3D printer kevlar

NylonK Kevlar Fiber Filament - 1.75mm (0.5kg)

- Home

- Store

- 3D Printer Filament

- Nylon Filament

- NylonK

NylonK is a kevlar fiber reinforced nylon 3D printing filament which boasts excellent abrasion resistance and durability, making it ideal for applications that require more stiffness than unfilled nylons and improved durability under frictional forces. For makers looking to create with engineering-grade materials or those in need of ultra-high-performance nylon - this filament delivers.

Remove from wishlist Add to wishlist loading...

Tagged: 0.5kg Filament Spools, 1.75mm Filament and Nylon Filament

Product No. loading...

Notify me when this item becomes available Success You will be notified when ... becomes available.NylonK is the perfect material for the maker of any experience level who is ready to get into the exciting world of materials that can do more than the commonly used PLA and ABS. NylonK has a few more considerations when 3D printing, but don't let that intimidate you - NylonK is designed to for its strength, durability and abrasion resistance, all while remaining as soft and flexible as PRO Series Nylon. In fact, it warps less due to the added Kevlar, so it's a very easy to use material, too! Whether you're already printing with nylon, or you're only experienced with PLA, give NylonK a try - you'll soon be an expert, and making the coolest prints yet!

Which nylon is right for me?

| Filament | Benefit | Optimal Use |

|---|---|---|

| PRO Series Nylon | Strong, low friction | General Purpose 3D Printing |

| NylonG | Impact Resistance | Parts subjected to repeated shock |

| NylonK | Abrasion Resistance | Parts subject to constant friction |

| NylonX | Tensile Strength | Parts needing stiffness and strength |

Engineering-Grade Material for High-End and Everyday Use

Nylon is an incredible 3D printing material thanks to its inter-layer adhesion and low friction. Nylon is a rigid filament, but under load does flex slightly to stop the part from shattering. These properties make nylon the right choice for functional parts that go from the printer directly to an end-use part. MatterHackers offers many different nylons for 3D printing from PRO Series to NylonX and NylonG all the way to the new NylonK. No matter what you are making with nylon - we've got you covered.

Nylon is a rigid filament, but under load does flex slightly to stop the part from shattering. These properties make nylon the right choice for functional parts that go from the printer directly to an end-use part. MatterHackers offers many different nylons for 3D printing from PRO Series to NylonX and NylonG all the way to the new NylonK. No matter what you are making with nylon - we've got you covered.

Printing Recommendations

Like all nylons, NylonK must be kept dry! If it does not remain packaged with desiccant, it will readily absorb moisture from the air; this will lead to degraded print quality and wasted filament. You can dry it out by baking it in an oven at 180°F for 4-6 hours. We also carry the PrintDry Filament Drying System for more precise dehydration for all filament types.

- Nominal Diameter: 1.75mm ± 0.02mm

- Print temperature: 250-265°C

- Print speed: 25mm/s - 35mm/s

- Bed temperature: 60-65°C with PVA glue stick OR unheated garolite

- Nozzle: Stainless Steel, Olsson Ruby, or other hardened nozzle types

| List Price: | $ (with add-ons) | |

|---|---|---|

| Price: | $ (with add-ons) | |

| Sale Price: | $ (with add-ons) | |

| — Available for Pre-order — | ||

| Availability: | ... | |

| Est. In Stock: ... | ||

| Order Now: | Processed Immediately | Ships = 3500"> Free U.S. Shipping |

| Arrives after Christmas. Need something sooner? | ||

This item cannot be shipped to a PO Box or APO/FPO/DPO address.

This item takes longer to ship due to its size and/or weight.

Qty

Checkout

Notify me when this is available

3D Printed Kevlar – RE3DTECH

[fusion_builder_container hundred_percent=”no” equal_height_columns=”no” menu_anchor=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” background_color=”” background_image=”” background_position=”center center” background_repeat=”no-repeat” fade=”no” background_parallax=”none” parallax_speed=”0.3″ video_mp4=”” video_webm=”” video_ogv=”” video_url=”” video_aspect_ratio=”16:9″ video_loop=”yes” video_mute=”yes” overlay_color=”” video_preview_image=”” border_size=”” border_color=”” border_style=”solid” padding_top=”” padding_bottom=”” padding_left=”” padding_right=””][fusion_builder_row][/fusion_builder_row][/fusion_builder_container][fusion_builder_container hundred_percent=”no” hundred_percent_height=”no” hundred_percent_height_scroll=”no” hundred_percent_height_center_content=”yes” equal_height_columns=”no” menu_anchor=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” status=”published” publish_date=”” class=”” id=”” gradient_top_color=”” gradient_bottom_color=”” gradient_type=”linear” gradient_direction=”0deg” gradient_force=”yes” link_color=”” link_hover_color=”” border_size=”3″ border_color=”” border_style=”solid” margin_top=”” margin_bottom=”” padding_top=”20″ padding_right=”” padding_bottom=”20″ padding_left=”” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ radial_direction=”center center” linear_angle=”180″ background_color=”” background_image=”” background_position=”center center” background_repeat=”no-repeat” fade=”no” background_parallax=”none” enable_mobile=”no” parallax_speed=”0. 3″ background_blend_mode=”none” video_mp4=”” video_webm=”” video_ogv=”” video_url=”” video_aspect_ratio=”16:9″ video_loop=”yes” video_mute=”yes” video_preview_image=”” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ admin_label=”Application 1st Container”][fusion_builder_row][fusion_builder_column type=”1_2″ layout=”1_1″ background_position=”left top” background_color=”” border_size=”” border_color=”” border_style=”solid” border_position=”all” spacing=”yes” background_image=”” background_repeat=”no-repeat” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”0px” margin_bottom=”0px” class=”” id=”” animation_type=”” animation_speed=”0.3″ animation_direction=”left” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” center_content=”no” last=”no” min_height=”” hover_type=”none” link=””][iee_special_heading title=”Kevlar 3D Printing” heading_size=”h2″ description=”” alignment=”left” separator_position=”after_heading” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” element_typography=”default” typography_title=”Open Sans:regular” title_font_size=”42″ typography_description=”Open Sans:300″ description_font_size=”18″ title_color=”#21598c” description_color=”” background_color=”” background_image=”” background_position=”left top” background_repeat=”no-repeat” height=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” mobile_padding_top=”” mobile_padding_right=”” mobile_padding_bottom=”” mobile_padding_left=”” /][fusion_text columns=”” column_min_width=”” column_spacing=”” rule_style=”default” rule_size=”” rule_color=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” animation_type=”” animation_direction=”left” animation_speed=”0.

