worth of light at a given time. The difference between CLIP™ and DLP is that, though they have comparable resolutions, the CLIP™ process smoothly blurs the layers together and eliminates the so-called voxelated effect that is typically seen in DLP prints. Not only does this lead to excellent out-of-print finishes, but also faster build times and less post-processing work.

Not only does this lead to excellent out-of-print finishes, but also faster build times and less post-processing work.

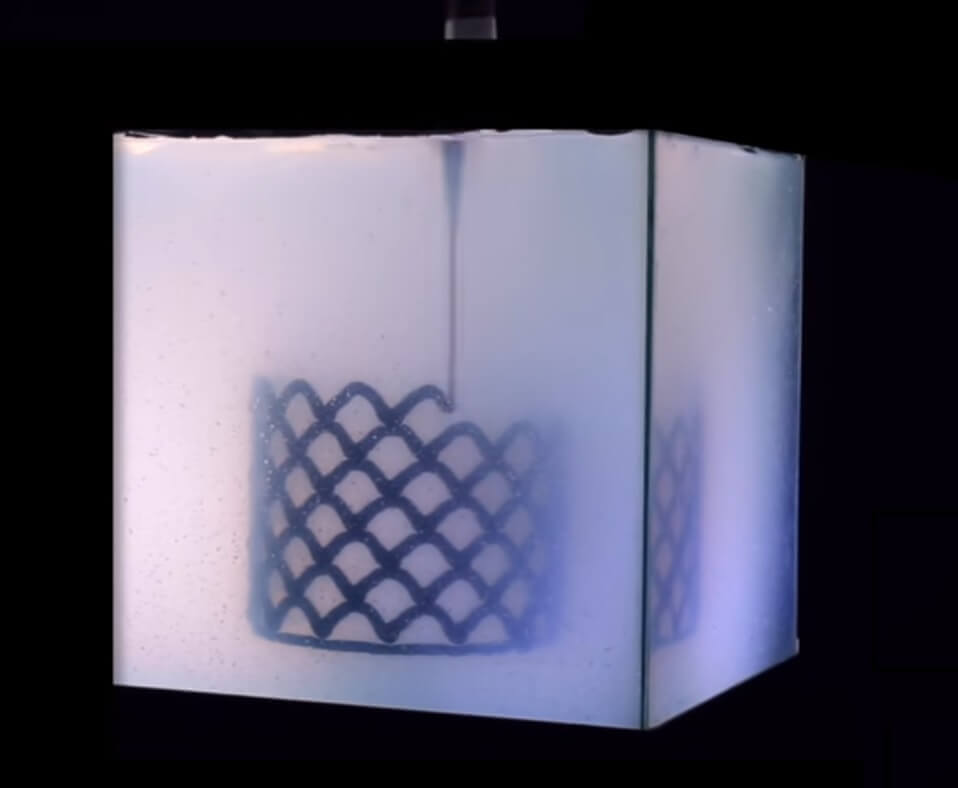

Photopolymer Vat & Oxygen-Permeable Window

The photopolymer vat is the vessel where the UV-cured resin is held, and where the magic of CLIP™ printing takes place. Below, Figure 3 shows a close-up of the interface between the resin (dark blue) and the photopolymer vat (sky blue):

Image credit: Christian Cavallo Consulting, LLC

Figure 3: Cross-section close-up of the interfaces between the photopolymer vat and the printing resin. Note the dead zone, as well as the flow of arrows from the resin to the printed par

t.

The floor of the photopolymer vat is composed of a transparent oxygen-permeable window. This window allows both incoming light and oxygen to pass through to the resin. The oxygenated resin will not cure in the presence of light and forms a so-called “dead zone” of liquid resin that remains under the printed part.

This permeable membrane is the key component of CLIP™ technology; as the part is slowly raised out of the vat, the liquid dead zone allows the resin to flow under the part at a constant rate while preventing resin from curing on the window. The incoming light then cures the resin outside of the dead zone as the part is pulled up, creating the 3D print. Carbon 3D will not exactly divulge the chemistry of how this all works, but the result is a continually growing 3D printed part with no peeling or stopping necessary.

UV-Curable Resin

CLIP™ printers use thermosetting resin – or a polymeric liquid that solidifies in the presence of UV light. Though CLIP™ printers use similar materials to SLA/DLP designs, their unique printing process creates parts with enhanced surface finishes and mechanical properties and allows for more interesting materials. Below is a table that provides some examples of resins currently used in a CLIP™/DLS printer:

Table 1: Typical resins used in CLIP™ printing.

Note this table is not exhaustive.

Note this table is not exhaustive. | Material | Material Name(s) |

| Rigid Polyurethane | RPU 70 |

| Urethane Methacrylate | UMA 90 |

| Impact-resistant epoxy | EPX 82 |

| High-Temp Cyanate Ester | CE 220, CE 221 |

| Flexible Polyurethane | FPU 50, FPU 230 |

| Elastomeric Polyurethane | EPU 40, EPU 60 |

| Elastomeric Silicone-Urethane | SIL 30 |

| Prototyping Resin | PR 25 |

Many resins require a mixture of two separate parts. Operators must calculate exactly how much resin they need, how much of each part they need, and how long their working time is before the resin becomes unusable. There is no re-using resin once it is mixed, so it is important to get the timing and ratios right before beginning the print.

Operators must calculate exactly how much resin they need, how much of each part they need, and how long their working time is before the resin becomes unusable. There is no re-using resin once it is mixed, so it is important to get the timing and ratios right before beginning the print.

The part is not yet finished after it has solidified. After the print, it must be cleaned of excess resin and any supports must be removed. Depending upon the material, a final thermal-post cure is needed to fully harden the part. This involves placing the part in an oven for an extended period (4-13 hours), where a secondary chemical reaction occurs, strengthening the part further.

