3D printer ups power

Best Uninterruptible Power Supply (UPS) for 3D Printers 2022

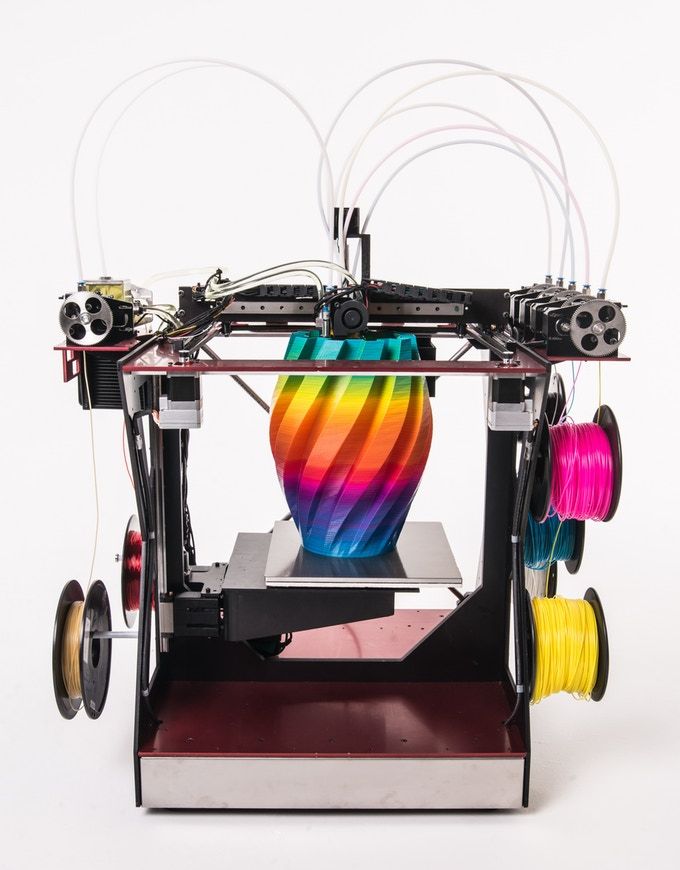

Jackery And 3d Printer (Image credit: Windows Central)Power cuts are par for the course out here in California and in many places around the world. Even a one-second power cut to your 3D printer is enough for a 22-hour print-to-stop to be ruined. An Uninterruptable Power Supply (UPS) like the CyberPower CP1500 will keep power flowing to your printer via high-capacity batteries and magic (OK, maybe not real magic), so you should never have to worry. If you're looking to get started in 3D printing, then a UPS is an important first step. Here are the best UPS for 3D printers.

CyberPower CP1500 Intelligent LCD UPS System

The one I use

This was the first UPS I used on my 3D printers, and it works wonderfully. Using a system called Automatic Voltage Regulation (AVR), the CyperPower regulates all the power going into your printer so you have a consistent feed of electricity at all times, even when the power goes out. The 1500va and 900w battery backup is enough to get you through about 15 minutes of a power outage.

APC BackUPS Pro

Hot swappable batteries

Like most of the UPS on this list, the APC BackUPS has AVR and the added bonus of hot-swappable batteries. This gives you the option of changing batteries out with replacement batteries to keep your UPS running for longer. Anything you can do to keep your printer running until the power comes back is a good thing.

CyberPower Sinewave UPS System

Powerhouse

This one is for those of you with multiple printers you want to attach to the same UPS. With eight battery backup sockets and a whopping 1540w of power, the Sinewave is a powerhouse and will keep your printers going for much longer than the standard UPS. It also comes with a three-year warranty covering you for $300,000 of connected equipment damage to rest easy.

It also comes with a three-year warranty covering you for $300,000 of connected equipment damage to rest easy.

Jackery Solar Generator 1000

The overkill you need

The Jackery 1000 with solar panels is a little different from the rest of the UPS options in this list. The solar panels allow it to generate power while in use, and in my Jackery 1000 review, I used it to power a 3D printer for almost 11 hours. If you know you are likely to have a long power cut for the day, then a Jackery might save you from printing delays.

