3D printers malta

Home - Invent 3D

Design Develop Disrupt Your Industry

Creative

We work in, out and around the box.

Innovative

Our solutions give our clients the edge over competition.

Low waste, and straight to solving the problem.

Professional

Engineer-driven and goal-oriented.

Our DNA

R&D, Product Development, Innovation and 3D Printing Applications, creating Brands, Products & Stories.

What our Clients say About Us

From Trophies to Tooling, to Production components and full R&D Projects, Client Satisfaction is our Top Priority.

Contact Us

“The team at Invent 3D helped us take our initial product idea to a strong MVP stage and initial prototype run. Thanks to Invent 3D’s Product Development support, we’re now able to expedite our innovation through them.

”

Michael DebonoCEO, Debono Group

“Invent 3D has been instrumental in helping Toly Group explore 3D printing as a means of production for unique, short run items with sustainable goals.”

James Attard KingswellInnovation Manager, Toly Group

“The team at Invent 3D assisted us in rapid design and manufacturing, helping us design and manufacture an alternative solution to solve an issue due to a delay in supply chain. within a few hours.”

Alistair Buttigieg VellaCEO, Universal Import & Export Ltd

“Invent 3D has been highly supportive in our rapid prototyping needs, as well as production runs of 300 units. Manufacturing with Invent 3D has helped us cut down on inventory, as well as save on tooling and logistics costs.

”

Melchior BusuttilGeneral Manager, New Energy Ltd

“Invent 3D is challenging Malta’s perception of 3D Printing, and re-introducing the technology as a viable and sustainable means of production. Rapid Prototyping & Agile Product iteration are driving product innovation.”

Michael AzzopardiTechnology Consulting Lead, EY Malta

“Invent 3D has helped us in rapid product development of one of our best-selling products, as well as manufacturing to order. This has helped us save on logistics, both in terms of time and costs, and keep inventory levels low, whilst remaining at a competitive price point and utilising sustainable and recyclable materials.”

COMTECPest Control

“Invent 3D is our go-to for bringing our creative ideas and concepts to life in a fast and efficient manner.

”

Lovin Malta

“Invent 3D was a key player in helping me develop my ideas into tangible, manufacturable products to pitch on Shark Tank and develop into a scalable startup.”

Chris MerciecaEntrepreneur

Rapid Tooling & Jig Design“Invent 3D provides us with rapid prototyping and manufacturing solutions in a fast & efficient way, while also guiding us in best design practices for 3D Printed components.”

Ing. Reuben CamilleriGeneral Manager, IoTSolutions Ltd

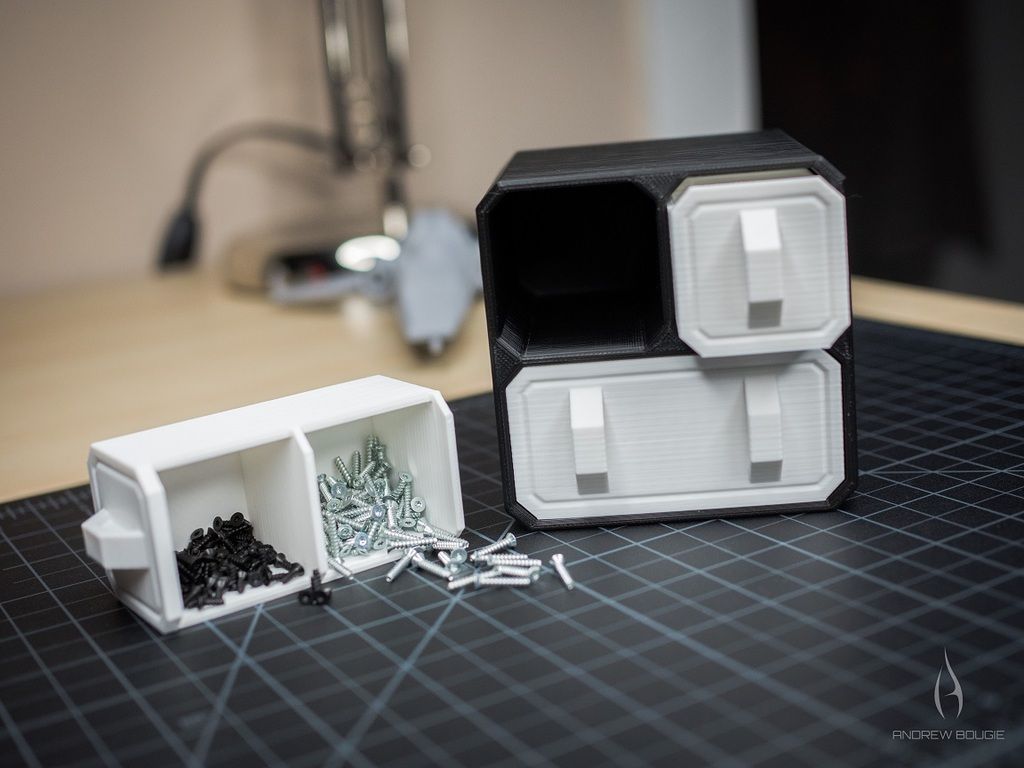

Reduce downtime and increase agility with 3D Printed jigs

Medical-grade and high strength materials

Prototyping

Top-tier FDM, SLA and SLS printing and excellent model-making facilities in vacuum forming, finishing and hand painting

Ultra-high resolution

Large Build Volume

Product Design & DevelopmentFull Idea to Market cycle for new innovative products

Mass ManufacturingLow MOQ & Highly customizable products manufactured rapidly, with no tooling delays or capital costs.

Spare & Rare parts design & manufacturing

ConsultationImplementation of 3D Printing in your workflow

Digital Parts Library SystemDesign and store your essential parts virtually, and print on demand

R&D for 3D Printing ManufacturersTesting of printers, components & Materials

EducationKnowledge sharing in the 3D Printing space

Filter

All

Founded in 2018, the company has become a household name in Malta for 3D printing, and it is currently expanding its operations through partnerships with European customers and worldwide exports.

Agile and Hungry for Innovation!

Dave

CEO, Co-Founder, Engineer

David focuses on generating business, securing strategic investment & partnerships, and opportunities for the company to advance in new niches. He also focuses on marketing and sales, and email communications. In his free time he’s probably working on reviving his old BMWs, or at the gym, warming up with your max.

He also focuses on marketing and sales, and email communications. In his free time he’s probably working on reviving his old BMWs, or at the gym, warming up with your max.

Alex

COO, Co-Founder, Lead Designer

Alex handles the day-to-day running of the office, keeping it organised. She also handles dental and medical resin applications, finances and purchasing, as well as running and communications of the smaller brands. In her free time, she's probably lifting at the gym, meal prepping, illustrating, or feeding her kids their 27th snack of the day.

Angelo

Senior Additive Manufacturing Engineer

Angelo manages the FDM side of the Print Farm, handling maintenance, repairs, upgrades, and calibrations. He also handles the more technical design clients and projects, and innovative R&D applications. In his free time, he’s probably messing with his DIY CNC at home. Full time nerd.