3″ background_blend_mode=”none” video_mp4=”” video_webm=”” video_ogv=”” video_url=”” video_aspect_ratio=”16:9″ video_loop=”yes” video_mute=”yes” video_preview_image=”” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ admin_label=”Application 1st Container”][fusion_builder_row][fusion_builder_column type=”1_2″ layout=”1_1″ background_position=”left top” background_color=”” border_size=”” border_color=”” border_style=”solid” border_position=”all” spacing=”yes” background_image=”” background_repeat=”no-repeat” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”0px” margin_bottom=”0px” class=”” id=”” animation_type=”” animation_speed=”0.3″ animation_direction=”left” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” center_content=”no” last=”no” min_height=”” hover_type=”none” link=””][iee_special_heading title=”Kevlar 3D Printing” heading_size=”h2″ description=”” alignment=”left” separator_position=”after_heading” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” element_typography=”default” typography_title=”Open Sans:regular” title_font_size=”42″ typography_description=”Open Sans:300″ description_font_size=”18″ title_color=”#21598c” description_color=”” background_color=”” background_image=”” background_position=”left top” background_repeat=”no-repeat” height=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” mobile_padding_top=”” mobile_padding_right=”” mobile_padding_bottom=”” mobile_padding_left=”” /][fusion_text columns=”” column_min_width=”” column_spacing=”” rule_style=”default” rule_size=”” rule_color=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” animation_type=”” animation_direction=”left” animation_speed=”0. 3″ animation_offset=””]

3″ animation_offset=””]

Six times stronger and eighteen times stiffer than Onyx, Carbon Fiber reinforcement is commonly used for parts that replace machined aluminum. Formed from the combination of two materials, composite parts are incredibly strong and versatile. Our unique fabrication process enables you to print parts that are an order of magnitude stiffer and stronger than typical 3D printed objects.

From PA12 Nylon to continuous carbon fiber composites are used in traditional manufacturing. Let Re3dTech help you choose the right materials to achieve the best results for your additive manufacturing needs.

[/fusion_text][/fusion_builder_column][fusion_builder_column type=”1_2″ layout=”1_1″ background_position=”left top” background_color=”” border_size=”” border_color=”” border_style=”solid” border_position=”all” spacing=”yes” background_image=”” background_repeat=”no-repeat” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”0px” margin_bottom=”0px” class=”” id=”” animation_type=”” animation_speed=”0. 3″ animation_direction=”left” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” center_content=”no” last=”no” min_height=”” hover_type=”none” link=””][iee_special_heading title=”Markforged X7″ heading_size=”h3″ description=”” alignment=”left” separator_position=”after_heading” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” element_typography=”default” typography_title=”Open Sans:regular” title_font_size=”42″ typography_description=”Open Sans:300″ description_font_size=”18″ title_color=”#21598c” description_color=”” background_color=”” background_image=”” background_position=”left top” background_repeat=”no-repeat” height=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” mobile_padding_top=”” mobile_padding_right=”” mobile_padding_bottom=”” mobile_padding_left=”” /][fusion_text columns=”” column_min_width=”” column_spacing=”” rule_style=”default” rule_size=”” rule_color=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” animation_type=”” animation_direction=”left” animation_speed=”0.

3″ animation_direction=”left” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” center_content=”no” last=”no” min_height=”” hover_type=”none” link=””][iee_special_heading title=”Markforged X7″ heading_size=”h3″ description=”” alignment=”left” separator_position=”after_heading” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” element_typography=”default” typography_title=”Open Sans:regular” title_font_size=”42″ typography_description=”Open Sans:300″ description_font_size=”18″ title_color=”#21598c” description_color=”” background_color=”” background_image=”” background_position=”left top” background_repeat=”no-repeat” height=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” mobile_padding_top=”” mobile_padding_right=”” mobile_padding_bottom=”” mobile_padding_left=”” /][fusion_text columns=”” column_min_width=”” column_spacing=”” rule_style=”default” rule_size=”” rule_color=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” animation_type=”” animation_direction=”left” animation_speed=”0. 3″ animation_offset=””]

3″ animation_offset=””]

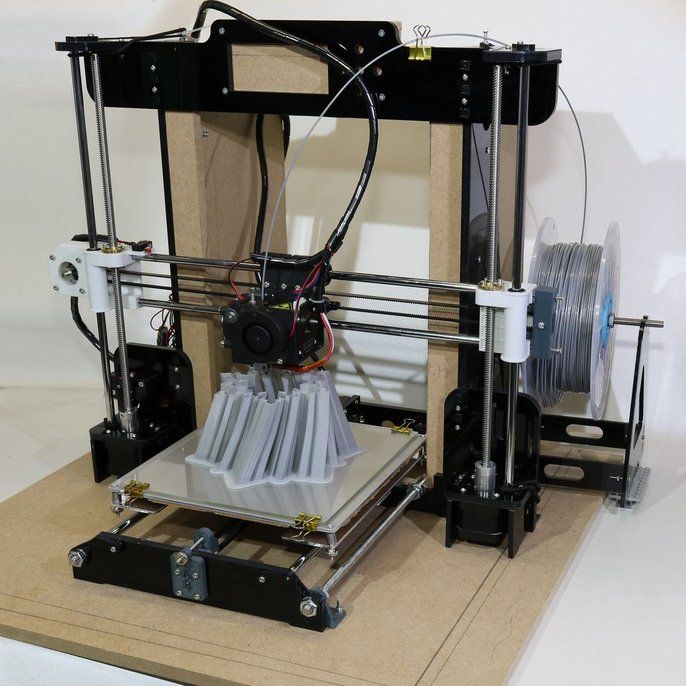

Fiber Reinforcement Continuous Filament Fabrication (CFF) is our unique technology that adds fiber reinforcement to printed parts. Within the thermoplastic matrix, the X7 uses proprietary technology to lay down continuous long-strand fiber. Users can control the layers reinforced, amount, orientation, and type of reinforcing fiber.