CyberPower Compact UPS System

Budget power

While this is a perfectly good UPS for keeping a server or router going for an hour or two, it isn't going to give you more than five or six minutes of printing time. However, if you live in an area with a fairly good track record of tiny outages, then this could work for you. Sometimes you only need it to last 10 seconds anyway, so why spend a fortune?

Sometimes you only need it to last 10 seconds anyway, so why spend a fortune?

Goal Zero Yeti

Good for travel

The Yeti is slightly different from the other UPS in this collection. It's designed for charging multiple devices while traveling or in an emergency rather than being attached all the time. Because of that, however, it's a great purchase if all you want is a UPS for planned outages at your home as well as using it for its original purpose: travel.

Forza - UPS 1000VA

Small and cheap

This is another budget offering, this time by Forza. The smaller UPS work great if you aren't using a heated bed since the stepper motors use such a small amount of power. So if you're using a printer without a heated bed or don't use it when you are printing PLA, something like the Forza may be just enough to keep you going in a short power outage.

CyberPower PR3000

Small business protection

This is overkill for a hobbyist with one or two printers, but if you're a small business owner using 3D Printers, this one UPS could power them for as long as you needed to get a backup generator running. Its 3000va 2700w batteries will keep a rack of printers running for at least an hour, and the three-year warranty covers $375,000 of equipment.

Why you can trust Windows Central Our expert reviewers spend hours testing and comparing products and services so you can choose the best for you. Find out more about how we test.

These UPS will give your 3D printing a fighting chance when it comes to power outages, and really, the bigger, the better when it comes to power. If you're lucky and live with constant power but still want a UPS as added security, remember to use your UPS occasionally anyway. The batteries need to be used, so they don't fail when you need them most.

Most 3D printing people choose the APC BackupPro for their UPS needs from the research I have done, but I am partial to the Jackery 1000 as it has many other applications, not just as a battery backup. I've used the Jackery to power a printer at a talk I gave on 3D printing, and it worked so well I forgot it wasn't on mains power at all.

Get the best of Windows Central in in your inbox, every day!

Contact me with news and offers from other Future brandsReceive email from us on behalf of our trusted partners or sponsorsJames built his first PC when he was 13 and has never looked back. He can be found on Windows Central, usually in the corner where all the 3D printers are, or huddled around the Xbox playing the latest games.

The facts of uninterruptable power supply (UPS) system in 3D printers

Some of the main concerns our technical support team hears from our customers:

“Why did my 3D printer stop in the middle of the print job?”

“I must restart my print job wasting valuable time and materials?”

“My 3D printer doesn’t even start now.

Can you please help me?”

All the above are related to power supply issues!

The primary task of the uninterruptable power supply (UPS) system is to provide uninterrupted power to 3D printers.

What each of us have experienced in a point in time, is the intermittent loss of electrical power network supply or complete power outage. There are also invisible issues to the power network supply, in which our equipment is very “sensitive” to. These are voltage and frequency fluctuations (disturbances).

The UPS delivers protection from these typical power problems that threaten your 3D printer:

- Power failures

- High voltages spikes

- Power sags

- Frequency variations

- Power surges

- Switching transients

- Brownouts

- Harmonic distortion

- Line noise

The most common problems are power outages, surges, spikes and sags.

- Power outage is a complete loss of electrical power network which could be detrimental for your 3D printer

- Surge has a significantly higher voltage than what would be dedicated to the printer for optimal operation.

It is usually short lived (about a few milliseconds) but can be dangerous to your 3D printer.

It is usually short lived (about a few milliseconds) but can be dangerous to your 3D printer. - High voltage spikes is a large increase in the voltage supply that occurs upon the return of power during a thunderstorm.

- Undervoltage (Sag) is commonly found in our suburbs and less populated areas.