Joe

Additive Manufacturing Technician

Joe handles R&D projects involving Electronics & Coding, as well as Resin slicing, maintenance and setups. He also manages the order processing & packages of The Giants’ Tower. In his free time, he’s probably rerunning Skyrim for the 100th time.

He also manages the order processing & packages of The Giants’ Tower. In his free time, he’s probably rerunning Skyrim for the 100th time.

Manolo

Artist & Designer

Manolo handles the artistic and intricate side of Invent 3D, such as painting of miniatures, trophies & exhibits, as well as assembly of complex models. He also supports the resin station. In his free time he’s painting his own miniatures or rewatching The Lord Of The Rings.

Jeremy

Additive Manufacturing Designer

Jeremy focuses on free-form 3D Design on Blender, such as models, trophies and sculptures. He also helps maintain the print farm as a whole, optimizing processes and workflows. In his free time, he’s occupying a squat rack chugging BCAAs and thinking about how low he needs to squat.

Luca

Additive Manufacturing Technician

Luca handles the processing and cleaning of all resin models, as well as order fulfillment for The Giants’ Tower. He also handles designing of the cookie cutter shapes. In his free time, he’s probably playing Dungeons & Dragons or watching Deadpool.

He also handles designing of the cookie cutter shapes. In his free time, he’s probably playing Dungeons & Dragons or watching Deadpool.

How 3D Printing Is Set To Revolutionise Manufacturing In Malta

The manufacturing sector in Malta is set to be transformed by 3D printing, according to stakeholders, who have stated that the digital technology is gaining ground locally. This is due to its capability to decrease time, cost and logistical requirements, reduce waste and ensure more flexible working methods, resulting in a more varied output, they said.

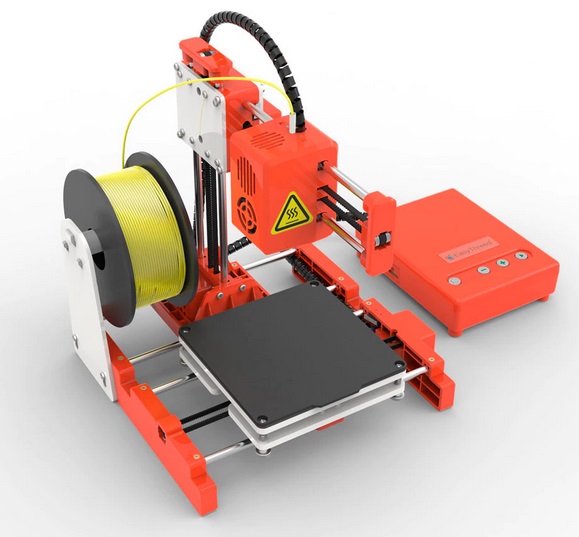

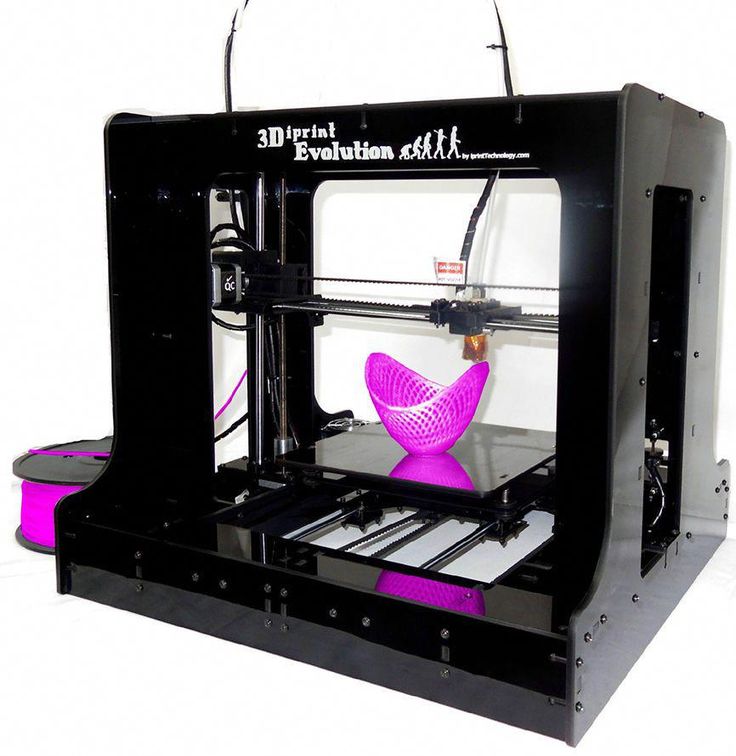

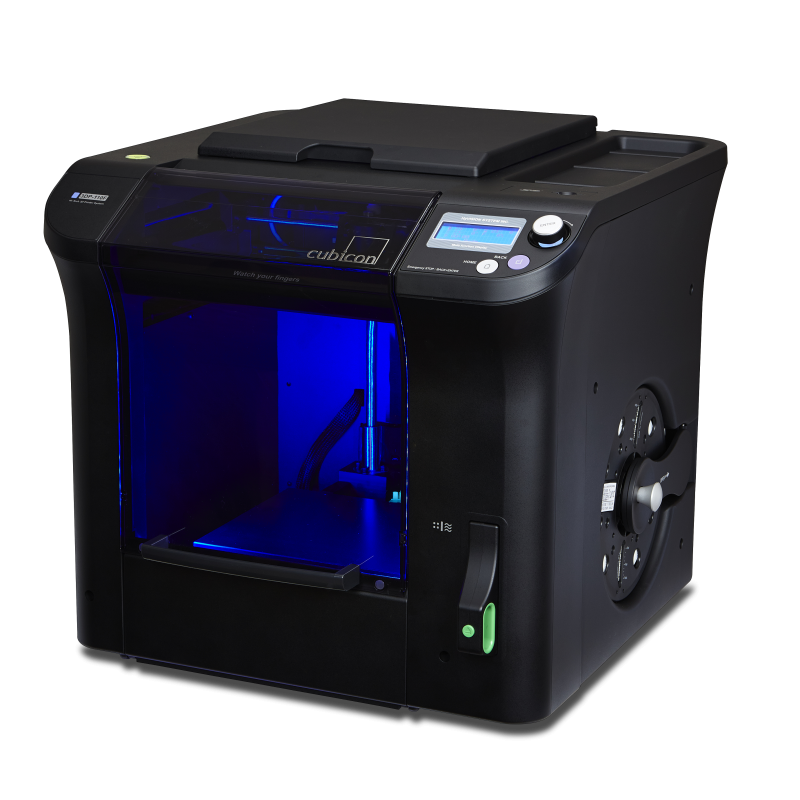

“With 3D printing, you are working in a digital world, in which each and every product can be unique, customisable and created on demand,” James Attard Kingswell, Innovation Manager at manufacturing giant Toly, said. Indeed, in his view, these advantages have enabled the technology to grow from strength to strength on the island, with “more and more companies purchasing both lower-cost machines to provide their engineers with quick ways to prototype, and larger-scale machines for higher-end applications.”