Lightweight, Durable, and Strong Kevlar® possesses excellent durability, making it optimal for parts that experience repeated and sudden loading. As stiff as fiberglass and much more ductile, it’s best used for end of arm tooling. Compatible with Mark Two and X7.

[/fusion_text][/fusion_builder_column][fusion_builder_column type=”1_1″ layout=”1_1″ spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” background_image_id=”” gradient_top_color=”” gradient_bottom_color=”” gradient_type=”linear” gradient_direction=”0deg” gradient_force=”yes” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius_top_left=”” border_radius_top_right=”” border_radius_bottom_right=”” border_radius_bottom_left=”” box_shadow=”no” box_shadow_vertical=”” box_shadow_horizontal=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”20″ padding_right=”” padding_bottom=”20″ padding_left=”” margin_top=”” margin_bottom=”” background_type=”single” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ radial_direction=”center center” linear_angle=”180″ background_color=”#21598c” background_image=”” background_position=”left top” background_repeat=”no-repeat” background_blend_mode=”none” animation_type=”” animation_direction=”left” animation_speed=”0. 3″ animation_offset=”” filter_type=”regular” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ last=”no”][fusion_button link=”https://re3dtech.com/request-for-quote/” text_transform=”” title=”” target=”_self” link_attributes=”” alignment=”center” modal=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” color=”custom” button_gradient_top_color=”#ffffff” button_gradient_bottom_color=”#ffffff” button_gradient_top_color_hover=”” button_gradient_bottom_color_hover=”” accent_color=”#21598c” accent_hover_color=”#21598c” type=”” bevel_color=”” border_width=”” border_radius=”” border_color=”” border_hover_color=”” size=”xlarge” stretch=”default” icon=”” icon_position=”left” icon_divider=”no” animation_type=”” animation_direction=”left” animation_speed=”0.

3″ animation_offset=”” filter_type=”regular” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ last=”no”][fusion_button link=”https://re3dtech.com/request-for-quote/” text_transform=”” title=”” target=”_self” link_attributes=”” alignment=”center” modal=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” color=”custom” button_gradient_top_color=”#ffffff” button_gradient_bottom_color=”#ffffff” button_gradient_top_color_hover=”” button_gradient_bottom_color_hover=”” accent_color=”#21598c” accent_hover_color=”#21598c” type=”” bevel_color=”” border_width=”” border_radius=”” border_color=”” border_hover_color=”” size=”xlarge” stretch=”default” icon=”” icon_position=”left” icon_divider=”no” animation_type=”” animation_direction=”left” animation_speed=”0. 3″ animation_offset=””]Get A Quote[/fusion_button][/fusion_builder_column][fusion_builder_column type=”1_2″ layout=”1_1″ gradient_top_color=”” gradient_bottom_color=”” gradient_type=”linear” gradient_direction=”0deg” gradient_force=”yes” spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” background_type=”single” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ radial_direction=”center center” linear_angle=”180″ background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” background_blend_mode=”none” animation_type=”” animation_direction=”left” animation_speed=”0.

3″ animation_offset=””]Get A Quote[/fusion_button][/fusion_builder_column][fusion_builder_column type=”1_2″ layout=”1_1″ gradient_top_color=”” gradient_bottom_color=”” gradient_type=”linear” gradient_direction=”0deg” gradient_force=”yes” spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” background_type=”single” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ radial_direction=”center center” linear_angle=”180″ background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” background_blend_mode=”none” animation_type=”” animation_direction=”left” animation_speed=”0. 3″ animation_offset=”” filter_type=”regular” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ last=”no”][fusion_imageframe image_id=”968|full” max_width=”” style_type=”” blur=”” stylecolor=”” hover_type=”none” bordersize=”” bordercolor=”” borderradius=”” align=”none” lightbox=”no” gallery_id=”” lightbox_image=”” lightbox_image_id=”” alt=”” link=”” linktarget=”_self” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” animation_type=”” animation_direction=”left” animation_speed=”0.3″ animation_offset=”” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″]https://re3dtech.

3″ animation_offset=”” filter_type=”regular” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ last=”no”][fusion_imageframe image_id=”968|full” max_width=”” style_type=”” blur=”” stylecolor=”” hover_type=”none” bordersize=”” bordercolor=”” borderradius=”” align=”none” lightbox=”no” gallery_id=”” lightbox_image=”” lightbox_image_id=”” alt=”” link=”” linktarget=”_self” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” animation_type=”” animation_direction=”left” animation_speed=”0.3″ animation_offset=”” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″]https://re3dtech. com/wp-content/uploads/2017/04/onyx.jpg[/fusion_imageframe][/fusion_builder_column][fusion_builder_column type=”1_2″ layout=”1_1″ gradient_top_color=”” gradient_bottom_color=”” gradient_type=”linear” gradient_direction=”0deg” gradient_force=”yes” spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” background_type=”single” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ radial_direction=”center center” linear_angle=”180″ background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” background_blend_mode=”none” animation_type=”” animation_direction=”left” animation_speed=”0.

com/wp-content/uploads/2017/04/onyx.jpg[/fusion_imageframe][/fusion_builder_column][fusion_builder_column type=”1_2″ layout=”1_1″ gradient_top_color=”” gradient_bottom_color=”” gradient_type=”linear” gradient_direction=”0deg” gradient_force=”yes” spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” background_type=”single” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ radial_direction=”center center” linear_angle=”180″ background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” background_blend_mode=”none” animation_type=”” animation_direction=”left” animation_speed=”0. 3″ animation_offset=”” filter_type=”regular” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ last=”no”][fusion_imageframe image_id=”967|full” max_width=”” style_type=”” blur=”” stylecolor=”” hover_type=”none” bordersize=”” bordercolor=”” borderradius=”” align=”none” lightbox=”no” gallery_id=”” lightbox_image=”” lightbox_image_id=”” alt=”” link=”” linktarget=”_self” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” animation_type=”” animation_direction=”left” animation_speed=”0.3″ animation_offset=”” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″]https://re3dtech.