Here are some features and specifications of a typical UPS system:

So, based on your needs and type of the 3D printer, you can determine which type of UPS is right for you.

Small UPS systems will provide battery backup power for a few minutes, just enough to safely power down the printer in an orderly manner, while larger system would have extended battery power for several hours.

But that is not all you need to know before making your selection, you must also consider the power of the printer that will be powered through the UPS. One should consider the power factor (PF) as it represents the ratio of actual energy consumed (W) and the apparent power supplied to the circuit (VA). The range should be between 0-1 PF in decimal point or a percentage; i.e. 0.9 PF = 90%. Higher PF number means the electricity is more useful and power is consumed more efficiently.

The range should be between 0-1 PF in decimal point or a percentage; i.e. 0.9 PF = 90%. Higher PF number means the electricity is more useful and power is consumed more efficiently.

In case of voltage fluctuations which include, surge, spike, sag, noise etc., UPS compensates these disturbances so the 3D printer can successfully operate and complete the print job.

In case of a power failure, the primary role of the UPS is to provide enough time for the 3D printer to properly stop the printing process and safely shut down the system.

Printing material that remains in the print block (Polyjet Printer) during a power failure can polymerize. This might cause serious damage to the print heads. A UPS can prevent this if it is configured to execute a “graceful shutdown” after a power failure. The “graceful shutdown” process removes resin from the print head and turns off the built in PC and the printer.

In summary, UPS is important in keeping your 3D printer safe during unexpected power changes. The type of 3D printer and power factor can help you determine the right UPS for your needs.

The type of 3D printer and power factor can help you determine the right UPS for your needs.

How much electricity does a 3D printer consume?

Author Kirill Sokolov Reading 8 min. 353 views Posted by

While 3D printing is certainly a fun hobby, there's no doubt that it can also get quite expensive. Apart from the cost of the printer and filaments, you can easily spend a few hundred dollars just to get started. Another recurring cost that we should not ignore is the cost of electricity consumed by a 3D printer. nine0005

Whether you're 3D printing for fun or business, the money you spend on electricity is what you need. keep in mind. How much electricity does a 3D printer use and what can you do to reduce your energy bills?

Table of Contents

- Step One: Check Your Printer's Power Rating

- What Factors Affect How Much Power 3D Printing Uses?

- Hot end heating

- Heating of the printed platform

- Heating losses

- Step engines

- Control board

- Comparison of energy consumption of various models of 3D printers

- Tips for reducing the costs of 3D printer

- 1.

Use the printer with the building 9

Use the printer with the building 9 - 3. Print with high temperature fibers only when necessary

- Final Thoughts

Step One: Check Your Printer's Power Rating

Like any electrical device, your 3D printer must be rated. For example, a 3D printer that requires 30A 12V consumes up to 360W of power (power = current x voltage). This is a very high figure, but only because it is the maximum power that this particular 3D printer can draw.

There can be a very significant difference in power consumption if you print at high temperatures. , high speed settings or heated beds. However, between different models, you can expect printers with larger platforms to use more power, as well as printers that can print at higher temperatures. nine0005

What factors affect how much energy 3D printing consumes?

If you are interested in the specific power your 3D printer requires, then the best way is to use a power consumption monitoring tool. These tools act as an interface between your 3D printer and an electrical outlet, giving you an accurate measurement of the volts, amps, and power your 3D printer draws. A good example is Kill A Watt Electricity Usage Monitor by P3. nine0005

These tools act as an interface between your 3D printer and an electrical outlet, giving you an accurate measurement of the volts, amps, and power your 3D printer draws. A good example is Kill A Watt Electricity Usage Monitor by P3. nine0005

It would be impossible to isolate any particular part of the 3D printing process and test how it affects the power consumption of the printer. Instead, we can sum up these factors and infer how much electricity they consume.