Indeed, in his view, these advantages have enabled the technology to grow from strength to strength on the island, with “more and more companies purchasing both lower-cost machines to provide their engineers with quick ways to prototype, and larger-scale machines for higher-end applications.”

He stated that the uptake had increased drastically more recently. “Both our intelligent workforce and our economy, which is focused on digital industries and services, make 3D printing very attractive as we move further away from traditional manufacturing,” he noted. These upward trends are set to continue, according to Ing. Attard Kingswell, who said that “once a company experiments with small investments in the technology”, they begin to see the potential and “become less risk-averse in terms of applying it to larger problems.”

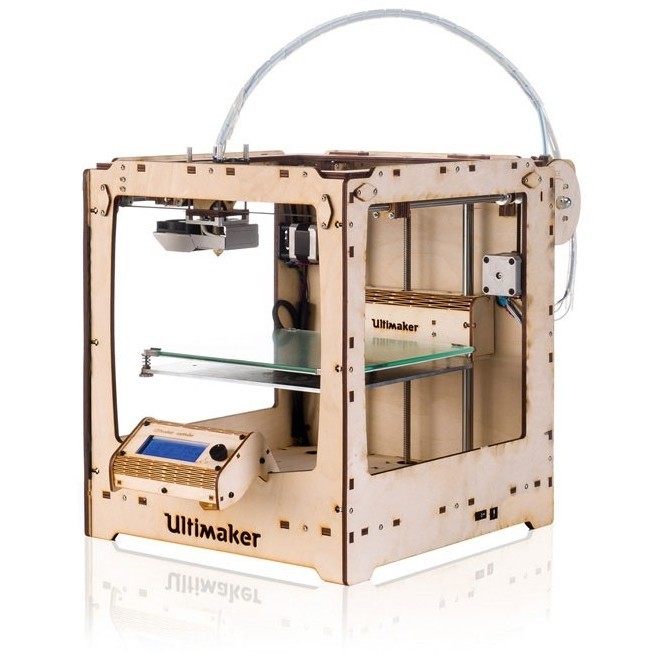

Toly was one of the first companies in Malta to invest heavily in the technology, and is one of the first to adopt 3D Systems ProJet machine based on Polyjet technology – a high-end, ultra-precise 3D printer – for its corporate offices. It has gone on to establish partnerships with leading suppliers, such as Ultimaker and 3DZ, and is also currently rolling out a worldwide programme which will see several small Ultimaker 3D printers set up in their manufacturing, trading and even sales offices, as well as those of their clients, allowing for time and cost savings.

It has gone on to establish partnerships with leading suppliers, such as Ultimaker and 3DZ, and is also currently rolling out a worldwide programme which will see several small Ultimaker 3D printers set up in their manufacturing, trading and even sales offices, as well as those of their clients, allowing for time and cost savings.

“Our Maltese design team can design something, start it printing on our US sales office printer remotely, and owing to the time difference, by the time the US team arrives in the office in the morning, the part will be ready to be removed and shown to a client on the same day,” he said. “3D files can be sent over and products manufactured locally with 3D print farms, thus allowing for a reduction in carbon emissions along the supply chain.” Moreover, this eliminates many of the other hurdles currently facing the manufacturing sector, such as the necessity to have a “minimum order quantity” and “capital investments” which, the Innovation Manager states, “are often a barrier for manufacturing of new products. ”

”

Companies can “merge traditional processes with 3D printing,” creating hybrid systems such as ”3D printing injection moulding tools using metal or polymer 3D printing machines”. Furthermore, the technology allows for a more efficient use of human and automation resources. “With 3D printing you can create a multi-part product with moving features in one instance, whereas with traditional manufacturing you would need an operator or an automaton to assemble different parts together to make your final product, which is a slow process.”

This means that the new technology will require a new and more advanced skillset. “Local educational institutions are adapting to the change: we get requests from schools to demonstrate the technology as part of their STEM initiatives. Higher educational institutions, such as the University, not only have their own equipment, but generally co-share capabilities with us and other local manufacturers. In this way, students have a greater range of different 3D printing equipment to work and learn with. All of this gives them a much better grasp of the technology for when they enter the workforce.”

All of this gives them a much better grasp of the technology for when they enter the workforce.”

These views were echoed by Carla Aguirre, Sales Account Manager at 3DZ, a global retailer of 3D printing equipment and supplies, who also highlighted the increasing popularity of the technology in Malta. “It is getting more and more popular. In 2018, we had five companies who purchased a professional 3D printer for their products and the take-up of 3D scanning is also on the rise. It is indeed a revolution for the manufacturing industry, since you can print basically anything, anytime and in the quantity required.” She also stressed its capability to allow the “manufacture of something that was not possible with traditional methods”, giving an incredible “design freedom” to engineers and designers.

The company, which has offices on the island, sees Malta as instrumental to its operations. “3DZ is present in several countries and Malta, being so central, has been the perfect choice to operate from. The financial support available and the access to international professionals is unparalleled,” Ms Aguirre stated. Indeed, the company has invested in educational initiatives designed to further enhance knowledge and awareness of 3D printing and scanning capabilities, including two workshops on how the technology is used in architecture and in R&D, though the manufacturing sector also stands to make continued substantial gains.

The financial support available and the access to international professionals is unparalleled,” Ms Aguirre stated. Indeed, the company has invested in educational initiatives designed to further enhance knowledge and awareness of 3D printing and scanning capabilities, including two workshops on how the technology is used in architecture and in R&D, though the manufacturing sector also stands to make continued substantial gains.

“There is a tsunami of opportunity within the manufacturing industry, even when it comes to jobs. We do not expect job losses, but the jobs created will be different. There will be huge opportunities for 3D designers, engineers trained to handle the technology and sales people ready to sell customised products – not only those categorised as ‘off the shelf’.”

Issam Bahloul, the director of Full Circle 3D, and Amber Keurntjes, the company’s coordinator and 3D modeller, corroborated many of these sentiments. The SME, which provides 3D printing services to a variety of local professionals, including within the manufacturing sector, stated that while 3D technology is still “quite costly”, prices are expected to go down, resulting in increased profitability within the industry.

“3D printing is a great step towards the future. It has opened new doors and its technology has shown to be beneficial for humanity at large, making our lives easier. We have seen that ourselves. A recent project we completed a few months ago involved the creation of over a thousand prototypes of the same design.” This is something which would not have been possible before the advent of the technology, according to the two entrepreneurs, who stated that “its wide applicational uses and few restrictions allow it to be of benefit to many industries, especially in a small country such as Malta, allowing for larger possibilities regarding product design, manufacturing and range of products.”

Both expressed belief in the future of the technology, stating that while new technologies take time to root within a society, they expect the use of 3D capabilities to “continue to ascend drastically.” They stressed that “it won't be long till other businesses will start to specialise in the provision of such services or commence to make use of the technology”, voicing a high-degree of confidence in the technology and its ability to change the way systems and procedures are currently carried out.