3″ animation_offset=”” filter_type=”regular” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ last=”no”][fusion_imageframe image_id=”967|full” max_width=”” style_type=”” blur=”” stylecolor=”” hover_type=”none” bordersize=”” bordercolor=”” borderradius=”” align=”none” lightbox=”no” gallery_id=”” lightbox_image=”” lightbox_image_id=”” alt=”” link=”” linktarget=”_self” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” animation_type=”” animation_direction=”left” animation_speed=”0.3″ animation_offset=”” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″]https://re3dtech. com/wp-content/uploads/2017/04/fiber-infused-parts.jpg[/fusion_imageframe][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container][fusion_builder_container admin_label=”Blog and Videos” hundred_percent=”no” hundred_percent_height=”no” hundred_percent_height_scroll=”no” hundred_percent_height_center_content=”yes” equal_height_columns=”yes” menu_anchor=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” status=”published” publish_date=”” class=”” id=”” gradient_top_color=”” gradient_bottom_color=”” gradient_type=”linear” gradient_direction=”0deg” gradient_force=”yes” link_color=”” link_hover_color=”” border_size=”0″ border_color=”” border_style=”solid” margin_top=”” margin_bottom=”” padding_top=”10″ padding_right=”” padding_bottom=”10″ padding_left=”” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ radial_direction=”center center” linear_angle=”180″ background_color=”” background_image=”” background_position=”center center” background_repeat=”no-repeat” fade=”no” background_parallax=”none” enable_mobile=”no” parallax_speed=”0.

com/wp-content/uploads/2017/04/fiber-infused-parts.jpg[/fusion_imageframe][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container][fusion_builder_container admin_label=”Blog and Videos” hundred_percent=”no” hundred_percent_height=”no” hundred_percent_height_scroll=”no” hundred_percent_height_center_content=”yes” equal_height_columns=”yes” menu_anchor=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” status=”published” publish_date=”” class=”” id=”” gradient_top_color=”” gradient_bottom_color=”” gradient_type=”linear” gradient_direction=”0deg” gradient_force=”yes” link_color=”” link_hover_color=”” border_size=”0″ border_color=”” border_style=”solid” margin_top=”” margin_bottom=”” padding_top=”10″ padding_right=”” padding_bottom=”10″ padding_left=”” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ radial_direction=”center center” linear_angle=”180″ background_color=”” background_image=”” background_position=”center center” background_repeat=”no-repeat” fade=”no” background_parallax=”none” enable_mobile=”no” parallax_speed=”0. 3″ background_blend_mode=”none” video_mp4=”” video_webm=”” video_ogv=”” video_url=”” video_aspect_ratio=”16:9″ video_loop=”yes” video_mute=”yes” video_preview_image=”” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″][fusion_builder_row][fusion_builder_column type=”1_3″ layout=”1_1″ gradient_top_color=”” gradient_bottom_color=”” gradient_type=”linear” gradient_direction=”0deg” gradient_force=”yes” spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” background_type=”single” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ radial_direction=”center center” linear_angle=”180″ background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” background_blend_mode=”none” animation_type=”” animation_direction=”left” animation_speed=”0.

3″ background_blend_mode=”none” video_mp4=”” video_webm=”” video_ogv=”” video_url=”” video_aspect_ratio=”16:9″ video_loop=”yes” video_mute=”yes” video_preview_image=”” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″][fusion_builder_row][fusion_builder_column type=”1_3″ layout=”1_1″ gradient_top_color=”” gradient_bottom_color=”” gradient_type=”linear” gradient_direction=”0deg” gradient_force=”yes” spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” background_type=”single” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ radial_direction=”center center” linear_angle=”180″ background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” background_blend_mode=”none” animation_type=”” animation_direction=”left” animation_speed=”0. 3″ animation_offset=”” filter_type=”regular” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ last=”no”][fusion_youtube id=”pqYXxSTj19c” alignment=”center” width=”” height=”” autoplay=”false” api_params=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” css_id=”” /][/fusion_builder_column][fusion_builder_column type=”1_3″ layout=”1_1″ gradient_top_color=”” gradient_bottom_color=”” gradient_type=”linear” gradient_direction=”0deg” gradient_force=”yes” spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” background_type=”single” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ radial_direction=”center center” linear_angle=”180″ background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” background_blend_mode=”none” animation_type=”” animation_direction=”left” animation_speed=”0.

3″ animation_offset=”” filter_type=”regular” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ last=”no”][fusion_youtube id=”pqYXxSTj19c” alignment=”center” width=”” height=”” autoplay=”false” api_params=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” css_id=”” /][/fusion_builder_column][fusion_builder_column type=”1_3″ layout=”1_1″ gradient_top_color=”” gradient_bottom_color=”” gradient_type=”linear” gradient_direction=”0deg” gradient_force=”yes” spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” background_type=”single” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ radial_direction=”center center” linear_angle=”180″ background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” background_blend_mode=”none” animation_type=”” animation_direction=”left” animation_speed=”0. 3″ animation_offset=”” filter_type=”regular” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ last=”no”][fusion_youtube id=”sjNS6S4-CdE” alignment=”center” width=”” height=”” autoplay=”false” api_params=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” css_id=”” /][/fusion_builder_column][fusion_builder_column type=”1_3″ layout=”1_1″ gradient_top_color=”” gradient_bottom_color=”” gradient_type=”linear” gradient_direction=”0deg” gradient_force=”yes” spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” background_type=”single” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ radial_direction=”center center” linear_angle=”180″ background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” background_blend_mode=”none” animation_type=”” animation_direction=”left” animation_speed=”0.