Heating at the hot end

One of the most energy intensive drain parts of a 3D printer is the hot end, specifically the part of the nozzle that melts the filament. How much energy this process consumes depends on the temperature you set as well as the type of filament you are working with. If you're working with a lot of high temperature fibers like nylon or ABS, then you're probably using a lot of electricity for just that part. nine0005

Print bed heating

The print bed temperature depends on the nozzle temperature. This is a measure that improves adhesion to the layer and prevents warping, which is one of the constant problems when working with high temperature fibers.

This is a measure that improves adhesion to the layer and prevents warping, which is one of the constant problems when working with high temperature fibers.

There are two factors to consider when evaluating the energy consumption of a heater. bed – temperature setting and bed size. The temperature also depends on the type of filament you are printing with. The size of the bed depends on your 3D printer. The larger the bed, the more energy will be required to maintain the set temperature. nine0005

Heat loss

3D printer components can reach temperatures above 200°C. They must also remain at this temperature, so any heat loss to the environment must be compensated by the heating element. This is another issue for high temperature 3D printing as a hotter nozzle and print bed will inevitably have higher heat loss. If there is a way to minimize heat loss, you can save a lot on your energy costs. nine0005

Stepper Motors

There are two important sets of stepper motors in one 3D printer: those that drive the extruder gears and those that drive the movement of the nozzle. While these motors are very small and draw little power, they also need to be constantly running for the hours needed to complete a single 3D printing project.

While these motors are very small and draw little power, they also need to be constantly running for the hours needed to complete a single 3D printing project.

Control Board

The control board or "brain" of a 3D printer consists of several electrical components that help control the printer's temperature, nozzle placement, extruder gears, and various other trivial tasks. Despite the importance of this feature, the control board does not actually consume much power. nine0005

The conclusion that we can draw from this little exercise is that most of the energy consumed by a 3D printer goes towards heating the nozzle and the print bed. While not surprising, this fact also gives us insight into how we can reduce the power consumption of our 3D printing projects.

Comparison of power consumption of various 3D printer models

Since it is impossible to determine the exact power consumption of a 3D printer without specifying the model, we will look at how much power consumption of various 3D printer models and how this affects costs. nine0005

nine0005

Let's start with the Monoprice Mini Delta, a very small and inexpensive Delta type device. A 3D printer that has proven to be quite popular among beginners. Among its distinguishing features are a small build platform and a print head driven by three stepper motors. The Monoprice Mini Delta reportedly only consumes up to 45W during bed and nozzle preheating. Power consumption during printing increases slightly to 60W, probably due to the action of the stepper motors. nine0005

To provide contrast, let's look at the power consumption of Flashforge Creator Pro. This is a much more expensive 3D printer with a larger print bed, a rigid metal frame, and a built-in housing. Preheating the large print bed required a staggering 300W of power, while the nozzle required slightly less than 280W. The case proved to be very useful in reducing heat loss and stabilizing the printer's power to 250W during printing.

The two 3D printers we referenced here give us a useful range for how much power models of varying complexity can consume, from 60W to 250W when printed. In terms of kWh, this range corresponds to 0.07–0.24 kWh.

In terms of kWh, this range corresponds to 0.07–0.24 kWh.

This also allows us to compare the power consumption of 3D printers with other devices we have in the house. For example, a typical desktop computer consumes about 1.05 kWh, which is more than four times the power consumption of Flashforge Creator Pro. nine0005

Based on electricity tariff data from April 2020, the average US consumer pays 13.31 cents per kWh. This means that you will pay approximately 3.2 cents for every hour you use Flashforge Creator Pro. The numbers for the Monoprice Mini Delta are even more pleasantly surprising - you pay less than 1 cent for every hour of use.

These numbers are likely to come as a relief to 3D printing enthusiasts, especially those who leave their printers running for hours on end. While this isn't an excuse for wasting electricity, it's still nice to know that you haven't been hit hard on your running costs just because you got into 3D printing. nine0005

Cost Saving Tips 3D Printer Power Consumption

Although you've come to terms with the fact that you're unlikely to add a huge amount to your energy bill just because you use a 3D printer, many of you probably we still appreciate any advice on how to reduce power consumption.