This article originally appeared in The Malta Business Observer

Comparison of 3D printing technologies: FDM, SLA and SLS

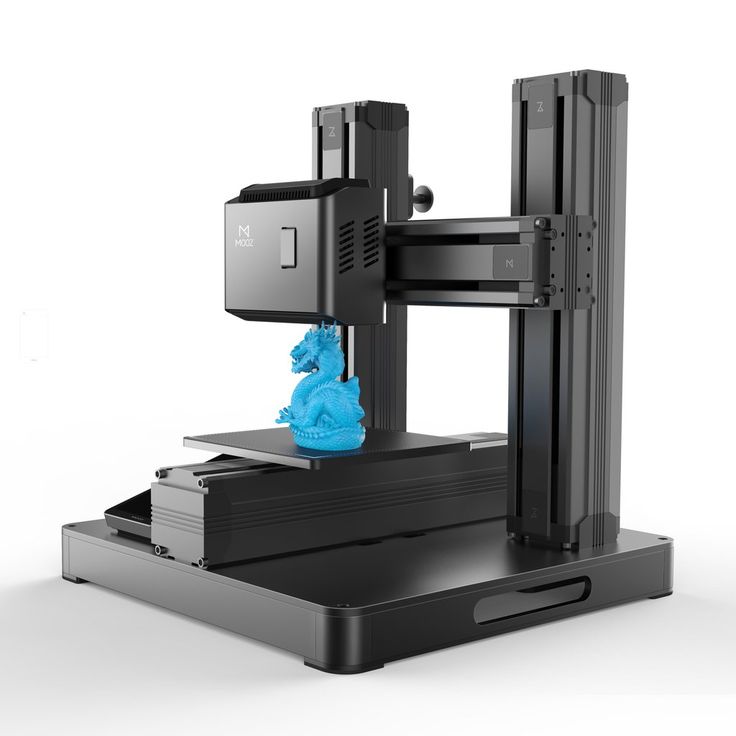

Additive manufacturing or 3D printing reduces costs, saves time and expands the technological possibilities in product development. 3D printing technologies offer versatile solutions for applications ranging from rapid concept and functional prototypes in the field of prototyping to fixtures and clamps or even final parts in manufacturing.

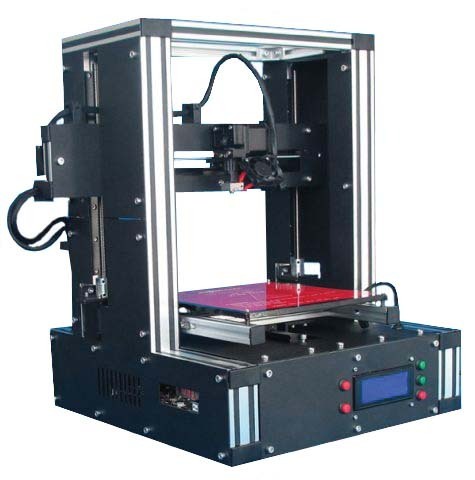

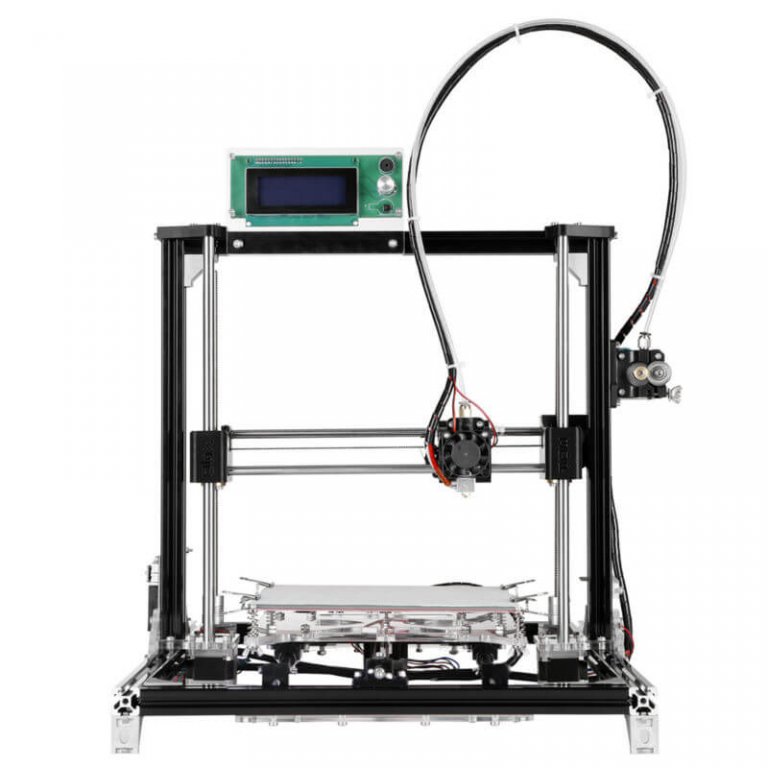

Over the past few years, high resolution 3D printers have become more affordable, more reliable and easier to use. As a result, more companies have been able to use 3D printing technology, but choosing between different competing 3D printing solutions can be difficult.

Which technology is right for your needs? What materials are available for her? What equipment and training is needed to get started? What are the costs and payback?

In this article, we take a closer look at three of today's most well-known plastic 3D printing technologies: Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Choosing between FDM and SLA 3D printer? Check out our detailed comparison of FDM and SLA technologies.

Download this high resolution infographic here.

VIDEO MANUAL

Can't find the 3D printing technology that best suits your needs? In this video tutorial, we compare Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS) technologies in terms of the top factors to consider when purchasing.