Build Platform & Elevator

The build platform is the working space to which the resin adheres, and it is mounted to an elevator that controls the vertical (z-axis) movement of the part. The build platform starts partly submerged in the resin vat and is raised up via the elevator. The elevator is precisely controlled by the printer to keep resin flowing underneath the part, and is responsible for the “growing” effect of this 3D printer. These components are tied into an array of sensors and microprocessors to ensure the print is accurate and maintains structural integrity.

These components are tied into an array of sensors and microprocessors to ensure the print is accurate and maintains structural integrity.

Advantages & Limitations of CLIP™

Emerging CLIP™ technology is an upgrade from more conventional 3D printers and is an incredibly promising additive manufacturing tool. This section will detail the advantages and disadvantages of CLIP™ technology.

The advantages of CLIP™ printing are as follows:

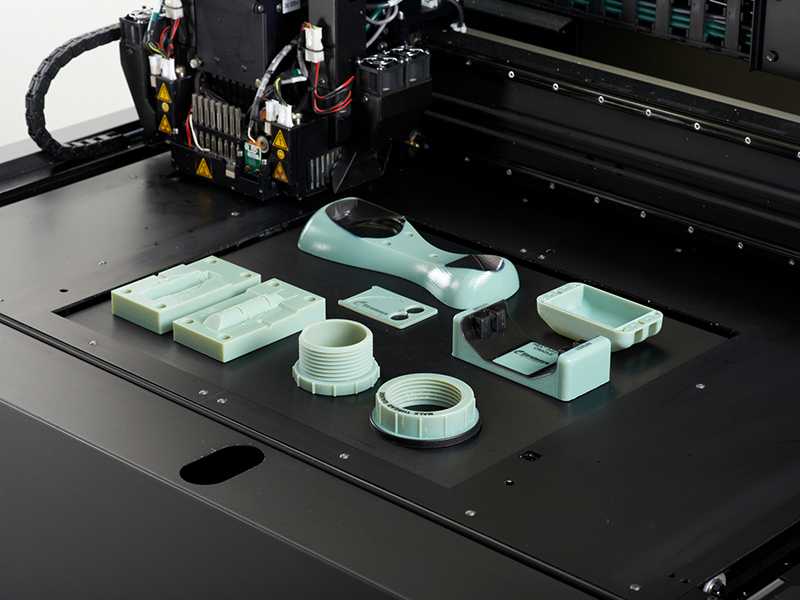

- CLIP™ prints have the accuracy and the surface quality of DLP/SLA prints but are completed 100 times faster.

- CLIP™ prints are layer-less, enhancing their surface finish to be comparable to injection-molded parts.

- Parts are watertight, fully isotropic (have strength in any orientation), and have increased strength over SLA/DLP prints.

- Parts can be used for functional prototyping and even for full production runs.

- The material choices for CLIP™/DLS printers are widely varied and unique to many other printer types.

The limitations of CLIP™ printing are as follows:

- Carbon3D’s line of CLIP™/DLS printers can only be rented, and the printers themselves are very expensive to rent and train personnel on (upfront cost is $64,000+). The resin is also expensive ($99-$399 for each container).

- CLIP™ is still an emerging technology, so support is difficult to find and there are few options (if any) to choose from.

- CLIP™/DLS is still under active patent, so alternatives will not be available for a long time or until the rights are sold. Access to Carbon’s rental program is also limited.

- While creating amazing, production-quality parts, investment in CLIP™ technology can be harder to justify at present given so many affordable 3D printers provide good results at lower price points.

Applications of DLP 3D Printing

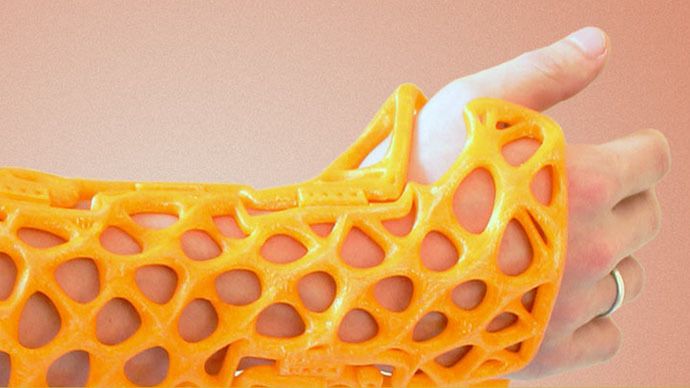

CLIP™/DLS printers are used in applications that require mass customization and fast lead times. Such a versatile machine has nearly infinite applications, but the brief list below shows off some of its most well-known uses:

- Medical equipment/tools/impressions

- Footwear midsoles & athletic equipment

- Automotive parts

- Prototyping

- An alternative process to injection molding

- End-use functional parts & direct digital manufacturing

and much more..jpg)

Summary

This article presented an understanding of what continuous liquid interface production is and how it works. We hope this brief article showed the advanced capabilities of CLIP™ technology and how it can benefit your business. For more information on related products, consult our other guides or visit the Thomas Supplier Discovery Platform to locate potential sources of supply or view details on specific products.

Sources

- How Continuous Liquid Interface Production is Speeding Up the 3D Process (azom.com)

- AM 101: Digital Light Synthesis (DLS) | Additive Manufacturing

- Continuous Liquid Interface Production (CLIP™) - Dinsmore Inc.