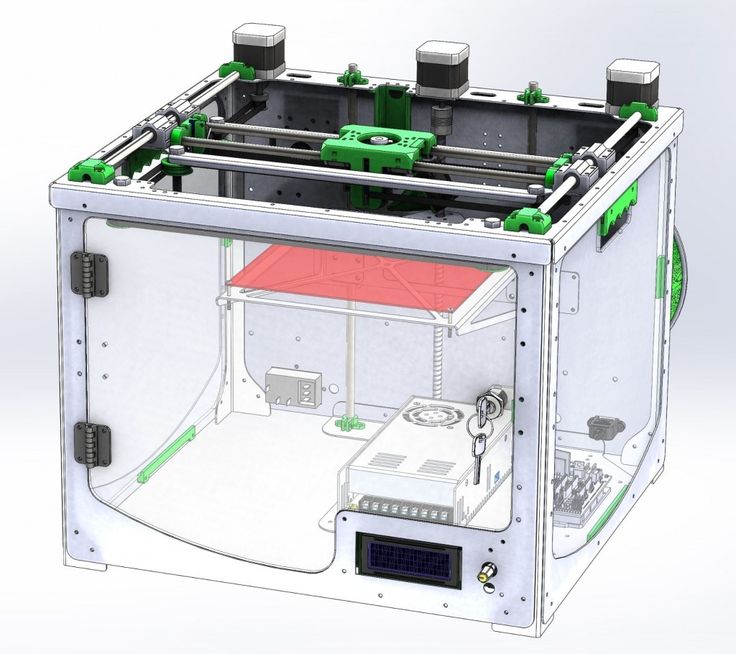

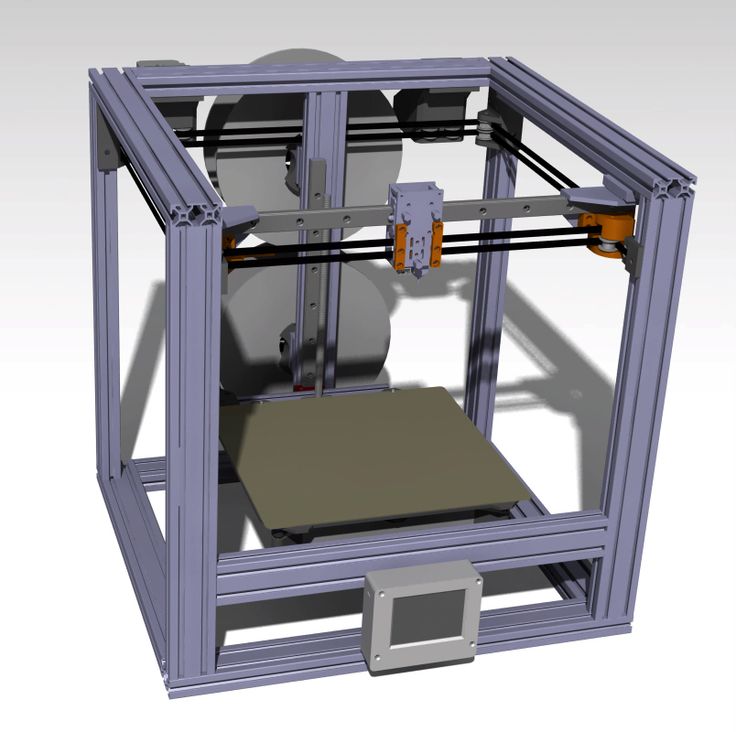

1. Use the Printer with the

Enclosure As our analysis of Flashforge Creator Pro has shown, having a platen enclosure can significantly reduce the power consumption of a 3D printer during the printing process. This becomes even more pronounced if you are printing with a filament that requires high temperatures for both the nozzle and the print bed. If you're using an inexpensive printer without a built-in case, you can simply make your own using a couple of plastic sheets and wood frames. There are many tutorials on the internet for DIY 3D printer cases. nine0005

2. Reduce print time

Time is a factor we haven't talked about much, but it's certainly one of the most important when determining how much power a 3D printer consumes. If you can reduce your project's print time, you can significantly reduce your energy costs.