3″ animation_offset=”” filter_type=”regular” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ last=”no”][fusion_youtube id=”sjNS6S4-CdE” alignment=”center” width=”” height=”” autoplay=”false” api_params=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” css_id=”” /][/fusion_builder_column][fusion_builder_column type=”1_3″ layout=”1_1″ gradient_top_color=”” gradient_bottom_color=”” gradient_type=”linear” gradient_direction=”0deg” gradient_force=”yes” spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” background_type=”single” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ radial_direction=”center center” linear_angle=”180″ background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” background_blend_mode=”none” animation_type=”” animation_direction=”left” animation_speed=”0. 3″ animation_offset=”” filter_type=”regular” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ last=”no”][fusion_youtube id=”2JBrk_fQaPI” alignment=”center” width=”” height=”” autoplay=”false” api_params=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” css_id=”” /][/fusion_builder_column][fusion_builder_column type=”1_3″ layout=”1_1″ gradient_top_color=”” gradient_bottom_color=”” gradient_type=”linear” gradient_direction=”0deg” gradient_force=”yes” spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” background_type=”single” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ radial_direction=”center center” linear_angle=”180″ background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” background_blend_mode=”none” animation_type=”” animation_direction=”left” animation_speed=”0.

3″ animation_offset=”” filter_type=”regular” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ last=”no”][fusion_youtube id=”2JBrk_fQaPI” alignment=”center” width=”” height=”” autoplay=”false” api_params=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” css_id=”” /][/fusion_builder_column][fusion_builder_column type=”1_3″ layout=”1_1″ gradient_top_color=”” gradient_bottom_color=”” gradient_type=”linear” gradient_direction=”0deg” gradient_force=”yes” spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” background_type=”single” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ radial_direction=”center center” linear_angle=”180″ background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” background_blend_mode=”none” animation_type=”” animation_direction=”left” animation_speed=”0. 3″ animation_offset=”” filter_type=”regular” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ last=”no”][fusion_youtube id=”HWx9yXcQte4″ alignment=”center” width=”” height=”” autoplay=”false” api_params=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” css_id=”” /][/fusion_builder_column][fusion_builder_column type=”1_3″ layout=”1_1″ gradient_top_color=”” gradient_bottom_color=”” gradient_type=”linear” gradient_direction=”0deg” gradient_force=”yes” spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” background_type=”single” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ radial_direction=”center center” linear_angle=”180″ background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” background_blend_mode=”none” animation_type=”” animation_direction=”left” animation_speed=”0.

3″ animation_offset=”” filter_type=”regular” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ last=”no”][fusion_youtube id=”HWx9yXcQte4″ alignment=”center” width=”” height=”” autoplay=”false” api_params=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” css_id=”” /][/fusion_builder_column][fusion_builder_column type=”1_3″ layout=”1_1″ gradient_top_color=”” gradient_bottom_color=”” gradient_type=”linear” gradient_direction=”0deg” gradient_force=”yes” spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” background_type=”single” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ radial_direction=”center center” linear_angle=”180″ background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” background_blend_mode=”none” animation_type=”” animation_direction=”left” animation_speed=”0. 3″ animation_offset=”” filter_type=”regular” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ last=”no”][fusion_youtube id=”uNsB0TDHK_I” alignment=”center” width=”” height=”” autoplay=”false” api_params=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” css_id=”” /][/fusion_builder_column][fusion_builder_column type=”1_3″ layout=”1_1″ gradient_top_color=”” gradient_bottom_color=”” gradient_type=”linear” gradient_direction=”0deg” gradient_force=”yes” spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” background_type=”single” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ radial_direction=”center center” linear_angle=”180″ background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” background_blend_mode=”none” animation_type=”” animation_direction=”left” animation_speed=”0.

3″ animation_offset=”” filter_type=”regular” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ last=”no”][fusion_youtube id=”uNsB0TDHK_I” alignment=”center” width=”” height=”” autoplay=”false” api_params=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” css_id=”” /][/fusion_builder_column][fusion_builder_column type=”1_3″ layout=”1_1″ gradient_top_color=”” gradient_bottom_color=”” gradient_type=”linear” gradient_direction=”0deg” gradient_force=”yes” spacing=”” center_content=”no” link=”” target=”_self” min_height=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” id=”” hover_type=”none” border_size=”0″ border_color=”” border_style=”solid” border_position=”all” border_radius=”” box_shadow=”no” dimension_box_shadow=”” box_shadow_blur=”0″ box_shadow_spread=”0″ box_shadow_color=”” box_shadow_style=”” padding_top=”” padding_right=”” padding_bottom=”” padding_left=”” margin_top=”” margin_bottom=”” background_type=”single” gradient_start_color=”” gradient_end_color=”” gradient_start_position=”0″ gradient_end_position=”100″ radial_direction=”center center” linear_angle=”180″ background_color=”” background_image=”” background_image_id=”” background_position=”left top” background_repeat=”no-repeat” background_blend_mode=”none” animation_type=”” animation_direction=”left” animation_speed=”0. 3″ animation_offset=”” filter_type=”regular” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ last=”no”][fusion_youtube id=”X021kZsMrak” alignment=”center” width=”” height=”” autoplay=”false” api_params=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” css_id=”” /][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