- Carbon DLS - Xometry

- 3D Printing Guide - Xometry

- IRJET-V4I1003.pdf

- Bits to Atoms: How Carbon's CLIP™ 3D Printing Technology Works - Tested

- Layerless fabrication with continuous liquid interface production (pnas.org)

- CLIP™: The New Game-Changing Layerless 3D Printing Technology (designorate.

com)

com) - DLS 3D Printing Technology | Carbon (carbon3d.com)

- SLA 3D Printer vs DLP 3D Printer vs DLS 3D Printer - MANUFACTUR3D (manufactur3dmag.com)

Copyright and Trademark Notices

- CLIP™ is a trademark of Carbon 3D Inc., Redwood City, CA

Other Types of 3D Printing

- All About Material Jetting 3D Printing

- All About Multi Jet Modeling (MJM) 3D Printing

- All About Fused Deposition Modeling (FDM) 3D Printing

- All About Stereolithography 3D Printing

- All About Photopolymerization 3D Printing

- All About Sheet Lamination/Laminated Object Manufacturing

- All About Electron Beam Additive Manufacturing

- All About Direct Energy Deposition 3D Printing

- All About Digital Light Processing (DLP) 3D Printing

Related Articles

- Top 3D Printing Services Companies in the USA

- Origins of 3D Printing and Additive Manufacturing

- Overview of 3D Printing Technologies

- Top 3D Printing Manufacturers and Suppliers (Publicly Traded and Privately-Owned)

- Top Suppliers of Additive Manufacturing Consulting Services

- The Best 3D Printers under $300

- The Best 3D Printers under $200

- The Best 3D Printing Software

- The Best 3D Printer Under $1000

- The Best 3D Printer Under $500

More from Custom Manufacturing & Fabricating

DLS 3D Printing Technology - Carbon

The Carbon DLS™ Process

Digital Light Projection: UV Light Shapes the Part

The Digital Light Synthesis process is driven by Carbon’s groundbreaking Continuous Liquid Interface Production™, or CLIP™. CLIP is a photochemical process that cures liquid plastic resin into solid parts using ultraviolet light. It works by projecting light through an oxygen-permeable window into a reservoir of UV-curable resin. As a sequence of UV images is projected, the part solidifies and the build platform rises.

CLIP is a photochemical process that cures liquid plastic resin into solid parts using ultraviolet light. It works by projecting light through an oxygen-permeable window into a reservoir of UV-curable resin. As a sequence of UV images is projected, the part solidifies and the build platform rises.

Oxygen-Permeable Optics: Fast Printing via the “Dead Zone”

The heart of the CLIP process is the “dead zone”—a thin, liquid interface of uncured resin between the window and the printing part. Light passes through the dead zone, curing the resin above it to form a solid part without curing the part onto the window. Resin flows beneath the curing part as the print progresses, maintaining the “continuous liquid interface” that powers CLIP and avoiding the slow and forceful peeling process that is inherent to many other resin-based printers.

Dual-Cure Materials: Mechanical Properties Set by Heat

Traditional resin-based 3D printing processes produce weak, brittle parts. Carbon overcomes this by embedding a second heat-activated programmable chemistry in our materials. Once a part is printed on a Carbon printer, it’s baked in an oven. Heat sets off a secondary chemical reaction that causes the materials to adapt and strengthen, taking on exceptionally strong characteristics. This produces high-resolution parts with engineering-grade mechanical properties.

Carbon overcomes this by embedding a second heat-activated programmable chemistry in our materials. Once a part is printed on a Carbon printer, it’s baked in an oven. Heat sets off a secondary chemical reaction that causes the materials to adapt and strengthen, taking on exceptionally strong characteristics. This produces high-resolution parts with engineering-grade mechanical properties.

The Results? Isotropic Parts with Exceptional Surface Finish

3D printed parts are notoriously inconsistent. Because of a layer-by-layer process, conventional 3D printed materials often exhibit variable strength and mechanical properties depending on the direction in which they were printed.

The Carbon DLS™ process, on the other hand, produces parts with predictable isotropic mechanical properties. These printed parts are solid on the inside like injection-molded parts and behave consistently in all directions. The resolution and gentleness of our process—where parts aren’t harshly repositioned with every slice—make it possible to leverage a broad range of materials that meet the surface finish and detail requirements needed for end-use parts.

The Carbon Isotropic Difference

Carbon’s isotropic properties are a feature of our dual-cure materials technology. Each stage in the process contributes to the mechanical integrity of every printed part.

Stage 01: Print

The isotropic difference of parts printed on the Carbon platform is due in part to the dead zone. In this small region, a thin layer of oxygen prohibits curing closest to the window with its effect falling off to zero at ~20 µm from the surface of the window.

Liquid resin begins to intersect and cure along the z-axis as light escapes the oxygen layer of the dead zone.

Stage 02: Bake

The isotropy of each printed part is reinforced with a thermal curing stage. Here, a secondary reaction creates a molecular weaving, adding strength in all directions.

Fully Dense Parts with End-Use Quality

Unlike powder-bed fusion 3D printing technologies, Carbon technology produces fully dense parts.

Why the Carbon DLS™ Process?

Accelerate Every Step of Product Development

Rapid Design Iterations

Test dozens of designs in the time it used to take to try one.

Functional and Rapid Prototyping

Don’t settle for fragile prototypes. Bring your designs to life with the industry’s best materials, then start testing and iterating immediately.

Scale to Production

Seamlessly transition into production, while still having the ability to revise your designs immediately and without retooling. Scaling has already been done by leading brands like adidas, Specialized, and fizik.

Find the Perfect Design for Your Application, Not the Mold

Undercuts and Undrafted Walls

Moldability constraints don’t apply here. Enjoy the freedom of designing with undercuts and perfectly straight walls without sacrificing manufacturability.