Watch Video

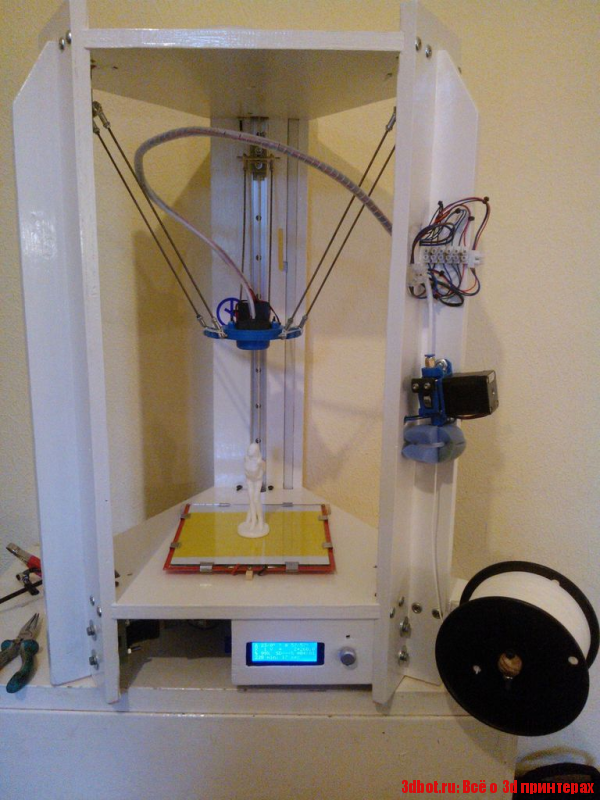

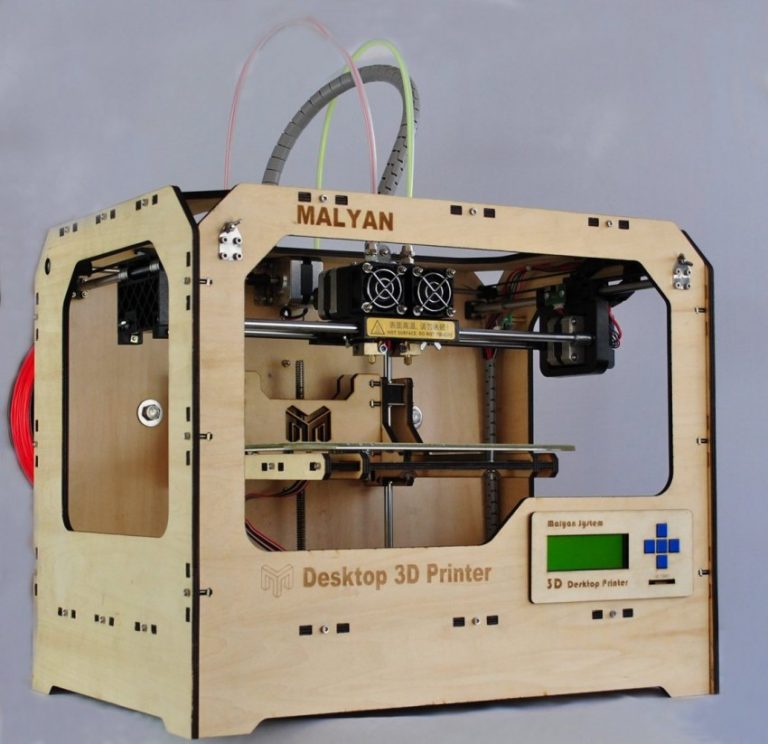

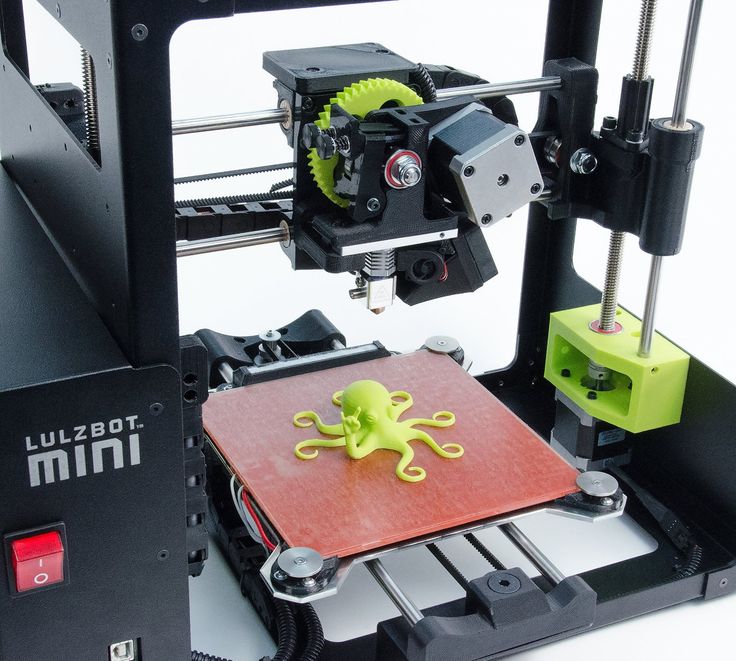

Fused Deposition Modeling (FDM), also known as Fused Filament Manufacturing (FFF), is the most widely used form of 3D printing at the consumer level, fueled by the rise of consumer 3D printers. On FDM printers, models are made by melting and extruding a thermoplastic filament, which the printer's nozzle applies layer by layer to the model being built.

The FDM method uses a range of standard plastics such as ABS, PLA and their various blends. It is well suited for making basic experimental models, as well as for quickly and inexpensively prototyping simple parts, such as parts that are usually machined.

It is well suited for making basic experimental models, as well as for quickly and inexpensively prototyping simple parts, such as parts that are usually machined.

FDM models often show layer lines and may have inaccuracies around complex features. This sample was printed on a Stratasys uPrint FDM industrial 3D printer with soluble support structures (printer price starting at $15,900).

FDM printers have the lowest resolution and accuracy of SLA or SLS and are not the best option for printing complex designs or parts with complex features. Surface quality can be improved by chemical and mechanical polishing processes. To address these issues, industrial FDM 3D printers use soluble support structures and offer a wider range of engineering thermoplastics, but they are also expensive.

FDM printers do not handle complex designs or parts with complex features well (left) compared to SLA printers (right).

Invented in the 1980s, stereolithography is the world's first 3D printing technology and is still one of the most popular technologies among professionals today. SLA printers use a process called photopolymerization, which is the conversion of liquid polymers into hardened plastic using a laser.

SLA printers use a process called photopolymerization, which is the conversion of liquid polymers into hardened plastic using a laser.

See stereolithography in action.

Models printed on SLA printers have the highest resolution and accuracy, the sharpest detail and the smoothest surface of all plastic 3D printing technologies, but the main advantage of the SLA method is its versatility. Materials manufacturers have developed innovative formulas for SLA polymers with a wide range of optical, mechanical and thermal properties that match those of standard, engineering and industrial thermoplastics.

Models created using SLA technology have sharp edges, a smooth surface and almost invisible layer lines. This sample was printed on a Formlabs Form 3 Desktop Stereolithographic 3D Printer (price starting at $3499).

SLA is an excellent option for making highly detailed prototypes that require tight tolerances and smooth surfaces such as molds, templates and functional parts. SLA technology is widely used in industries ranging from engineering and design to manufacturing, dentistry, jewelry, modeling, and education.

SLA technology is widely used in industries ranging from engineering and design to manufacturing, dentistry, jewelry, modeling, and education.

White Paper

Download our in-depth white paper to learn how SLA printing works, why thousands of professionals use it today, and how this 3D printing technology can be useful in your work.

Download white paper

free sample

Experience Formlabs print quality firsthand. We will send a free 3D printing sample directly to your office.

Request a free sample

Selective laser sintering is the most common additive manufacturing technology used in industry.

Selective Laser Sintering (SLS) 3D printers use a high power laser to sinter fine polymer powder particles. The unsprayed powder supports the model during printing and eliminates the need for special support structures. This makes SLS ideal for complex geometries, including internal features, grooves, thin walls, and negative taper. Models produced using SLS printing have excellent mechanical characteristics: their strength can be compared with the strength of injection molded parts.

This makes SLS ideal for complex geometries, including internal features, grooves, thin walls, and negative taper. Models produced using SLS printing have excellent mechanical characteristics: their strength can be compared with the strength of injection molded parts.

Models created with SLS technology have a slightly rough surface, but almost no visible layer lines. This sample was printed on the Formlabs Fuse 1 SLS workshop 3D printer (price starting at $18,500).

The most common selective laser sintering material is nylon, a popular engineering thermoplastic with excellent mechanical properties. Nylon is light, strong and flexible, resistant to impact, heat, chemicals, UV radiation, water and dirt.