3″ animation_offset=”” filter_type=”regular” filter_hue=”0″ filter_saturation=”100″ filter_brightness=”100″ filter_contrast=”100″ filter_invert=”0″ filter_sepia=”0″ filter_opacity=”100″ filter_blur=”0″ filter_hue_hover=”0″ filter_saturation_hover=”100″ filter_brightness_hover=”100″ filter_contrast_hover=”100″ filter_invert_hover=”0″ filter_sepia_hover=”0″ filter_opacity_hover=”100″ filter_blur_hover=”0″ last=”no”][fusion_youtube id=”X021kZsMrak” alignment=”center” width=”” height=”” autoplay=”false” api_params=”” hide_on_mobile=”small-visibility,medium-visibility,large-visibility” class=”” css_id=”” /][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

DELIVERING SUCCESS AT SCALE

My partner and I approached David at Re3dtech with our project and were greeted with kind and caring service. Throughout the last couple of months we have placed several orders in varying size and were even able to sit down with David and the owner to discuss our needs as a small business. Through this sit down we saw their passion for assisting both small and large clients in achieving their goals. We even had a hiccup with a batch of prints that was immediately addressed and remedied with precision and care. I almost don't want to recommend these guys because I feel like I have stumbled upon a hidden gem in 3D printing services and selfishly want to keep it to myself. Jokes aside we will be continuing our business relationship with the folks there and look forward to growing our order quantities and business with their help.

Through this sit down we saw their passion for assisting both small and large clients in achieving their goals. We even had a hiccup with a batch of prints that was immediately addressed and remedied with precision and care. I almost don't want to recommend these guys because I feel like I have stumbled upon a hidden gem in 3D printing services and selfishly want to keep it to myself. Jokes aside we will be continuing our business relationship with the folks there and look forward to growing our order quantities and business with their help.

Re3DTech was instrumental in helping us get our product, Stroba™, to market faster! We needed a technology that could do snap fits and looks and feels as close the injection molded part as possible, and Re3D Tech was there for us. We used SOLIDWORKS Make to get in touch originally, upload models directly, and sign an NDA directly with their excellent team. It was really simple and easy to use their quoting tool as well. Excellent prices, excellent lead times, and superior quality are perfect words to describe our experience with Re3DTech. We went through many prototypes for Stroba™, and we at Goodfriend Innovations™ use Re3DTech for our other rapid prototyping jobs to help get our additional productions out to market faster than the competition. 5 Stars

We went through many prototypes for Stroba™, and we at Goodfriend Innovations™ use Re3DTech for our other rapid prototyping jobs to help get our additional productions out to market faster than the competition. 5 Stars

I provided RE3DTECH three laser scanned ".stl" files for 3-D printing of prototypes. I used their on-line quote and file delivery process. The file acceptance and resultant quote were returned quickly. The parts were received at the quoted time. The parts are quite complex with many holes, angles, curvatures and notches. Each of the parts came out identical to the scanned parts dimensionally and passed the form/fit/function test in the upper level assembly. RE3DTECH has a high quality business process and produces high quality products. I will use them for future prototyping projects and recommend RE3DTECH.

Re3dtech is one of the most honest and reputable companies we have done business with. We decided to look into options for getting parts made in the USA for the retail market. It was awesome to find a local company with humble staff looking to provide their services meeting our criteria, not to mention meeting the Re3tech crew face to face and checking out their operation. Peter was very honest, knowledgable about design. Peter's creative element made working with him a great pleasure. Jim's flexibility was a breath of fresh air and greatly appreciated. CentralSound is proud to scratch the surface with Made in the USA parts in the retail market now, thanks to Re3dtech. Hope to do more business with them in the future.

It was awesome to find a local company with humble staff looking to provide their services meeting our criteria, not to mention meeting the Re3tech crew face to face and checking out their operation. Peter was very honest, knowledgable about design. Peter's creative element made working with him a great pleasure. Jim's flexibility was a breath of fresh air and greatly appreciated. CentralSound is proud to scratch the surface with Made in the USA parts in the retail market now, thanks to Re3dtech. Hope to do more business with them in the future.

Re3dtech has consistently delivered the best service I have ever received in the industry. Their response time is unmatched and they always stand by their parts and quality. They regularly make me look like an all star at my job.

It is always a pleasure to have a vendor that provides quality, experience, and always shows as much care for your order, and your product as you do!

Nylon for 3D printing with Kevlar, glass and carbon fibers will allow you to print even body armor

News

Everyone knows that advances in 3D printing technology are entirely dependent on advances in 3D printing materials.

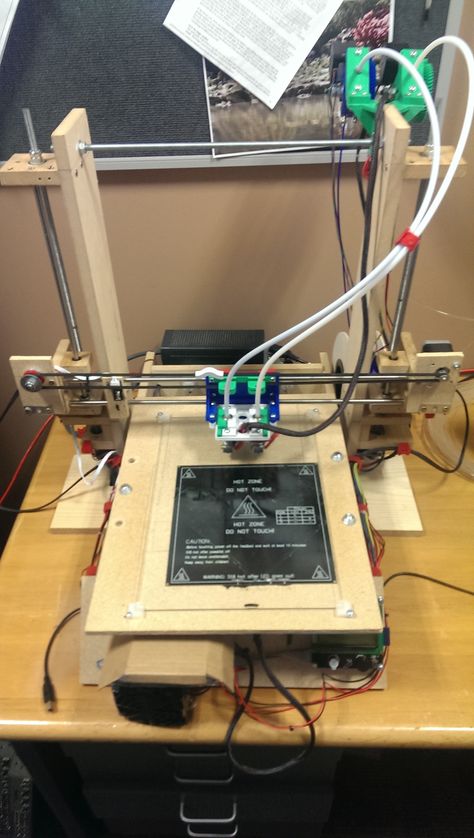

If we talk about industrial production, the choice is huge here: metal, wood, ceramics, etc. But for ordinary people, the situation is rather deplorable, because they only have different types of plastic at their disposal. But a celebration has come on their street too: the worldwide network of 3D printers 3D Hubs, in collaboration with Markforged, has released a new series of nylon materials reinforced with Kevlar, glass and carbon fiber.