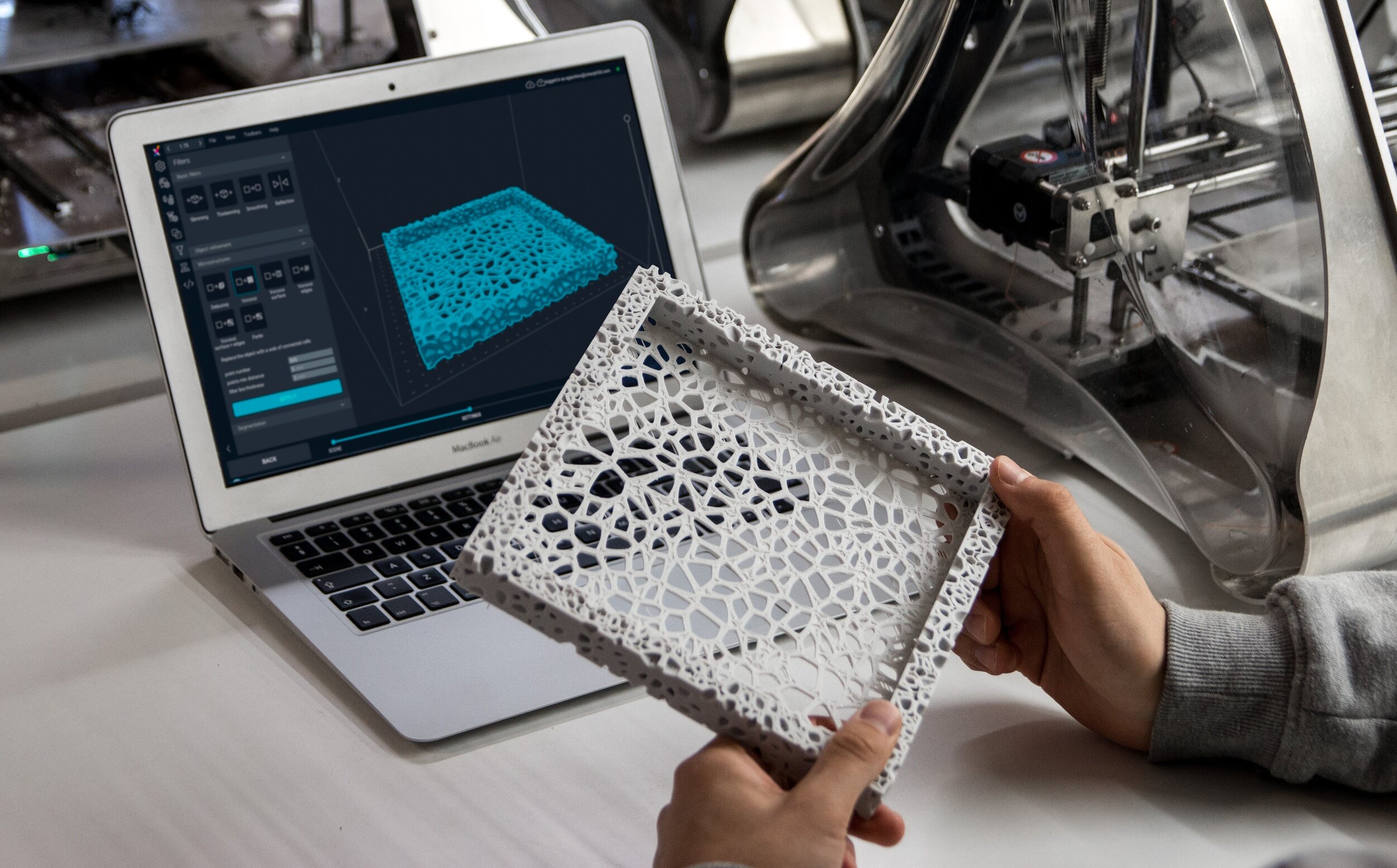

Performance-oriented Lattices

Lattices allow you to specify your required characteristics at every millimeter. Determine your product’s ideal mechanical response and leverage Carbon Design Engine™ software to generate the right lattice for it.

Consolidated Parts

A single printed part frequently offers better overall mechanical performance than an assembled part. Streamline production with reduced SKUs and less labor by consolidating assemblies.

Streamline production with reduced SKUs and less labor by consolidating assemblies.

Discover New Aesthetics

Customization

With no tooling costs, you’re free to make every unit unique. Offer personalized designs, or build entire products around individuals.

Surface Design and Textures

Enhance your parts by applying textures to complex curved surfaces like grips and enclosures with Carbon design software.

Perfecting Product Design with the Carbon DLS™ Process

3D printing sends modern design soaring, giving designers and engineers the freedom to bring their most inspired ideas to life without the constraints of molding or machining.

Learn about how the Carbon DLS™ process unlocks a new world of design.

Read more

Ready to Get Started?

Contact us to see if the Carbon DLS™ process is the right fit for your production needs.

Contact us

Carbon 3D Printers

The L and M Series printers and Smart Part Washer offer versatility and enable scalable manufacturing.

Learn More

Materials

Find the right material for your project, from consumer product elastomers to high-temperature automotive materials.

Learn More

Carbon Design Engine

Design high-performance conformal lattices to improve product performance and speed up print time.

Learn More

3D as It’s Meant to Be

A new 3D printing method is 25-100 times faster than the traditional one / Habr

marks

Time to read 2 min

Number of views41K

Gadgets Computer hardware Popular science 3D printers Physics

The 3D printing method proposed by the California company Carbon 3D may well become the “killer” of the traditional method familiar to many. The thing is that the new technology is 25-100 times faster than the old methods of creating 3D objects. The company has been developing its technology since its founding in 2013.

The company has been developing its technology since its founding in 2013.

The technology is called Continuous Liquid Interface Productiongo technology (CLIP), the principle of the new method is the use of light and oxygen to cure a photosensitive material (a special type of resin). The method of exposing the photosensitive material to light is similar to what we see in the traditional SLA process. But there are differences, and significant ones.

There is no layer-by-layer work here, when plastic is applied to the base layer by layer until a whole object is obtained.

Instead, human-safe spectrum and strength of light is used to cure the resin. Oxygen is also used as an inhibitor.

The use of oxygen allows you to control the photochemical reaction while speeding up the printing process. At the same time, there is no layered structure of the created object, the figure turns out to be whole, single. When printing using this method, a special transparent and permeable "window" is required, through which both light and oxygen pass simultaneously. You can think of it like a big contact lens. The device can control the exact amount of oxygen entering the resin tank. The oxygen then acts as an inhibitor during the photochemical reaction, leaving the necessary parts of the object in liquid. Light allows solidification only to those parts of the system where oxygen does not enter.