The combination of low part cost, high productivity, and widely used materials makes SLS a popular method for engineering functional prototyping and a cost-effective alternative to injection molding in cases where production runs are limited.

White Paper

Looking for a 3D printer to create durable, functional models? Download our white paper to learn how selective laser sintering (SLS) technology works and why it is popular in 3D printing for functional prototypes and end-use products.

Download white paper

Each 3D printing technology has its strengths, weaknesses, limitations and applications. The following table summarizes the key characteristics and factors.

| Modeling method (FDM) | Stereolithography (SLA) | Selective laser sintering (SLS) | |

|---|---|---|---|

| ★★★★☆ | |||

| accuracy | ★cle ★cle \ ★★★★★ | ||

| Easy to use | ★★★★★ | ★★★★★ | ★★★★★★★★★★★★★0104 |

| Benefits | Speed Inexpensive custom machines and materials | High cost efficiency High accuracy Smooth surface Wide range of functional applications | Robust functional parts Design flexibility No need for supporting structures |

| Disadvantages | Poor accuracy low detail Limited Compliance with Design Design | Susceptibility to prolonged UV exposure | Uneven surface Material Limitations |

| Applications | Inexpensive Rapid Prototyping Basic experimental models | Functional prototyping Templates, forms and tools Dental products Prototyping jewelry and molds Model building | Functional prototyping Small-scale and custom manufacturing |

| Print volume | Up to ~300 x 300 x 600 mm (desktop 3D printers) | Up to ~300 x 335 x 200 mm (Desktop and Workshop 3D printers) | Up to 165 x 165 x 300 mm (Workshop 3D printers) |

| Materials | ABS plastic, PLA and their various mixtures. | Various polymers (thermosets). Standard, engineering (with properties of ABS plastic, polypropylene, flexible, heat-resistant), molding, dental and medical (biocompatible). | Engineering thermoplastics. Nylon 11, Nylon 12 and their composites. |

| Training | Minimum training in equipment setup, machine operation and surface treatment; short maintenance training. | Plug and play concept. Minimal training in equipment setup, maintenance, machine operation and surface treatment. | Short training in equipment setup, maintenance, machine operation and surface treatment. |

| Room requirements | Air-conditioned environment or preferably individual ventilation for desktop machines. | Desktop machines suitable for office use. | Workshop systems have moderate space requirements and can be installed in a production environment. |

| Accessories | Support removal system for machines with soluble support structures (optionally automated), finishing tools. | Finishing station, washing station (optionally automated), finishing tools. | Post-processing station for cleaning models and restoring materials. |

Either way, you should choose the technology that best suits your business. Prices have dropped significantly in recent years, and today all three technologies are offered in compact and affordable systems.

3D printing costing doesn't end with initial equipment costs. Material and labor costs have a significant impact on the cost of each part, depending on the application and production needs.

Below is a detailed breakdown by technology.

| Modeling method (FDM) | Stereolithography (SLA) | Selective laser sintering (SLS) | Equipment costs and sets for 3D-dimensions for 3Ds and sets several hundred dollars. Offering higher quality, mid-range desktop printers start at $2,000, while industrial systems start at $15,000. | Professional desktop printers start at $3,500, large-format workshop printers start at $10,000, industrial systems for large-scale production start at $80,000. |

|---|---|---|---|

| Material cost | $50-$150/kg for most standard and engineering yarns and $100-$200/kg for auxiliary materials. | $50-$150/L for most standard and engineering polymers. | $100/kg for nylon. SLS does not require supporting structures and unused powder can be reused, reducing material costs. |

| Labor | Manual removal of support structures (may be automated for industrial systems with dissolvable supports). Long post-processing is required to obtain a high quality surface. | Washing and final polymerization (both can be automated). Simple post-processing to remove supporting structures. | Easy cleaning to remove excess powder. |

INTERACTIVE MATERIAL

Try our interactive ROI tool to see how much time and money you can save by printing with Formlabs 3D printers.

Calculate savings

FDM, SLA and SLS printed prototype ski goggle frames (left to right).

We hope this article has helped you narrow down your search for the 3D printing technology best suited to your needs.

Take advantage of our additional resources to learn the ins and outs of 3D printing, learn more about each technology and learn more about specific 3D printing systems.

Learn more about 3D printing technologies

The Complete Guide to Stereolithographic (SLA) 3D Printing

Stereolithographic (SLA) 3D printing is gaining immense popularity due to its ability to produce highly accurate, isotropic and waterproof prototypes and models with fine details and smooth surfaces from various modern materials.

This comprehensive guide explains how SLA printing technologies work, why thousands of professionals use them today, and how this 3D printing technology can be useful in your work.

White Paper

Download our White Paper to find out how SLA printing works, why thousands of people use it today, and how this 3D printing technology can help your work.

Download technical report

The development of 3D printing technology continues to influence how companies approach prototyping and manufacturing. This technology is becoming more accessible, and equipment and materials are developing in accordance with the possibilities and requirements of the market. That's why today designers, engineers and others are integrating 3D printing into workflows at all stages of development.

3D printing is helping industry professionals reduce recruitment costs, accelerate iteration, streamline manufacturing processes, and even discover entirely new business models.

Stereolithographic 3D printing technology has evolved significantly. In the past, resin 3D printers were monolithic and costly, requiring skilled technicians and costly service contracts to operate. Today's small desktop printers are highly flexible and produce industrial-quality products at a much lower cost.

Today's small desktop printers are highly flexible and produce industrial-quality products at a much lower cost.

Stereolithography is a type of additive manufacturing. It is also known as photopolymerization in the bath or 3D printing using polymer resin. Devices that use this technology have a common principle of operation: under the influence of a light source (laser or projector), a liquid polymer turns into a solid plastic. The main differences are in the location of the main components such as the light source, work platform and resin tank.

See how stereolithography 3D printing is done.

Stereolithographic 3D printers use light-sensitive curable materials called "polymers". When stereolithographic polymers are exposed to specific wavelengths of light, short molecular chains join together causing the monomers and oligomers to polymerize into either rigid or flexible patterns.

Graphical representation of the main mechanisms of stereolithographic 3D printing.

Models printed on SLA printers have the highest resolution and accuracy, the finest detail, and the smoothest surface of any 3D printing technology, but the main advantage of this method is its versatility.

Materials manufacturers have developed innovative formulas for stereolithographic polymers with a wide range of optical, mechanical and thermal properties similar to standard, engineering and industrial thermoplastic resins.

Comparison of 3D stereolithography with two other common plastic modeling technologies: Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS).

Sample

Experience the quality of 3D stereolithography for yourself. We will send a free sample of the printed model directly to your office.

Request a Free Print Sample

Learn how to go from design to 3D printing with a Form 3 3D printer. Watch this 5-minute video to learn the fundamentals of using a Form 3 printer, from software and materials to processes printing and post-processing.

Use any CAD software or 3D scan data to design the model and export it to a 3D print file format (STL or OBJ). All printers based on SLA technology work with software that allows you to set print parameters and separate the digital model into layers. After the settings are complete, the model preparation software sends instructions to the printer via a wireless or cable connection.

More advanced users can design directly for SLA technology or, for example, print models with voids to save materials.