If we talk about industrial production, the choice is huge here: metal, wood, ceramics, etc. But for ordinary people, the situation is rather deplorable, because they only have different types of plastic at their disposal. But a celebration has come on their street too: the worldwide network of 3D printers 3D Hubs, in collaboration with Markforged, has released a new series of nylon materials reinforced with Kevlar, glass and carbon fiber. The goal of the developers of unique advanced materials is to enable users to create 3D printed products as strong as metal and cheap as plastic. In numbers, fiber-reinforced materials have a higher strength-to-weight ratio than 6061-T6 Aluminum, plus products are 24 times stronger and 27 times more resilient than ABS.

New items will be presented at 17 certified 3D Hubs dealers in Europe, USA and Canada. These materials are ideal for manufacturing factory parts, live prototypes and equipment. True, representatives of 3D Hubs specify that these materials are of little use for the production of small products with fine details.

As mentioned above, 3D Hubs has developed new materials in collaboration with 3D printer manufacturer Markforged, so the new materials are suitable for use on the Mark Two industrial 3D printer and are compatible with the patented Continuous Filament Fabrication (CFF) system. 3D Hubs said in a press release: “Adding fibers in the 3D printing process is a complex procedure and requires the presence of a specially trained operator. Through our network of vendors, we have been able to make this technology more accessible to everyone.”

Of course, the new materials are slightly different from each other. Carbon fiber reinforced nylon has a higher strength to weight ratio than 6061 Aluminum and the highest thermal conductivity of the three. Nylon reinforced with Kevlar has the highest abrasion resistance. In addition, it is the most flexible, so it is a great option for making impact-resistant and durable products. Fiberglass-reinforced nylon is perhaps the most budget-friendly of all, but it still has the same strength as carbon-reinforced nylon. However, it is 60% stiffer and twice as heavy as the latter.

However, it is 60% stiffer and twice as heavy as the latter.

3D Hubs staff has prepared useful tips for those who decide to try their luck with new products. Firstly, these materials are not intended for the production of small and oversaturated objects with details (the minimum part size should be 0.8 mm). The minimum size of the product should not be less than 3 mm, while for products made of pure nylon, the allowable minimum is 1.6 mm.

With regard to the production of movable and interlocking products, make sure that there are gaps of at least 0.5 mm so that the products can be separated from each other at the end of the print session. The wall thickness corresponds to the minimum value of the product, i.e. for reinforced nylon this is at least 3 mm, while for pure nylon it is only 1.6 mm.

Fibre-reinforced nylons require a continuous fiber technology that is based on deposition modeling technology, but requires a second printhead that infuses the nylon with "carbon, kevlar and fiberglass filaments between layers". As the 3D Hubs website says, "These long filaments take all the load, resulting in strong products with properties comparable to those made of composite materials."

As the 3D Hubs website says, "These long filaments take all the load, resulting in strong products with properties comparable to those made of composite materials."

If you are looking to order a new Reinforced Nylon product from 3D Hubs and Markforged, please follow this link to the 3D Hubs website.

Source

Follow author

Follow

Don't want

5

More interesting articles

6

Subscribe to the author

Subscribe

Don't want

Scientists from the Ural Federal University and the Ural Branch of the Russian Academy of Sciences determine...

Read more

5

Subscribe to the author

Subscribe

Don't want

New systems are initially tailored for the extended functionality of the Klipper firmware and equipped with a 32-bit e. ..

..

Read more

44

Subscribe to the author

Subscribe

Don't want

American startup Iro3D shipped the first 3D printers for printing metal products using the village method...

Read more

A closer look at 3D printing materials: composites

Composite 3D printing has become increasingly popular in recent years. One of the youngest branches of 3D printing, this technology is now used by many additive manufacturing players such as Impossible Objects. In fact, it has become so popular that some studies estimate that the composite 3D printing market will reach $1.73 billion by 2030. Logically, when we talk about composite 3D printing, we are thinking not only about composite printers, but also about composite materials. Composite materials consist of at least two components and have special properties that make them unique for use in various industries.

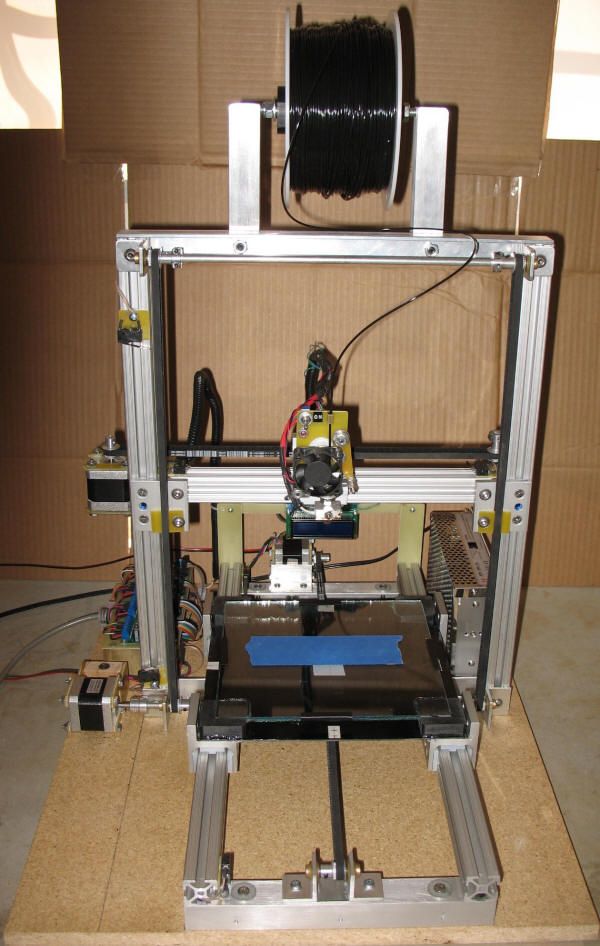

In most cases, the production of these materials requires the mixing of a plastic, which we will refer to as a matrix, with fibers. There are many different types of fibers today, but three are mostly used for 3D printing: carbon fiber, which is probably the most popular, fiberglass, and PPD-T (known as Kevlar). Depending on requirements, short or long fibers can be used. Short fibers are integrated into the entire matrix and will strengthen the entire part; this type of material is compatible with a wide range of 3D printers. The long fibers are placed during the actual printing process and are not cut into small pieces, allowing for reinforcement only where needed. At the moment they are only compatible with certain machines.