You can think of it like a big contact lens. The device can control the exact amount of oxygen entering the resin tank. The oxygen then acts as an inhibitor during the photochemical reaction, leaving the necessary parts of the object in liquid. Light allows solidification only to those parts of the system where oxygen does not enter.

Thus, oxygen in this system can create a "dead" zone tens of microns thick. And just in this zone, photopolymerization is impossible. The device projects a series of overlapping images using ultraviolet light. This process is similar to playing a movie.

Carbon3D has now partnered with Sequoia Capital, one of the world's most reputable investment funds. In addition, investments were also provided by Silver Lake Kraftwerk. In total, Carbon3D has already received $41 million in investment.

The author of the new technology is the current CEO Joseph DeSimone, as well as Professor Edward Samulski and Dr. Alex Ermoshkin.

Tags:

- Carbon3d

- Liquid metal robot

- 3D Print

Habs:

- Gadgets

- Scientific and Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Popular-Poplar0042

Total votes 74: ↑72 and ↓2 +70

Comments 57

Maxim Agadzhanov @marks

Editor

Telegram

Comments Comments 57

3D printing for "dummies" or "what is a 3D printer?"

- 1 3D printing term

- 2 3D printing methods

- 2.1 Extrusion printing

- 2.2 Melting, sintering or gluing

- 2.

3 Stereolithography

3 Stereolithography - 2.4 Lamination

- 3 Fused Deposition Printing (FDM)

- 3.1 Consumables

- 3.2 Extruder

- 3.3 Working platform

- 3.4 Positioners

- 3.5 Control

- 3.6 Varieties of FDM printers

- 4 Laser stereolithography (SLA)

- 4.1 Lasers and projectors

- 4.2 Cuvette and resin

- 4.3 Varieties of Stereolithography Printers

The term 3D printing

The term 3D printing has several synonyms, one of which quite briefly and accurately characterizes the essence of the process - "additive manufacturing", that is, production by adding material. The term was not coined by chance, because this is the main difference between multiple 3D printing technologies and the usual methods of industrial production, which in turn received the name "subtractive technologies", that is, "subtractive". If during milling, grinding, cutting and other similar procedures, excess material is removed from the workpiece, then in the case of additive manufacturing, material is gradually added until a solid model is obtained.

If during milling, grinding, cutting and other similar procedures, excess material is removed from the workpiece, then in the case of additive manufacturing, material is gradually added until a solid model is obtained.

Soon 3D printing will even be tested on the International Space Station

Strictly speaking, many traditional methods could be classified as "additive" in the broad sense of the word - for example, casting or riveting. However, it should be borne in mind that in these cases, either the consumption of materials is required for the manufacture of specific tools used in the production of specific parts (as in the case of casting), or the whole process is reduced to joining ready-made parts (welding, riveting, etc.). In order for the technology to be classified as “3D printing”, the final product must be built from raw materials, not blanks, and the formation of objects must be arbitrary - that is, without the use of forms. The latter means that additive manufacturing requires a software component. Roughly speaking, additive manufacturing requires computer control so that the shape of final products can be determined by building digital models. It was this factor that delayed the widespread adoption of 3D printing until the moment when numerical control and 3D design became widely available and highly productive.

Roughly speaking, additive manufacturing requires computer control so that the shape of final products can be determined by building digital models. It was this factor that delayed the widespread adoption of 3D printing until the moment when numerical control and 3D design became widely available and highly productive.

3D printing techniques

3D printing technologies are numerous, and there are even more names for them due to patent restrictions. However, you can try to divide technologies into main areas:

Extrusion printing

This includes methods such as deposition fusion (FDM) and multi-jet printing (MJM). This method is based on the extrusion (extrusion) of consumables with the sequential formation of the finished product. As a rule, consumables consist of thermoplastics or composite materials based on them.

Melting, sintering or bonding

This approach is based on bonding powdered material together. Formation is done in different ways. The simplest is gluing, as is the case with 3D inkjet printing (3DP). Such printers deposit thin layers of powder onto the build platform, which are then selectively bonded with a binder. Powders can be made up of virtually any material that can be ground to a powder—plastic, wood, metal.

Formation is done in different ways. The simplest is gluing, as is the case with 3D inkjet printing (3DP). Such printers deposit thin layers of powder onto the build platform, which are then selectively bonded with a binder. Powders can be made up of virtually any material that can be ground to a powder—plastic, wood, metal.

This model of James Bond's Aston Martin was successfully printed on a Voxeljet SLS printer and blown up just as successfully during the filming of Skyfall instead of the expensive original

sintering (SLS and DMLS) and smelting (SLM), which allow you to create all-metal parts. As with 3D inkjet printing, these devices apply thin layers of powder, but the material is not glued together, but sintered or melted using a laser. Laser sintering (SLS) is used to work with both plastic and metal powders, although metal pellets usually have a more fusible shell, and after printing they are additionally sintered in special ovens. DMLS is a variant of SLS installations with more powerful lasers that allow sintering metal powders directly without additives. SLM printers provide not just sintering of particles, but their complete melting, which allows you to create monolithic models that do not suffer from the relative fragility caused by the porosity of the structure. As a rule, printers for working with metal powders are equipped with vacuum working chambers, or they replace air with inert gases. Such a complication of the design is caused by the need to work with metals and alloys subject to oxidation - for example, with titanium.

SLM printers provide not just sintering of particles, but their complete melting, which allows you to create monolithic models that do not suffer from the relative fragility caused by the porosity of the structure. As a rule, printers for working with metal powders are equipped with vacuum working chambers, or they replace air with inert gases. Such a complication of the design is caused by the need to work with metals and alloys subject to oxidation - for example, with titanium.

Stereolithography

How an SLA printer works

Stereolithography printers use special liquid materials called "photopolymer resins". The term "photopolymerization" refers to the ability of a material to harden when exposed to light. As a rule, such materials react to ultraviolet irradiation.

Resin is poured into a special container with a movable platform, which is installed in a position near the surface of the liquid. The layer of resin covering the platform corresponds to one layer of the digital model. Then a thin layer of resin is processed by a laser beam, hardening at the points of contact. At the end of illumination, the platform together with the finished layer is immersed to the thickness of the next layer, and illumination is performed again.