There are several ways to achieve this goal, but there are two that are particularly effective: increasing print speed and printing with thicker layers.![]() Obviously, this is not advice that can be taken in a vacuum. When making these adjustments, you need to consider other factors such as print temperature, filament type, and the quality level of the finished product..

Obviously, this is not advice that can be taken in a vacuum. When making these adjustments, you need to consider other factors such as print temperature, filament type, and the quality level of the finished product..

3. Print with high temperature fibers only when necessary

Experimenting with different types of fiber materials is a natural part of 3D printing, but using those that require very high print temperatures can be quite expensive in the long run. . This requires not only more heat in the nozzle, but also a hotter print bed. The difference between 30 and 40°C may not seem like much, but every little thing counts – at least depending on which point of view you take. nine0005

Your 3D printer is unnecessary, then you can stick with low temperature fibers like PLA if you're printing just for fun. PLA not only saves energy, but is also a more environmentally friendly choice due to its biodegradable nature.

Closing Thoughts

Consider how much power each of our electrical devices we consume on a regular basis is only part of being a responsible consumer. The same principle applies to 3D printers. As 3D printing is quickly becoming a hobby for more and more people, now is the perfect time to be more aware of how much power 3D printers use. nine0005

The same principle applies to 3D printers. As 3D printing is quickly becoming a hobby for more and more people, now is the perfect time to be more aware of how much power 3D printers use. nine0005

It's nice to know how energy efficient 3D printers are, especially when compared to the computers and TVs we usually have at home. However, this is no excuse for not making any effort to reduce the power consumption of our 3D printers. When used responsibly, we can reduce energy costs by fulfilling our responsibilities as responsible citizens.

Attention! Never leave 3D printers unattended. They can pose a fire safety hazard. nine0005

How are 3D printing lasers different from cutting lasers?

EOS uses lasers to fuse polymer powders (SLS) and metals (DMLS).

Over the past four decades, laser cutting machines have become a must-have tool for the vast majority of sheet metal fabricators.

From CO2 lasers to their newer and more capable solid-state counterparts, what began as a laboratory experiment in the 1960s is today the method of choice for quickly and accurately cutting virtually any metal less than 2. 54 cm thick.

54 cm thick.

However, soon after lasers began to appear in workshops everywhere, another use was found for collimated light, which seems destined to play an equally important role in production.

In 1987, 3D Systems co-founder Chuck Hull sold the first SLA-1 machine using an ultraviolet laser to cure thin layers of photoreactive resin. Additive manufacturing (AM), better known as 3D printing, was born.

Since then, 3D printing has evolved from a photopolymer-only prototyping process to a viable method for producing final parts. With a variety of materials available, including engineering plastics, superalloys such as titanium and INCONEL, maraging steels, tool steels, and stainless steels, there is nothing that 3D printers cannot produce. And while laser light is not the only technology used to solidify, sinter, melt, or otherwise combine these various materials, it is definitely the leader in additive manufacturing. nine0005

Note: This article is a translation.

Long live the difference?

How is a laser capable of cutting through 18 mm thick steel different from a laser used to print tooling for press brakes, assembly fixtures and robotic end effectors?

"Metal 3D printing in industry mainly uses fiber lasers with a wavelength of 1070 nanometers, i.e. in the infrared range, while for cutting, a continuous solid-state fiber or disk laser with a wavelength in the range from 1030 to 1080 nm is usually used" , explains Dave Locke, Sales Specialist for Additive Manufacturing at TRUMPF Inc. nine0005

Obviously the wavelengths are similar, but this is not the case for power. The power of lasers installed in TRUMPF printers for metal processing by powder coating (PBF) does not exceed 500 W. Lasers used for cutting, on the contrary, produce up to 6 kilowatts - 12 times more. If you put that much laser power into a 3D printer, it will burn a hole in the bottom of the machine.