After a quick check of the settings, the printing process starts. The printer may run unattended until printing is complete. In printers with a cartridge system, material is replenished automatically.

Formlabs' online Dashboard allows you to remotely manage printers, resins, and employee access.

After printing is complete, models should be rinsed with isopropyl alcohol to remove resin residue from their surface. After the washed models have dried, some materials require final polymerization, a process that ensures the best possible strength and stability of the parts. Finally, remove the support structures from the models and sand down the remaining traces of the supports for a clean finish. Models produced with SLA technology can be machined, primed, painted or assembled depending on the intended use.

After the washed models have dried, some materials require final polymerization, a process that ensures the best possible strength and stability of the parts. Finally, remove the support structures from the models and sand down the remaining traces of the supports for a clean finish. Models produced with SLA technology can be machined, primed, painted or assembled depending on the intended use.

Final polymerization is particularly important for functional polymer resins used in engineering, dentistry and jewellery.

Engineers, designers, fabricators and others choose 3D stereolithography because it provides excellent detail, smooth surfaces, superior model fidelity, isotropy, and water resistance. In addition, it allows you to work with various materials.

Because 3D printing builds models layer by layer, the strength of finished parts can vary depending on the orientation of the part relative to the printing process: the X, Y, and Z axes will have different properties.

Extrusion-based 3D printing processes such as deposition filament modeling (FDM) are anisotropic due to a special approach to creating different layers during the manufacturing process. This anisotropy limits the application of FDM technology or requires additional changes in the design of the model to compensate for it.

Check out our detailed guide comparing FDM vs. SLA 3D printers to see how they differ in terms of print quality, materials, application, workflow, speed, cost, and more.

Stereolithographic 3D printers, on the other hand, allow the production of highly isotropic models. Achieving detail isotropy relies on a number of factors that can be tightly controlled by integrating the chemical composition of materials with the printing process. During printing, the components of the polymers form covalent bonds, but when creating subsequent layers, the model remains in an "immature" state of partial reaction.

When immature, the resin retains polymerizable groups that can form bonds between layers, giving the model isotropic and waterproof properties after final curing. At the molecular level, there are no differences between the X, Y, and Z planes. This results in models with predictable mechanical characteristics critical for applications such as jigs and fixtures and finished parts, as well as functional prototyping.

At the molecular level, there are no differences between the X, Y, and Z planes. This results in models with predictable mechanical characteristics critical for applications such as jigs and fixtures and finished parts, as well as functional prototyping.

SLA printed parts are highly isotropic compared to FDM parts.

Due to its isotropic nature, stereolithographic printed models, such as this jig for Pankl Racing Systems, can withstand directional loads during production.

SLA printed objects are continuous, whether they are solid or have internal channels. Watertightness is important when it is necessary to control and predict the impact of air or liquid flows. Engineers and designers are using the water resistance of stereolithography printers for air and fluid flow applications in the automotive industry, biomedical research, and to test the design of parts in consumer products such as kitchen appliances.

OXO relies on the water resistance of stereolithographic printed models to create durable working prototypes of air and liquid products such as coffee makers.

Stereolithographic 3D printing is used to produce precise, reproducible components in a variety of industries, including dentistry and manufacturing. In order to produce accurate models during the printing process, many factors must be strictly controlled.

The quality of stereolithographic 3D printing is between standard and precision machined. SLA has the highest tolerance compared to other commercial 3D printing technologies. Learn more about tolerances, accuracy and precision in 3D printing.

The heated resin tank combined with the closed working environment provide virtually the same conditions for every model. The higher accuracy also depends on the lower printing temperature compared to thermoplastic-based technologies in which the raw material is melted. Because stereolithography uses light instead of heat, it prints at close to room temperature and models are not subject to thermal expansion and contraction.

Dental example (comparing a scanned component to an original CAD model) demonstrating the ability to maintain tight tolerances for an entire stereolithographic model.

LFS stereolithography 3D printing involves an optic in a Light Processing Unit (LPU) that moves along the x-axis. parabolic mirrors so that it is always perpendicular to the plane of the platform, so it always moves in a straight line, ensuring maximum precision and accuracy. This allows consistency to be achieved as the size of the equipment increases, for example, when working with a large-sized Formlabs Form 3L stereolithography printer. The LPU also uses a spatial filter, which forms a clear laser spot.

The characteristics of the individual materials also play an important role in ensuring the reliability and reproducibility of print results.

Formlabs Rigid Resin has a high green modulus, or modulus of elasticity, prior to final polymerization, allowing very thin models to be printed with high precision and reliability.

Stereolithography printers are considered the best 3D printers due to the smooth surface of the models produced, the appearance of which is comparable to parts produced by traditional methods such as machining, injection molding and extrusion.

This surface quality is ideal when a perfect finish is needed and also helps reduce post-processing time because these models are easy to sand, polish and paint. For example, large companies like Gillette use stereolithography 3D printing to create finished products such as razor handles in their Razor Maker platform.

Large companies such as Gillette use stereolithography 3D printing to create finished products such as razor handles in their Razor Maker platform.

The Z layer height is often used to determine the resolution of a 3D printer. On Formlabs stereolithographic 3D printers, it can be adjusted from 25 microns to 300 microns to trade off speed and print quality.

FDM and SLS printers typically print Z-axis layers between 100 and 300 microns wide. At the same time, a part printed with 100 micron layers on an FDM or SLS printer is very different from a part printed with 100 micron layers on an SLA printer. Models printed on a stereolithographic printer have a smoother surface immediately after printing, because their outer walls are straight, and each new printed layer interacts with the previous one, smoothing out the effect of the stairs. When printed on an FDM printer, layers are often visible in models, and the surface of models printed on an SLS printer has a grainy structure due to sintered powder.

Models printed on a stereolithographic printer have a smoother surface immediately after printing, because their outer walls are straight, and each new printed layer interacts with the previous one, smoothing out the effect of the stairs. When printed on an FDM printer, layers are often visible in models, and the surface of models printed on an SLS printer has a grainy structure due to sintered powder.

In addition, the stereolithography printer can print fine details: the Form 3 laser spot size is 85 microns, while industrial SLS printers have a 350 micron laser spot, and FDM-based devices use nozzles with a diameter of 250– 800 microns.

Models printed on FDM printers often show layer lines and may have inaccuracies around complex features. Models printed on stereolithography printers have sharp edges, a smooth surface, and almost imperceptible layer lines.

The advantage of SLA polymers lies in a wide range of formulations offering a variety of characteristics: they can be soft or hard, contain additives such as glass and ceramics, or have special mechanical properties such as high bending temperature under load or impact resistance. Materials can be designed for a particular industry, such as dentures, or have properties close to those of final materials to create prototypes that can be tested and run under stress.

Materials can be designed for a particular industry, such as dentures, or have properties close to those of final materials to create prototypes that can be tested and run under stress.

Ceramic Resin can be 3D printed with a stone-like texture and then fired to create a ceramic product.

In some cases, it is this combination of versatility and functionality that is leading businesses to adopt polymer-based 3D printing in-house. After solving existing problems through the use of a certain functional polymer, other applications are usually quickly discovered. In this case, the printer becomes a tool for discovering the various properties of different polymers.