Then a thin layer of resin is processed by a laser beam, hardening at the points of contact. At the end of illumination, the platform together with the finished layer is immersed to the thickness of the next layer, and illumination is performed again.

Lamination

Laminating (LOM) 3D printers workflow

Some 3D printers build models using sheet materials - paper, foil, plastic film.

Layers of material are glued on top of each other and cut along the contours of the digital model using a laser or blade.

These machines are well suited for prototyping and can use very cheap consumables, including regular office paper. However, the complexity and noise of these printers, coupled with the limitations of the models they produce, limit their popularity.

Fused deposition modeling (FDM) and laser stereolithography (SLA) have become the most popular 3D printing methods used in the home and office.

Let's take a closer look at these technologies.

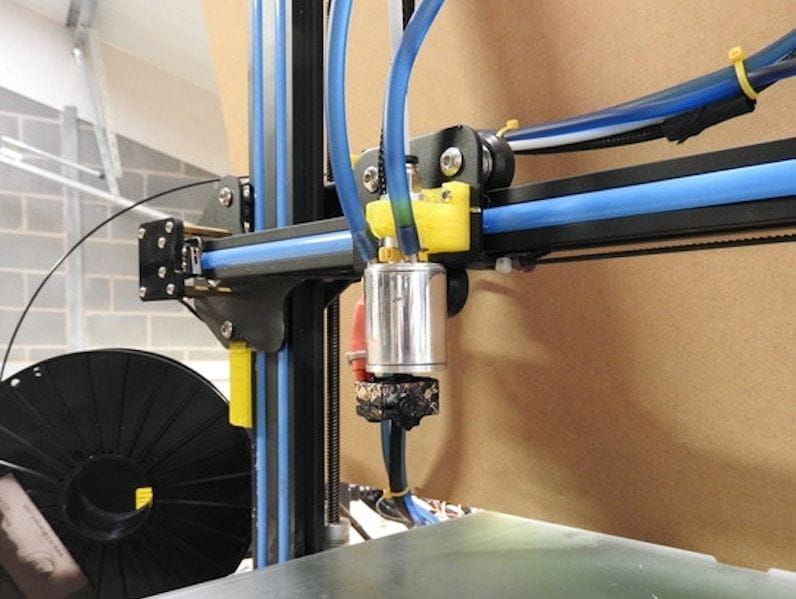

Fused Deposition Printing (FDM)

FDM is perhaps the simplest and most affordable 3D printing method, which makes it very popular.

High demand for FDM printers is driving device and consumable prices down rapidly, along with technology advances towards ease of use and improved reliability.

Consumables

ABS filament spool and finished model

FDM printers are designed to print with thermoplastics, which are usually supplied as thin filaments wound on spools. The range of "clean" plastics is very wide. One of the most popular materials is polylactide or "PLA plastic". This material is made from corn or sugar cane, which makes it non-toxic and environmentally friendly, but makes it relatively short-lived. ABS plastic, on the other hand, is very durable and wear-resistant, although it is susceptible to direct sunlight and can release small amounts of harmful fumes when heated. Many plastic items that we use on a daily basis are made from this material: housings for household appliances, plumbing fixtures, plastic cards, toys, etc.

Many plastic items that we use on a daily basis are made from this material: housings for household appliances, plumbing fixtures, plastic cards, toys, etc.

In addition to PLA and ABS, printing is possible with nylon, polycarbonate, polyethylene and many other thermoplastics that are widely used in modern industry. More exotic materials are also possible, such as polyvinyl alcohol, known as "PVA plastic". This material dissolves in water, which makes it very useful for printing complex geometric patterns. But more on that below.

Model made from Laywoo-D3. Changing the extrusion temperature allows you to achieve different shades and simulate annual rings

It is not necessary to print with homogeneous plastics. It is also possible to use composite materials imitating wood, metals, stone. Such materials use all the same thermoplastics, but with impurities of non-plastic materials.

So, Laywoo-D3 consists partly of natural wood dust, which allows you to print "wooden" products, including furniture.

The material called BronzeFill is filled with real bronze, and models made from it can be ground and polished, achieving a high similarity to products made from pure bronze.

One has only to remember that thermoplastics serve as a connecting element in composite materials - they determine the thresholds of strength, thermal stability and other physical and chemical properties of finished models.

Extruder

Extruder - FDM print head. Strictly speaking, this is not entirely true, because the head consists of several parts, of which only the feed mechanism is directly "extruder". However, by tradition, the term "extruder" is commonly used as a synonym for the entire print assembly.

FDM extruder general design

The extruder is designed for melting and applying thermoplastic thread. The first component is the thread feed mechanism, which consists of rollers and gears driven by an electric motor. The mechanism feeds the thread into a special heated metal tube with a small diameter nozzle, called a "hot end" or simply a "nozzle". The same mechanism is used to remove the thread if a change of material is needed.

The mechanism feeds the thread into a special heated metal tube with a small diameter nozzle, called a "hot end" or simply a "nozzle". The same mechanism is used to remove the thread if a change of material is needed.

The hot end is used to heat and melt the thread fed by the threader. As a rule, nozzles are made from brass or aluminum, although more heat-resistant, but also more expensive materials can be used. For printing with the most popular plastics, a brass nozzle is quite enough. The “nozzle” itself is attached to the end of the tube with a threaded connection and can be replaced with a new one in case of wear or if a change in diameter is necessary. The nozzle diameter determines the thickness of the molten filament and, as a result, affects the print resolution. The heating of the hot end is controlled by a thermistor. Temperature control is very important, because when the material is overheated, pyrolysis can occur, that is, the decomposition of plastic, which contributes both to the loss of the properties of the material itself and to clogging of the nozzle.