Composite printing (Photo: SABIC)

Carbon Fiber Materials

As stated earlier, carbon fiber composites are the most common in the additive manufacturing market. Carbon fiber, first produced in 1860 by chemist Joseph Swan, is, as the name suggests, made up of many carbon atoms bonded together. It is considered by many to be the most effective fiber for creating composite materials. Indeed, materials made from this fiber have high rigidity, high tensile strength and good chemical resistance. In addition, these composite materials are characterized by low weight and high temperature resistance - they are especially known for their weight / strength ratio, which is twice that of, for example, aluminum.

It is considered by many to be the most effective fiber for creating composite materials. Indeed, materials made from this fiber have high rigidity, high tensile strength and good chemical resistance. In addition, these composite materials are characterized by low weight and high temperature resistance - they are especially known for their weight / strength ratio, which is twice that of, for example, aluminum.

Carbon fiber composites can be found in many applications such as aerospace, automotive, civil engineering and many more. Matrix materials such as PLA, PETG, nylon, ABS or polycarbonate become stronger and lighter when carbon fiber is added, and it can also be blended with ceramic. The creation of these composite materials has led to the development of new applications in the printing industry, such as the first 3D printed carbon fiber electric scooter.

3D printed carbon filled nylon part (Photo: Stratasys)

Fiberglass Filled Composites

Patented in 1930, glass fiber, like carbon fiber, is used to reinforce many polymers. However, compared to carbon fiber filled materials, glass fiber materials are less rigid but also less brittle. It is mainly for these reasons that fiberglass-filled materials are generally less expensive. However, fiberglass has good mechanical properties. In addition, it is considered a good electrical insulator and has low thermal conductivity. It is more comparable to other polymers: for example, it is 11 times stiffer than ABS.

However, compared to carbon fiber filled materials, glass fiber materials are less rigid but also less brittle. It is mainly for these reasons that fiberglass-filled materials are generally less expensive. However, fiberglass has good mechanical properties. In addition, it is considered a good electrical insulator and has low thermal conductivity. It is more comparable to other polymers: for example, it is 11 times stiffer than ABS.

Whether in construction, shipbuilding or even sports, this composite material is now widely used. For example, in collaboration with Autodesk, Catmarine, Micad and Owens Corning, Moi Composites created the MAMBO boat, the first 3D printed fiberglass boat.

Fiberglass printed prototype part of the bridge (photo: CEAM)

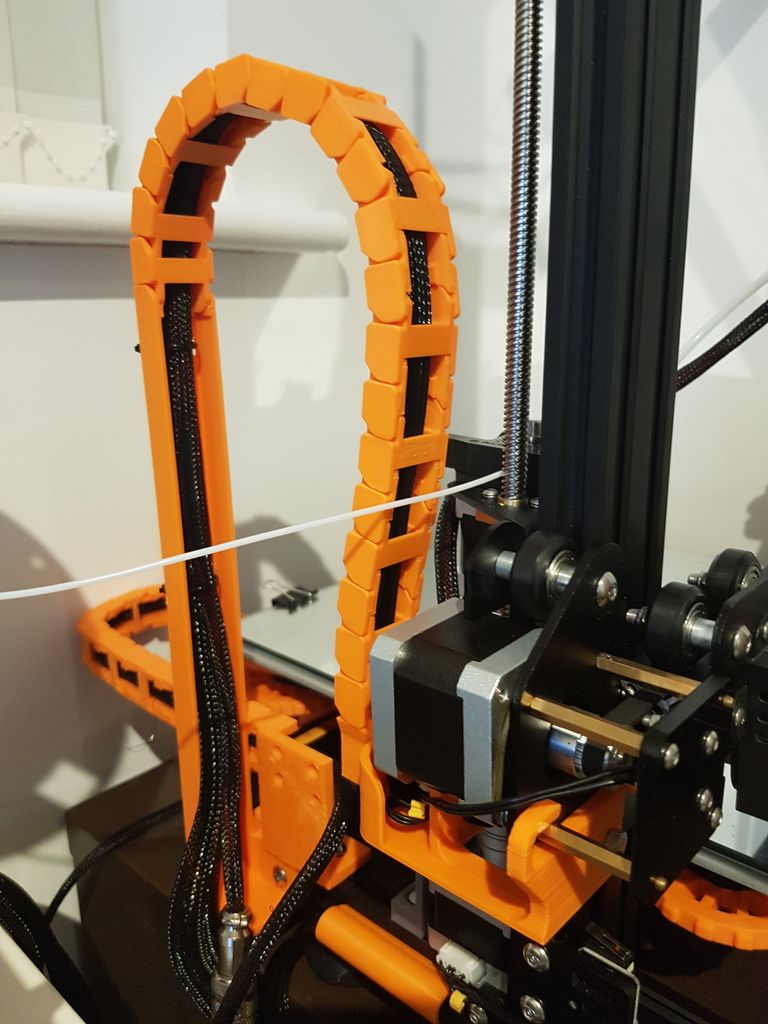

Kevlar Materials

Like the other fibers mentioned above, Kevlar is regularly mixed with several types of plastics to form composite materials. Kevlar is registered under a trademark of DuPont de Nemours.