For example, hundreds of engineers in the Design and Prototyping group at the University of Sheffield's Advanced Manufacturing Research Center (AMRC) have access to 12 stereolithographic 3D printers and various construction materials that they use in numerous research projects for these partner companies like Boeing, Rolls-Royce, BAE Systems and Airbus. They printed High Temp Resin washers, brackets, and a mounting system for a sensor that must operate in high temperature conditions, and used Durable Resin to create complex spring components for a material handling robot as part of a composite manufacturing automation system.

They printed High Temp Resin washers, brackets, and a mounting system for a sensor that must operate in high temperature conditions, and used Durable Resin to create complex spring components for a material handling robot as part of a composite manufacturing automation system.

AMRC engineers have access to 12 stereolithographic 3D printers and various construction materials, allowing them to create custom-designed parts for a variety of research projects, such as brackets for a stacking robot (above) and mounts for an environmental sensor high temperature (below).

Material selection

Need help choosing a material for 3D printing? Our new interactive materials wizard will help you make the right material decision based on what you're going to use it for and the properties you care most about in our growing range of polymers.

Get material recommendations

Stereolithographic 3D printing makes it easier for businesses across industries to innovate. Such industries include engineering, manufacturing, dentistry, healthcare, education, entertainment, jewelry, and audiology.

Such industries include engineering, manufacturing, dentistry, healthcare, education, entertainment, jewelry, and audiology.

Rapid prototyping with 3D printing enables engineers and developers to turn ideas into working proofs of concept, transform concepts into high-quality prototypes that look and work like end products, and take products through testing phases to launch into mass production.

Find out more

By creating the necessary prototypes and 3D printing special tools, molds and production aids, manufacturing companies can automate production and optimize workflows at a much lower cost and in much faster time than traditional manufacturing. Thus, production costs are reduced and defects are prevented, quality is improved, assembly is accelerated and labor productivity is increased.

Find out more

Digital Dentistry reduces the risks and uncertainties associated with human error, enabling consistent quality and precision at every step of the workflow, and improving patient care. 3D printers can produce a range of high quality custom products at low cost, providing exceptional fit and reproducible results.

3D printers can produce a range of high quality custom products at low cost, providing exceptional fit and reproducible results.

Learn more

3D printers are multifunctional tools for creating immersive learning and research environments. They stimulate creativity and introduce students to professional-level technology, enabling the implementation of the STEAM method in the fields of science, technology, art and design.

Find out more

Affordable, professional-grade desktop 3D printers help clinicians produce medical devices that meet individual needs and improve patient outcomes. At the same time, the organization significantly reduces time and money costs: from laboratories to operating rooms.

Learn more

High resolution printed physical models are widely used in digital sculpting, 3D character modeling and prop making. 3D-printed models have been featured in animated films, video game characters, theatrical costumes, and even special effects for blockbuster films.

Learn more

Professional jewelers use the power of CAD and 3D printing to rapidly prototype, customize jewelry to customer specifications and produce large batches of blanks for casting. Digital tools allow you to create dense, highly detailed models without the tedious, error-prone production of stencils.

Learn more

Hearing professionals and labs use digital workflows and 3D printing to simplify the production of high-quality custom and hearing aids, as well as to mass-produce behind-the-ear hearing aids, hearing protectors, custom earmoulds, and headphones .

Find out more

Many companies are starting to use 3D printing technology through service bureaus and laboratories. Outsourcing can be a great solution when the need for 3D printing is infrequent or you need to do one-off jobs using materials that have unique properties or produce special models. Service bureaus can also provide advice on various materials and offer additional services such as design or improved finishes.

The main disadvantages of outsourcing are the high cost and duration of production. Often, outsourcing becomes a step on the way to in-house production as needs grow. One of the main advantages of 3D printing is its speed compared to traditional production methods. But it is noticeably reduced when the delivery of the model produced by the involved organization takes several days or even weeks. As demand and production capacity increase, the costs of outsourcing are rising rapidly.

With the increasing availability of industrial quality 3D printing today, more companies are opting to bring 3D printing into their factory right away, vertically integrating it into existing workshops or labs, or providing printers to engineers, designers and other professionals who benefit from digital transformation. projects into physical models or are engaged in the production of products in small batches.

Compact desktop stereolithography 3D printers are an excellent solution for rapid model production. Depending on the number of parts needed and the volume of prints, the investment in a compact 3D printer can pay for itself in just a few months. In addition, compact appliances allow you to purchase just the amount of equipment you need to run your business and scale your production by adding more units as demand grows. Using multiple 3D printers also allows you to print models from different materials at the same time. And when the need arises for the production of large parts or the use of non-standard materials, service bureaus can come to the rescue.

Depending on the number of parts needed and the volume of prints, the investment in a compact 3D printer can pay for itself in just a few months. In addition, compact appliances allow you to purchase just the amount of equipment you need to run your business and scale your production by adding more units as demand grows. Using multiple 3D printers also allows you to print models from different materials at the same time. And when the need arises for the production of large parts or the use of non-standard materials, service bureaus can come to the rescue.

INTERACTIVE

Try our interactive ROI tool to see how much time and money you can save by printing with Formlabs 3D printers.

Calculate your savings

High production speed is an important reason to buy a desktop 3D printer. When working with a print bureau, there are delays related to the speed of production, communication and delivery. A desktop 3D printer like the Form 3 delivers models in hours, allowing designers and engineers to print multiple parts a day. This contributes to faster iterations and significant time savings in product development, as well as rapid testing of mechanisms and assemblies, avoiding costly tool changes.

This contributes to faster iterations and significant time savings in product development, as well as rapid testing of mechanisms and assemblies, avoiding costly tool changes.

Purchasing a desktop 3D printer saves a lot of money by eliminating bureau services and traditional processing methods, as their cost rises sharply with increasing demand and production volumes.

For example, the production engineer and others at Pankl Racing Systems used stereolithographic 3D printing technology to produce products on a tight schedule. This allowed them to independently manufacture custom-designed jigs and other small-sized components for the production line. While stereolithography was initially viewed with skepticism, this technology proved to be an ideal solution to replace the machining of a number of tools. In one of the cases, it made it possible to reduce the manufacturing time of conductors by 90% - from two to three weeks to several hours. At the same time, production costs decreased by 80-90%.

| Cost | Production term | |||

|---|---|---|---|---|

| Stereolithographic 3D printer installed at the enterprise | 9-28 $ | 5–9 h, | $45-$340 | 2-3 weeks |

| 3D printing 3rd party | $51-$137 |

By 3D printing custom-designed jigs, Pankl Racing Systems has significantly reduced both order preparation time and production costs.

Compact units allow you to purchase just the amount of equipment you need to run your business and scale your production by adding new units as demand grows. Using multiple 3D printers also allows you to print models from different materials at the same time.

The University of Sheffield's Manufacturing Advanced Research Center (AMRC) has an additive manufacturing station with 12 Form 2 stereolithography (SLA) 3D printers that hundreds of engineers working on various projects have access to.