PrintBox3D One FDM Printer Extruder

To prevent the filament from melting too early, the top of the hot end is cooled by heatsinks and fans. This point is of great importance, since thermoplastics that pass the glass transition temperature significantly expand in volume and increase the friction of the material with the walls of the hot end. If the length of such a section is too long, the pulling mechanism may not have enough strength to push the thread.

The number of extruders may vary depending on the purpose of the 3D printer. The simplest options use a single printhead. The dual extruder greatly expands the capabilities of the device, allowing you to print one model in two different colors, as well as using different materials. The last point is important when building complex models with overhanging structural elements: FDM printers cannot print “over the air”, since the applied layers require support. In the case of hinged elements, temporary support structures have to be printed, which are removed after printing is completed. The removal process is fraught with damage to the model itself and requires accuracy. In addition, if the model has a complex structure with internal cavities that are difficult to access, building conventional supports may not be practical due to the difficulty in removing excess material.

The removal process is fraught with damage to the model itself and requires accuracy. In addition, if the model has a complex structure with internal cavities that are difficult to access, building conventional supports may not be practical due to the difficulty in removing excess material.

Finished model with PVA supports (white) before and after washing

In such cases, the very water-soluble polyvinyl alcohol (PVA) comes in handy. Using a dual extruder, you can build a model from waterproof thermoplastic using PVA to create supports.

After printing, PVA can be simply dissolved in water and a complex product of perfect quality can be obtained.

Some FDM printers can use three or even four extruders.

Work platform

Heated platform covered with removable glass work table

Models are built on a special platform, often equipped with heating elements. Preheating is required for a wide range of plastics, including the popular ABS, which are subject to a high degree of shrinkage when cooled. The rapid loss of volume by cold coats compared to freshly applied material can lead to model distortion or delamination. The heating of the platform makes it possible to significantly equalize the temperature gradient between the upper and lower layers.

The rapid loss of volume by cold coats compared to freshly applied material can lead to model distortion or delamination. The heating of the platform makes it possible to significantly equalize the temperature gradient between the upper and lower layers.

Heating is not recommended for some materials. A typical example is PLA plastic, which requires a fairly long time to harden. Heating PLA can lead to deformation of the lower layers under the weight of the upper ones. When working with PLA, measures are usually taken not to heat up, but to cool the model. Such printers have characteristic open cases and additional fans blowing fresh layers of the model.

Calibration screw for work platform covered with blue masking tape

The platform needs to be calibrated before printing to ensure that the nozzle doesn't hit the applied layers and move too far causing air-to-air printing resulting in plastic vermicelli. The calibration process can be either manual or automatic. In manual mode, calibration is performed by positioning the nozzle at different points on the platform and adjusting the platform inclination using the support screws to achieve the optimal distance between the surface and the nozzle.

In manual mode, calibration is performed by positioning the nozzle at different points on the platform and adjusting the platform inclination using the support screws to achieve the optimal distance between the surface and the nozzle.

As a rule, platforms are equipped with an additional element - a removable table. This design simplifies the cleaning of the working surface and facilitates the removal of the finished model. Stages are made from various materials, including aluminum, acrylic, glass, etc. The choice of material for the manufacture of the stage depends on the presence of heating and consumables for which the printer is optimized.

For a better adhesion of the first layer of the model to the surface of the table, additional tools are often used, including polyimide film, glue and even hairspray! But the most popular tool is inexpensive, but effective masking tape. Some manufacturers make perforated tables that hold the model well but are difficult to clean. In general, the expediency of applying additional funds to the table depends on the consumable material and the material of the table itself.

In general, the expediency of applying additional funds to the table depends on the consumable material and the material of the table itself.

Positioning mechanisms

Scheme of operation of positioning mechanisms

Of course, the print head must move relative to the working platform, and unlike conventional office printers, positioning must be carried out not in two, but in three planes, including height adjustment.

Positioning pattern may vary. The simplest and most common option involves mounting the print head on perpendicular guides driven by stepper motors and providing positioning along the X and Y axes.

Vertical positioning is carried out by moving the working platform.

On the other hand, it is possible to move the extruder in one plane and the platforms in two.

SeemeCNC ORION Delta Printer

One option that is gaining popularity is the delta coordinate system.

Such devices are called "delta robots" in the industry.

In delta printers, the print head is suspended on three manipulators, each of which moves along a vertical rail.

The synchronous symmetrical movement of the manipulators allows you to change the height of the extruder above the platform, and the asymmetric movement causes the head to move in the horizontal plane.

A variant of this system is the reverse delta design, where the extruder is fixed to the ceiling of the working chamber, and the platform moves on three support arms.

Delta printers have a cylindrical build area, and their design makes it easy to increase the height of the working area with minimal design changes by extending the rails.

In the end, everything depends on the decision of the designers, but the fundamental principle does not change.

Control

Typical Arduino-based controller with add-on modules

FDM printer operation, including nozzle and platform temperature, filament feed rate, and stepper motors for positioning the extruder, is controlled by fairly simple electronic controllers. Most controllers are based on the Arduino platform, which has an open architecture.

Most controllers are based on the Arduino platform, which has an open architecture.

The programming language used by printers is called G-code (G-Code) and consists of a list of commands executed in turn by the 3D printer systems. G-code is compiled by programs called "slicers" - standard 3D printer software that combines some of the features of graphics editors with the ability to set print options through a graphical interface. The choice of slicer depends on the printer model. RepRap printers use open source slicers such as Skeinforge, Replicator G and Repetier-Host. Some companies make printers that require proprietary software.

Program code for printing is generated using slicers

As an example, we can mention Cube printers from 3D Systems. There are companies that offer proprietary software but allow third-party software, as is the case with the latest generation of MakerBot 3D printers.

Slicers are not intended for 3D design per se. This task is done with CAD editors and requires some 3D design skills. Although beginners should not despair: digital models of a wide variety of designs are offered on many sites, often even for free. Finally, some companies and individuals offer 3D design services for custom printing.