However, it is important to understand that laser power is only one operating parameter of many, whether the metal is being fused or cut into pieces. In addition to power, manufacturers are also looking to provide versatility. For example, they go to great lengths to make their products "customizable" (adjustable to work with different materials) depending on the grade and thickness of the material being cut. nine0005

In addition to power, manufacturers are also looking to provide versatility. For example, they go to great lengths to make their products "customizable" (adjustable to work with different materials) depending on the grade and thickness of the material being cut. nine0005

Fiber lasers are now able to effectively cut thicker materials that were previously reserved for CO2 lasers.

"bell-shaped Gaussian waveform, similar to that generated by fiber lasers provide very high spot densities, which is what gives them the ability to cut through thin materials,” explains Dustin Deal, product manager for Amada America's laser division. “However, this small spot size becomes less effective when you move up to 1.3 mm cm and above, and this is the reason why CO2 lasers have long offered better speeds and better edge quality on thicker materials."

"But as technology evolved, Amada (and other companies) found ways to adjust the laser beam diameter and waveform to create a larger spot - shaped like a hat. This is why, and for other reasons, Amada has completely switched to fiber in its standard line of laser cutting machines,” says Deal.

This is why, and for other reasons, Amada has completely switched to fiber in its standard line of laser cutting machines,” says Deal.

Does this mean that CO2 lasers are going down in history? Unlikely. "Polymers are basically transparent to shorter fiber laser wavelengths, so using them in 3D printing is like shining a flashlight through the snow," says Damien Gray, Principal Laser Optics Engineer at EOS North America Inc, Pflugerville, Texas. It goes right through. "The light from a CO2 laser, on the other hand, is strongly absorbed by most polymers." nine0005

This is good news for selective laser sintering (SLS), the plastic alter ego of PBF metal printing. But there is a caveat: CO2 lasers provide lower print resolution and cannot do the fine details that fiber lasers can.

David Cullen, Director of Application Engineering, 3D Systems Inc. in Rock Hill, South Carolina, explained that the CO2 laser used in his company's SLS printers has a wavelength of about 10,600 nm, which is 10 times longer than a conventional fiber laser. As the wavelength increases, so does the spot size. nine0005

As the wavelength increases, so does the spot size. nine0005

"You get a print resolution of 475 microns, or about half a millimeter, which is much better than a powder coated machine," he says. "On a positive note, the SLS print speed is one of the fastest in the industry."

Two spots beat one

Like laser cutting equipment manufacturers, 3D printer manufacturers use advanced optics and electronics to change laser parameters on the fly - at least in some cases. nine0005

The detail layer is printed on an SLA 3D printer from 3D Systems, the inventor of the stereolithography system.

The SLS setup just reviewed has a fixed beam size, but Cullen said stereolithography (SLA), the technology his company was founded on, now offers two spot sizes.

"By adjusting the crystal orientation in the YAG laser, we can generate a large spot to quickly scan large areas on the inside of a part, and then dynamically switch to a small spot for fine detail and contour tracking," he said. "The result is better part quality and faster assembly." nine0005

"The result is better part quality and faster assembly." nine0005

Ankit Saharan, application development and R&D manager at EOS, agreed on the importance of spot size control, but added that in the case of additive laser manufacturing, there are many more characteristics than spot size and the wavelength or type of laser used for it. creation.

"A small spot size is better than a large spot because the smaller the spot, the smaller the melt pool, which means less stress in the workpiece," Saharan said. "We start at around 45 µm on small platforms and go up to 100 µm on large platforms." nine0005

However, smaller spot sizes also mean slower settling rates, so a balance must be struck between process stability and cost. In addition, there are many other factors such as layer thickness, powder grain size, powder delivery and application mechanisms, feed material reflectance, and various equipment parameters.

Saharan says, "This is a very complex scenario, and a high quality laser, although important, is only part of what is needed to create a stable additive process.