This task is done with CAD editors and requires some 3D design skills. Although beginners should not despair: digital models of a wide variety of designs are offered on many sites, often even for free. Finally, some companies and individuals offer 3D design services for custom printing.

Finally, 3D printers can be used in conjunction with 3D scanners to automate the process of digitizing objects. Many of these devices are designed specifically to work with 3D printers. Notable examples include the 3D Systems Sense handheld scanner and the MakerBot Digitizer handheld desktop scanner.

MakerBot Replicator 5th Generation FDM Printer with built-in control module on the top of the frame

The user interface of a 3D printer can consist of a simple USB port for connecting to a personal computer. In such cases, the device is actually controlled by the slicer.

The disadvantage of this simplification is a rather high probability of printing failure when the computer freezes or slows down.

A more advanced option includes an internal memory or memory card interface to make the process standalone.

These models are equipped with control modules that allow you to adjust many print parameters (such as print speed or extrusion temperature). The module may include a small LCD display or even a mini-tablet.

Varieties of FDM printers

Professional Stratasys Fortus 360mc FDM printer that allows printing with nylon

FDM printers are very, very diverse, ranging from the simplest homemade RepRap printers to industrial installations capable of printing large-sized objects.

Stratasys, founded by Scott Crump, the inventor of FDM technology, is a leader in the production of industrial installations.

You can build the simplest FDM printers yourself. Such devices are called RepRap, where "Rep" indicates the possibility of "replication", that is, self-reproduction.

RepRap printers can be used to print custom built plastic parts.

Controller, rails, belts, motors and other components can be easily purchased separately.

Of course, assembling such a device on your own requires serious technical and even engineering skills.

Some manufacturers make it easy by selling DIY kits, but these kits still require a good understanding of the technology. RepRap Printers

And, despite their "home-made nature", RepRap printers are quite capable of producing models with quality at the level of expensive branded counterparts.

Ordinary users who do not want to delve into the intricacies of the process, but require only a convenient device for household use, can purchase a ready-made FDM printer.

Many companies are focusing on the development of the consumer market segment, offering 3D printers for sale that are ready to print “straight out of the box” and do not require serious computer skills.

3D Systems Cube consumer 3D printer

The most famous example of a consumer 3D printer is the 3D Systems Cube.

While it doesn't boast a huge build area, ultra-fast print speed, or unrivaled model build quality, it's easy to use, affordable, and safe: This printer has received the necessary certification to be used even by children.

Mankati FDM printer demonstration: http://youtu.be/51rypJIK4y0

Laser Stereolithography (SLA)

Stereolithographic 3D printers are widely used in dental prosthetics

Stereolithographic printers are the second most popular and widespread after FDM printers.

These units deliver exceptional print quality.

The resolution of some SLA printers is measured in a matter of microns - it is not surprising that these devices quickly won the love of jewelers and dentists.

The software side of laser stereolithography is almost identical to FDM printing, so we will not repeat ourselves and will only touch on the distinctive features of the technology.

Lasers and projectors

Projector illumination of a photopolymer model using Kudo3D Titan DLP printer as an example

The cost of stereolithography printers is rapidly declining, due to growing competition due to high demand and the use of new technologies that reduce the cost of construction.

Although the technology is generically referred to as "laser" stereolithography, most recent developments use UV LED projectors for the most part.

Projectors are cheaper and more reliable than lasers, do not require the use of delicate mirrors to deflect the laser beam, and have higher performance. The latter is explained by the fact that the contour of the whole layer is illuminated as a whole, and not sequentially, point by point, as is the case with laser options. This variant of the technology is called projection stereolithography, "DLP-SLA" or simply "DLP". However, both options are currently common - both laser and projector versions.

Cuvette and resin

Photopolymer resin is poured into a cuvette

A photopolymer resin that looks like epoxy is used as consumables for stereolithography printers. Resins can have a variety of characteristics, but they all share one key feature for 3D printing applications: these materials harden when exposed to ultraviolet light. Hence, in fact, the name "photopolymer".

When polymerized, resins can have a wide variety of physical characteristics. Some resins are like rubber, others are hard plastics like ABS. You can choose different colors and degrees of transparency. The main disadvantage of resins and SLA printing in general is the cost of consumables, which significantly exceeds the cost of thermoplastics.

On the other hand, stereolithographic printers are mainly used by jewelers and dentists who do not need to build large parts but appreciate the savings from fast and accurate prototyping. Thus, SLA printers and consumables pay for themselves very quickly.

Thus, SLA printers and consumables pay for themselves very quickly.

An example of a model printed on a laser stereolithographic 3D printer. In this case, the printer uses a leveling device to flatten the thin layer of resin covering the platform just prior to irradiation. As the model is being made, the platform, together with the finished layers, is “embedded” in the resin. Upon completion of printing, the model is removed from the cuvette, treated with a special solution to remove liquid resin residues and placed in an ultraviolet oven, where the final illumination of the model is performed.

Some SLA and DLP printers work in an "inverted" scheme: the model is not immersed in the consumable, but "pulled" out of it, while the laser or projector is placed under the cuvette, and not above it. This approach eliminates the need to level the surface after each exposure, but requires the use of a cuvette made of a material transparent to ultraviolet light, such as quartz glass.

The accuracy of stereolithographic printers is extremely high. For comparison, the standard for vertical resolution for FDM printers is considered to be 100 microns, and some variants of SLA printers allow you to apply layers as thin as 15 microns. But this is not the limit. The problem, rather, is not so much in the accuracy of lasers, but in the speed of the process: the higher the resolution, the lower the print speed. The use of digital projectors allows you to significantly speed up the process, because each layer is illuminated entirely. As a result, some DLP printer manufacturers claim to be able to print with a vertical resolution of one micron!

Video from CES 2013 showing Formlabs Form1 stereolithography 3D printer in action: http://youtu.be/IjaUasw64VE

Stereolithography Printer Options

Formlabs Form1 Desktop Stereolithography Printer

As with FDM printers, SLA printers come in a wide range in terms of size, features and cost.